Molecular Dynamics Simulation of Femtosecond Laser Ablation of Cu50Zr50 Metallic Glass Based on Two-Temperature Model

Abstract

1. Introduction

2. Computational Modeling

2.1. TTM-MD Method

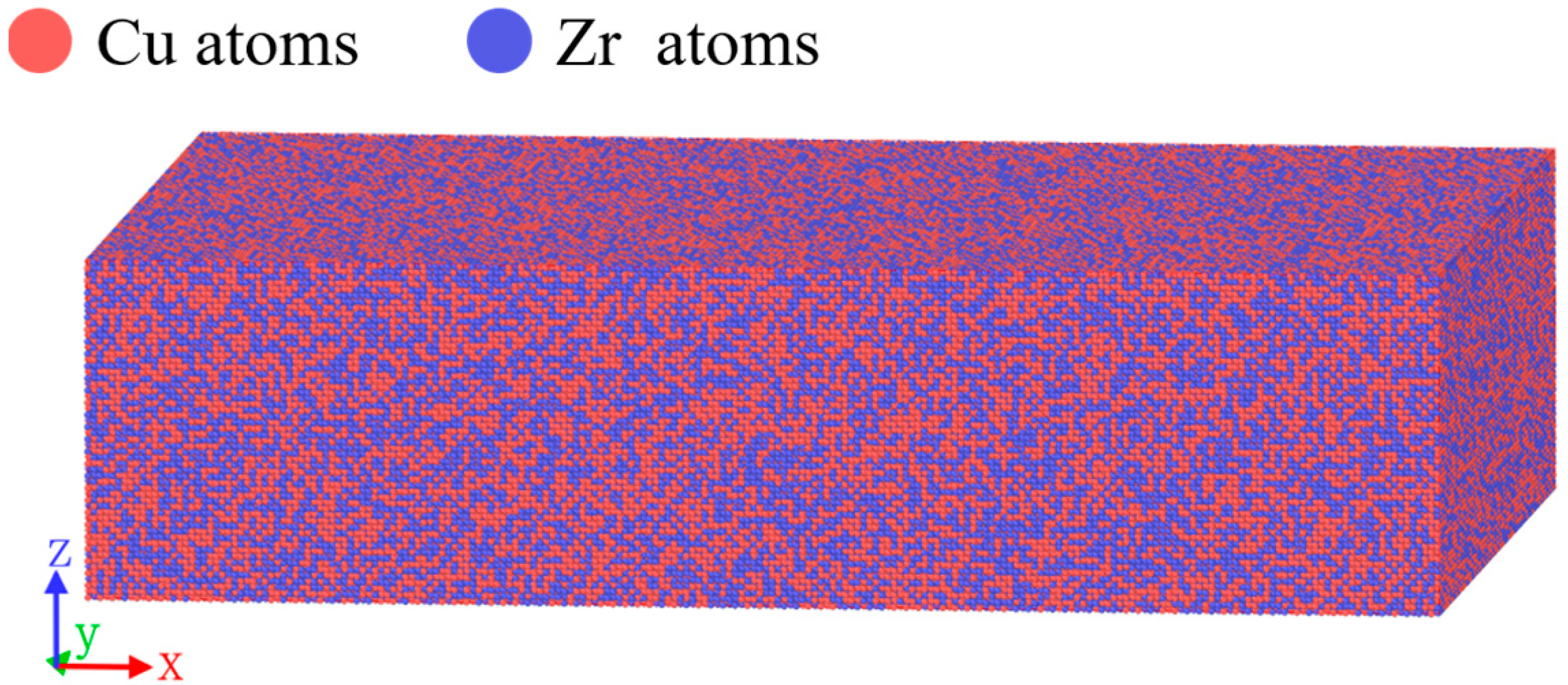

2.2. Computational Details

- The model assumes that the interactions between atoms can be accurately represented by our chosen force field.

- The model assumes the availability of accurate and reliable parameters to set up the force field.

- The model assumes that the simulation time step is small enough to capture the dynamics of the system under investigation.

- The model assumes that the simulation is conducted in a vacuum environment and heat exchange with the surroundings is neglected.

- The model assumes that all of the laser energy is absorbed by the target and the reflectivity is zero.

3. Results

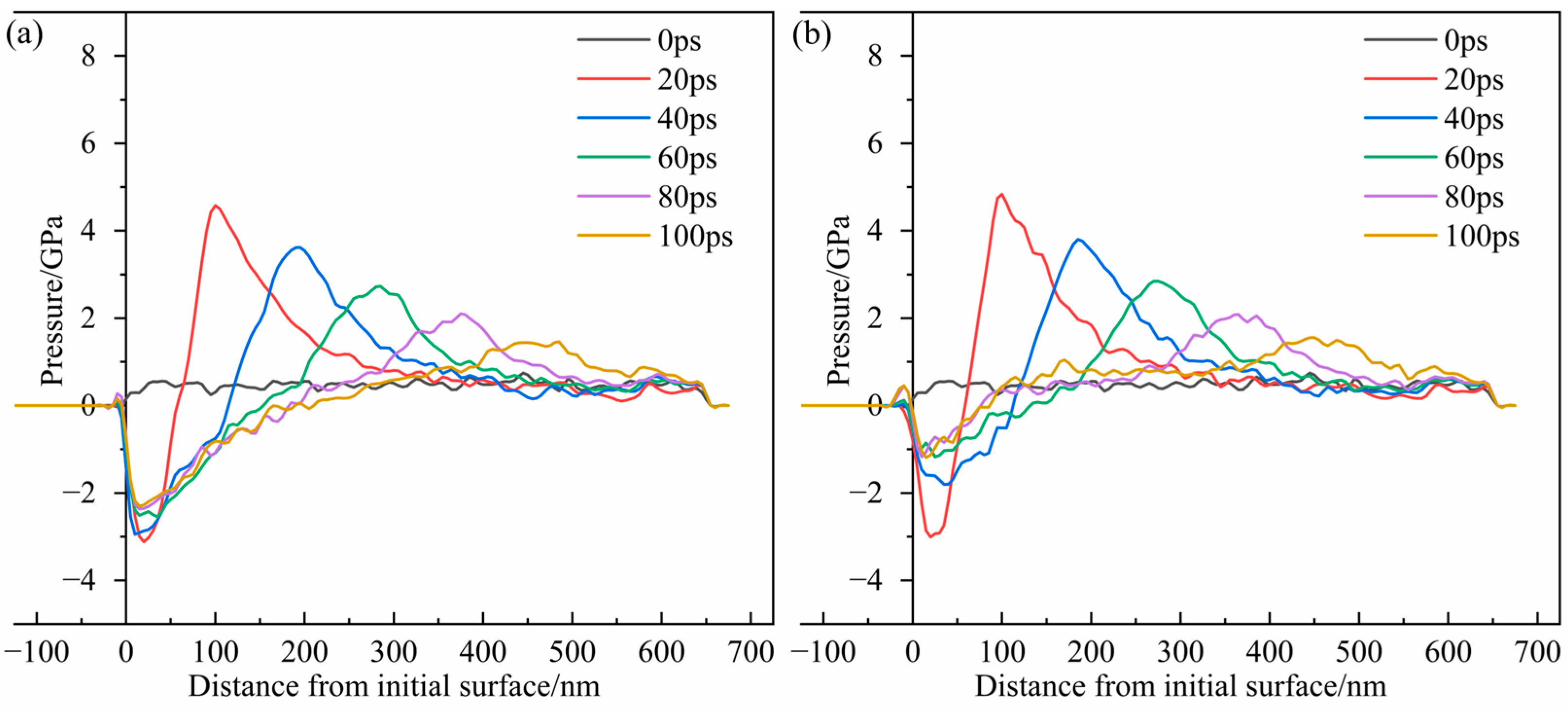

3.1. Ablation Threshold

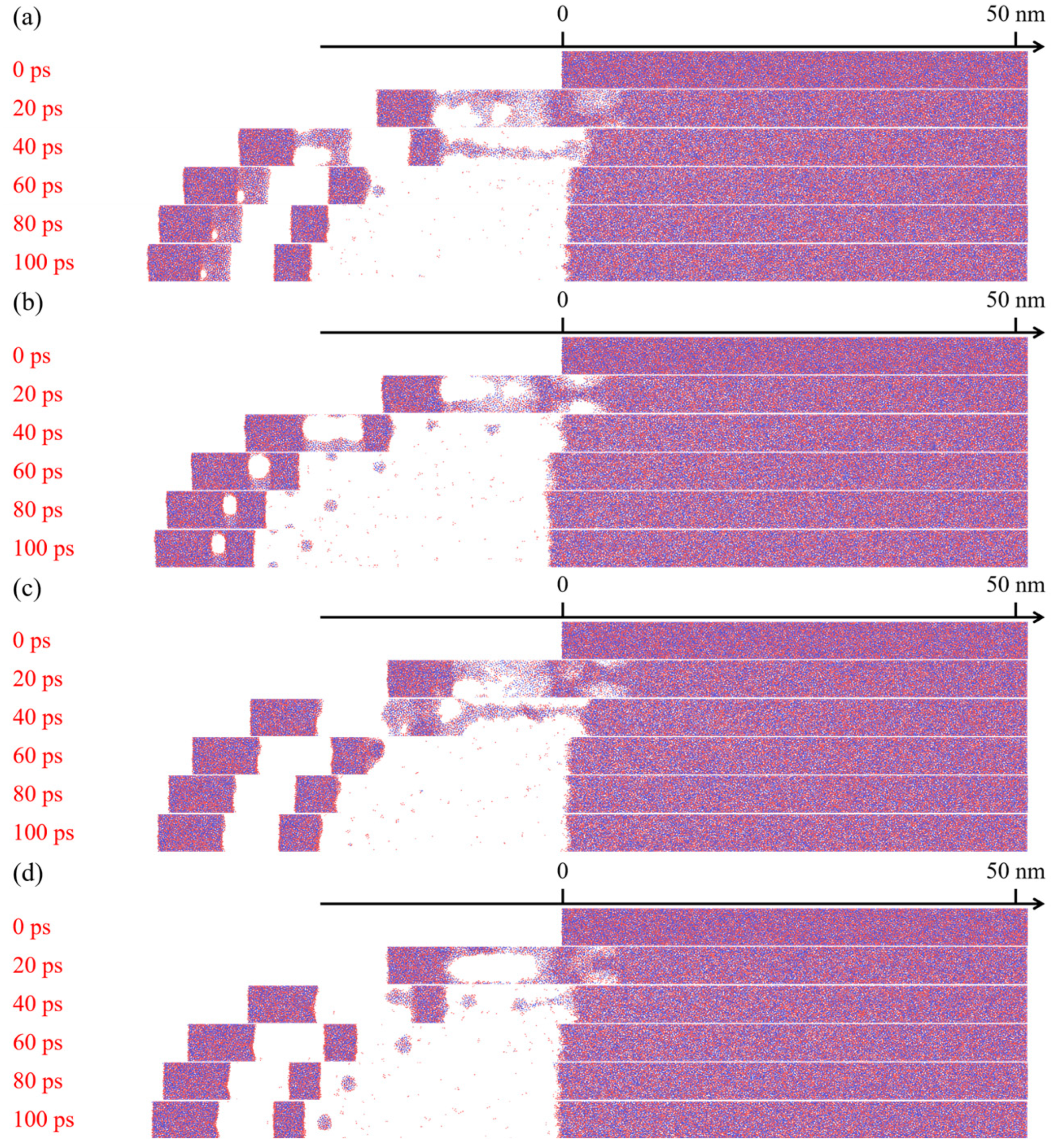

3.2. Evolution of Femtosecond Laser Ablation at Different Fluences

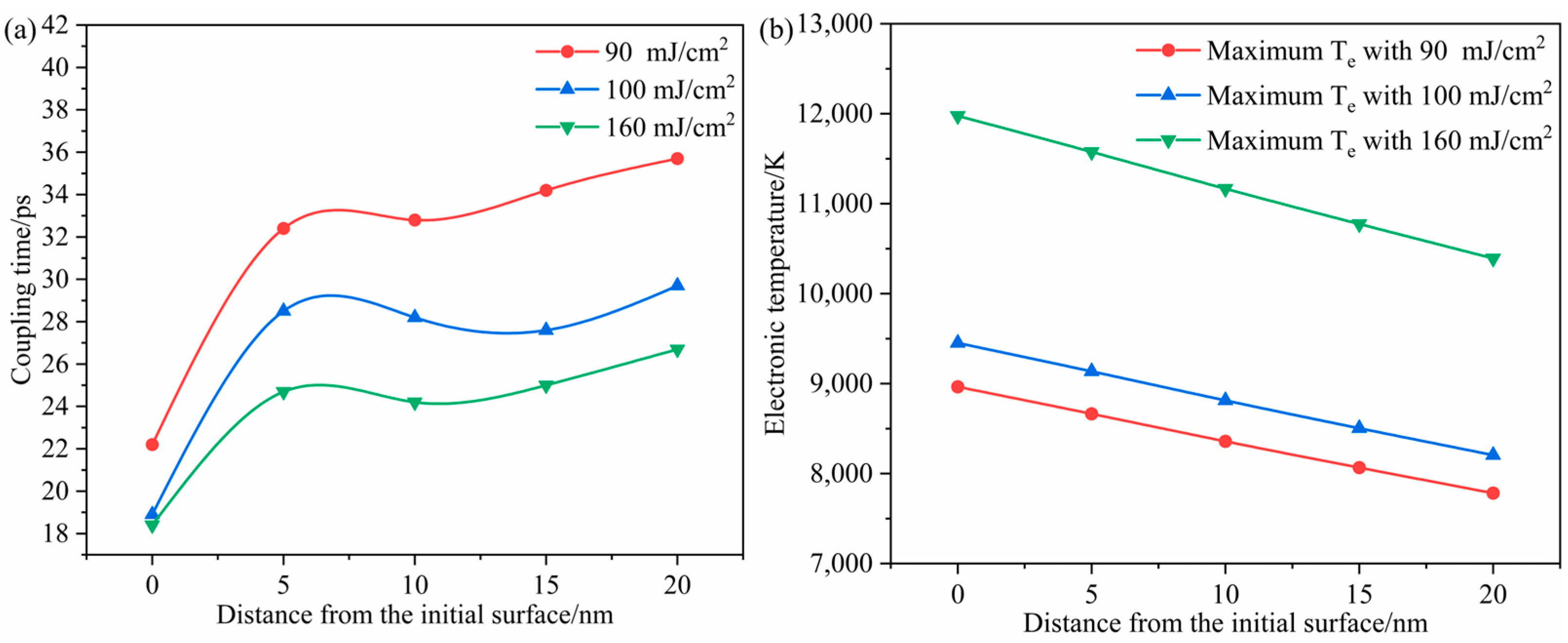

- Increasing the absorbed fluence can increase the number of photons, which in turn improves the laser absorption rate and energy conversion efficiency. This promotes the absorption and conversion of energy into thermal energy in a more effective way.

- More laser energy being absorbed into the material can lead to more excited electrons in a high-energy state, which results in an increase in electron temperature.

- The increase in electron temperature can also lead to an increase in the thermal conductivity of the material, which accelerates the transfer of heat, causing the overall material temperature to rise. This temperature increase may continue to occur during the reflux period, and the increase in electron temperature may be the result of complicated interactions between temperature and pressure.

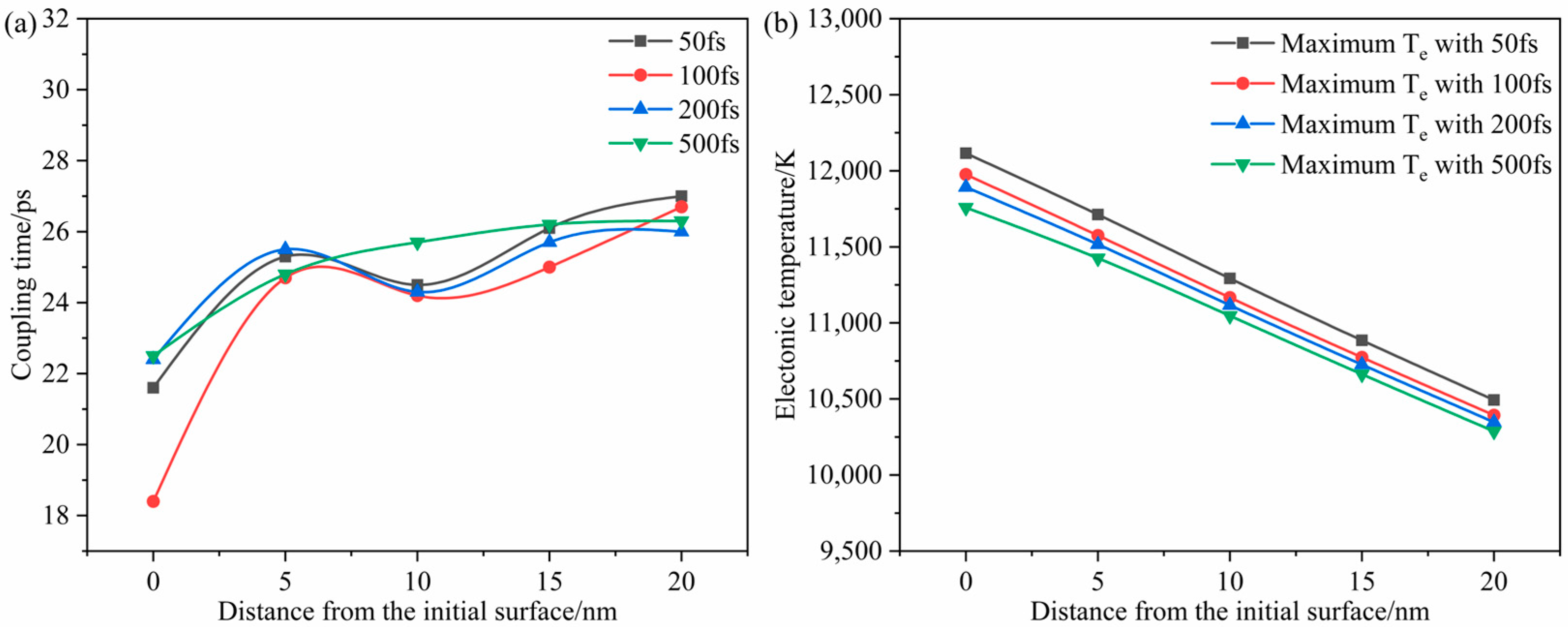

3.3. Evolution of Femtosecond Laser Ablation at Different Pulse Durations

4. Conclusions

- 1.

- It was determined that the ablation threshold of a target under fs was 84 mJ/cm2. Further, the tension near the surface decreased because it was “absorbed” by the cavities that finally caused ablation on the target material.

- 2.

- The process of the single-pulse femtosecond laser machining of Cu50Zr50 metallic glass was studied with mJ/cm2. As increased, the maximum at the same position on the target surface decreased, while the coupling time showed no significant difference. Further, it was found that the increase in leads to various forms of surface ablation on the target material, including melting, cavitation, spallation, material ejection, and phase explosion.

- 3.

- The mechanism between the femtosecond laser and metallic glass was researched by fs. It was found that the variation of had little effect on the electron–lattice temperature evolution, but it did have an impact on the structural changes during the ablation process. As the absorbed fluence increased, the maximum at the same position on the target surface increased, while the coupling time became shorter.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, W. Brief History, Present and Future of Metallic Glasses. Chin. J. Nat. 2022, 44, 173–181. [Google Scholar]

- Wu, Y.; Liu, X.; Lv, Z. A New Member of the Glass Family—Metallic Glass. Physics 2022, 51, 691–700. [Google Scholar]

- Han, L.; Ming, P.; Kong, Z.; Zhang, X. Status and Research Progress of Metallic Glass Micro-Manufacturing Technology. J. Netshape Form. Eng. 2022, 14, 40–49. [Google Scholar]

- Yao, Y.; Tang, J.; Zhang, Y.; Hu, Y.; Wu, D. Development of Laser Fabrication Technology for Amorphous Alloys. Chin. J. Lasers 2021, 48, 174–189. [Google Scholar]

- Sano, T.; Takahashi, K.; Hirose, A.; Kobayashi, K.F. Femtosecond Laser Ablation of Zr55Al10Ni5Cu30 Bulk Metallic Glass. Mater. Sci. Forum 2007, 539–543, 1951–1954. [Google Scholar] [CrossRef]

- Wang, X.; Lu, P.; Dai, N.; Li, Y.; Liao, C.; Zheng, Q.; Liu, L. Noncrystalline Micromachining of Amorphous Alloys Using Femtosecond Laser Pulses. Mater. Lett. 2007, 61, 4290–4293. [Google Scholar] [CrossRef]

- Ma, F.; Yang, J.; Zhu, X.; Liang, C.; Wang, H. Femtosecond Laser-Induced Concentric Ring Microstructures on Zr-Based Metallic Glass. Appl. Surf. Sci. 2010, 256, 3653–3660. [Google Scholar] [CrossRef]

- Anisimov, S.I.; Kapeliovich, B.L.; Perelman, T.L. Electron Emission from Metal Surfaces Exposed to Ultrashort Laser Pulses. J. Exp. Theor. Phys. 1974, 66, 375–377. [Google Scholar]

- Perez, D.; Lewis, L.J. Ablation of Solids under Femtosecond Laser Pulses. Phys. Rev. Lett. 2002, 89, 255504. [Google Scholar] [CrossRef]

- Lorazo, P.; Lewis, L.J.; Meunier, M. Short-Pulse Laser Ablation of Solids: From Phase Explosion to Fragmentation. Phys. Rev. Lett. 2003, 91, 225502. [Google Scholar] [CrossRef]

- Perez, D.; Lewis, L.J. Molecular-Dynamics Study of Ablation of Solids under Femtosecond Laser Pulses. Phys. Rev. B 2003, 67, 184102. [Google Scholar] [CrossRef]

- Smirnova, J.A.; Zhigilei, L.V.; Garrison, B.J. A Combined Molecular Dynamics and Finite Element Method Technique Applied to Laser Induced Pressure Wave Propagation. Comput. Phys. Commun. 1999, 118, 11–16. [Google Scholar] [CrossRef]

- Kotake, S.; Kuroki, M. Molecular Dynamics Study of Solid Melting and Vaporization by Laser Irradiation. Int. J. Heat Mass Transf. 1993, 36, 2061–2067. [Google Scholar] [CrossRef]

- Xie, J.; Yan, J.; Zhu, D. Atomic Simulation of Irradiation of Cu Film Using Femtosecond Laser with Different Pulse Durations. J. Laser Appl. 2020, 32, 022016. [Google Scholar] [CrossRef]

- Förster, G.D.; Lewis, L.J. Numerical Study of Double-Pulse Laser Ablation of Al. Phys. Rev. B 2018, 97, 224301. [Google Scholar] [CrossRef]

- Ivanov, D.S.; Zhigilei, L.V. Combined Atomistic-Continuum Modeling of Short-Pulse Laser Melting and Disintegration of Metal Films. Phys. Rev. B 2003, 68, 064114. [Google Scholar] [CrossRef]

- Yuan, W.; Sizyuk, T. Ablation Study in Gold Irradiated by Single Femtosecond Laser Pulse with Electron Temperature Dependent Interatomic Potential and Electron–Phonon Coupling Factor. Laser Phys. 2021, 31, 036002. [Google Scholar] [CrossRef]

- Marinier, S.; Lewis, L.J. Femtosecond Laser Ablation of CuxZr1-x Bulk Metallic Glasses: A Molecular Dynamics Study. Phys. Rev. B Condens. Matter Mater. Phys. 2015, 92, 184108. [Google Scholar] [CrossRef]

- Iabbaden, D.; Amodeo, J.; Fusco, C.; Garrelie, F.; Colombier, J.P. Molecular Dynamics Simulation of Structural Evolution in Crystalline and Amorphous CuZr Alloys upon Ultrafast Laser Irradiation. Phys. Rev. Mater. 2022, 6, 126001. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Chen, J.K.; Tzou, D.Y.; Beraun, J.E. A Semiclassical Two-Temperature Model for Ultrafast Laser Heating. Int. J. Heat Mass Transf. 2006, 49, 307–316. [Google Scholar] [CrossRef]

- Falkovsky, L.A.; Mishchenko, E.G. Electron-Lattice Kinetics of Metals Heated by Ultrashort Laser Pulses. J. Exp. Theor. Phys. 1999, 88, 84–88. [Google Scholar] [CrossRef]

- Choy, C.L.; Tong, K.W.; Wong, H.K.; Leung, W.P. Thermal Conductivity of Amorphous Alloys above Room Temperature. J. Appl. Phys. 1991, 70, 4919–4925. [Google Scholar] [CrossRef]

- Mendelev, M.I.; Kramer, M.J.; Ott, R.T.; Sordelet, D.J.; Yagodin, D.; Popel, P. Development of Suitable Interatomic Potentials for Simulation of Liquid and Amorphous Cu–Zr Alloys. Philos. Mag. 2009, 89, 967–987. [Google Scholar] [CrossRef]

- Daw, M.S.; Baskes, M.I. Embedded-Atom Method: Derivation and Application to Impurities, Surfaces, and Other Defects in Metals. Phys. Rev. B 1984, 29, 6443–6453. [Google Scholar] [CrossRef]

- Finnis, M.W.; Sinclair, J.E. A Simple Empirical N-Body Potential for Transition Metals. Philos. Mag. A 1984, 50, 45–55. [Google Scholar] [CrossRef]

- Zhu, P.; Fang, F. On the Mechanism of Material Removal in Nanometric Cutting of Metallic Glass. Appl. Phys. A 2014, 116, 605–610. [Google Scholar] [CrossRef]

- Murali, P.; Guo, T.F.; Zhang, Y.W.; Narasimhan, R.; Li, Y.; Gao, H.J. Atomic Scale Fluctuations Govern Brittle Fracture and Cavitation Behavior in Metallic Glasses. Phys. Rev. Lett. 2011, 107, 215501. [Google Scholar] [CrossRef]

- Shugaev, M.V.; He, M.; Levy, Y.; Mazzi, A.; Miotello, A.; Bulgakova, N.M.; Zhigilei, L.V. Laser-Induced Thermal Processes: Heat Transfer, Generation of Stresses, Melting and Solidification, Vaporization, and Phase Explosion. In Handbook of Laser Micro- and Nano-Engineering; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–81. [Google Scholar]

- Shugaev, M.V.; Zhigilei, L.V. Thermoelastic Modeling of Laser-Induced Generation of Strong Surface Acoustic Waves. J. Appl. Phys. 2021, 130, 185108. [Google Scholar] [CrossRef]

- Available online: https://docs.lammps.org/fix_viscous.html (accessed on 1 March 2023).

- Zhigilei, L.V.; Lin, Z.; Ivanov, D.S. Atomistic Modeling of Short Pulse Laser Ablation of Metals: Connections between Melting, Spallation, and Phase Explosion. J. Phys. Chem. C 2009, 113, 11892–11906. [Google Scholar] [CrossRef]

- Schäfer, C.; Urbassek, H.M.; Zhigilei, L.V. Metal Ablation by Picosecond Laser Pulses: A Hybrid Simulation. Phys. Rev. B 2002, 66, 115404. [Google Scholar] [CrossRef]

- Hu, Y.; Jiang, G. Study on the Damage Dynamics of CuZr Amorphous Alloy Nanofilm Irradiated by Femtosecond Laser. J. Sichuan Univ. Nat. Sci. Ed. 2019, 56, 897–902. [Google Scholar]

- Stukowski, A. Visualization and Analysis of Atomistic Simulation Data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Xue, D.; Gaidai, O.; Wang, Y.; Xu, S. Molecular Dynamics Simulation of Femtosecond Laser Ablation of Cu50Zr50 Metallic Glass Based on Two-Temperature Model. Processes 2023, 11, 1704. https://doi.org/10.3390/pr11061704

Xu J, Xue D, Gaidai O, Wang Y, Xu S. Molecular Dynamics Simulation of Femtosecond Laser Ablation of Cu50Zr50 Metallic Glass Based on Two-Temperature Model. Processes. 2023; 11(6):1704. https://doi.org/10.3390/pr11061704

Chicago/Turabian StyleXu, Jingxiang, Dengke Xue, Oleg Gaidai, Yang Wang, and Shaolin Xu. 2023. "Molecular Dynamics Simulation of Femtosecond Laser Ablation of Cu50Zr50 Metallic Glass Based on Two-Temperature Model" Processes 11, no. 6: 1704. https://doi.org/10.3390/pr11061704

APA StyleXu, J., Xue, D., Gaidai, O., Wang, Y., & Xu, S. (2023). Molecular Dynamics Simulation of Femtosecond Laser Ablation of Cu50Zr50 Metallic Glass Based on Two-Temperature Model. Processes, 11(6), 1704. https://doi.org/10.3390/pr11061704