1. Introduction

It is well known that a butterfly valve is widely used in the industrial pipeline systems because of its smaller pressure loss and simple structure [

1,

2]. In the past decades, numerous researchers have focused on the optimization of butterfly valve structure and the analysis of flow characteristics in order to reduce its pressure drop. Kimura et al. [

3] established the theoretical prediction equations for the pressure loss coefficients of the butterfly valve and found that the theoretical predictions and experimental values were in good agreement. Kim et al. [

4] conducted preliminary numerical simulation to analyze the internal flow field of the butterfly valve but did not quantify the regulating characteristics. Corbera et al. [

5,

6] used genetic algorithms to optimize the design of butterfly valve plates to improve the regulating characteristics of butterfly valves. The results proved the ability of the techniques to improve the valve disc, thereby improving the control of the flow. Cui et al. [

7] improved the butterfly plate structure to reduce the resistance coefficient. The results show that when the valve opening is 100%, the resistance coefficient decreases by 12%. Sun et al. [

8] found that an increase in the roughness height significantly increased the frictional pressure drop. Liu et al. [

9] changed the tri-eccentric butterfly from a full-axis type to a double-end-axis and reduced the valve pressure drop at a small opening, but this does not work when the valve is fully opened. Banis [

10] investigated and evaluated the idle speed parameters of a novel throttle body. The advantages of his novel design include no obstructions or resistances in the flow path at the fully open throttle position. However, his novel throttle body required alteration in fuel injector angle, a different idle air bypass system, and increased leakage at fully closed throttle position. Danbon and Solliec [

11] compared the effect of a straight pipe with that of an elbow on the flow through a butterfly valve. The comparison showed that the installation of the elbow ahead of the valve might produce significant fluctuations in flow, especially when the valve is fully open. The influence ceased to be visible on the far side at eight times the pipe diameter when the flow became steady.

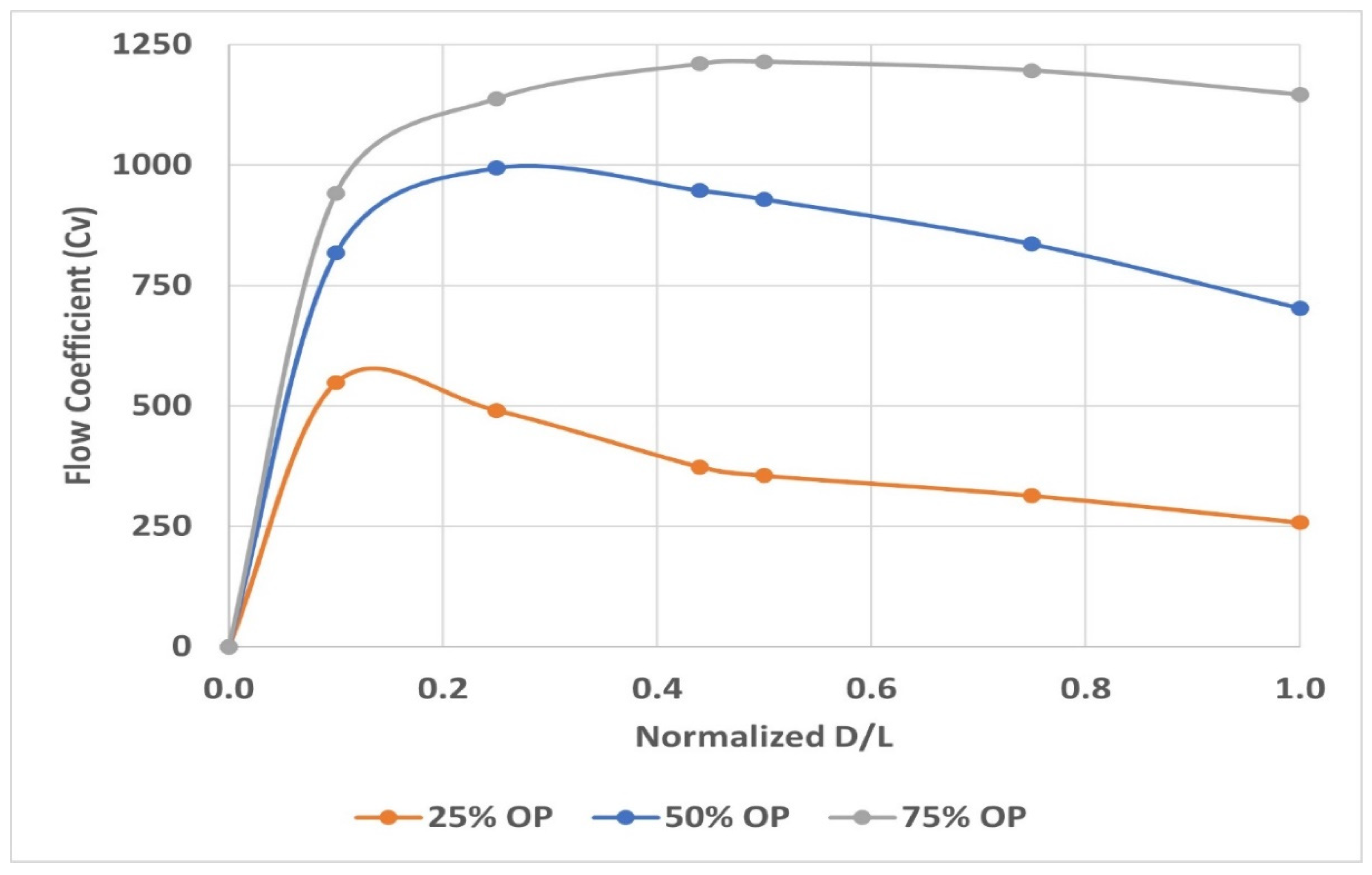

The flow coefficients of various types of butterfly valves were also studied by Kim and Yoon [

12], and their results showed that the eccentric valve produces a greater flow coefficient than the concentric valve. In the most recent work, Nguyen et al. [

13] studied the relationship between the flow coefficient of a globe valve and the Reynolds number. The flow coefficient increases steadily before becoming convergent, and it remains at a constant level when the Reynolds number is 105.

Park et al. [

14] evaluated the effects of different flow characteristics of various valves in order to reduce water hammer in seawater treatment piping. They suggested that an equal-percentage butterfly valve be used to mitigate the pressure oscillation of the system during the time the valve was being closed.

Using CFD in analyzing the flow characteristics of BFV and predicting the flow behavior based on valve geometry was also investigated by many scholars. Kapri [

15] and Balaji et al. [

16] numerically investigated the pressure drop passing through the BFV. They conducted a comparative study of the throttle body with different shaft profiles using CFD analysis. They simulated a steady flow of air passing through the BFV using different shaft profiles. Their conclusion was that the rectangular shaft of the BFV creates less of a pressure drop than the circular shaft, and thus improves the engine performance, fuel economy and emissions. The prediction equations were functions of the valve’s opening angle, thickness, and the diameter of the valve disc. Changchun and Haengmuk [

17] and Chang Chun et al. [

18] carried out numerous investigations to obtain the best design to reduce pressure drop across the BFV by analyzing the flow based on mathematical models, CFD and experimental results. Leutwyler and Dalton [

19,

20] performed a CFD study in two and three dimensions for symmetric butterfly valves in compressible fluids at various angles and over a range of pressure ratios. FLUENT software was used with the different turbulence models. They favored the k-ε turbulence model for its well-rounded capabilities and moderate computational costs. In addition, they also validated grid refinement, coefficients for lift, drag and torque against experimental values. Said et al. [

21] also investigated, both numerically and experimentally, the flow characteristics of the butterfly valve using Fluent. The simulation succeeded in predicting the flow coefficient; however, at small angles, care must be paid.

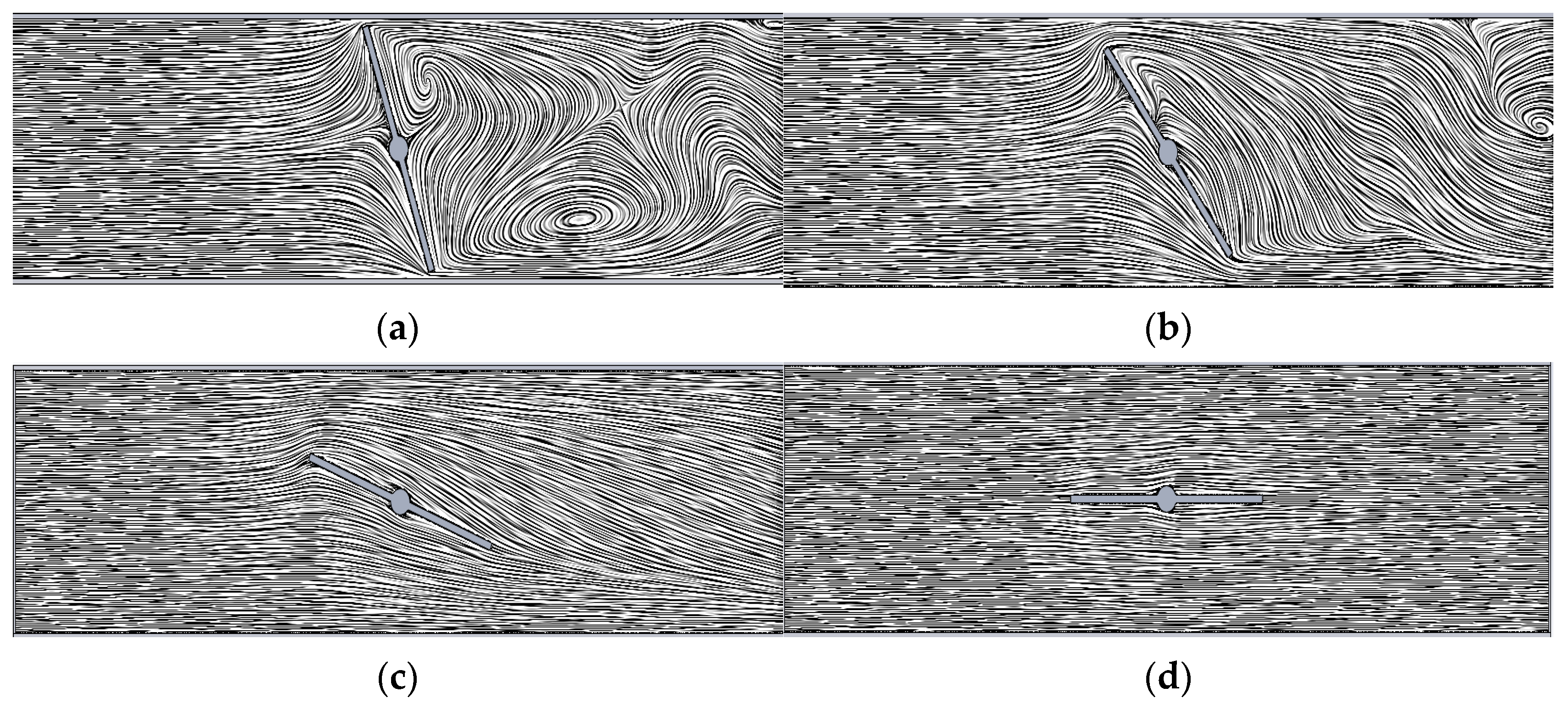

Although the above studies have improved the regulating characteristics of the butterfly valve to a certain extent, the structural pressure drop cannot be completely eliminated for the condition of large-valve opening, that is, the valve stem and the valve plate in the butterfly valve assembly are always in the flow field, which obstructs the fluid flow.

On the other hand, pinch valves are a type of flow control device that use a pinching mechanism to open and close the inner tube that is in contact with the fluid [

22]. This mechanism can be operated manually, pneumatically, or electrically. The main benefits of pinch valves are that they have no flow control mechanism in the fluid flow path in which dead zones or fluid pockets can be trapped, and they create minimal turbulence in the flow compared to other types of valves. Little work has been carried out in the pinch valve area, experimentally or numerically. In an effort to evaluate the flow characteristics through pinch valves and the profile area while pinching, Chaudhari [

23] carried out a numerical simulation to determine the pressure drop, volumetric flow rate, and flow coefficient of a pinch valve at several valve openings. The shape of the cross-section of the pinched area was assumed to be elliptical. Hirtum [

24] formulated three quasi-analytical geometrical ring models, namely, ellipse, stadium, and peanut, to serve as a low-cost ring shape estimation as a function of the pinching degree. A circular elastic tube was compressed between two parallel bars for pinching efforts between 40 and 95 percent. The stadium ring model showed a characteristic error of less than 4 percent of the tube diameter when compared to the experimental results.

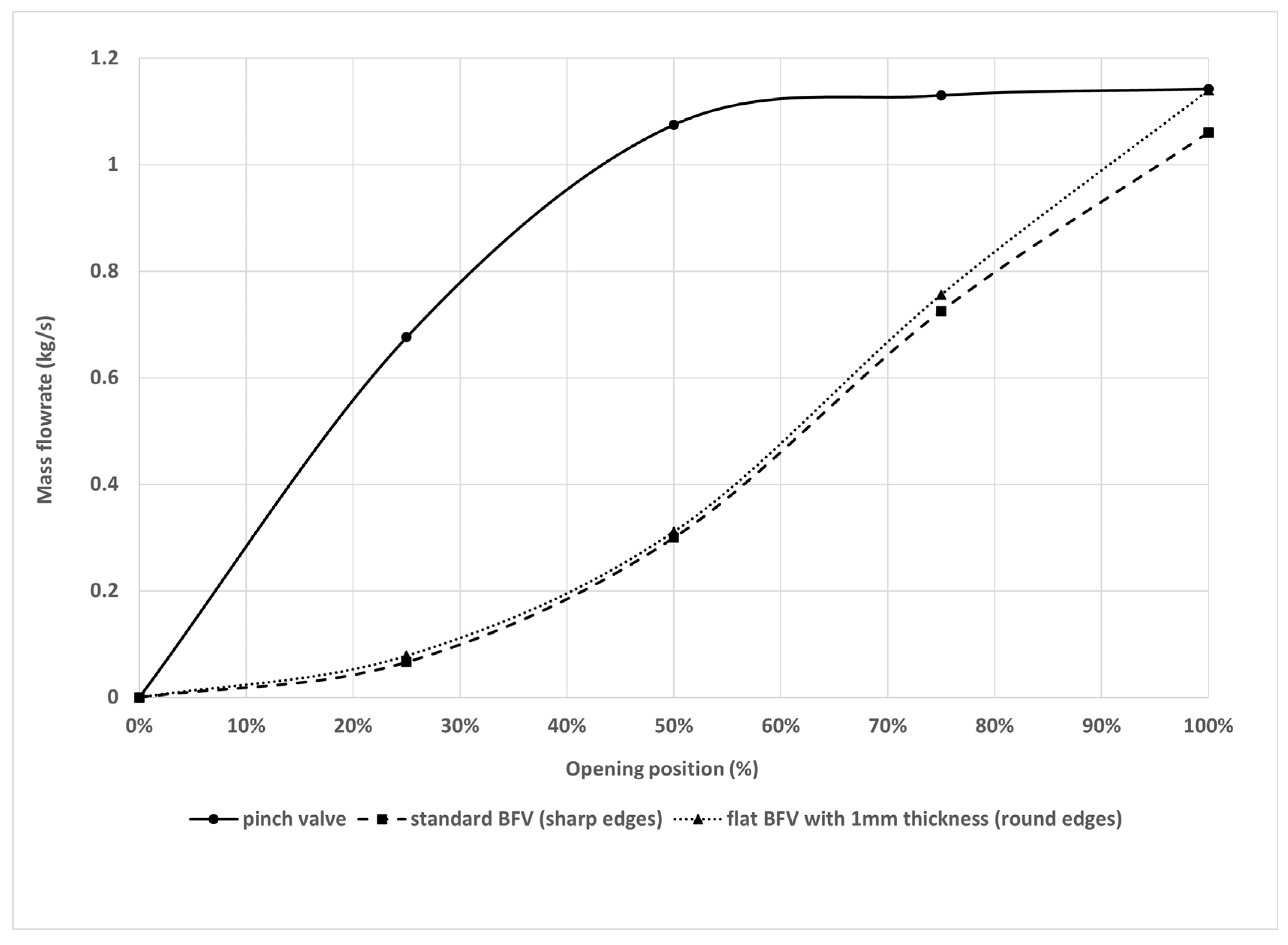

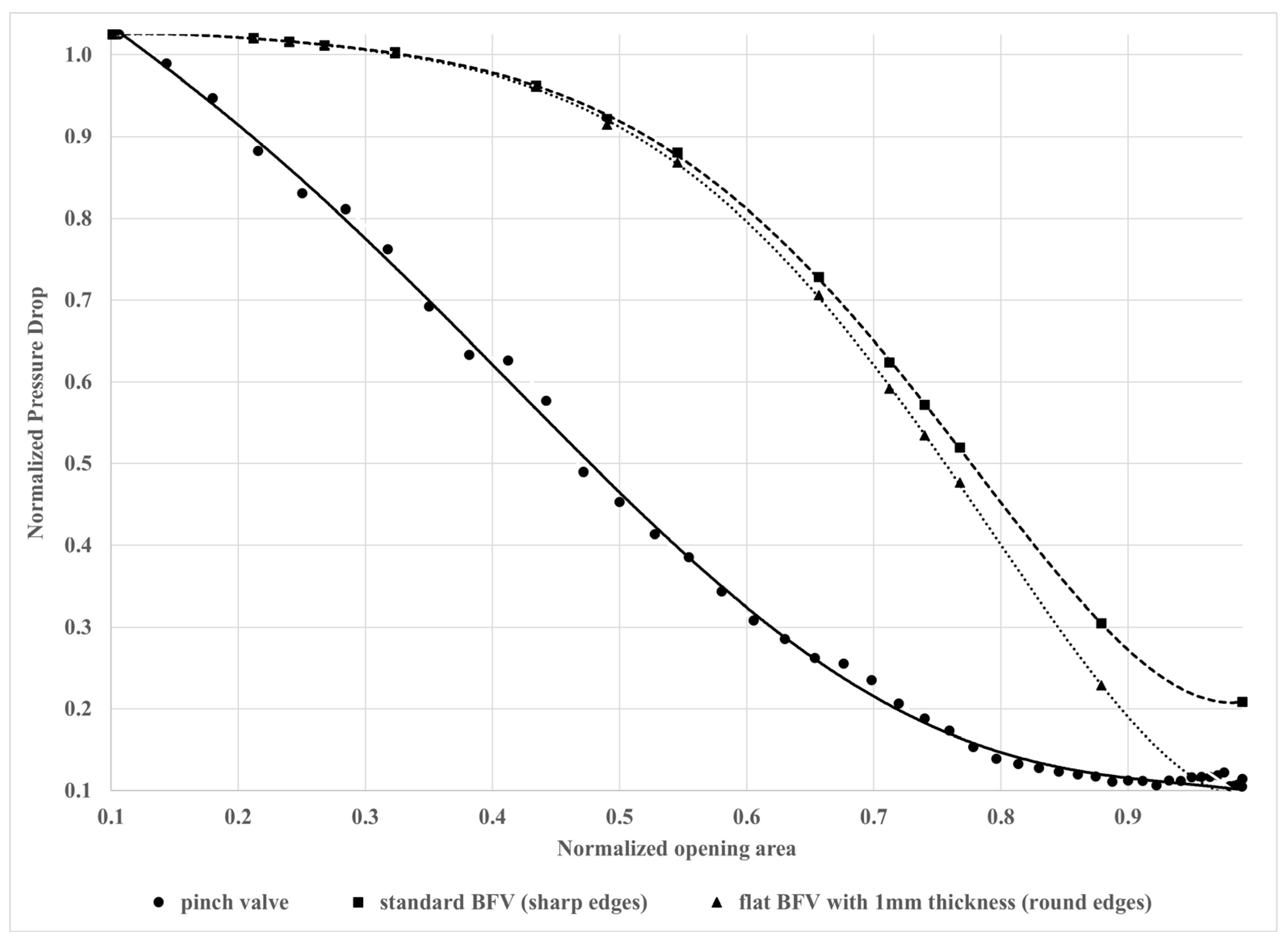

It is evident that many scholars have extensively investigated BFVs, both experimentally and numerically, and little work has been carried out on pinch valves, especially regarding their flow characteristics. Therefore, based on the literature survey, no previous attempts have been made to assess the flow characteristics of pinch valves at various pinching degrees versus BFVs in steady flow applications. Therefore, this work aims to fill this research gap by investigating the flow characteristics of air through butterfly valves with different design parameters and pinch valves at different pinching degrees using CFD software. Furthermore, a new mathematical model to estimate the profile area of a pinch valve at various pinching degrees is developed and compared with the CFD analysis. Thus, the following items summarize the aim of this work:

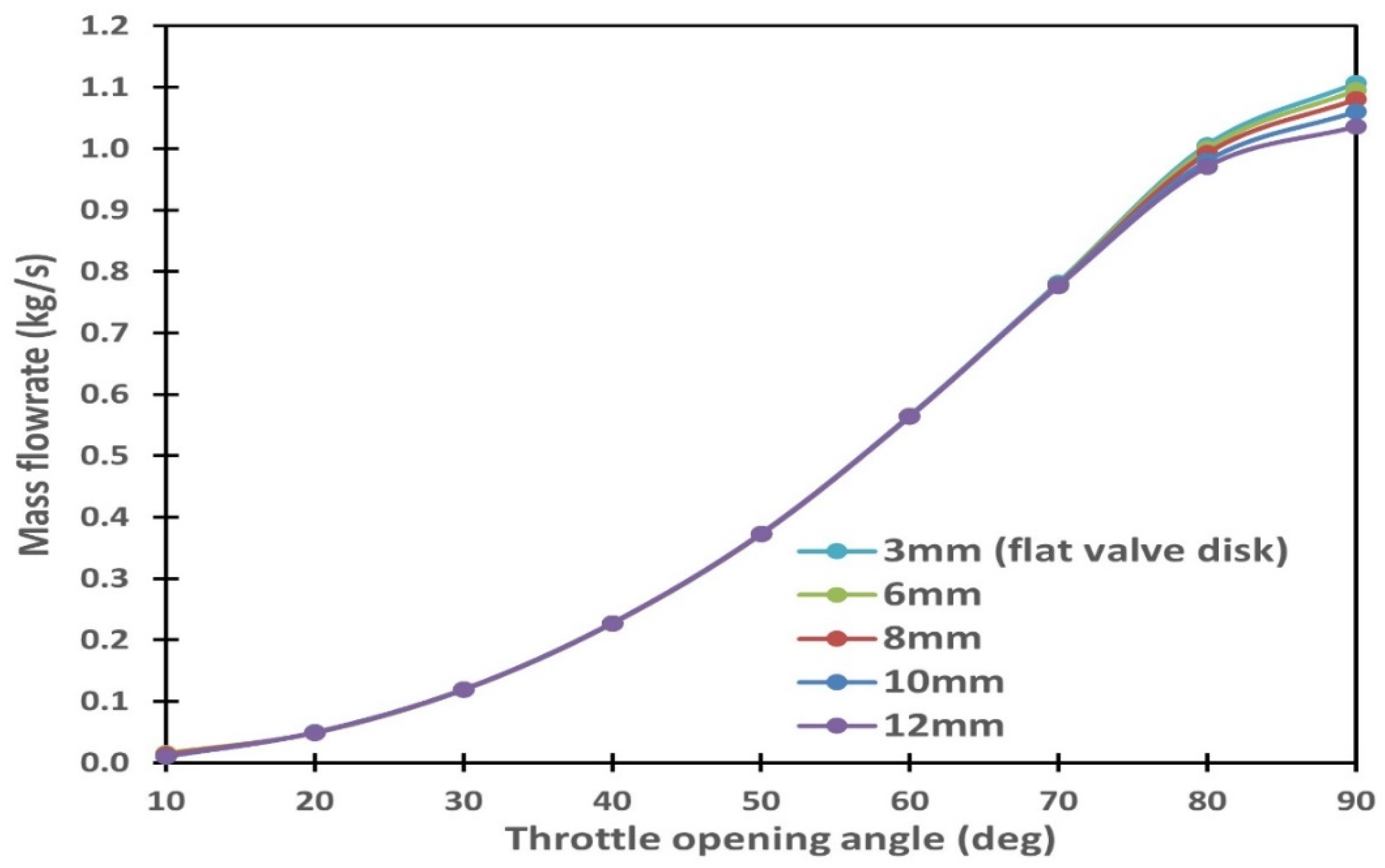

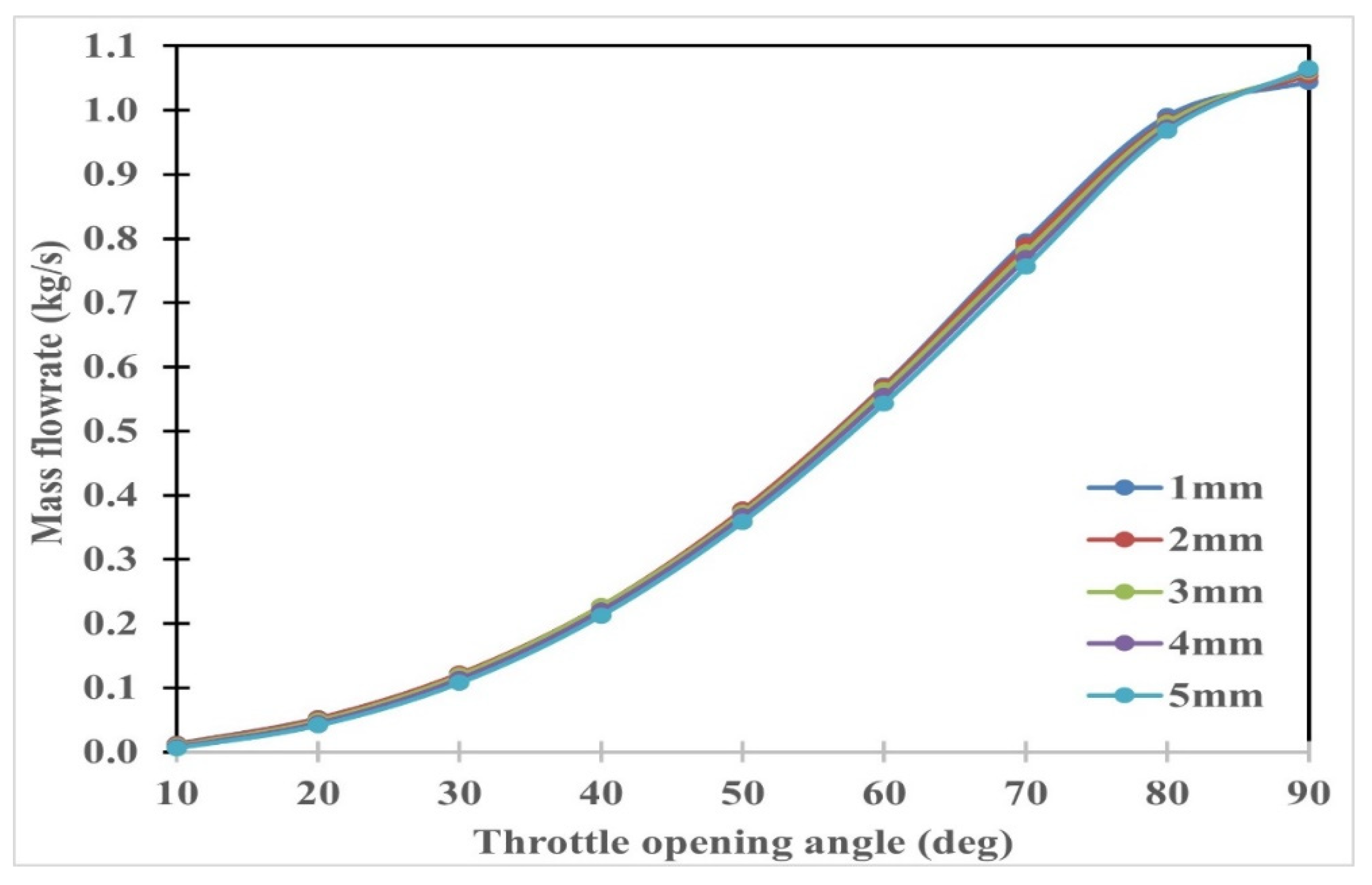

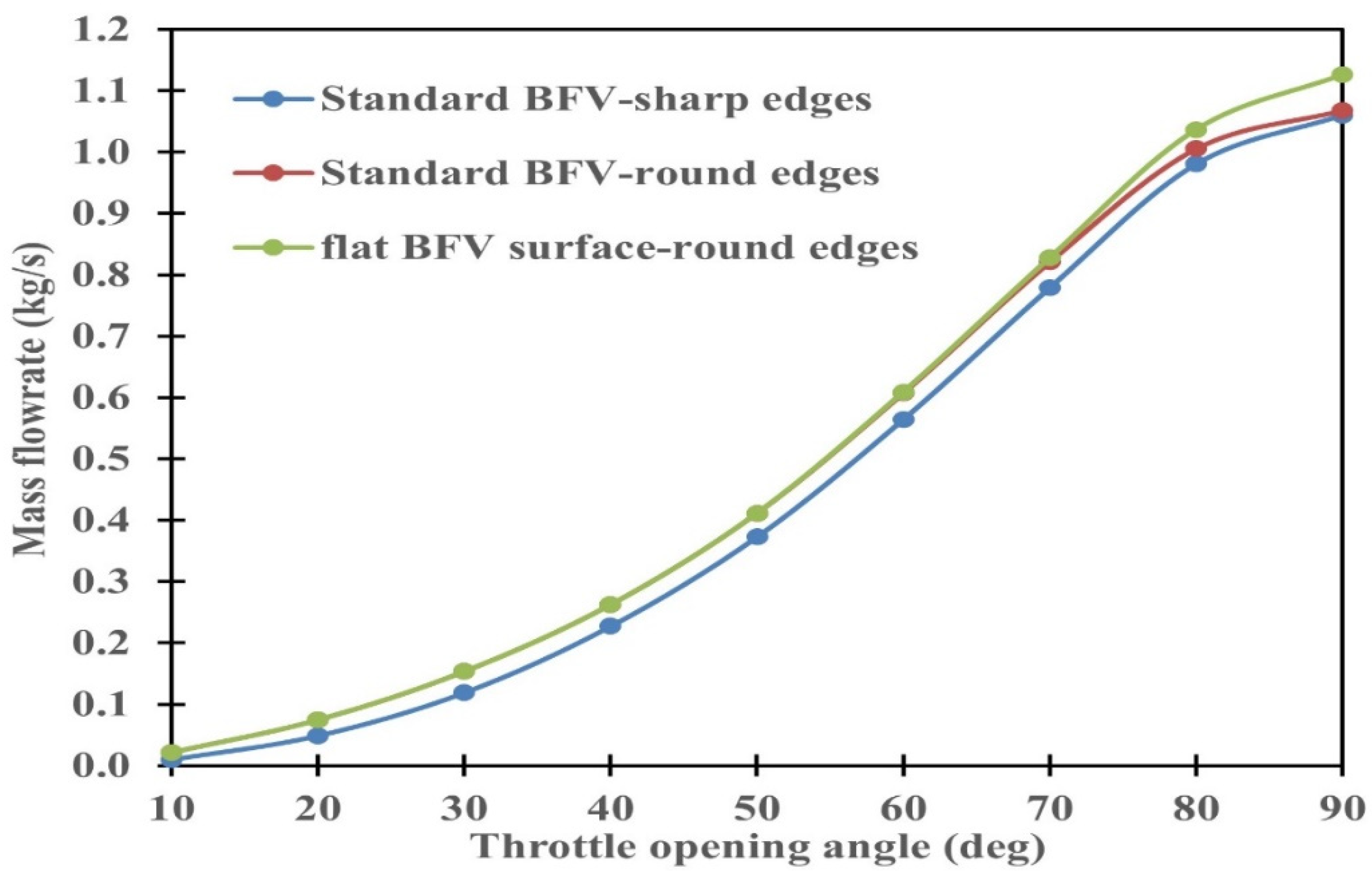

Numerically investigate air flow characteristics of BFVs at various valve parameters, namely, shaft diameter, valve thickness, and valve disk edge.

Numerically investigate the air flow characteristics of pinch valves at various pinching degrees.

Develop a simple mathematical model for determining the area of the pinch valve at various pinching degrees.

Compare the air flow characteristics of BFVs and pinch valves.

2. Numerical Simulation and Boundary Conditions

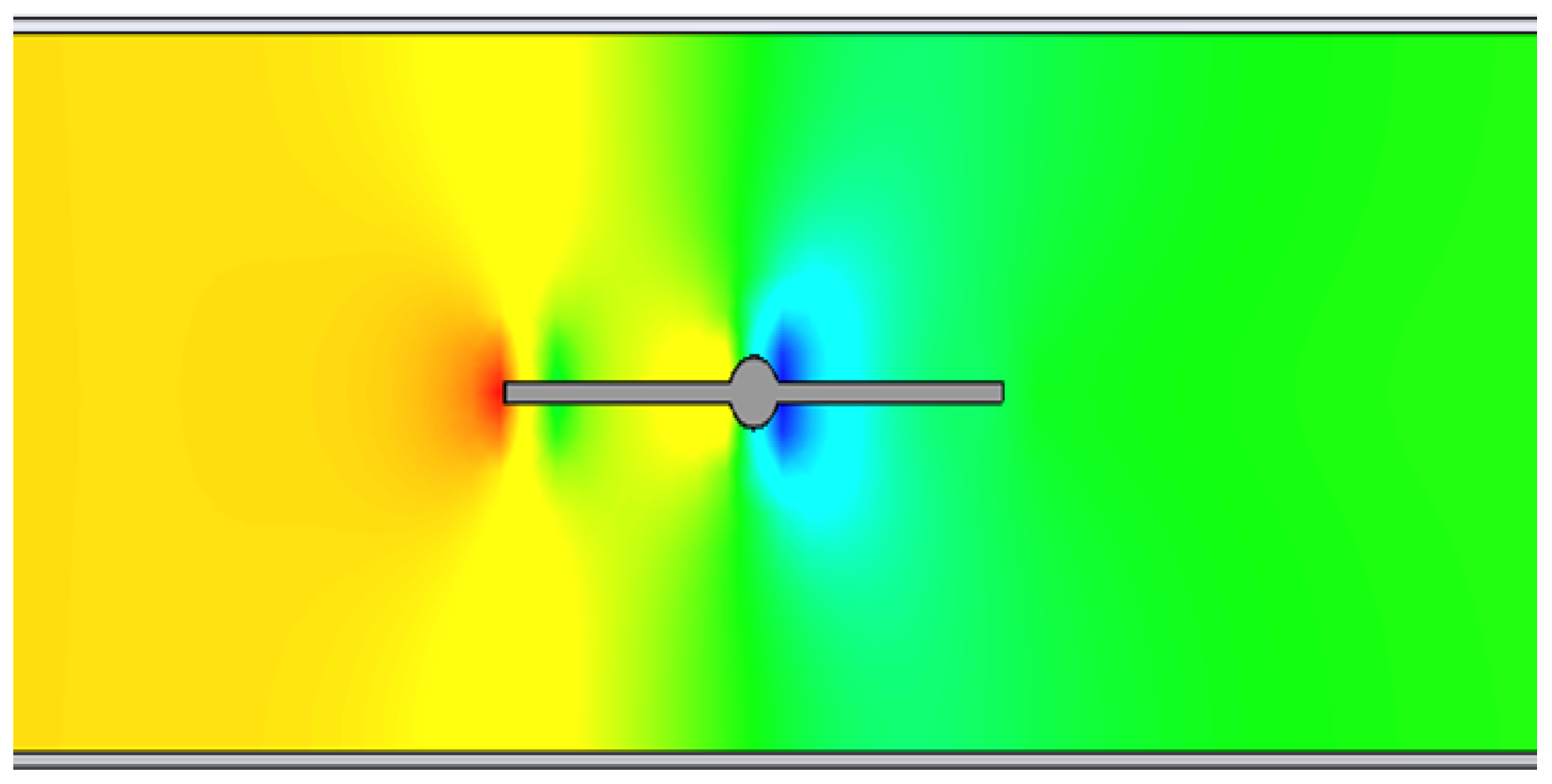

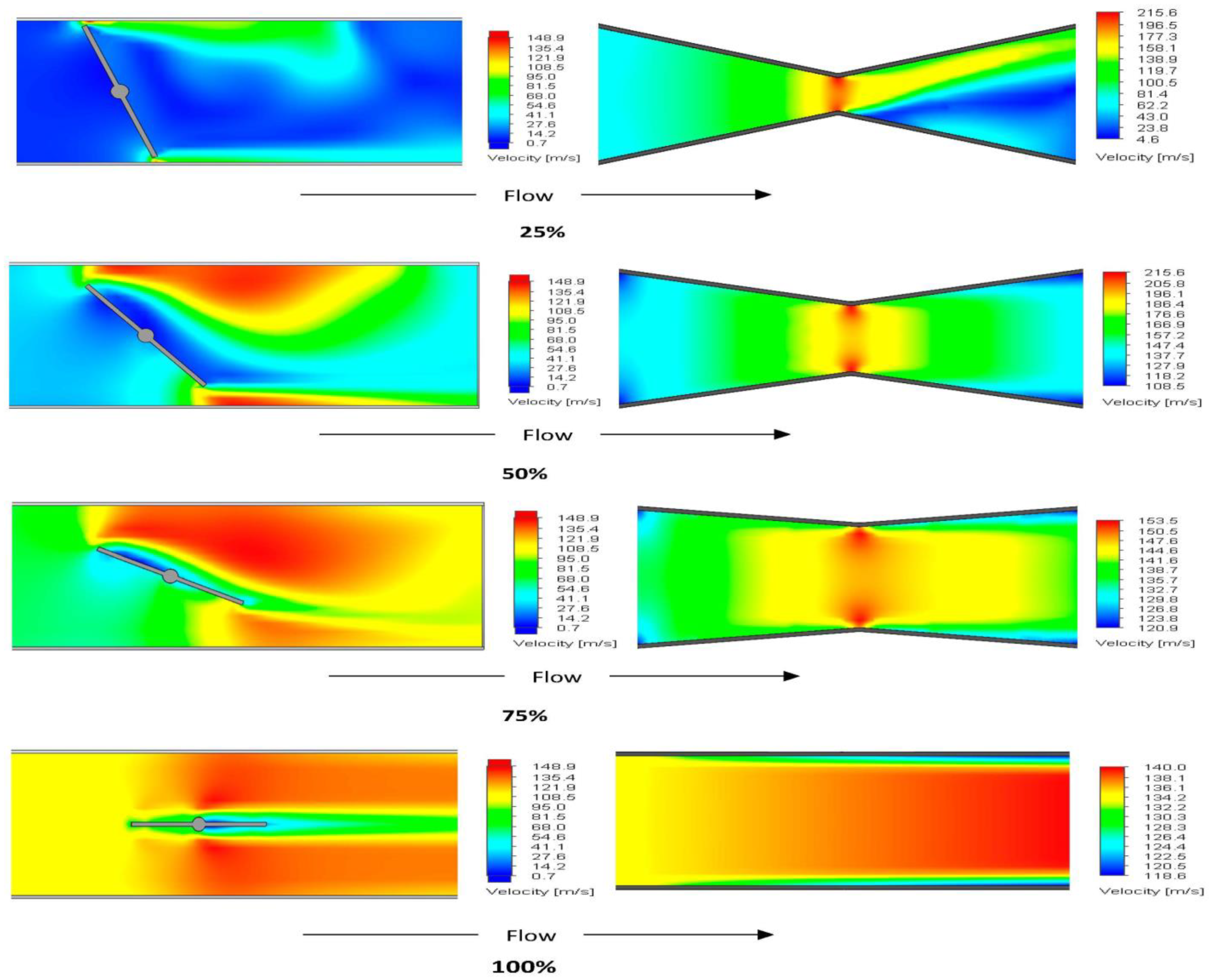

A steady-state fluid dynamics analysis was conducted using air as the fluid. The performed analysis used standard BFV and pinch valves for comparison. The SolidWorks 2020 software was used using its flow simulation module. Three boundaries were involved, namely, inlet, outlet, and wall. The inlet pressure boundary condition was set at 1 bar while outlet pressure was set at 0.9 bar. Walls were assumed to be adiabatic with no-slip condition while the standard k-ε turbulence model was used. The analysis was carried out using air flowing at 20 °C. These boundary conditions were also used for the pinch valve. Hence, the performance analysis was performed to compare the mass flow rate of air through BFV and pinch valve.

2.1. Governing Equations

The standard k-ε model in CFD was used which describes the flow characteristics in a pipe. The steady air flow in the pipe is governed by the momentum and continuity equations as expressed below.

Momentum Conservation equation

SolidWorks uses the Finite Volume Method (FVM) to solve the Navier–Stokes equations which is considered to be more accurate especially when having structured mesh such as cartesian mesh which is used in SolidWorks.

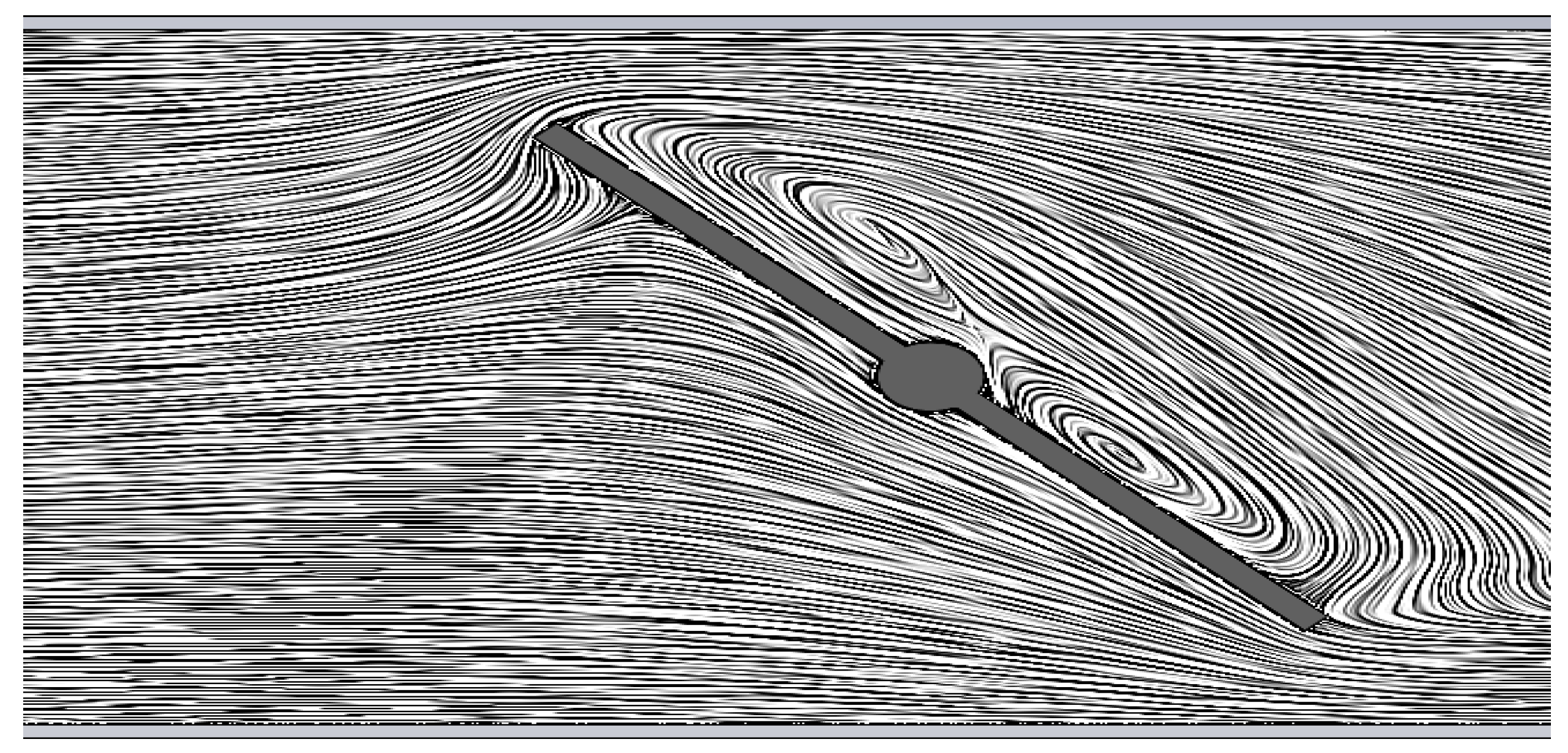

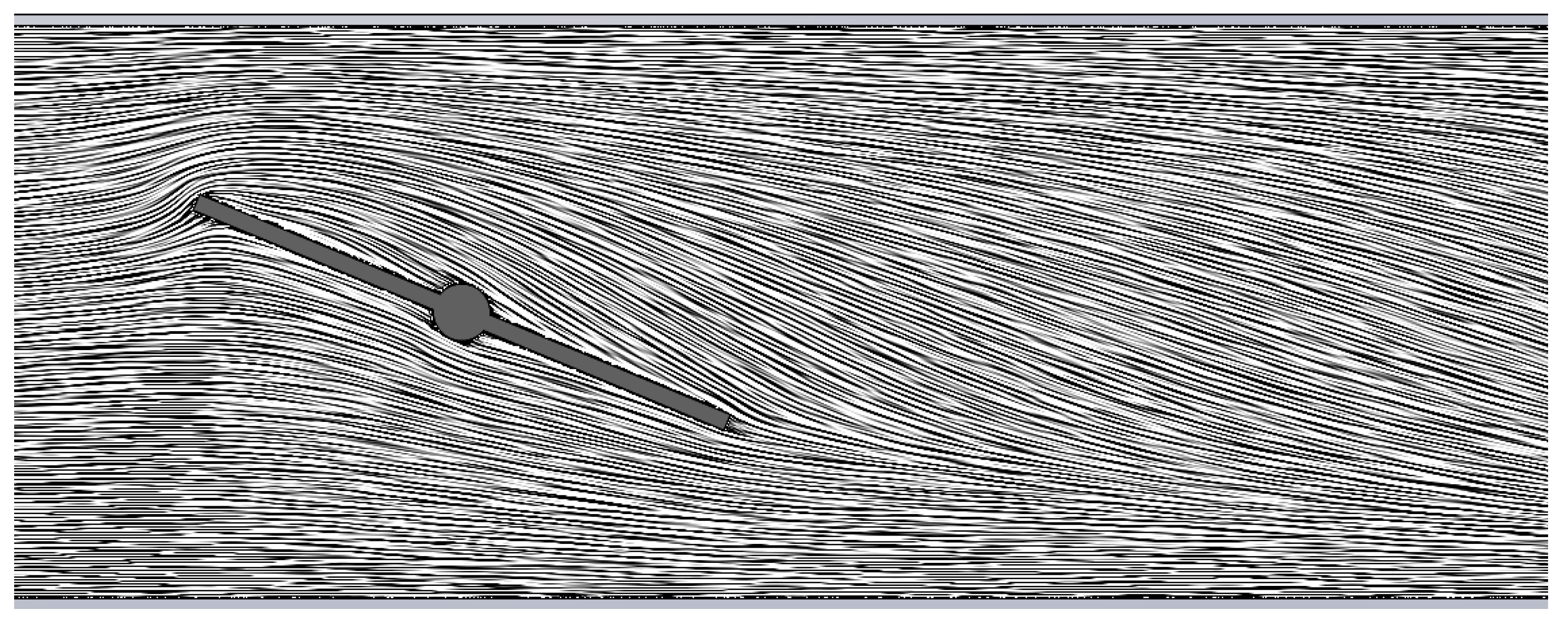

2.2. The Butterfly Valve Model

The model is based on the steady flow of air passing through a standard BFV in a 400 mm length pipe with an inner diameter of 100 mm and zero roughness. The butterfly valve has a diameter of 100 mm, valve shaft diameter of 10 mm, and a thickness of 3 mm. The BFV is located in the middle of the pipe with a 200 mm pipe on each side of the throttle valve. The opening angle of the BFV varied from 10 degrees to fully open in increments of 10 degrees while the BFV rest angle was set at 5 degrees. The geometry of the BFV and its meshing (global and local) were carried out with the assumption of gas-tight, meaning that there is zero leakage at the fully closed position. It is important to note that since this is a numerical study, manufacturing inconsistencies and tolerances are not considered.

2.2.1. Mesh Independence Test for BFV

The most frequent challenge in simulated engineering cases using CFD is the meshing resolution. It has a strong influence on the quality of the numerical results and computational time required. In this case, the pressure drop across the BFV of a 0.1 bar throughout the 400 mm length pipe was tested numerically versus number of cells while keeping the BFV at 60° opening position. The global meshing was started from a level of 3 for the mesh until a maximum level of 7 which corresponds to 126,354 cells. Using the parametric study option in the SolidWorks 2020 software, the number of mesh elements was increased gradually until the maximum setting of the mesh level of 7 was reached.

As illustrated in

Table 1, as the mesh level increases, the error in the numerical solution decreases. Although the error at mesh level 5 is less than 1%, all results obtained in this study were conducted at mesh level 6, as this would result in a more accurate result.

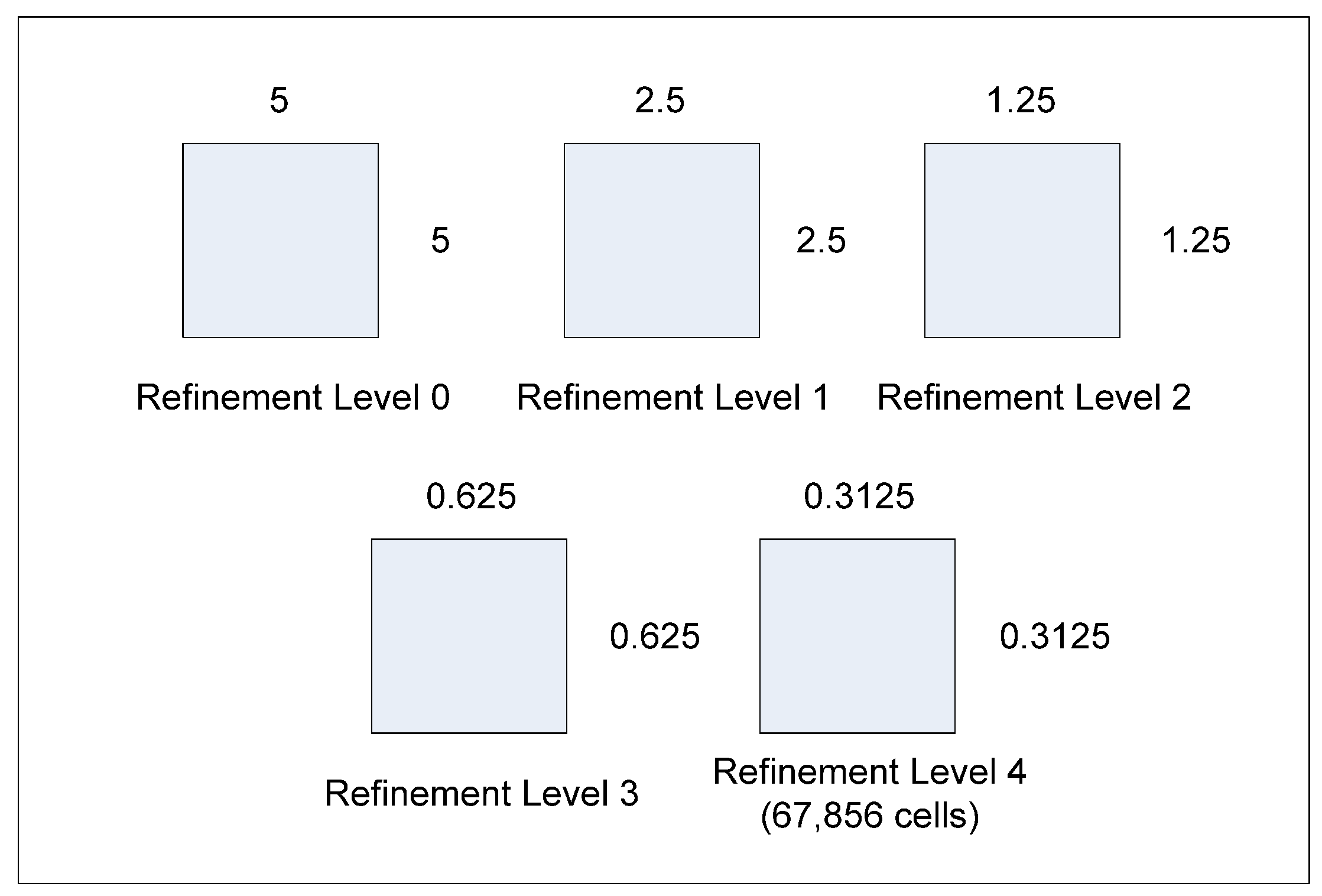

Since air is in direct contact with the BFV as it passes through the valve, it is necessary to provide a local mesh in order to capture the behavior of air through the short distance of the valve. Therefore, a local mesh of 6 cells across the gap with a refinement level 4 was used to carry out this study. This refinement level corresponds to a mesh size of 0.3125 mm which resulted in 67,856 number of cells.

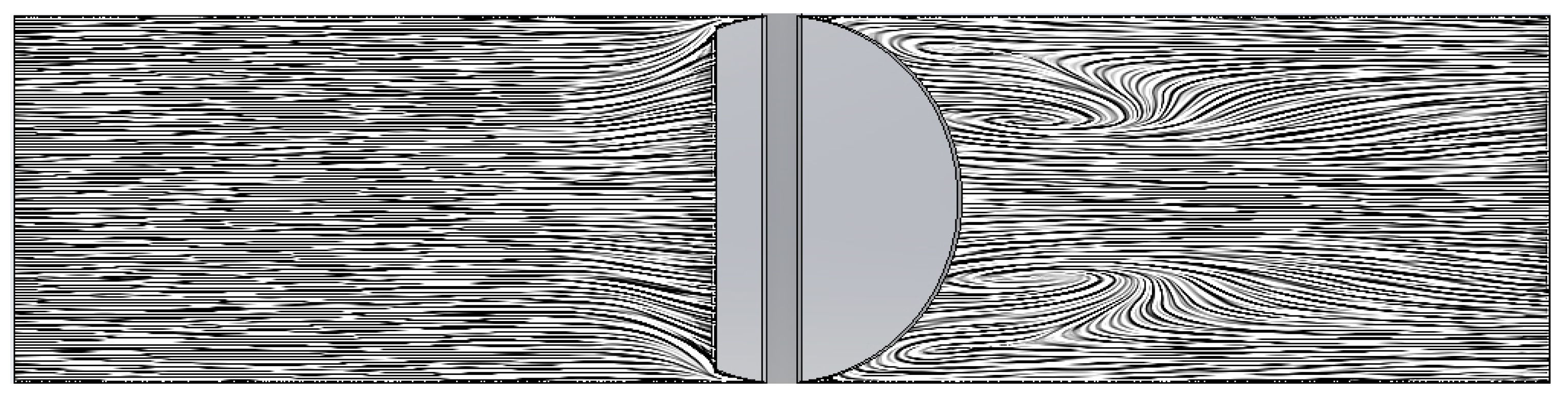

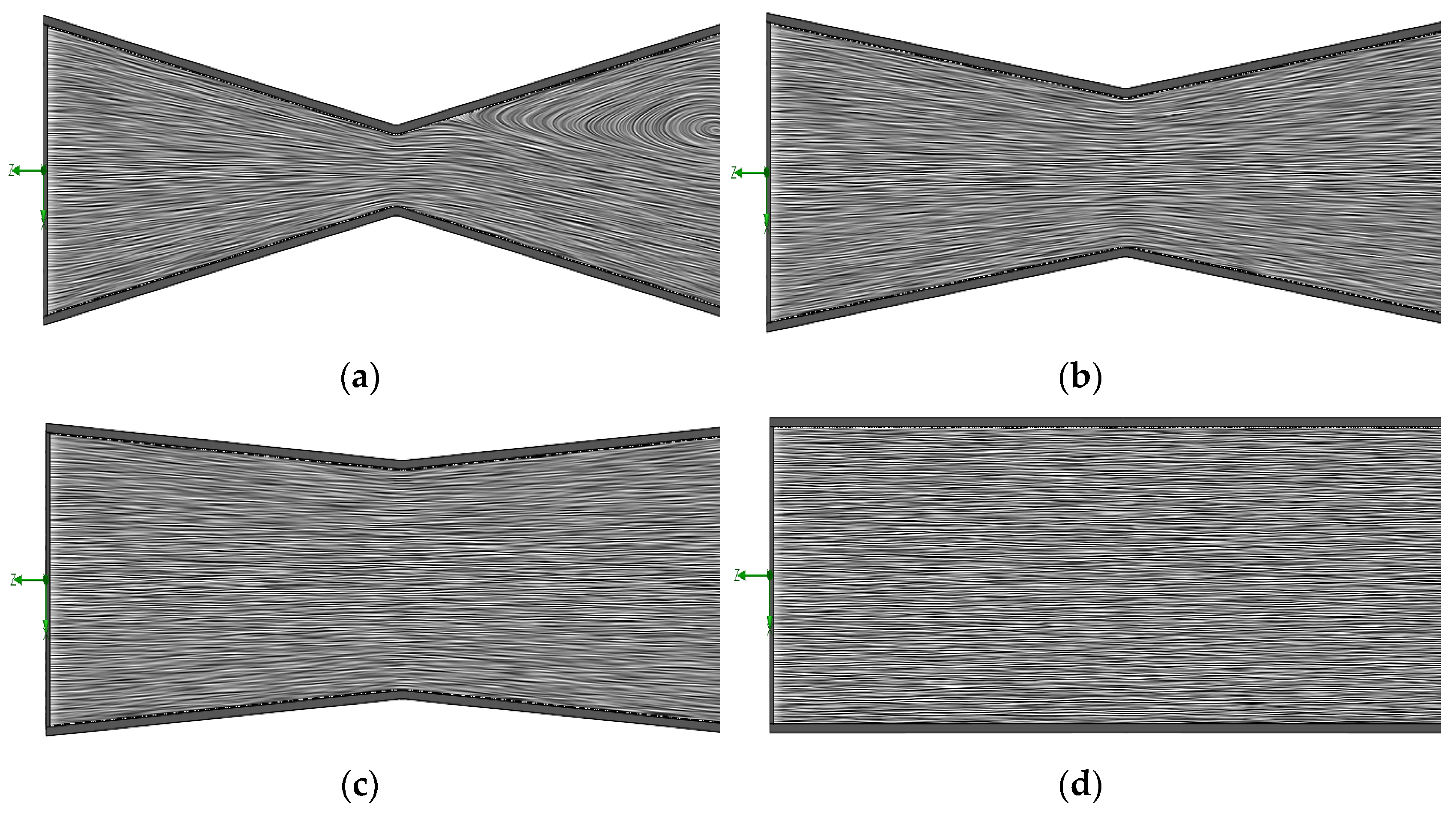

Figure 1 shows the cell size based on refinement level:

2.2.2. Model Validation

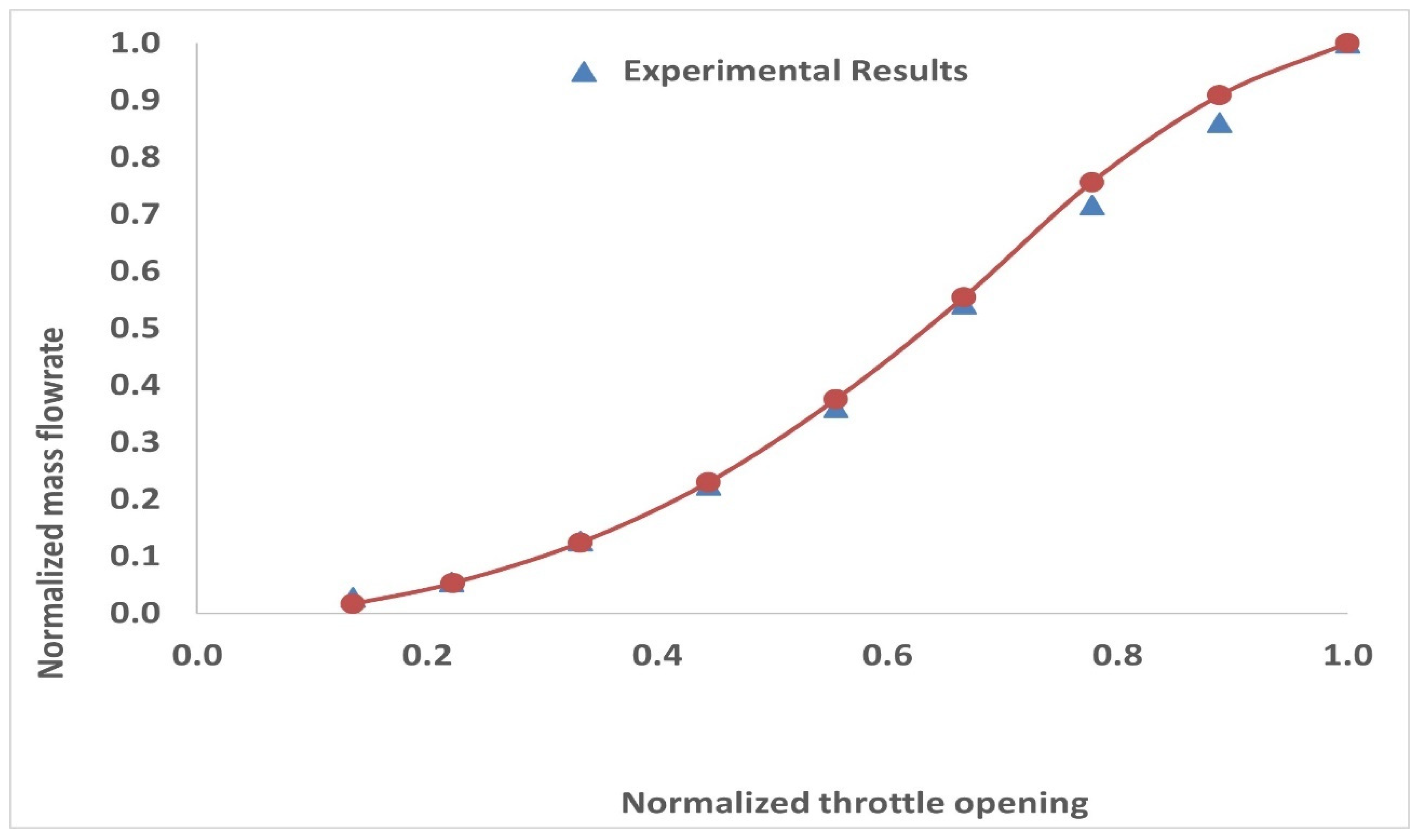

In order to evaluate the accuracy of the CFD results for BFV, model validation was performed with the published experimental data in [

25]. The experiment was performed using a steady-state air flow passing through a single cylinder engine bench at different throttle opening positions. This throttle body bore was 30 mm. These data were all used in the SolidWorks flow simulation module to validate the results.

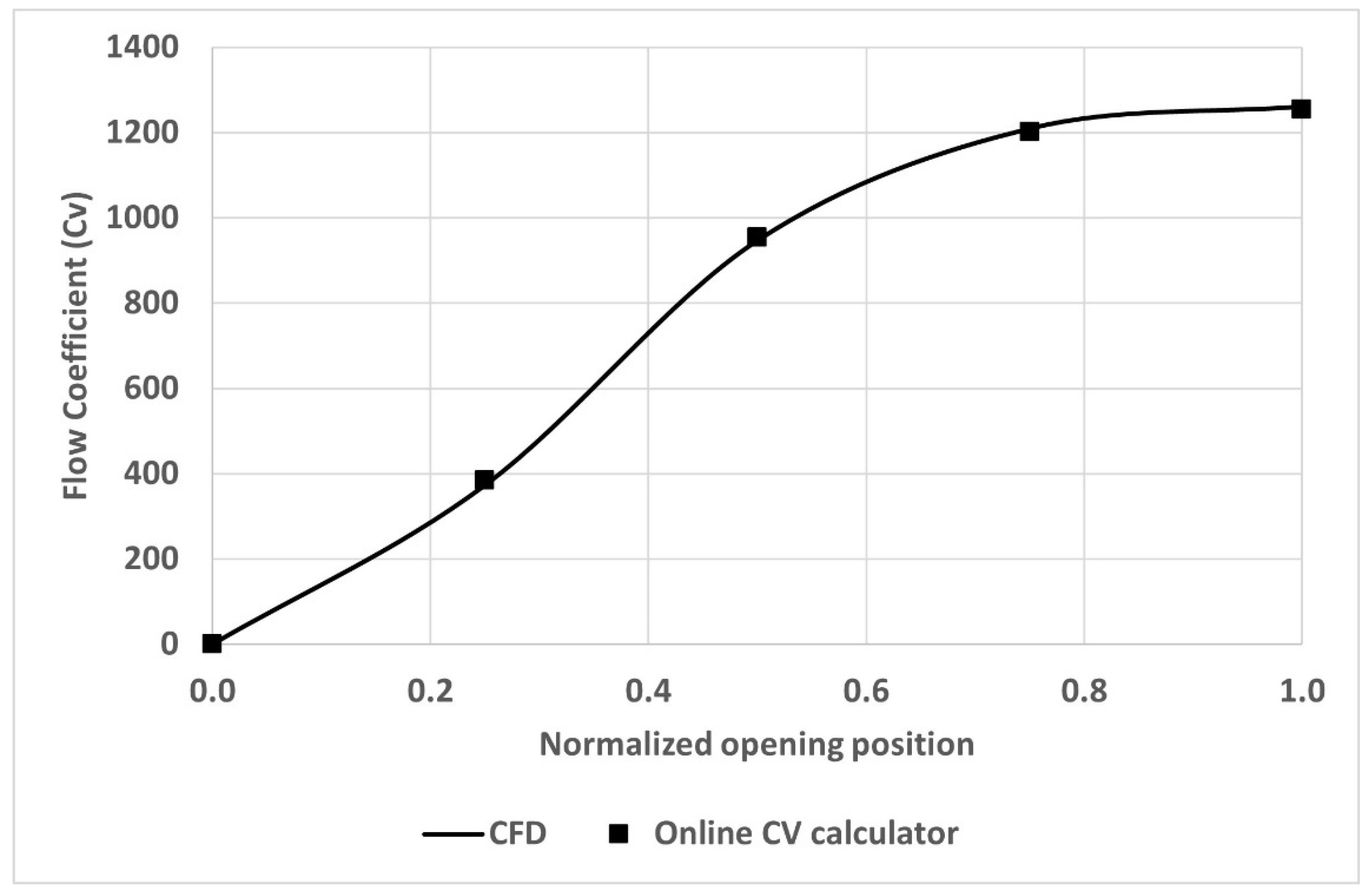

Figure 2 shows that the CFD predicted values are in reasonably good agreement with those of experimental results within an error of about 5%.

2.3. The Pinch Valve Model

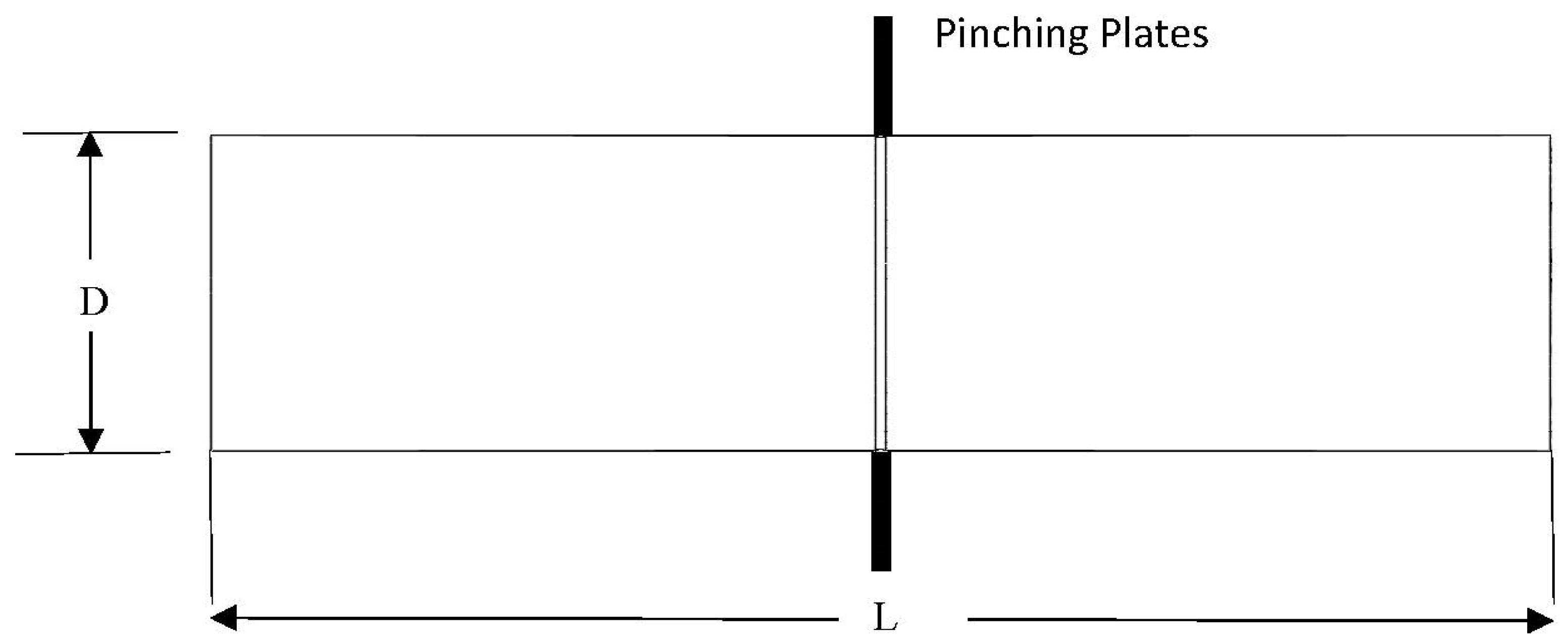

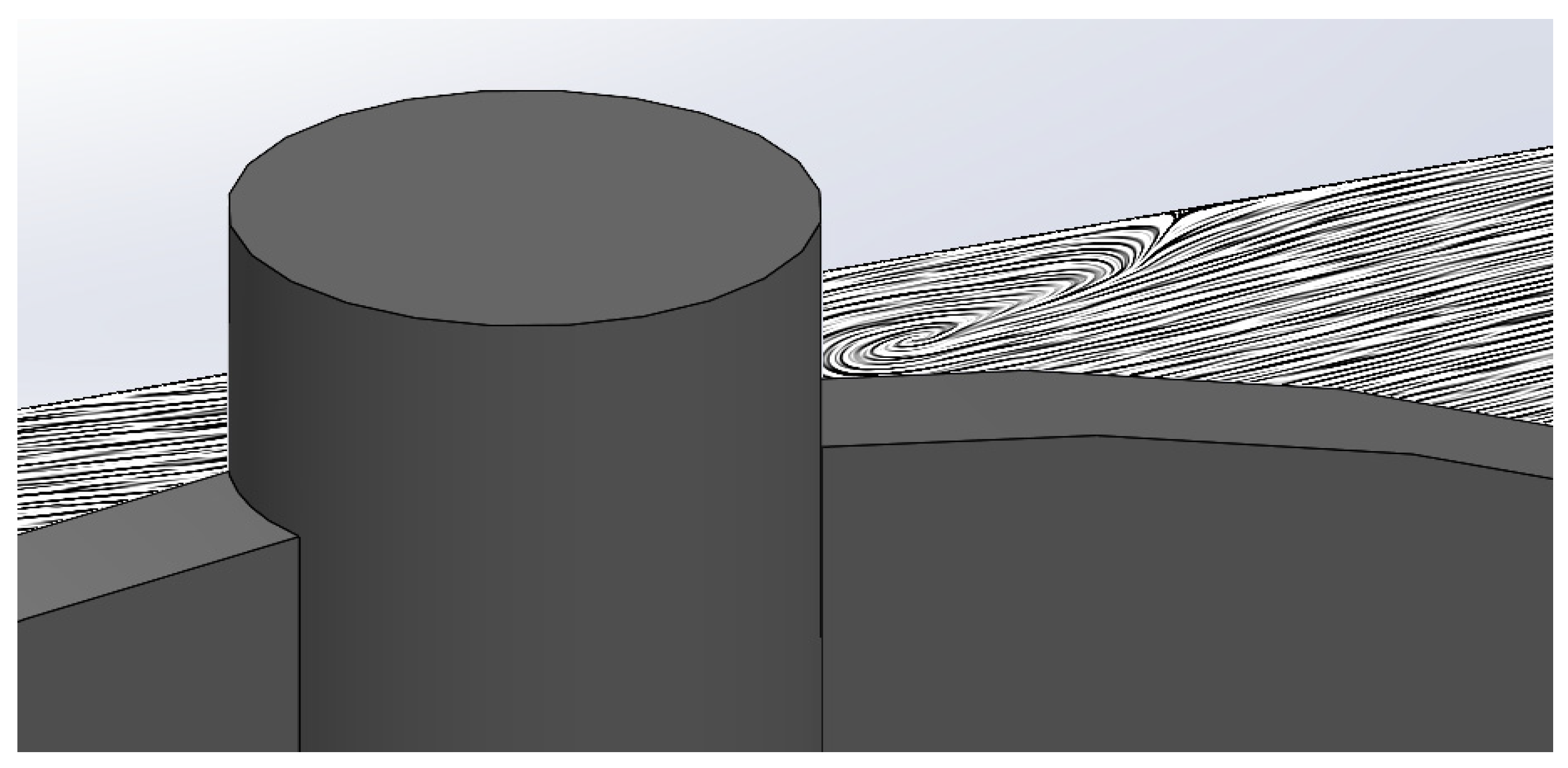

The pinch valve model is based on the steady flow of air passing through a flexible rubber (sleeve). Two parallel plates which are made of aluminum (1060 aluminum alloy) and have a thickness of 5 mm are used to pinch the valve from the middle section of the sleeve as shown in

Figure 3. The height of the aluminum plates is assumed to be 155 mm which is higher than the flexible rubber when fully pinched.

The length of the sleeve (L) is 400 mm, its internal diameter (D) is 100 mm, and its thickness is 3 mm. The material of the pinch valve sleeve was assumed to be natural rubber with elastic behavior. Material properties of the sleeve are shown in

Table 2.

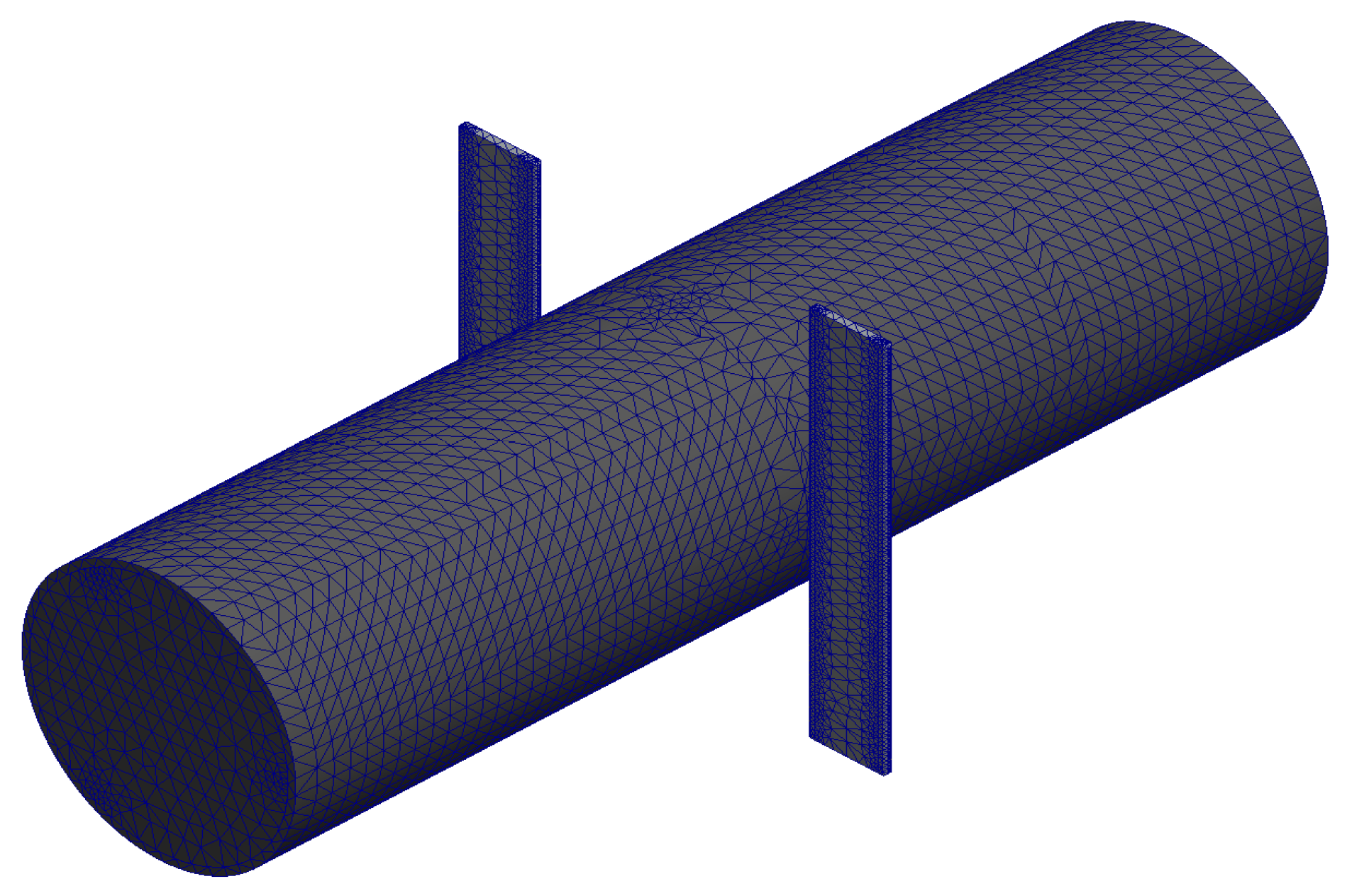

Nonlinear static analysis of the pinching process was performed with the activation of Large Deformation Formulation. The Newton–Raphson iterative technique and Newmark integration method were selected while the time increment was set to auto-stepping. There was no penetration contact type between the pinching plates and the valve sleeve and a friction value of 0.05 was used. Standard mesh method was applied. The final refined mesh created 49,324 nodes and 25,386 elements. The pinching degree started at zero to 49 mm with 1 mm step increment from both sides.

Figure 4 shows the meshed valve sleeve and pinching plates.

2.3.1. Mesh Independence Test for the Pinch Valve

As in the case of BFV in which mesh independence was tested, the pinch valve test was also carried out for mesh independence. A pressure drop across the pinch valve of 0.1 bar throughout the 400 mm length sleeve was tested numerically versus number of cells while keeping the pinching degree at 20 mm from both sides of the sleeve using the type of material mentioned in

Table 2. The global meshing started from level 3 with 3148 cells until a maximum level of 7 with 96,294 cells which corresponds to the most accurate result. Using the parametric study option in the SolidWorks 2020 software, the number of mesh elements was increased gradually until the maximum setting of the automatic mesh level 7 was reached. As illustrated in

Table 3, as the level of meshing was increased, the error in the numerical solution decreased. Although the error at mesh level 5 is less than 1%, all results obtained in this study were conducted at mesh level 6, which would result in a more accurate result. The mesh level of 6 created 34,749 cells. No local mesh was used in the pinch valve flow simulation since flow goes through a smooth convergence and divergence of the sleeve.

2.3.2. Model Validation

Validating the CFD model is crucial and must be performed in accordance with various characteristics and specifications for the studied valve. Thus, for better accuracy of the CFD results, the flow coefficient (C

V) obtained numerically for the pinch valve was validated against available manufacturer data sheets [

26]. The pinch pipe modeled in CFD was nine inches in length with a 2D pipe length upstream and 6D downstream. The flow was assumed to be fully developed with a constant flow rate of 0.1 m

3/s for all pinching degrees. The surface roughness for the material was assumed to be 10 micron and the material used was ethylene propylene (EDPM) rubber which is in accordance with the material mentioned in the experimental data.

Figure 5 shows that the CFD results match well with the available data for the flow coefficients with error of less than 2%.

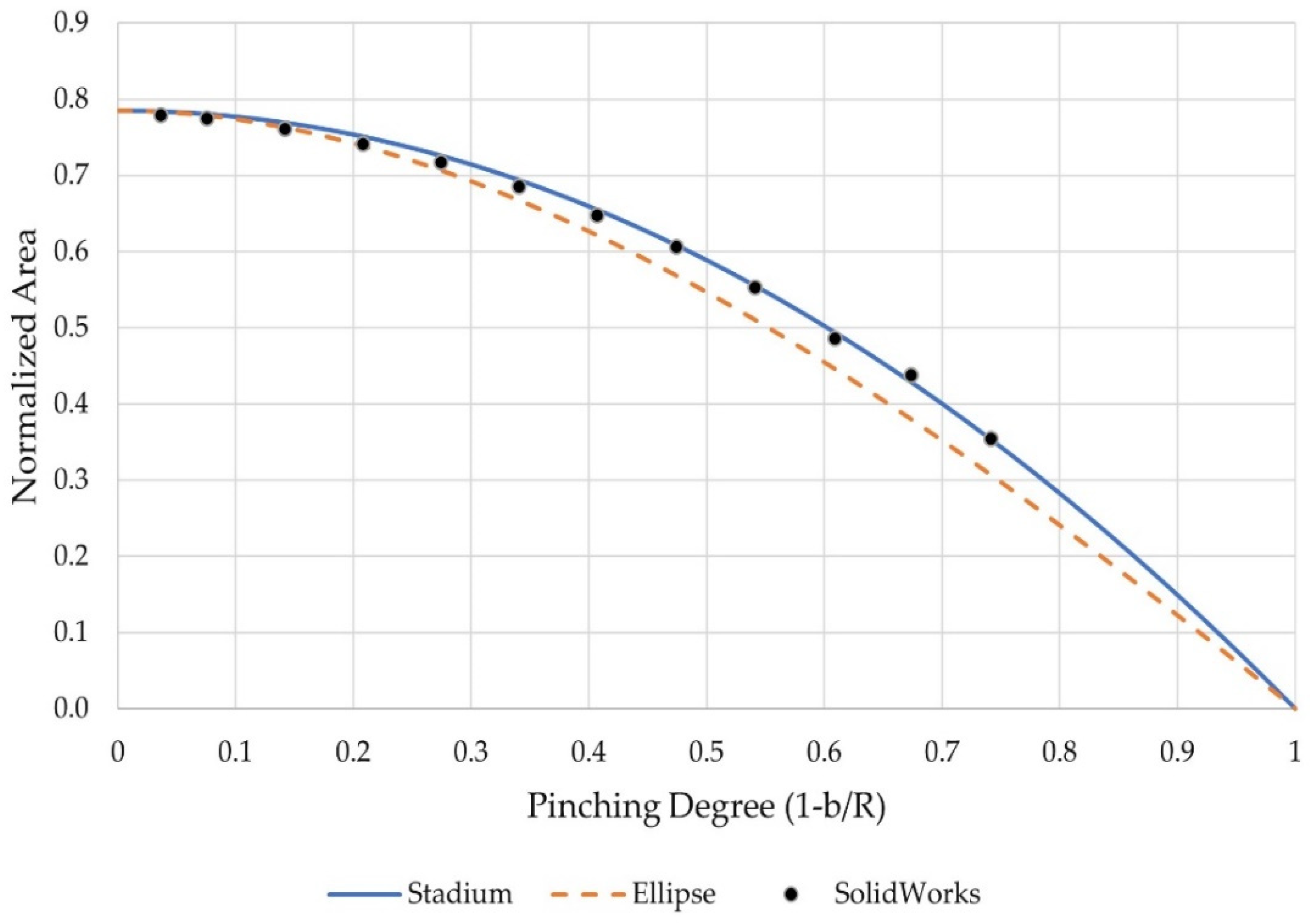

2.3.3. Pinch Valve Area Model

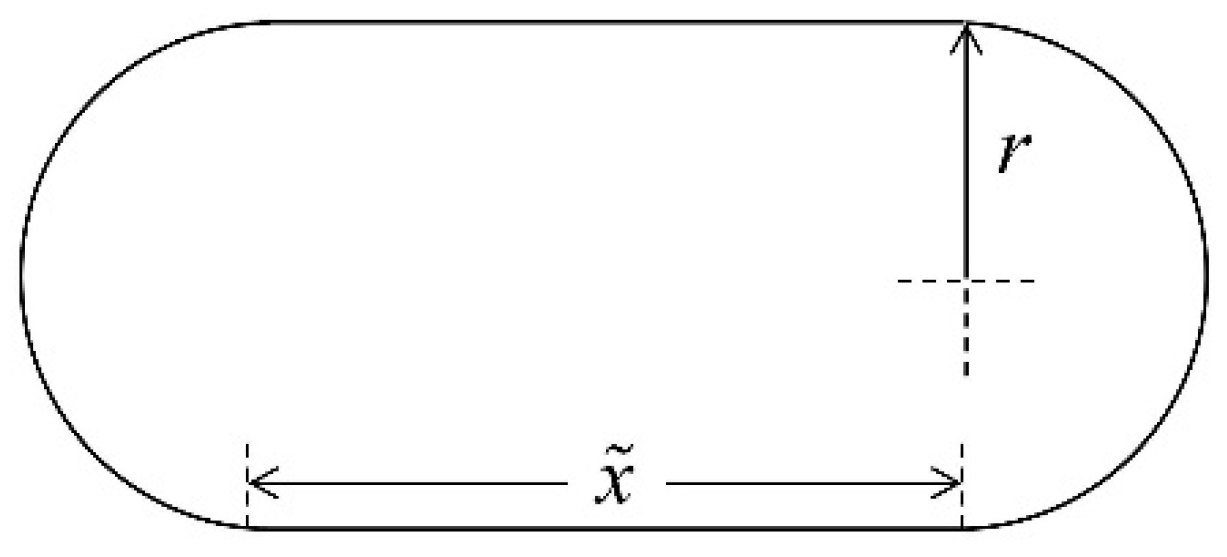

In order to formulate the mathematical model for determining the pinch valve area at various pinching degrees, the main assumption made here is that the pinch valve sleeve is in direct contact with the aluminum squeezing plates and is assumed to follow the shape of these pinching horizontal parallel plates which forms the horizontal lengths while the non-contact rubber forms a semi-circle on each side of the profile as shown in

Figure 6. The upper and lower horizontal length (

) sides that are in contact with the pinching plates while the vertical length (

r) represents the radius of the semi-circle. Therefore, the final shape of the squeezed profile forms a rectangle and a circle.

The resulting profile is usually referred to as the stadium or disco rectangle [

27,

28]. The results from the new method will be compared later with the CFD results. At each step of pinching degree, the perimeter of the valve sleeve remains constant throughout. Based on this assumption, the area and perimeter of a stadium shape are given by

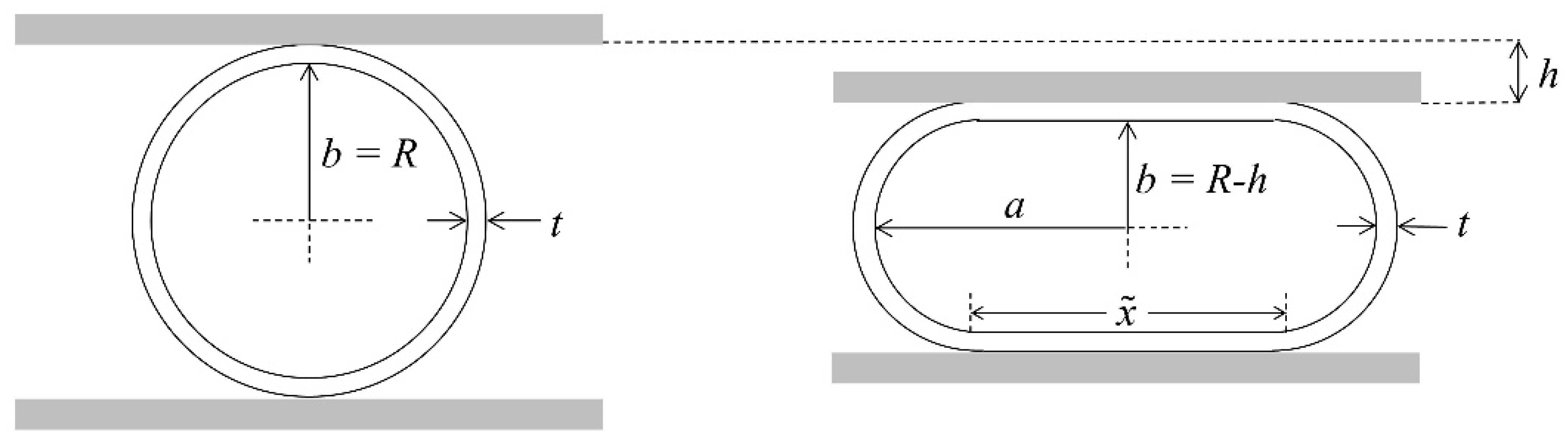

These two equations need to be modified to account for the distance the pinching plates travel from each side (

h). The undeformed and deformed pinch valve sleeve of a stadium profile with the new variable

h are shown in

Figure 7.

The area of the two semi-circles at both ends where the pinching plates are not in contact with the valve is

and the perimeter of the two semi-circles is

The total deformed area could be expressed in terms of the semi-minor axis b, where