1. Introduction

As the primary channel for transporting finished coal products, personnel, equipment, and other important materials, the safety of coal mine shafts is related to the safe production of the entire coal mine, which is deemed as the top–priority component of the coal mine safety system [

1,

2]. In the past few years, intelligent mining inspection robots, which integrate coal mine safety monitoring and robotics, have been widely applied in the field of the underground safety inspection of coal mines [

3,

4]. Using the wall climbing method, the intelligent monitoring robot completes the work tasks; therefore, the working space of the robot is expanded. Moreover, due to the limited working space in vertical shafts, it is difficult to conduct safety monitoring, and this technical issue is overcome [

5,

6] accordingly. During the construction phase of the shaft, and under the premise that the production equipment, power supply cables, and communication methods are uncertain and unstable, resource consumption is minimized, while the monitoring function is maximized. During the service period of the well shaft, by replacing manual daily safety inspections, the effectiveness and timeliness of monitoring data are improved, and the purpose of saving costs without affecting the normal production of coal mines is achieved, which is of great value for its practical application.

The key technologies of wall–climbing robots revolve around their adsorption capacity and motor capabilities. In view of how to solve the hindering effect of one’s own gravity during wall climbing, a variety of methods are tried by researchers at home and abroad, namely, negative pressure adsorption [

7,

8], bionics adsorption [

9,

10], climbing adsorption [

11,

12] and electromagnetic adsorption technology [

13,

14]. Those technologies have their own merits and demerits; consequently, it is essential to select according to the actual situation and specific needs. Combined with the structural characteristics of the composite well shaft lining and the gas properties in the working environment, the analysis indicates that the permanent magnet adsorption uses high–power magnets to form a stable magnetic field. There is no need for a power supply and control system, merely the structural design and mechanical properties of the robot body should be taken into account, and there is no danger of slipping even when the system is suddenly powered down [

15,

16].

However, the biggest defect of permanent magnet adsorption is that it is impossible to adjust the adsorption force dynamically. The adsorption force generated at any moment remains unchanged. To ensure reliable adsorption, the adsorption force generated must be greater than the maximum adsorption force required at all times during the robot’s crawling process. Excessive adsorption force increases the pressure and friction of the drive wheel on the wall. The drive system has to deliver more energy to ensure the normal movement of the robot, causing excessive energy consumption and affecting the flexibility of movement. Due to the use of the magnetic force of the magnetic field generated by the electromagnetic equipment on the ferromagnetic material as the adsorption source, the electromagnetic adsorption is not affected by the smoothness of the lining, bringing it better lining surface adaptability. The electromagnetic adsorption force can be adjusted by voltage [

17,

18]; however, due to the limitations of the shaft lining structure, it is difficult to achieve a fully reliable adsorption guarantee in areas where the reinforcement bar spacing is too wide or the concrete protective layer is too thick. Based on the principles of fluid mechanics and pneumatic aerothermodynamics, a negative pressure mechanism is used to create the pressure difference between the air in the cavity and the external atmosphere; thus, the negative pressure adsorption force is generated. Getting rid of the limitations of lining structure and material, the mechanism of the negative pressure–generating system of the negative pressure adsorption method is relatively simple, which can provide a stable adsorption guarantee [

19,

20]. Meanwhile, in areas where the shaft lining is too rough or in ravines or protrusions, the inevitable hazard of losing negative pressure due to excessive air leakage from the sealing mechanism may occur occasionally.

The previous research on the application of wall–climbing robots in the industrial field was normally limited to merely a single scenario. It was either electromagnetic adsorption on a planar guide magnet or negative pressure adsorption on a smooth surface, which made it more demanding on the adsorption conditions of the vertical lining. The lack of in–depth research on complex environmental applications or coupled adsorption technologies made it difficult for wall–climbing robots to be widely used in industrial production and civil life. In the practical application of wall–climbing robot technology in the safety monitoring of coal mine shafts, due to the composite shaft lining structure and rough surface commonly used in the coal mine shaft’s lining, it was difficult to provide safe and stable adsorption pressure for the wall–climbing robot with a single adsorption method. As a result, based on the structural characteristics of reinforced concrete on the inner lining of the well shaft, the electromagnetic adsorption device and the negative pressure adsorption device that meet the actual needs are designed to produce electromagnetic adsorption and negative pressure adsorption to achieve complementary effects, which are consistent with the lining adsorption requirements of wall–climbing robots under the well shaft environment.

Taking the maximum negative pressure required by the system under independent negative pressure adsorption as the actual working condition point, through this research, the basic data and boundary values of the experimental entry conditions are set, the structural parameters and outlet and inlet angles of the centrifugal fan are calculated, and the pressure distribution, fluid flow, velocity component, and direction of movement at different stages of fluid movement are analyzed. The changes in the electromagnetic parameters of the electromagnetic channel of the electromagnetic unit and the reinforcement bar in the lining under changes in reinforcement bar model, posture angle, and coil current are explored. According to the experimental results, the formation mechanism of electromagnetic adsorption and negative pressure adsorption have been verified. Numerical analysis has revealed the feasibility and advanced nature of coupled adsorption technology. Moreover, based on the comparative analysis results of power loss under the same operating conditions, the law of change of system power with output adsorption force in the coupled adsorption mechanism and the general principle of electromagnetic and negative pressure adsorption power distribution in system’s operation are derived. In the simulation experiment of this paper, multiple inspection surfaces were established, and the investigation and analysis of the overall experimental process was highlighted, thereby avoiding the excessive singularity and one–sided situation in previous experimental research. Through the comparative analysis of the calculation results and the experimental results, the persuasiveness of the experimental conclusions was enhanced. Adopting the coupled adsorption method, the intelligent safety monitoring wall–climbing robot system can not only be applied for safety monitoring during the construction and production of coal mine shafts, but it can also be widely used in other non–ferrous metal mines, as well as in the local safety monitoring of civil engineering facilities such as railways and subway tunnels.

2. Admission Conditions for Negative Pressure Adsorption Experiment

- (1)

Basic data of negative pressure adsorption experiment

For the digital simulation experiment of the negative pressure adsorption mechanism of the wall–climbing robot, in the preparation stage of the experiment, a variety of the entry conditions of the experiment should be defined—namely, the components and structural dimensions of the negative pressure adsorption device, the environmental parameters and fluid pneumatic parameters of the working conditions, the blade structure of the centrifugal fan, and the outlet and inlet angles. Consequently, the theoretical basis and data support for the establishment of simulation models and pre–calculation processing can be provided.

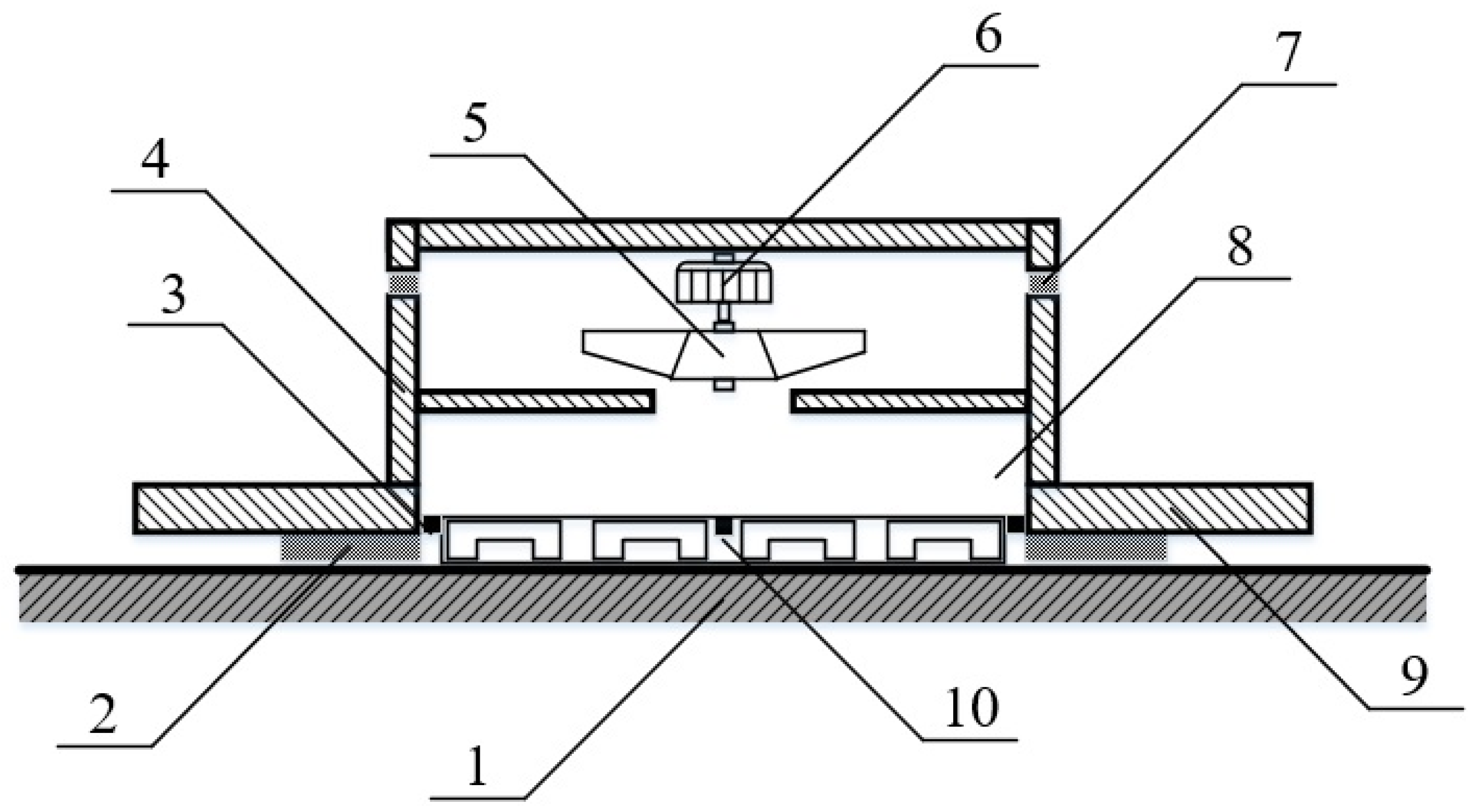

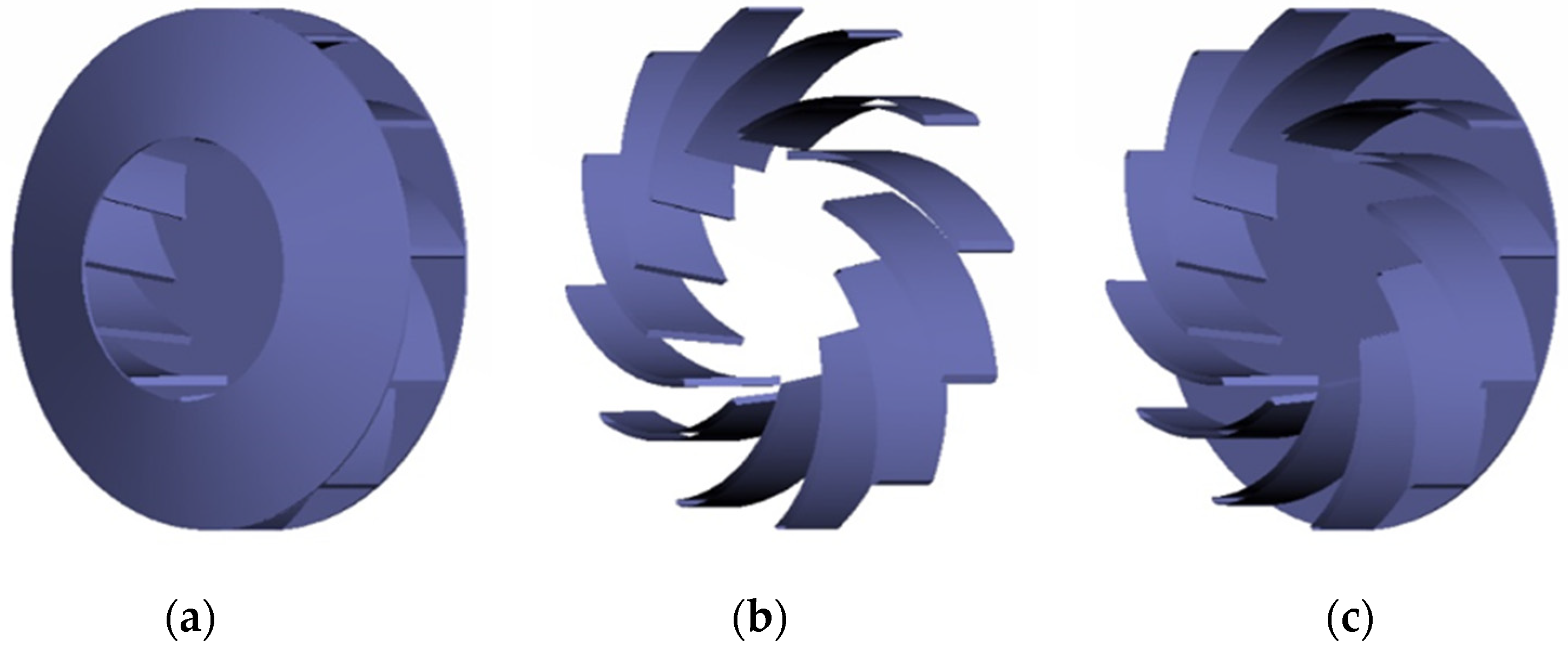

The designed length of the wall–climbing robot chassis is 0.8 m, and the width is 0.6 m. According to

Figure 1, the coupling adsorption mechanism adopts an integrated design. The electromagnetic adsorption device is fixed to the lower part of the robot chassis and is nested and installed at the air inlet of the negative pressure adsorption mechanism. The diameter of the center ring of the electromagnetic array is 0.3 m, and the longitudinal diameter extends <0.05 m upward and downward. The structural conditions of the electromagnetic array determine that the shape of the negative pressure chamber is cylindrical, with an overall height of 0.2 m and an inlet radius of 0.2 m. A high–speed motor and a centrifugal fan are installed in the upper part of the negative pressure chamber, and a sealing device is connected to the lower part. The sealing device adopts a circular structure. Since the diameter of the outer ring of the sealing device shall not exceed the structural limit of the width of the robot chassis, the length of the sealing device is set to 0.1 m.

Calculated according to a design mass of the body and load of 30 Kg, without considering the electromagnetic adsorption force and under the premise of ensuring the safe adsorption of the wall–climbing robot, the negative pressure adsorption force required in the vertical motionless state is 327 N, and the negative pressure adsorption force required in the vertical motion is 393 N.

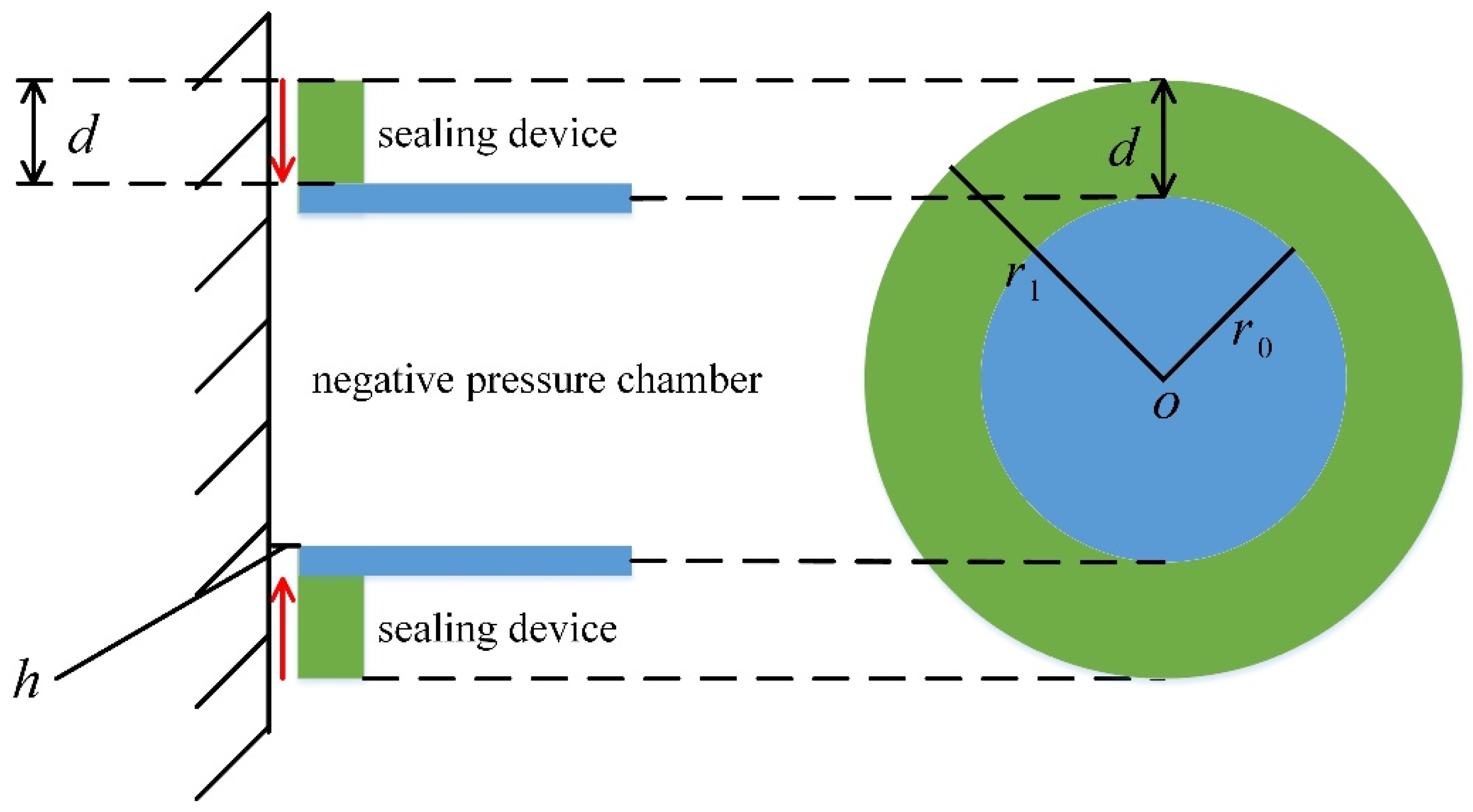

As illustrated in

Figure 2,

r1 is the sum of the inlet radius of the vacuum cavity and the length of the sealing device. The negative pressure chamber and the sealing device have a pressure difference with the external atmosphere simultaneously, and they are subject to the normal thrust from the atmosphere. The equation of the action area of the negative pressure adsorption force is as follows:

Among which:

S—The action area of the negative pressure adsorption force;

r0—Inlet radius of the negative pressure chamber, r0 = 0.2 m;

d—Length of the sealing device, d = 0.1 m.

By calculating

S = 0.1963 m

2, from the pressure formula, the minimum safe negative pressure in the two motion states of the robot is 1666 Pa and 2002 Pa, respectively. In the state of vertical motion, the output negative pressure of the wall–climbing robot is the highest negative pressure required by the system. At this time, the motion state of the air flow is used as the calculation standard for working conditions. Substituting the working condition point pressure difference Δ

p = 2002 Pa into the internal and external pressure difference formula of the sealing device,

Among which:

v—The main velocity of the air flow in the fluid channel (m/s);

ρ—The air density. At standard atmospheric pressure and at 20 °C, ρ = 1.205 kg/m3;

μ—The aerodynamic viscosity. At standard atmospheric pressure and at 20 °C, μ = 17.9 × 10−6 Pa·s.

The main velocity of the air flow in the fluid channel

v = 61.11 m/s is calculated. Under the premise that the main velocity is fixed, the height of the fluid channel of the sealing device is

The channel height

h = 0.0016 m corresponding to the critical pressure difference is calculated. According to the empirical formula, the flow rate of air flow under working conditions is

Among which:

h—Fluid channel height;

l—Length of the middle line of the sealing device, l = 2π (r0 + d/2) = 1.5708 m.

Substitute the data and calculate

qv = 0.5548 m

3. Based on the specific analysis of the structure of the experimental model of the negative pressure adsorption device and the fluid pneumatic parameters of the highest negative pressure operating condition point, the basic data and boundary values of the negative pressure adsorption experiment are obtained, as shown in

Table 1.

- (2)

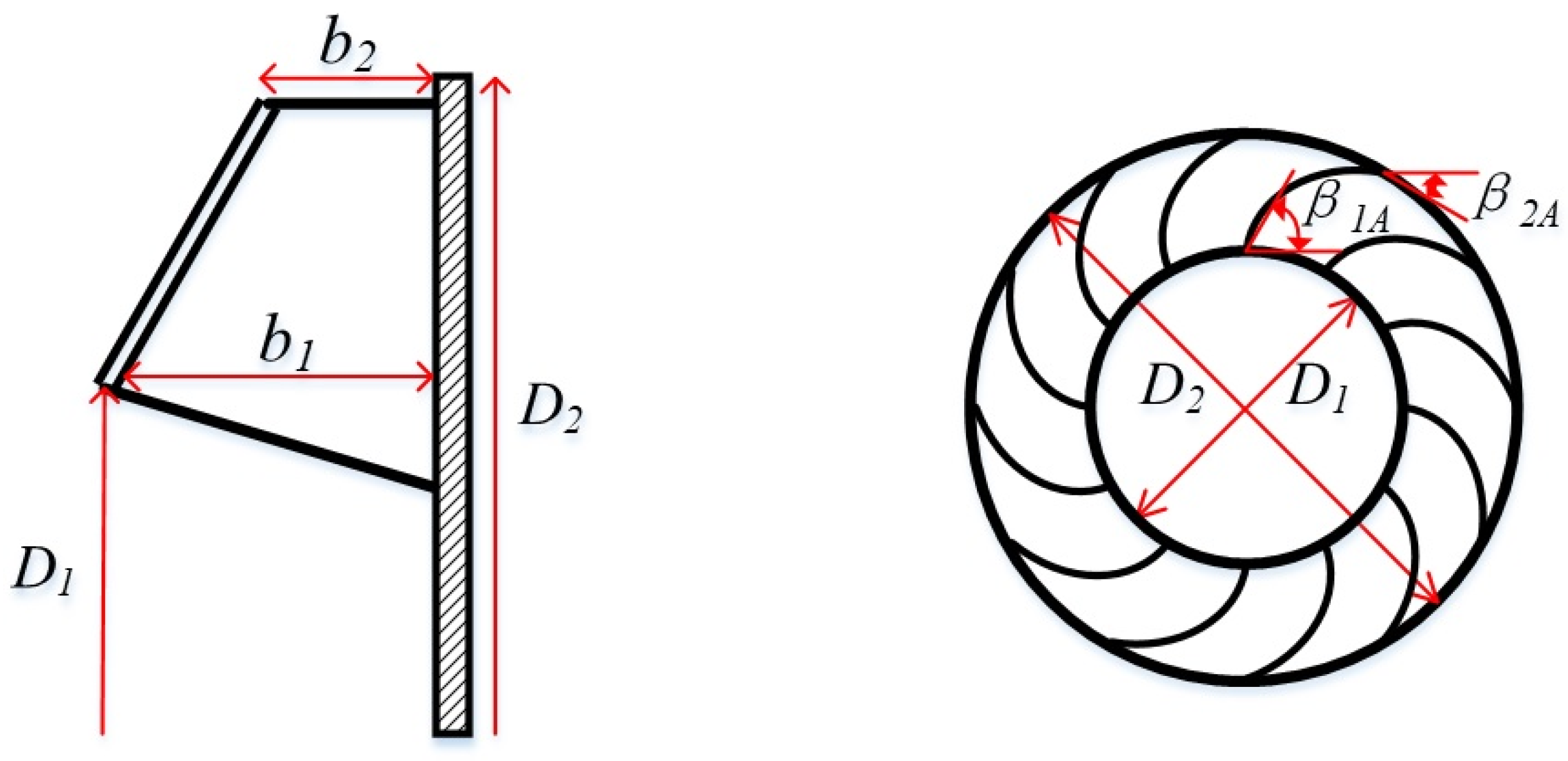

Calculation of structural parameters of centrifugal fan

As the most important component of the robot’s negative pressure adsorption mechanism, the centrifugal fan is the negative pressure–generating device in the negative pressure chamber. The efficiency of the negative pressure adsorption device directly depends on the performance of the centrifugal fan. Through analysis of the entry conditions of the negative pressure adsorption experiment, and based on empirical formulas and parameter standards, the geometric dimensions of the fan impeller are calculated, including impeller inlet diameter

D1, impeller outlet diameter

D2, blade inlet width

b1, blade outlet width

b2, blade inlet mounting angle

β1A, blade outlet mounting angle

β2A, blade number

Z, etc. [

21,

22], as illustrated in

Figure 3.

The impeller of the centrifugal fan adopts a tapered front disc structure, and the blade profile adopts a backward–leaning design. There is no front axial impeller in front to adjust the air flow. There is no chassis at the rear, and the air flowing out of the air outlet directly merges with the atmosphere and is then discharged from the air outlet. In this working state, the full pressure of the centrifugal fan is equal to the static pressure at the inlet of the fan:

Among which:

pt—Centrifugal fan full pressure;

ps1—Static pressure at the inlet of the fan, namely the negative pressure in the negative pressure chamber.

Drawing on the design experience of ventilation devices, the outlet angle

β2A of the impeller of the backward–leaning centrifugal fan has a greater influence on the dimension and performance of the fan. The recommended range of literature is between 30° and 50° [

23]. To obtain higher full–pressure efficiency,

β2A = 30

° is selected, the corresponding full pressure coefficient

ψ = 0.8417, and the entrainment velocity

v2e of the air flow at the outlet of the centrifugal fan is

Among which:

ψ—the full pressure coefficient of the air flow.

Substitute the data and calculate,

v2e = 62.83 m/s. The outlet diameter

D2 of the fan impeller is not only positively related to the entrainment velocity of the fluid outlet, but also directly related to the fan speed

n. The calculation equation is as follows:

Among which:

n—The fan speed (r/min).

Under the conditions of structural space constraints, the value of the fan speed is adjusted several times for verification, and it is determined that the fan speed n = 4000 r/min and the outlet diameter D2 = 0.31 m are convenient for calculation. Here, D2 is set to 0.3 m.

To calculate the inlet diameter

D1 of the fan impeller, the flow coefficient

φ of the air flow should be calculated first:

Among which:

φ—The flow coefficient of the air flow;

k—The scale factor for the smaller fan impeller of D1, k = 1.5;

Substitute the data and calculate, φ = 0.1249, D1 = 0.1235~0.1744 m. The inlet diameter D1 is limited by the structural space as well, and the ratio to the outlet diameter D2 should be set within a reasonable range. Synchronously, the flow coefficient φ and the full pressure coefficient ψ of the air flow also have a certain adjustment effect on the value of the inlet diameter D1. To simplify the calculation, here, D1 is set to 0.15 m.

Blade inlet width

b1 refers to the projection of the inlet edge curve of the fan impeller on the meridian surface. The value depends on the fluid flow through the centrifugal fan:

Among which:

D1c—Average value of inlet diameter (m);

ξ—Inlet area proportional coefficient, ξ = 0.7;

μ—Airflow filling coefficient before inlet. For tapered front plate, μ = 0.83~0.91.

Substitute the data and calculate,

b1 = 0.0595 m, which is in line with the system space requirements. To simplify the calculation, here,

b1 is set to 0.06 m. The value of the blade outlet width

b2 depends on

D1c,

D2 and

b1. The simplified empirical equation is

Among which:

k—Outlet outflow velocity coefficient, k = v*2n/v2n.

The variable k is a metric coefficient, and it represents the change in speed before and after the air flows out of the centrifugal fan. Variable v2n represents the normal velocity of the corresponding vector diameter when the fluid reaches the edge of the blade and has not yet flowed out. Variable v*2n represents the normal velocity of the corresponding vector diameter when the fluid has just flowed out of the fan blade.

Due to the difficulty of measuring and calculating the itemized speed of the air flow and according to the recommendations of the relevant literature, when the specific speed of the centrifugal fan is between 35 and 70, k = 0.7. Substitute the data and calculate, b2 = 0.042 m. For convenience of calculation, b2 is set to 0.04 m here.

Based on the principle of minimizing the relative speed of the inlet [

24], the relevant literature calculates that the optimal solution of the inlet angle of the backward fan is 35.26°. Variable

β1A is set to 35° here.

In theory, the increase in the number of impeller blades is conducive to increasing the impeller pressure and reducing the influence of relative eddy currents on the air flow. Meanwhile, increasing the blades narrows the impeller fluid, increases friction loss, and reduces the total fan pressure. Therefore, it is essential to calculate the optimal number of blades for centrifugal fans:

Among which:

τ—Cascade density, τ = 0.5 + 1.7β2A;

Substitute the data and calculate, τ = 1.35, Z = 11.5314. For the convenience of marking, here, Z is set to 12.

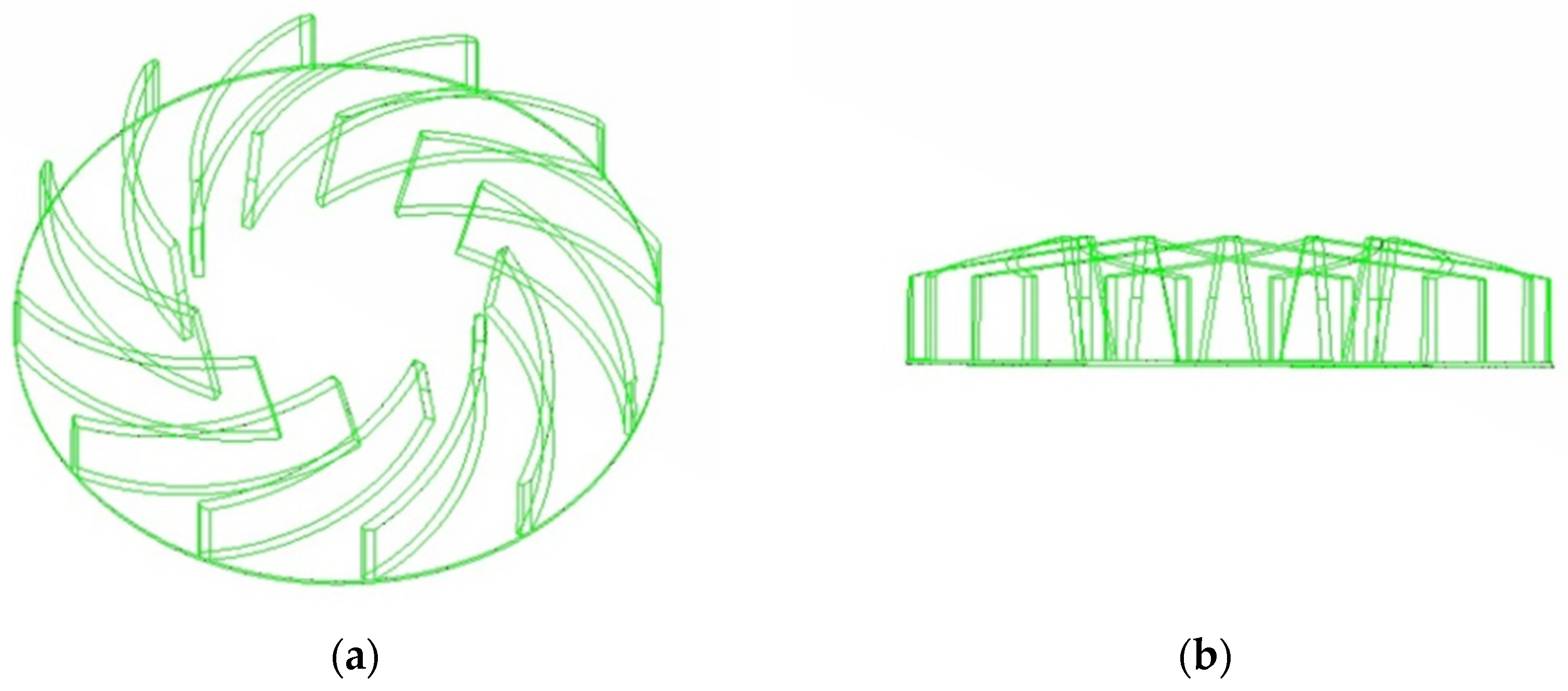

In the above, the structural parameters such as the geometry, installation angle, and number of blades of the centrifugal fan impeller are calculated. According to the structural calculation results, the impeller structure of the centrifugal fan is generated, as shown in

Figure 4.

The calculation results of the structural parameters of the centrifugal fan are summarized in

Table 2.

3. Negative Pressure Chamber Control Volume Fluid Field Experiment

Following the requirements of the experimental purpose, the negative pressure chamber control volume experiment aims to investigate the variations in the pressure distribution, fluid flow, and fluid velocity of the air flow in the sealing device and the negative pressure chamber during the continuous change in the negative pressure of the system in the negative pressure chamber. According to the experimental design, sub–experiments are carried out according to the pressure difference between the internal and external pressure of the negative pressure device. The design differential pressure, denoted as Δ

p, is set to 500 Pa, 1000 Pa, 1500 Pa, and 2000 Pa, respectively. The structure model of the negative pressure chamber control volume is shown in

Figure 5.

- (1)

Analysis of experimental results of fluid channel inspection surface

The intermediate height value of the fluid channel of the sealing device is selected to establish the inspection surface. Parallel to the surface of the sealing device and the shaft lining, the inspection surface is located between the two, and its purpose is to investigate the movement state of the air flow in the fluid channel of the sealing device before entering the negative pressure chamber.

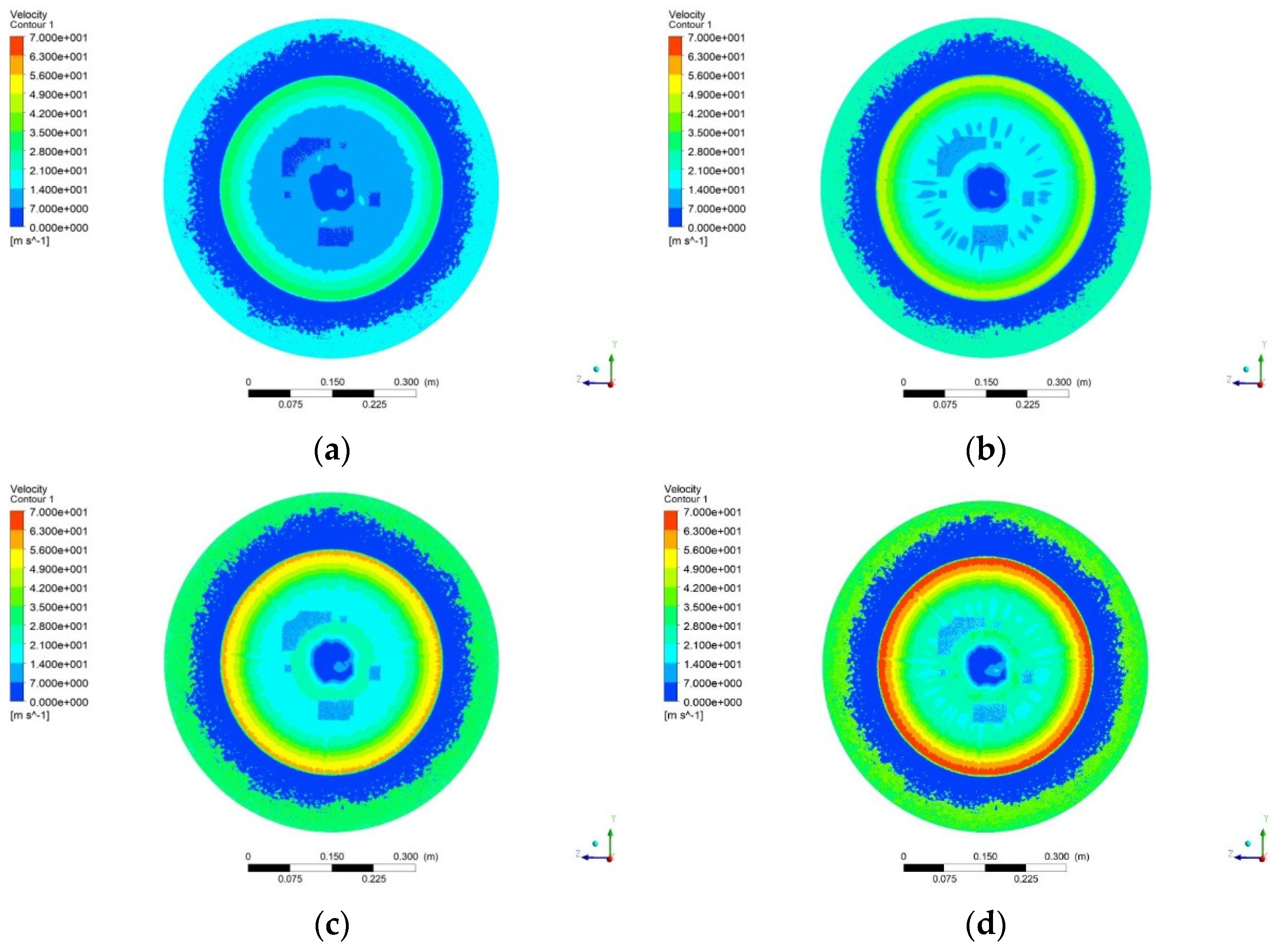

As shown in

Figure 6, the legend view of the Δ

p = 2000 sub–experiment is used as a reference. In each sub–experiment, the color of the edge of the outer ring of the sealing device is the same, indicating that the gas pressure is not much different from the atmospheric pressure outside the channel in the initial stage of the air flow entering the fluid channel. With the continuous flow of air flow in the channel, the gas pressure gradually increases, reaching the maximum value at the inner edge of the fluid channel, which is numerically equal to the average negative pressure in the negative pressure chamber—namely, the set value of the negative pressure of the system. After the air flow enters the negative pressure chamber, the suction effect of the centrifugal fan on the rear side of the negative pressure chamber changes the direction of movement of the air flow from the horizontal movement to the vertical movement, resulting in a decrease in the horizontal gas pressure. In the pressure cloud diagram, it is manifested as the pressure of the annular area near the center of the circle at the inner edge of the channel is less than the pressure of the annular area near the circumference at the inner edge of the channel.

The legend range view is 0 m/s~70 m/s in

Figure 7. Based on the figure, since the air flow pressure on the inside of the channel is directly affected by the change in the pressure of the negative pressure chamber, the fluid velocity on both sides of the channel in the fluid channel is greater than the fluid velocity in the middle of the channel, and the fluid velocity on the inside of the channel is greater than the fluid velocity on the outside of the channel. The pressure of the air flow on the outside of the channel is directly affected by the atmospheric pressure, and the gas pressure decreases faster during the fluid movement. However, compared with the air flow on both sides of the channel, the air flow in the middle of the channel has a pressure buffer at a certain distance, due to which the gas pressure does not change much, resulting in a lower fluid velocity. From the figure, it is also found that the inlet speed and outlet speed of the air flow in the fluid channel are directly affected by the negative pressure of the system. The greater the pressure difference between the inside and outside of the adsorption device, the greater the inlet speed and outlet speed of the air flow in the channel.

- (2)

Analysis of the experimental results of the inspection surface of the negative pressure chamber

The intermediate value of the length of the negative pressure chamber is selected to establish the inspection surface. Parallel to the cross–section of the sealing device and the front plate of the centrifugal fan, the inspection surface is located between the two, mainly to investigate the horizontal movement state of the air flow after entering the negative pressure chamber.

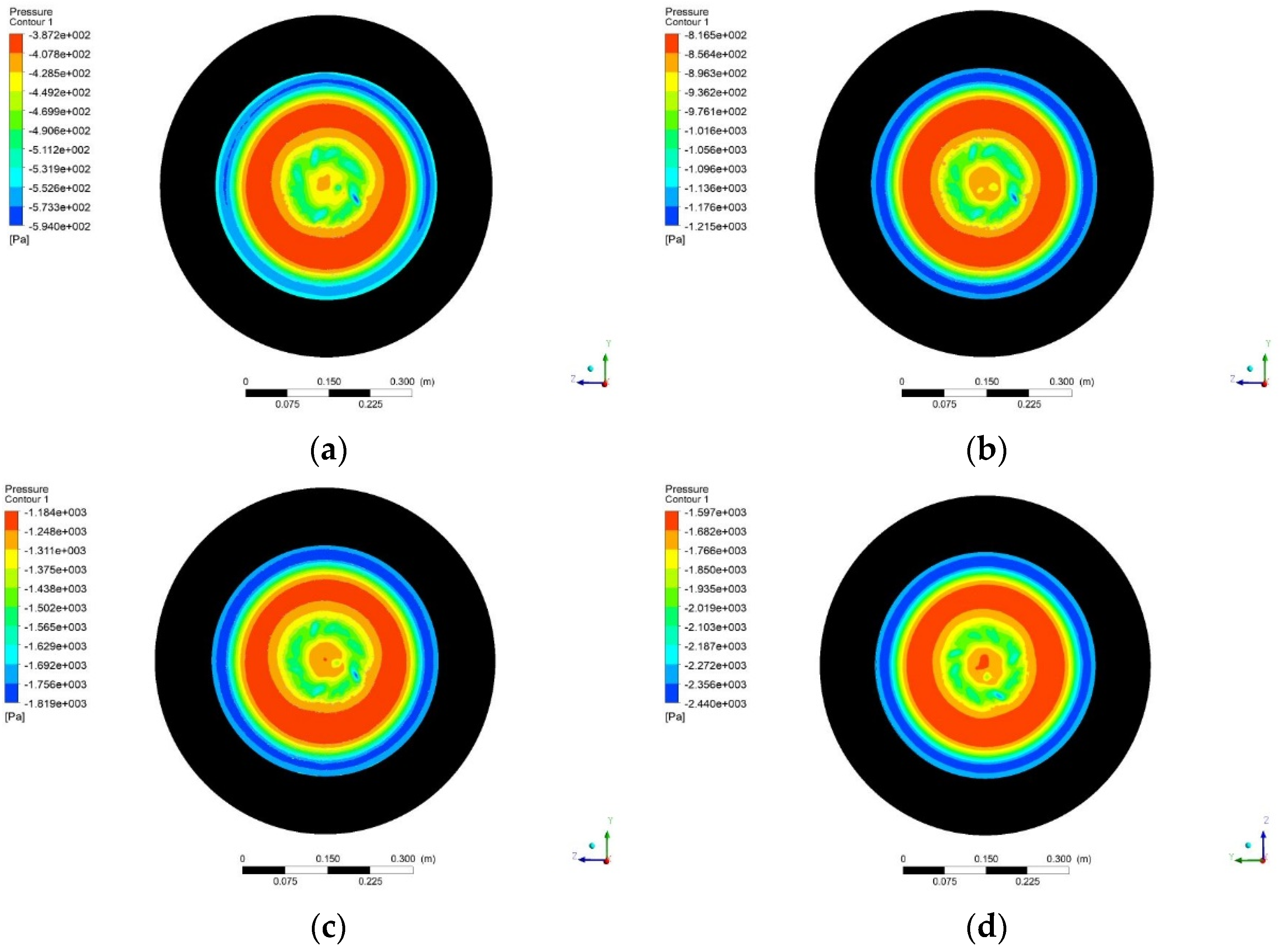

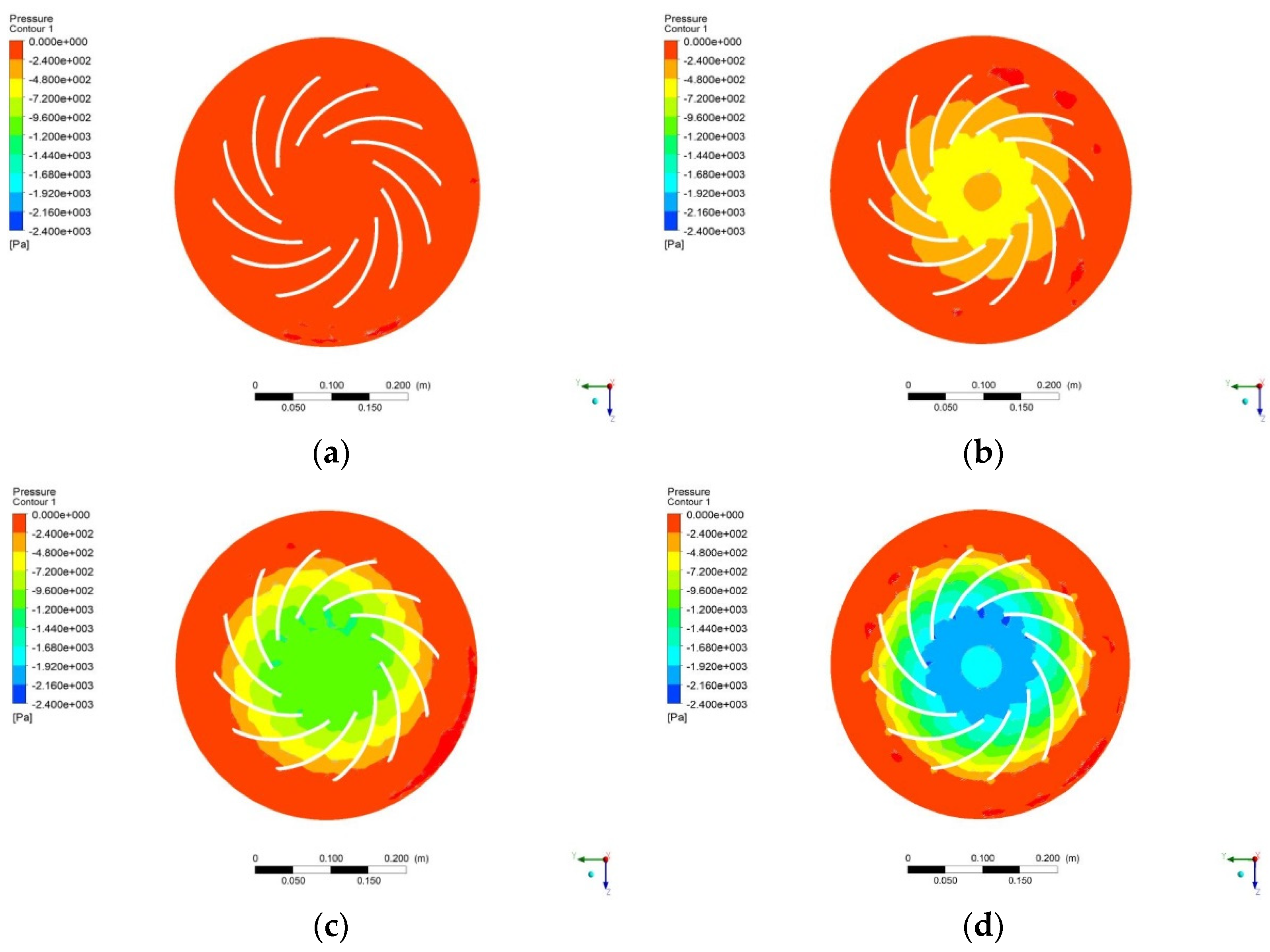

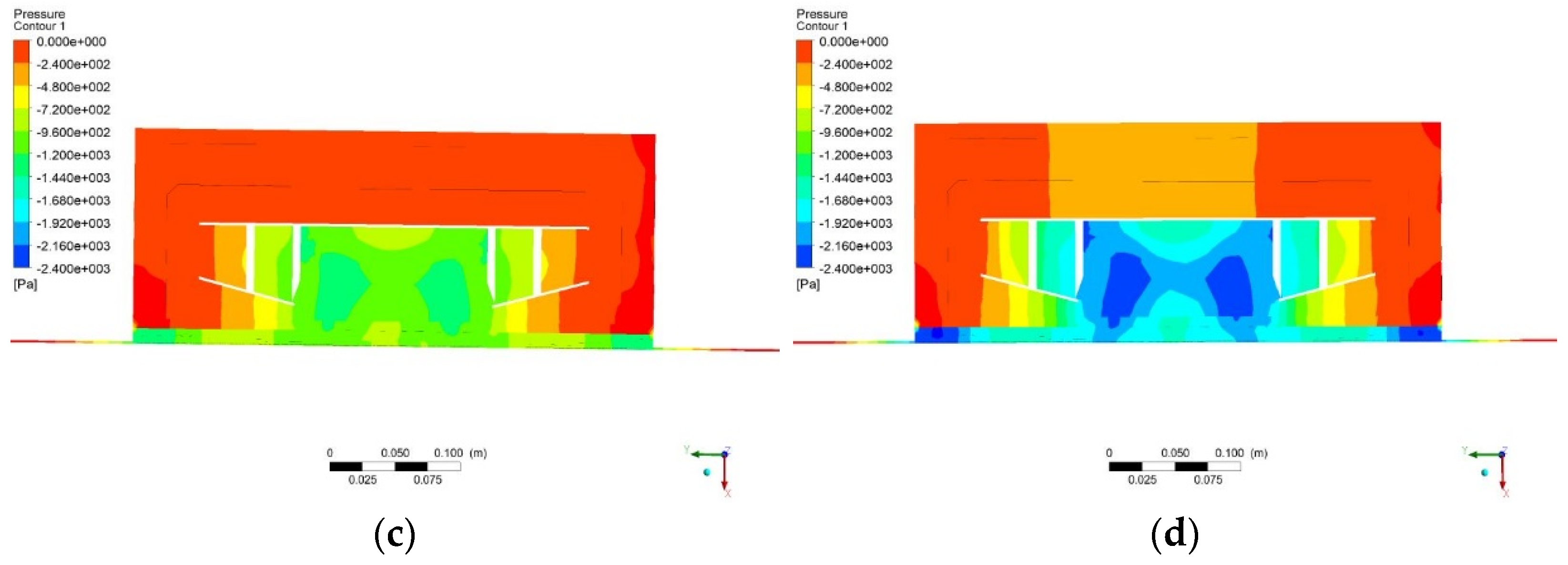

In

Figure 8, at Δ

p = 500, the pressure range is −594 Pa~−387 Pa; at Δ

p = 1000, the pressure range is −1215 Pa~−817 Pa; at Δ

p = 1500, the pressure range is −1819 Pa~−1184 Pa; and at Δ

p = 2000, the pressure range is 2440 Pa~−1597 Pa. Observing the pressure distribution in the figure, it is found that in the transverse extension area of the negative pressure chamber, the pressure of the air flowing into the negative pressure chamber from the fluid channel is relatively high, so accordingly, the gas pressure in this area is relatively high. Subsequently, during the movement of the air flow to the center of the negative pressure chamber, the direction of fluid movement gradually changes from horizontal to vertical due to the influence of the suction force of the centrifugal fan, thereby decreasing the air pressure on the transverse surface of the negative pressure chamber gradually. In the central area of the negative pressure chamber, the suction power of the centrifugal fan dominates the direction of movement of the air flow. The vertical speed of the air flow increases rapidly, causing a certain increase in the gas pressure in this area.

The legend range of legend view is 0 m/s~40 m/s in

Figure 9. At the working condition points of Δ

p = 500 and Δ

p = 1000, after the air flow enters the negative pressure chamber through the fluid channel, its transverse velocity is basically reduced to near 0 m/s. At the working condition points of Δ

p = 1500 and Δ

p = 2000, under the same circumstances, the air flow can maintain a transverse inertial speed of 4 m/s~8 m/s, and then it drops to about 0 m/s, indicating that in the fluid channel of the sealing device, the direction of movement of the air flow and the main velocity depend on the internal and external pressure difference of the negative pressure adsorption mechanism. The greater the internal and external pressure difference, the greater the velocity of the fluid entering the negative pressure chamber. After the air flow enters the negative pressure chamber, the average pressure of the gas in the negative pressure chamber is the same as the pressure of the incoming gas, causing the incoming gas to lose differential pressure power, and the fluid velocity drops rapidly. Inside the negative pressure chamber, the direction of movement of the air flow and the main velocity depend on the speed of the centrifugal fan. In the negative pressure chamber, the air flow that has slowed to 0 m/s in the transverse direction is turned by the suction force of the centrifugal fan to the inlet of the centrifugal fan. The faster the speed of the centrifugal fan, the faster the vertical speed of the air flow entering the inlet of the centrifugal fan and thus the higher the negative pressure in the negative pressure chamber.

- (3)

Numerical analysis of experimental data

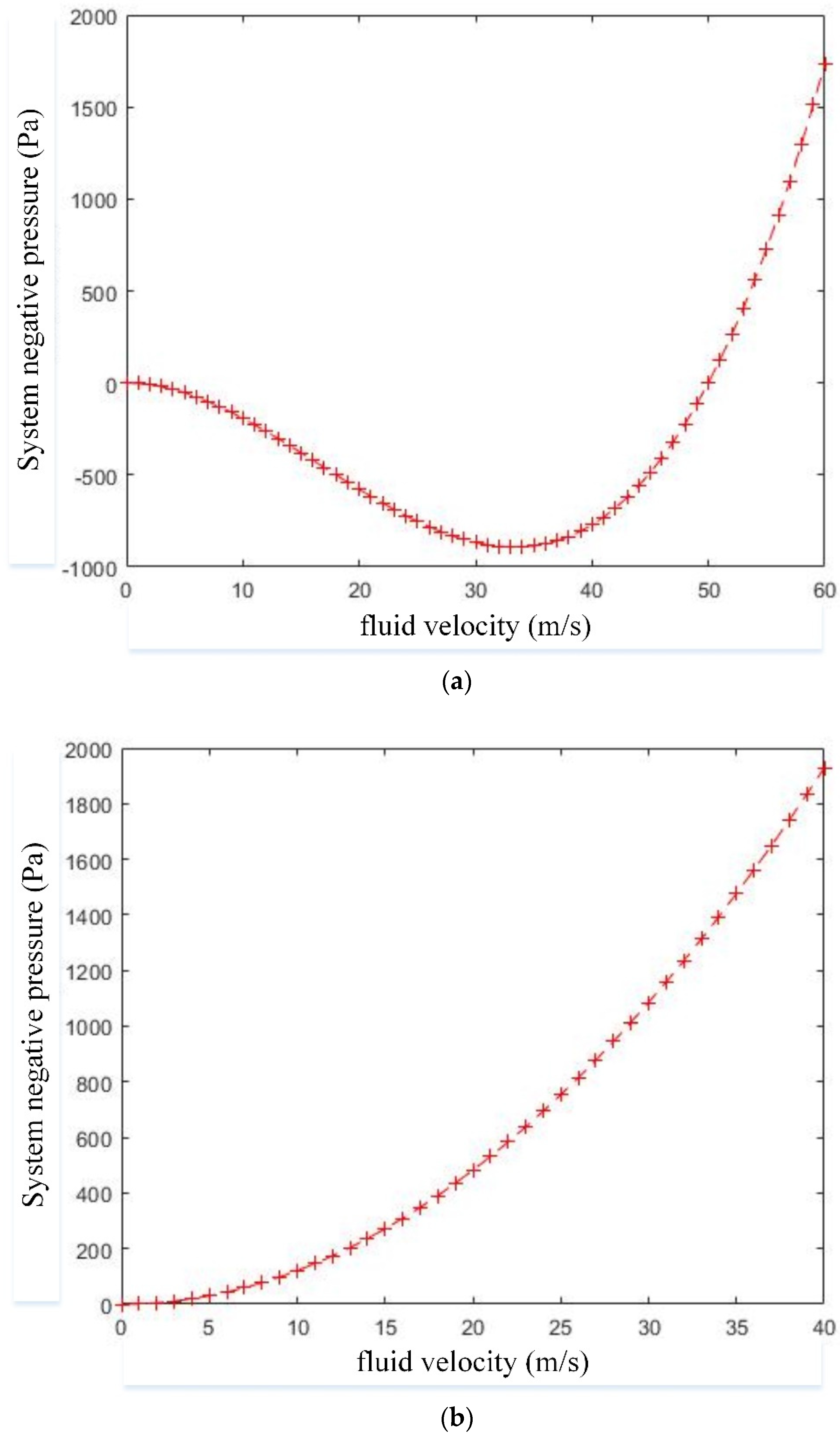

The corresponding

Figure 9a of the internal and external pressure difference of the sealing device and the air velocity of the fluid channel is shown in

Figure 10a. It has been observed that in the range of the fluid velocity <50 m

3/s interval, the internal and external pressure difference of the sealing device is numerically negative; therefore, the system’s negative pressure value in this interval does not have any practical significance. In the fluid velocity range of 50~60 m

3/s, the pressure difference between the inside and the outside of the sealing device is increased from 0 to 1735 Pa. The corresponding curve of the negative pressure in the negative pressure chamber and the air velocity in the chamber is shown in

Figure 10b. The movement process of the air flow in the negative pressure chamber is relatively simple, and the movement stroke is relatively short. In the fluid velocity range of 0~40 m

3/s, the pressure difference between the inside and the outside of the sealing device is increased from 0 to 1928 Pa. On the basis of the comprehensive analysis of the corresponding curve representing the negative pressure of the system and the sealing device and the flow rate of the air flow in the negative pressure chamber, the calculated value conforms to the expected result of the negative pressure system. In the process of pressure boost, the curve is smooth, and the negative pressure parameters do not fluctuate up and down, which is convenient for reducing the difficulty of controlling the negative pressure adjustment of the mechanism in the later stage. The experimental numerical calculation results can be found in

Appendix A Table A1.

4. Centrifugal Fan Control Volume Fluid Field Experiment

According to the requirements of the experimental purpose, the purpose of the centrifugal fan control volume experiment is to investigate the ability of the centrifugal fan to adjust the static pressure of the inlet and outlet by adjusting the motor speed and the changes in the important pneumatic parameters of the air flow inside the control volume during fan speed changes. Experimental design and sub–experiments are carried out according to the speed of the centrifugal fan. The design speed

n is 1000 r/min, 2000 r/min, 3000 r/min, and 4000 r/min, respectively. The structure model of the centrifugal fan control volume is shown in

Figure 11.

- (1)

Analysis of the experimental results of the horizontal inspection surface of the centrifugal fan

The intermediate value of the length of the centrifugal fan is selected to establish the inspection surface. Parallel to the front plate of the fan and the rear plate of the fan, the inspection surface is located in the middle of the longitudinal length of the impeller, which mainly investigates the horizontal movement state of the air flow after entering the centrifugal fan.

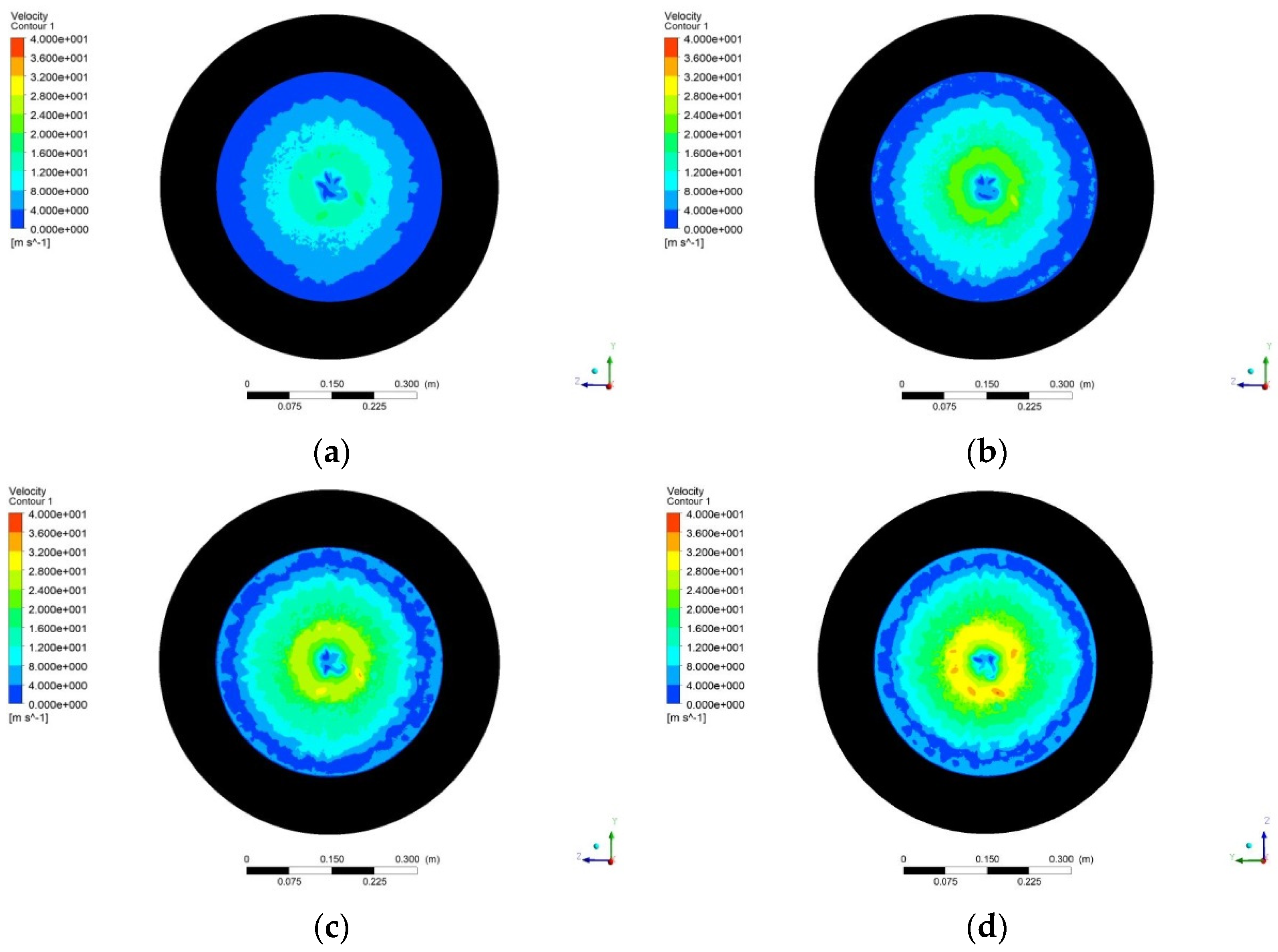

The legend range view is −2400 Pa~0 Pa in

Figure 11. The inlet static pressure corresponding to the fan speed of each sub–experiment is as follows: at

n = 1000 r/min,

Ps1 = 125 Pa; at

n = 2000 r/min,

Ps1 = 500 Pa; at

n = 3000 r/min,

Ps1 = 1126 Pa; and at

n = 4000 r/min,

Ps1 = 2002 Pa. It can be observed from the figure that when the centrifugal fan speed is low, the inlet static pressure formed by the fan rotation is small, resulting in a small overall pressure gradient, and the pressure distribution shown in the pressure cloud diagram is not obvious. As the fan speed increases, both the static pressure at the fan inlet and the overall pressure gradient continue to increase, making the fluid pressure distribution depicted in the pressure cloud map more prominent. As shown in

Figure 12d, the fluid pressure value at the inlet of the fan is the largest. Subsequently, due to the change in the direction of movement of the air flow between the fan blades, the fluid pressure decreases gradually until it is thrown out by the blades and merges with the external atmosphere at the air outlet, thereby, the fluid pressure returning to the standard atmospheric pressure.

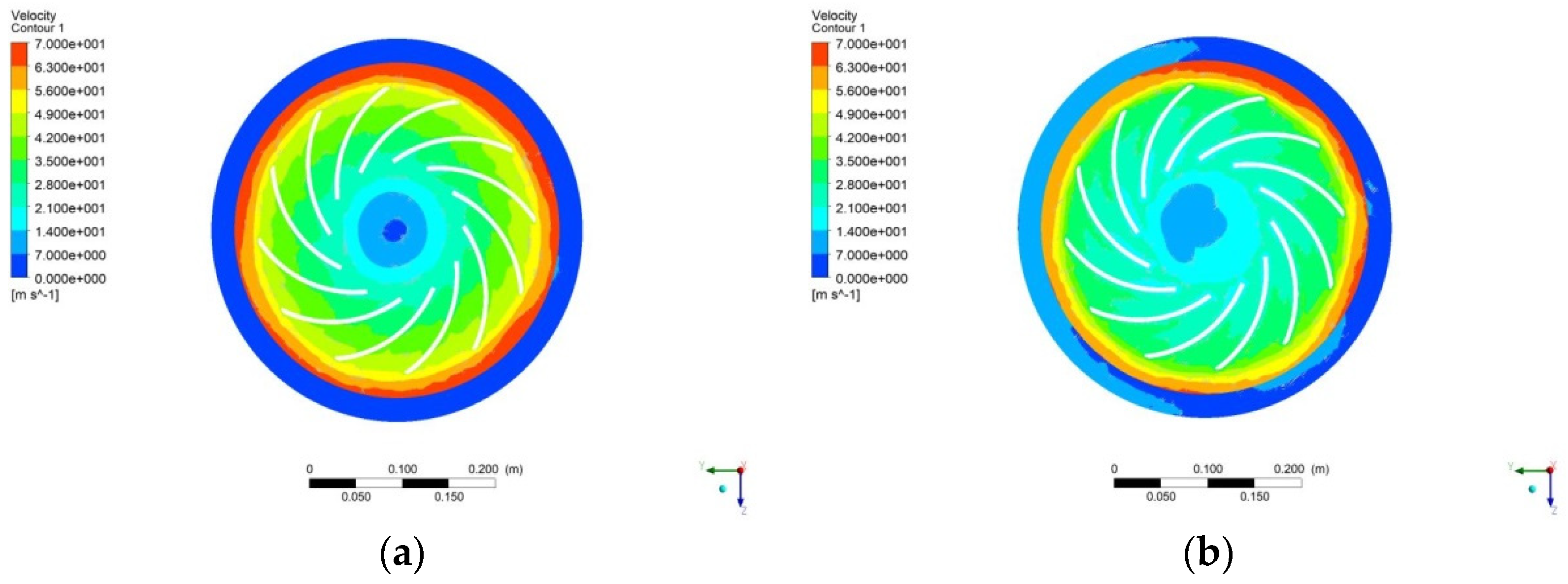

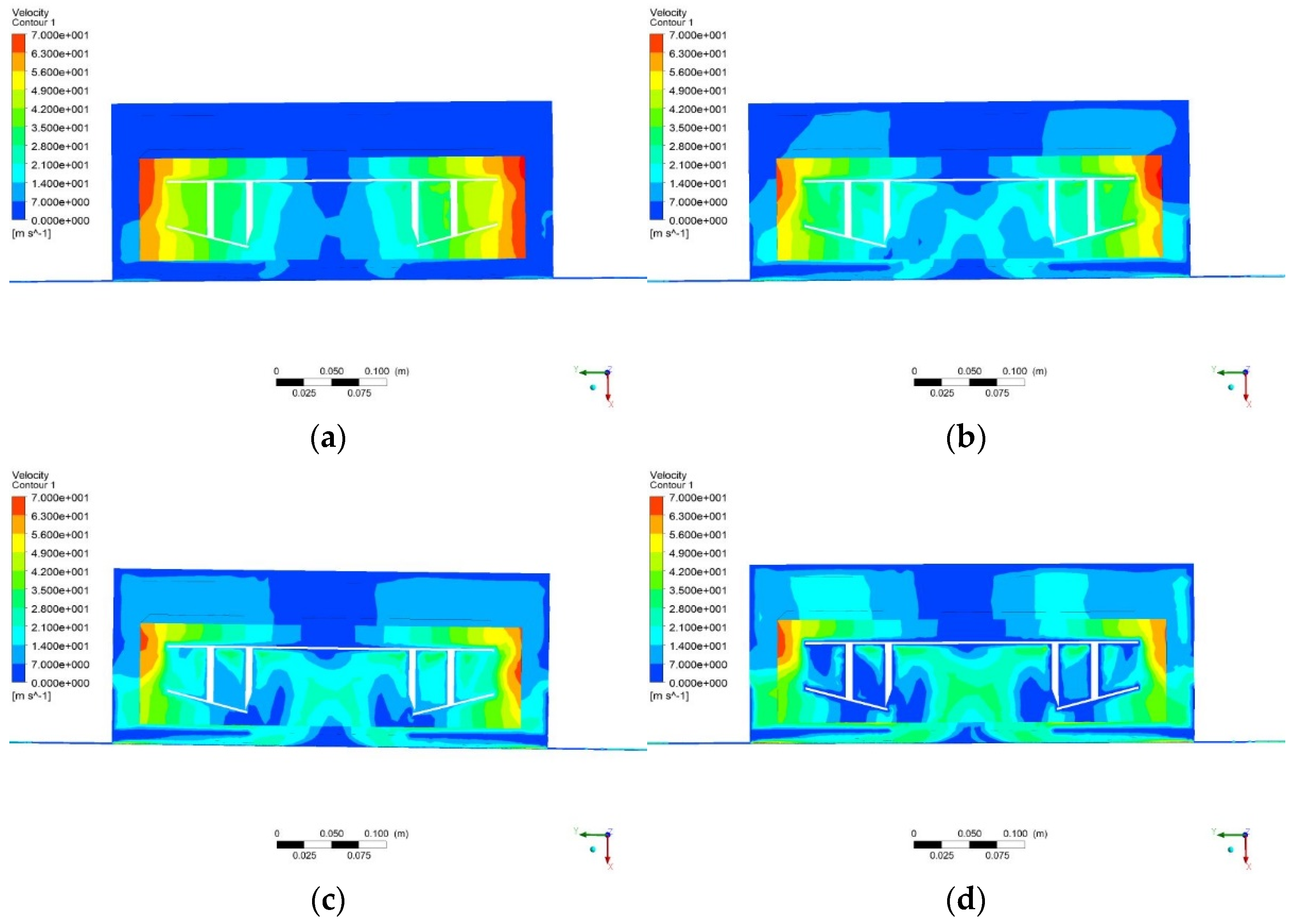

The legend range of legend view is 0 m/s~70 m/s in

Figure 12. At speed

n = 1000 r/min, as shown in

Figure 13a, the fan speed is low, and the overall speed gradient is distributed in a ring, gradually increasing from the center of the fan to the radial direction until the maximum value is reached at the outlet of the fan. At

n = 2000 r/min, as displayed in

Figure 13b, as the fan speed increases, the fluid velocity distribution has a more obvious velocity separation phenomenon, and the fluid velocity close to the front blade is gradually smaller than the fluid velocity close to the rear blade. At

n = 3000 r/min, as illustrated in

Figure 13c, due to the continuous increase in fan speed, the circular distribution trend of the overall speed gradient can no longer be observed from the speed cloud map, and the speed separation phenomenon of the air flow in the middle of the blade is more obvious. At

n = 4000 r/min, as shown in

Figure 13d, since the fan speed reaches the maximum value of the operating condition point, in the area close to the front blade, a large low–speed area is formed along the direction of the fluid movement, and the fluid speed is significantly smaller than the fluid speed in the area close to the rear blade.

- (2)

Analysis of the experimental results of the longitudinal inspection surface of the centrifugal fan

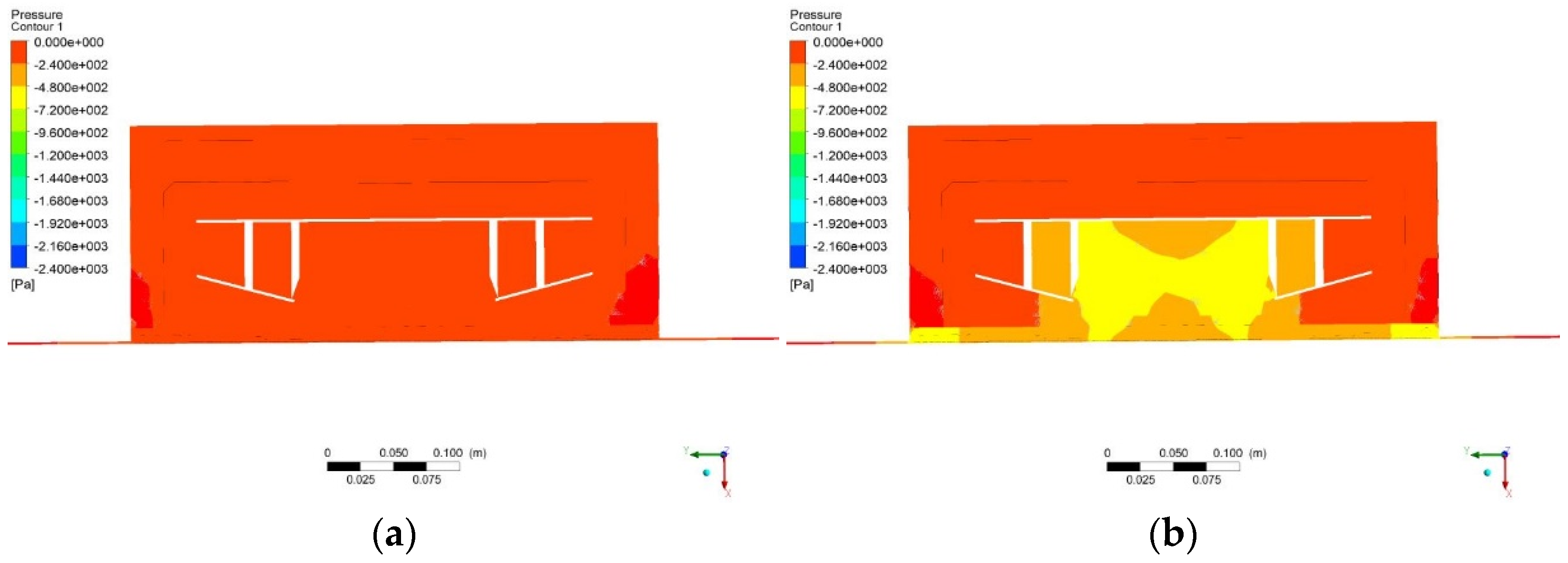

The tangential direction of the diameter of the centrifugal fan is selected to establish the inspection surface. Perpendicular to the horizontal inspection surface of the centrifugal fan, the inspection surface is in the cross–sectional diameter of the negative pressure chamber, which is designed to investigate the longitudinal movement state of the air flow after entering the centrifugal fan.

In

Figure 14, legend view is set to −2400 Pa~0 Pa. In each sub–experiment, the gas pressure at the edge of the negative pressure chamber and at the inlet of the centrifugal fan is large, which is numerically close to the negative pressure of the system at the working condition point. The air pressure in the fluid transition area and the front–end area of the fan is small, which is mainly due to the small design length of the negative pressure chamber. After passing through the fluid channel, the air flow with higher pressure enters the negative pressure chamber; because there is no longitudinal flow interval, it can only flow horizontally according to the inertial speed. Throughout this process, the inertial velocity of the air flow is consumed continuously, and the horizontal flow velocity decreases, causing the gas pressure to decrease. At the inlet of the centrifugal fan, and under the action of the suction force of the centrifugal fan, the movement speed of the air flow accelerates and the gas pressure increases. At the front end of the centrifugal fan, a certain eddy current formed by the air flow in this area causes the speed of the air flow here to decrease. Therefore, the gas pressure is lower than the gas pressure at the inlet of the centrifugal fan.

The legend range view is 0 m/s~70 m/s in

Figure 15. According to the figure, on the side of the negative pressure chamber of the front plate of the centrifugal fan, the speed of the air flow has basically approached 0 m/s. The greater the differential pressure, the thinner the zeroing velocity layer. Meanwhile, the thicker the transition speed layer, the greater the negative pressure demand of the system and the higher the speed of the centrifugal fan adjustment, which in turn produces greater suction power to make the air flow at a higher speed. It is observed that the fluid velocity rises slowly in the middle channel of the blade and rises faster after flowing out of the fan, suggesting that the air flow is affected by the blade profile during the movement of the blade channel. The direction of fluid movement is not in a straight line; it is in a curved line in accordance with the blade profile. The development of fluid velocity is limited by the separation of velocity during movement.

- (3)

Numerical analysis of experimental data

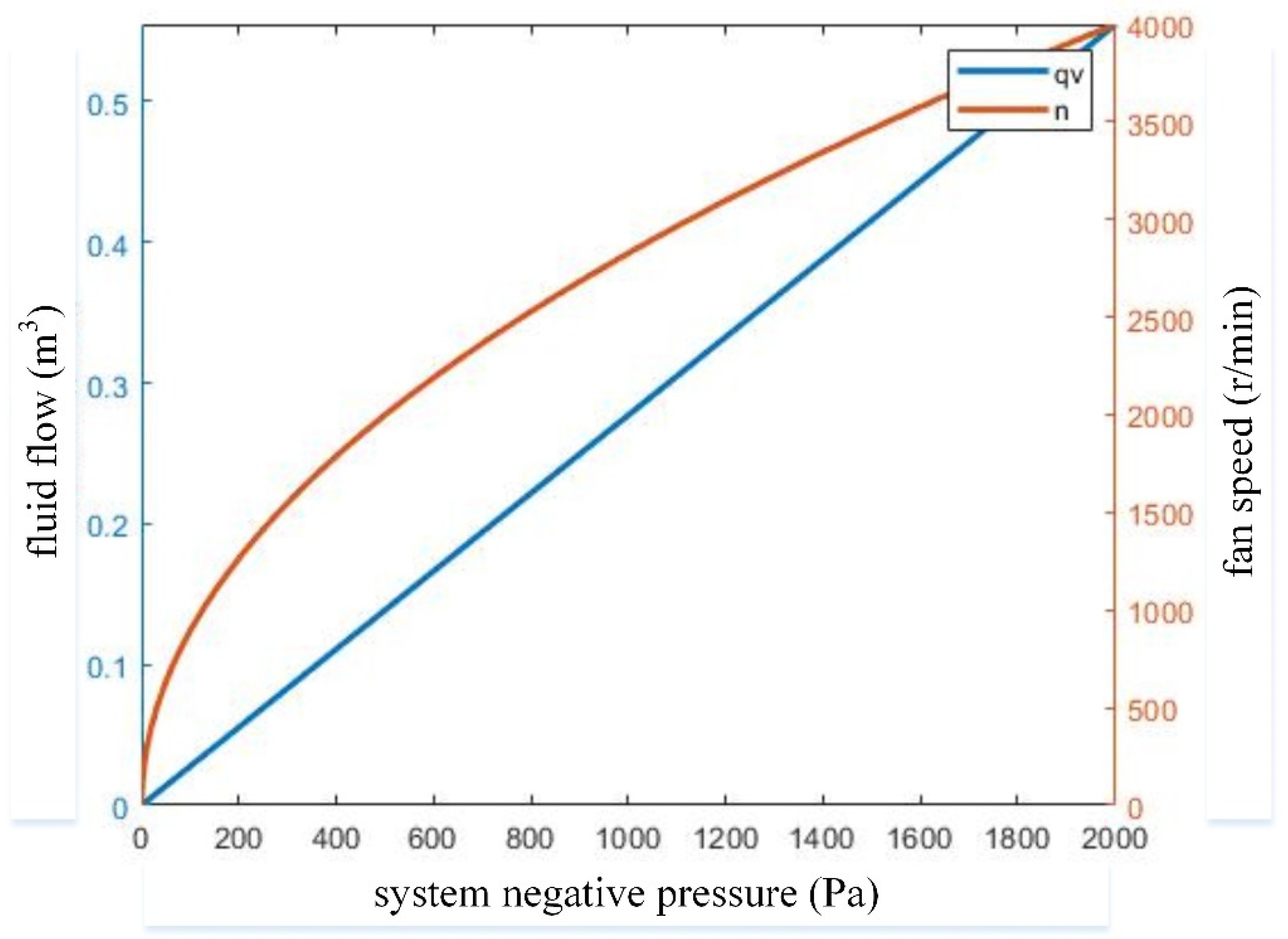

The curve corresponding to the negative pressure of the system between the flow rate of the air flow and the fan speed during the movement of the centrifugal fan control volume is shown in

Figure 16. From the curve in the figure, it can be seen that the three pneumatic parameters of the air flow are positive linear relationship hips, and their respective numerical boundaries are consistent with the simulation results. Under the premise of determining the values of other parameters, the height of the fluid channel has a very subtle impact on the negative pressure and gas flow of the system, and the size of the fluid flow is mainly determined by the negative pressure required by the system. At the same time, in the initial stage of the system’s negative pressure and gas flow increase, the fan speed increases faster. When the immediate speed reaches 1/2 of the boundary speed, that is, after 2000 r/min, the speed curve flattens, and the slope of the curve gradually decreases. At this time, the negative pressure value of the system is 500 Pa, and the gas flow rate is 0.1387 m

3, which are all at 1/4 of the boundary of their respective values, indicating the initial stage of the start of the centrifugal fan. The negative pressure adsorption mechanism has to output more power to increase the fan speed, making the system loss increase. In the process of speeding up the fan from the intermediate speed to the boundary speed, the year–on–year increase in the negative pressure and gas flow of the system is large, and a better operating efficiency is obtained by the negative pressure adsorption mechanism. The experimental numerical calculation results can be found in

Appendix A Table A2.

5. Electromagnetic Field Experiment of Electromagnetic Adsorption Device

The purpose of the electromagnetic field experiment is to investigate the changes in electromagnetic suction and magnetic field parameters under different adsorption conditions between the electromagnetic unit and the reinforcement bar of the shaft lining during the movement of the wall–climbing robot. In the sub–experiment, the model of the reinforcement bar model and the corresponding angle to the electromagnetic unit and the input current of the wire coil are adjusted in turn, and the changes in electromagnetic adsorption force, magnetic flux density, magnetic field strength, adsorption area and electric field strength are analyzed. The experimental model of the electromagnetic adsorption device is illustrated in

Figure 17.

In

Figure 17, the winding coil is modeled as a whole. The current module is designed to guide the current input direction. The material properties of the unit iron core and reinforcement bar model are defined as steel–like materials. The relative permeability is set to 43,372 and 8000, respectively, and the conductivity is set to 2 MS/m; the material properties of the winding coil are selected as copper. The default relative permeability in the component library is set to 0.999991, and the conductivity is set to 58 MS/m. The material attribute of the gap filling is set to vacuum air, the relative permeability is set to 1, and the conductivity is set to 0 MS/m. In the sub–experiments where current changes are excluded, the excitation current value is set to 1950 (

N ×

I).

The intermediate value of the side width of the electromagnetic unit and the intermediate value of the end face width are selected to establish two inspection surfaces perpendicular to each other in the horizontal and vertical directions. The intensity distribution and direction of movement of the magnetic flux inside the model under different states of electromagnetic adsorption between the electromagnetic unit and the reinforcement bar in the wall, as well as the change in electromagnetic adsorption force with the experimental variables, are analyzed.

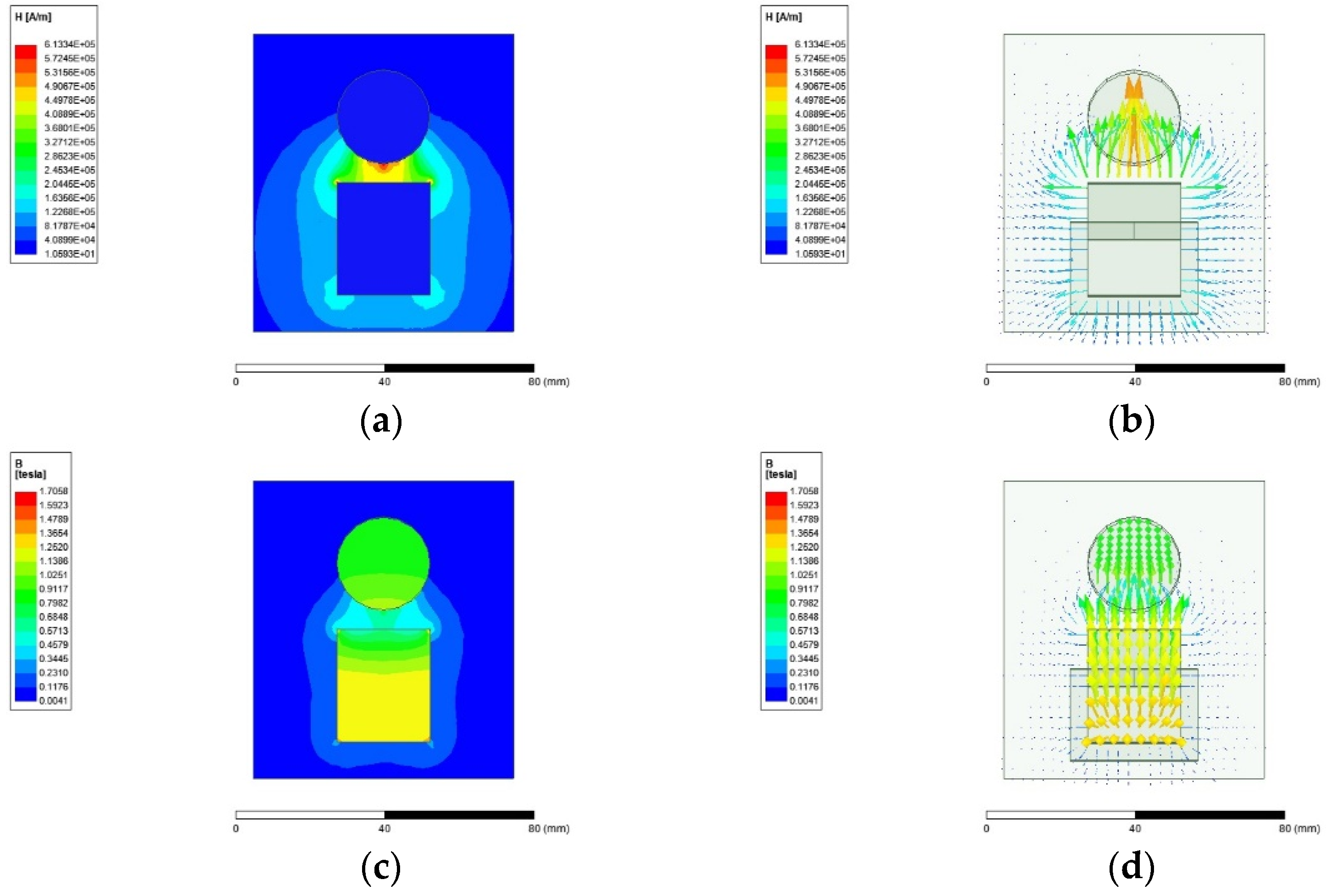

In typical fixed–value state investigation experiments, the purpose of the experiment is to investigate the real–time state of the electromagnetic field at the time of the effective adsorption of the model. Experimental conditions: the radius of the reinforcement bar is 12.5 mm; the gap distance is 5 cm; the number of turns of the coil is 195; the rotation angle is 0°; and the input current is 10 A. After the experiment, according to the experimental results, the intensity distribution and motion vector of the magnetic field strength and magnetic flux density of different inspection surfaces are generated as illustrated in

Figure 18 and

Figure 19.

The experimental model is equivalent to an annular closed magnetic core with an air gap. The relative permeability of the iron core of the electromagnetic unit and the reinforcement bars in the borehole wall is very large. Therefore, the magnetic field strength is mainly concentrated in the air gap, and the storage capacity inside the iron core and the reinforcement bars is extremely small, as shown in

Figure 18a. The direction of magnetic flux movement is circular. The magnetic field strength in the vertical direction at the air gap is the greatest, and the edge magnetic flux at the inner and outer corners of the end of the unit has a strong magnetic field strength, as shown in

Figure 18b. The magnetic flux is the same everywhere in the electromagnetic circuit, and the magnetic flux density is proportional to the area of the magnetic circuit channel. At the yoke of the iron core, the magnetic flux is relatively concentrated, and the channel area is smallest. Thus, the magnetic flux density here is the largest. At the air gap, due to the divergence of the edge magnetic flux, the magnetic flux density here is the smallest, as exhibited in

Figure 18c. The vector direction of the magnetic flux density is consistent with the magnetic field strength, but the intensity distribution is the opposite, as shown in

Figure 18d.

The electromagnetic intensity and magnetic flux density diagram of the longitudinal investigation surface of the experiment are shown in

Figure 19. It can be observed that the magnetic field intensity distribution and motion vector direction of the magnetic flux in the longitudinal direction of the model are consistent with the experimental results of the transverse inspection surface. In the meantime, the value of the magnetic field strength in the midline of the width of the side of the unit reaches the maximum. Subsequently, it gradually decreases to both sides, and the direction of the magnetic flux vector also shows a clear trend of movement from both sides to the center. The electromagnetic intensity is mainly concentrated in the normal direction of the end of the unit, and it is negligible in the tangent direction.

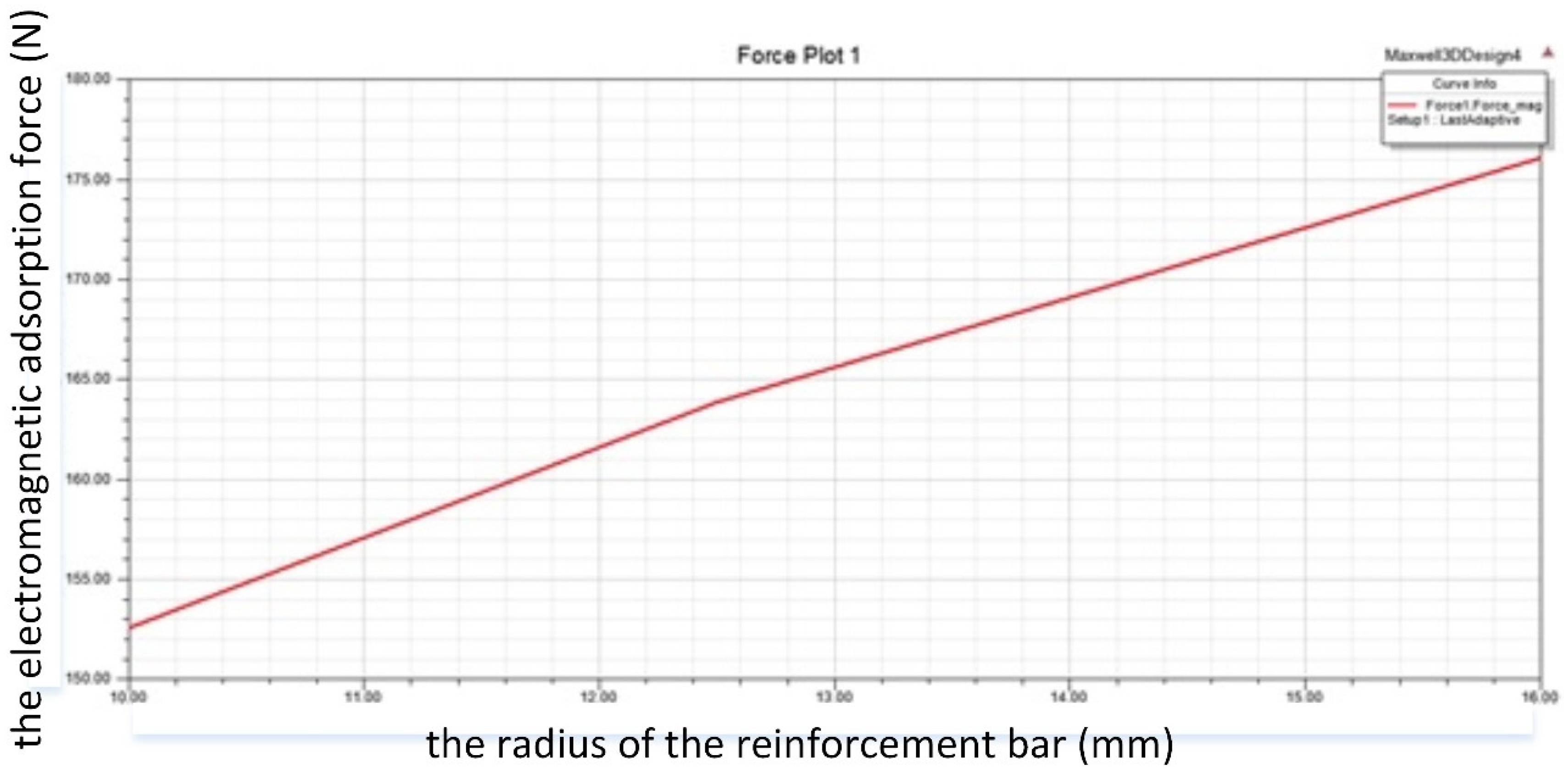

The purpose of the investigation experiment of the law of interval variables is to investigate the law of change of the electromagnetic adsorption force generated by the model within the limit range of different variables. The sub–experimental conditions are as follows: 1. the radius of the reinforcement bar is from 0 to 16 mm; 2. the rotation angle is from 0° to 30°; and 3. the input current is from 0 to 10 A. In the sub–experiment, in addition to the experimental variables, the general values of other experimental parameters are selected. After the experiment, based on the experimental results, the numerical corresponding curve is generated, as shown in

Figure 20,

Figure 21 and

Figure 22. Among them, increasing the radius of the reinforcement bar and increasing the input current are conducive to increasing the magnetic flux in the electromagnetic circuit and increasing the electromagnetic adsorption force. Increasing the rotation angle is equivalent to reducing the effective adsorption area of the electromagnetic unit and the reinforcement bar in the lining, so that the electromagnetic adsorption force is reduced. In the corresponding curve of the value, the value of the electromagnetic adsorption force changes linearly within the expected range with the change of the experimental variable, and it is concluded that the simulation experiment results are consistent with the calculation results of the formula.

6. Efficiency Analysis of Coupling Adsorption Mechanism

The theoretical basis and mechanism of electromagnetic adsorption are distinct from those of negative pressure adsorption. The power loss generated in the adsorption production process is different. For the study of the law of the change of system power with the output adsorption force in the coupled adsorption mechanism, the power calculation results of the two adsorption methods should be summarized, and the overall power of the electromagnetic adsorption device and the negative pressure adsorption device under the same adsorption force requirements should be compared and analyzed.

- (1)

Calculation of loss and power of centrifugal fan

The loss of air flow in the negative pressure adsorption device mainly occurs in the centrifugal fan stage, which specifically includes leakage loss, flow loss, and mechanical loss. Among them, leakage loss reduces system flow, flow loss reduces fan static pressure, and mechanical loss increases power consumption. Among the above three losses, the first two consume system power indirectly by reducing the operating efficiency of the fan, while the latter rely on the system to directly increase the output power to offset the loss [

25,

26,

27,

28].

Normally, leakage loss refers to the loss of gas flow leaked by the gap between the inner wall baffle of the negative pressure chamber and the front cover of the centrifugal fan. Under actual working conditions (

Pt = 2002 Pa), the leakage loss Δ

qv of the centrifugal fan is as below:

Among which:

Δqv—The loss of gas flow (m3);

δ—Clearance distance, δ = 2 mm;

a—Clearance edge shrinkage coefficient, a = 07.

Substitute the data and calculate, Δ

qv = 0.0311 m

3. Then, the theoretical flow rate of the centrifugal fan is

Substituting the working conditions gas flow rate qv = 0.5548 m3 calculated by Equation (4) into Equation (14), ql = 0.5859 m3 can be obtained.

Mainly, the flow loss includes the axial and radial conversion pressure loss caused by the change in the direction of fluid movement, the pressure loss of the blade channel generated by the air flow between the adjacent blades of the impeller, and the outlet diffuser pressure loss caused by the deceleration of the fluid caused by the increase in the fan outlet fluid channel [

29,

30,

31,

32].

The air flow axis and radial conversion pressure loss Δ

p1 is as below:

Among which:

v1—Absolute velocity of airflow at blade inlet (m/s);

ζ1—Loss coefficient, ζ1 = 0.15.

The absolute velocity of airflow at blade inlet

v1 is equal to the normal velocity of the vector diameter

v1n:

Substitute the data and calculate, v1 = 20.7223 m/s, Δp1 = 38.8048 Pa.

The pressure loss of the air flow blade channel, Δ

p2, is

Among which:

v1r—Relative velocity of airflow at blade inlet (m/s);

ζ2—Loss coefficient, ζ2 = 0.15.

Based on the fluid inlet velocity triangle, the relative velocity of airflow at blade inlet

v1r is

Substitute the data and calculate, v1r = 36.1283 m/s, Δp2 = 117.9624 Pa.

The diffuser pressure loss at the air fluid outlet Δ

p3 is

Among which:

v2—Absolute velocity of airflow at blade outlet (m/s):

ζ3—Loss coefficient, ζ3 = 0.15.

Substitute the data and calculate, v2 = 36.2760 m/s, Δp3 = 118.9287 Pa.

Under actual working conditions, the total flow loss of the centrifugal fan is

Substituting the calculation result of (15), (17) and (19) into Equation (20), Δph = 275.6995 Pa can be obtained.

Mechanical loss, also known as roulette wheel friction loss, is characterized by a certain flow and pressure loss. However, it only causes power loss, does not reduce the full pressure of the fan, and has no effect on the theoretical flow rate. Under actual working conditions, the mechanical loss of the centrifugal fan is

Among which:

v2e—Entrainment velocity of blade outlet flow (m/s);

Bd—Strouhal coefficient, Bd = 0.81.

Substitute the data and calculate, v2 = 62.8319 m/s, Δqr = 3.4679 × 10−4. Through the calculation results, it is found that the mechanical loss value of the centrifugal fan is extremely small under the negative pressure condition of the system with the largest system demand.

In the centrifugal fan stage, after all the itemized analysis of possible energy loss and based on the centrifugal fan power calculation formula, the effective power of the centrifugal fan is as follows:

Substitute the data and calculate,

Pe = 1110.7 W; the internal power of the centrifugal fan is

Substitute the data and calculate,

Pin = 1334.5 W. When the centrifugal fan is directly connected to the drive motor, the mechanical efficiency of the fan is

ƞm = 1. Numerically, the internal power of the centrifugal fan is equal to the shaft power—that is, the input power of the centrifugal fan [

33,

34,

35,

36].

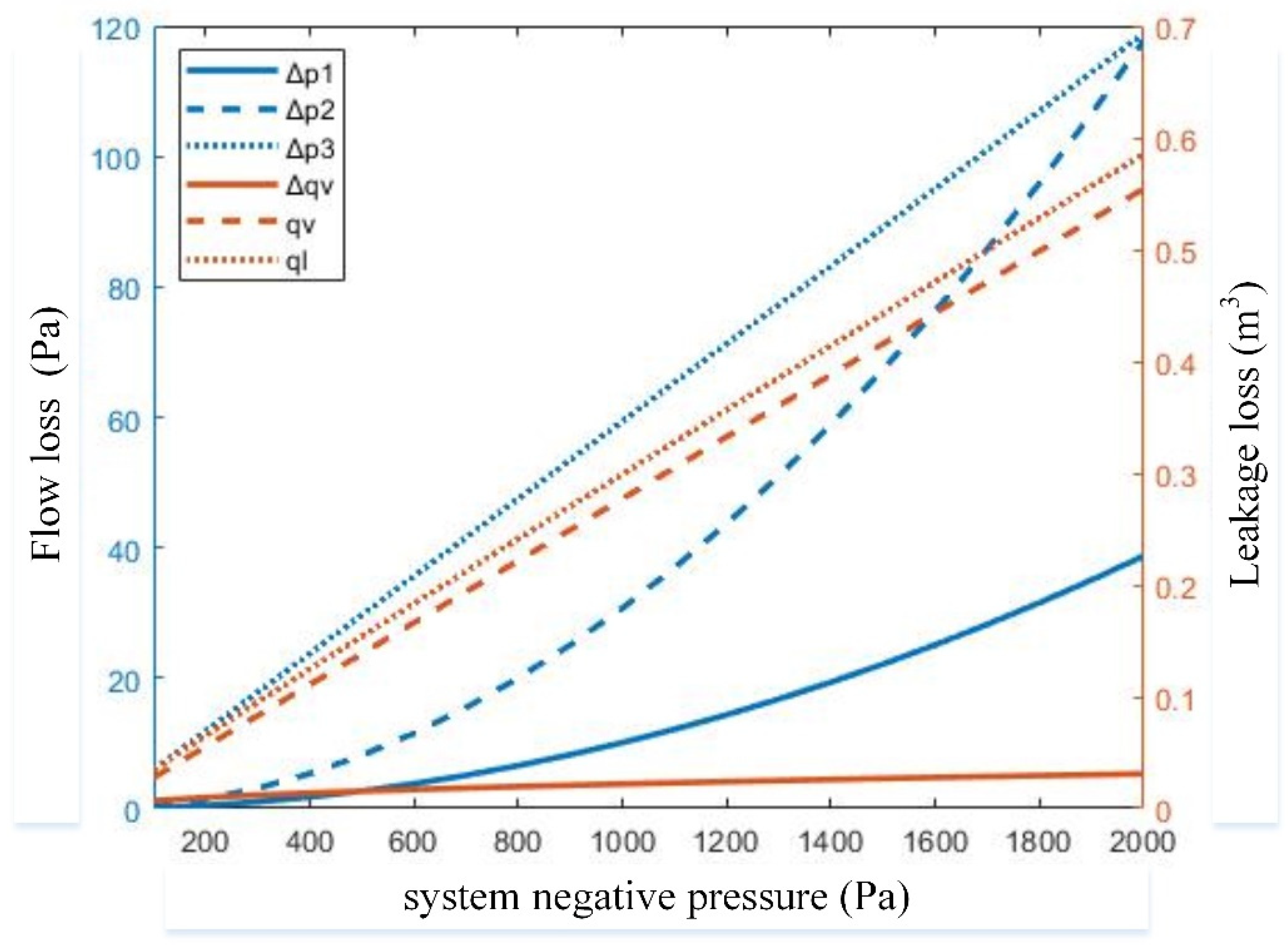

The corresponding curve of the negative pressure and flow loss and leakage loss of the centrifugal fan system is illustrated in

Figure 23. The impact of fan mechanical loss on system power is too small to be excluded in the figure. According to the figure, in the pressure flow loss part, the loss coefficients of the three losses are the same. The degree of loss is principally dominated by the itemized velocity of the fluid entering the inspection channel, as well as the leakage loss and the inlet angle. Among them, the outlet diffuser pressure loss directly depends on the negative pressure of the system; the shaft, radial conversion loss, and blade channel loss are indirectly determined by the negative pressure of the system; and the total amount of pressure loss increases with the increase in the negative pressure of the system. In the flow leakage loss process, as the negative pressure of the system increases, the fluid leakage flow rate increases little by little, but it is always maintained at a low level without causing much impact on the system’s power. The difference between the theoretical flow rate of the fan and the actual flow rate is proportional to the leakage flow rate. To sum up, it is verified that the negative pressure of the system is the major factor that determines the total power loss of the centrifugal fan. Under the condition of high negative pressure demand, the negative pressure adsorption system should put out more compensation power. The experimental numerical calculation results can be found in

Appendix A Table A3.

- (2)

Comparative analysis of adsorption force and power

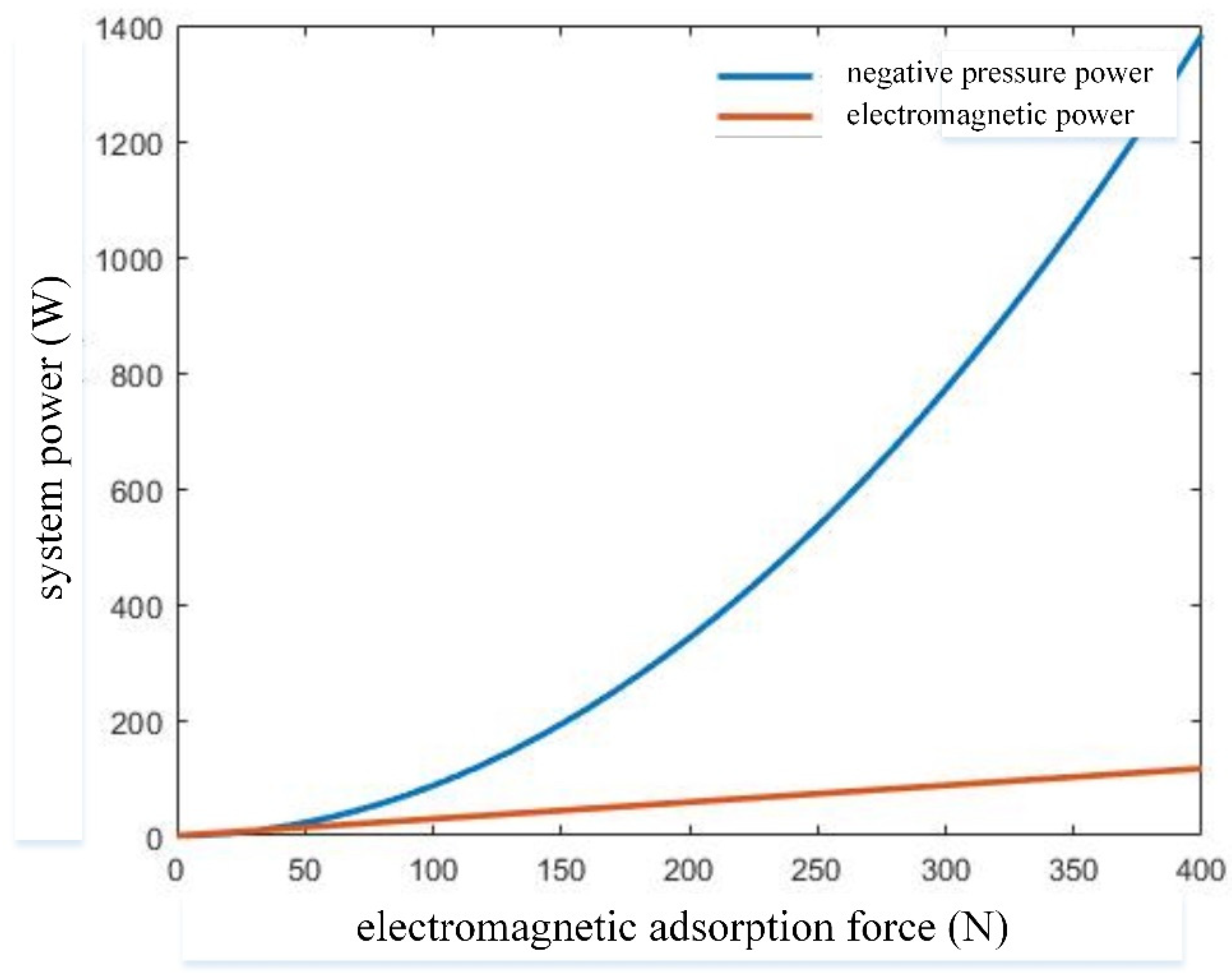

The corresponding curves of the various power parameters in the process of generating electromagnetic adsorption force by the single electromagnetic unit in the electromagnetic array are displayed in

Figure 24. From

Figure 24a, the electromagnetic adsorption force of the unit increases with the increase in the magnetic flux of the channel. It is verified that under the premise of certain structural parameters, material parameters, and the number of turns of the wire, the electromagnetic adsorption system enhances the electromagnetic adsorption force of the unit by increasing the input current and then enhancing the magnetic flux in the magnetic circuit channel. In

Figure 24b, the electromagnetic power of the unit increases with the increase in the input current, and the standard curve slope shows an increasing trend, implying that the input current is the principal factor determining the power of the electromagnetic unit. Furthermore, in the initial stage of increasing the input current of the unit, the electromagnetic adsorption force is slightly increased; the loss of electromagnetic power is relatively small. In the stage of increasing the input current of the unit from 1/3 node to the numerical boundary, the increase in electromagnetic adsorption force and electromagnetic power is faster, indicating that the power loss of the electromagnetic unit is small when it starts. The experimental numerical calculation results can be found in

Appendix A Table A4.

The power comparison curve of the electromagnetic adsorption device and the negative pressure adsorption device corresponding to the adsorption force output value in the coupled adsorption system is shown in

Figure 25. Based on the observation of the curve in the figure, under the premise of outputting the same adsorption force, the power consumption of the negative pressure adsorption system is much larger than that of the electromagnetic adsorption system. Furthermore, within the range of the adsorption force inspection interval, the power increment of the negative pressure adsorption system is much greater than that of the electromagnetic adsorption system. Through numerical comparison and analysis, it can be inferred that to maintain the stable operation of the wall–climbing robot on the vertical shaft lining, the negative pressure adsorption method is bound to consume several times the energy and power of the electromagnetic adsorption method, and the adsorption efficiency of electromagnetic adsorption is significantly higher than that of negative pressure adsorption.