Effective Removal of Ammonium from Aqueous Solution by Ball-Milled Biochar Modified with NaOH

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of the Pristine and Modified Biochars

2.2. Characterization

2.3. Sorption Experiment

2.4. Statistical Analysis

3. Results and Discussion

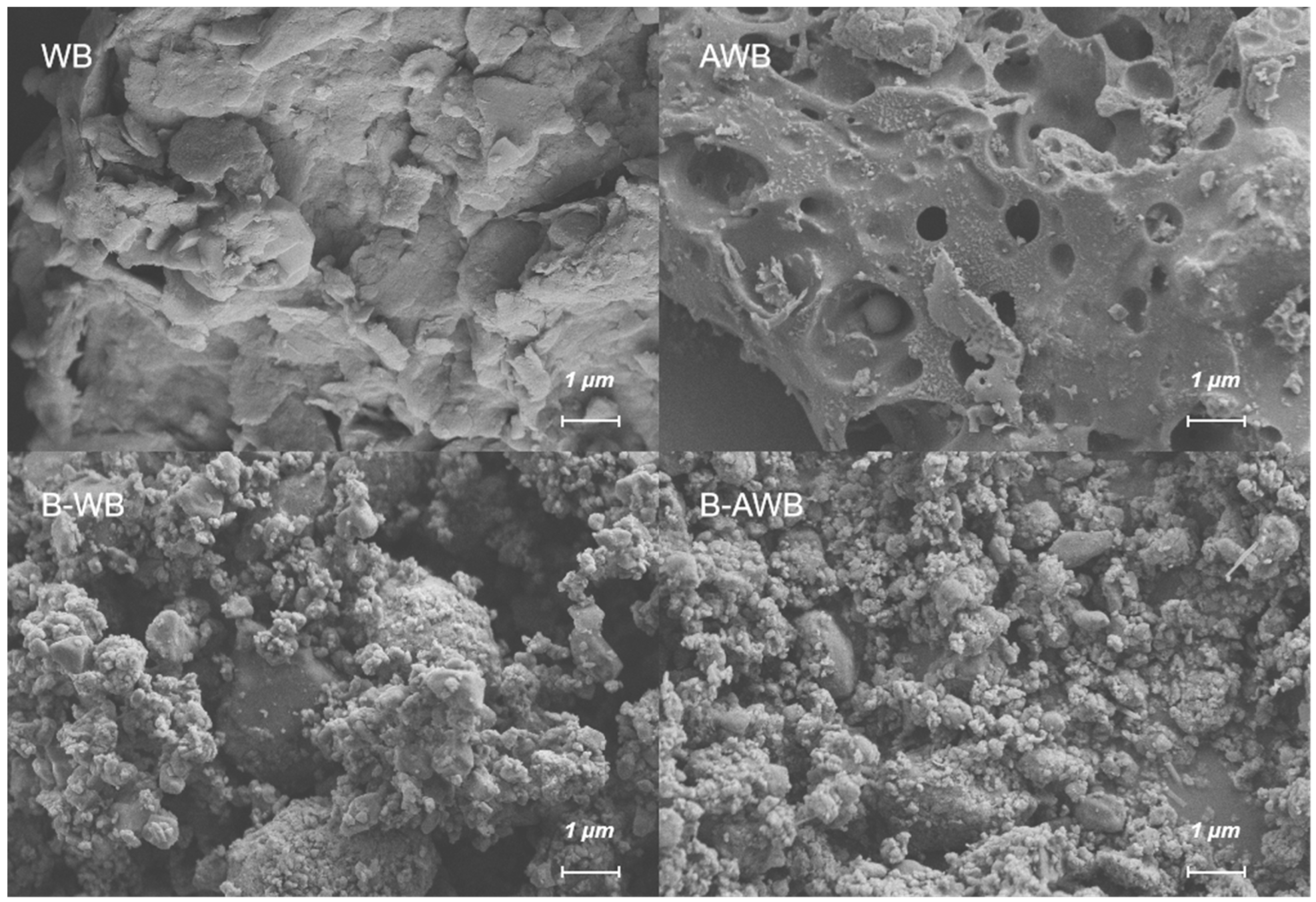

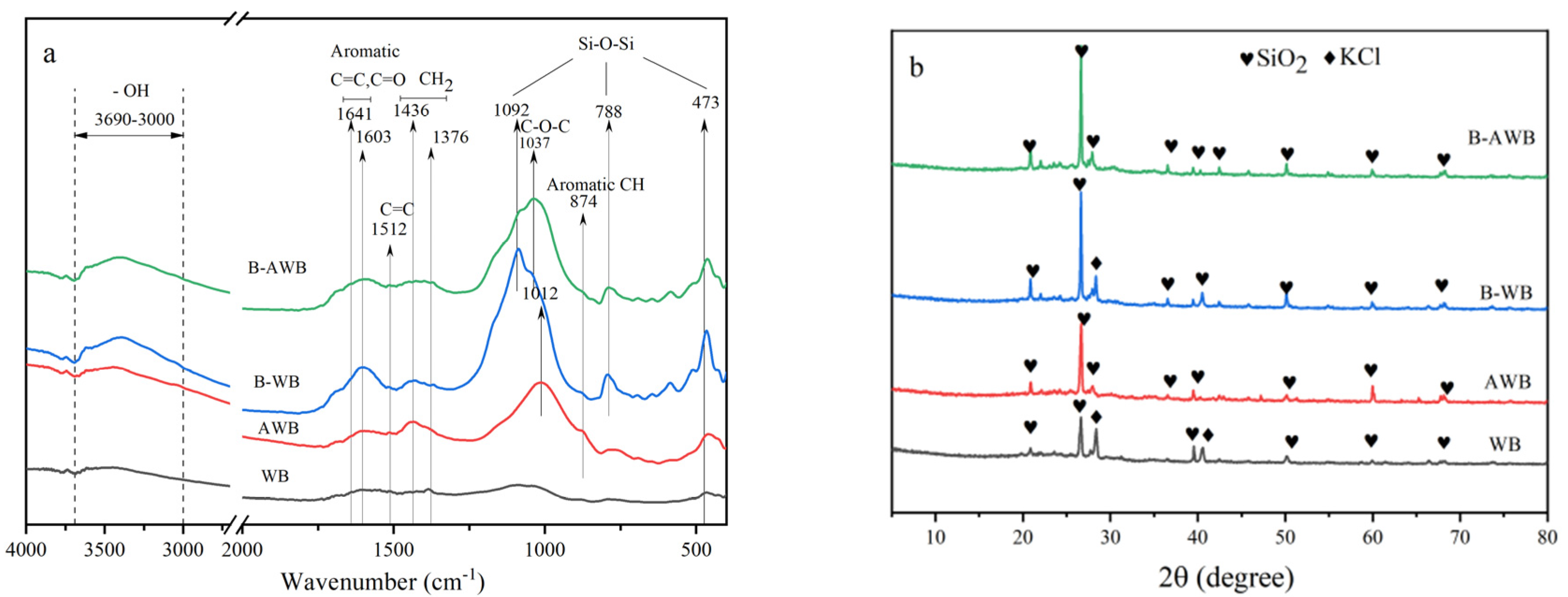

3.1. Effects of Modification on Biochar Properties

3.2. Ammonium Sorption

3.2.1. pH Dependent Sorption

3.2.2. Ammonium Sorption Kinetics

3.2.3. Ammonium Sorption Isotherm

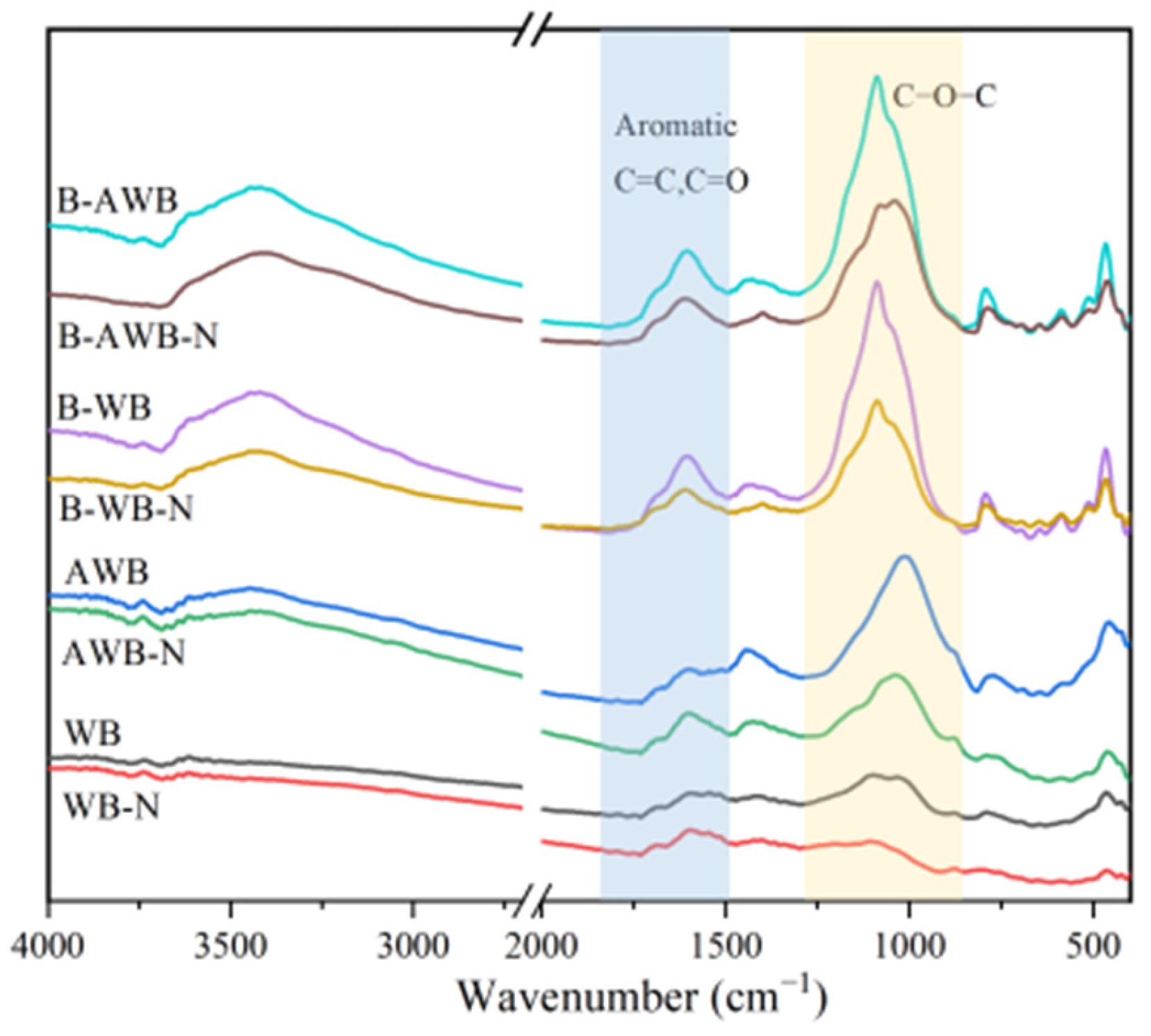

3.3. Ammonium Sorption Mechanisms on the Modified Biochars

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qin, Y.; Zhu, X.; Su, Q.; Anumah, A.; Gao, B.; Lyu, W.; Zhou, X.; Xing, Y.; Wang, B. Enhanced removal of ammonium from water by ball-milled biochar. Environ. Geochem. Health 2020, 42, 1579–1587. [Google Scholar] [CrossRef] [PubMed]

- Conley, D.J.; Paerl, H.W.; Howarth, R.W.; Boesch, D.F.; Seitzinger, S.P.; Havens, K.E.; Lancelot, C.; Likens, G.E. Controlling Eutrophication: Nitrogen and Phosphorus. Science 2009, 323, 1014–1015. [Google Scholar] [CrossRef] [PubMed]

- Cameron, K.C.; Di, H.J.; Moir, J.L. Nitrogen losses from the soil/plant system: A review. Ann. Appl. Biol. 2013, 162, 145–173. [Google Scholar] [CrossRef]

- MEPC. China Environmental Status Bulletin in 2020; Ministry of Environment Protection of the People’s Republic of China: Beijing, China, 2021.

- Cui, X.; Hao, H.; Zhang, C.; He, Z.; Yang, X. Capacity and mechanisms of ammonium and cadmium sorption on different wetland-plant derived biochars. Sci. Total Environ. 2016, 539, 566–575. [Google Scholar] [CrossRef] [PubMed]

- Ji, Z.-Y.; Yuan, J.-S.; Li, X.-G. Removal of ammonium from wastewater using calcium form clinoptilolite. J. Hazard. Mater. 2007, 141, 483–488. [Google Scholar] [CrossRef]

- Chen, S.-T.; Wickramasinghe, S.R.; Qian, X. High Performance Mixed-Matrix Electrospun Membranes for Ammonium Removal from Wastewaters. Membranes 2021, 11, 440. [Google Scholar] [CrossRef]

- Motlagh, A.R.A.; LaPara, T.M.; Semmens, M.J. Ammonium removal in advective-flow membrane-aerated biofilm reactors (AF-MABRs). J. Membr. Sci. 2008, 319, 76–81. [Google Scholar]

- Al-Ajalin, F.A.H.; Abdullah, S.R.S.; Idris, M.; Kurniawan, S.B.; Ramli, N.N.; Imron, M.F. Removal of ammonium, phosphate, and COD by bacteria isolated from Lepironia articulata and Scirpus grossus root system. Int. J. Environ. Sci. Technol. 2022, 19, 11893–11904. [Google Scholar] [CrossRef]

- IBI. Standardized Product Definition and Product Testing Guidelines for Biochar That Is Used in Soil; International Biochar Initiative: Canandaigua, NY, USA, 2012. [Google Scholar]

- Ahmad, M.; Rajapaksha, A.U.; Lim, J.E.; Zhang, M.; Bolan, N.; Mohan, D.; Vithanage, M.; Lee, S.S.; Ok, Y.S. Biochar as a sorbent for contaminant management in soil and water: A review. Chemosphere 2014, 99, 19–33. [Google Scholar] [CrossRef]

- Cui, X.; Wang, J.; Wang, X.; Khan, M.B.; Lu, M.; Khan, K.Y.; Song, Y.; He, Z.; Yang, X.; Yan, B.; et al. Biochar from constructed wetland biomass waste: A review of its potential and challenges. Chemosphere 2022, 287, 132259. [Google Scholar] [CrossRef]

- Cui, X.; Yang, X.; Sheng, K.; He, Z.; Chen, G. Transformation of Phosphorus in Wetland Biomass during Pyrolysis and Hydrothermal Treatment. ACS Sustain. Chem. Eng. 2019, 7, 16520–16528. [Google Scholar] [CrossRef]

- Gao, S.; DeLuca, T.H.; Cleveland, C.C. Biochar additions alter phosphorus and nitrogen availability in agricultural ecosystems: A meta-analysis. Sci. Total Environ. 2019, 654, 463–472. [Google Scholar] [CrossRef] [PubMed]

- Fan, R.; Chen, C.-L.; Lin, J.-Y.; Tzeng, J.-H.; Huang, C.-P.; Dong, C. Adsorption characteristics of ammonium ion onto hydrous biochars in dilute aqueous solutions. Bioresour. Technol. 2019, 272, 465–472. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Alam, S.; Konhauser, K.O.; Alessi, D.S.; Xu, S.; Tian, W.; Liu, Y. Influence of pyrolysis temperature on production of digested sludge biochar and its application for ammonium removal from municipal wastewater. J. Clean. Prod. 2019, 209, 927–936. [Google Scholar] [CrossRef]

- Zhao, Y.; Huang, L.; Chen, Y. Biochars derived from giant reed (Arundo donax L.) with different treatment: Characterization and ammonium adsorption potential. Environ. Sci. Pollut. Res. 2017, 24, 25889–25898. [Google Scholar] [CrossRef]

- Gai, X.; Wang, H.; Liu, J.; Zhai, L.; Liu, S.; Ren, T.; Liu, H. Effects of feedstock and pyrolysis temperature on biochar adsorption of ammonium and nitrate. PLoS ONE 2014, 9, e113888. [Google Scholar] [CrossRef]

- Bai, X.; Li, Z.; Zhang, Y.; Ni, J.; Wang, X.; Zhou, X. Recovery of Ammonium in Urine by Biochar Derived from Faecal Sludge and its Application as Soil Conditioner. Waste Biomass Valorization 2017, 9, 1619–1628. [Google Scholar] [CrossRef]

- Chandra, S.; Medha, I.; Bhattacharya, J. Potassium-iron rice straw biochar composite for sorption of nitrate, phosphate, and ammonium ions in soil for timely and controlled release. Sci. Total Environ. 2020, 712, 136337. [Google Scholar] [CrossRef]

- Liu, Z.; Xue, Y.; Gao, F.; Cheng, X.; Yang, K. Removal of ammonium from aqueous solutions using alkali-modified biochars. Chem. Speciat. Bioavailab. 2016, 28, 26–32. [Google Scholar] [CrossRef]

- Vu, T.M.; Trinh, V.T.; Doan, D.P.; Van, H.T.; Nguyen, T.V.; Vigneswaran, S.; Ngo, H.H. Removing ammonium from water using modified corncob-biochar. Sci. Total Environ. 2017, 579, 612–619. [Google Scholar] [CrossRef]

- Wang, S.; Ai, S.; Nzediegwu, C.; Kwak, J.-H.; Islam, S.; Li, Y.; Chang, S.X. Carboxyl and hydroxyl groups enhance ammonium adsorption capacity of iron (III) chloride and hydrochloric acid modified biochars. Bioresour. Technol. 2020, 309, 123390. [Google Scholar] [CrossRef] [PubMed]

- Amusat, S.O.; Kebede, T.G.; Dube, S.; Nindi, M.M. Ball-milling synthesis of biochar and biochar–based nanocomposites and prospects for removal of emerging contaminants: A review. J. Water Process. Eng. 2021, 41, 101993. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, J.; Lyu, H.; Zhao, Q.; Jiang, L.; Liu, L. Ball-milled biochar for galaxolide removal: Sorption performance and governing mechanisms. Sci. Total Environ. 2019, 659, 1537–1545. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Wan, Y.; Chen, J.; Chen, H.; Gao, B. MgO modified biochar produced through ball milling: A dual-functional adsorbent for removal of different contaminants. Chemosphere 2020, 243, 125344. [Google Scholar] [CrossRef]

- Zhuang, Z.; Wang, L.; Tang, J. Efficient removal of volatile organic compound by ball-milled biochars from different preparing conditions. J. Hazard. Mater. 2021, 406, 124676. [Google Scholar] [CrossRef] [PubMed]

- Feng, Q.; Chen, M.; Wu, P.; Zhang, X.; Wang, S.; Yu, Z.; Wang, B. Simultaneous reclaiming phosphate and ammonium from aqueous solutions by calcium alginate-biochar composite: Sorption performance and governing mechanisms. Chem. Eng. J. 2021, 429, 132166. [Google Scholar] [CrossRef]

- Li, B.; Yang, L.; Wang, C.-Q.; Zhang, Q.-P.; Liu, Q.-C.; Li, Y.-D.; Xiao, R. Adsorption of Cd(II) from aqueous solutions by rape straw biochar derived from different modification processes. Chemosphere 2017, 175, 332–340. [Google Scholar] [CrossRef]

- Bashir, S.; Zhu, J.; Fu, Q.; Hu, H. Comparing the adsorption mechanism of Cd by rice straw pristine and KOH-modified biochar. Environ. Sci. Pollut. Res. 2018, 25, 11875–11883. [Google Scholar] [CrossRef]

- Chen, Z.; Xiao, X.; Chen, B.; Zhu, L. Quantification of chemical states, dissociation constants and contents of oxygen-containing groups on the surface of biochars produced at different temperatures. Environ. Sci. Technol. 2015, 49, 309–317. [Google Scholar] [CrossRef]

- Zhu, K.; Fu, H.; Zhang, J.; Lv, X.; Tang, J.; Xu, X. Studies on removal of NH4+-N from aqueous solution by using the activated carbons derived from rice husk. Biomass Bioenergy 2012, 43, 18–25. [Google Scholar] [CrossRef]

- Hou, J.; Huang, L.; Yang, Z.; Zhao, Y.; Deng, C.; Chen, Y.; Li, X. Adsorption of ammonium on biochar prepared from giant reed. Environ. Sci. Pollut. Res. 2016, 23, 19107–19115. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.I.; Lou, K.; Rajapaksha, A.U.; Ok, Y.S.; Anyia, A.O.; Chang, S.X. Adsorption of ammonium in aqueous solutions by pine sawdust and wheat straw biochars. Environ. Sci. Pollut. Res. 2018, 25, 25638–25647. [Google Scholar] [CrossRef] [PubMed]

- Rezaee, M.; Gitipour, S.; Sarrafzadeh, M.H. EVALUATION OF PHOSPHATE AND AMMONIUM ADSORPTION DESORPTION OF SLOW PYROLYZED WOOD BIOCHAR. Environ. Eng. Manag. J. 2021, 20, 217–227. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, R.; Song, G.; Wu, L.; Ye, H.; Xu, L.; Parikh, S.J.; Nguyen, T.; Khan, E.; Vithanage, M.; et al. Enhanced removal of ammonium from water using sulfonated reed waste biochar-A lab-scale investigation. Environ. Pollut. 2022, 292, 118412. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, X.; Ngo, H.H.; Guo, W.; Wen, H.; Li, C.; Zhang, Y.; Ma, C. Comparison study on the ammonium adsorption of the biochars derived from different kinds of fruit peel. Sci. Total Environ. 2020, 707, 135544. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, H.; Shen, F.; Yang, G.; Zhang, Y.; Zeng, Y.; Wang, L.; Xiao, H.; Deng, S. Biochar produced from oak sawdust by Lanthanum (La)-involved pyrolysis for adsorption of ammonium (NH4+), nitrate (NO3−), and phosphate (PO43−). Chemosphere 2015, 119, 646–653. [Google Scholar] [CrossRef]

- Zheng, H.; Wang, Z.; Deng, X.; Zhao, J.; Luo, Y.; Novak, J.; Herbert, S.; Xing, B. Characteristics and nutrient values of biochars produced from giant reed at different temperatures. Bioresour. Technol. 2013, 130, 463–471. [Google Scholar] [CrossRef]

| Sample a | pH | Ash | N | C | H | O | Atomic Ratio | SSA | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (%) | O/C | H/C | (O + N)/C | (m2/g) | ||||||

| WB | 10.25 ± 0.02 | 50.19 ± 0.37 | 0.82 | 38.16 | 1.764 | 8.62 | 0.17 | 0.55 | 0.19 | 20.9 |

| AWB | 11.01 ± 0.00 | 54.22 ± 0.75 | 0.46 | 32.18 | 1.583 | 11.44 | 0.27 | 0.59 | 0.28 | 51.4 |

| B-WB | 9.25 ± 0.01 | 48.79 ± 0.20 | 0.81 | 37.74 | 1.978 | 10.38 | 0.21 | 0.63 | 0.22 | 145.6 |

| B-AWB | 10.53 ± 0.01 | 51.06 ± 0.26 | 0.53 | 33.11 | 1.884 | 13.34 | 0.30 | 0.68 | 0.32 | 121.7 |

| Biochar | Pseudo-First-Order a | Pseudo-Second-Order b | ||||

|---|---|---|---|---|---|---|

| K1 (h−1) | Qe (mg/g) | R2 | K2 (g/mg·h) | Qe (mg/g) | R2 | |

| WB | 2.13 | 0.73 | 0.95 | 3.11 | 0.82 | 0.92 |

| AWB | 23.57 | 1.34 | 0.98 | 46.56 | 1.37 | 0.98 |

| B-WB | 13.86 | 1.06 | 0.94 | 22.54 | 1.12 | 0.98 |

| B-AWB | 7.98 | 2.04 | 0.94 | 7.09 | 2.12 | 0.95 |

| Biochar | Langmuir a | Freundlich b | ||||

|---|---|---|---|---|---|---|

| KL (L/mg) | Qm (mg/g) | R2 | KF (mg/g) | N | R2 | |

| WB | 0.02 | 3.09 | 0.95 | 0.15 | 0.53 | 0.89 |

| AWB | 0.01 | 6.93 | 0.99 | 0.26 | 0.57 | 0.95 |

| B-WB | 0.03 | 4.64 | 0.98 | 0.16 | 0.58 | 0.96 |

| B-AWB | 0.02 | 8.93 | 0.98 | 0.65 | 0.48 | 0.92 |

| Adsorbents | Modification Method | Solid-Liquid Ratio (g/L) | Sorption Capacity (mg/g) |

|---|---|---|---|

| Bamboo biochar [15] | Unmodified | 1.00 | 4.96 |

| Digested sludge [16] | Unmodified | 10.00 | 1.40 |

| Rice straw [20] | Unmodified | 1.60 | 3.20 |

| Rice straw [20] | Potassium-iron modified | 1.60 | 10.77 |

| Pine wood chips biochar [35] | Unmodified | 1.00 | 2.86 |

| Reed waste biochar [36] | Unmodified | 5.00 | 1.92 |

| Reed waste biochar [36] | Sulfonation modified | 10.00 | 5.19 |

| Orange peel [37] | Unmodified | 10.00 | 4.36 |

| B-AWB (this study) | NaOH-ball-milled modified | 3.33 | 8.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Li, X.; Wang, Y.; Wang, J.; Yang, L.; Ma, Z.; Luo, J.; Cui, X.; Yan, B.; Chen, G. Effective Removal of Ammonium from Aqueous Solution by Ball-Milled Biochar Modified with NaOH. Processes 2023, 11, 1671. https://doi.org/10.3390/pr11061671

Yang H, Li X, Wang Y, Wang J, Yang L, Ma Z, Luo J, Cui X, Yan B, Chen G. Effective Removal of Ammonium from Aqueous Solution by Ball-Milled Biochar Modified with NaOH. Processes. 2023; 11(6):1671. https://doi.org/10.3390/pr11061671

Chicago/Turabian StyleYang, Hefeng, Xiangming Li, Yuting Wang, Junxia Wang, Lihong Yang, Zhiqiang Ma, Jipeng Luo, Xiaoqiang Cui, Beibei Yan, and Guanyi Chen. 2023. "Effective Removal of Ammonium from Aqueous Solution by Ball-Milled Biochar Modified with NaOH" Processes 11, no. 6: 1671. https://doi.org/10.3390/pr11061671

APA StyleYang, H., Li, X., Wang, Y., Wang, J., Yang, L., Ma, Z., Luo, J., Cui, X., Yan, B., & Chen, G. (2023). Effective Removal of Ammonium from Aqueous Solution by Ball-Milled Biochar Modified with NaOH. Processes, 11(6), 1671. https://doi.org/10.3390/pr11061671