1. Introduction

Automated manufacturing systems (AMSs) are prone to failures that can alter their intended behavior, resulting in equipment damage and posing a potential hazard to human operators. To mitigate such risks and prevent damage to the systems, it is essential to implement an automatic fault diagnosis system to detect and isolate fault occurrences. The problem of fault detection and diagnosis of discrete-event systems (DESs) has gained significant attention in the literature [

1,

2,

3,

4,

5], with the most common approaches focusing on systems described by automata [

6,

7,

8] or Petri nets (PN) [

9,

10,

11,

12]. Additionally, fault tolerance, fault recovery, and fault repair in a system are crucial challenges that need to be addressed in many industrial processes [

13,

14,

15]. Furthermore, Petri nets have been extensively used as DES models to validate various features [

16] of flexible manufacturing systems [

17,

18], ensure system safety [

19], and verify information-flow properties of cyberphysical systems, such as opacity [

20,

21]. The significance of these efforts is highlighted in numerous studies that emphasize the importance of fault diagnosis and mitigation in the context of automated manufacturing systems.

In the field of supervisory control for DESs, automata and Petri nets are two significant mathematical tools for modeling, analyzing, and controlling AMSs. Automata provide simpler approaches to model and study the dynamic behavior of AMSs. On the other hand, Petri nets allow for more powerful modeling capabilities of complex AMSs and enable the analysis of system performance. Petri nets have a more intricate structure, making them more suitable for describing certain structural properties of a system than automata. As a result, Petri nets lead to more concise models [

22,

23].

In the real world, resource failures in AMSs can occur due to various reasons, making most existing deadlock control approaches ineffective. These failures can be caused by a multitude of factors, including component malfunctions, sensor failures, tool breakages, and part defects [

24,

25,

26,

27]. As a result, many robust supervisory control policies for AMSs with unreliable resources have been developed [

25,

26,

28,

29,

30]. The primary objective of these policies is to ensure that a system can continue to operate smoothly even if some of its resources fail. This approach aims to maintain the system’s performance and prevent any disruption or downtime, which can lead to significant financial losses and delays in production.

The literature discusses several supervisory control policies that address the challenge of ensuring reliability in automated manufacturing systems (AMSs) with one or multiple unreliable resources. Chew et al. [

31] proposed two supervisory controllers that utilized a central buffer to handle multiple unreliable resources. In [

25], resource failures and deadlocks were addressed through the design of control places using a divide-and-conquer strategy and the addition of subnets for resource recovery. Inhibitor arcs and normal arcs were also added between monitors and the recovery subnets. Yue et al. [

32] developed a deadlock control strategy for an AMS with multiple unreliable resources using a set of resource capacity constraints and modified Banker’s algorithm. Similarly, the work in [

33] proposed a robust supervisory control technique to avoid deadlock and the blockage of multiple unreliable resources. In [

34], a deadlock controller for an AMS with resource failures was presented. The supervisor, consisting of three controllers, ensured that AMS operations involving an unreliable resource could be deadlock-free while still meeting the necessary requirements. Finally, two robust supervisory control policies were proposed in [

35]: the first policy applied to systems with one unreliable resource, whereas the second was designed for systems with multiple unreliable resources.

Redundancy is a crucial concept in engineering, which involves duplicating essential components or functions of a system to increase its reliability, usually in the form of a fail-safe or backup mechanism, or to improve its performance. In [

36], redundant hardware was utilized to recover from a system failure. A model-based approach was used in [

37] to develop a supervisory control system that switched the faulty controller to a backup controller when a fault occurred. On the other hand, both hardware and software reconfiguration redundancies were provided in [

38,

39].

Load-shared redundancy is a concept in which multiple devices share the workload and perform the same task. A mechanism is usually in place to assign jobs to these devices, and in case of failure, the remaining devices take over the tasks that the failed devices were supposed to perform. Keizer et al. [

40] noted that the load-sharing effect created a strong incentive to prevent failures in failure-based load sharing. Therefore, preventive replacements should be conducted relatively early. This effect was further amplified for degradation-based load sharing. In [

41], a new reliability technique was proposed for systems with dependent components that evenly shared the system load before and after the failure of other components.

In the shared-load model, redundant components share the workload equally, and when one or more components fail, the remaining components must handle an increased workload [

42]. The failure rate of load-sharing components can be time-dependent and nonlinearly reduced, as demonstrated in [

43]. To evaluate the dependability of phased-mission systems with load-sharing components, Mohammed et al. [

44] proposed an efficient iterative algorithm that utilized a modularization approach for subsystems with a recursive reliability formula across phases. The algorithm also included a closed-form formula for the conditional reliability of load-sharing subsystems that could be easily computed.

In this article, we approach the issue of fault tolerance and propose a way to enable a system to persist in fulfilling its duties while taking actions to repair and recover the fault. Our previous work in [

36] dealt with some of the critical problems in designing a fault-tolerant controller to maintain the safety of the system. While the idea presented in [

36] required the addition of redundant elements for each target element when a fault occurred in the target element, the submodel of its overflow element was utilized to substitute the model’s faulty target element. In this work, redundant elements become part of the components of the system and have tasks to perform, regardless of whether an unreliable element is a failure or not. Such a redundant element is called a load-sharing redundant element (LSRE). An LSRE shares tasks with a failure-prone element in a system, and if the failure-prone element fails, the LSRE takes over and completes all the tasks of the failed element. Robotic manufacturing cells are used as a case study to demonstrate the idea. The contributions of this work are: (i) the elimination of redundant elements and their replacement with existing elements in a system compared with the study in [

36]; (ii) the continuous processing of all parts, whether or not the unreliable resource fails compared with the studies in [

45,

46,

47,

48]; and (iii) the proposed technique does not necessitate the use of inhibitor arcs resulting in lower computational overheads.

The remainder of the paper is structured as follows. The motivation for this article is exposed in

Section 2.

Section 3 describes a system with load-sharing redundant elements. The development of the supervisory controller design is presented in

Section 4.

Section 5 includes some realistic examples and comparisons. The conclusion of this research is reached in

Section 6.

2. Motivation

In this section, we justify the motivation of this work. We introduce a class of Petri nets, derived from the most typical net subclasses in the manufacturing community (e.g., S

PR), which models an automated manufacturing system with unreliable resources. As seen, we outline the main ideas in this section via a small yet illustrative example. Due to the economy of space, a reader is referred to [

49] for the preliminaries of Petri nets to make the research understandable.

Definition 1. Let be a marked SPR of an AMS with an unreliable resource denoted by and a set of resources , where is the set of reliable resources. An SPR net model of an AMS with an unreliable target resource is an unreliable SPR net model denoted by USPR.

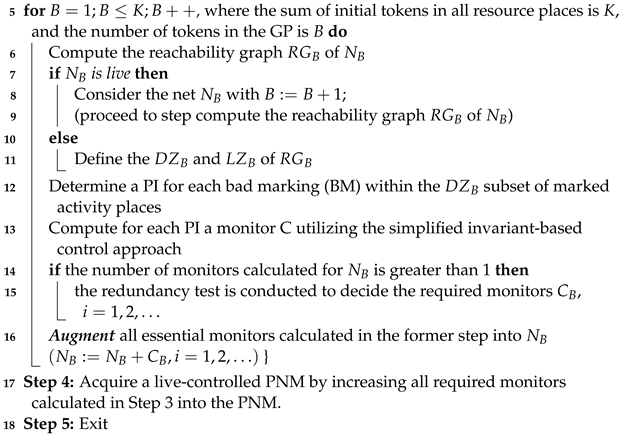

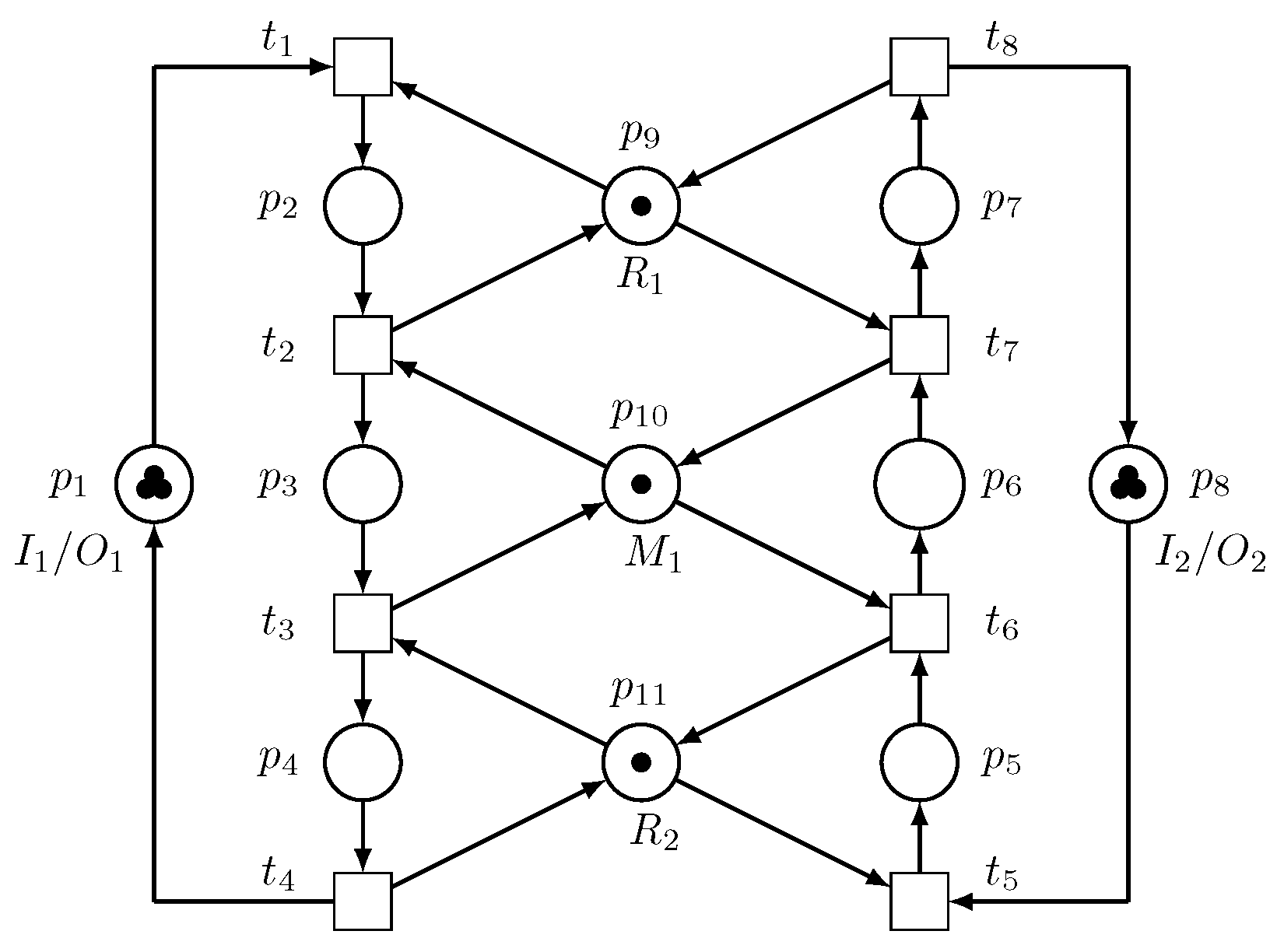

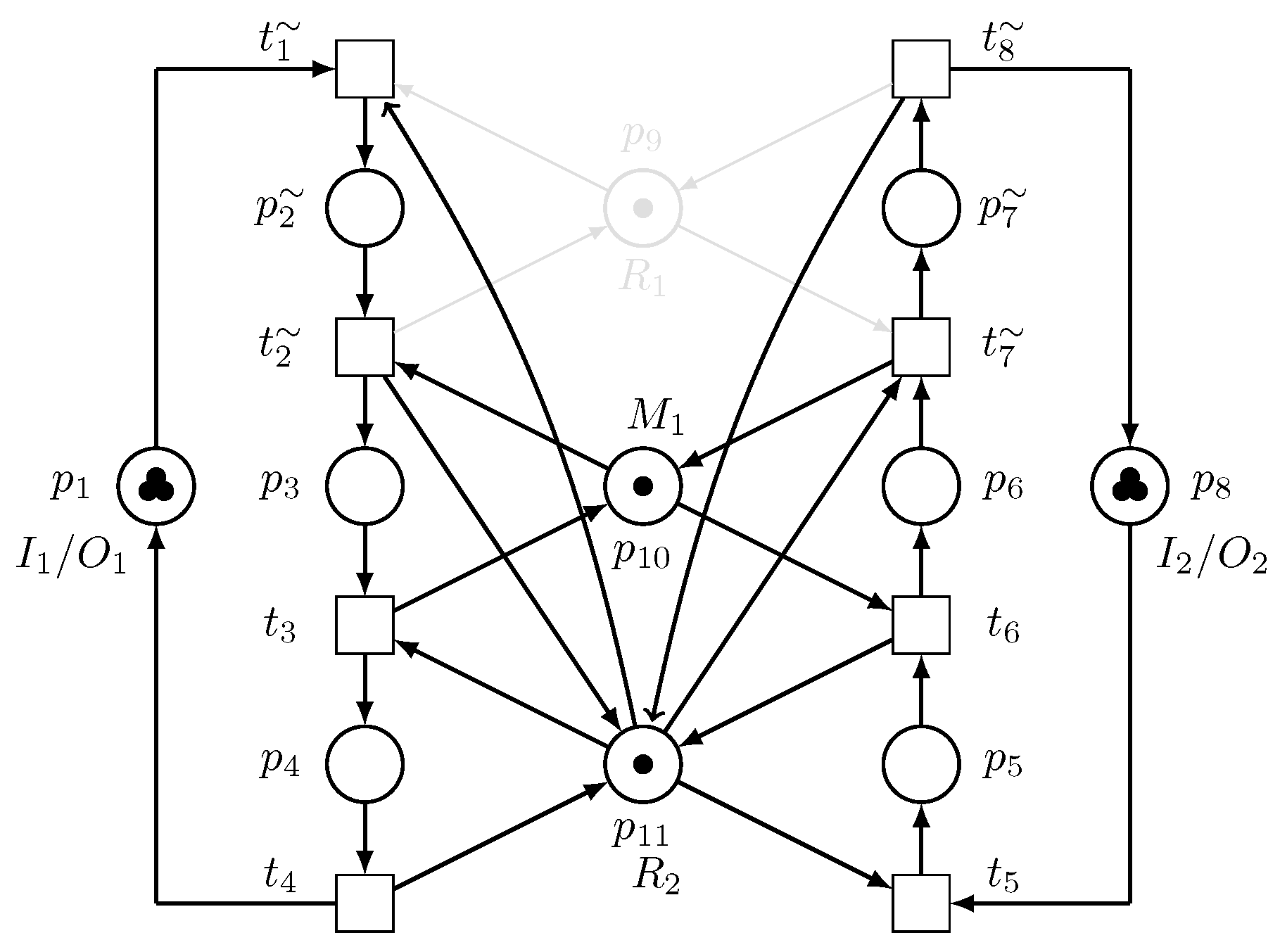

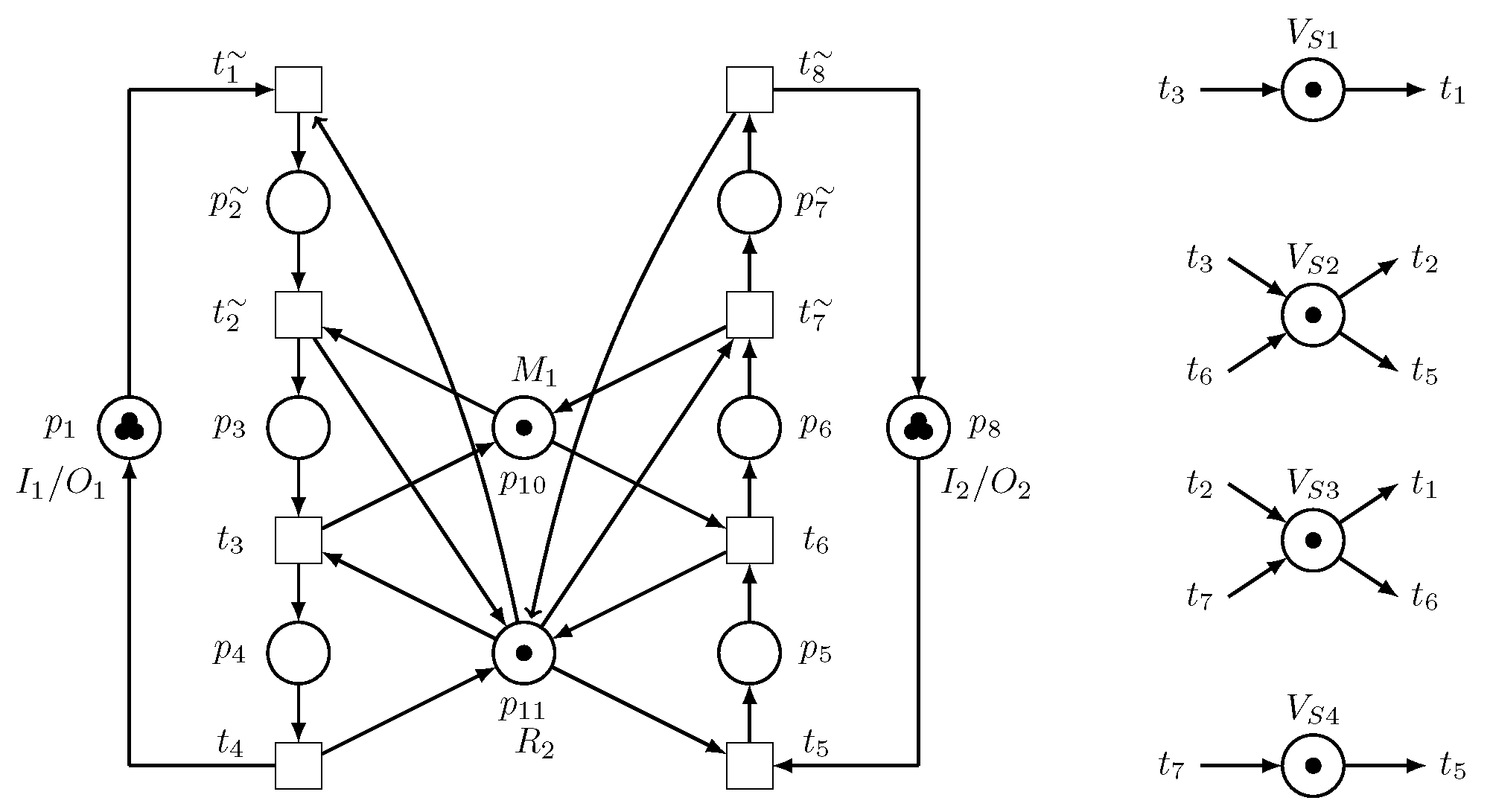

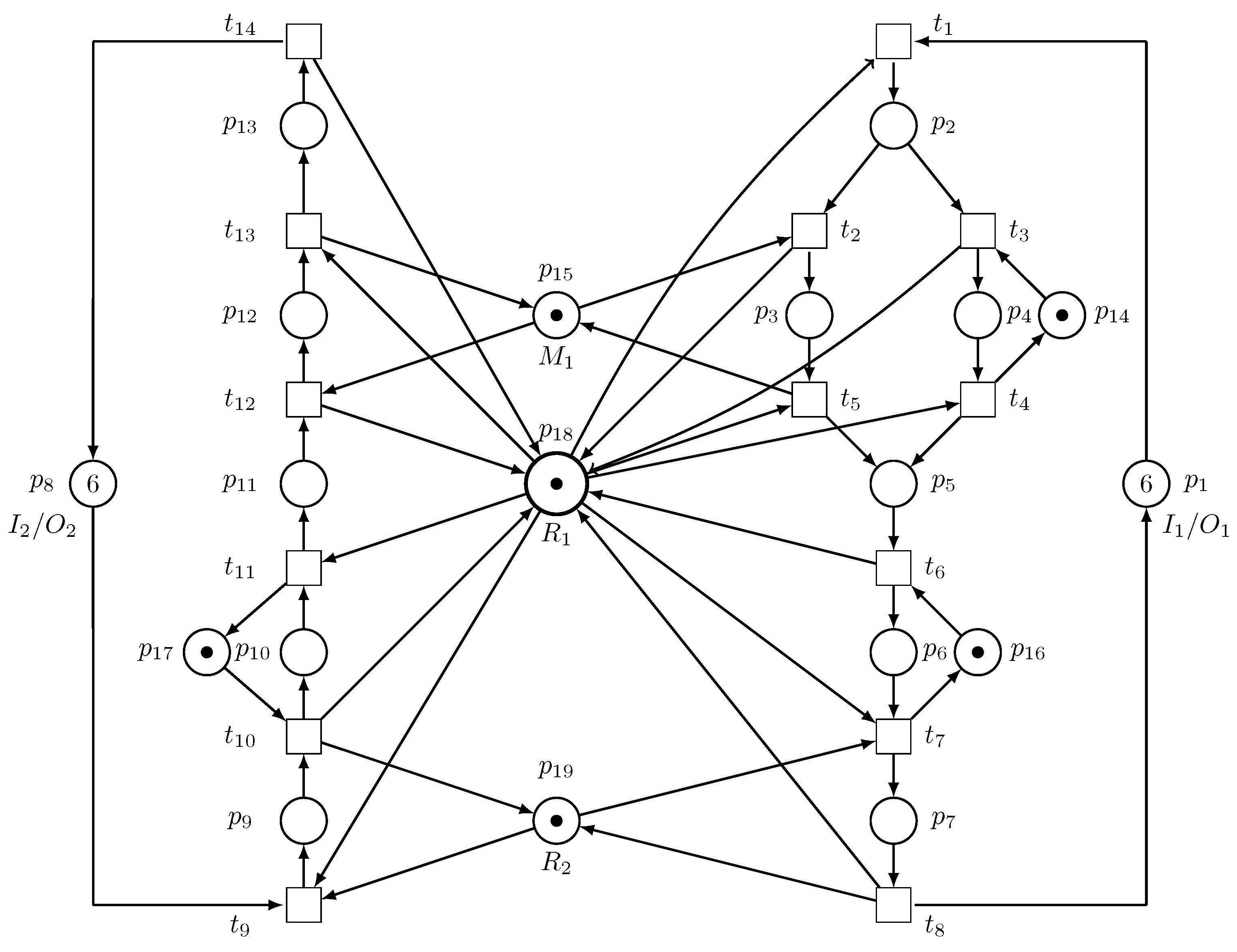

Example 1. Consider the robotic manufacturing cell in Figure 1, consisting of an unreliable robot performing the task of loading parts onto the machine , which processes one part at a time. The parts are picked by the robot from two loading buffers and . After the machine finishes processing a part, the robot unloads it onto the unloading buffers or . The tasks that performs are represented by activities that are a holder of , i.e., . The production sequences of the robotic cell are as follows: The Petri net model of the robotic manufacturing cell is depicted in

Figure 2. Since

is an unreliable resource, designing only a deadlock controller for the system cannot guarantee a continued processing of parts by the manufacturing cell if

fails. To increase the system’s reliability and improve the system performance, we propose the utilization of another robot that is reliable, or at least more reliable than

, which can perform the same task as

to reduce the amount of tasks performed by

, and can perform all the tasks being performed by

if

fails.

3. Synthesis Method of AMS with LSRE

In this section, we first present the model of an AMS with an LSRE via an example such that a reader can readily capture the physical idea under the stated methodology.

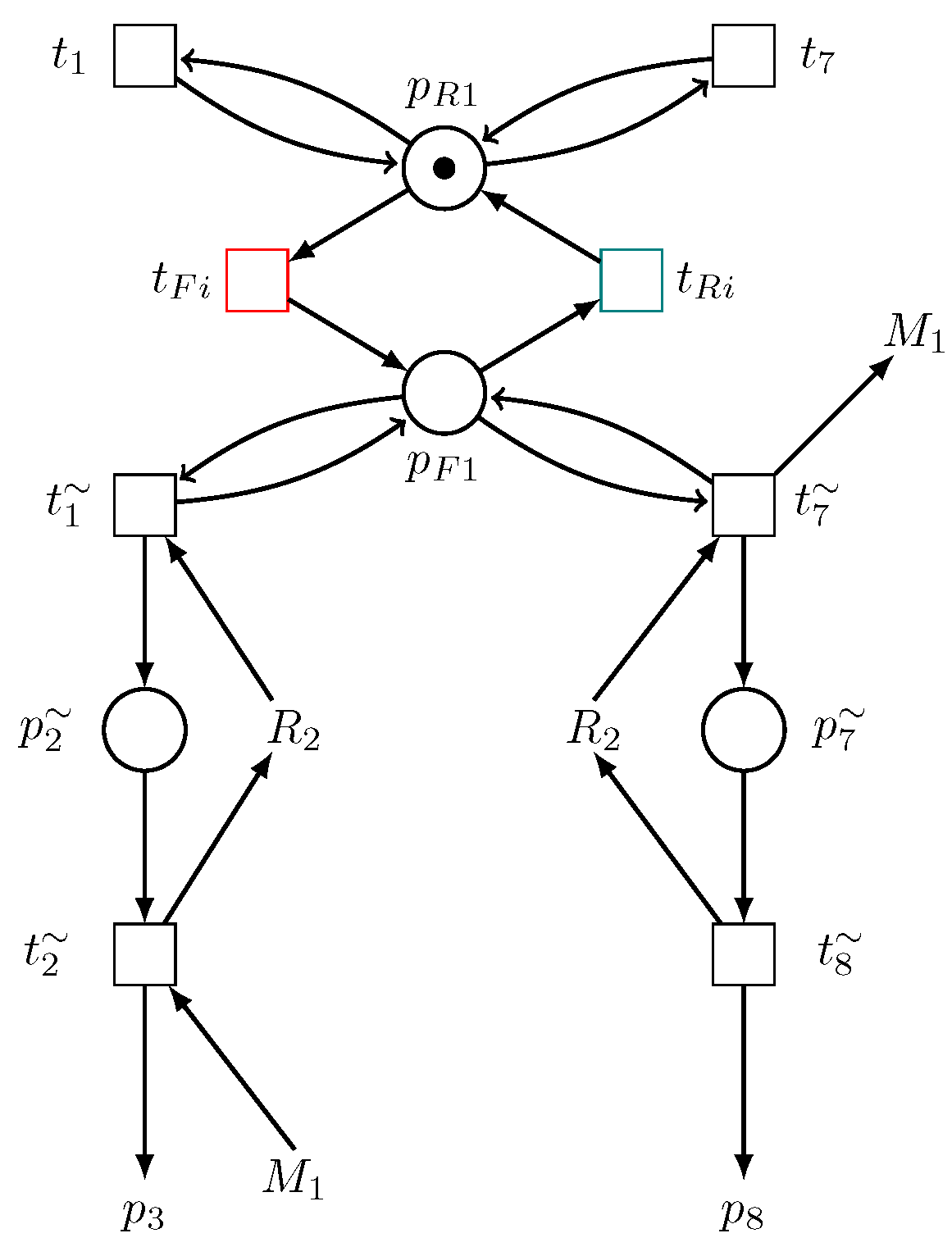

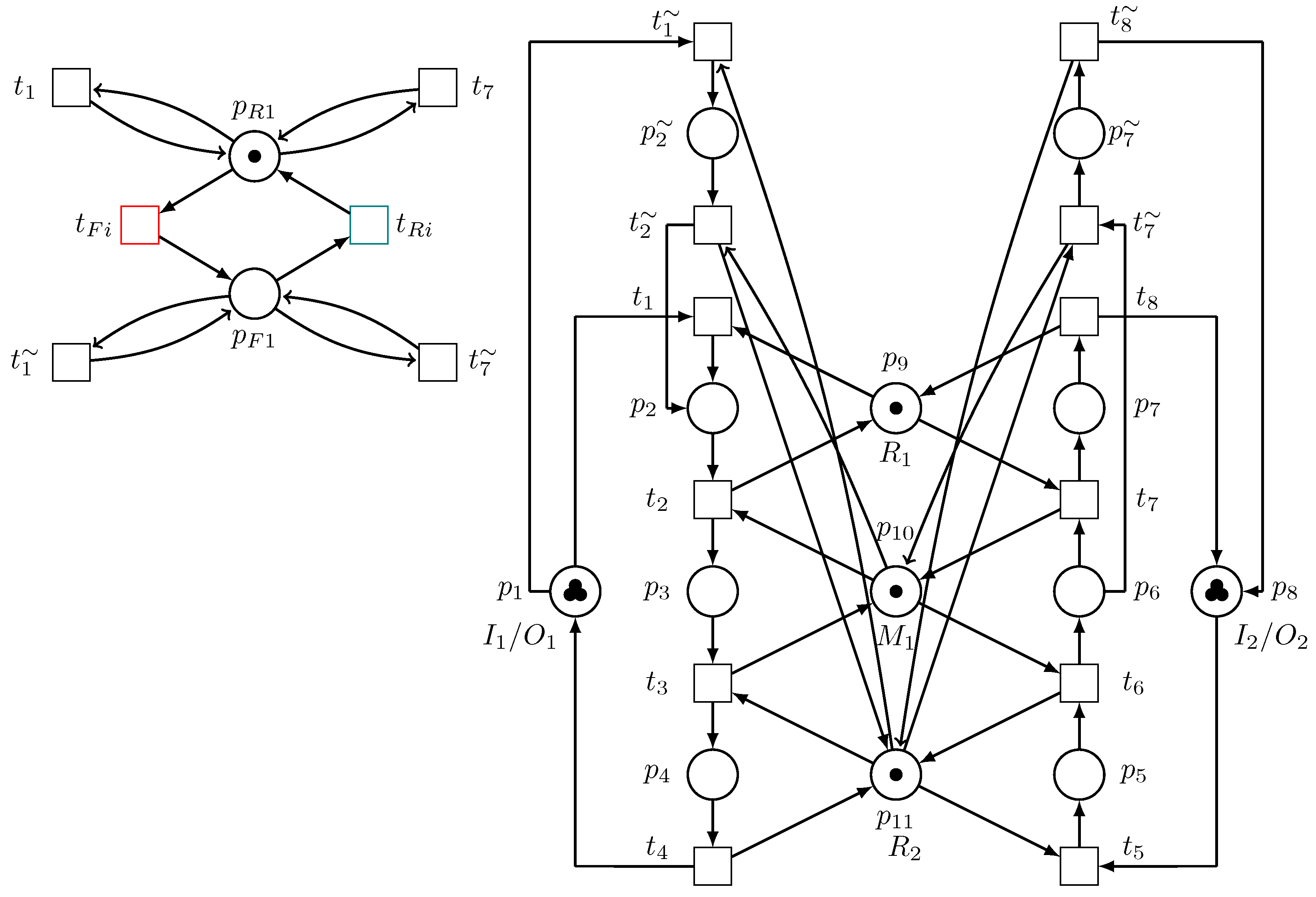

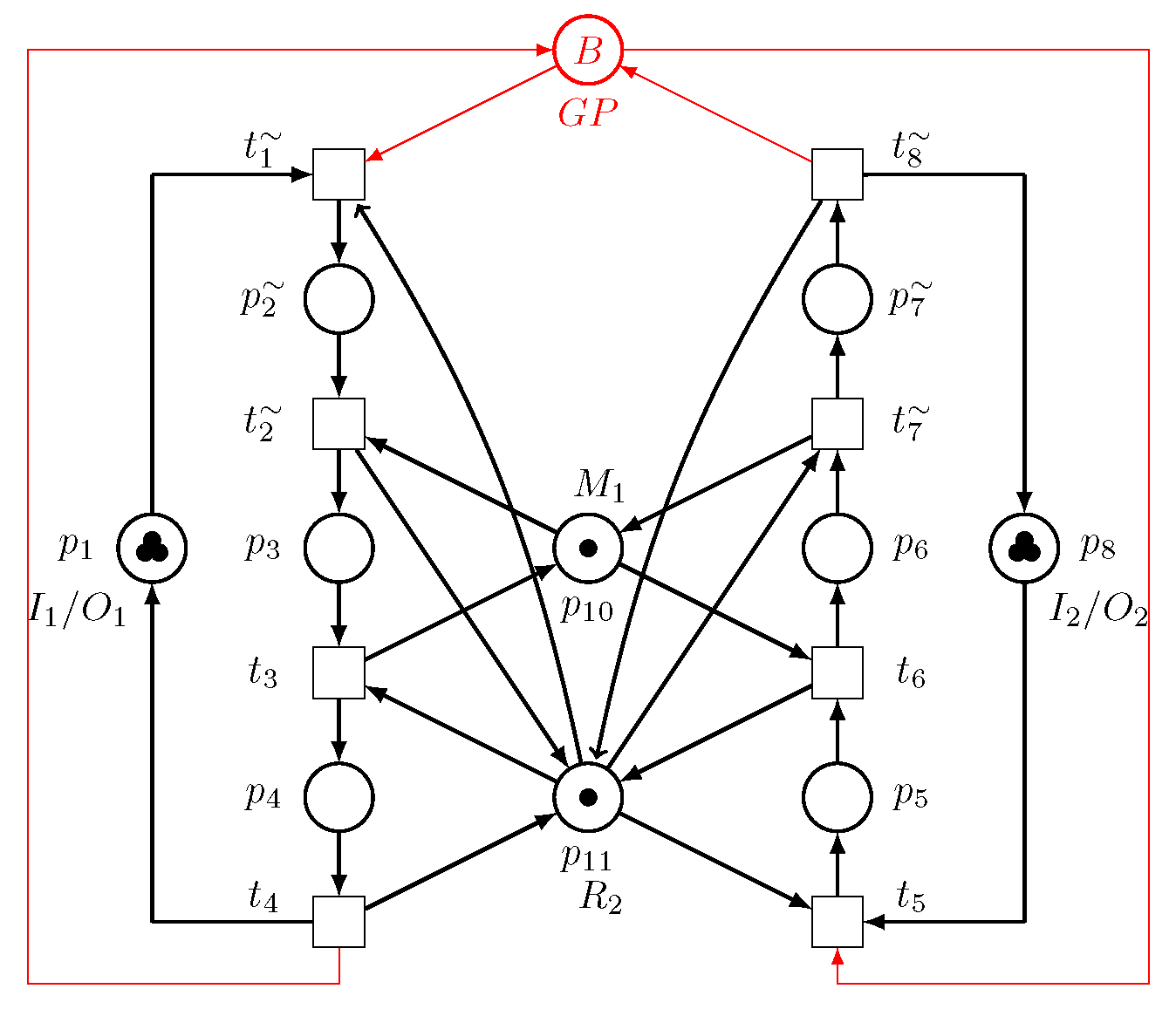

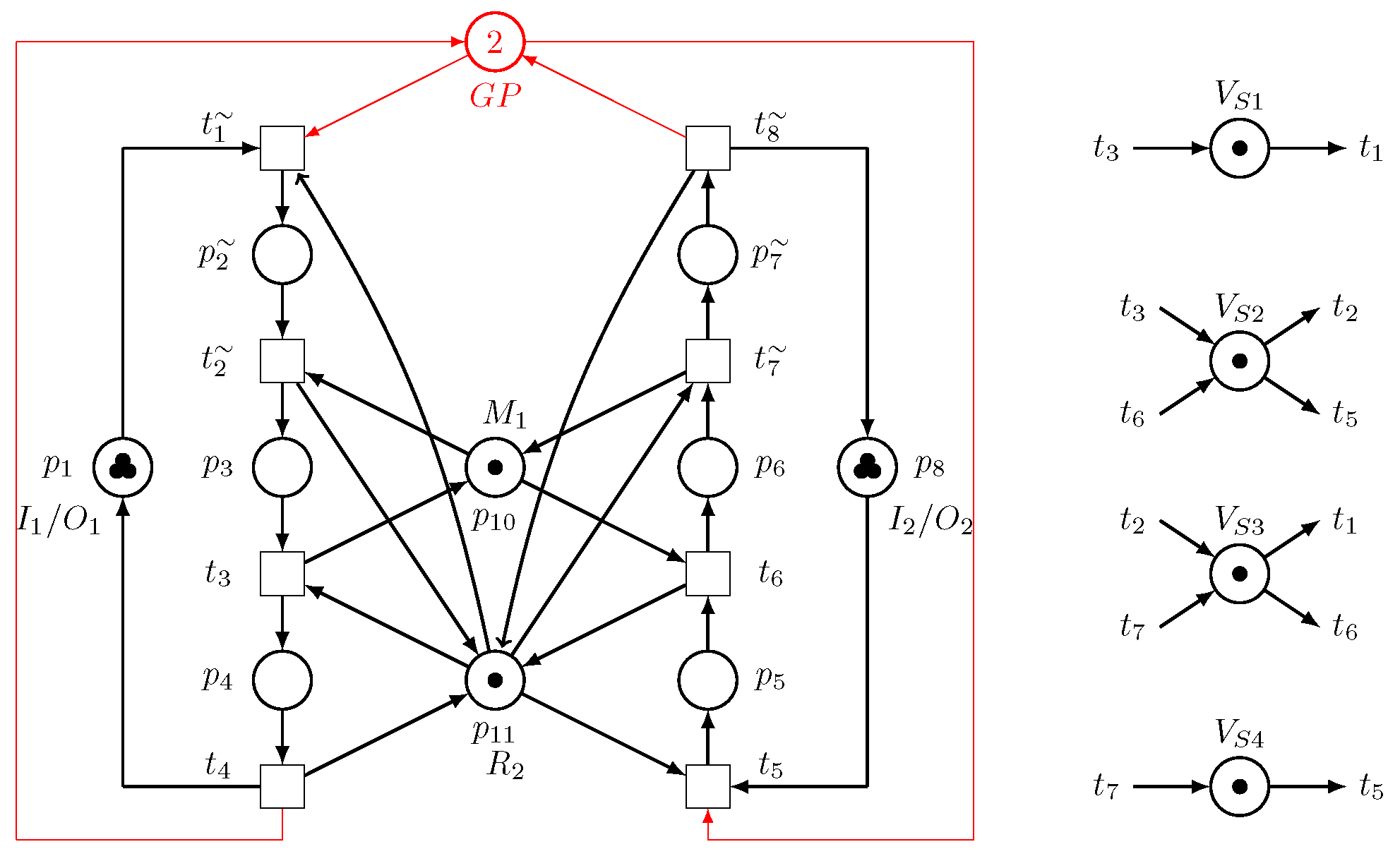

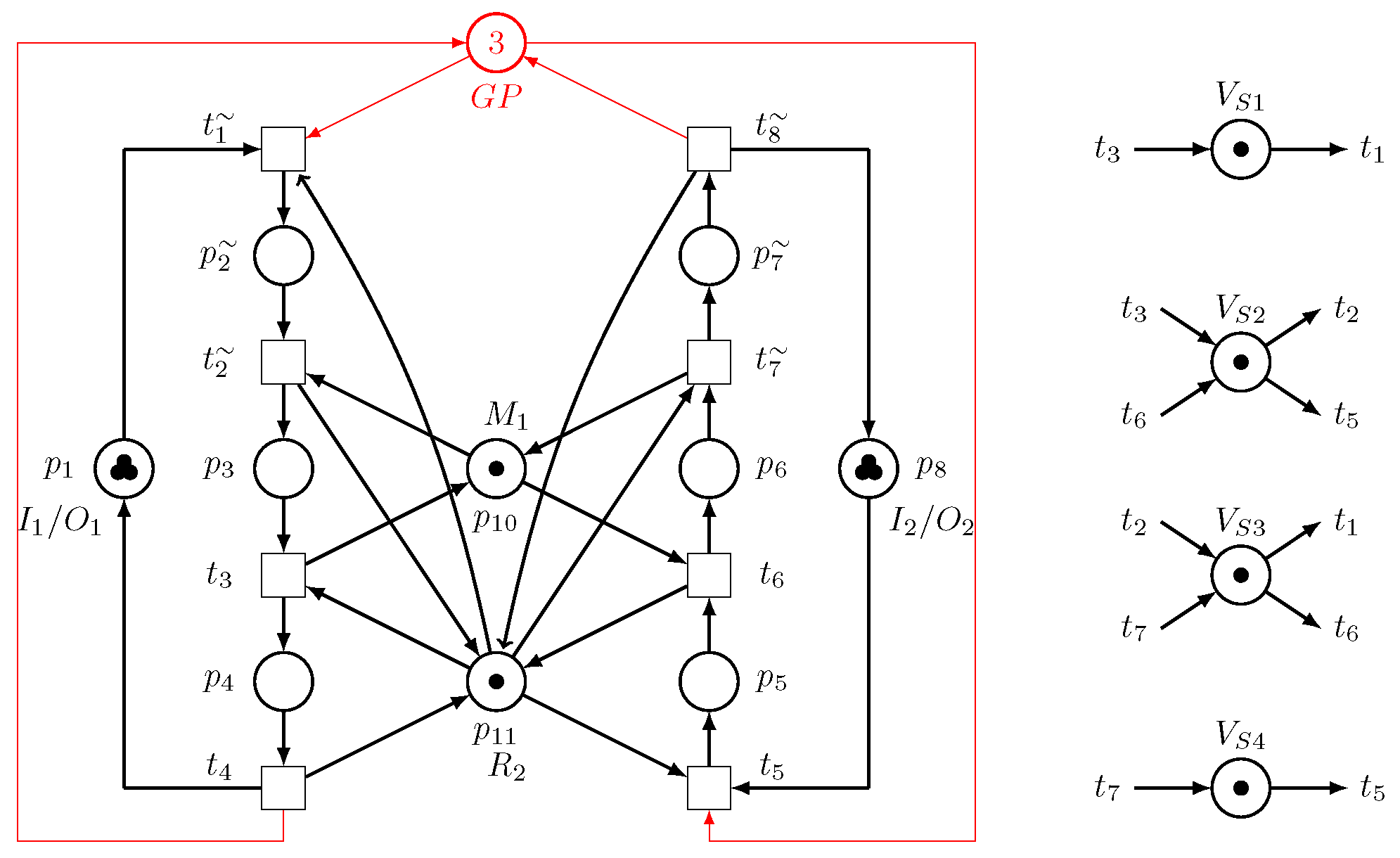

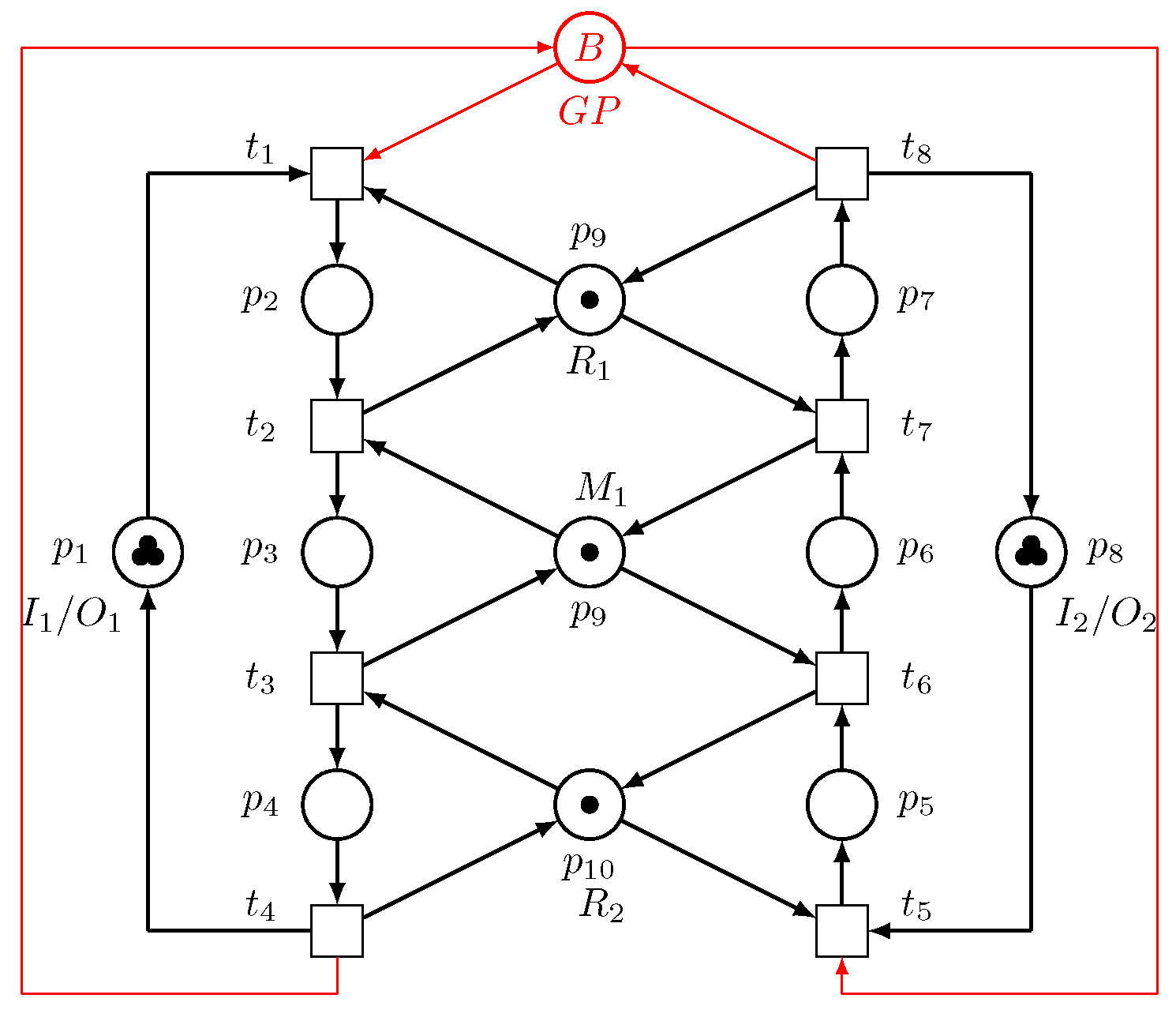

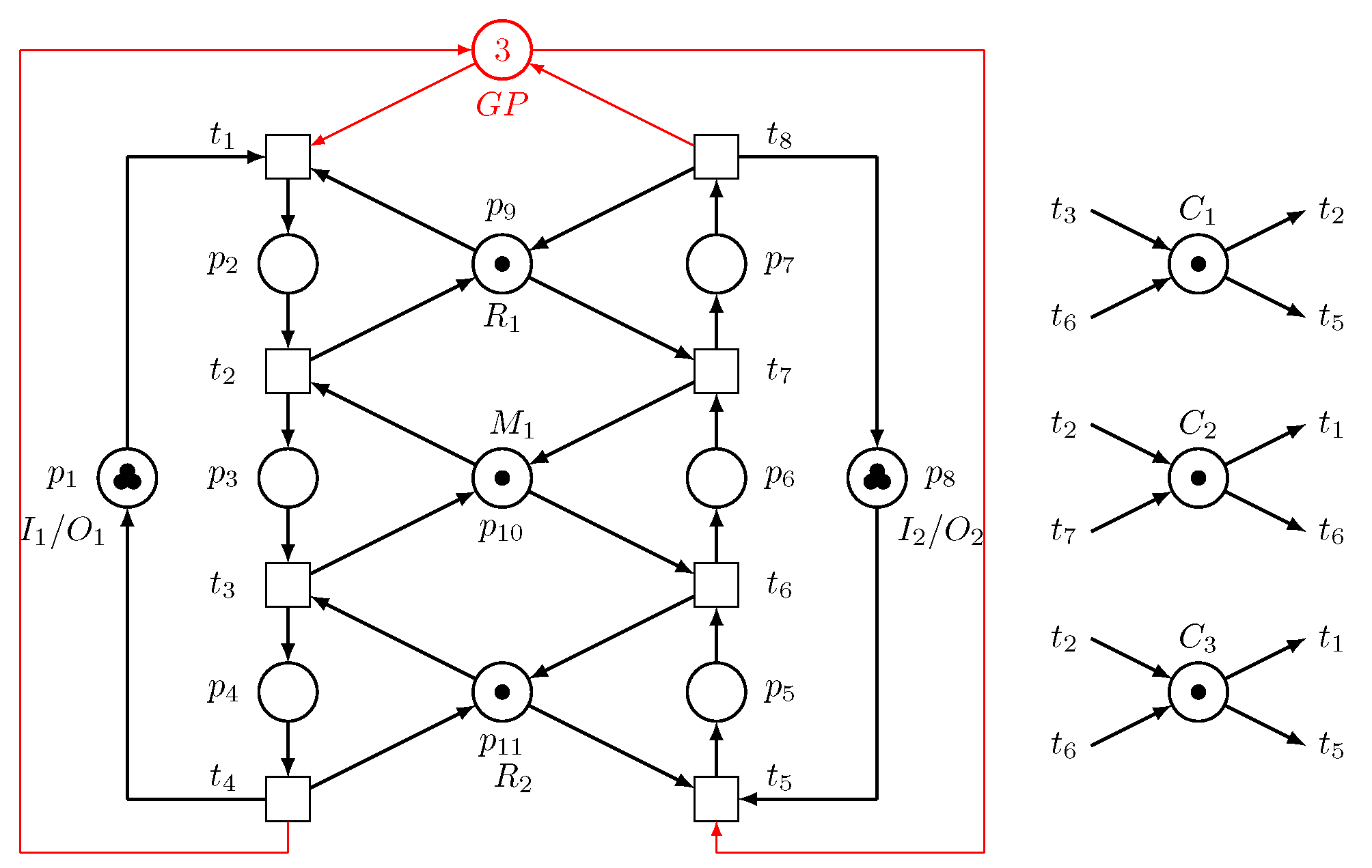

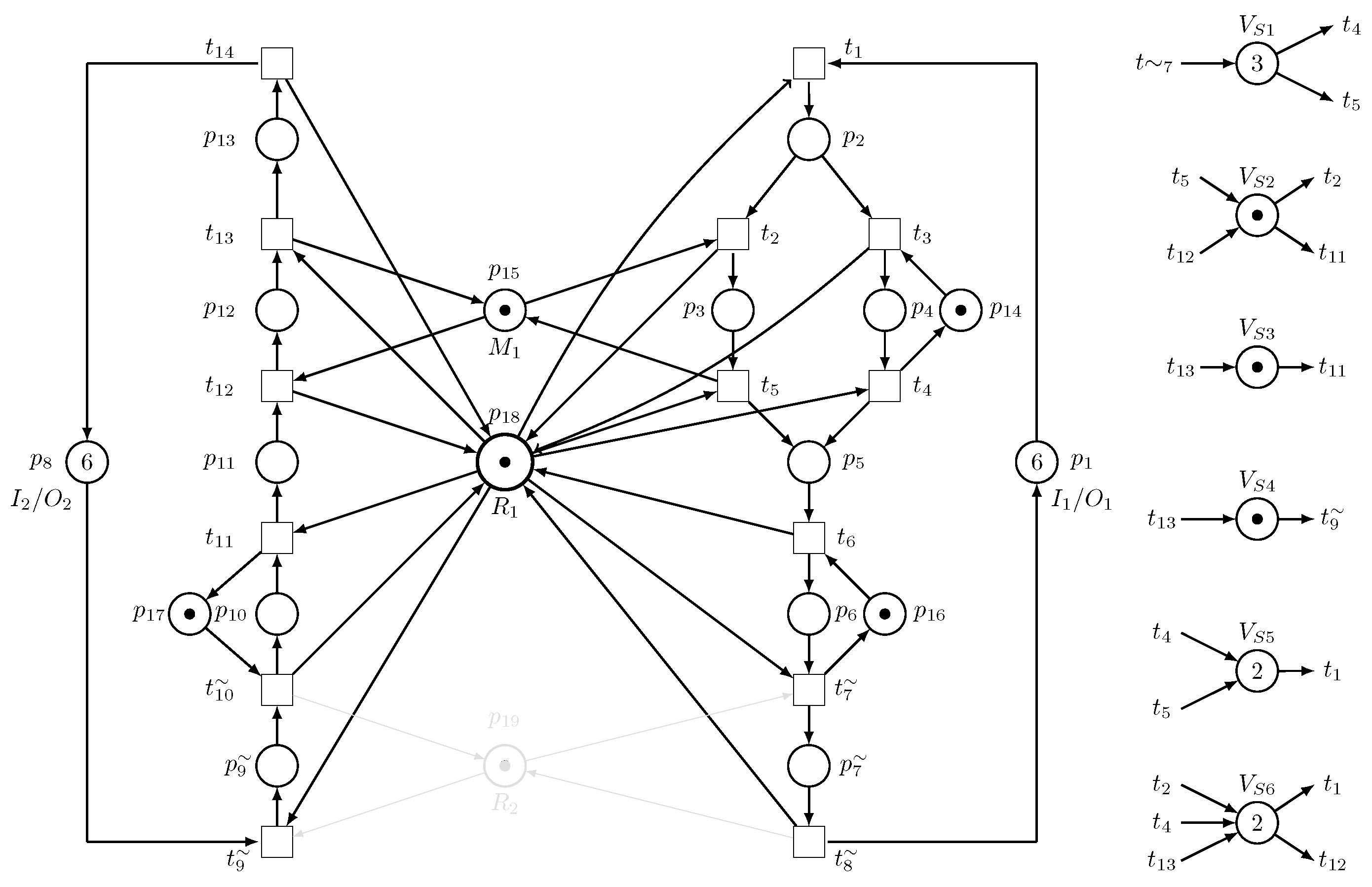

Example 2. Consider the system in Figure 1. It is a fact that when fails, all the processes in the system stop. If a robot that is reliable is introduced as an LSRE, both and can actively load and unload parts to/from , and if fails, can step up and take over performing the tasks of loading and unloading the parts until is repaired. This fact is depicted in Figure 3 and the Petri net model of the manufacturing cell is visualized in Figure 4. The production sequence of the new robotic manufacturing cell becomes: The tasks of loading or unloading parts are shared equally by and the added LSRE . The tasks represented by activity places and that are being performed by in Example 1 are no longer performed by . They are now being taken care of by . Hence, and become holders of , i.e., and the set of holders of becomes . The following definition can naturally be derived from Example 2.

Definition 2. Let be a marked USPR of an AMS with an unreliable target resource . Let be the set of activity places that form the holder of . A resource is said to be an LSRE of if (i) , (ii) it shares the tasks with such that there exists an activity place such that and hold after the introduction of into the system, and (iii) it can perform all the tasks of in the event of an failure.

Remark 1. From Definition 2 and Example 2, the introduction of an LSRE is done by connecting to the input and output transitions of via arcs and removing all the arcs connecting to the input and output transitions of p.

Definition 3. Let be a marked UPR of an AMS with an unreliable target. Let , , be the subnet of the load-sharing redundant element, where is the load-sharing redundant element, and . An SPR with an added load-sharing element is an SPR Petri net model denoted by SU-SPR and defined as .

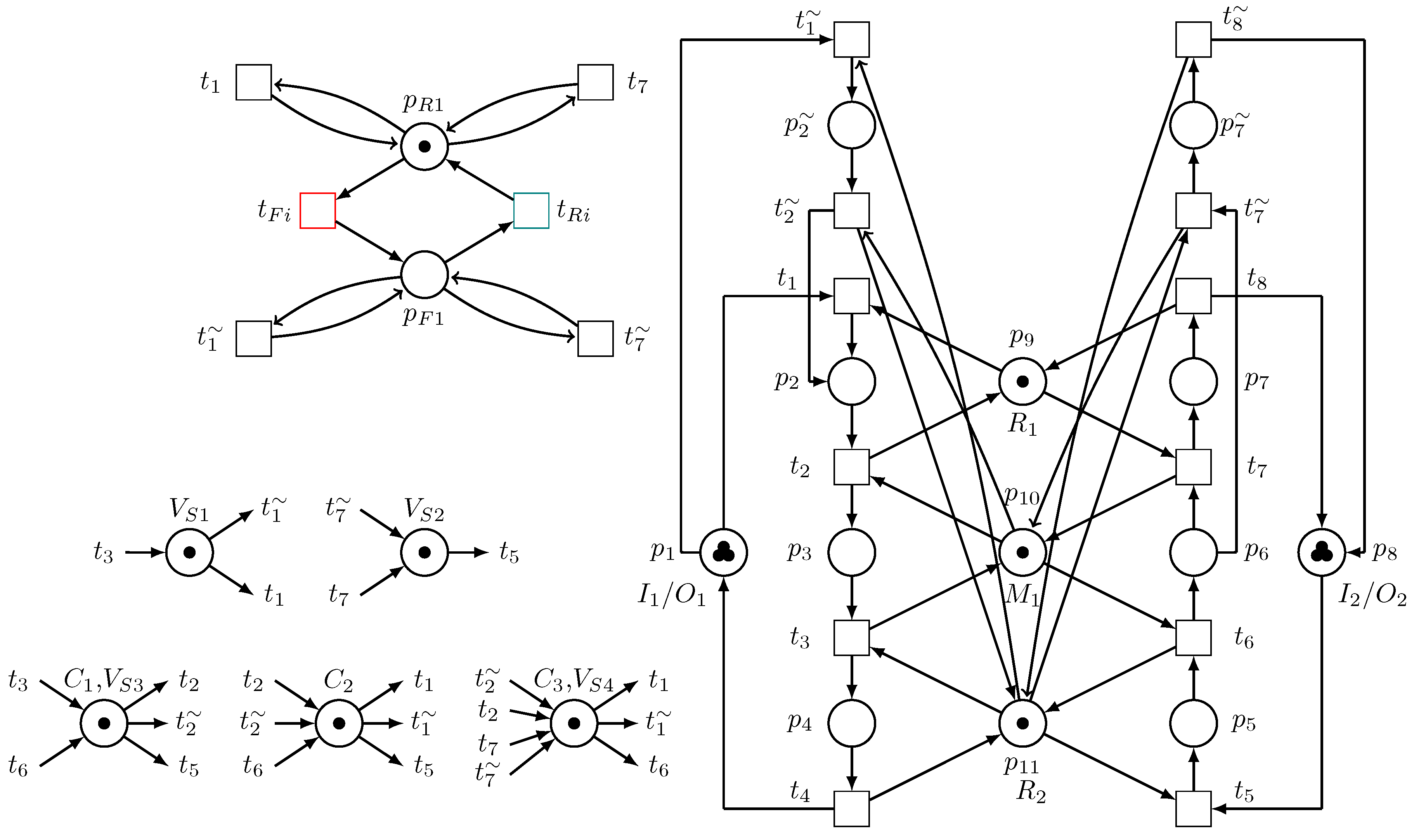

If the unreliable target resource fails, the load-sharing redundant element becomes the only resource that is operating and performing all the tasks. The Petri net model obtained as a result of adding an LSRE to a Petri net of an AMS with unreliable resource does not model the failure and recovery of and how can process parts that are supposed to be processed by if fails. In this case, we need a switch subnet that models the failure and recovery of . The switch submodel is a controller that is switched on when fails in order for to take over and process any ; when is repaired, the controller is switched off and resumes processing the parts that require it.

Definition 4. Let be a Petri net of an AMS with an unreliable target element and an LSRE. Let , , be a switch submodel, where is the load-sharing redundant resource, represents the condition under which an unreliable resource is operational, models the failure of , represents the condition in which is processing under the failure of , denotes the failure event of , is the recovery event of , , and . Moreover, we define Definition 5. Let be a Petri net of an AMS with an unreliable target element and an added load-sharing redundant element, and let be a switch submodel. A Petri net model with an unreliable element, an added load-sharing redundant element and a switch submodel is the composition of and , denoted by , , where ⊗ defines the composition of two Petri net models.

Example 3. Figure 5 shows the switch submodel of the unreliable target element of Figure 5 and Figure 6 represents the Petri net model of the system with an added switch submodel. Figure 7 shows what the system will be like with only the load-sharing redundant element operating, while Figure 8 describes what the Petri net model of the system will be like if both unreliable and loading sharing redundant resources (robots) are operating. The function of the switch submodel is to switch between these two conditions whenever there are failures and recoveries in the system. 5. Experimental Results

This section uses real-world examples with a significant state space to demonstrate the applicability and efficacy of our suggested strategy.

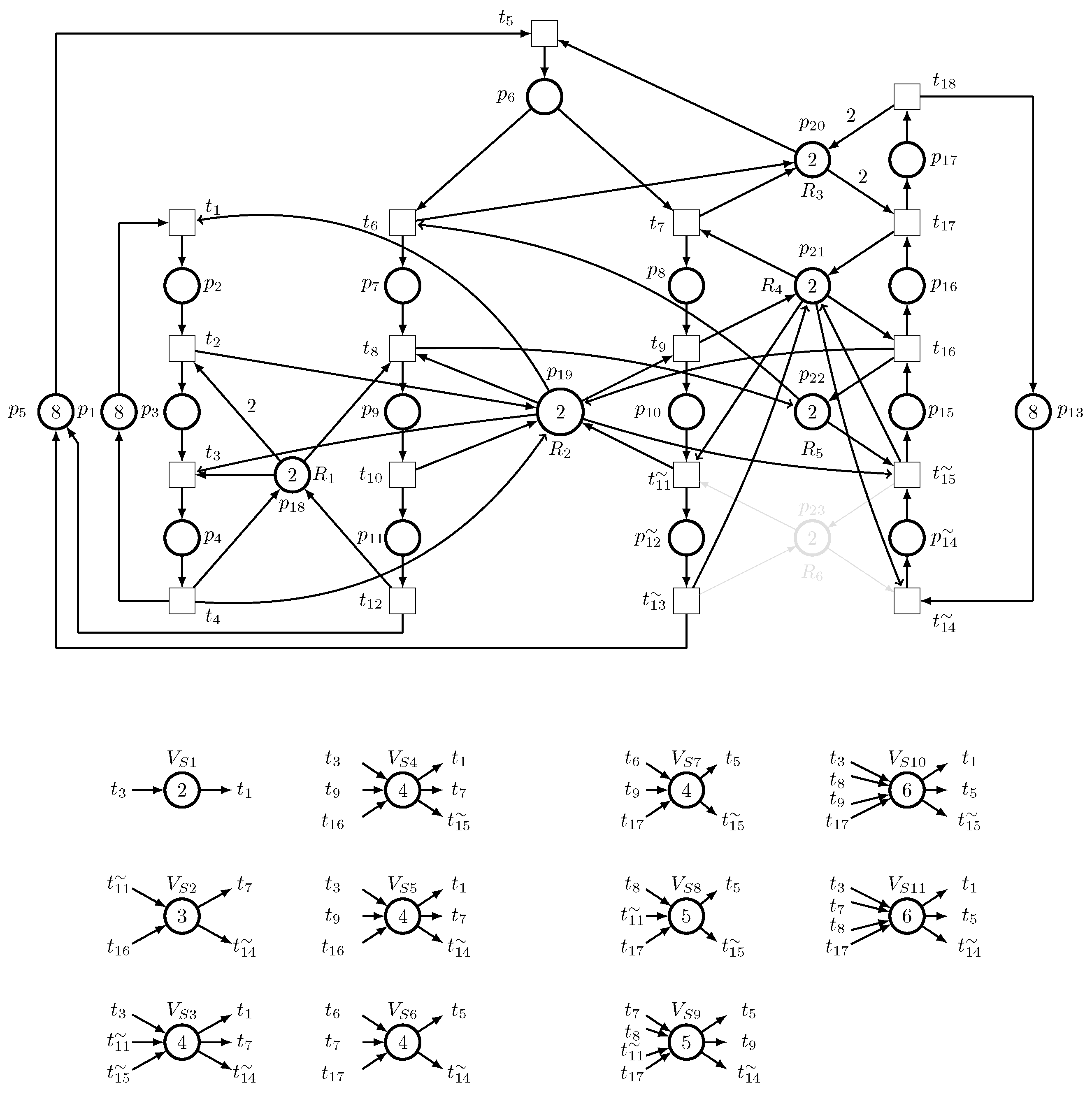

Example 4. Consider a robotic manufacturing cell [56] consisting of two loading buffers –, four machines –, two robots – ( introduced as an LSRE and an unreliable robot), and two unloading buffers –, as shown in Figure 18. Its Petri net model of the AMS is shown in Figure 19. There are 14 transitions and 19 places. It has the following place partitions: , , and . It has 282 reachable states, 77 of which are bad states and thus, a maximally permissive LES should have 205 states. Consider the system operating using the load-sharing redundant robot

only, i.e., an unreliable robot

fails, as shown in

Figure 20. In this case, the monitors are provided for a Petri net model using the TGAL method, as shown in

Table 5.

In the case when both unreliable and loading-sharing redundant resources (robots) are operating, i.e., an unreliable robot

is not a failure, as depicted in

Figure 21, the monitors for the Petri net model are provided using the TGAL method, as shown in

Table 6.

In the third stage, the two Petri net models resulting from the first and second stages, respectively, are merged into a unified Petri net model, and any deadlocks that may have occurred as a result of their combination are addressed, as shown in

Figure 22. Furthermore, redundant control places in the final model are discovered and deleted.

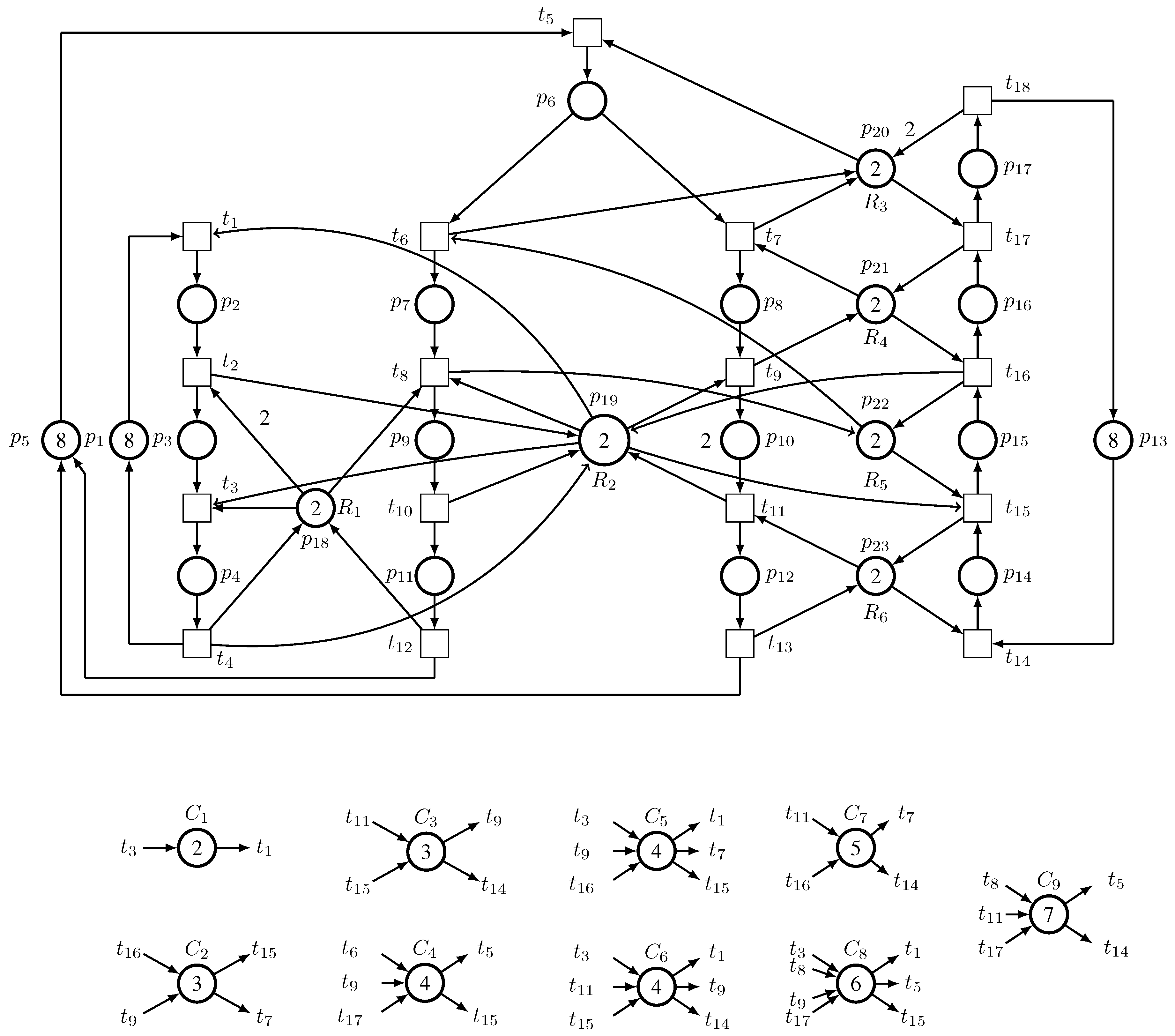

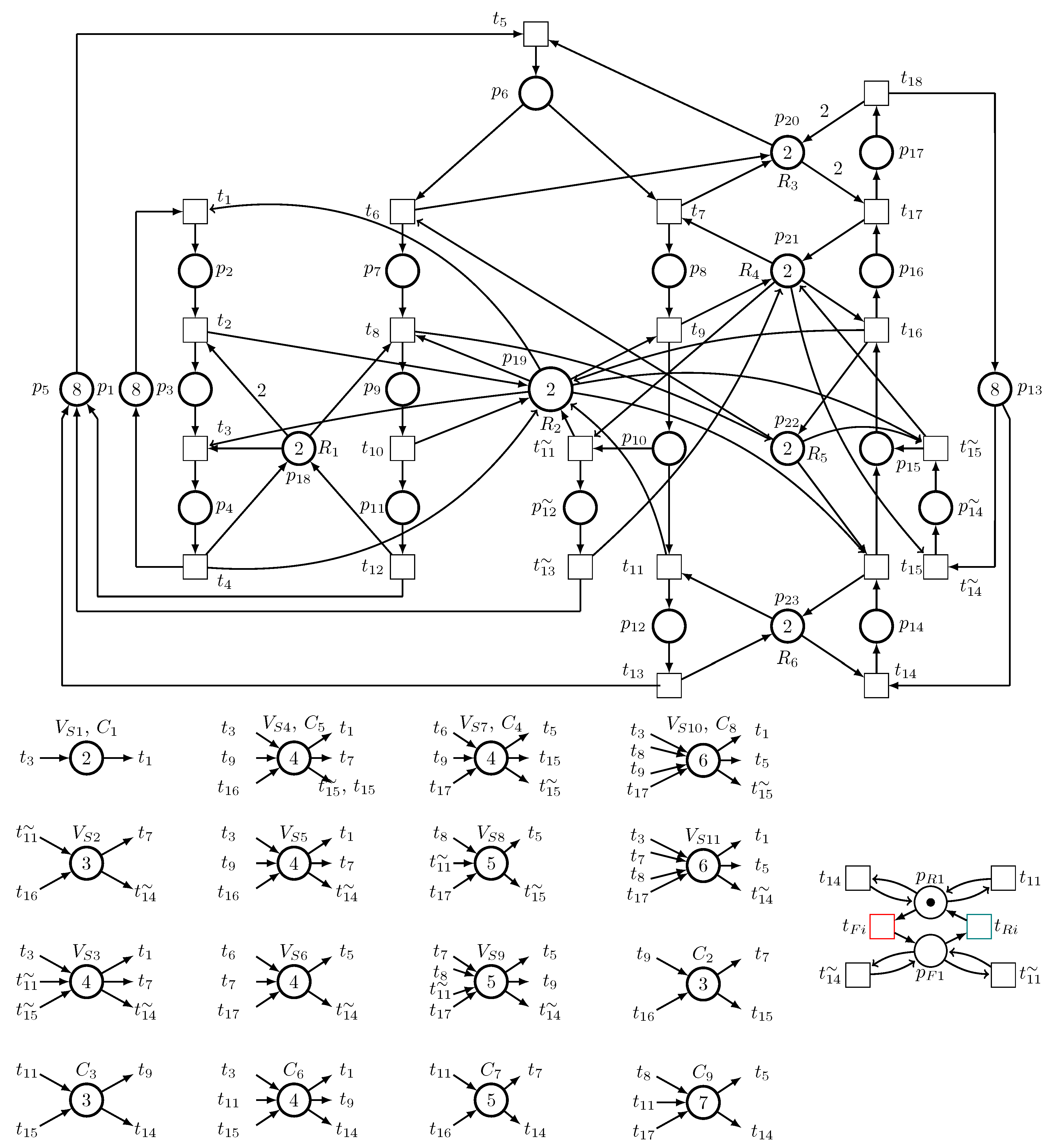

Example 5. Consider a robotic manufacturing cell [57] containing six robots, – ( introduced as an LSRE and an unreliable robot), and the SR Petri net model of the manufacturing cell is visualized in Figure 23, where , , , , , and . Consider the system operating using the load-sharing redundant robot

, i.e., an unreliable robot

fails, as shown in

Figure 24. In this case, the monitors are provided for a Petri net model using the TGAL method, as given in

Table 7.

In the case when both unreliable and loading-sharing redundant resources (robots) are operating, i.e., an unreliable robot

is not a failure, as depicted in

Figure 25, the monitors for the Petri net model are provided using the TGAL method, as shown in

Table 8.

The third stage is the merging stage, and in the following, two Petri net models resulting from the first stage and the second stage are merged as a unified Petri net model, and deadlocks that may exist as a result of their combination are resolved as shown in

Figure 26. Moreover, redundant control places from the resulting final model are identified and removed.

Finally, simulation is an important method for evaluating the performance and validating a proposed method. TINA (TIme Petri Net Analyzer) is a software application that simulates, evaluates, and models discrete event systems using Petri net models [

58]. To validate the proposed method, a simulation was performed using an applied example (the previous Example 1) based on TINA.

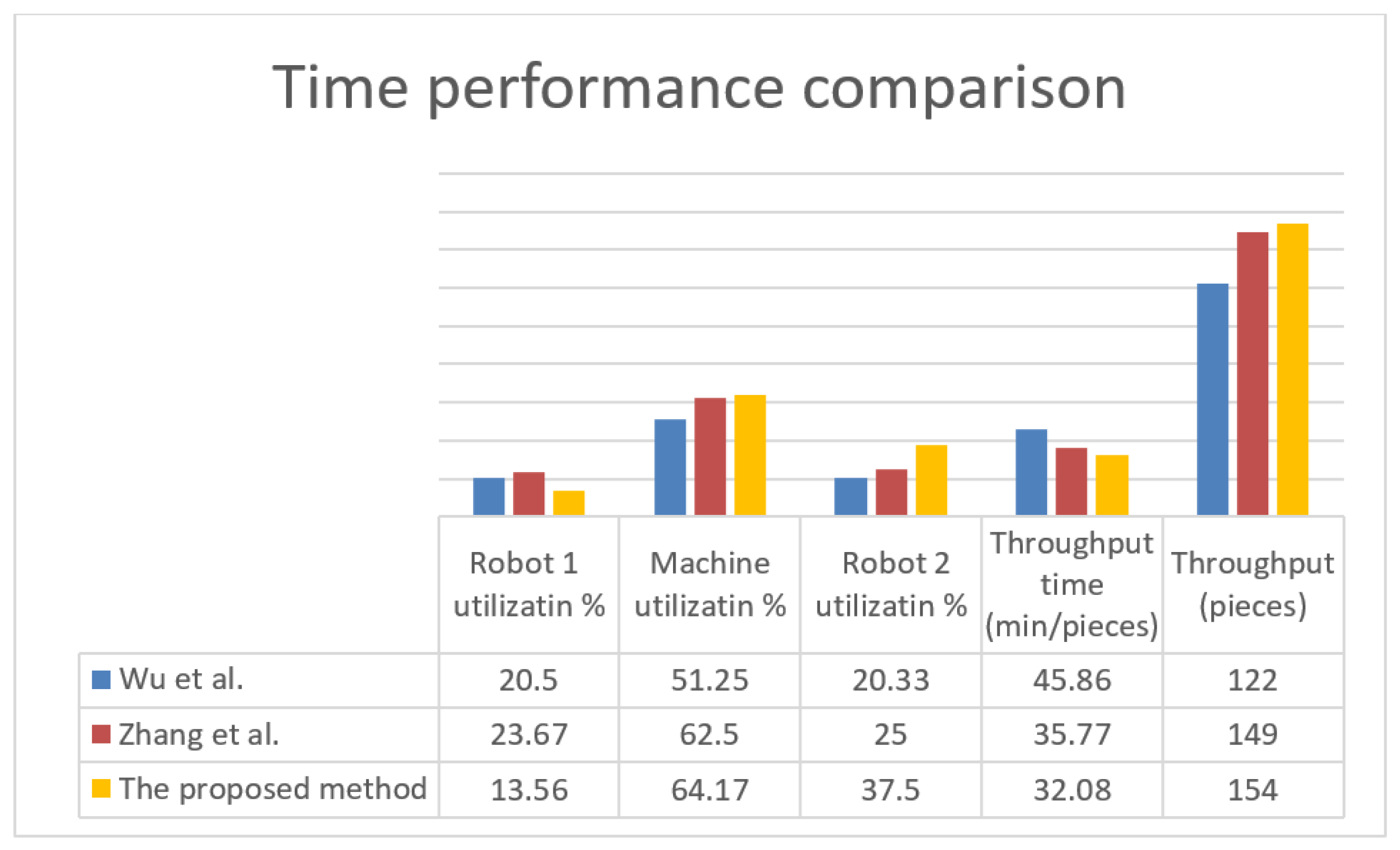

The proposed method was compared with the methods by Wu et al. [

59] and Zhang et al. [

60] for its testing and validation. In the simulation, we considered failures that happened to the target elements after a period of operation for the system over different time periods. We obtained the results as summarized in

Table 9 after running and simulating the Petri net model using TINA tools, which illustrated a comparison of the performance of the proposed method and that of other methods in the literature.

Figure 27 depicts the results in terms of machine and robot utilization, the throughput of parts

and

, work-in-process, and total time in the system (throughput time). In terms of throughput, the productivity of other techniques was less than that of the proposed method. The proposed method achieved better results than the other techniques in terms of work-in-process. In terms of throughput time for parts

and

, the proposed method achieved a lower overall throughput time than other techniques. As a result, the proposed method is valid, can produce adequate results, and can potentially be applied to other cases.