New Methodology for Benchmarking Hydrodynamics in Bubble Columns with Intense Internals Using the Radioactive Particle Tracking (RPT) Technique

Abstract

1. Introduction

- The calibration points for RPT were not defined properly in the presence of the dense internals during measurements due to narrow distances between the internals.

- A calibration dataset is critical for reconstructing the positions of radioactive particles during operation. As a result, the post data processing of regular RPT data processes was questionable and required validation. Because of that, Al Mesfer et al. [2] used different and limited approaches to process the data without relying fully on the collected calibration data.

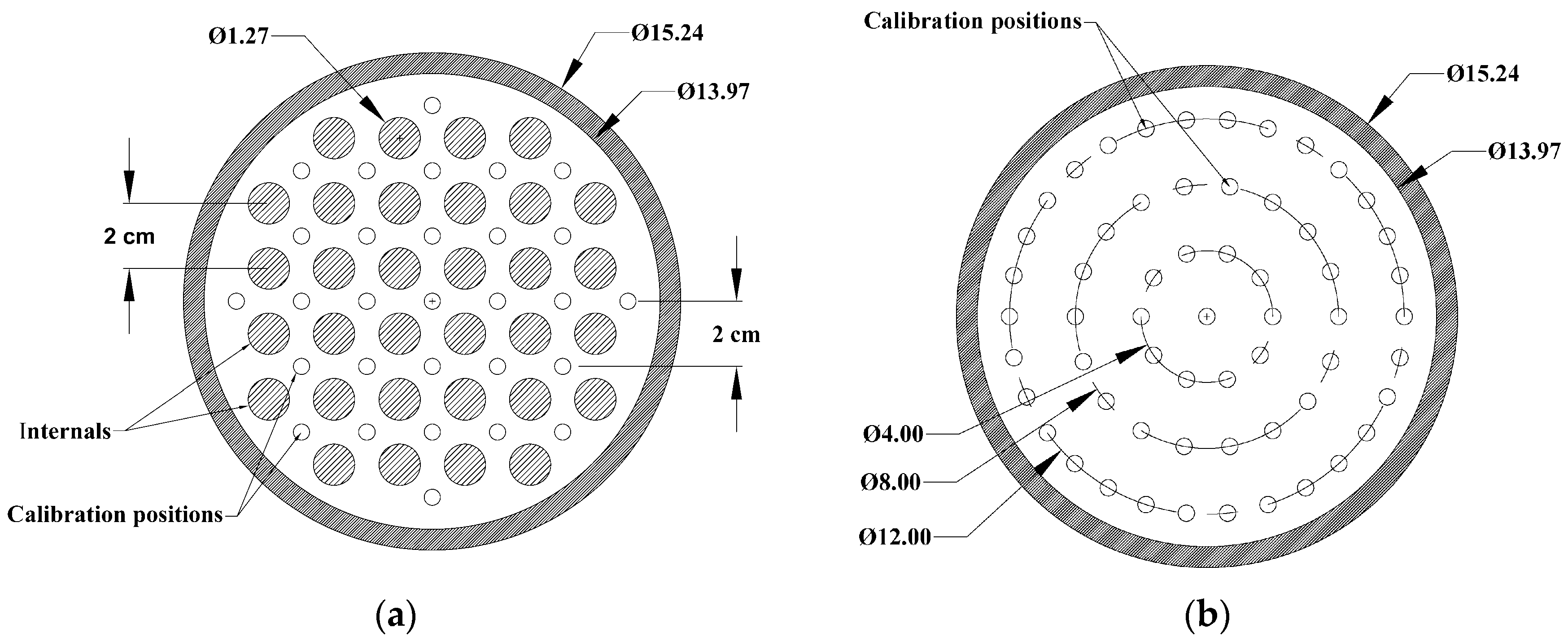

- When regular RPT processing data were implemented, azimuthal liquid velocity averages were estimated without subtracting the width of the internals where no velocities were measured in these spaces. The data obtained from this study was found to be unreliable [31]. Therefore, Al Mesfer et al. [2] used line-averaged data for the lines that did not pass through internals. Unfortunately, this information is limited and not adequate for reliable CFD validation.

- Performing limited reliable RPT calibration points and using Monte Carlo N-Particle (MCNP) simulation to generate the needed supplementary calibration dataset in a bubble column with and without dense internals. Due to the difficulties of executing RPT calibration with dense internals, this new method has been undertaken.

- Validating the new method in identifying radioactive particle positions inside the bubble column with and without internals by reconstructing known positions of the radioactive particle, as discussed in the validation section.

- When post-processing RPT data and performing azimuthally averaging, the spaces occupied by the internals were subtracted. Hence, estimated liquid field velocities in the bubble column with dense internals are reliable, including turbulence parameters for properly validating CFD models.

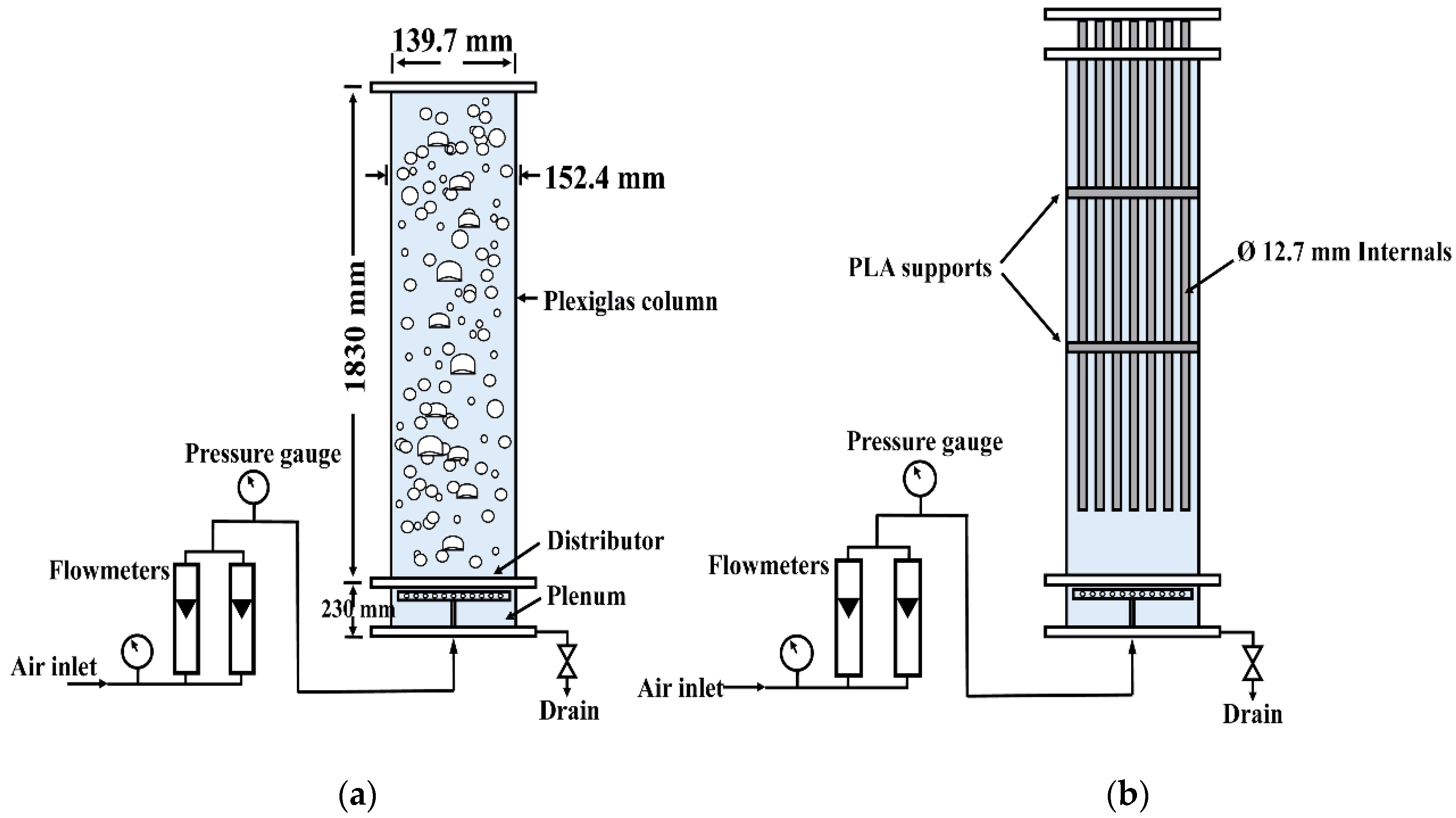

2. Experimental Setup

3. Implementation of the RPT Technique with Dense Internals

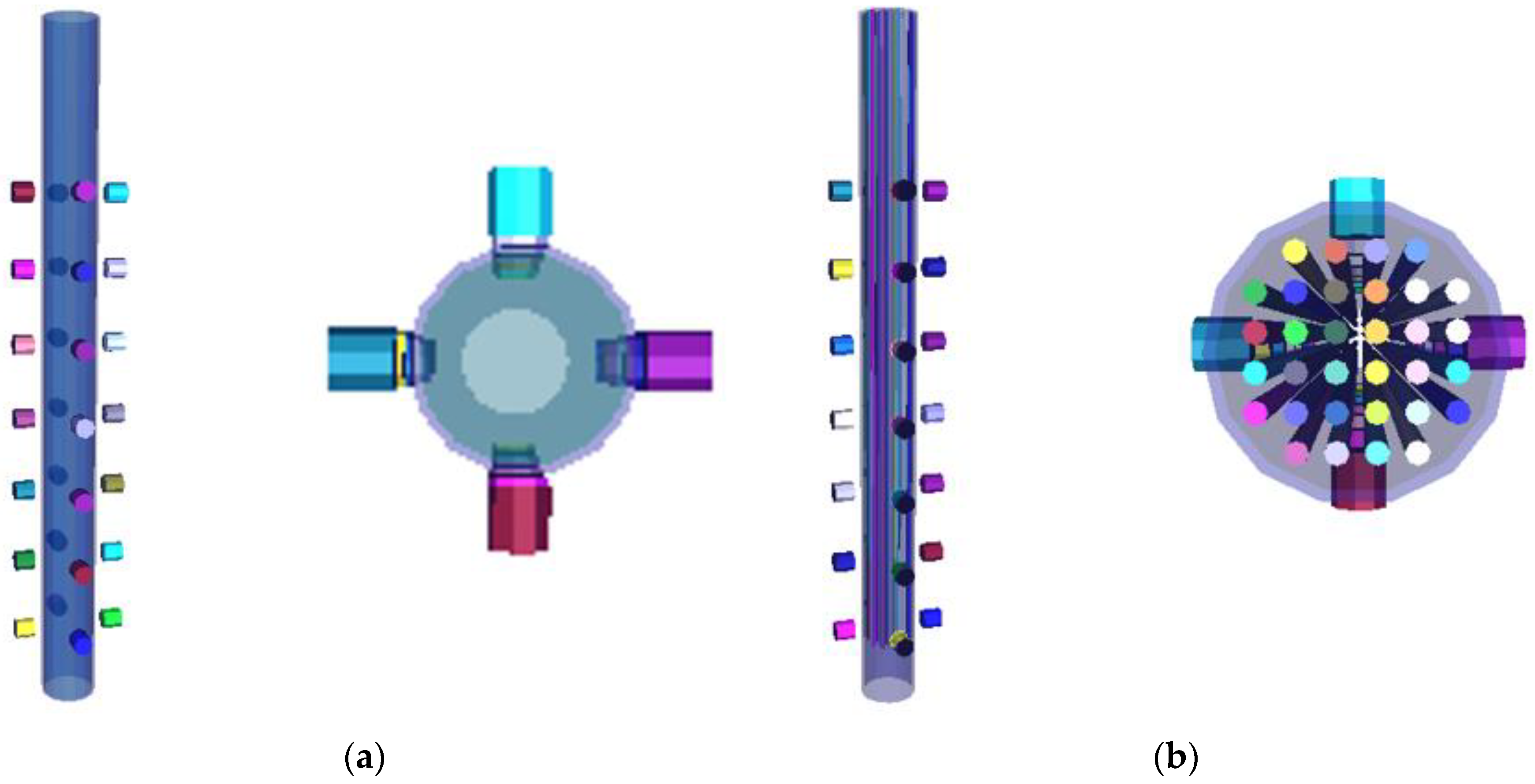

3.1. Radioactive Particle Tracking (RPT) Technique

3.2. Monte Carlo Simulation

3.3. Instantaneous Position Identification of the Radioactive Particle

3.4. Estimation of the Hydrodynamic Parameters

3.5. Validation of the Monte Carlo N-Particle (MCNP) Simulation

4. Results and Discussion

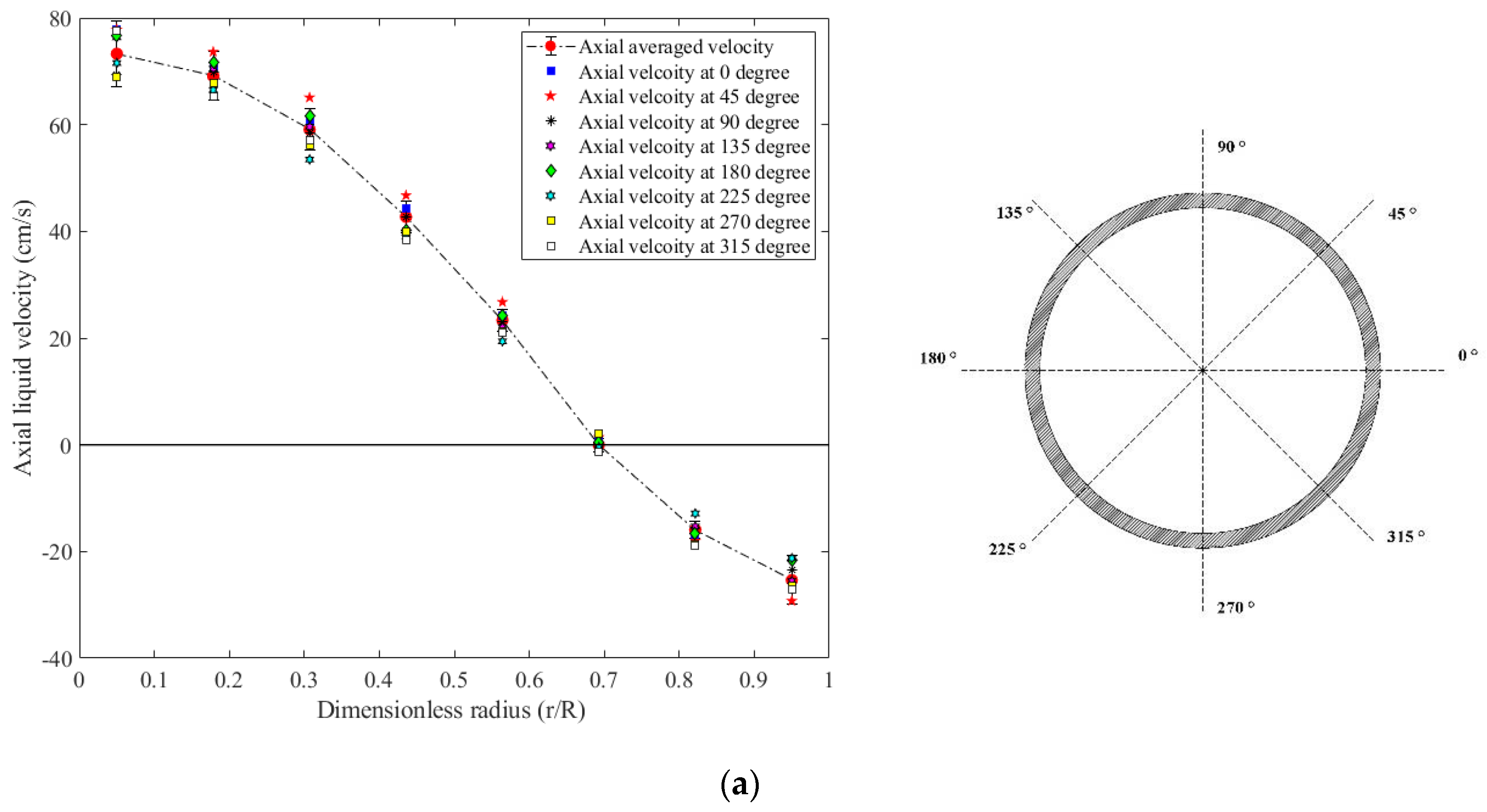

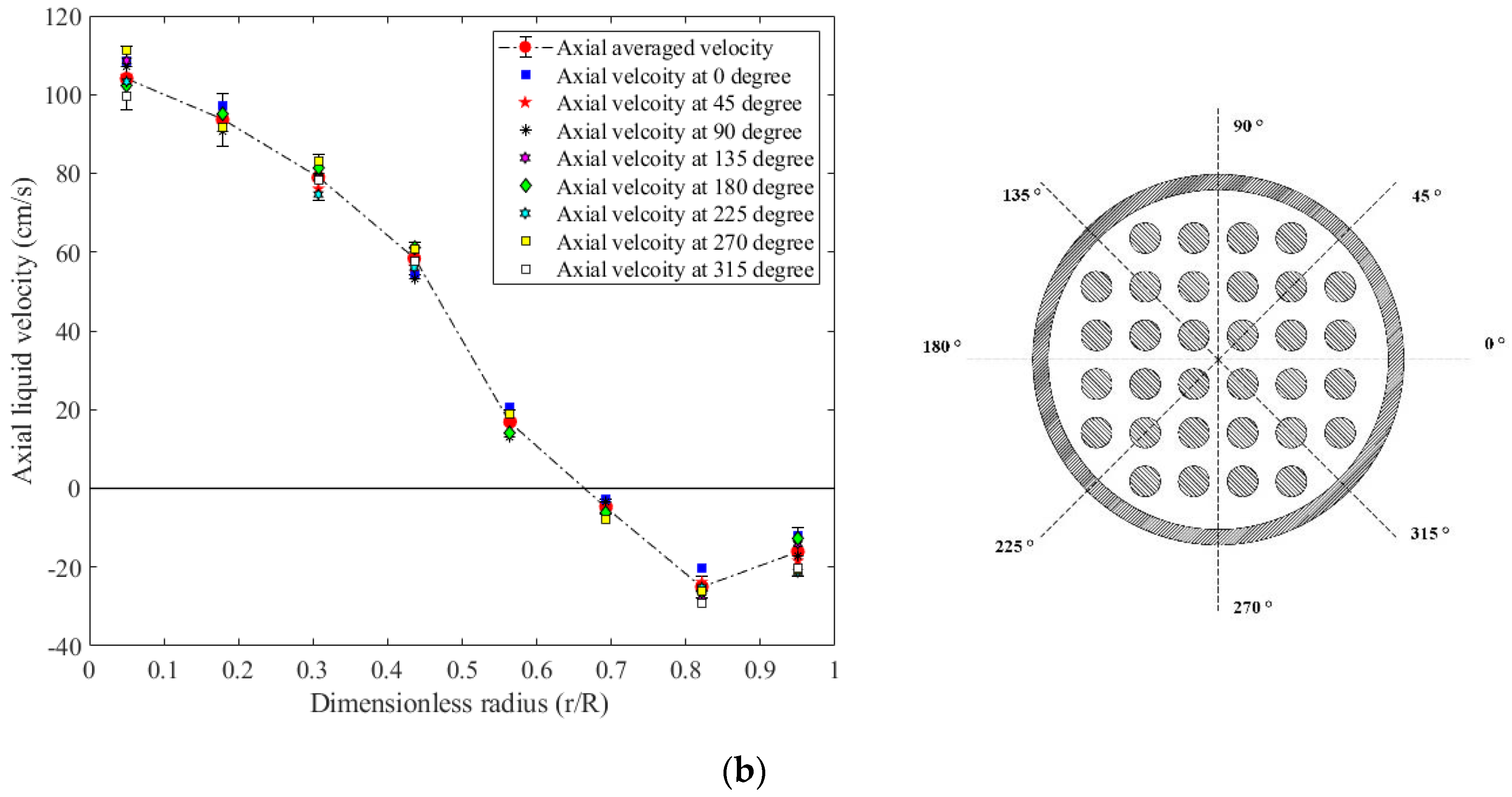

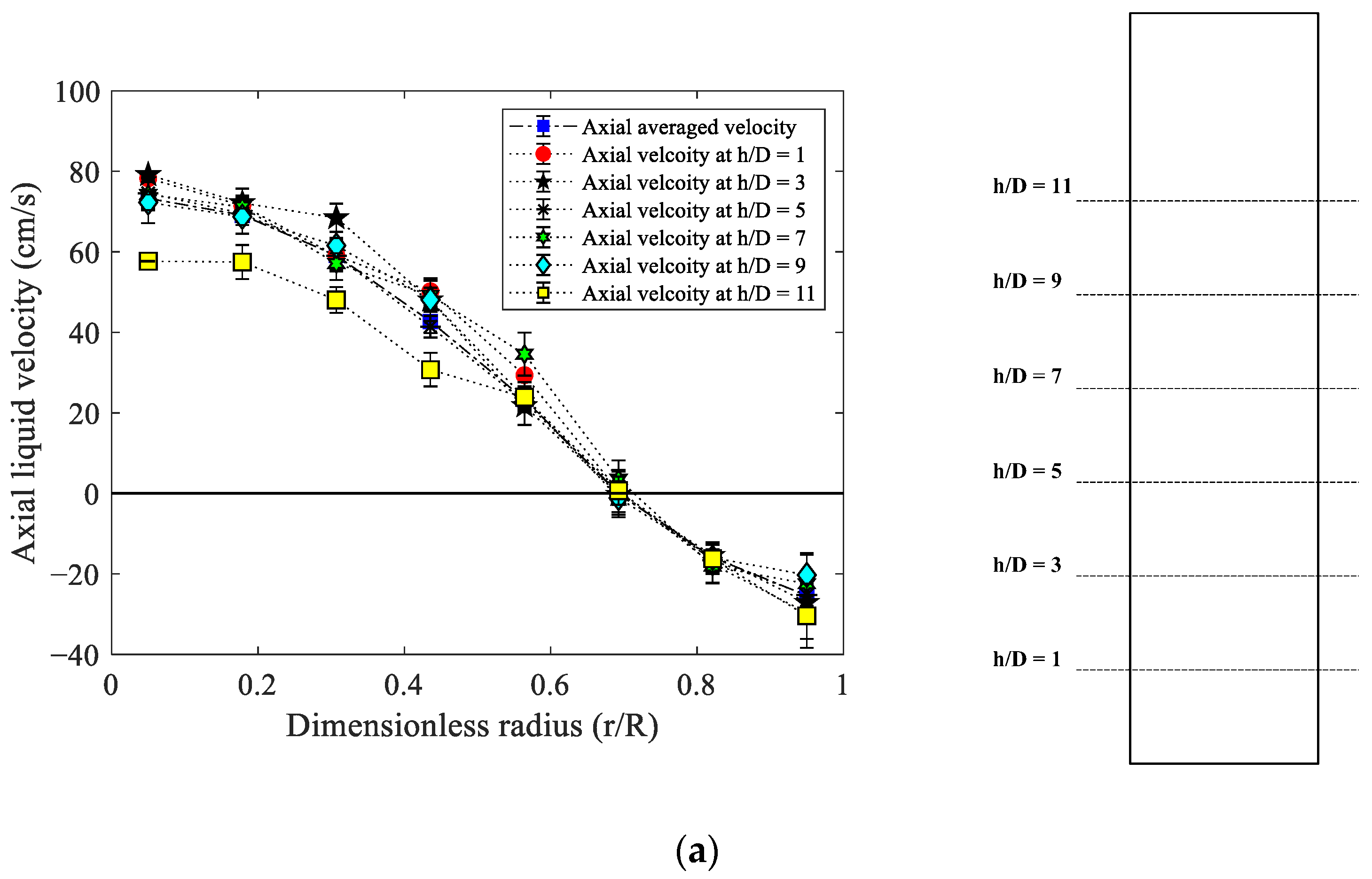

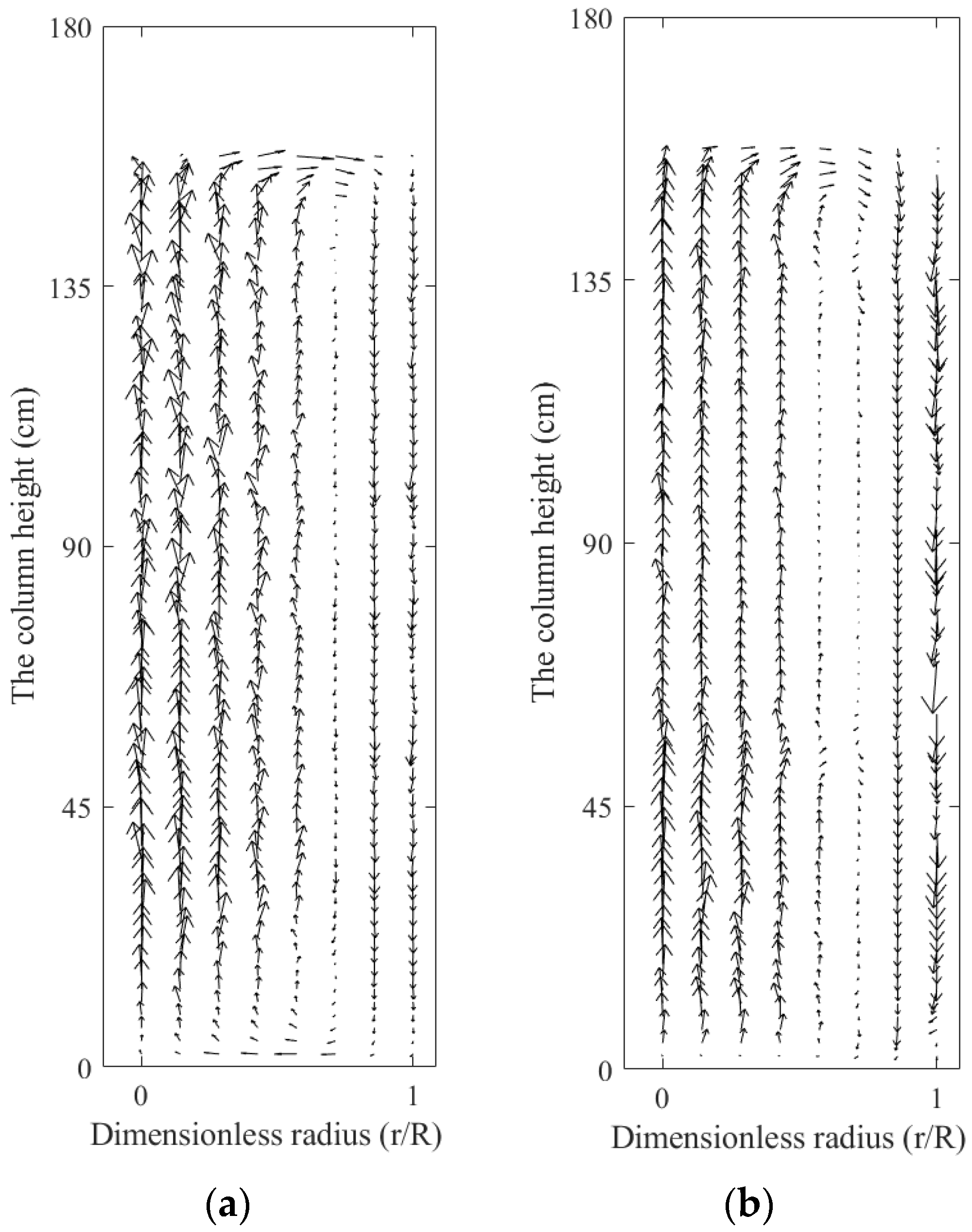

4.1. Axial and Radial Liquid-Phase Movement (Frequency of Moving Eddies of Liquid) Distribution

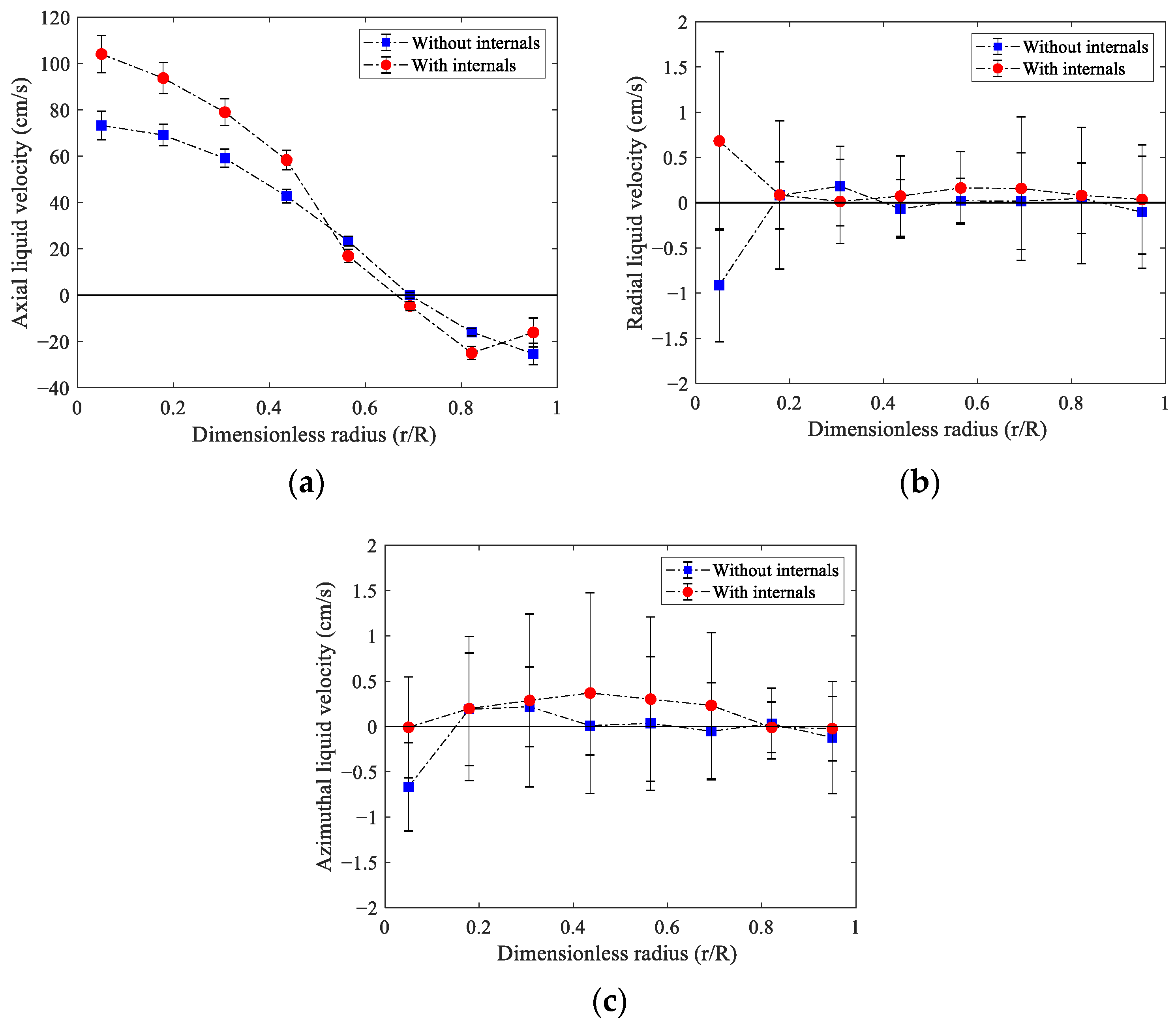

4.2. Effect of the Internals on the Liquid Velocity Field

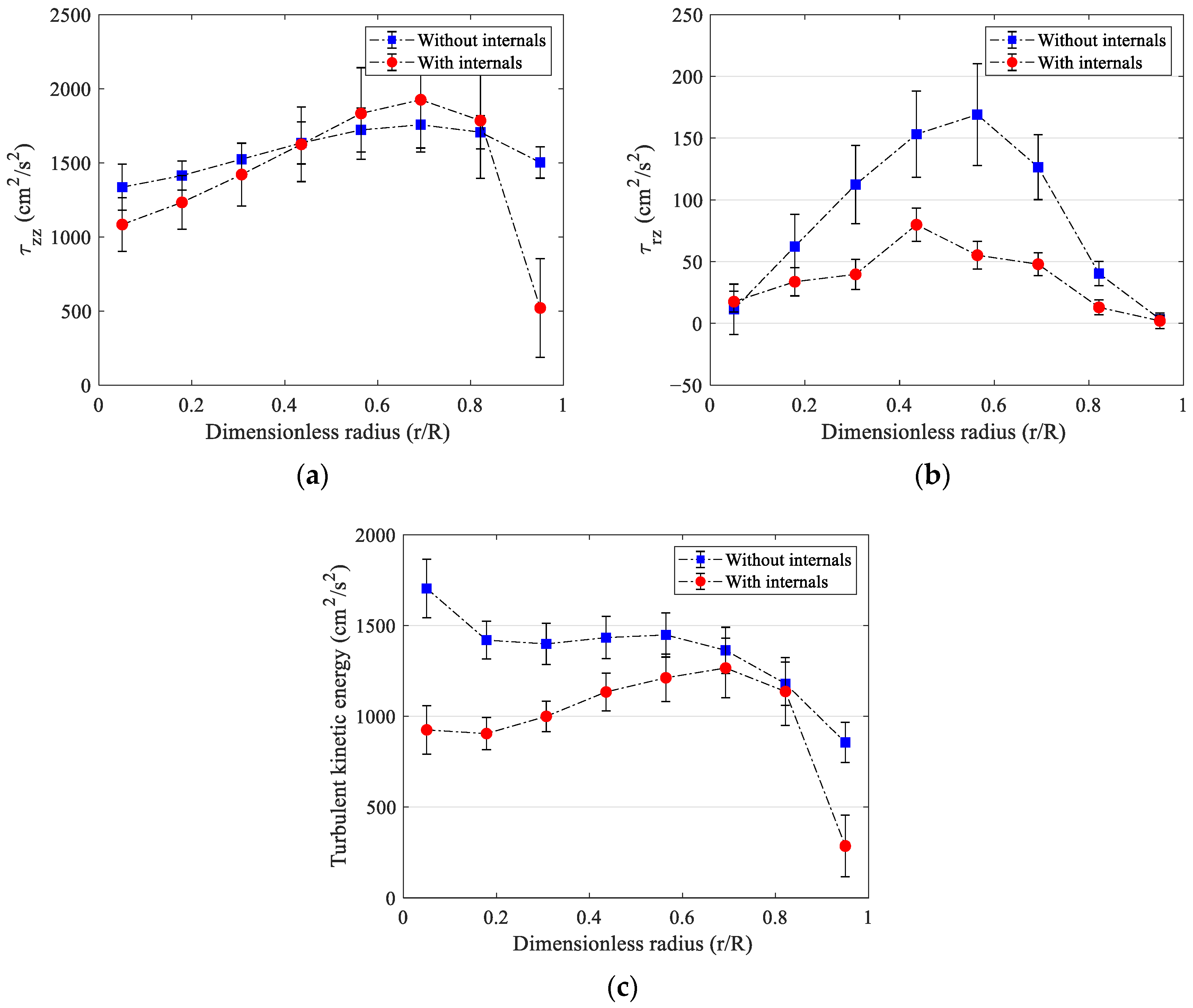

4.3. Effect of Internals on Turbulent Parameters

5. Conclusions

- -

- The integrated method using MCNP simulation and a calibration dataset from RPT successfully generated a huge number of calibration points to enhance the accuracy of the reconstruction of radioactive particle positions, as shown in the validation steps of the bubble column with and without dense internals. The maximum relative error for both cases of each validation point was less than 4.2%.

- -

- A similarity algorithm can be used to reconstruct the instantaneous positions of the radioactive particle with less computation power over a short time.

- -

- The square pitch configuration generated symmetric flow patterns that can be used to average azimuthally averaged liquid velocity fields.

- -

- Dense internal rods increased time-averaged axial liquid velocity in the center of the column by creating channels in the bubble column but dampened fluctuations and hence turbulent parameters. Thus, liquid axial normal stress values decreased due to the effect of rods at the center of the column and near the wall.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Han, L.; Kamalanathan, P.; Al-Dahhan, M. Study of the detailed catalyst hydrodynamics using radioactive particle tracking technique in a mimicked Fischer-Tropsch slurry bubble column. Chem. Eng. Sci. 2021, 241, 116659. [Google Scholar] [CrossRef]

- Al Mesfer, M.K.; Sultan, A.J.; Al-Dahhan, M.H. Study the Effect of Dense Internals on the Liquid Velocity Field and Turbulent Parameters in Bubble Column for Fischer–Tropsch (FT) Synthesis by Using Radioactive Particle Tracking (RPT) Technique. Chem. Eng. Sci. 2016, 161, 228–248. [Google Scholar] [CrossRef]

- Kagumba, M.; Al-Dahhan, M.H. Impact of internals size and configuration on bubble dynamics in bubble columns for alternative clean fuels production. Ind. Eng. Chem. Res. 2015, 54, 1359–1372. [Google Scholar] [CrossRef]

- Kumar, S.B.; Moslemian, D.; Duduković, M.P. Gas-Holdup Measurements in Bubble Columns Using Computed Tomography. AIChE J. 1997, 43, 1414–1425. [Google Scholar] [CrossRef]

- Veera, U.P.; Joshi, J.B. Measurement of gas hold-up profiles by gamma ray tomography: Effect of sparger design and height of dispersion in bubble columns. Chem. Eng. Res. Des. 1999, 77, 303–317. [Google Scholar] [CrossRef]

- Devanathan, N.; Moslemian, D.; Dudukovic, M.P. Flow mapping in bubble columns using CARPT. Chem. Eng. Sci. 1990, 45, 2285–2291. [Google Scholar] [CrossRef]

- Yang, Y.B.; Devanathan, N.; Duduković, M.P. Liquid backmixing in bubble columns via computer-automated radioactive particle tracking (CARPT). Exp. Fluids 1993, 16, 1–9. [Google Scholar] [CrossRef]

- Upadhyay, R.K.; Pant, H.J.; Roy, S. Liquid flow patterns in rectangular air-water bubble column investigated with Radioactive Particle Tracking. Chem. Eng. Sci. 2013, 96, 152–164. [Google Scholar] [CrossRef]

- Degaleesan, S.; Roy, S.; Kumar, S.B.; Duduković, M.P. Liquid mixing based on convection and turbulent dispersion in bubble columns. Chem. Eng. Sci. 1996, 51, 1967–1976. [Google Scholar] [CrossRef]

- Jung, H.; Yang, J.I.; Yang, J.H.; Lee, H.T.; Chun, D.H.; Kim, H.J. Investigation of Fischer-Tropsch synthesis performance and its intrinsic reaction behavior in a bench scale slurry bubble column reactor. Fuel Process. Technol. 2010, 91, 1839–1844. [Google Scholar] [CrossRef]

- Basha, O.M.; Sehabiague, L.; Abdel-Wahab, A.; Morsi, B.I. Fischer-Tropsch Synthesis in Slurry Bubble Column Reactors: Experimental Investigations and Modeling—A Review. Int. J. Chem. React. Eng. 2015, 13, 201–288. [Google Scholar] [CrossRef]

- Van de Loosdrecht, J.; Botes, F.G.; Ciobica, I.M.; Ferreira, A.C.; Gibson, P.; Moodley, D.J.; Saib, A.M.; Visagie, J.L.; Weststrate, C.J.; Niemantsverdriet, J.W. Fischer-Tropsch Synthesis: Catalysts and Chemistry; Elsevier Ltd.: Amsterdam, The Netherlands, 2013; Volume 7. [Google Scholar]

- Youssef, A.; Al-Dahhan, M. Impact of Internals on the Gas Holdup and Bubble Properties of a Bubble Column. Ind. Eng. Chem. Res. 2009, 48, 8007–8013. [Google Scholar] [CrossRef]

- An, M.; Guan, X.; Yang, N.; Bu, Y.; Xu, M.; Men, Z. Effects of internals on fluid dynamics and reactions in pilot-scale slurry bubble column reactors: A CFD study for Fischer-Tropsch synthesis. Chem. Eng. Process. Process Intensif. 2018, 132, 194–207. [Google Scholar] [CrossRef]

- Manjrekar, O.N.; Dudukovic, M.P. Application of a 4-point optical probe to a Slurry Bubble Column Reactor. Chem. Eng. Sci. 2015, 131, 313–322. [Google Scholar] [CrossRef]

- Shaikh, A.; Al-Dahhan, M. A new method for online flow regime monitoring in bubble column reactors via nuclear gauge densitometry. Chem. Eng. Sci. 2013, 89, 120–132. [Google Scholar] [CrossRef]

- Behkish, A.; Men, Z.; Inga, J.R.; Morsi, B.I. Mass transfer characteristics in a large-scale slurry bubble column reactor with organic liquid mixtures. Chem. Eng. Sci. 2002, 57, 3307–3324. [Google Scholar] [CrossRef]

- Abdulmohsin, R.S.; Abid, B.A.; Al-Dahhan, M.H. Heat transfer study in a pilot-plant scale bubble column. Chem. Eng. Res. Des. 2011, 89, 78–84. [Google Scholar] [CrossRef]

- Ahmed, F.S.; Sensenich, B.A.; Gheni, S.A.; Znerdstrovic, D.; Al Dahhan, M.H. Bubble dynamics in 2D bubble column: Comparison between high-speed camera imaging analysis and 4-point optical probe. Chem. Eng. Commun. 2015, 202, 85–95. [Google Scholar] [CrossRef]

- Esmaeili, A.; Guy, C.; Chaouki, J. The effects of liquid phase rheology on the hydrodynamics of a gas-liquid bubble column reactor. Chem. Eng. Sci. 2015, 129, 193–207. [Google Scholar] [CrossRef]

- Gupta, A.; Roy, S. Euler-Euler simulation of bubbly flow in a rectangular bubble column: Experimental validation with Radioactive Particle Tracking. Chem. Eng. J. 2013, 225, 818–836. [Google Scholar] [CrossRef]

- De Mesquita, C.H.; De Sousa Carvalho, D.V.; Kirita, R.; Vasquez, P.A.S.; Hamada, M.M. Gas-liquid distribution in a bubble column using industrial gamma-ray computed tomography. Radiat. Phys. Chem. 2014, 95, 396–400. [Google Scholar] [CrossRef]

- Besagni, G.; Inzoli, F. The effect of liquid phase properties on bubble column fluid dynamics: Gas holdup, flow regime transition, bubble size distributions and shapes, interfacial areas and foaming phenomena. Chem. Eng. Sci. 2017, 170, 270–296. [Google Scholar] [CrossRef]

- Jasim, A.A.; Sultan, A.J.; Al-Dahhan, M.H. Impact of heat exchanging internals configurations on the gas holdup and bubble properties in a bubble column. Int. J. Multiph. Flow 2019, 112, 63–82. [Google Scholar] [CrossRef]

- Sultan, A.J.; Sabri, L.S.; Al-Dahhan, M.H. Influence of the size of heat exchanging internals on the gas holdup distribution in a bubble column using gamma-ray computed tomography. Chem. Eng. Sci. 2018, 186, 1–25. [Google Scholar] [CrossRef]

- Al-Naseri, H.; Schlegel, J.P.; Al-Dahhan, M.H. The effects of internals and low aspect ratio on the fully developed flow region and bubble properties in a pilot-plant bubble column. Exp. Therm. Fluid Sci. 2019, 104, 284–301. [Google Scholar] [CrossRef]

- Sultan, A.J.; Sabri, L.S.; Shao, J.; Al-Dahhan, M.H. Overcoming the gamma-ray computed tomography data processing pitfalls for bubble column equipped with vertical internal tubes. Can. J. Chem. Eng. 2018, 96, 2206–2226. [Google Scholar] [CrossRef]

- Rados, N. Slurry Bubble Column Hydrodynamics; Washington University: St. Louis, MO, USA, 2003. [Google Scholar]

- Rados, N.; Shaikh, A.; Al-Dahhan, M.H. Solids flow mapping in a high pressure slurry bubble column. Chem. Eng. Sci. 2005, 60, 6067–6072. [Google Scholar] [CrossRef]

- Kalaga, D.V.; Yadav, A.; Goswami, S.; Bhusare, V.; Pant, H.J.; Dalvi, S.V.; Joshi, J.B.; Roy, S. Comparative analysis of liquid hydrodynamics in a co-current flow-through bubble column with densely packed internals via radiotracing and Radioactive Particle Tracking (RPT). Chem. Eng. Sci. 2017, 170, 332–346. [Google Scholar] [CrossRef]

- Al Mesfer, M. Effect of Dense Heat Exchanging Internals On the Hydrodynamics of Bubble Column Reactors Using Non-Invasive Measurement Techniques. Ph.D. Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2013; pp. 1–198. [Google Scholar]

- Jasim, A.A.; Sultan, A.J.; Al-Dahhan, M.H. Influence of heat-exchanging tubes diameter on the gas holdup and bubble dynamics in a bubble column. Fuel 2019, 236, 1191–1203. [Google Scholar] [CrossRef]

- Youssef, A.A.; Hamed, M.E.; Grimes, J.T.; Al-Dahhan, M.H.; Duduković, M.P. Hydrodynamics of pilot-scale bubble columns: Effect of internals. Ind. Eng. Chem. Res. 2013, 52, 43–55. [Google Scholar] [CrossRef]

- Youssef, A.A.; Al-Dahhan, M.H.; Dudukovic, M.P. Bubble columns with internals: A review. Int. J. Chem. React. Eng. 2013, 11, 169–223. [Google Scholar] [CrossRef]

- Farid, O.; Qi, B.; Uribe, S.; Al-dahhan, M. New dual modality technique of gamma-ray densitometry (GRD) and optical fiber probe (OFP) to investigate line-averaged diameter profiles of gas, liquid, and solid holdups along the height of a slurry bubble column. Chem. Eng. Sci. 2023, 119032. [Google Scholar] [CrossRef]

- Sabri, L.S.; Sultan, A.J.; Al-Dahhan, M.H. Mapping of microalgae culturing via radioactive particle tracking. Chem. Eng. Sci. 2018, 192, 739–758. [Google Scholar] [CrossRef]

- Vesvikar, M.S.; Al-Dahhan, M. Hydrodynamics investigation of laboratory-scale Internal Gas-lift loop anaerobic digester using non-invasive CAPRT technique. Biomass Bioenergy 2016, 84, 98–106. [Google Scholar] [CrossRef]

- Mosorov, V. An iterative position reconstruction algorithm for radioactive particle techniques. Appl. Radiat. Isot. 2013, 79, 56–61. [Google Scholar] [CrossRef]

- Mosorov, V.; Abdullah, J. MCNP5 code in radioactive particle tracking. Appl. Radiat. Isot. 2011, 69, 1287–1293. [Google Scholar] [CrossRef]

- Bhusarapu, S.; Al-Dahhan, M.; Dudukovic, M.P. Quantification of solids flow in a gas-solid riser: Single radioactive particle tracking. Chem. Eng. Sci. 2004, 59, 5381–5386. [Google Scholar] [CrossRef]

- Velo, A.F.; Hamada, M.M.; Carvalho, D.V.S.; Martins, J.F.T.; Mesquita, C.H. A portable tomography system with seventy detectors and five gamma-ray sources in fan beam geometry simulated by Monte Carlo method. Flow Meas. Instrum. 2017, 53, 89–94. [Google Scholar] [CrossRef]

- Salgado, C.M.; Brandão, L.E.B.; Schirru, R.; Pereira, C.M.N.A.; Conti, C.C. Validation of a NaI(Tl) detector’s model developed with MCNP-X code. Prog. Nucl. Energy 2012, 59, 19–25. [Google Scholar] [CrossRef]

- Moreira, M.C.F.; Conti, C.C.; Schirru, R. A new NaI(Tl) four-detector layout for field contamination assessment using artificial neural networks and the Monte Carlo method for system calibration. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2010, 621, 302–309. [Google Scholar] [CrossRef]

- Jehouani, A.; Ichaoui, R.; Boulkheir, M. Study of the NaI(Tl) efficiency by Monte Carlo method. Appl. Radiat. Isot. 2000, 53, 887–891. [Google Scholar] [CrossRef]

- Khane, V.; Said, I.A.; Al-Dahhan, M.H. Experimental investigation of pebble flow dynamics using radioactive particle tracking technique in a scaled-down Pebble Bed Modular Reactor (PBMR). Nucl. Eng. Des. 2016, 302, 1–11. [Google Scholar] [CrossRef]

- Salierno, G.; Maestri, M.; Piovano, S.; Cassanello, M.; Cardona, M.A.; Hojman, D.; Somacal, H. Solid motion in a three-phase bubble column examined with Radioactive Particle Tracking. Flow Meas. Instrum. 2018, 62, 196–204. [Google Scholar] [CrossRef]

- Qi, B.; Farid, O.; Velo, A.F.; Mendil, J.; Uribe, S.; Kaneko, Y.; Sakakura, K.; Kagota, Y.; Al-Dahhan, M. Tracking the Heavy Metal Contaminants Entrained with the Flow into a Trickle Bed Hydrotreating Reactor Packed with Different Catalyst Shapes Using Newly Developed Noninvasive Dynamic Radioactive Particle Tracking. Chem. Eng. J. 2021, 429, 132277. [Google Scholar] [CrossRef]

- Moslemian, D.; Devanathan, N.; Dudukovic, M.P. Radioactive particle tracking technique for investigation of phase recirculation and turbulence in multiphase systems. Rev. Sci. Instrum. 1992, 63, 4361–4372. [Google Scholar] [CrossRef]

- Efhaima, A.; Al-Dahhan, M.H. Bed diameter effect on the hydrodynamics of gas-solid fluidized beds via radioactive particle tracking (RPT) technique. Can. J. Chem. Eng. 2017, 95, 744–756. [Google Scholar] [CrossRef]

- Ali, N.; Al-Juwaya, T.; Al-Dahhan, M. An advanced evaluation of the mechanistic scale-up methodology of gas–solid spouted beds using radioactive particle tracking. Particuology 2017, 34, 48–60. [Google Scholar] [CrossRef]

- Chabot, J.; de Lasa, H.I. Gas Holdups and Bubble Characteristics in a Bubble Column Operated at High Temperature. Ind. Eng. Chem. Res. 1993, 32, 2595–2601. [Google Scholar] [CrossRef]

- Agahzamin, S.; Pakzad, L. A comprehensive CFD study on the effect of dense vertical internals on the hydrodynamics and population balance model in bubble columns. Chem. Eng. Sci. 2019, 193, 421–435. [Google Scholar] [CrossRef]

- Al Mesfer, M.K.; Sultan, A.J.; Al-Dahhan, M.H. Impacts of dense heat exchanging internals on gas holdup cross-sectional distributions and profiles of bubble column using gamma ray Computed Tomography (CT) for FT synthesis. Chem. Eng. J. 2016, 300, 317–333. [Google Scholar] [CrossRef]

- Sultan, A.J.; Sabri, L.S.; Al-Dahhan, M.H. Impact of heat-exchanging tube configurations on the gas holdup distribution in bubble columns using gamma-ray computed tomography. Int. J. Multiph. Flow 2018, 106, 202–219. [Google Scholar] [CrossRef]

- Mezui, Y.; Cartellier, A.; Obligado, M. An experimental study on the liquid phase properties of a bubble column operated in the homogeneous and in the heterogeneous regimes. Chem. Eng. Sci. 2023, 268, 118381. [Google Scholar] [CrossRef]

- Azizi, S.; Yadav, A.; Lau, Y.M.; Hampel, U.; Roy, S.; Schubert, M. Hydrodynamic correlations for bubble columns from complementary UXCT and RPT measurements in identical geometries and conditions. Chem. Eng. Sci. 2019, 208, 115099. [Google Scholar] [CrossRef]

- Lindner, G.A.; Mišković, S. GIPPE-RPT: Geant4 interface for particle physics experiments applied to Radioactive Particle Tracking. Appl. Radiat. Isot. 2022, 180, 110041. [Google Scholar] [CrossRef]

- Möller, F.; Lau, Y.M.; Seiler, T.; Hampel, U.; Schubert, M. A study on the influence of the tube layout on sub-channel hydrodynamics in a bubble column with internals. Chem. Eng. Sci. 2018, 179, 265–283. [Google Scholar] [CrossRef]

- Al-Juwaya, T.; Ali, N.; Al-Dahhan, M. Investigation of hydrodynamics of binary solids mixture spouted beds using radioactive particle tracking (RPT) technique. Chem. Eng. Res. Des. 2019, 148, 21–44. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farid, O.J.; Velo, A.F.; Qi, B.; Al-Dahhan, M. New Methodology for Benchmarking Hydrodynamics in Bubble Columns with Intense Internals Using the Radioactive Particle Tracking (RPT) Technique. Processes 2023, 11, 2107. https://doi.org/10.3390/pr11072107

Farid OJ, Velo AF, Qi B, Al-Dahhan M. New Methodology for Benchmarking Hydrodynamics in Bubble Columns with Intense Internals Using the Radioactive Particle Tracking (RPT) Technique. Processes. 2023; 11(7):2107. https://doi.org/10.3390/pr11072107

Chicago/Turabian StyleFarid, Omar J., Alexandre França Velo, Binbin Qi, and Muthanna Al-Dahhan. 2023. "New Methodology for Benchmarking Hydrodynamics in Bubble Columns with Intense Internals Using the Radioactive Particle Tracking (RPT) Technique" Processes 11, no. 7: 2107. https://doi.org/10.3390/pr11072107

APA StyleFarid, O. J., Velo, A. F., Qi, B., & Al-Dahhan, M. (2023). New Methodology for Benchmarking Hydrodynamics in Bubble Columns with Intense Internals Using the Radioactive Particle Tracking (RPT) Technique. Processes, 11(7), 2107. https://doi.org/10.3390/pr11072107