Abstract

The growing demand for energy and the concern about environmental impacts reinforce the necessity for renewable energy sources such as biofuels. In this study, cake generated in the babassu oil extraction was evaluated as a potential feedstock for solid biofuel production, and it contains a blend of cashew nutshell, sugarcane bagasse, carnauba straw, and carnauba stalk. All samples were characterized by proximate analysis and Higher Heating Value. Carbonization was used to improve energy performance and compaction to understand the mechanism and the characteristics of the biomasses compacted. In the extraction of babassu oil, fresh and aged (90 days) kernel samples were used. The fresh samples reached a yield of 59.8%, and the aged samples reached a yield of 70.66%. The carbonization of babassu cake was carried out in a Muffle furnace at temperatures of 250, 300, 350, and 400 °C. The fresh babassu cake showed an HHV of 23.06 MJ kg−1 and after carbonization of 28.07 (250 °C), 30.69 (300 °C), 28.24 (350 °C), and 18.27 MJ kg−1 (400 °C). At 400 °C, a decrease in HHV of 20.8% occurred, and an increase in Ash (%) of 195% occurred. Proximate analysis showed that biomasses are compatible, with some having a higher compatibility than other biological materials already used as fuels in the industry.

1. Introduction

Topics such as reducing Greenhouse Gas Emissions and energy security have been motivating countries to use renewable energy sources. In Brazil, the electricity matrix is predominantly renewable, with emphasis on hydroelectric sources, which account for 53.4% of the internal supply within Brazil [1]. Considering the internal supply of electricity in Brazil, renewable sources account for 78.1%; Brazil is a powerful country in the bioenergy sector. In 2021, biomass represented 8.8% of the installed capacity within the country, and sugarcane accounted for 16.4% of the internal energy supply, which amount to 49.4 × 106 toe (tons of oil equivalent) [1].

Regarding the use of biomass in the combustion field, this can be a safe source of energy because when biomass is burned or used to produce other types of biofuels, such as biodiesel or briquette, the biomass carbon reacts with oxygen in the air to form carbon dioxide [2]. However, if the biofuel is fully combusted, the amount of carbon dioxide produced is equal to the amount which was taken from the atmosphere during the growing stage of the plant. Thus, there is no contribution to the increase in CO2 emissions, and the biomass can be regarded as a carbon sink, which is known as the carbon cycle or zero carbon emissions. In contrast, if a fossil fuel is burned, a net addition of CO2 in the atmosphere occurs [2,3,4].

Among the sources of biomass are purpose-grown energy crops and wastes. Energy crops include woody and agricultural plants, and wastes include wood residues, agro-industrial residues, forestry residues, sewage, municipal solid wastes, and animal wastes [2,5,6]. In general, biomass is composed mainly of cellulose, hemicellulose, lignin, small amounts of lipids, proteins, simple sugars, and starches; it also contains inorganic constituents and a fraction of water [2,7,8]. Lignocellulosic biomass is a potential sustainable source compared to fossil fuels and coal, and sugarcane biomass is a good example. With the growing demand for bioenergy, it is crucial to investigate cheap raw materials with energy potential. Thus, this manuscript shows the evaluation of the babassu cake generated in the extraction of oil as feedstock for biofuel production. Babassu (Orbignya sp.) is a native palm tree from Brazil’s Northeast, especially in Maranhão and Piauí. The fruit weight varies between 90 and 280 g and is composed of four parts: endocarp (hard wooden inner part), epicarp (external fibrous part), mesocarp (layer of starch-rich granulous), and kernel (rich in oil) [9,10,11,12,13].

Despite the low cost and high energy potential, some characteristics inherent in biomass, such as low density, irregular shape and size, and high moisture content, may contribute to the low efficiency of combustion [2,14,15,16,17]. For this reason, an alternative is biomass densification technology, which facilitates transportation and has solved the inconvenience of low energy efficiency of the direct combustion of biomass [18,19,20,21,22,23,24,25,26]. The use of densified biomass for combustion can also show many advantages when compared to coal, firewood, or raw material: the compaction concentrates the calorific value per unit volume and has more uniform combustion. In addition to some logistical advantages such as facilitating transportation, handling, and storage, the use of densified biomass for combustion reduces the possibility of spontaneous combustion during storage and includes some ecological benefits, such as reducing particle emissions, decreasing deforestation by replacing the fuel wood, and helping to minimize the problem of residue disposal [2,18,19,20]. This work considered babassu cake, cashew nutshell, sugarcane bagasse, carnauba straw, and carnauba stalk as potential raw materials for the production of solid biofuel from their blends. Compaction was used as a strategy to densify biomasses and analyze them as probable solid fuels considering the increase in the higher volumetric energy content, which reduces transportation costs.

As reported, biomass can be burned directly as a fuel or as a solid fuel, which improves its energetic density. However, biomass’s energy quality can still be enhanced through thermal conversion processes such as carbonization, gasification, or pyrolysis [2,18]. Biomass carbonization is a technology that uses heat sources to generate volatiles from biomass pyrolysis and, thus, obtain a solid carbon of higher calorific value [21,22,23].

This paper aimed to present the characterization of the babassu cake and four types of agricultural residues—cashew nutshell, sugarcane bagasse, carnauba straw, and carnauba stalk—as potential raw materials for the production of solid biofuels from their blends. Proximate analysis (moisture, ash, volatile matter, and fixed carbon) was performed, and Higher Heating Value was determined for all samples, including the biomasses compacted (probable solid fuels) and carbonized babassu cake. Carbonization is a strategy to enrich the heating value and energy content of biomass, expanding its scientific and commercial applications. Thus, the behavior of biomass in the carbonization process is an important point to be studied. The carbonized samples were prepared using a Muffle Furnace and different temperatures. The novelty of the work was the evaluation of the waste generated in the babassu oil extraction as feedstock for the production of solid fuels in blends with various residual biomasses. The influence of carbonization on the babassu cake was also studied.

2. Materials and Methods

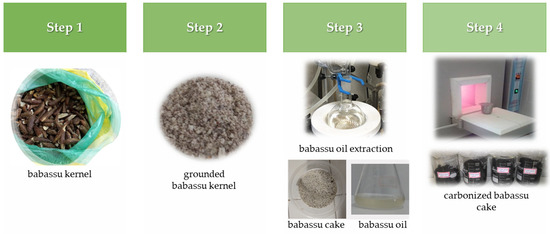

The raw materials used include babassu coconut, cashew nutshell, sugarcane bagasse, carnauba straw, and carnauba stalk (Figure 1). Babassu coconut was collected in São Luís-Maranhão-Brazil, geographical coordinates—Latitude: 2°31′51″ S and Longitude: 44°18′24″ W; carnauba straw and carnauba stalk were collected in Morrinhos-Ceará-Brazil, geographical coordinates—Latitude: 3°14′20″ S and Longitude: 40°7′0″ W; sugarcane bagasse and cashew nutshell in Redenção-Ceará-Brazil, geographical coordinates—Latitude: 4°13′35″ S and Longitude: 38°43′53″ W. The biomasses were ground, sieved, and stored in plastic bags until the execution of the experiments. Figure 2 shows specific steps in the preparation of babassu kernel (fresh and aged (storage condition (90 days))), babassu cakes, and carbonized babassu cake.

Figure 1.

Samples: (a) babassu coconut, (b) cashew nutshell, (c) sugarcane bagasse, (d) carnauba straw, and (e) carnauba stalk.

Figure 2.

Flow chart of the preparation of the samples: babassu kernel, babassu cakes, and carbonized babassu cake.

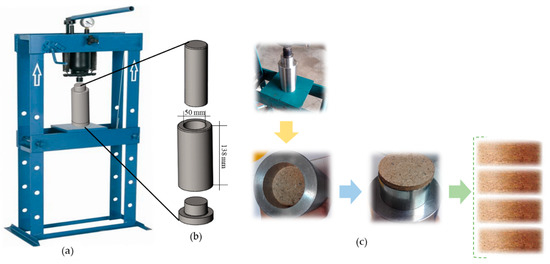

Babassu cakes were generated from babassu oil extraction by the Soxhlet method using hexane as the solvent (purity 99%). After extraction, the oils obtained from fresh babassu kernel and aged babassu kernel (storage condition (90 days)) were stored for biodiesel production. The carbonized babassu cake was prepared by the carbonization process in a Muffle Furnace (Quimis model 0318M24, SP, Brazil) at temperatures of 250, 300, 350, and 400 °C. A mechanical densification process was used to compress the raw materials. For this, a hydraulic press with a capacity of 15 tons (Marcon MPH-15, SP, Brazil) and a cylindrical stainless steel (AISI 304) mold with an internal diameter of 50 mm and a height of 138 mm were used. The solid fuels were produced using 10.50 or 10.00 g of raw material and 5 tons applied in the cylindrical mold for 5 min. Figure 3 shows the mechanical densification process.

Figure 3.

Mechanical densification process: (a) hydraulic press, (b) cylindrical mold, (c) steps of the process.

Proximate analysis (ASTM D3172-13 [27]) and Higher Heating Value (ASTM D5865/D5865M-19 [28]) were used to characterize the samples. The proximate analysis covers the determination of moisture (Laboratory oven, De Leo model 1980W, ASTM D3173/D3173M−17a [24]), volatile matter (Muffle furnace, Quimis model 0318M24, ASTM D3175-18 [25]), ash (Muffle furnace, Quimis model 0318M24, ASTM D3174-12(2018)e1 [26]), and fixed carbon (Equation (1), ASTM D3172-13 [27]).

Fixed carbon (%) = 100% − (moisture (%)+ ash (%) + volatile matter (%))

The Higher Heating Value (HHV) was determined using a calorimeter (Model IKA C1). All experiments were performed at least in duplicate and reported on a dry and wet basis (see Supplementary material).

3. Results

3.1. Proximate Analysis and Higher Heating Value of Babassu Kernel

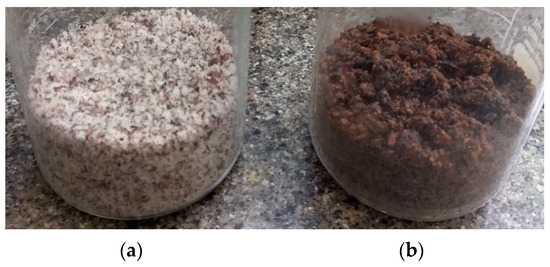

An important step for the application of given biomass as fuel is its characterization, and proximate analysis and Higher Heating Value (HHV) can be used for this evaluation [7]. Figure 4a,b show the samples of ground babassu kernel—fresh and aged.

Figure 4.

Fresh sample of ground babassu kernel (a). Aged sample of ground babassu kernel (b).

The aged sample presented changes in color, odor, and texture; thus, the aged sample was included for characterization. Table 1 shows the mean values of proximate analysis and HHV for the fresh and aged samples of ground babassu kernel. The experiments were carried out in quadruplicate.

Table 1.

Mean values of proximate analysis and Higher Heating Value (HHV) for the fresh and aged samples of ground babassu kernel (dry basis).

The main difference between fresh and aged samples occurred in the fixed carbon (%), ash (%), and volatile matter (%). After characterization, the samples were submitted to the oil extraction using two steps: first via the Soxhlet method and second by pressing. The fresh sample reached an extraction yield of 59.8%, and the aged sample reached an extraction yield of 70.66%.

3.2. Proximate Analysis and Higher Heating Value of Babassu Cakes

The oilseed extraction for the production of vegetable oils generates large amounts of cakes as by-products. Thus, with the aim of achieving the integrated use of babassu coconut and its further technological application, chemical characterization of fresh and aged sample cakes was obtained from the babassu oil extraction to evaluate the proximate analysis, and the Higher Heating Value was obtained, see Table 2.

Table 2.

Mean values of proximate analysis and Higher Heating Value (HHV) for the fresh and aged sample cakes obtained from the babassu oil extraction (dry basis).

The main difference between fresh and aged sample cakes obtained from the babassu oil extraction occurred in the moisture (%), ash (%), and fixed carbon (%).

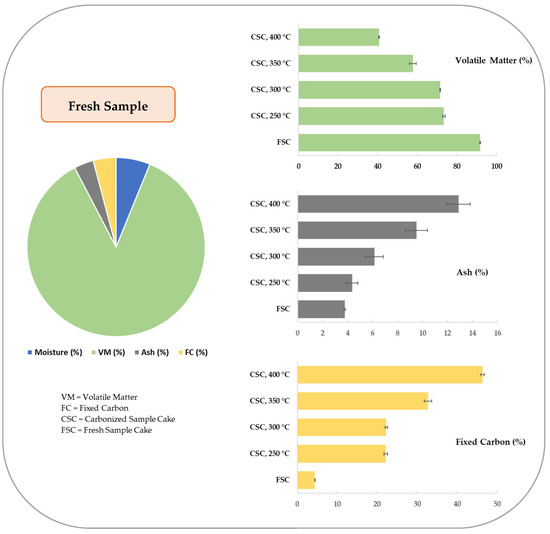

3.3. Proximate Analysis and Higher Heating Value of Carbonized Babassu Cake

During babassu oil extraction, a cake is generated that is generally not used. Considering the potential of the cake for bioenergy production, the valorization of the fresh sample cake by carbonization was proposed. The results of proximate analysis and HHV are presented in Table 3. The carbonization was carried out in a Muffle Furnace at temperatures of 250, 300, 350, and 400 °C. The experiments of proximate analysis were carried out in quadruplicate.

Table 3.

Mean values of proximate analysis and Higher Heating Value (HHV) for the fresh sample cake carbonized in a Muffle Furnace at temperatures 250, 300, 350, and 400 °C (dry basis).

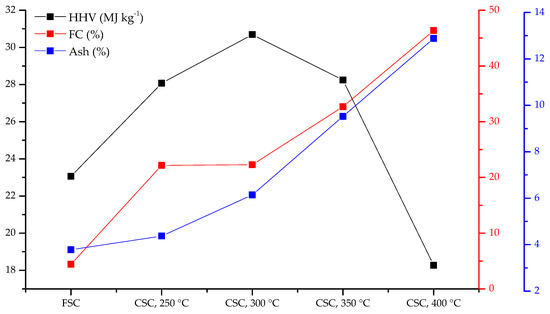

In a comparison of the results of the fresh and carbonized samples, a decrease in the volatile matter and an increase in fixed carbon and ash were observed. The Higher Heating Value of the carbonized sample at 400 °C shows a significant reduction, whereas the ash has the highest value in this carbonization temperature. Figure 5 shows the comparative analysis of the fresh sample cake with carbonized sample cake at 250, 300, 350, and 400 °C, and Figure 6 presents a comparison of the parameters HHV, fixed carbon, and ash.

Figure 5.

Comparative analysis of the fresh sample cake with carbonized sample cake at 250, 300, 350, and 400 °C (dry basis).

Figure 6.

Comparative analysis of the parameters HHV (MJ kg−1), Fixed Carbon (%), and Ash (%) for the fresh sample cake and carbonized sample cake at 250, 300, 350, and 400 °C (dry basis).

According to the results shown in Figure 5, the influence of carbonization temperature on the parameters VM, Ash, and FC is observed. The main aim of the carbonization process is to increase the energy potential of biomass as solid compounds rich in carbon are produced.

Up to the carbonization temperature of 300 °C, Figure 6 shows an increase in the Higher Heating Value of 21.7% (250 °C) and 33.1% (300 °C). At 400 °C, a decrease in HHV of 20.8% and an increase in Ash (%) of 195% occurred. Thus, it can be inferred that the Ash (%) increase may have impacted negatively on the HHV.

3.4. Solid Fuels of Babassu Cake and Babassu Cake Combined with Other Residual Biomasses

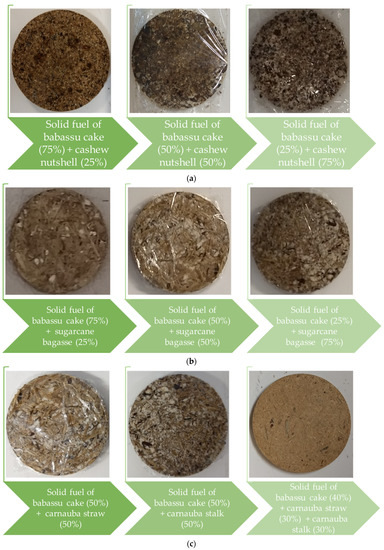

Several types of biomasses can be used as biofuels. However, the limitation associated with its low bulk density generates problems in transportation, storage, and energy content in comparison to fossil fuels. Thus, with the aim of minimizing the low bulk density of the biomasses and consequently obtaining a high energy content per unit volume, a mechanical densification process is realized [29]. The authors produced probable solid fuels of babassu cake (Figure 7) and the blends of babassu cake and cashew nutshell (25, 50, and 75%); babassu cake and sugarcane bagasse (25, 50, and 75%); babassu cake and carnauba straw (50%); babassu cake and carnauba stalk (50%); and babassu cake and carnauba straw and carnauba stalk (40% + 30% + 30%), see Figure 8a–c.

Figure 7.

Solid fuel of babassu cake.

Figure 8.

(a) Solid fuels of blends of babassu cake and cashew nutshell (25, 50, and 75%); (b) babassu cake and sugarcane bagasse (25, 50, and 75%); (c) babassu cake and carnauba straw (50%); babassu cake and carnauba stalk (50%); and babassu cake and carnauba straw and carnauba stalk (40% + 30% + 30%).

For the production of the solid fuel of babassu cake, a mass of 10.50 g was used, whereas for the blends, 10.00 g (±0.10 g) was used. During the mechanical pressurization to compress the biomasses, a residual babassu oil was observed in the steel mold. All experiments were carried out by applying 5 tons in the time interval of 5 min, and after this period, the solid fuels were removed from the steel mold and stored for characterization.

3.5. Proximate Analysis and Higher Heating Value of the Probable Solid Fuels

Solid fuel is one of the most used biofuels, especially in the industrial field. Compared to raw materials, densified biomasses have a higher density, Higher Heating Value, more convenient transportation, and 70% higher thermal efficiency [2]. However, due to biomass differences, solid fuels must be characterized to provide a better direction for their industrial applications. Thus, probable solid fuels were evaluated using proximate analysis and Higher Heating Value, see Table 4.

Table 4.

Values of proximate analysis and Higher Heating Value (HHV) for the solid fuel of babassu cake and solid fuels of blends of babassu cake and cashew nutshell (25, 50, and 75%); babassu cake and sugarcane bagasse (25, 50, and 75%); babassu cake and carnauba straw (50%); babassu cake and carnauba stalk (50%); and babassu cake and carnauba straw and carnauba stalk (40% + 30% + 30%) (dry basis).

The main difference between the solid fuel of babassu cake and the solid fuels of biomass blends occurred in moisture, fixed carbon, and HHV. However, the difference for the Higher Heating Value (HHV) did not exceed 18.4%. Despite the variety of biomasses, volatile matter and ash percentages did not show significant differences, which represents a positive result for the application of these probable solid fuels as biofuels in the industrial field.

4. Discussion

According to the results shown in Figure 4 and Table 1, the aged sample presented changes in the color, texture, and contents of fixed carbon, ash, volatile matter, and moisture. Queiroga et al. (2015) [30] reported that the dark appearance is due to the aging of the sample. However, this inconvenience did not interfere with the yield of the oil extraction process. Thus, for the production of biofuels such as solid fuels and biodiesel, aged samples of babassu kernel would not represent a problem. Nevertheless, fresh and aged samples reached different extraction yields, which can be attributed to the long storage period, as the variability in oil content depends on the physiological maturity of the babassu fruits, the region of palm production, and the species [30,31]. Pessoa et al. (2012) [32] reported that physiological maturity defines the moment of maximum seed quality, including oil content, and is usually followed by visible changes in the external appearance and color of the fruits and seeds. The highest oil content was observed in the last maturation stages. Pípolo et al. (2015) [33] observed that the variation in soybean seed oil content is determined mainly by genetic factors; the oil content increases from the beginning of grain development and reaches a maximum on physiological maturity. Ducca et al. (2015) [34] investigated the species Jatropha curcas L. and detected that the maximum oil content, dry matter mass, and physiological quality occurred seventy-five days after flowering. According to the literature [35,36,37], the dry matter mass of seeds has shown a good correlation with physiological maturity. In their study, total lipids showed similar behavior to the dry matter mass variable. Laviola et al. (2008) [38] reported that the accumulation of the dry matter mass provides an increase in the seed oil content. Cremonez et al. (2017) [39] reinforced this hypothesis when reporting that the dry matter mass can be correlated to the oil content and maturation stages. Maeda et al. (1987) [40] observed that the oil content in sunflower seeds reached full maturation between 30 and 40 days after harvest when presented with the highest oil content. The fixed carbon content can be related to the calorific value as it has a positive effect on the energy potential of the biomass. However, the same correlation cannot always be applied to the volatile matter content because a high volatile matter content does not guarantee a high calorific value, as some compounds of the volatile matter are formed from non-combustible gases (CO2 and H2O) [2,20,41]. Ash content decreases the calorific value and damages the apparent heat obtained from burning the biomass once the energy needed by ash forming inorganics, thermal breakdown, and phase transition is taken from the burning of biomass, and it leads to a reduction in the calorific value. The Higher Heating Value (HHV) of the fresh and aged samples showed significant values when compared to other biomasses [42]. This parameter is variable and depends on genetic factors (species and cultivars) [40], cultivation conditions (soil quality and management methods) [38,39], and plant age [40,41,42,43,44,45,46].

The biomass used as fuel for the industrial field includes agricultural wastes (straw, stalk, cashew nutshell, sugarcane bagasse, rice husk, etc.), oil extraction wastes (soybean oil extractive byproduct, babassu cake, etc.), forest wastes (fallen leaves, branches), and sawdust [18]. In this study, the cakes generated from babassu oil extraction were studied, and the mean values of proximate analysis and HHV are shown in Table 2. The results are compatible with those of other residual biomasses used as biofuels [2,41,42]. The energy in the biomass originally comes from the sun, and the molecules containing carbon, such as sugars, are synthesized through photosynthesis. These sugars are called carbohydrates and are stored in plants and animals or in plant or animal wastes and can be applied to bioenergy [2]. When compared to the HHV of the fresh and aged samples of ground babassu kernel, the HHV of the cakes were lower. This behavior can be attributed to the extraction of the babassu oil. However, the HHV for the cakes is still higher than many other biomasses used as fuel for boilers [2], and as the heating value of any biomass is necessary to analyze and design a bioenergy system, it can be inferred from the outcomes that the babassu cakes show an outstanding energy potential for use as biofuels in the industrial field.

Numerous processes can be used to convert biomass into fuel, and the choice of the process depends on the type and quantity of available feedstock, end-use, environmental standards, economic conditions, and other factors [2,46]. Thus, it is imperative to search for appropriate processes to convert wastes into energy to establish a circular bioeconomy toward sustainable development [22], and carbonization acts as an important route among thermochemical processes. The effect of temperature on the carbonization of the fresh sample cake was evaluated by the proximate analysis and Higher Heating Value (HHV), see Table 3. According to the results, increasing the temperature in the 250–400 °C range improved fixed carbon content, reduced volatile matter, and increased ash content. As the high fixed carbon content is proportional to a Higher Heating Value of any fuel, its analysis is important for the choice of biomass for its application as bioenergy. The increase in fixed carbon content as a consequence of the increase in the carbonization temperature is a well-known behavior and has been mentioned by Legarra et al. (2019) [47], Yang et al. (2020) [48], and Machado et al. (2014) [49]. The increase in carbon content occurs due to the release of condensable and gaseous compounds during carbonization formed mainly by CO, CO2, and hydrocarbons. In this thermochemical process, the factors that influence the quality and yield of the final product are temperature, heating rate, and retention time [48].

Concerning the volatile matter content, when the temperature carbonization increased from 250 to 350 °C, a large number of volatile compounds of low boiling points were released rapidly, and as a consequence, VM (%) decreased rapidly from 73.47% to 57.78%. When the temperature increased from 350 to 400 °C, volatile materials of high boiling points decomposed, and the VM (%) decreased from 57.78% to 40.76%, see Figure 5. The results demonstrate that VM (%) decreased rapidly when the temperature of carbonization increased from 250 to 400 °C, which was consistent with other reported results [48]. The proximate and ultimate analyses are important for biochar and hydrochar characterization and are crucial for ascertaining the contents of VM, ash, and FC, as biochar and hydrochar characterization are also used to study the combustion phenomenon of these materials [49]. In general, lignocellulosic biomass has a high VM content and a low FC, and its thermal decomposition during carbonization and hydrothermal carbonization (HTC) changes its VM and FC contents [13,21,47,49]. Concerning coal, biomass differs from this fuel in many characteristics, including the organic, inorganic, and energy content. Generally, biomass has less carbon, more oxygen, higher hydrogen content, a higher quantity of volatile components, and a lower heating value [50]. Therefore, carbonization and HTC can produce biofuels with lower VM and higher FC than raw biomass, although it can also increase the ash content when ash-rich feedstocks are employed [21,48,49,51]. In this study, the carbonized fresh sample cake showed compatible VM and FC with other biomasses [4,48,49,51], which indicates that this biochar can be used as biofuel.

Regarding ash content, a higher value in biomass fuel can cause ignition and combustion problems because the melting point of the dissolved ash can be low, which causes fouling and slagging problems [2]. Saidur et al. (2011) reported that the composition of biomass ash is strongly dependent on the species and part of the plant, and especially in agro-biomass ashes, the available nutrients, soil quality, fertilizers, and weather conditions have a significant impact on the contents of potassium, sodium, chlorine, and phosphorus [2]. The fresh sample cake that was carbonized in a Muffle Furnace in the temperature range of 250–400 °C presented an increasing ash content with the increase in the carbonization temperature, as shown in Table 3 and Figure 5. Comparing the ash contents of biomass and coal, the ash of the biomass fuels is more alkaline, which may worsen the fouling problems [2]. Thus, to obtain a high-quality biochar from the carbonized babassu cake, it is recommended for the carbonization process to be set at a maximum temperature of 300 °C, which presented an ash content of 6.14%. Figure 6 presented the correlation between HHV (MJ kg−1), FC (%), ash (%), and temperature of carbonization (°C). According to the results, it can be reported that HHV increases with temperature until it reaches a maximum at approximately 300 °C, after which it starts decreasing. For temperatures above 300 °C, despite the increase in FC (%), the HHV shows a decrease, probably due to the increase in the ash content.

The last section of the paper shows the results of the production and characterization of solid fuels using the babassu cake as raw materials (Figure 7) and the blends of the babassu cake with cashew nutshell, sugarcane bagasse, carnauba straw, and carnauba stalk (Figure 8a–c). For the conversion of biomasses into solid fuels, various proportions were used ((25, 50, and 75%), (50%), and (40% + 30% + 30%)). The diameter of the solid fuels was 5.00 cm, and the average weights were 10.50 g (solid fuel of babassu cake) and 10.00 g (blends). According to Figure 7 and Figure 8a–c, all solid fuels were well-compacted and, therefore, are suitable for use as biofuel. In addition to the economic viability of the production of solid fuels from agricultural wastes, this biofuel contributes to solving the problem of the loose structure of biomass raw materials, which facilitates transportation and mitigates the inconvenience of the low-energy efficiency of direct biomass combustion. Compared to fossil fuels, solid biofuel combustion emits less sulfur dioxide [18,19,20]. The characterization of the solid fuels includes proximate analysis and Higher Heating Value (HHV), see Table 4. The four industrial parameters that classify biomass fuels are moisture, ash, volatile matter, and fixed carbon contents. Thus, despite the variety of biomasses, volatile matter and ash contents did not show significant differences, which represents a benefit for the application of solid fuels in the industrial field. In addition, all values of HHV were higher than 18 MJ kg−1, which is superior to many results reported previously [2,46]. Because Brazil is a country with a high agricultural potential, which implies a wide range of agricultural resources, the results of this study could lead to further investigation of the integrated use of the waste babassu coconut as feedstock for solid fuel production with other agricultural residues available in the northeastern part of Brazil, such as cashew nutshell, sugarcane bagasse, carnauba straw, and carnauba stalk.

5. Conclusions

The integrated use of the waste babassu coconut obtained from oil extraction was evaluated. The storage condition of the babassu kernel did not represent a problem because interference in the yield of the oil extraction was not observed. Thus, feedstock storage does not represent a limitation for the biodiesel industry. For chemical characterization of the fresh and aged sample cakes, the main difference occurred in the moisture, ash, and fixed carbon content. However, the results, including the Higher Heating Value, are compatible with other residual biomasses already used as solid fuels. Carbonization was successfully used for the production of solid fuel from the babassu cake, with a significatively increased fixed carbon content and high calorific value, which improved the fuel quality. Thus, the sample produced from the carbonization of the cake generated in the babassu oil extraction may be a promising alternative for the production of solid fuels for application in the combustion sector. The biomass densification was carried out using a hydraulic press machine and a stainless-steel cylinder. All samples were well-compacted and indicated a possible application as solid fuel. In addition, moisture, ash, volatile matter, and fixed carbon contents did not show significant differences. Thus, it is possible to report that waste biomasses show potential for application in the renewable energy industry. The findings of this work provide crucial information to researchers, decision-makers, and technical operators of the biomass densification process. Overall, solid fuels from agricultural residues could offer benefits for their use in many industrial segments.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/pr11020585/s1, Table S1. Mean values of proximate analysis and Higher Heating Value (HHV) for the fresh and aged samples of ground babassu kernel (wet basis). Table S2. Mean values of proximate analysis and Higher Heating Value (HHV) for the fresh and aged sample cakes obtained from the babassu oil extraction (wet basis). Table S3. Mean values of proximate analysis and Higher Heating Value (HHV) for the fresh sample cake carbonized in a Muffle Furnace at temperatures 250, 300, 350, and 400 °C (wet basis). Table S4. Values of proximate analysis and Higher Heating Value (HHV) for the solid fuel of babassu cake and solid fuels of blends of babassu cake + cashew nutshell (25, 50, and 75 %), babassu cake + sugarcane bagasse (25, 50, and 75 %), babassu cake + carnauba straw (50%), babassu cake + carnauba stalk (50%), and babassu cake + carnauba straw + carnauba stalk (40% + 30% + 30%) (wet basis).Table S5. Proximate analysis values for the cashew nutshell, sugarcane bagasse, carnauba straw, and carnauba stalk (wet basis). Table S6. Proximate analysis values for the cashew nutshell, sugarcane bagasse, carnauba straw, and carnauba stalk (dry basis).

Author Contributions

Conceptualization, M.R. and C.S.; methodology, C.S., J.N., R.M. and J.M.; software, B.S. and L.D.; validation, C.S., J.N. and E.B.; formal analysis, C.S., J.N. and R.M.; investigation, M.R., L.B., T.L. and M.M.; resources, M.R. and J.M.; data curation, M.R.; writing—original draft preparation, C.S., J.N. and B.S.; writing—review and editing, M.R.; visualization, M.R., L.B., T.L. and M.M.; supervision, M.R.; project administration, M.R., L.B. and T.L.; funding acquisition, M.R. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by CNPq (308280/2017-2, 313647/2020-8); FUNCAP (PS1-00186-00255.01.00/21); FINEP; and CAPES (Finance Code 001).

Data Availability Statement

All data are available in the manuscript and supplementary material.

Acknowledgments

The authors acknowledge Jose Silva Machado for the babassu coconut picture.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Matos, R.A.S.; Soares, F.K. Brazilian Energy Balance 2022/Year 2021; Empresa de Pesquisa Energética, Ministry of Mines and Energy: Rio de Janeiro, Brazil, 2022. [Google Scholar]

- Saidur, R.; Abdelaziz, E.A.; Demirbas, A.; Hossain, M.S.; Mekhilef, S. A Review on Biomass as a Fuel for Boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- de Luna, M.Y.; Rodrigues, P.M.; Torres, G.A.M.; Eufrázio, D.C.J.A.; Queiroz, M.J.; Elaine, M.S.; de Sousa, R.M.A. A Thermogravimetric Analysis of Biomass Wastes from the Northeast Region of Brazil as Fuels for Energy Recovery. Energy Sources Part A Recover. Util. Environ. Eff. 2018, 41, 1557–1572. [Google Scholar] [CrossRef]

- Ponte, M.R.; Gadelha, A.M.; Machado, Y.D.; Lopes, A.A.; Malveira, J.Q.; Mazzetto, S.E.; Lomonaco, D.; Rios, M.A. Blends of Sugarcane Bagasse with the Mango Tree and Cashew Tree’s Pruning: Properties Characterization and Investigation of Their Energy Potentials. Matéria 2019, 24, 1–12. [Google Scholar] [CrossRef]

- Pütün, A.E.; Apaydin, E.; Pütün, E. Bio-Oil Production from Pyrolysis and Steam Pyrolysis of Soybean-Cake: Product Yields and Composition. Energy 2002, 27, 703–713. [Google Scholar] [CrossRef]

- Qyyum, M.A.; Ali Shah, S.F.; Qadeer, K.; Naquash, A.; Yasin, M.; Rehan, M.; Tabatabaei, M.; Aghbashlo, M.; Lee, M.; Nizami, A.S. Biowaste to Bioenergy Options for Sustainable Economic Growth Opportunities in Developing Countries: Product Space Model Analysis and Policy Map Development. Renew. Sustain. Energy Rev. 2022, 169, 112832. [Google Scholar] [CrossRef]

- Huang, Y.-F.; Lo, S.-L. Predicting Heating Value of Lignocellulosic Biomass Based on Elemental Analysis. Energy 2020, 191, 116501. [Google Scholar] [CrossRef]

- Chen, Z.; Hu, M.; Zhu, X.; Guo, D.; Liu, S.; Hu, Z.; Xiao, B.; Wang, J.; Laghari, M. Characteristics and Kinetic Study on Pyrolysis of Five Lignocellulosic Biomass via Thermogravimetric Analysis. Bioresour. Technol. 2015, 192, 441–450. [Google Scholar] [CrossRef]

- Santos, F.F.P.; Almeida, F.D.L.; Mota, F.A.S.; Rios, M.A.S.; Lima, A.A.S. Analysis of Surface Response of Blends of Castor Oil And Babassu. Rev. Gestão Inovação E Tecnol. 2014, 4, 1139–1149. [Google Scholar] [CrossRef]

- Paula, R.S.F.; Figueredo, I.M.; Vieira, R.S.; Nascimento, T.L.; Cavalcante, C.L.; Machado, Y.L.; Rios, M.A.S. Castor-Babassu Biodiesel Blends: Estimating Kinetic Parameters by Differential Scanning Calorimetry Using the Borchardt and Daniels Method. SN Appl. Sci. 2019, 1, 884. [Google Scholar] [CrossRef]

- Figueredo, I.; Rios, M.A.D.S.; Cavalcante, C.L.; Luna, F.M.T.T. Effects of Amine and Phenolic Based Antioxidants on the Stability of Babassu Biodiesel Using Rancimat and Differential Scanning Calorimetry Techniques. Ind. Eng. Chem. Res. 2019, 59, 18–24. [Google Scholar] [CrossRef]

- Rangel, N.V.P.; da Silva, L.P.; Pinheiro, V.S.; Figueredo, I.M.; Campos, O.S.; Costa, S.N.; Luna, F.M.T.; Cavalcante, C.L., Jr.; Marinho, E.S.; de Lima-Neto, P.; et al. Effect of Additives on the Oxidative Stability and Corrosivity of Biodiesel Samples Derived from Babassu Oil and Residual Frying Oil: An Experimental and Theoretical Assessment. Fuel 2021, 289, 119939. [Google Scholar] [CrossRef]

- Costa, R.S.; Vieira, L.H.S.; Ghosh, A.; Santos, A.M.S.; Ferreira, O.P.; Viana, B.C. Hydrothermal Carbonization of Waste Babassu Coconut Biomass for Solid Fuel Production. Rev. Virtual De Química 2019, 11, 626–641. [Google Scholar] [CrossRef]

- Blennow, K.; Persson, E.; Lindner, M.; Faias, S.P.; Hanewinkel, M. Forest Owner Motivations and Attitudes towards Supplying Biomass for Energy in Europe. Biomass Bioenergy 2014, 67, 223–230. [Google Scholar] [CrossRef]

- Aguilar, F.X.; Daniel, M.J.; Narine, L.L. Opportunities and Challenges to the Supply of Woody Biomass for Energy from Missouri Nonindustrial Privately Owned Forestlands. J. For. 2013, 111, 249–260. [Google Scholar] [CrossRef]

- Lucas, P.U.; Gamborg, C.; Lund, T.B. Sustainability Concerns Are Key to Understanding Public Attitudes toward Woody Biomass for Energy: A Survey of Danish Citizens. Renew. Energy 2022, 194, 181–194. [Google Scholar] [CrossRef]

- Le, Y. Research on Data Resource Management of Biomass Energy Engineering Based on Data Mining. Energy Rep. 2022, 8, 1482–1492. [Google Scholar] [CrossRef]

- Huang, H.; Gao, Y.; Chen, H.; Wu, Y.; Wang, J.; Yu, C.; Li, J.; Zou, C. Biomass Briquette Fuel, Boiler Types and Pollutant Emissions of Industrial Biomass Boiler: A Review. Particuology 2023, 77, 79–90. [Google Scholar] [CrossRef]

- Ferronato, N.; Calle Mendoza, I.J.; Ruiz Mayta, J.G.; Gorritty Portillo, M.A.; Conti, F.; Torretta, V. Biomass and Cardboard Waste-Based Briquettes for Heating and Cooking: Thermal Efficiency and Emissions Analysis. J. Clean. Prod. 2022, 375, 134111. [Google Scholar] [CrossRef]

- Caposciutti, G.; Antonelli, M. Experimental Investigation on Air Displacement and Air Excess Effect on CO, CO2 and NOx Emissions of a Small Size Fixed Bed Biomass Boiler. Renew. Energy 2018, 116, 795–804. [Google Scholar] [CrossRef]

- Cao, X.; Ro, K.S.; Libra, J.A.; Kammann, C.I.; Lima, I.; Berge, N.; Li, L.; Li, Y.; Chen, N.; Yang, J.; et al. Effects of Biomass Types and Carbonization Conditions on the Chemical Characteristics of Hydrochars. J. Agric. Food Chem. 2013, 61, 9401–9411. [Google Scholar] [CrossRef]

- Cavali, M.; Libardi Junior, N.; de Sena, J.D.; Woiciechowski, A.L.; Soccol, C.R.; Belli Filho, P.; Bayard, R.; Benbelkacem, H.; de Castilhos Junior, A.B. A Review on Hydrothermal Carbonization of Potential Biomass Wastes, Characterization and Environmental Applications of Hydrochar, and Biorefinery Perspectives of the Process. Sci. Total Environ. 2023, 857, 159627. [Google Scholar] [CrossRef] [PubMed]

- Shan, G.; Li, W.; Bao, S.; Li, Y.; Tan, W. Co-Hydrothermal Carbonization of Agricultural Waste and Sewage Sludge for Product Quality Improvement: Fuel Properties of Hydrochar and Fertilizer Quality of Aqueous Phase. J. Environ. Manag. 2023, 326, 116781. [Google Scholar] [CrossRef] [PubMed]

- ASTM D3173/D3173M−17a; Standard Test Method for Moisture in the Analysis Sample of Coal and Coke. Book of Standards. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D3175-18; Standard Test Method for Volatile Matter in the Analysis Sample of Coal and Coke. Book of Standards. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D3174-12(2018)E1; Standard Test Method for Ash in the Analysis Sample of Coal and Coke from Coal. Book of Standards. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D3172-13; Standard Practice for Proximate Analysis of Coal and Coke. Book of Standards. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D5865/D5865M-19; Standard Test Method for Gross Calorific Value of Coal and Coke. Book of Standards. ASTM International: West Conshohocken, PA, USA, 2019.

- Silva, D.A.L.; Filleti, R.A.P.; Musule, R.; Matheus, T.T.; Freire, F. A Systematic Review and Life Cycle Assessment of Biomass Pellets and Briquettes Production in Latin America. Renew. Sustain. Energy Rev. 2022, 157, 112042. [Google Scholar] [CrossRef]

- Queiroga, V.P.; Girão, Ê.G.; Araújo, I.M.S.; Gondim, T.M.S.; Freire, R.M.M.; Veras, L.G.C. Composição Centesimal de Amêndoas de Coco Babaçu Em Quatro Tempos de Armazenamento. Rev. Bras. De Prod. Agroind. 2015, 17, 207–213. [Google Scholar] [CrossRef]

- Carrazza, L.R.; Ávila, J.C.C.; da Silva, M.L. Manual Tecnológico de Aproveitamento Integral Do Fruto Do Babaçu; Brasília—DF; Instituto Sociedade: Brasília, Brazil, 2012. [Google Scholar]

- Pessoa, Â.M.S.; Santos, Â.G.; Ribeiro, M.L.F.; Silva-Mann, R. Influência Da Maturação de Frutos Na Germinação, Vigor e Teor de Óleo de Sementes de Jatropha curcas L. Sci. Plena 2012, 8, 1–11. [Google Scholar]

- Pípolo, A.E.; Hungria, M.; Franchini, J.C.; Balbinot Junior, A.A.; Debiasi, H.; Mandarino, J.M.G. Teores de Óleo e Proteína Em Soja: Fatores Envolvidos e Qualidade Para a Indústria. Comun. Técnico 86 Embrapa Soja 2015, 1–16. [Google Scholar]

- Ducca, C.A.D.; de Souza, N.M.; Prete, C.E.C. Qualidade Fisiológica e Lipídios Totais de Sementes de Pinhão-Manso (Jatropha curcas L.) Em Função de Épocas de Colheita. Rev. Bras. De Eng. Agrícola E Ambient. 2015, 19, 364–368. [Google Scholar] [CrossRef]

- Alves, E.U.; Sader, R.; Bruno, R.d.L.A.; Alves, A.U. Maturação Fisiológica de Sementes de Sabiá. Rev. Bras. Sementes 2005, 27, 1–8. [Google Scholar] [CrossRef]

- Aguiar, F.F.A.; Pinto, M.M.; Tavares, A.R.; Kanashiro, S. Maturação de Frutos de Caesalpinia Echinata Lam., Pau-Brasil. Rev. Árvore 2007, 31, 1–6. [Google Scholar] [CrossRef]

- Dranski, J.A.L.; Pinto Júnior, A.S.; Steiner, F.; Zoz, T.; Malavasi, U.C.; Malavasi, M.d.M.; Guimarães, V.F. Physiological Maturity of Seeds and Colorimetry of Fruits of Jatropha curcas L. Rev. Bras. Sementes 2010, 32, 158–165. [Google Scholar] [CrossRef]

- Laviola, B.G.; Dias, L.A.; Dos, S. Teor e Acúmulo de Nutrientes Em Folhas e Frutos de Pinhão-Manso. Rev. Bras. Cienc. Solo 2008, 32, 1969–1975. [Google Scholar] [CrossRef]

- Cremonez, F.E.; Tessele, A.; Missio, R.F.; Cremonez, P.A.; Miranda, V.T. Estádios de maturação de frutos de pinhão manso visando maior rendimento no teor de óleo. Rev. Bras. De Energ. Renov. 2017, 6, 940–954. [Google Scholar] [CrossRef]

- Maeda, J.A.; Ungaro, M.R.G.; do Lago, A.A.; Razera, L.F. Estádio de Maturação e Qualidade de Sementes de Girassol. Bragantia 1987, 46, 35–44. [Google Scholar] [CrossRef]

- ÖzyuǧUran, A.; Yaman, S. Prediction of Calorific Value of Biomass from Proximate Analysis. Energy Procedia 2017, 107, 130–136. [Google Scholar] [CrossRef]

- Berbeć, A.K.; Matyka, M. Planting Density Effects on Grow Rate, Biometric Parameters, and Biomass Calorific Value of Selected Trees Cultivated as SRC. Agriculture 2020, 10, 583. [Google Scholar] [CrossRef]

- Sabatti, M.; Fabbrini, F.; Harfouche, A.; Beritognolo, I.; Mareschi, L.; Carlini, M.; Paris, P.; Scarascia-Mugnozza, G. Evaluation of Biomass Production Potential and Heating Value of Hybrid Poplar Genotypes in a Short-Rotation Culture in Italy. Ind. Crops Prod. 2014, 61, 62–73. [Google Scholar] [CrossRef]

- Nebeská, D.; Trögl, J.; Žofková, D.; Voslařová, A.; Štojdl, J.; Pidlisnyuk, V. Calorific Values of Miscanthus x Giganteus Biomass Cultivated under Suboptimal Conditions in Marginal Soils. Stud. Oecologica 2020, 13, 61–67. [Google Scholar] [CrossRef]

- Kumar, R.; Pandey, K.K.; Chandrashekar, N.; Mohan, S. Study of Age and Height Wise Variability on Calorific Value and Other Fuel Properties of Eucalyptus Hybrid, Acacia Auriculaeformis and Casuarina Equisetifolia. Biomass Bioenergy 2011, 35, 1339–1344. [Google Scholar] [CrossRef]

- Ajith Kumar, T.T.; Ramesh, S.T. Sustainable Production of Cashew Nutshell Briquettes: Experimental Assessment and Optimization of Factors Affecting the Physical and Fuel Characteristics. Biomass Convers. Biorefinery 2022, 12, 1–21. [Google Scholar] [CrossRef]

- Legarra, M.; Morgan, T.; Turn, S.; Wang, L.; Skreiberg, Ø.; Antal, M.J. Effect of Processing Conditions on the Constant-Volume Carbonization of Biomass. Energy Fuels 2019, 33, 2219–2235. [Google Scholar] [CrossRef]

- Yang, X.; Kang, K.; Qiu, L.; Zhao, L.; Sun, R. Effects of Carbonization Conditions on the Yield and Fixed Carbon Content of Biochar from Pruned Apple Tree Branches. Renew. Energy 2020, 146, 1691–1699. [Google Scholar] [CrossRef]

- Machado, G.d.O.; Vogel, F.; Silva, M.M. Influence of Temperature Carbonization in Physical, Chemical and Energy of Charcoal from Cinamomo (Melia azedarach L.). Ambiência 2014, 10, 83–96. [Google Scholar] [CrossRef]

- Lima, R.N.; Paixão, R.L.; Marques, R.B.; Malveira, J.Q.; Furtini, J.A.O.; Rios, M.A.D.S. Investigation of the Potential of the Carnauba Stalk and of the Carnauba’s Straw to Use as Biofuel. Matéria 2019, 24, 1–12. [Google Scholar] [CrossRef]

- Anggono, W.; Sutrisno; Suprianto, F.D.; Evander, J. Biomass Briquette Investigation from Pterocarpus Indicus Leaves Waste as an Alternative Renewable Energy. IOP Conf. Ser. Mater. Sci. Eng. 2017, 241, 012043. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).