Promising Porous Carbon Material Derived from Argan Paste Cake by KOH Activation, for Paracetamol Removal

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Pre-Treatment

2.1.1. Activation and Carbonization

2.1.2. Granular Activated Carbons (GACs)

2.2. Characterization

2.3. Adsorption Experiments

3. Results

3.1. Characterization of Materials

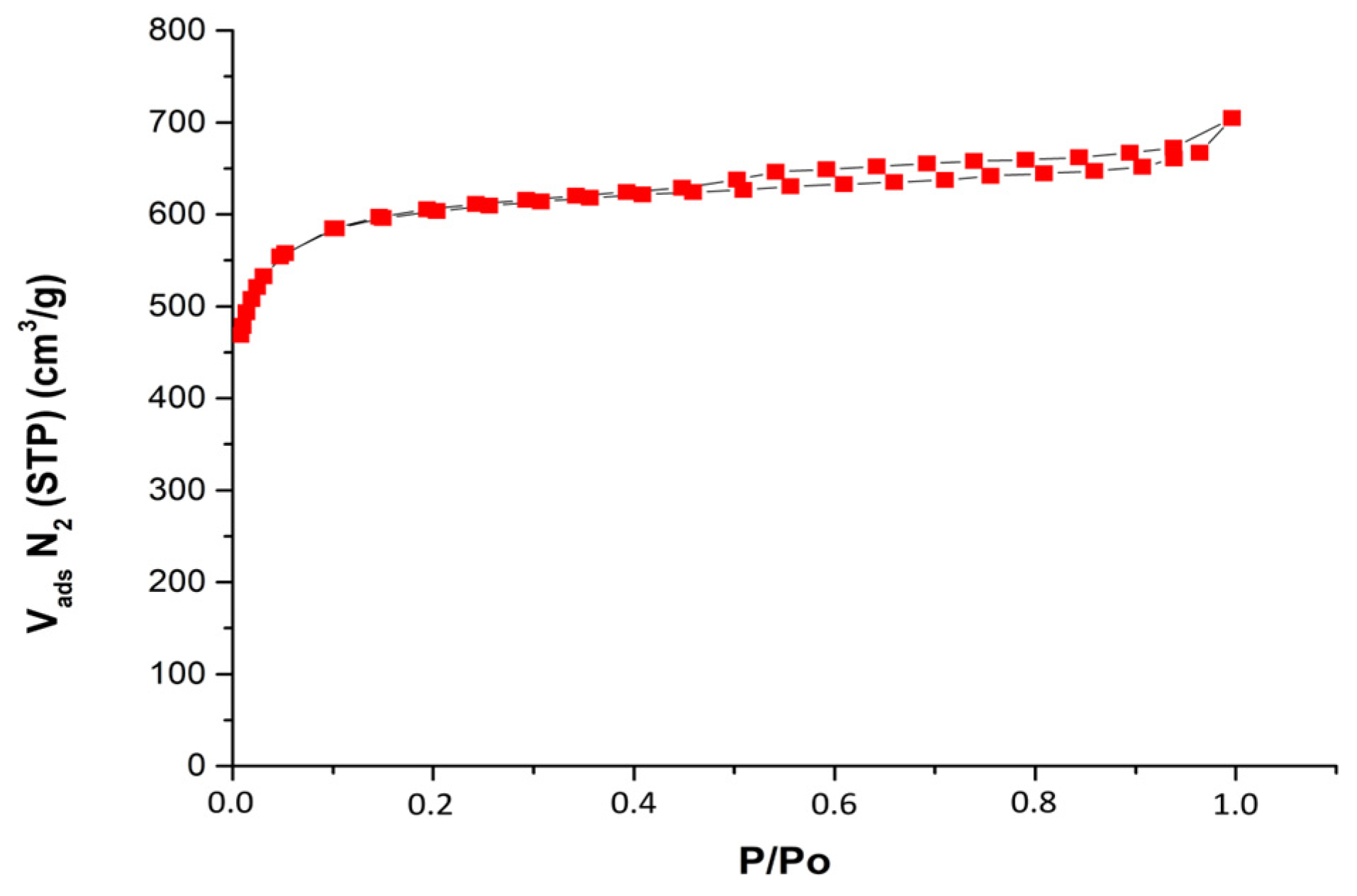

3.1.1. Textural Properties of APC-300-800

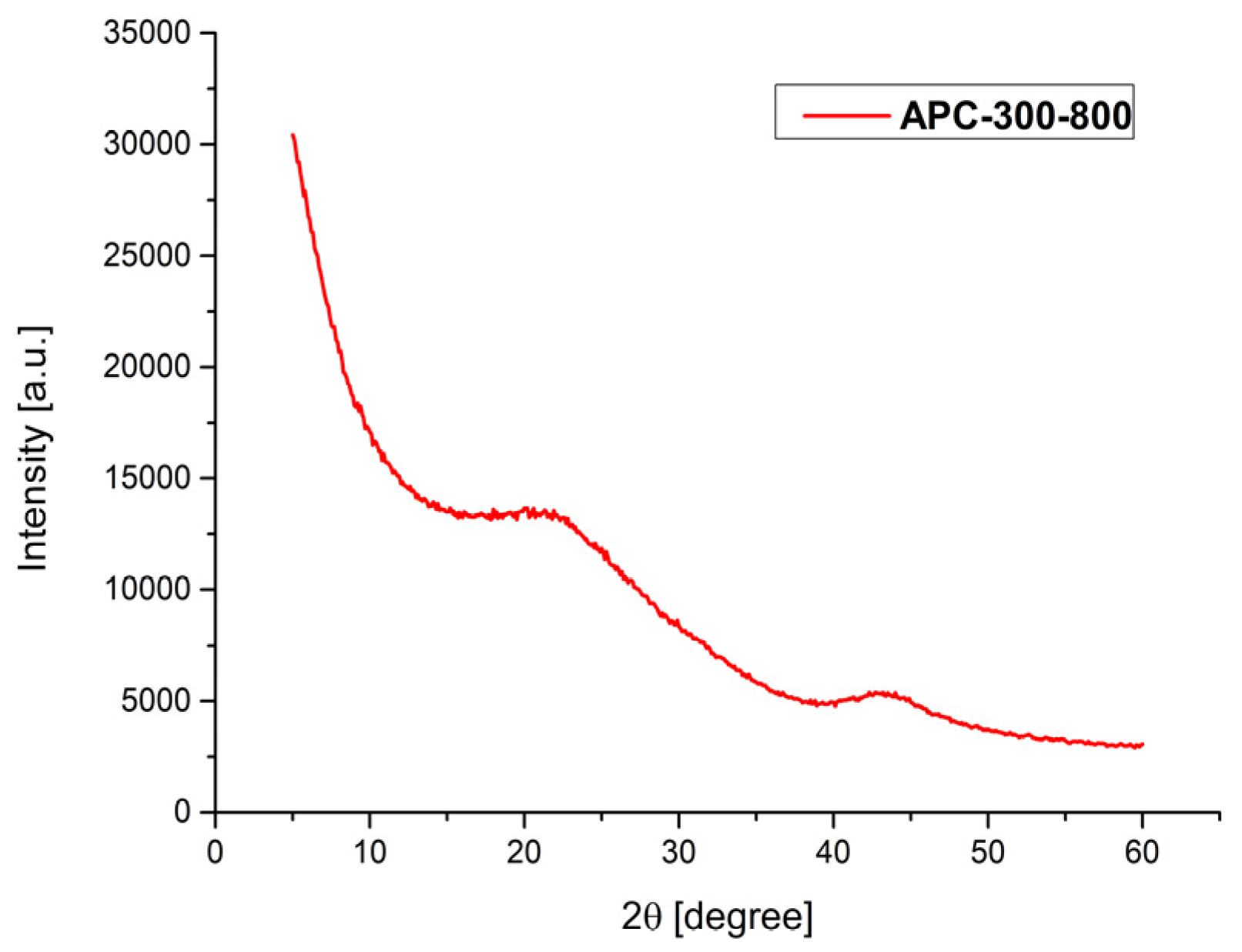

3.1.2. XRD Analysis

3.1.3. SEM Images

3.2. Adsorption Process

3.2.1. Influence of Adsorbent Dosage

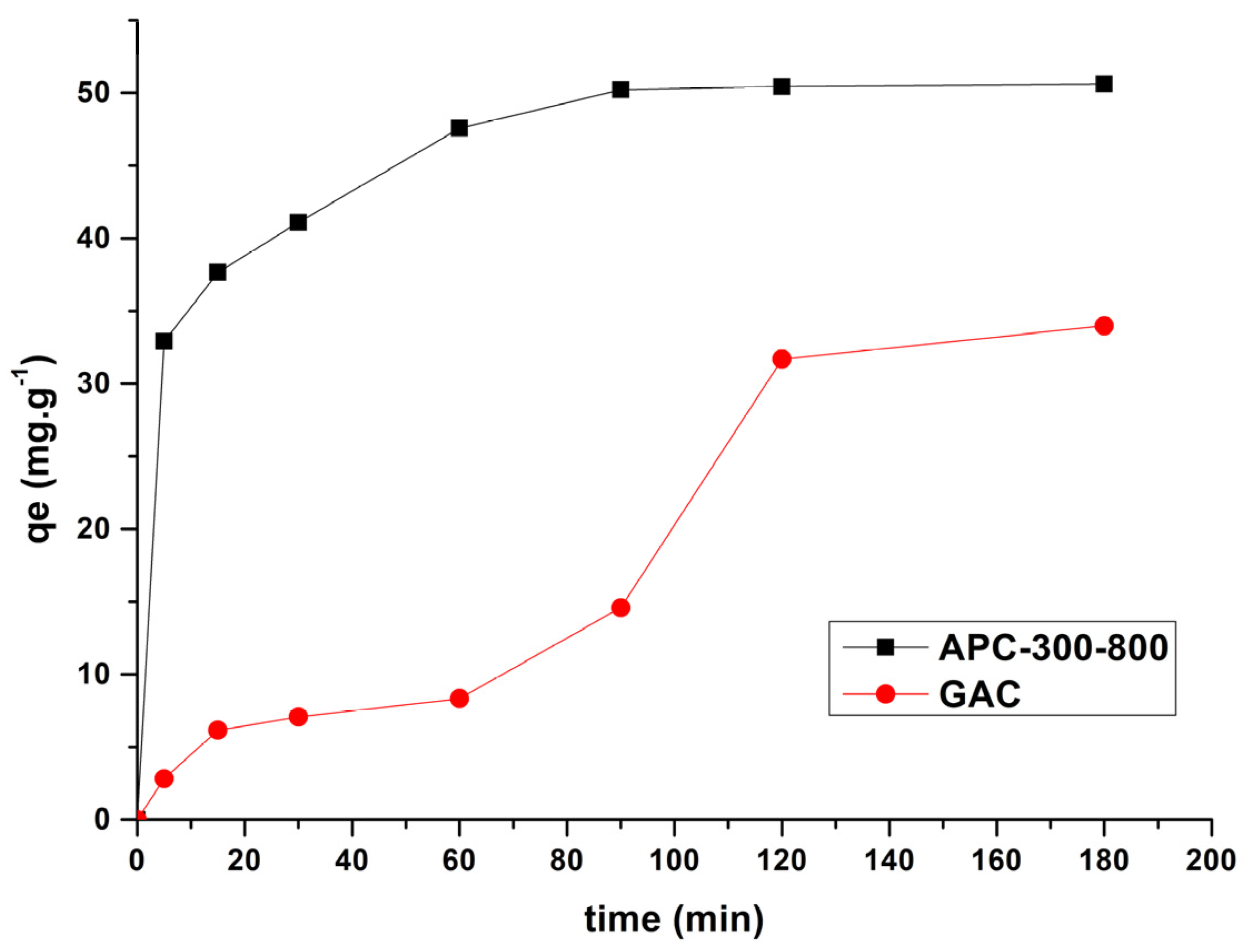

3.2.2. Influence of Contact Time

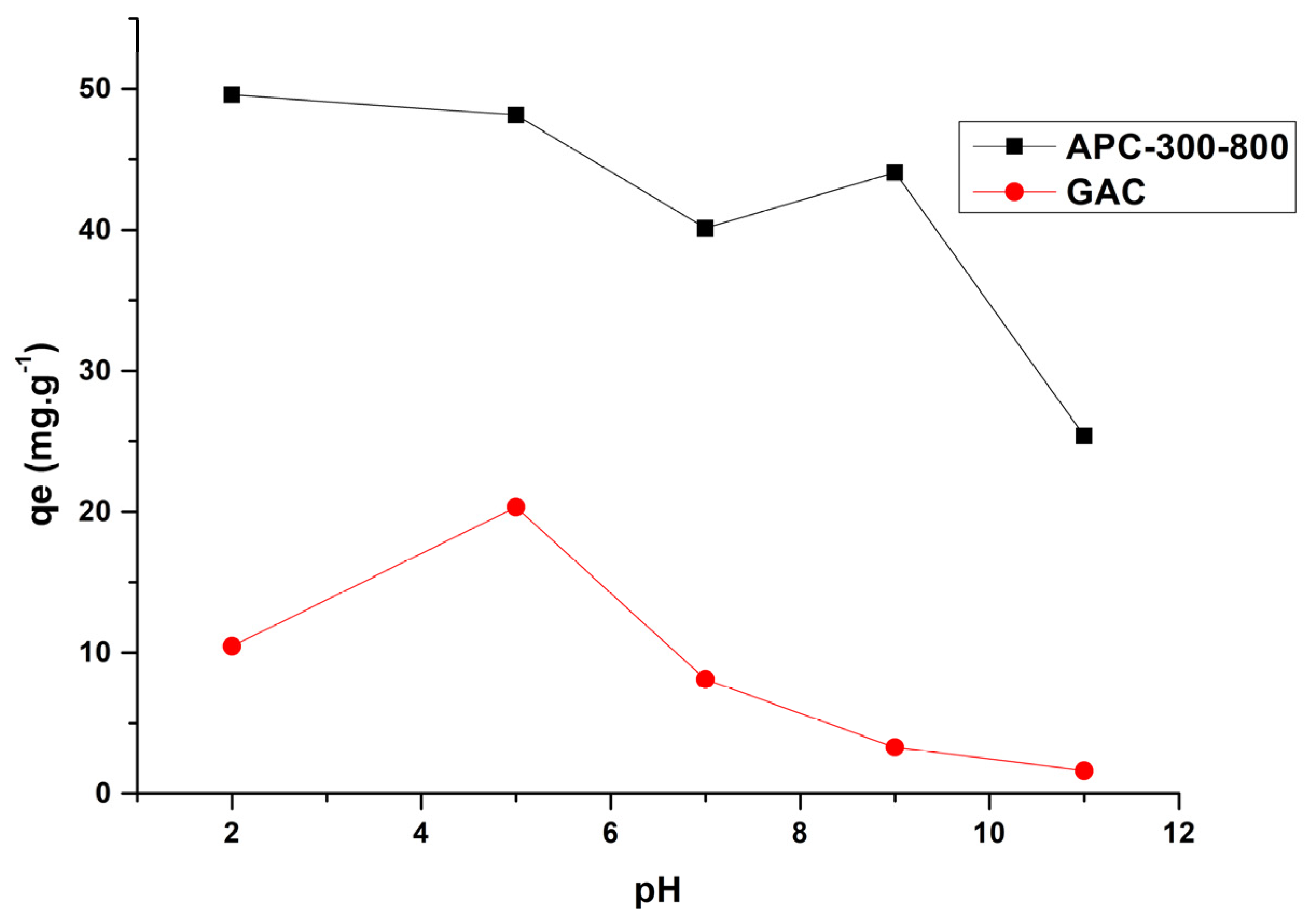

3.2.3. Influence of pH

3.2.4. Influence of Concentration

3.3. Kinetic Study

- qe (mg/g): Adsorption amount of paracetamol at equilibrium;

- qt (mg/g): Amount of paracetamol adsorbed onto the solid phase at time t;

- k1 (1/min): Pseudo-first-order rate constant;

- k2 (g/mg·min): Pseudo-second-order rate constant;

- α (mg/g·min): Initial adsorption coefficient;

- β (g/mg): Desorption coefficient;

- Kint (g/mg·min(1/2)): Rate constant of the intra-particle diffusion model;

- C: Constant.

3.4. Isotherm Studies

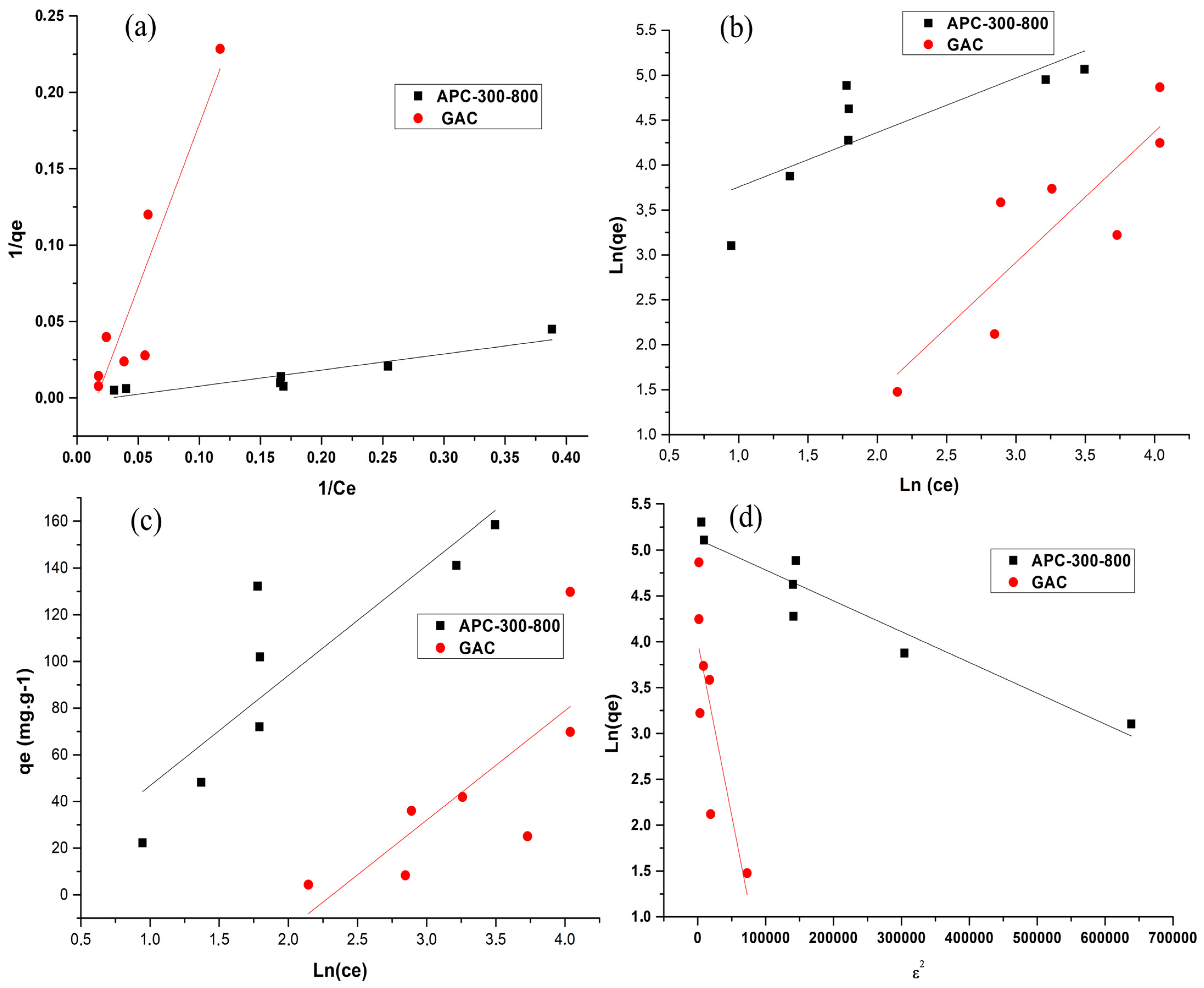

3.4.1. Plotting and Analysis of Langmuir Model

3.4.2. Plotting and Analysis of Freundlich Isotherm

3.4.3. Plotting and Analysis of Temkin Isotherm

3.4.4. Plotting and Analysis of Dubinin–Radushkevich

3.5. Thermodynamic Studies

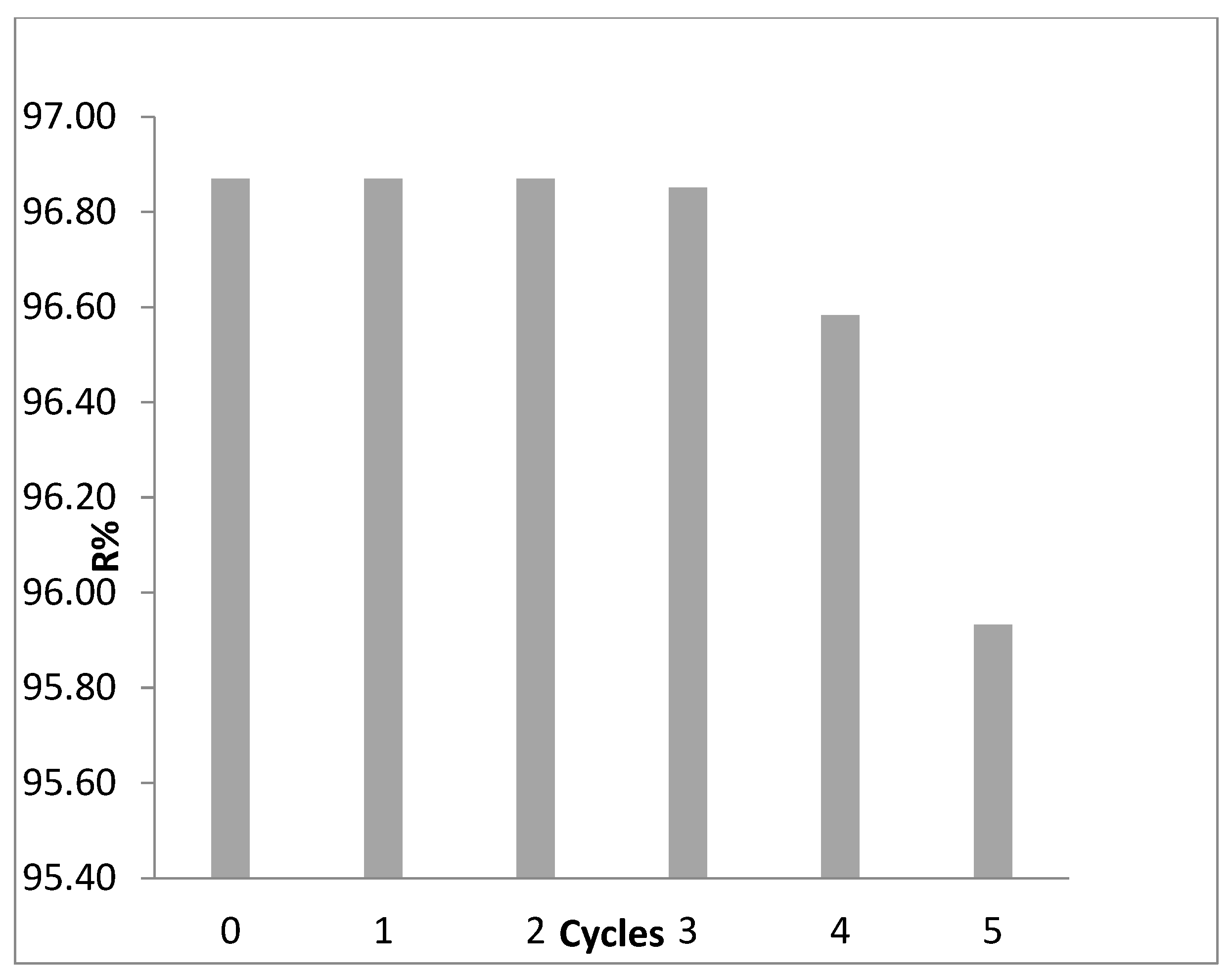

3.6. Regeneration Studies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carvalho, I.T.; Santos, L. Antibiotics in the Aquatic Environments: A Review of the European Scenario. Environ. Int. 2016, 94, 736–757. [Google Scholar] [CrossRef] [PubMed]

- Petrie, B.; Barden, R.; Kasprzyk-Hordern, B. A Review on Emerging Contaminants in Wastewaters and the Environment: Current Knowledge, Understudied Areas and Recommendations for Future Monitoring. Water Res. 2015, 72, 3–27. [Google Scholar] [CrossRef]

- Żur, J.; Piński, A.; Marchlewicz, A.; Hupert-Kocurek, K.; Wojcieszyńska, D.; Guzik, U. Organic Micropollutants Paracetamol and Ibuprofen—Toxicity, Biodegradation, and Genetic Background of Their Utilization by Bacteria. Environ. Sci. Pollut. Res. 2018, 25, 21498–21524. [Google Scholar] [CrossRef] [PubMed]

- Mostafa, E.M.A.; Tawfik, A.M.; Abd-Elrahman, K.M. Egyptian Perspectives on Potential Risk of Paracetamol/Acetaminophen-Induced Toxicities: Lessons Learnt during COVID-19 Pandemic. Toxicol. Rep. 2022, 9, 541–548. [Google Scholar] [CrossRef] [PubMed]

- Essawy, A.E.; Alkhuriji, A.F.; Soffar, A.A. Paracetamol Overdose Induces Physiological and Pathological Aberrations in Rat Brain. J. Appl. Pharm. Sci. 2017, 7, 185–190. [Google Scholar] [CrossRef]

- Tittarelli, R.; Pellegrini, M.; Scarpellini, M.G.; Marinelli, E.; Bruti, V.; Luca, N.M.D.; Busardò, F.P.; Zaami, S. Hepatotoxicity of Paracetamol and Related Fatalities. Eur. Rev. Med Pharmacol. Sci. 2017, 21, 95–101. [Google Scholar]

- Yoon, E.; Babar, A.; Choudhary, M.; Kutner, M.; Pyrsopoulos, N. Acetaminophen-Induced Hepatotoxicity: A Comprehensive Update. J. Clin. Transl. Hepatol. 2016, 4, 131–142. [Google Scholar] [CrossRef]

- Ortúzar, M.; Esterhuizen, M.; Olicón-Hernández, D.R.; González-López, J.; Aranda, E. Pharmaceutical Pollution in Aquatic Environments: A Concise Review of Environmental Impacts and Bioremediation Systems. Front. Microbiol. 2022, 13, 869332. [Google Scholar] [CrossRef]

- Teh, C.Y.; Budiman, P.M.; Shak, K.P.Y.; Wu, T.Y. Recent Advancement of Coagulation–Flocculation and Its Application in Wastewater Treatment. Ind. Eng. Chem. Res. 2016, 55, 4363–4389. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, L.; Chen, J. Paracetamol in the Environment and Its Degradation by Microorganisms. Appl. Microbiol. Biotechnol. 2012, 96, 875–884. [Google Scholar] [CrossRef]

- Gogate, P.R.; Pandit, A.B. A Review of Imperative Technologies for Wastewater Treatment I: Oxidation Technologies at Ambient Conditions. Adv. Environ. Res. 2004, 8, 501–551. [Google Scholar] [CrossRef]

- Chen, R.; Chai, L.; Wang, Y.; Liu, H.; Shu, Y.; Zhao, J. Degradation of Organic Wastewater Containing Cu–EDTA by Fe–C Micro-Electrolysis. Trans. Nonferrous Met. Soc. China 2012, 22, 983–990. [Google Scholar] [CrossRef]

- Rad, L.R.; Haririan, I.; Divsar, F. Comparison of Adsorption and Photo-Fenton Processes for Phenol and Paracetamol Removing from Aqueous Solutions: Single and Binary Systems. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2015, 136, 423–428. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharya, A. Remediation of Pesticide-Polluted Waters Through Membranes. Sep. Purif. Rev. 2006, 35, 1–38. [Google Scholar] [CrossRef]

- Soltani, R.D.C.; Miraftabi, Z.; Mahmoudi, M.; Jorfi, S.; Boczkaj, G.; Khataee, A. Stone Cutting Industry Waste-Supported Zinc Oxide Nanostructures for Ultrasonic Assisted Decomposition of an Anti-Inflammatory Non-Steroidal Pharmaceutical Compound. Ultrason. Sonochemistry 2019, 58, 104669. [Google Scholar] [CrossRef]

- Mirzaee, R.; Darvishi Cheshmeh Soltani, R.; Khataee, A.; Boczkaj, G. Combination of Air-Dispersion Cathode with Sacrificial Iron Anode Generating Fe2+Fe3+2O4 Nanostructures to Degrade Paracetamol under Ultrasonic Irradiation. J. Mol. Liq. 2019, 284, 536–546. [Google Scholar] [CrossRef]

- Norra, G.-F.; Radjenovic, J. Removal of Persistent Organic Contaminants from Wastewater Using a Hybrid Electrochemical-Granular Activated Carbon (GAC) System. J. Hazard. Mater. 2021, 415, 125557. [Google Scholar] [CrossRef]

- Karimi-Maleh, H.; Karimi, F.; Fu, L.; Sanati, A.L.; Alizadeh, M.; Karaman, C.; Orooji, Y. Cyanazine Herbicide Monitoring as a Hazardous Substance by a DNA Nanostructure Biosensor. J. Hazard. Mater. 2022, 423, 127058. [Google Scholar] [CrossRef]

- Ndoun, M.C.; Elliott, H.A.; Preisendanz, H.E.; Williams, C.F.; Knopf, A.; Watson, J.E. Adsorption of Pharmaceuticals from Aqueous Solutions Using Biochar Derived from Cotton Gin Waste and Guayule Bagasse. Biochar 2021, 3, 89–104. [Google Scholar] [CrossRef]

- Serafin, J.; Ouzzine, M.; Cruz Junior, O.F.; Sreńscek-Nazzal, J. Preparation of Low-Cost Activated Carbons from Amazonian Nutshells for CO2 Storage. Biomass Bioenergy 2021, 144, 105925. [Google Scholar] [CrossRef]

- Sajid, M.; Bai, Y.; Liu, D.; Zhao, X. Organic Acid Catalyzed Production of Platform Chemical 5-Hydroxymethylfurfural from Fructose: Process Comparison and Evaluation Based on Kinetic Modeling. Arab. J. Chem. 2020, 13, 7430–7444. [Google Scholar] [CrossRef]

- Bary, G.; Jamil, M.I.; Arslan, M.; Ghani, L.; Ahmed, W.; Ahmad, H.; Zaman, G.; Ayub, K.; Sajid, M.; Ahmad, R.; et al. Regio- and Stereoselective Functionalization of Alkenes with Emphasis on Mechanistic Insight and Sustainability Concerns. J. Saudi Chem. Soc. 2021, 25, 101260. [Google Scholar] [CrossRef]

- Mestre, A.S.; Bexiga, A.S.; Proença, M.; Andrade, M.; Pinto, M.L.; Matos, I.; Fonseca, I.M.; Carvalho, A.P. Activated Carbons from Sisal Waste by Chemical Activation with K2CO3: Kinetics of Paracetamol and Ibuprofen Removal from Aqueous Solution. Bioresour. Technol. 2011, 102, 8253–8260. [Google Scholar] [CrossRef] [PubMed]

- Terzyk, A.P. The Impact of Carbon Surface Composition on the Diffusion and Adsorption of Paracetamol at Different Temperatures and at Neutral PH. J. Colloid Interface Sci. 2000, 230, 219–222. [Google Scholar] [CrossRef] [PubMed]

- Terzyk, A.P. Adsorption of Biologically Active Compounds from Aqueous Solutions on to Commercial Unmodified Activated Carbons: Part II. Temperature Dependence of Adsorption Kinetics of 4-Hydroxyacetanilide (Paracetamol) at Neutral PH. Adsorpt. Sci. Technol. 2000, 18, 477–508. [Google Scholar] [CrossRef]

- Macías-García, A.; García-Sanz-Calcedo, J.; Carrasco-Amador, J.P.; Segura-Cruz, R. Adsorption of Paracetamol in Hospital Wastewater Through Activated Carbon Filters. Sustainability 2019, 11, 2672. [Google Scholar] [CrossRef]

- Song, X.; Zhang, Y.; Chang, C. Novel Method for Preparing Activated Carbons with High Specific Surface Area from Rice Husk. Ind. Eng. Chem. Res. 2012, 51, 15075–15081. [Google Scholar] [CrossRef]

- Aithammou, R.; Harrouni, C.; Aboudlou, L.; Hallouti, A.; Mlouk, M.; Elasbahani, A.; Daoud, S. Effect of Clones, Year of Harvest and Geographical Origin of Fruits on Quality and Chemical Composition of Argan Oil. Food Chem. 2019, 297, 124749. [Google Scholar] [CrossRef]

- Mechqoq, H.; El Yaagoubi, M.; Momchilova, S.; Msanda, F.; El Aouad, N. Comparative Study on Yields and Quality Parameters of Argan Oils Extracted by Conventional and Green Extraction Techniques. Grain Oil Sci. Technol. 2021, 4, 125–130. [Google Scholar] [CrossRef]

- González-Fernández, M.J.; Manzano-Agugliaro, F.; Zapata-Sierra, A.; Belarbi, E.H.; Guil-Guerrero, J.L. Green Argan Oil Extraction from Roasted and Unroasted Seeds by Using Various Polarity Solvents Allowed by the EU Legislation. J. Clean. Prod. 2020, 276, 123081. [Google Scholar] [CrossRef]

- Al-sareji, O.J.; Meiczinger, M.; Somogyi, V.; Al-Juboori, R.A.; Grmasha, R.A.; Stenger-Kovács, C.; Jakab, M.; Hashim, K.S. Removal of Emerging Pollutants from Water Using Enzyme-Immobilized Activated Carbon from Coconut Shell. J. Environ. Chem. Eng. 2023, 11, 109803. [Google Scholar] [CrossRef]

- Benstoem, F.; Nahrstedt, A.; Boehler, M.; Knopp, G.; Montag, D.; Siegrist, H.; Pinnekamp, J. Performance of Granular Activated Carbon to Remove Micropollutants from Municipal Wastewater—A Meta-Analysis of Pilot- and Large-Scale Studies. Chemosphere 2017, 185, 105–118. [Google Scholar] [CrossRef] [PubMed]

- Jacobi Aquasorb Catalytic Granular Coconut Shell-Based Activated Carbon. Available online: https://www.aquascience.net/jacobi-aquasorb-catalytic-granular-coconut-shell-based-activated-carbon (accessed on 2 June 2023).

- Mamane, O.S.; Zanguina, A.; Daou, I.; Natatou, I. Préparation et caractérisation de charbons actifs à base de coques de noyaux de Balanites Eagyptiaca et de Zizyphus Mauritiana. J. Société Ouest-Afr. Chim. 2016, 41, 59. [Google Scholar]

- Rouquerol, J.; Avnir, D.; Fairbridge, C.W.; Everett, D.H.; Haynes, J.H.; Pernicone, N.; Ramsay, J.D.F.; Sing, K.S.W.; Unger, K.K. Recommendations for the Characterization of Porous Solids (Technical Report). Pure Appl. Chem. 1994, 66, 1739–1758. [Google Scholar] [CrossRef]

- Yoshizawa, N.; Maruyama, K.; Yamada, Y.; Ishikawa, E.; Kobayashi, M.; Toda, Y.; Shiraishi, M. XRD Evaluation of KOH Activation Process and Influence of Coal Rankq. Fuel 2002, 81, 1717–1722. [Google Scholar] [CrossRef]

- El Khomri, M.; El Messaoudi, N.; Dbik, A.; Bentahar, S.; Lacherai, A. Efficient Adsorbent Derived from Argania Spinosa for the Adsorption of Cationic Dye: Kinetics, Mechanism, Isotherm and Thermodynamic Study. Surf. Interfaces 2020, 20, 100601. [Google Scholar] [CrossRef]

- Li, H.; Budarin, V.L.; Clark, J.H.; North, M.; Wu, X. Rapid and Efficient Adsorption of Methylene Blue Dye from Aqueous Solution by Hierarchically Porous, Activated Starbons®: Mechanism and Porosity Dependence. J. Hazard. Mater. 2022, 436, 129174. [Google Scholar] [CrossRef]

- Rincón-Silva, N.G.; Moreno-Piraján, J.C.; Giraldo, L.G. Thermodynamic Study of Adsorption of Phenol, 4-Chlorophenol, and 4-Nitrophenol on Activated Carbon Obtained from Eucalyptus Seed. J. Chem. 2015, 2015, 569403. [Google Scholar] [CrossRef]

- Edet, U.A.; Ifelebuegu, A.O. Kinetics, Isotherms, and Thermodynamic Modeling of the Adsorption of Phosphates from Model Wastewater Using Recycled Brick Waste. Processes 2020, 8, 665. [Google Scholar] [CrossRef]

- Taiwo, A.F.; Chinyere, N.J. Sorption Characteristics for Multiple Adsorption of Heavy Metal Ions Using Activated Carbon from Nigerian Bamboo. J. Mater. Sci. Chem. Eng. 2016, 4, 39–48. [Google Scholar] [CrossRef]

- Musah, M.; Azeh, Y.; Mathew, J.; Umar, M.; Abdulhamid, Z.; Muhammad, A. Adsorption Kinetics and Isotherm Models: A Review. CaJoST 2022, 4, 20–26. [Google Scholar] [CrossRef]

- Spaltro, A.; Pila, M.N.; Colasurdo, D.D.; Noseda Grau, E.; Román, G.; Simonetti, S.; Ruiz, D.L. Removal of Paracetamol from Aqueous Solution by Activated Carbon and Silica. Experimental and Computational Study. J. Contam. Hydrol. 2021, 236, 103739. [Google Scholar] [CrossRef]

- Sajid, M.; Bari, S.; Saif Ur Rehman, M.; Ashfaq, M.; Guoliang, Y.; Mustafa, G. Adsorption Characteristics of Paracetamol Removal onto Activated Carbon Prepared from Cannabis Sativum Hemp. Alex. Eng. J. 2022, 61, 7203–7212. [Google Scholar] [CrossRef]

- Langmuir, I. The adsorption of gases on plane surfaces of glass, mica and platinum. J. Am. Chem. Soc. 1918, 40, 1361–1403. [Google Scholar] [CrossRef]

- Dada, A.O.; Olalekan, A.P.; Olatunya, A.M.; Dada, O.J.I.J.C. Langmuir, Freundlich, Temkin and Dubinin–Radushkevich Isotherms Studies of Equilibrium Sorption of Zn2+ Unto Phosphoric Acid Modified Rice Husk. IOSR J. Appl. Chem. 2012, 3, 38–45. [Google Scholar] [CrossRef]

- Romero-González, J.; Peralta-Videa, J.R.; Rodríguez, E.; Ramirez, S.L.; Gardea-Torresdey, J.L. Determination of Thermodynamic Parameters of Cr(VI) Adsorption from Aqueous Solution onto Agave Lechuguilla Biomass. J. Chem. Thermodyn. 2005, 37, 343–347. [Google Scholar] [CrossRef]

- Ragadhita, R.; Nandiyanto, A.B.D. How to Calculate Adsorption Isotherms of Particles Using Two-Parameter Monolayer Adsorption Models and Equations. Indones. J. Sci. Technol. 2021, 6, 205–234. [Google Scholar] [CrossRef]

- Tran, H.N.; You, S.-J.; Chao, H.-P. Thermodynamic Parameters of Cadmium Adsorption onto Orange Peel Calculated from Various Methods: A Comparison Study. J. Environ. Chem. Eng. 2016, 4, 2671–2682. [Google Scholar] [CrossRef]

| Samples | SBET (m2/g) | VN2 (cm3/g) | VCO2 (cm3/g) | Vmeso (cm3/g) | VT (cm3/g) | Yield |

|---|---|---|---|---|---|---|

| APC-300-800 | 1937 | 0.97 | 0.89 | 0.12 | 1.09 | 24.53% |

| GAC | 1068 | 0.49 | 0.41 | 0.03 | 0.51 | - |

| Biomass | |||

|---|---|---|---|

| Models | Parameters | APC-300-800 | GAC |

| Pseudo-first-order | qe (mg/g) | 38.2139 | 48.6620 |

| K1 (1/min) | 0.0467 | 0.0189 | |

| R2 | 0.955 | 0.7277 | |

| Pseudo-second-order | qe (mg/g) | 52.631 | 66.666 |

| K2 (g/mg·min) | 3.567 × 10−3 | 6.741 × 10−5 | |

| R2 | 0.9992 | 0.237 | |

| Elovich | α (mg/g·min) | 8.1545 | 0.677 |

| β (g/mg) | 0.3308 | 0.5100 | |

| R2 | 0.8907 | 0.6511 | |

| Intraparticle diffusion | Kint (g/mg·min(1/2)) | 1.04 | 0.8633 |

| C | 6.02 | 1.3801 | |

| R2 | 0.7022 | 0.8407 | |

| Precursor | Qmax (mg·g−1) | KL (L·mg−1) | R𝑳 | R2 | Note |

|---|---|---|---|---|---|

| APC-300-800 | 344.827 | 0.0275 | 0.78 | 0.8497 | 0 < 𝑅𝐿 < 1 adsorption is favorable, R2 > 0.70 monolayer adsorption |

| GAC | 13.1061 | 0.0291 | 0.77 | 0.868 | 0 < 𝑅𝐿 < 1 adsorption is favorable, R2 > 0.70 monolayer adsorption |

| Precursors | 1/n | R2 | Note |

|---|---|---|---|

| APC-300-800 | 0.5065 | 0.6122 | 0 < 1/𝑛 < 1 means favorable adsorption process 𝑛 < 1, adsorption process with physical interaction R2 > 0.70, multilayer adsorption |

| GAC | 1.2508 | 0.5491 | 1/𝑛 > 1, cooperative adsorption 𝑛 < 1, chemical interaction between adsorbate molecules R2 < 0.70, monolayer adsorption |

| Precursor | KT (L·mg−1) | BT (J·mol−1) | R2 | Note |

|---|---|---|---|---|

| APC-300-800 | 40.449 | 60.116 | 0.7342 | 𝐵𝑇 < 8 kJ/mol Physical interaction between adsorbate molecules R2 > 0.70, adsorbate/adsorbent surface uniform distribution |

| GAC | 0.0985 | 157.439 | 0.5804 | 𝐵𝑇 < 8 kJ/mol Physical interaction between adsorbate molecules R2 < 0.70, no adsorbate/adsorbent surface uniform distribution |

| Precursor | qm (mg·g−1) | E (kJ·mol−1) | Kad | R2 | Note |

|---|---|---|---|---|---|

| APC-300-800 | 166.967 | 385,761 | 3.10–6 | 0.89665 | R2 > 0.70, micropore size exists in adsorbent surface |

| GAC | 54.266 | 114,992 | 3.10–5 | 0.58757 | R2 < 0.70, no micropore size exists in adsorbent surface |

| Adsorbents | ΔG° (kJ·mol−1) | ΔH° (kJ·mol−1) | ΔS° (J·mol−1·K−1) | ||

|---|---|---|---|---|---|

| 298 (K) | 318 (K) | 338 (K) | |||

| APC-300-800 | −151.74 | −556.78 | −575.19 | 10.152 | 54.3270 |

| GAC | −5.454 | −12.271 | −19.089 | 96.126 | 340.874 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yahia, E.H.; Cherif, E.K.; Ouzzine, M.; Touijer, A.; Coren, F.; Saidi, M. Promising Porous Carbon Material Derived from Argan Paste Cake by KOH Activation, for Paracetamol Removal. Processes 2023, 11, 2078. https://doi.org/10.3390/pr11072078

Yahia EH, Cherif EK, Ouzzine M, Touijer A, Coren F, Saidi M. Promising Porous Carbon Material Derived from Argan Paste Cake by KOH Activation, for Paracetamol Removal. Processes. 2023; 11(7):2078. https://doi.org/10.3390/pr11072078

Chicago/Turabian StyleYahia, El Habib, El Khalil Cherif, Mohammed Ouzzine, Abdellah Touijer, Franco Coren, and Mohamed Saidi. 2023. "Promising Porous Carbon Material Derived from Argan Paste Cake by KOH Activation, for Paracetamol Removal" Processes 11, no. 7: 2078. https://doi.org/10.3390/pr11072078

APA StyleYahia, E. H., Cherif, E. K., Ouzzine, M., Touijer, A., Coren, F., & Saidi, M. (2023). Promising Porous Carbon Material Derived from Argan Paste Cake by KOH Activation, for Paracetamol Removal. Processes, 11(7), 2078. https://doi.org/10.3390/pr11072078