Experimental Study on Wide-Graded Soil Transport in Unsteady Flow

Abstract

1. Introduction

2. Experimental Apparatus and Methods

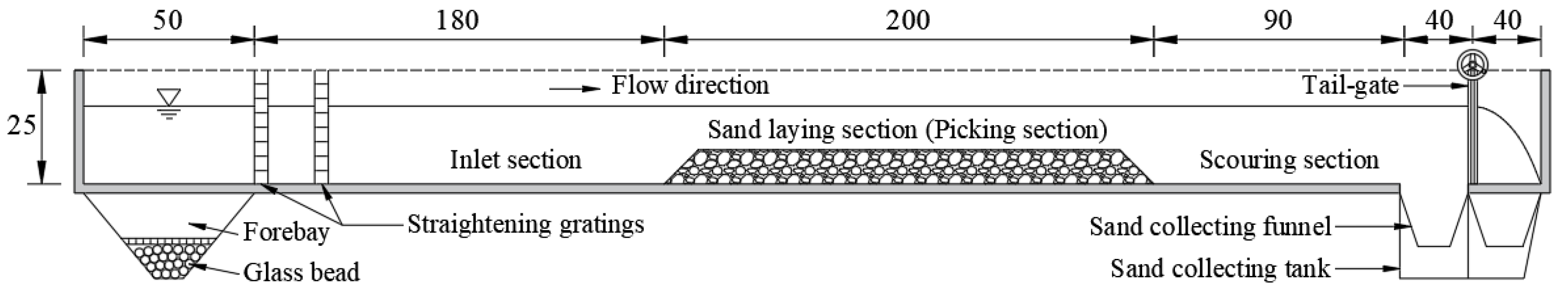

2.1. Unsteady Flow Scouring Experimental System

- (1)

- Test flume

- (2)

- Inlet flow control system

- (3)

- Hydraulic element measurement system

- (4)

- Sand transport measurement system

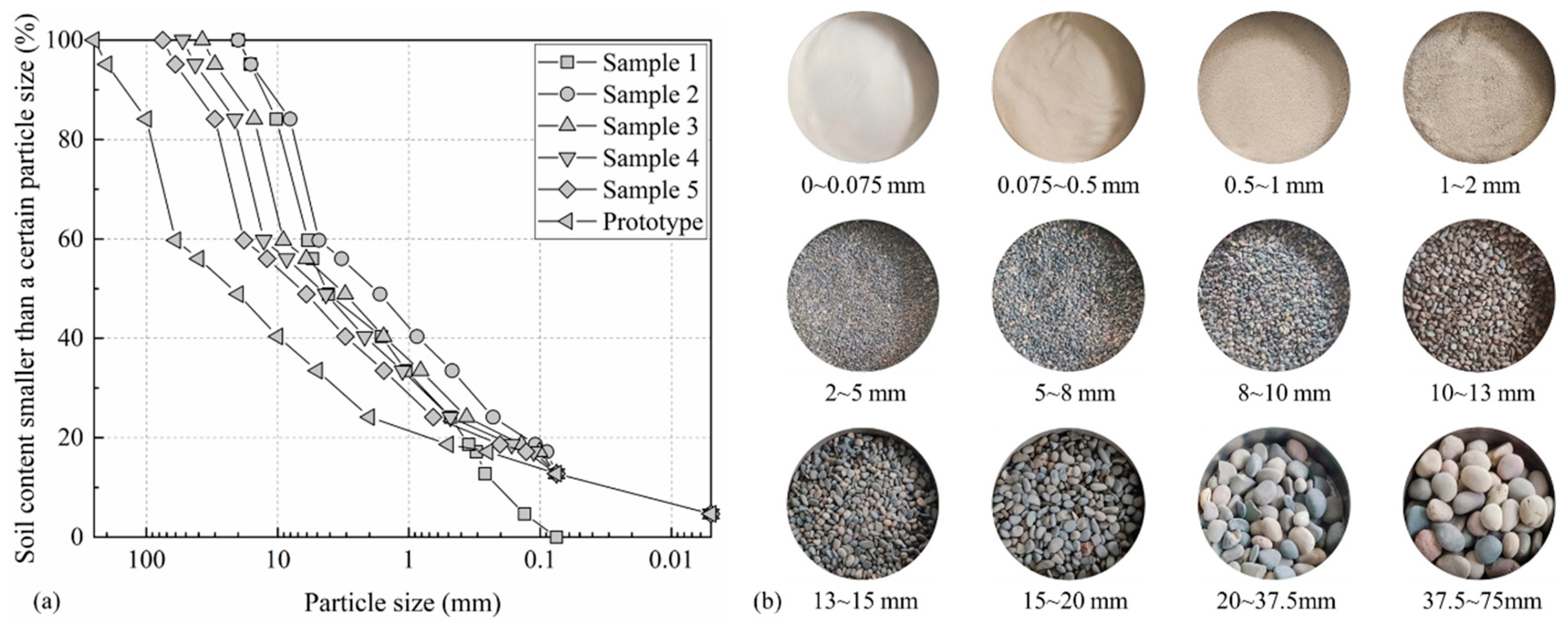

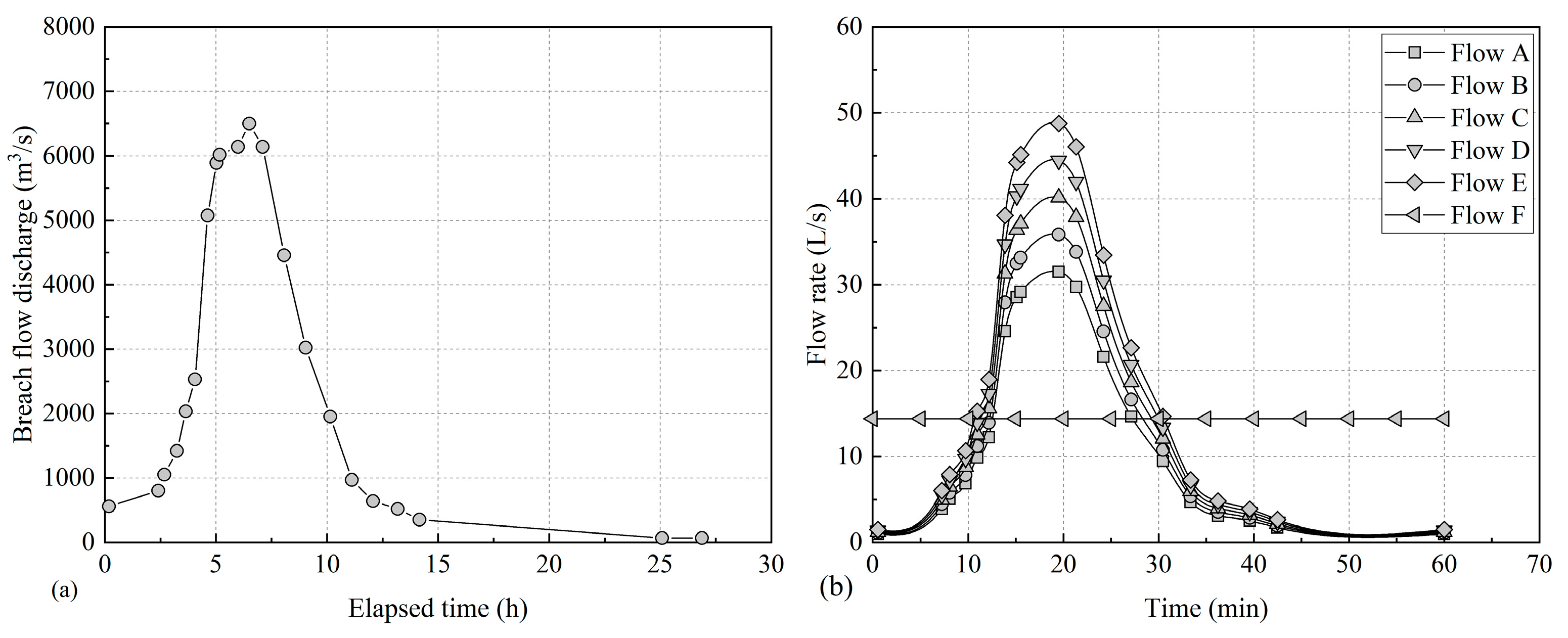

2.2. Test Condition

3. Characteristics of Sediment Transport Movement in Unsteady Flow

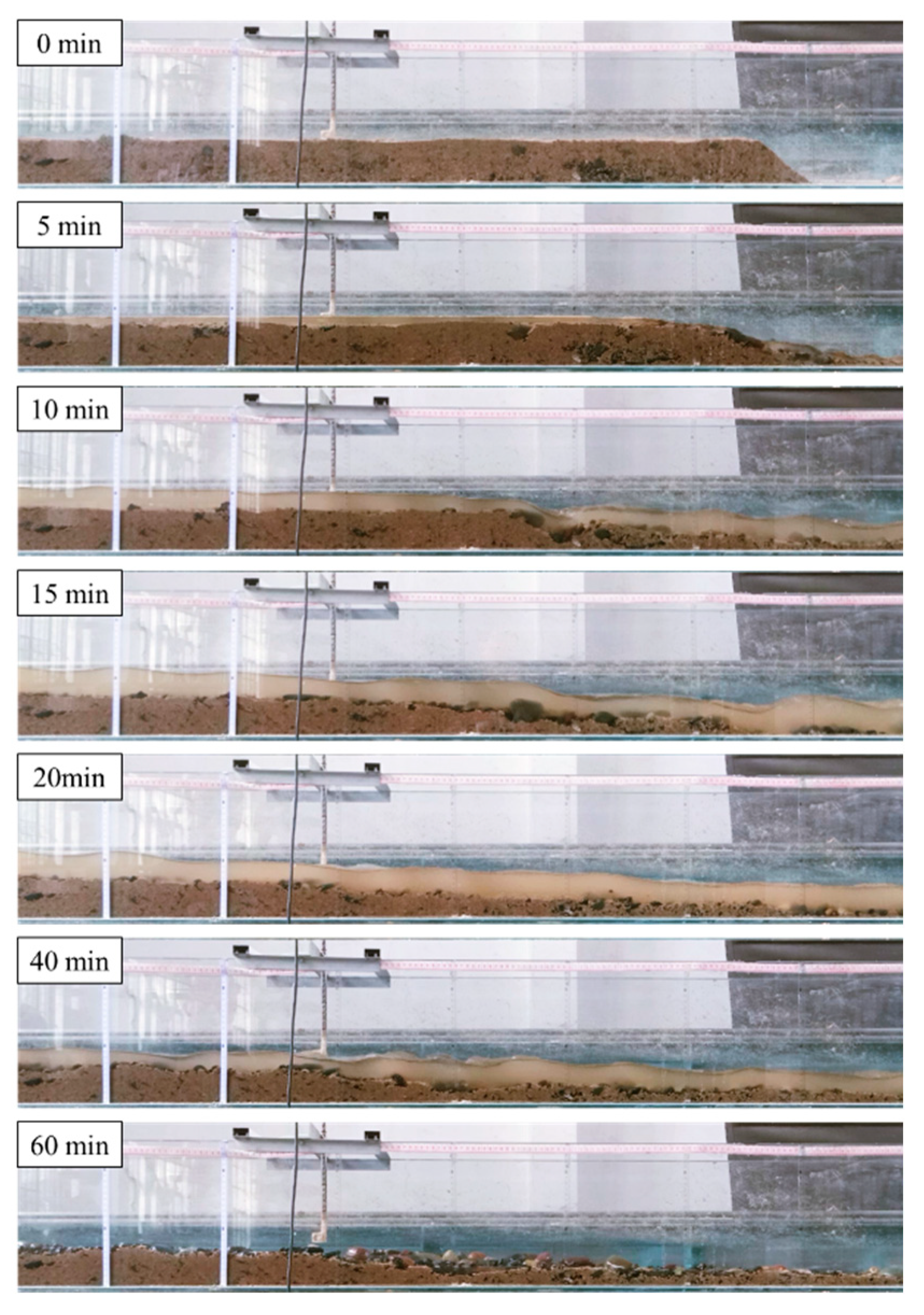

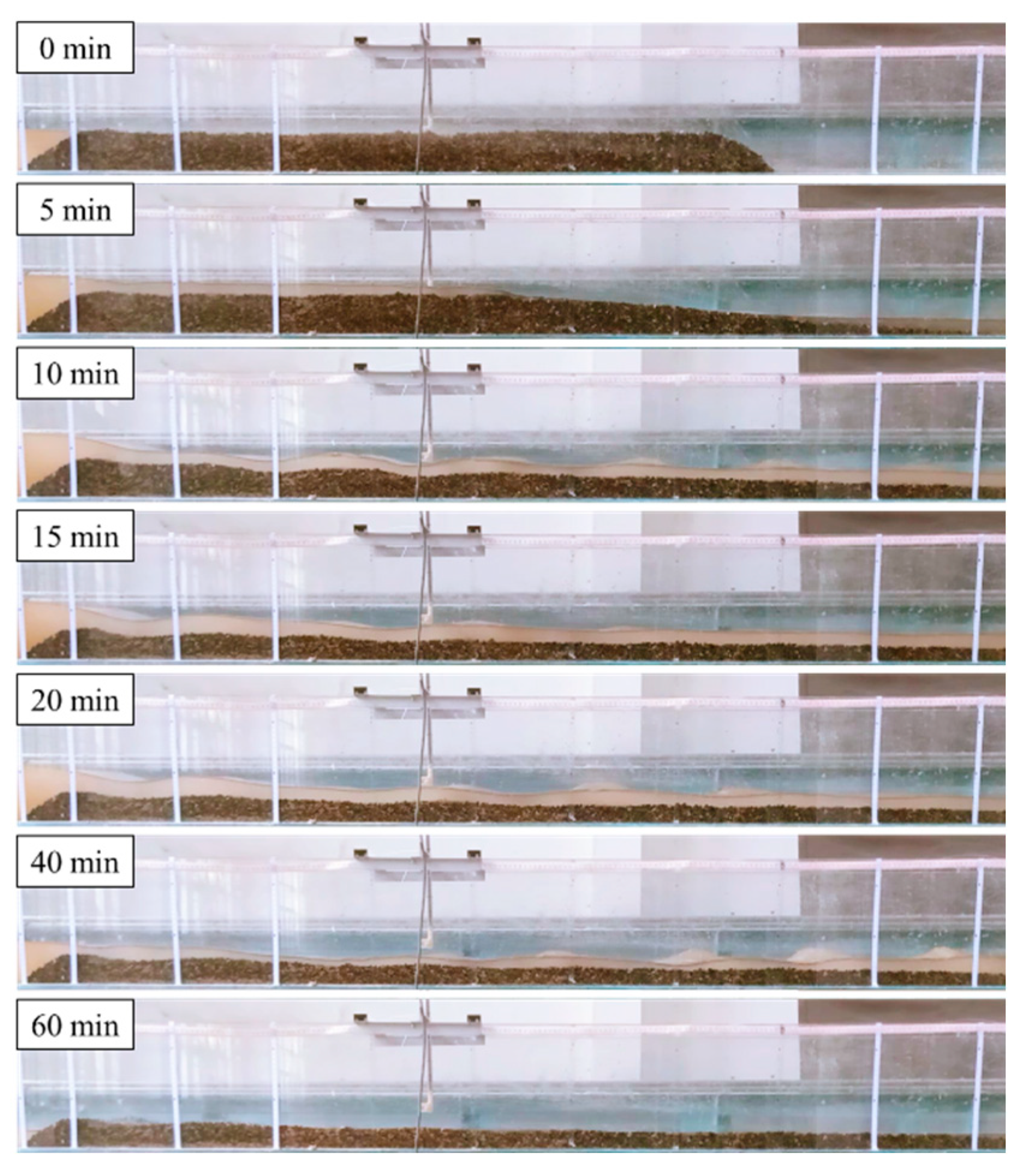

3.1. Wide-Graded Sediment Scouring and Transport Process

3.2. Uniform sand Scouring and Transport Process

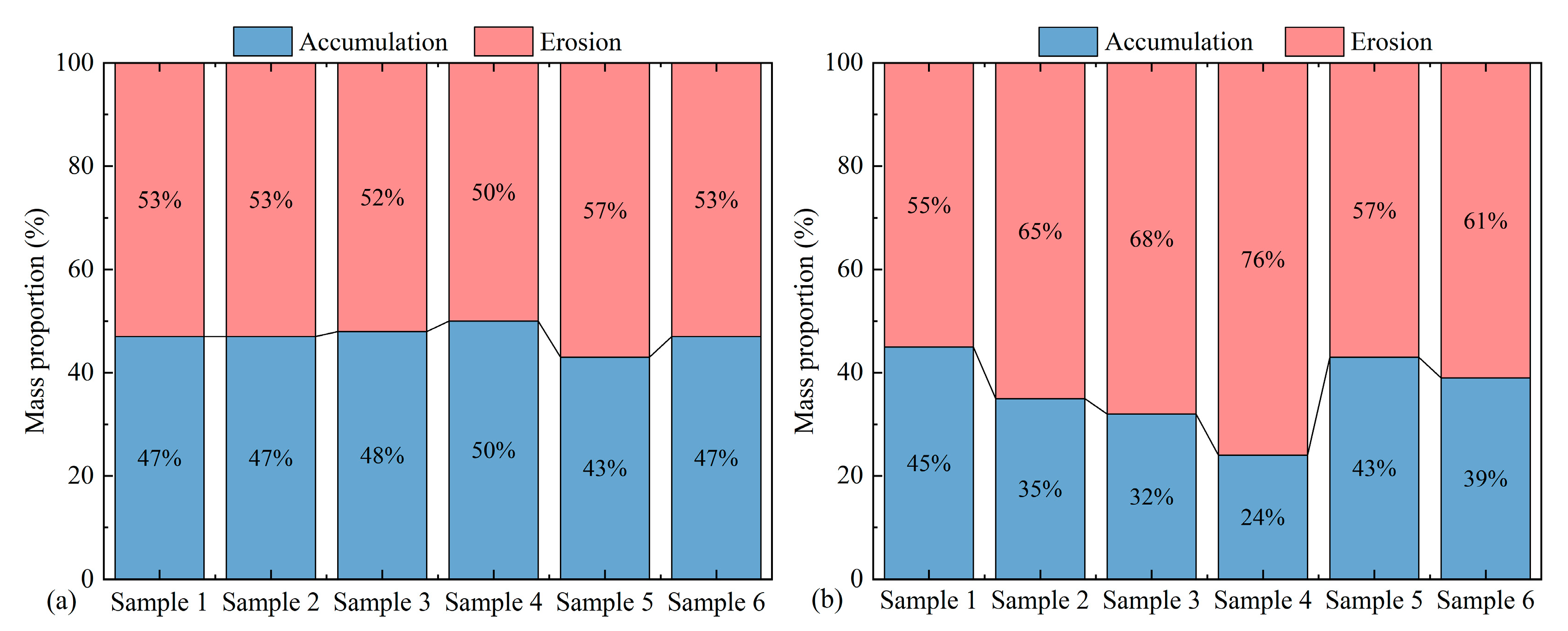

4. Influence of Sediment Grading Width on the Scouring Process

4.1. Scouring Amount

4.2. Scouring Soil and Stone Material Grading

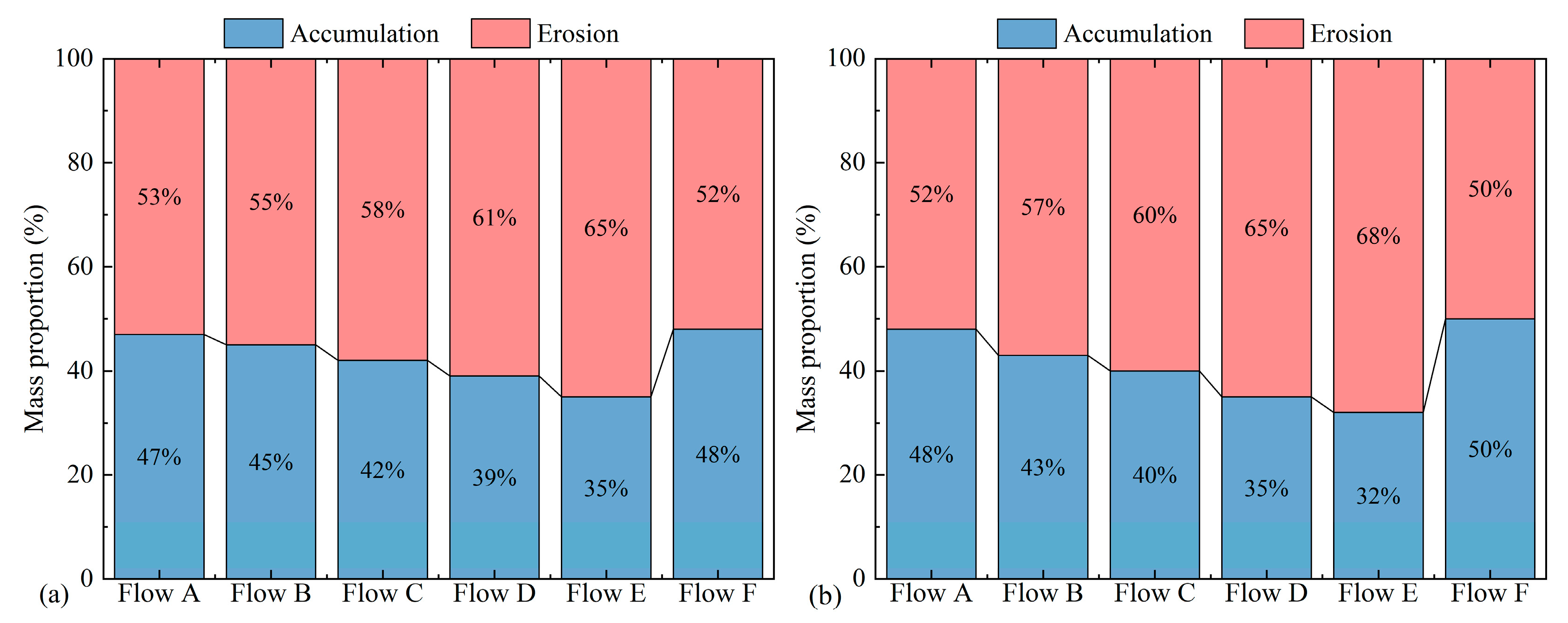

5. Influence of Flow Conditions on the Scouring Process

5.1. Scouring Amount

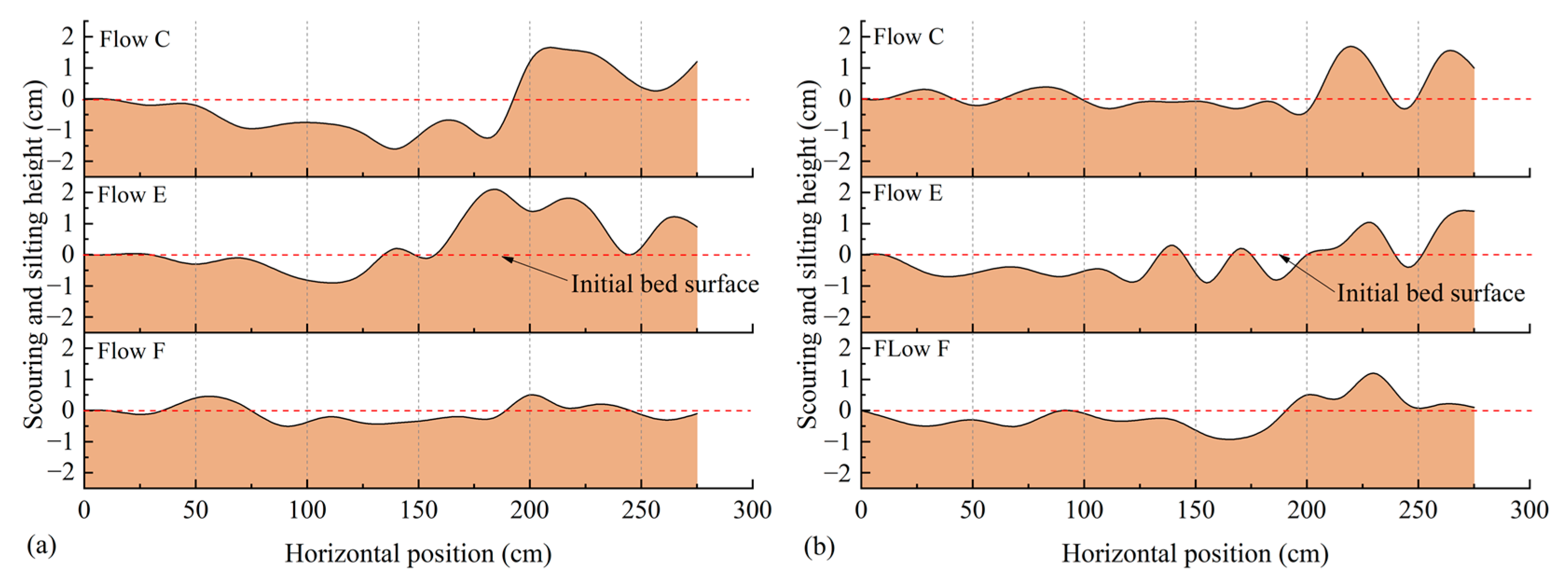

5.2. Erosion and Deposition Characteristics

6. Conclusions and Discussion

- (1)

- The scouring intensity downstream in the process of soil and sand scouring is much larger than that of upstream intensity, and large coarse particles mainly accumulate in the upstream area, which is more consistent with the location of the siltation area after the end of the scouring.

- (2)

- The wide-graded sediment scouring process develops in the form of scouring pit formation, expansion, and movement. The whole scouring process is influenced by the intermittent and paroxysmal start of coarse particles on the bed, and the scouring process is discontinuous. While the uniform sand scouring development process is dominated by continuous collapse damage of the downstream slope at the early stage, and mainly manifests as surface headward erosion at the later stage.

- (3)

- Under weak unsteady flow conditions, the shading effect of large particles in wide-graded sediment is obvious, and the erosion resistance is strong. However, under strong unsteady flow conditions, the water flow is more violent to the fine particles in wide-graded sediment, which causes the formation of a free surface on the downstream side of coarse particles and its start. The change in the shading relationship causes the fine particles to be further scoured, and the erosion resistance is weaker.

- (4)

- As the scouring intensity downstream of the sand laying section is higher than that upstream, the bed surface is easily inclined downstream. The accumulation range of barrier dams along the river is generally long and the breach is long and narrow. The change of slope rate at the breach bottom during breaching should be considered in the dam break calculation, otherwise, the calculation result would be conservative.

- (5)

- The scouring intensity under unsteady flow is greater than that under steady flow, so the bedload transport rate formula proposed based on the steady flow is not suitable for the calculation of the development process of barrier dam break.

- (6)

- The gradation width of dam material also has a significant influence on the erosion rule. Different types of landslide dams have different gradation widths. For example, in low position landslides, the dam body maintains the original slope stratigraphic sequence relationship and usually has wide gradation characteristics. However, in high position remote landslides, the dam body is mainly accumulated by debris flow due to sufficient vibration and fragmentation of the earth and rock, and the material gradation width is usually narrow. According to the conclusion of this study, the sediment transport equations used in the calculation of these two types of landslide dam failure should be different.

- (1)

- Non-constant water flow is a fluctuating process, and the number of discharge waves has a certain degree of influence on the sand transport rate of wide-graded sediment, while the flood breach process can be understood as just one discharge wave with a large fluctuation in its value. Therefore, it is necessary to explore more general conclusions about the mechanism of breach expansion under the influence of a single water discharge wave.

- (2)

- The reasonable quantification of the grading width of soil is the premise for the quantitative study of the influence of the grading width on the calculation of sediment transport. At present, there are relatively few methods to quantify the grading width of soil. There is not even a quantitative definition of what wide-graded sediment is, nor a dimensionless representation of the width of the gradation. Only in the early years, some scholars conducted some research work on the mathematical expression method of non-uniform bed sediment grading curves [39,40,41]. The grading width of earth rock materials should not only be the ratio (difference) of particle size. Different grading curve shapes also reflect different properties and laws in different aspects, such as erosion, permeability, compression characteristics, etc. Therefore, it is necessary to conduct further research and explore the quantitative description method of grading the width of soil, the dimensionless representation method for grading width, and its influence mechanism.

- (3)

- Due to limitations in experimental equipment, the scale used in this article is small; although, some important influencing factors were considered before the tests, such as water flow, soil grading, etc. While, as we know, it is impossible to achieve all parameters that can be strictly scaled to meet geometric similarity, kinematic similarity, and dynamic similarity, such as shear stress, flow rate, Reynolds number, Froude number, etc. However, even if this is achieved, it is still difficult to determine to what extent the measured data in the experiment represents the actual situation on site. Based on this consideration, the transport law of wide-graded soil under the action of unsteady flow, such as the transport mode, and erosion resistance, is qualitatively analyzed. The experimental data obtained in this paper are used cautiously, and the prototype data are not transformed, but the law reflected in it is emphasized.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Peng, M.; Zhang, L.M.; Chang, D.S.; Shi, Z.M. Engineering risk mitigation measures for the landslide dams induced by the 2008 Wenchuan earthquake. Eng. Geol. 2014, 180, 68–84. [Google Scholar] [CrossRef]

- Zhong, Q.M.; Chen, S.S.; Deng, Z. Simulation of diffuse toppling collapse mechanism and dam failure process of a barrier dam. Sci. Sin. Technol. 2018, 48, 959–968. [Google Scholar] [CrossRef]

- Pang, L.C.; Mo, D.Y.; Li, A.H. Analysis of formation conditions and processes of landslide-type barrier dams. People’s Yangtze River 2016, 47, 94–97+102. [Google Scholar] [CrossRef]

- Fan, X.; Scaringi, G.; Korup, O.; West, A.J.; Westen, C.J.; Tanyas, H.; Hovius, N.; Hales, T.C.; Jibson, R.W.; Allstadt, K.E.; et al. Earthquake-Induced Chains of Geologic Hazards: Patterns, Mechanisms, and Impacts. Rev. Geophys. 2019, 57, 421–503. [Google Scholar] [CrossRef]

- Zhao, T.; Dai, F.; Xu, N. Coupled DEM-CFD investigation on the formation of landslide dams in narrow rivers. Landslides 2017, 14, 189–201. [Google Scholar] [CrossRef]

- Jiang, X.G.; Cui, P.; Wang, Z.Y.; Heng, W.H. Experimental study of weir breach undercutting process. J. Sichuan Univ. 2016, 48, 38–44. [Google Scholar] [CrossRef]

- Liu, D.Z.; Cui, P.; Jiang, D.W. Experimental study on breach broadening process of landslide dam. Sci. Soil Water Conserv. 2017, 015, 19–26. [Google Scholar] [CrossRef]

- Zhao, G.W.; Jiang, Y.J.; Qiao, J.P.; Meng, H.J.; Yang, Z.J. Experimental investigation on overtopping failure of landslide dams with different conditions of compactness. J. Rock Mech. Eng. 2018, 37, 1496–1505. [Google Scholar] [CrossRef]

- Zhao, T.; Chen, S.; Fu, C.; Zhong, Q. Influence of diversion channel section type on landslide dam draining effect. Environ. Earth Sci. 2018, 77, 1–9. [Google Scholar] [CrossRef]

- Zhong, Q.M.; Shan, Y.B. Comparison of rapid evaluation methods for barrier dam’s stability. Yangtze River 2019, 50, 20–24+64. [Google Scholar] [CrossRef]

- Shen, G.Z.; Sheng, J.B.; Xiang, Y.; Zhong, Q.M. Numerical modeling of breach process of landslide dams due to overtopping and its application. Chin. J. Geotech. Eng. 2018, 40, 82–86. [Google Scholar]

- Zhong, Q.M.; Chen, S.S.; Mei, S.A.; Cao, W. Numerical simulation of landslide dam breaching due to overtopping. Landslides 2018, 15, 1183–1192. [Google Scholar] [CrossRef]

- Zhao, T.; Chen, S.; Fu, C.; Zhong, Q. Centrifugal model tests and numerical simulations for barrier dam break due to overtopping. J. Mt. Sci. 2019, 16, 630–640. [Google Scholar] [CrossRef]

- Li, Y.; Hu, W.; Wasowski, J.; Zheng, Y.; McSaveney, M. Rapid episodic erosion of a cohesionless landslide dam: Insights from loss to scour of Yangjia Gully check dams and from flume experiments. Eng. Geol. 2021, 280, 105971. [Google Scholar] [CrossRef]

- Gilbert, G.K.; Murphy, E.C. The Transportation of Débris by Running Water; Center for Integrated Data Analytics Wisconsin Science Center: Madison, WI, USA, 1914. [Google Scholar] [CrossRef]

- Meyer-Peter, E. Formulas for bed-load transport. Proc. Congr. Iahr. 1948, 3, 39–64. [Google Scholar]

- Mason, P.J. Erosion of plunge pools downstream of dams due to the action of free-t-rajectory jets. Proc. Inst. Civ. Eng. 1984, 76, 523–537. [Google Scholar] [CrossRef]

- Jing, H.; Chen, G.; Wang, W.; Li, G. Effects of concentration-dependent settling velocity on non-equilibrium transport of suspended sediment. Environ. Earth Sci. 2018, 77, 549. [Google Scholar] [CrossRef]

- Khosravi, K.; Chegini, A.H.N.; Cooper, J.; Mao, L.; Habibnejad, M.; Shahedi, K.; Binns, A. A laboratory investigation of bed-load transport of gravel sediments under dam break flow. Int. J. Sediment Res. 2021, 36, 229–234. [Google Scholar] [CrossRef]

- Bagnold, R.A. An Approach to the Sediment Transport Problem from General Physics; U.S. Geological Survey Professional Paper; U.S. Government Printing Office: Washington, DC, USA, 1966; p. 37. [CrossRef]

- Einstein, H. Formulas for the transportation of bed load. J. Hydraul. Div. ASCE 1942, 107, 561–597. [Google Scholar] [CrossRef]

- Han, Q.W.; He, M.M. Statistical theory of sediment movement. Chin. Sci. Bull. 1980, 36–38. [Google Scholar]

- Wei, L.; Lu, J.Y.; Xu, H.T. Experimental study on the distribution of vertical flow velocity in a discontinuous wide-graded riverbed. J. Water Resour. Water Transp. Eng. 2012, 26–31. [Google Scholar] [CrossRef]

- Jin, M.H. Experimental study on the starting law of bed sand with a wide size distribution. J. Mt. Sci. 2003, 493–497. [Google Scholar] [CrossRef]

- Xu, H.T.; Lu, J.Y.; Liu, X.B. Study on the Method of Calculating Transport Rate of Discontinuous Broadly Graded Bedload. J. Yangtze River Sci. Res. Inst. 2011, 28, 26–30+36. [Google Scholar] [CrossRef]

- Wang, S.Y.; Duan, W.G.; Li, L. Study on motion characteristics of wide graded non-uniform sand. Yangtze River 2011, 42, 72–75+105. [Google Scholar] [CrossRef]

- Wei, L.; Lu, J.Y.; Xu, H.T. Exploration on the characteristics and formation conditions of discontinuous wide-graded bed sand in natural river channels. J. Chang. Acad. Sci. 2012, 29, 6–10+15. [Google Scholar] [CrossRef]

- Xu, D.; Bai, Y.; Ji, C.; Williams, J. Experimental study of the density influence on the incipient motion and erosion modes of muds in unidirectional flows: The case of Huangmaohai Estuary. Ocean Dyn. 2015, 65, 187–201. [Google Scholar] [CrossRef]

- Mohamed, E.; Jasim, I. Bedload Model for Nonuniform Sediment. J. Hydraul. Eng. 2016, 142, 06016004. [Google Scholar] [CrossRef]

- Pilarczyk, K.W. Impact of the Delta Works on the recent developments in coastal engineering. Coast. Ocean. Eng. Pract. 2012, 1–37. [Google Scholar] [CrossRef]

- Xu, J.; Wei, W.; Bao, H.; Zhang, K.; Lan, H.; Yan, C.; Sun, W. Failure models of a loess stacked dam: A case study in the Ansai Area (China). Bull. Eng. Geol. Environ. 2020, 79, 1009–1021. [Google Scholar] [CrossRef]

- Faraci, C.; Musumeci, R.E.; Marino, M.; Ruggeri, A.; Carlo, L.; Jensen, B.; Foti, E.; Barbaro, G.; Elsaßer, B. Wave-and current-dominated combined orthogonal flows over fixed rough beds. Cont. Shelf Res. 2021, 220, 104403. [Google Scholar] [CrossRef]

- Lu, Q.; Deng, A.J.; Guo, Q.C.; Dong, X.Y. Study on the evolution pattern and mechanism of pebble bed flushing and siltation in the downstream of reservoirs. Sediment Res. 2019, 44, 26–32. [Google Scholar] [CrossRef]

- Cui, P.; Zhu, Y.Y.; Han, Y.S.; Chen, X.Q.; Zhuang, J.Q. The 12 May Wenchuan earthquake-induced landslide lakes: Distribution and preliminary risk evaluation. Landslides 2009, 6, 209–223. [Google Scholar] [CrossRef]

- Wang, G.Q.; Wang, Y.Q.; Liu, L.; Wang, D.Y. Reviewed on Barrier Dam and Simulation on Dam Breach. Yellow River 2015, 37, 1–7. [Google Scholar] [CrossRef]

- Liu, N.; Chen, Z.; Zhang, J.; Lin, W.; Chen, W.; Xu, W. Draining the Tangjiashan Barrier Lake. J. Hydraul. Eng. 2010, 136, 914–923. [Google Scholar] [CrossRef]

- Zhang, R.J. River Sediment Engineering; China Hydraulic Press: Beijing, China, 1981. [Google Scholar]

- Ma, A.X.; Lu, Y.J.; Lu, Y. Experimental study on gravel bed-load transport in unsteady flow. Shuili Xuebao 2013, 44, 800–809. [Google Scholar]

- Xie, B.L. Determination of functional relationship of experimental curve. J. Sediment Res. 1983, 64–66. [Google Scholar]

- Xiong, Z.P. Function formula of sediment gradation curve and determination of boundary grain size of bed sand and scour material. J. Sediment Res. 1985, 88–94. [Google Scholar]

- Wang, X.K.; Fang, D.; Cao, S.Y. Fractal Dimension on Characteristics of Pebble Sediment with Wide Size Distribution and Application. J. Yangtze River Sci. Res. Inst. 1999, 16, 9–12. [Google Scholar] [CrossRef]

| Conditions | Flow A | Flow B | Flow C | Flow D | Flow E | Flow F |

|---|---|---|---|---|---|---|

| P | 0.113 | 0.125 | 0.137 | 0.150 | 0.162 | 0 |

| 1# (%) | 2# (%) | 3# (%) | 4# (%) | 5# (%) | |

|---|---|---|---|---|---|

| 0.5~1 mm | 37.8 | 35.0 | 36.6 | 75.1 | 23.7 |

| 1~2 mm | 41.1 | 38.8 | 39.9 | 66.4 | 28.8 |

| 2~5 mm | 28.5 | 21.9 | 23.7 | 55.6 | 15.9 |

| 5~8 mm | 51.2 | 28.3 | 22.0 | 39.9 | 55.3 |

| 8~10 mm | 36.4 | 18.8 | 16.5 | 23.1 | 14.6 |

| 10~13 mm | 30.9 | 21.6 | 21.6 | 64.3 | 11.8 |

| 13~15 mm | 27.2 | 21.5 | 22.2 | 30.7 | 15.8 |

| 15~20 mm | 56.1 | 42.6 | 16.4 | 20.9 | 46.3 |

| 20~37.5 mm | / | 10.1 | 23.7 | 19.9 | / |

| 37.5~53 mm | / | / | 18.3 | 20.8 | / |

| 53~75 mm | / | / | / | 16.0 | / |

| Flow Conditions | Samples | Maximum Flush Condition | Maximum Siltation | ||

|---|---|---|---|---|---|

| Location (cm) | Depth (cm) | Location (cm) | Thickness (cm) | ||

| C | 2# | 140 | 1.6 | 215 | 1.6 |

| 4# | 200 | 0.4 | 215 | 1.5 | |

| E | 2# | 110 | 1.5 | 185 | 2.1 |

| 4# | 155 | 0.9 | 275 | 1.4 | |

| F | 2# | 90 | 0.5 | 200 | 0.5 |

| 4# | 170 | 0.9 | 230 | 1.2 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, T.; Ma, T.; Fu, C.; Zhang, C. Experimental Study on Wide-Graded Soil Transport in Unsteady Flow. Processes 2023, 11, 1965. https://doi.org/10.3390/pr11071965

Zhao T, Ma T, Fu C, Zhang C. Experimental Study on Wide-Graded Soil Transport in Unsteady Flow. Processes. 2023; 11(7):1965. https://doi.org/10.3390/pr11071965

Chicago/Turabian StyleZhao, Tianlong, Tingsen Ma, Changjing Fu, and Chuan Zhang. 2023. "Experimental Study on Wide-Graded Soil Transport in Unsteady Flow" Processes 11, no. 7: 1965. https://doi.org/10.3390/pr11071965

APA StyleZhao, T., Ma, T., Fu, C., & Zhang, C. (2023). Experimental Study on Wide-Graded Soil Transport in Unsteady Flow. Processes, 11(7), 1965. https://doi.org/10.3390/pr11071965