Assessing the Green Technology Innovation Efficiency in Yangtze River Delta Region under Dual Carbon Background

Abstract

:1. Introduction

2. Literature Review

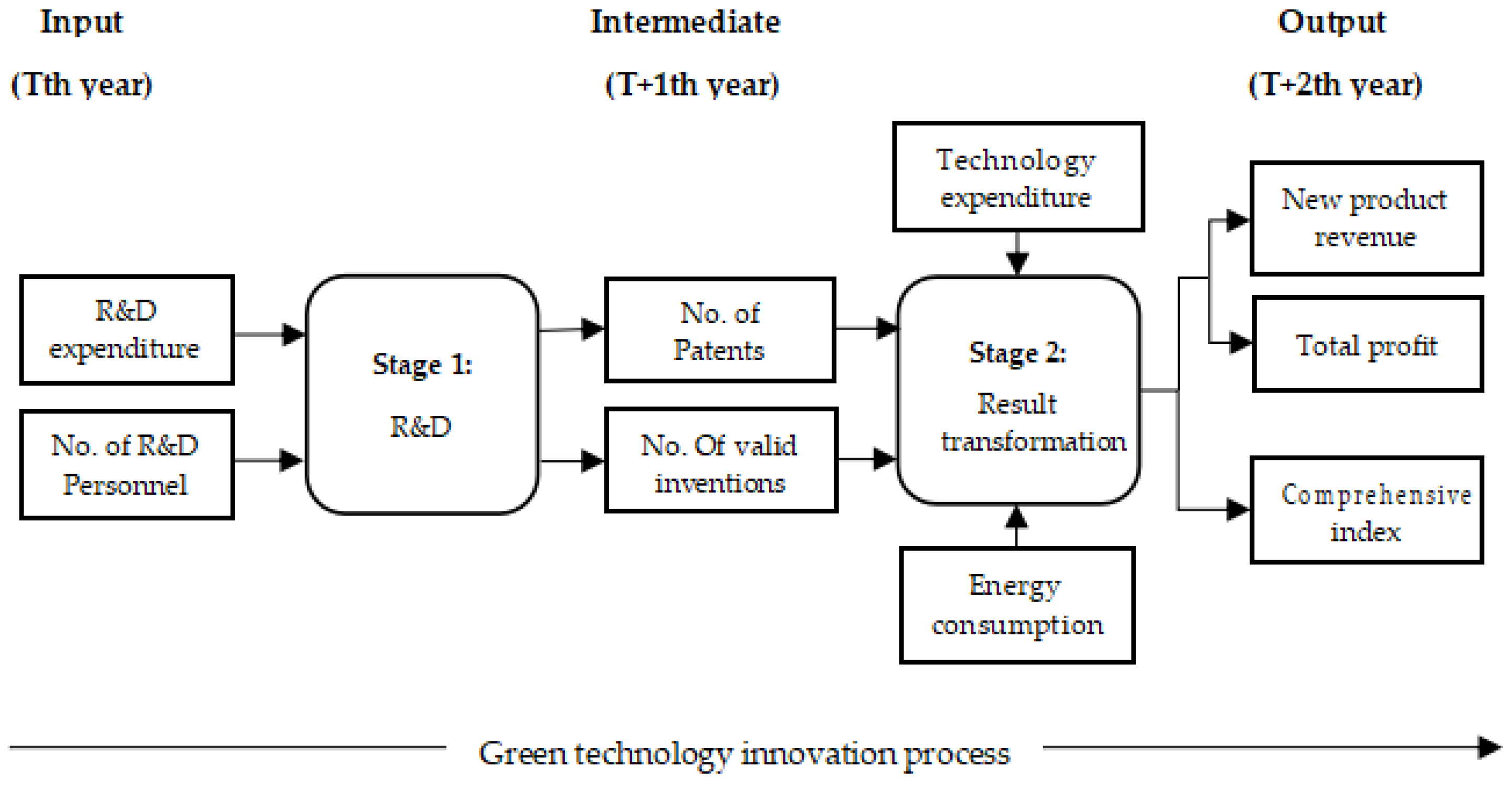

3. Data and Methodology

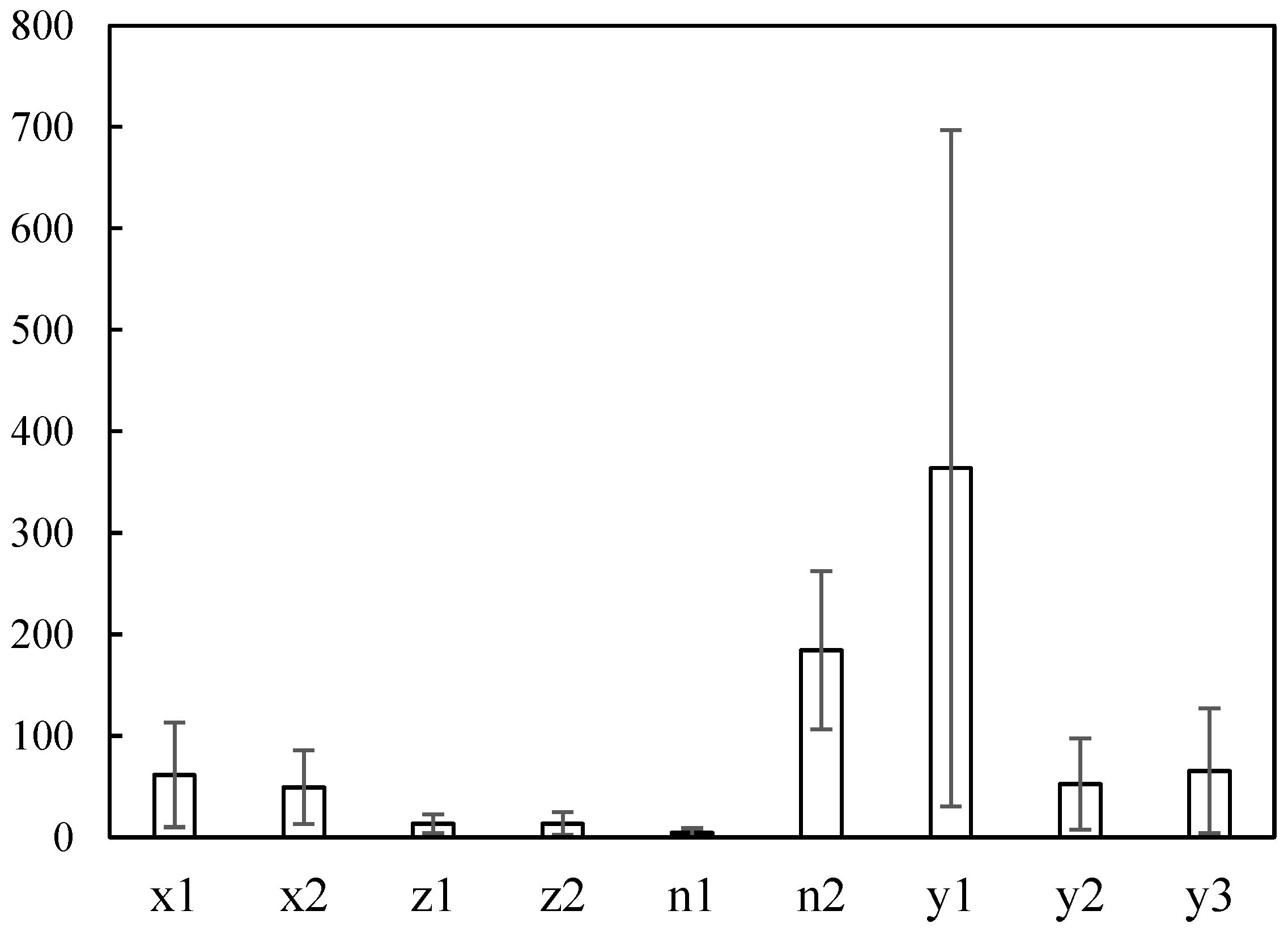

3.1. Data

3.2. Methodology

4. Empirical Analysis

4.1. Preliminary Analysis

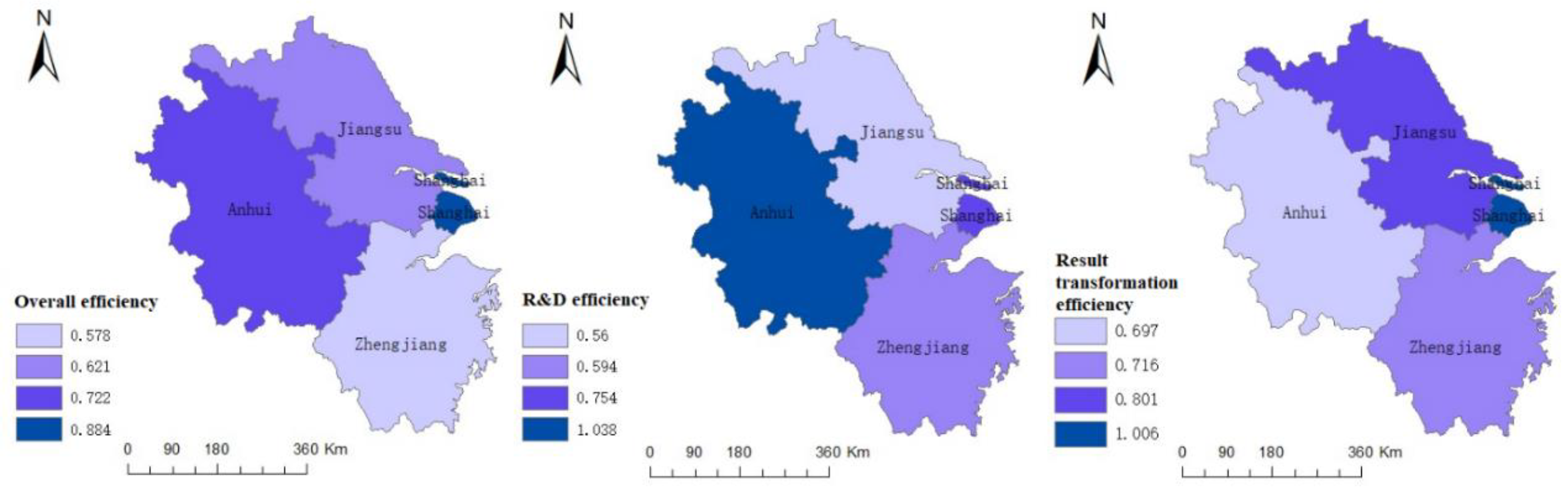

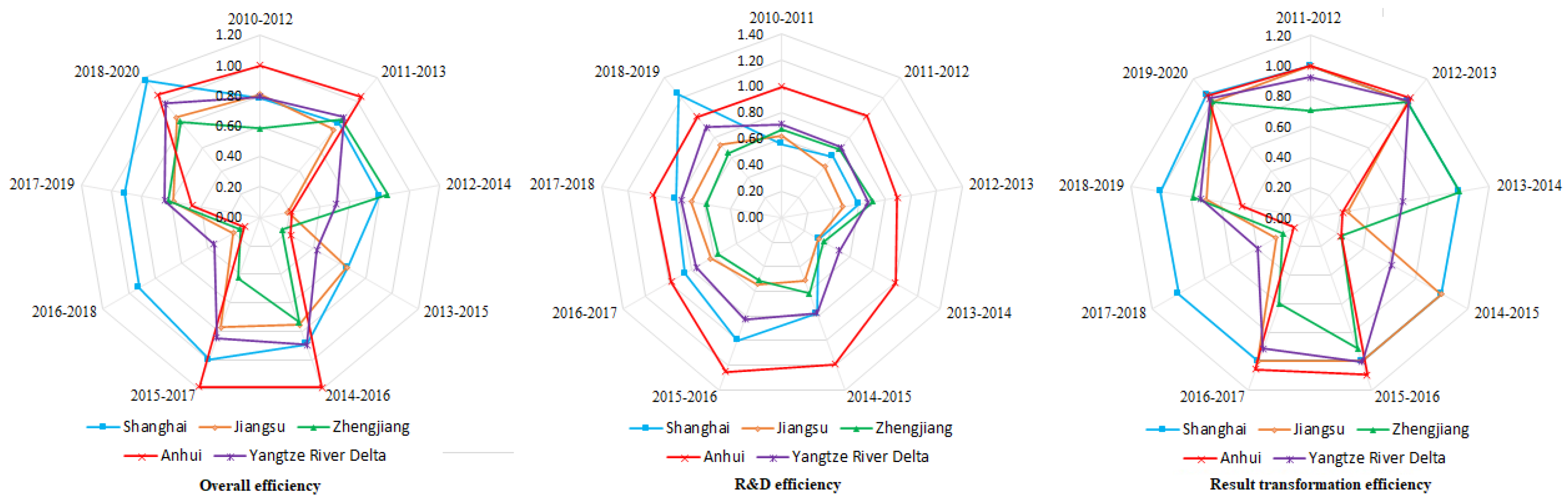

4.2. Distribution Analysis of Green Technology Innovation Efficiency by Region

4.2.1. Overall Efficiency

4.2.2. R&D Efficiency

4.2.3. Rseult Transformation Efficiency

5. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Wang, B.; Wu, Y.R.; Zhang, W.; Zhang, J.Q. Green technology innovation paths and policy paradigm transformation in the context of “Dual Carbon” target. Sci. Manag. Res. 2022, 40, 2–6. [Google Scholar]

- Qi, S.Z.; Xu, J. Environmental regulation and Low carbon international competitiveness of Manufacturing: A reexamination of the G20 Porter Hypothesis. Wuhan Univ. J. Philos. Soc. Sci. 2018, 71, 132–144. [Google Scholar]

- Brawn, E.; Wield, D. Regulation as a Means for the Social Control of Technology. Technol. Anal. Strateg. Manag. 1994, 6, 259–272. [Google Scholar] [CrossRef]

- Sun, Y.M.; Chen, S.M. Spatial and temporal evolution patterns and drivers of green technology innovation efficiency in the YRD region. Geogr. Res. 2021, 40, 2743–2759. [Google Scholar]

- Guo, H.R.; Li, S.Q. Analysis of green technology innovation efficiency and influencing factors of mining enterprises. Min. Res. Dev. 2022, 42, 187–192. [Google Scholar]

- Zhao, L.Y.; Miao, S.J.; Wu, T. Evaluation of green technology innovation efficiency of manufacturing industry in Shaanxi Province based on DEA-BCC and Malmquist. Future Dev. 2020, 44, 107–112. [Google Scholar]

- Huang, W.H.; Wang, M.D. Measuring the efficiency of green technology innovation in manufacturing industry in Yangtze River Economic Zone. Stat. Decis. Mak. 2021, 37, 61–63. [Google Scholar]

- Yuan, Y.J.; Chen, Z. Environmental regulation, green technology innovation and the transformation and upgrading of Chinese manufacturing industry. Sci. Res. 2019, 37, 1902–1911. [Google Scholar]

- Awan, U.; Nauman, S.; Sroufe, R. Exploring the effect of buyer engagement on green product innovation: Empirical evidence from manufacturers. Bus. Strategy Environ. 2020, 30, 463–477. [Google Scholar] [CrossRef]

- Li, Y.T.; Zhu, Z.Y. Institutional supply and green innovation efficiency in Chinese regions. J. Beijing Univ. Technol. Soc. Sci. Ed. 2019, 21, 50–58. [Google Scholar]

- Zhang, F.; Shi, Z.W.; Song, X.; Yan, X. Green technology innovation efficiency of high-tech manufacturing industry and its environmental regulation threshold effect. Sci. Technol. Prog. Countermeas. 2019, 36, 62–70. [Google Scholar]

- Liu, H.W.; Wang, Y.Q.; Shi, H.J. Green innovation efficiency and synergistic development of logistics industry—An empirical study from innovative cities in the Pearl River Delta. Logist. Technol. 2021, 40, 34–39+117. [Google Scholar]

- Lin, S.; Sun, J.; Marinova, D.; Zhao, D. Evaluation of the green technology innovation efficiency of China’s manufacturing industries: DEA window analysis with ideal window width. Technol. Anal. Strateg. Manag. 2018, 30, 1166–1181. [Google Scholar] [CrossRef]

- Zeng, J.Y.; Škare, M.; Lafont, J. The co-integration identification of green innovation efficiency in YRD region. J. Bus. Res. 2021, 134, 252–262. [Google Scholar] [CrossRef]

- Yang, H.C.; Zhu, X. Research on Green Innovation Performance of Manufacturing Industry and Its Improvement Path in China. Sustainability 2022, 14, 8000. [Google Scholar] [CrossRef]

- Li, T.; Liang, L.; Han, D. Research on the efficiency of green technology innovation in China’s provincial high-end manufacturing industry based on the RAGA-PP-SFA model. Math. Probl. Eng. 2018, 2018, 9463707. [Google Scholar] [CrossRef]

- Tone, K.; Tsutsui, M. Network DE: A SlacksBased Measure Approach. Eur. J. Oper. Res. 2009, 197, 243–252. [Google Scholar] [CrossRef]

- Ma, H.Y. Study on the efficiency of logistics development in Chinese provinces based on SBM-DEA model. Logistics Eng. Manag. 2022, 44, 113–116. [Google Scholar]

- Cole, M.A.; Elliott, R.J.; Shimamoto, K. Industrial characteristics, environmental regulations and air pollution: An analysis of the UK manufacturing sector. J. Environ. Econ. Manag. 2005, 50, 121–143. [Google Scholar] [CrossRef]

- He, Y.J.; Cai, D.Y. Analysis of green technology innovation efficiency of industrial enterprises in YRD and its influencing factors. Chongqing Soc. Sci. 2021, 1, 49–63. [Google Scholar]

- Wang, S.Q.; Wang, H. A study on technological efficiency and drivers of high-tech industries in China-Based on chain-linked network DEA model. J. Shandong Univ. Sci. Technol. 2015, 17, 13–21. [Google Scholar]

- Yang, Y.; Tian, Y.B.; Yin, T.B. Research on innovation efficiency of high-tech industries in Chongqing from the perspective of innovation value chain—Based on three-stage chain network DEA model. Technol. Econ. 2020, 33, 36–40. [Google Scholar]

- Liu, M.Y.; Yuan, B.L. Spatial heterogeneity effect of environmental regulation and green innovation efficiency-Based on data of industrial enterprises in Yangtze River Economic Zone. Financ. Account. Mon. 2018, 24, 144–153. [Google Scholar]

- Judge, W.Q.; Douglas, T.J.; Kutan, A.M. Institutional antecedents of corporate governance legitimacy. J. Manag. 2008, 34, 765–785. [Google Scholar] [CrossRef]

| Author | Method | Key Findings |

|---|---|---|

| Guo et al. (2022) [5] | Network DEA model | Ecological and green growth are primarily benefited from green innovation development. |

| Zhao et al. (2020) [6] | DEA-BCC model | Innovations in green techniques are essential to improving the enterprises’ green technology efficiency values. |

| Huang et al. (2021) [7] | Super-EBM model | The differentiation resulting from uncoordinated development affects the level of green technology innovation development in the overall region. |

| Yuan et al. (2019) [8] | GMM model | The manufacturing industry in the central region of China will achieve the transformation and upgrading of the manufacturing industry earlier. |

| Li et al. (2019) [16] | Network DEA model | Regional differentiation in innovation efficiency can occur due to differences in various characteristics in different regions. |

| Zhang et al. (2019) [11] | Network DEA model | Enterprises can turn most of their R&D achievements into profits at the commercialization stage. |

| Liu et al. (2021) [12] | Network DEA model | Maintaining a stable innovation input and controlling unwanted outcomes are crucial for the development of green innovation efficiency. |

| Lin et al. (2018) [13] | DEA window model | Technological innovation is necessary for enterprises to achieve their development. |

| Zeng et al. (2021) [14] | Super-SBM model | Enterprises need to increase their investment in the green technology innovation process. |

| Li et al. (2018) [10] | RAGA-PP-SFA model | High-end manufacturing industries across regions reported a lower value of green technology innovation efficiency than traditional technology innovation efficiency. |

| Yang et al. (2022) [15] | Three-stage DEA model | Chinese manufacturers have a comparatively low degree of green innovation efficiency. |

| Variable | Abbreviation | Explanation |

|---|---|---|

| R&D expenditure | R&D_E | The expenditure from the research and development process |

| No. of patents | Patents | The number of patent applications |

| No. of valid inventions | Inventions | The number of valid inventions |

| Technology expenditure | Technology_E | The sum of expenditure for the acquisition of foreign technology, expenditure for the assimilation of technology, expenditure for the purchase of domestic technology, and expenditure for technical renovation |

| Energy consumption | Energy_C | Consumption of energy |

| New product revenue | New_product | The revenue gathered from new products |

| Total profit | Total_Profit | The sum of profits |

| Comprehensive index of environmental pollution | Pollution_Index | Comprehensive index generated from the result by entropy method on the emissions of “three wastes”, including industrial wastewater emissions, industrial sulphur dioxide emissions, and industrial soot emissions |

| Overall efficiency | E | The value of the efficiency of the whole technological innovation process |

| R&D efficiency | E1 | The value of efficiency generated from the research and development sub-process |

| Result transformation efficiency | E2 | The value of efficiency generated from result transformation sub-process |

| Variable | Obs. | Min | Max | Mean | S.D. | ||

|---|---|---|---|---|---|---|---|

| Inputs | x1 | R&D_E | 44 | 6.020 | 210.260 | 61.687 | 51.625 |

| x2 | Patents | 44 | 6.690 | 118.290 | 49.383 | 36.479 | |

| Intermediates | z1 | Inventions | 44 | 2.290 | 40.790 | 13.380 | 9.342 |

| z2 | Technology_E | 44 | 0.690 | 47.540 | 13.538 | 11.343 | |

| n1 | Energy_C | 44 | 0.700 | 14.620 | 4.608 | 4.333 | |

| n2 | New_product | 44 | 105.700 | 325.260 | 184.377 | 78.064 | |

| Outputs | y1 | Total_Profit | 44 | 38.980 | 1246.980 | 363.695 | 333.427 |

| y2 | Pollution_Index | 44 | 12.090 | 147.690 | 52.486 | 45.159 | |

| y3 | R&D_E | 44 | 1.000 | 216.000 | 65.600 | 61.468 | |

| x1 | x2 | z1 | z2 | n1 | n2 | y1 | y2 | y3 | |

|---|---|---|---|---|---|---|---|---|---|

| x1 | 1 | 0.913 ** | 0.966 ** | 0.968 ** | 0.654 ** | 0.844 ** | 0.930 ** | 0.738 ** | 0.695 ** |

| x2 | 0.913 ** | 1 | 0.954 ** | 0.818 ** | 0.798 ** | 0.962 ** | 0.959 ** | 0.866 ** | 0.852 ** |

| z1 | 0.966 ** | 0.954 ** | 1 | 0.918 ** | 0.688 ** | 0.911 ** | 0.961 ** | 0.770 ** | 0.759 ** |

| z2 | 0.968 ** | 0.818 ** | 0.918 ** | 1 | 0.479 ** | 0.717 ** | 0.839 ** | 0.563 ** | 0.567 ** |

| n1 | 0.654 ** | 0.798 ** | 0.688 ** | 0.479 ** | 1 | 0.889 ** | 0.814 ** | 0.968 ** | 0.872 ** |

| n2 | 0.844 ** | 0.962 ** | 0.911 ** | 0.717 ** | 0.889 ** | 1 | 0.955 ** | 0.928 ** | 0.922 ** |

| y1 | 0.930 ** | 0.959 ** | 0.961 ** | 0.839 ** | 0.814 ** | 0.955 ** | 1 | 0.887 ** | 0.822 ** |

| y2 | 0.738 ** | 0.866 ** | 0.770 ** | 0.563 ** | 0.968 ** | 0.928 ** | 0.887 ** | 1 | 0.860 ** |

| y3 | 0.695 ** | 0.852 ** | 0.759 ** | 0.567 ** | 0.872 ** | 0.922 ** | 0.822 ** | 0.860 ** | 1 |

| E | YRD | E2 | YRD | E3 | YRD |

|---|---|---|---|---|---|

| 2010–2012 | 0.795 | 2010–2011 | 0.715 | 2011–2012 | 0.927 |

| 2011–2013 | 0.859 | 2011–2012 | 0.703 | 2012–2013 | 1.008 |

| 2012–2014 | 0.511 | 2012–2013 | 0.668 | 2013–2014 | 0.618 |

| 2013–2015 | 0.430 | 2013–2014 | 0.504 | 2014–2015 | 0.618 |

| 2014–2016 | 0.894 | 2014–2015 | 0.774 | 2015–2016 | 1.003 |

| 2015–2017 | 0.847 | 2015–2016 | 0.826 | 2016–2017 | 0.913 |

| 2016–2018 | 0.353 | 2016–2017 | 0.756 | 2017–2018 | 0.397 |

| 2017–2019 | 0.643 | 2017–2018 | 0.779 | 2018–2019 | 0.734 |

| 2018–2020 | 0.978 | 2018–2019 | 0.902 | 2019–2020 | 1.027 |

| Average | 0.701 | Average | 0.736 | Average | 0.805 |

| Time Period | Shanghai | Jiangsu | Zhejiang | Anhui | YRD |

|---|---|---|---|---|---|

| 2010–2012 | 0.782 | 0.811 | 0.587 | 1.000 | 0.795 |

| 2011–2013 | 0.805 | 0.755 | 0.840 | 1.036 | 0.859 |

| 2012–2014 | 0.798 | 0.183 | 0.853 | 0.209 | 0.511 |

| 2013–2015 | 0.663 | 0.661 | 0.163 | 0.232 | 0.430 |

| 2014–2016 | 0.891 | 0.754 | 0.739 | 1.193 | 0.894 |

| 2015–2017 | 1.000 | 0.771 | 0.426 | 1.189 | 0.847 |

| 2016–2018 | 0.928 | 0.207 | 0.156 | 0.122 | 0.353 |

| 2017–2019 | 0.912 | 0.583 | 0.619 | 0.459 | 0.643 |

| 2018–2020 | 1.173 | 0.863 | 0.822 | 1.054 | 0.978 |

| Average | 0.883 | 0.621 | 0.578 | 0.722 | 0.701 |

| Time Period | Shanghai | Jiangsu | Zhejiang | Anhui | YRD |

|---|---|---|---|---|---|

| 2010–2011 | 0.563 | 0.623 | 0.675 | 1.000 | 0.715 |

| 2011–2012 | 0.610 | 0.510 | 0.680 | 1.011 | 0.703 |

| 2012–2013 | 0.596 | 0.474 | 0.705 | 0.898 | 0.668 |

| 2013–2014 | 0.325 | 0.322 | 0.368 | 1.000 | 0.504 |

| 2014–2015 | 0.781 | 0.509 | 0.617 | 1.190 | 0.774 |

| 2015–2016 | 1.000 | 0.542 | 0.508 | 1.252 | 0.826 |

| 2016–2017 | 0.856 | 0.627 | 0.560 | 0.979 | 0.756 |

| 2017–2018 | 0.824 | 0.706 | 0.587 | 1.000 | 0.779 |

| 2018–2019 | 1.230 | 0.726 | 0.643 | 1.008 | 0.902 |

| Average | 0.754 | 0.560 | 0.594 | 1.038 | 0.736 |

| Time Period | Shanghai | Jiangsu | Zhejiang | Anhui | YRD |

|---|---|---|---|---|---|

| 2011–2012 | 1.000 | 1.000 | 0.708 | 1.000 | 0.927 |

| 2012–2013 | 1.000 | 1.000 | 1.000 | 1.031 | 1.008 |

| 2013–2014 | 1.000 | 0.253 | 1.000 | 0.221 | 0.618 |

| 2014–2015 | 1.000 | 1.000 | 0.238 | 0.232 | 0.618 |

| 2015–2016 | 1.000 | 1.000 | 0.914 | 1.098 | 1.003 |

| 2016–2017 | 1.000 | 1.000 | 0.598 | 1.056 | 0.913 |

| 2017–2018 | 1.000 | 0.259 | 0.205 | 0.124 | 0.397 |

| 2018–2019 | 1.000 | 0.695 | 0.784 | 0.459 | 0.734 |

| 2019–2020 | 1.058 | 1.000 | 1.000 | 1.050 | 1.027 |

| Average | 1.006 | 0.801 | 0.716 | 0.697 | 0.805 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, Y.; Zhou, L. Assessing the Green Technology Innovation Efficiency in Yangtze River Delta Region under Dual Carbon Background. Processes 2023, 11, 1082. https://doi.org/10.3390/pr11041082

Xie Y, Zhou L. Assessing the Green Technology Innovation Efficiency in Yangtze River Delta Region under Dual Carbon Background. Processes. 2023; 11(4):1082. https://doi.org/10.3390/pr11041082

Chicago/Turabian StyleXie, Yi, and Lingke Zhou. 2023. "Assessing the Green Technology Innovation Efficiency in Yangtze River Delta Region under Dual Carbon Background" Processes 11, no. 4: 1082. https://doi.org/10.3390/pr11041082

APA StyleXie, Y., & Zhou, L. (2023). Assessing the Green Technology Innovation Efficiency in Yangtze River Delta Region under Dual Carbon Background. Processes, 11(4), 1082. https://doi.org/10.3390/pr11041082