Numerical Study and Hydrodynamic Calculation of the Feasibility of Retrofitting Tangentially Fired Boilers into Slag-Tap Boilers

Abstract

:1. Introduction

2. Numerical Model Description

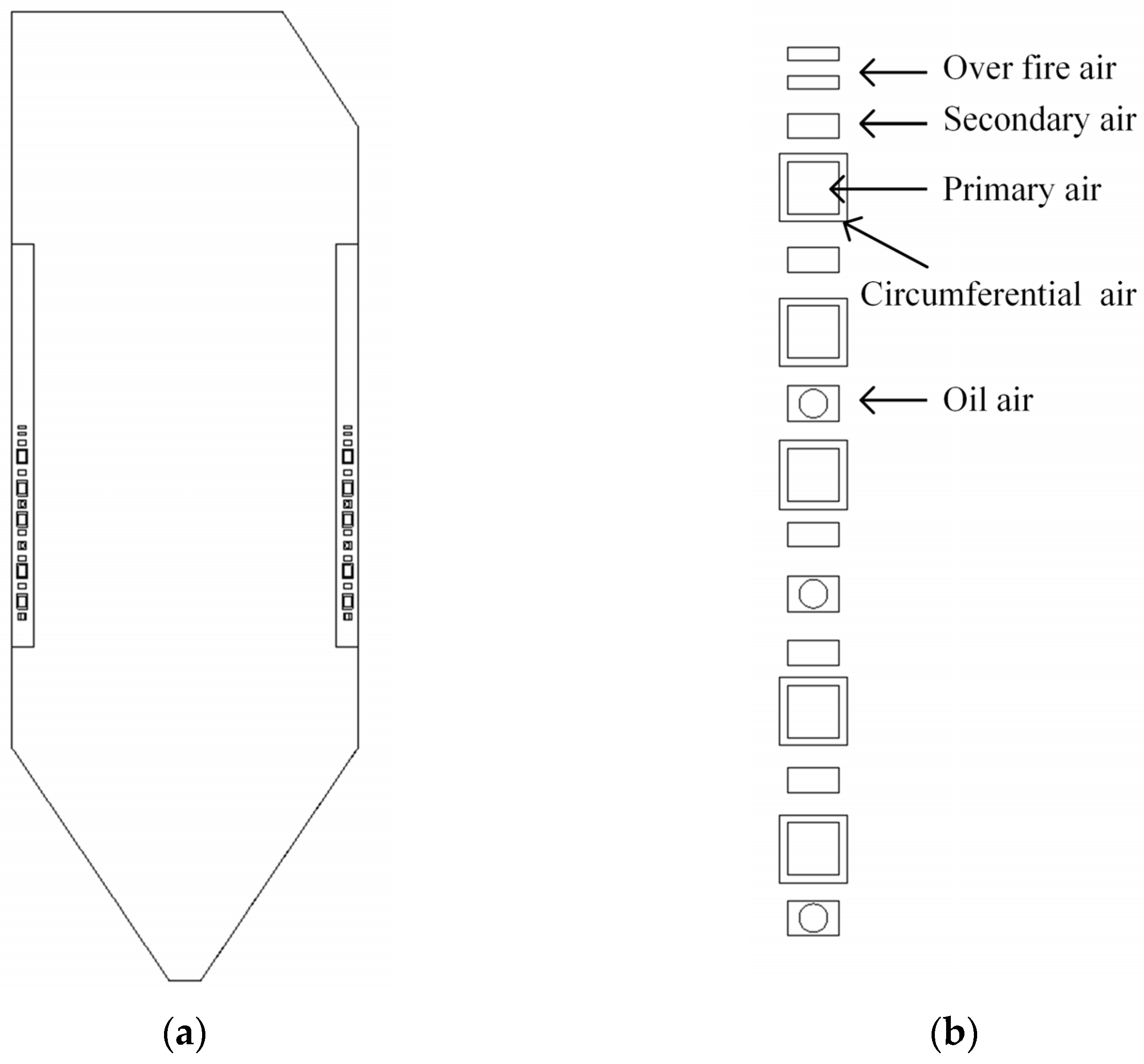

2.1. Retrofit Scheme

2.2. Numerical Model

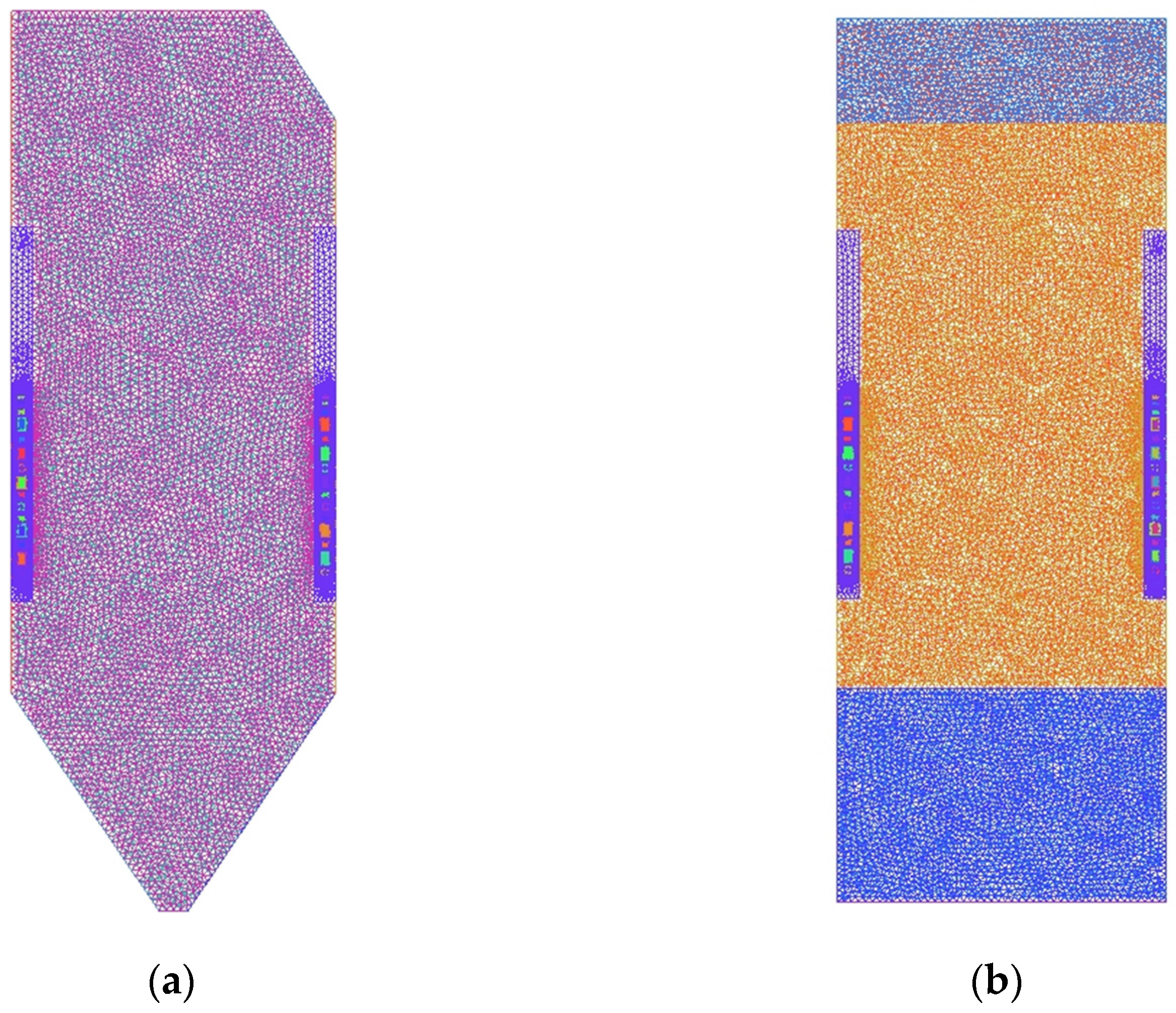

2.3. Mesh Generation

2.4. Boundary Conditions

2.5. Simulated Working Conditions

3. Hydrodynamic Calculation Methods

3.1. Calculation Principle

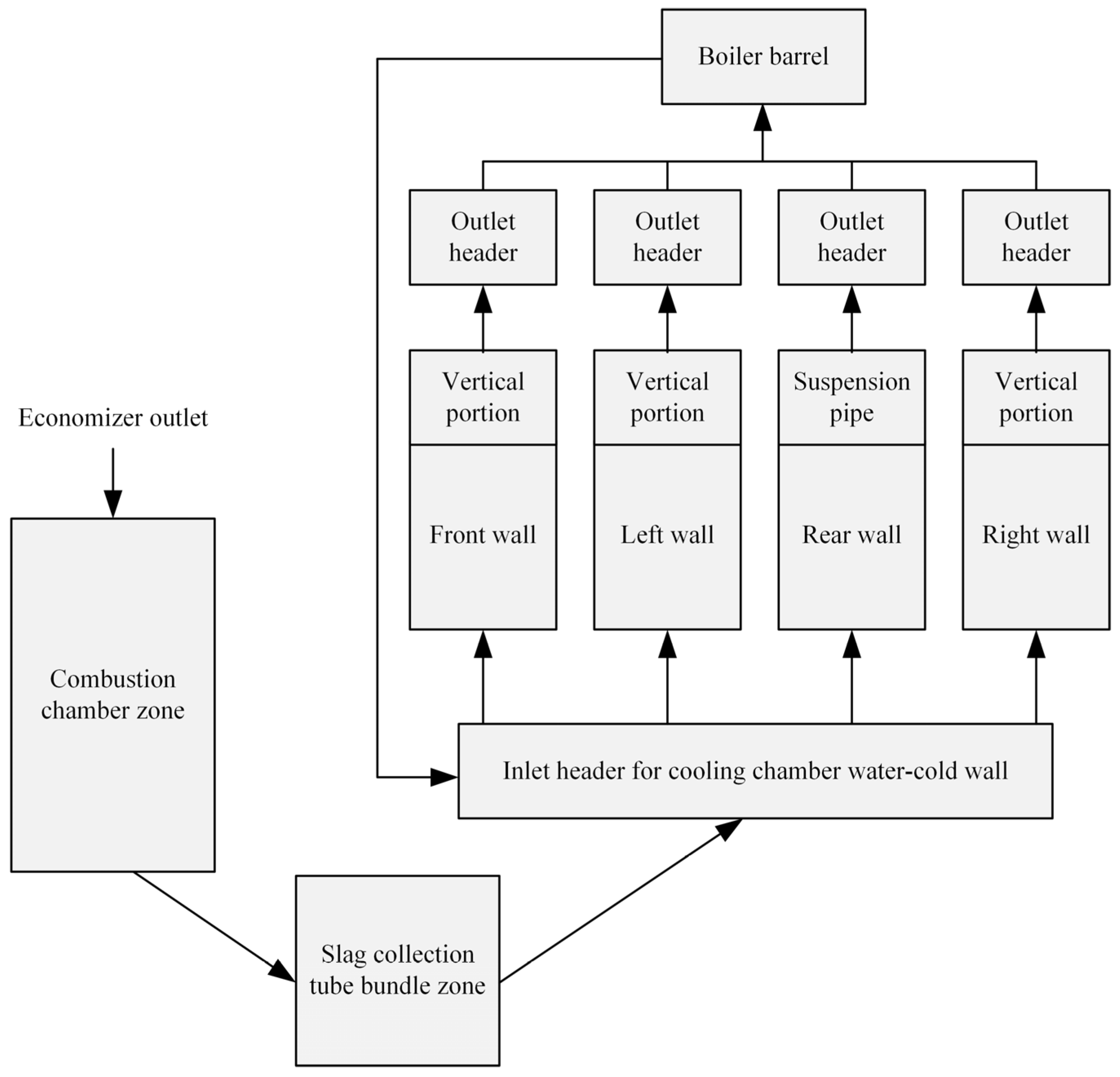

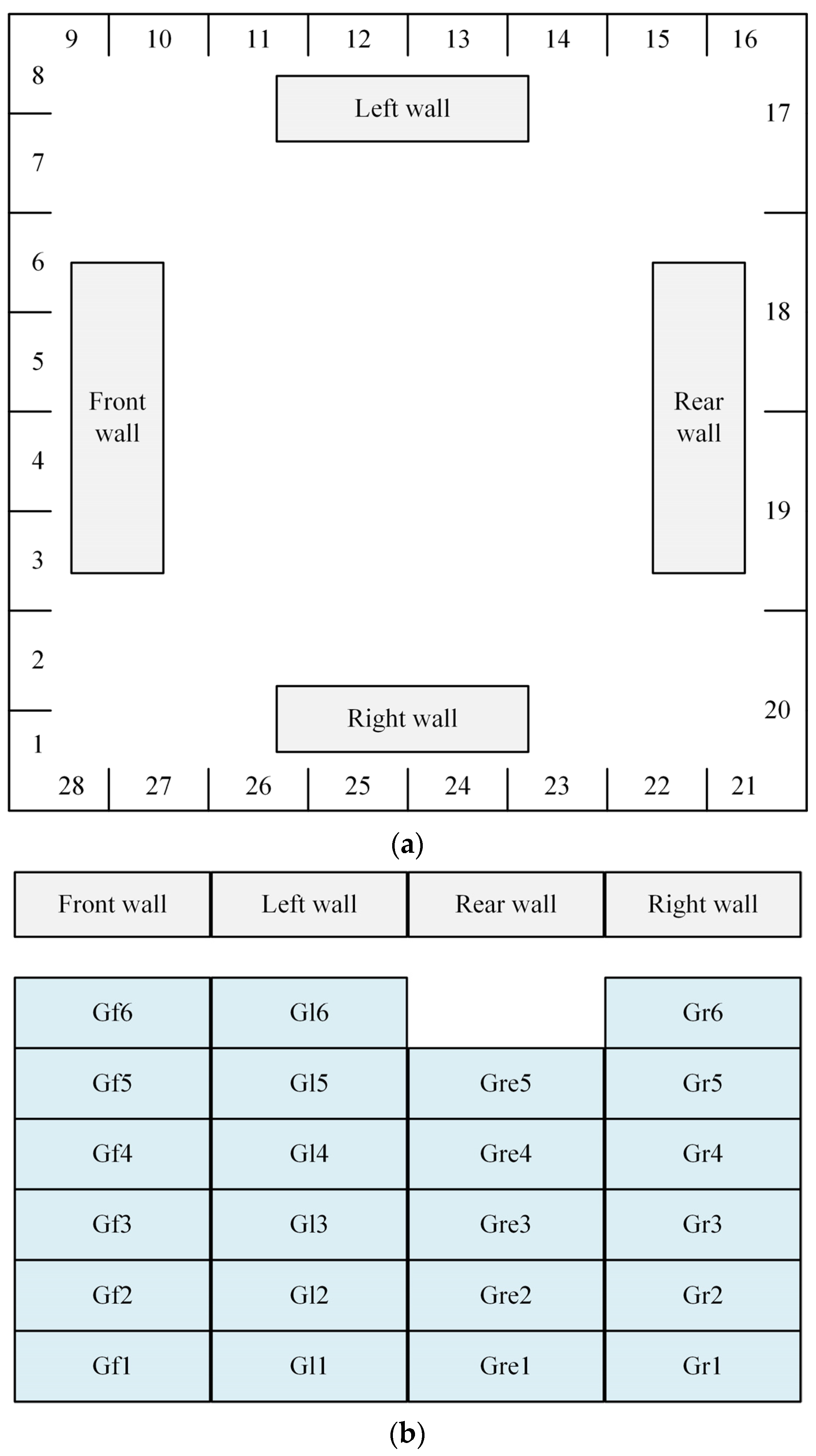

3.2. Division of Steam–Water System

4. Results and Discussion

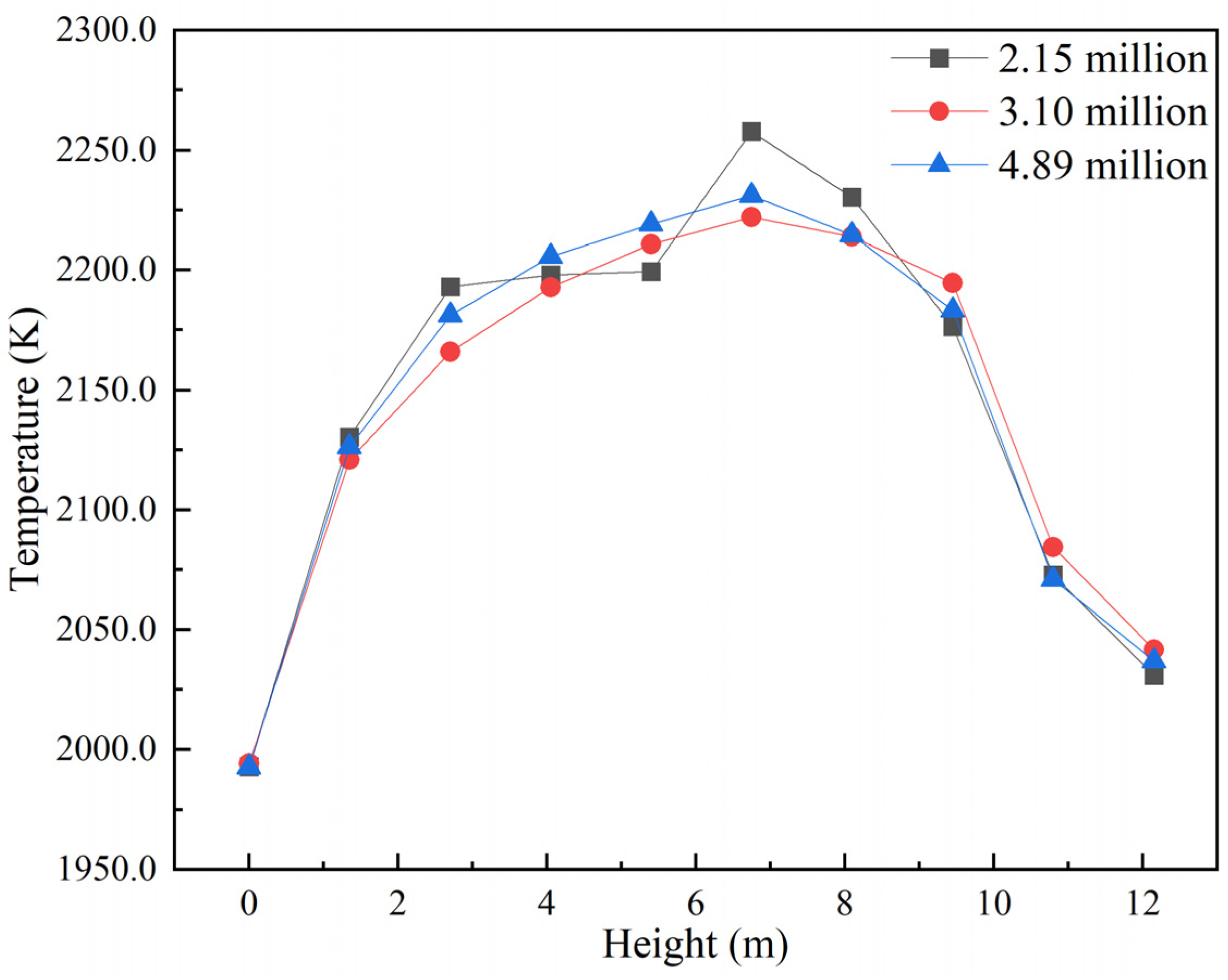

4.1. Model Validation

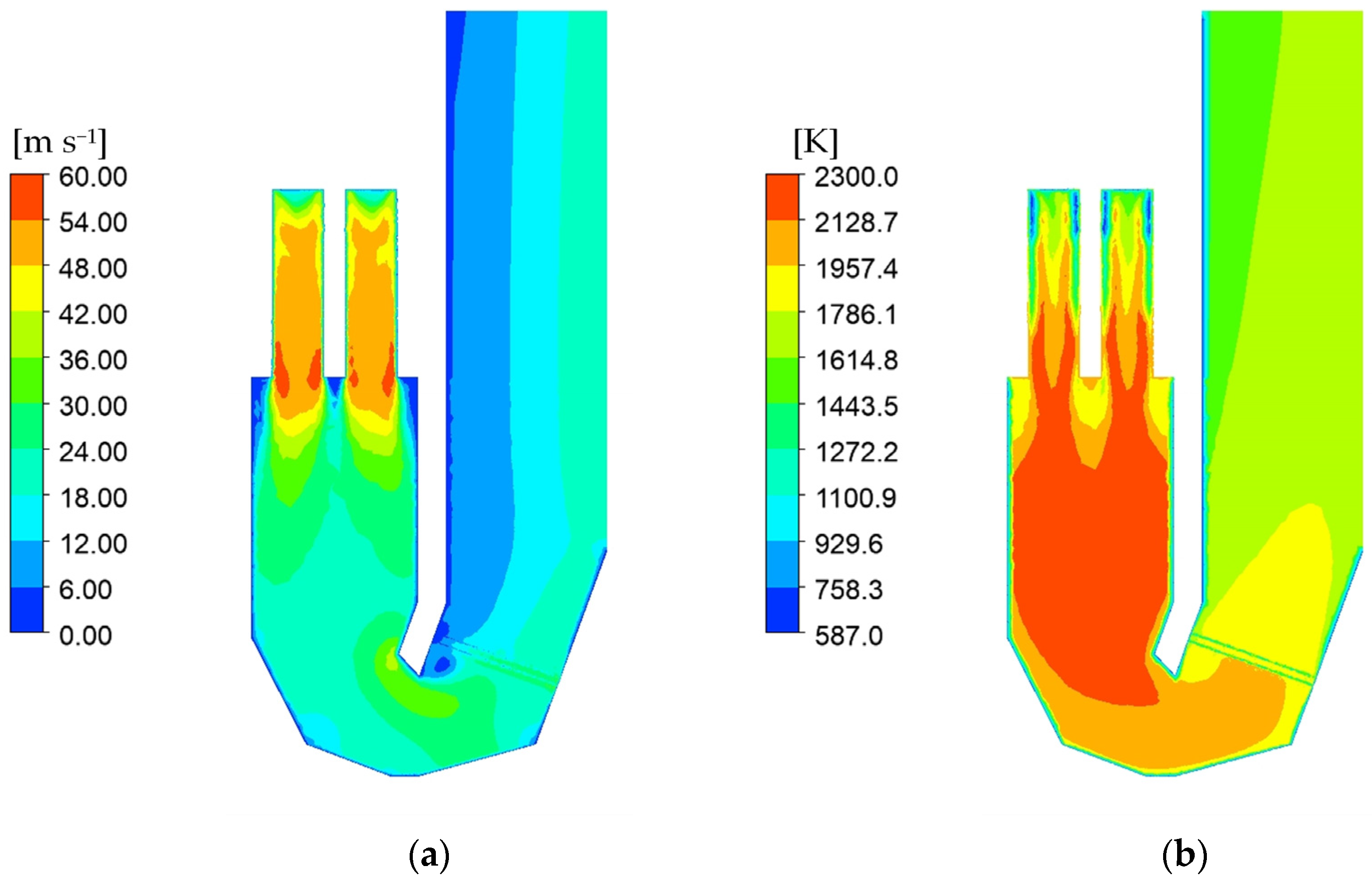

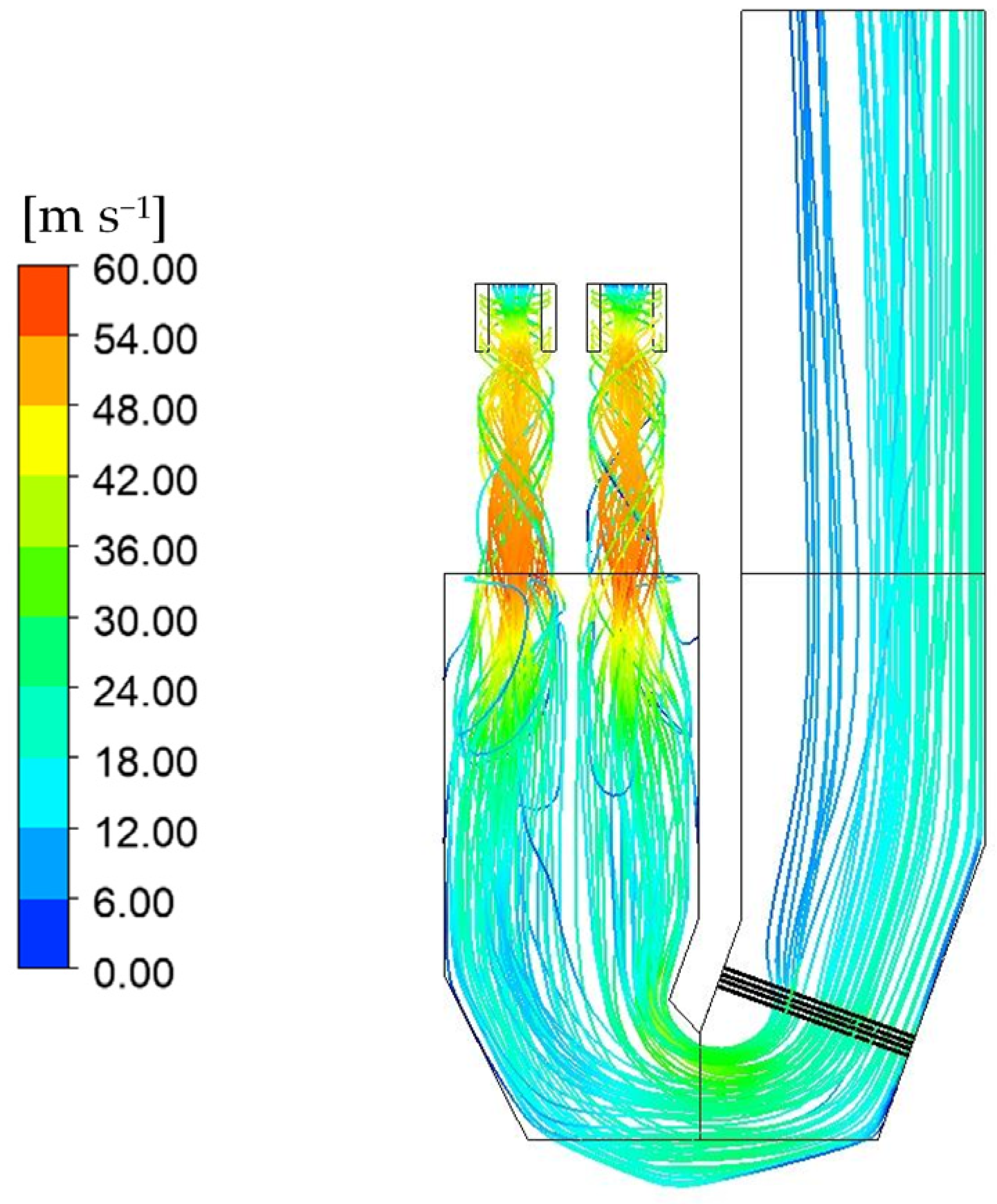

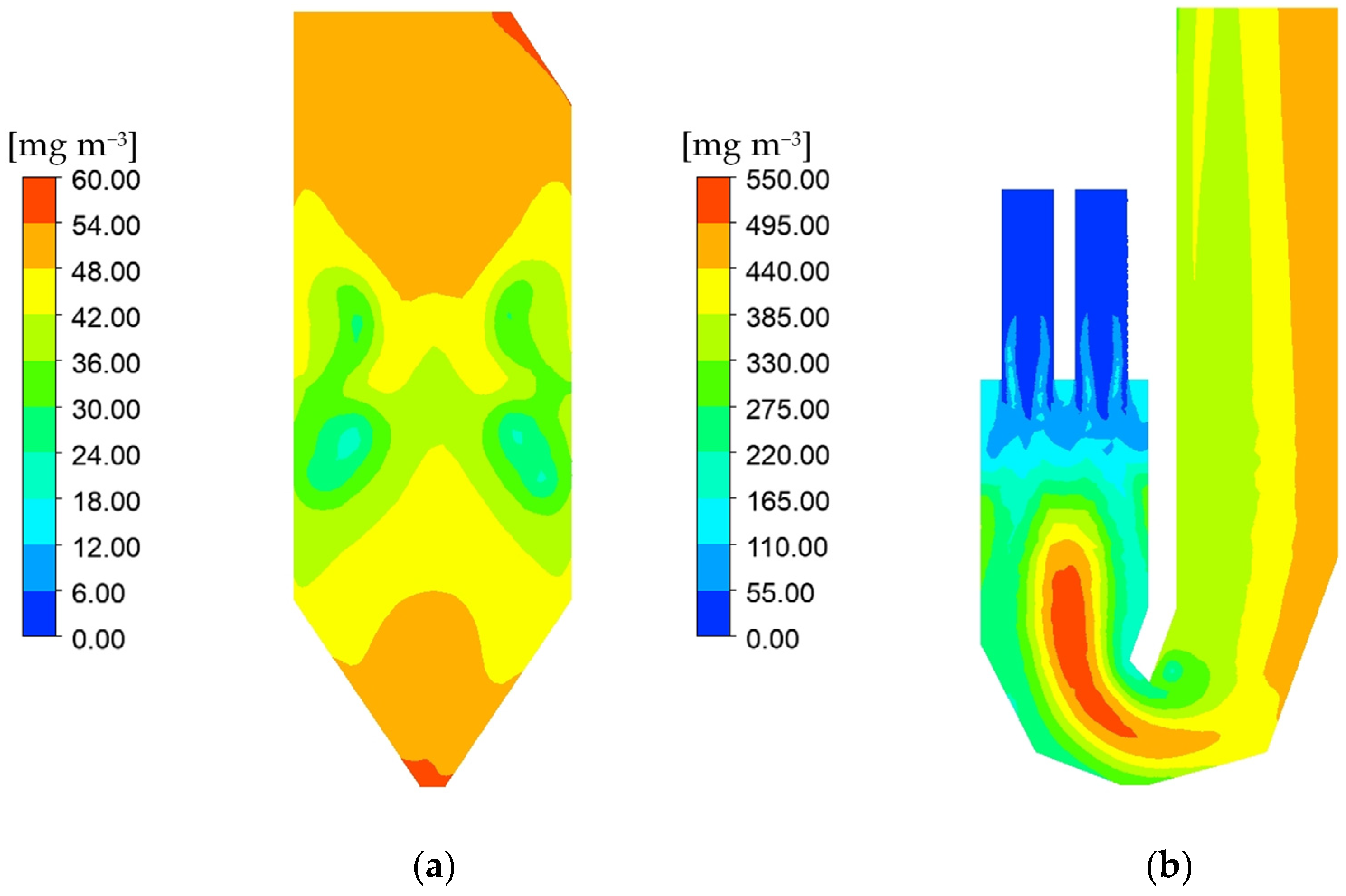

4.2. Comparison before and after Retrofit

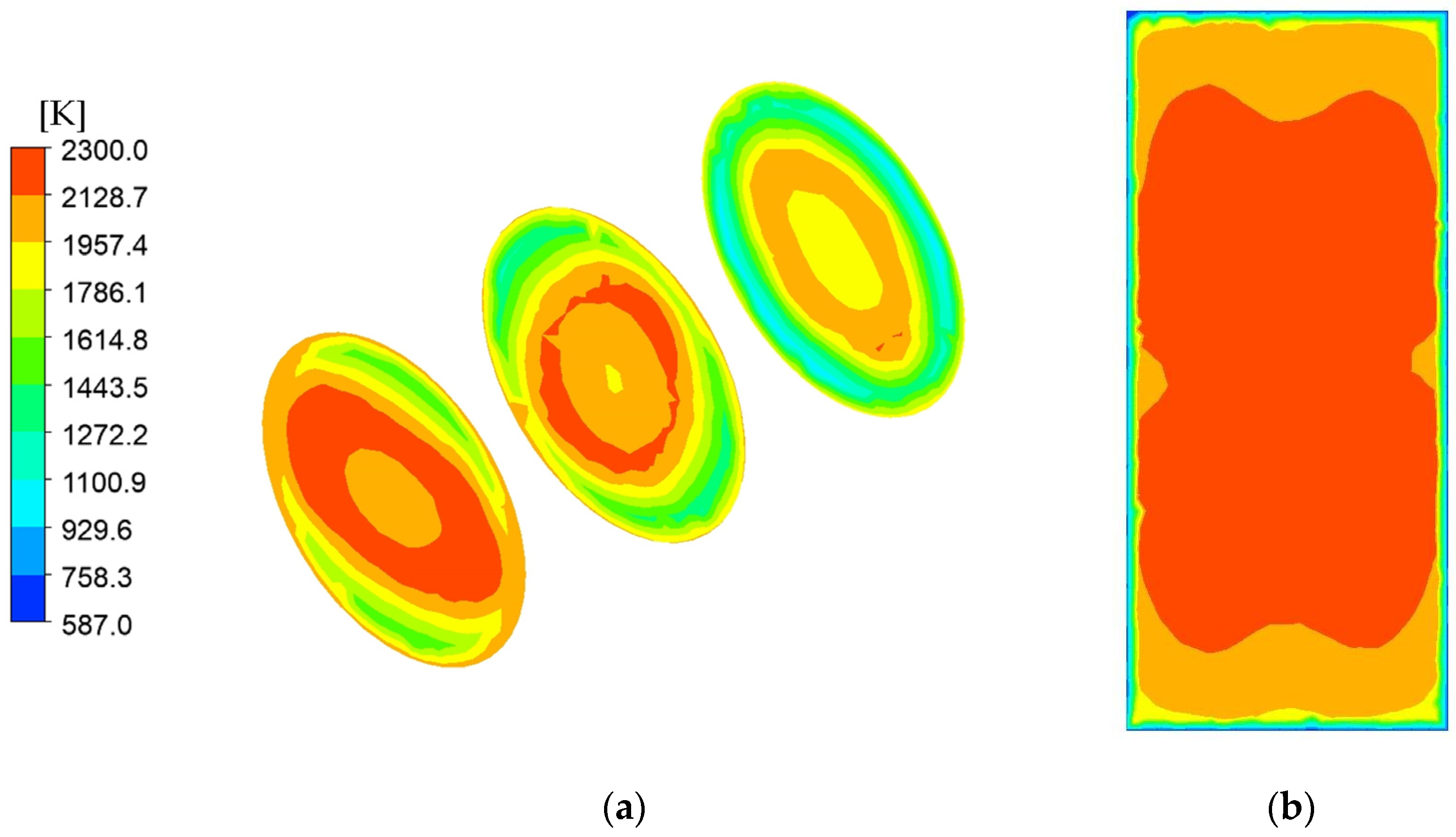

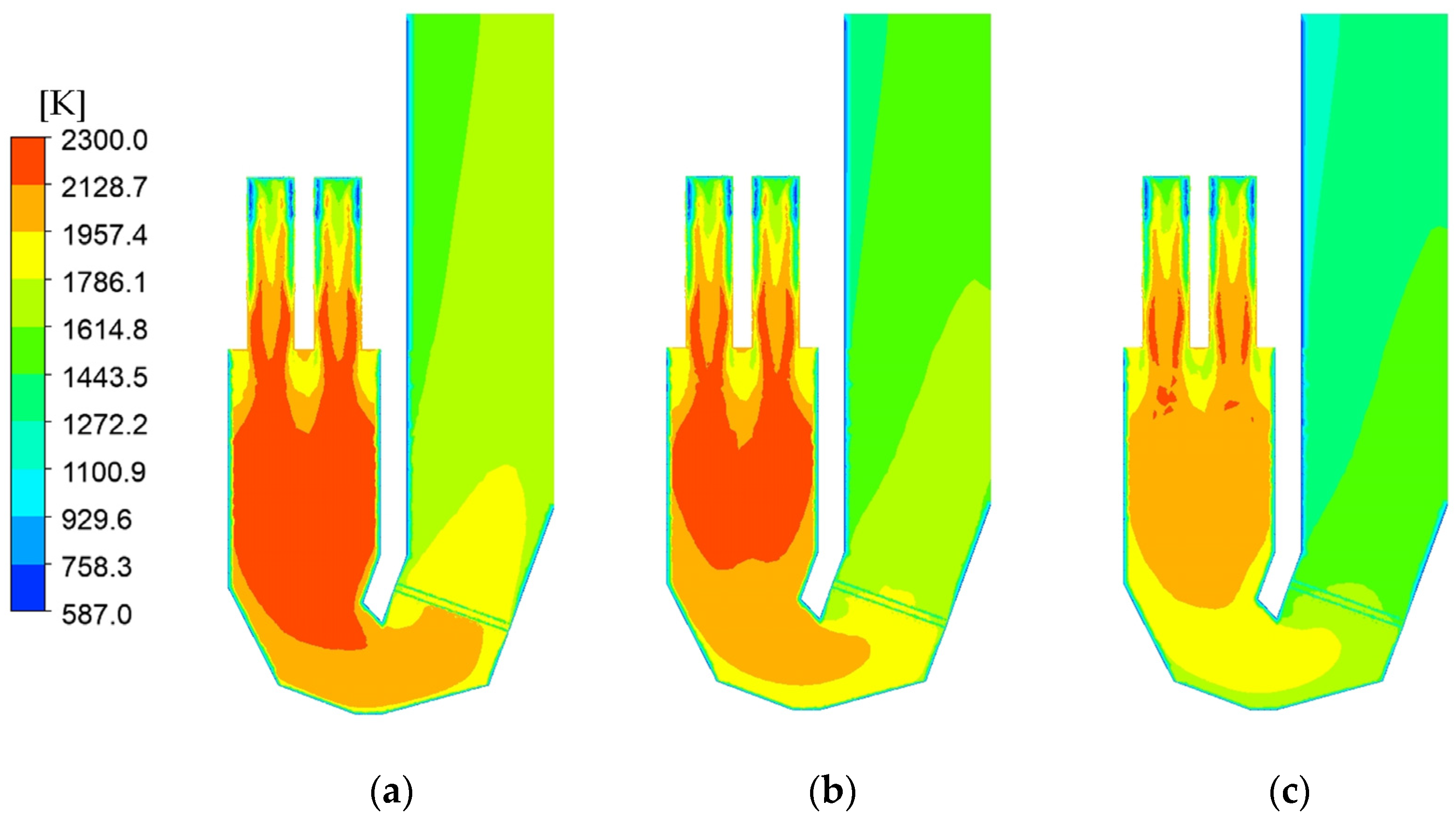

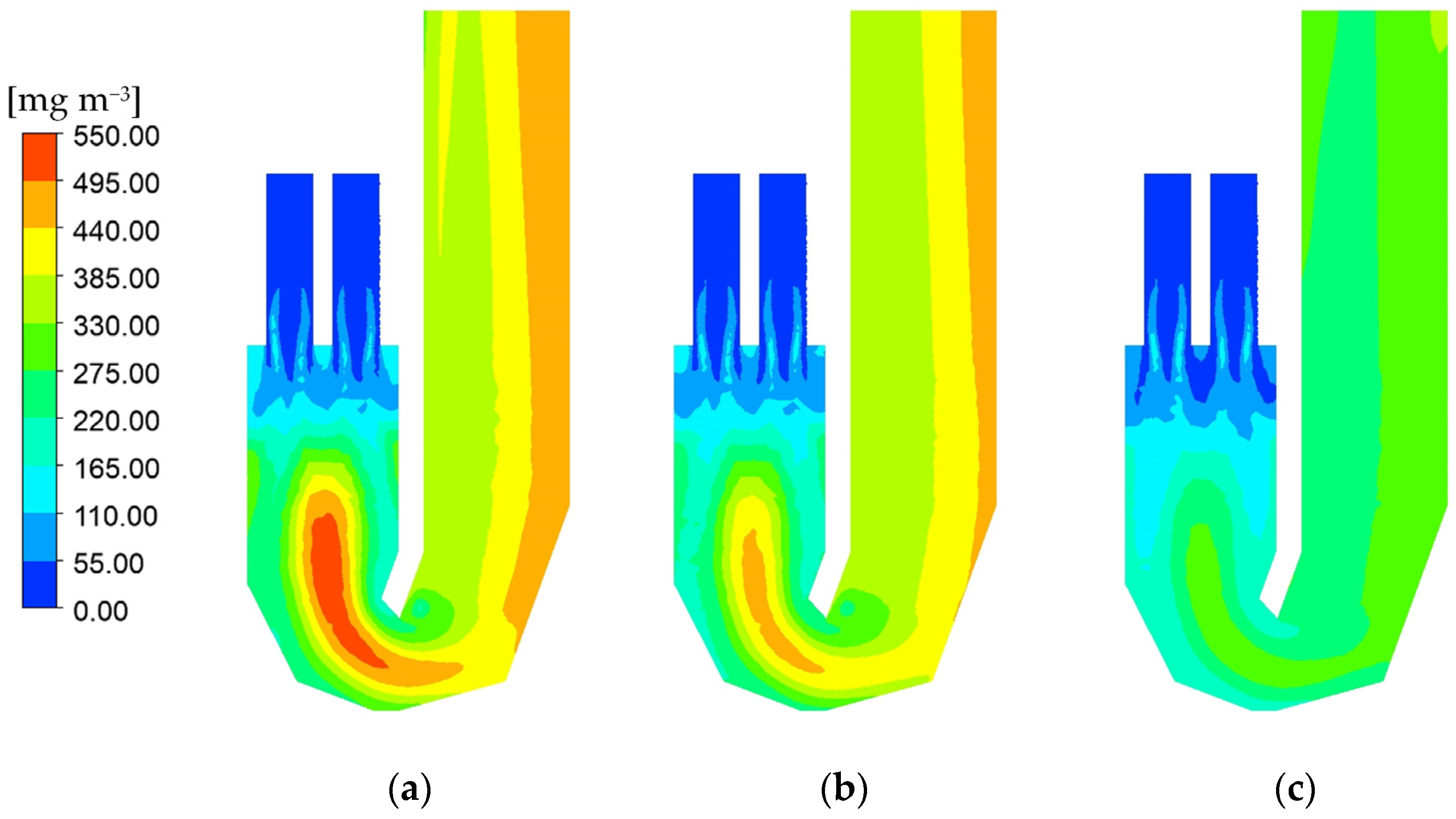

4.3. Combustion Characteristic of the Slag-Tap Boiler under Varying Boiler Loads

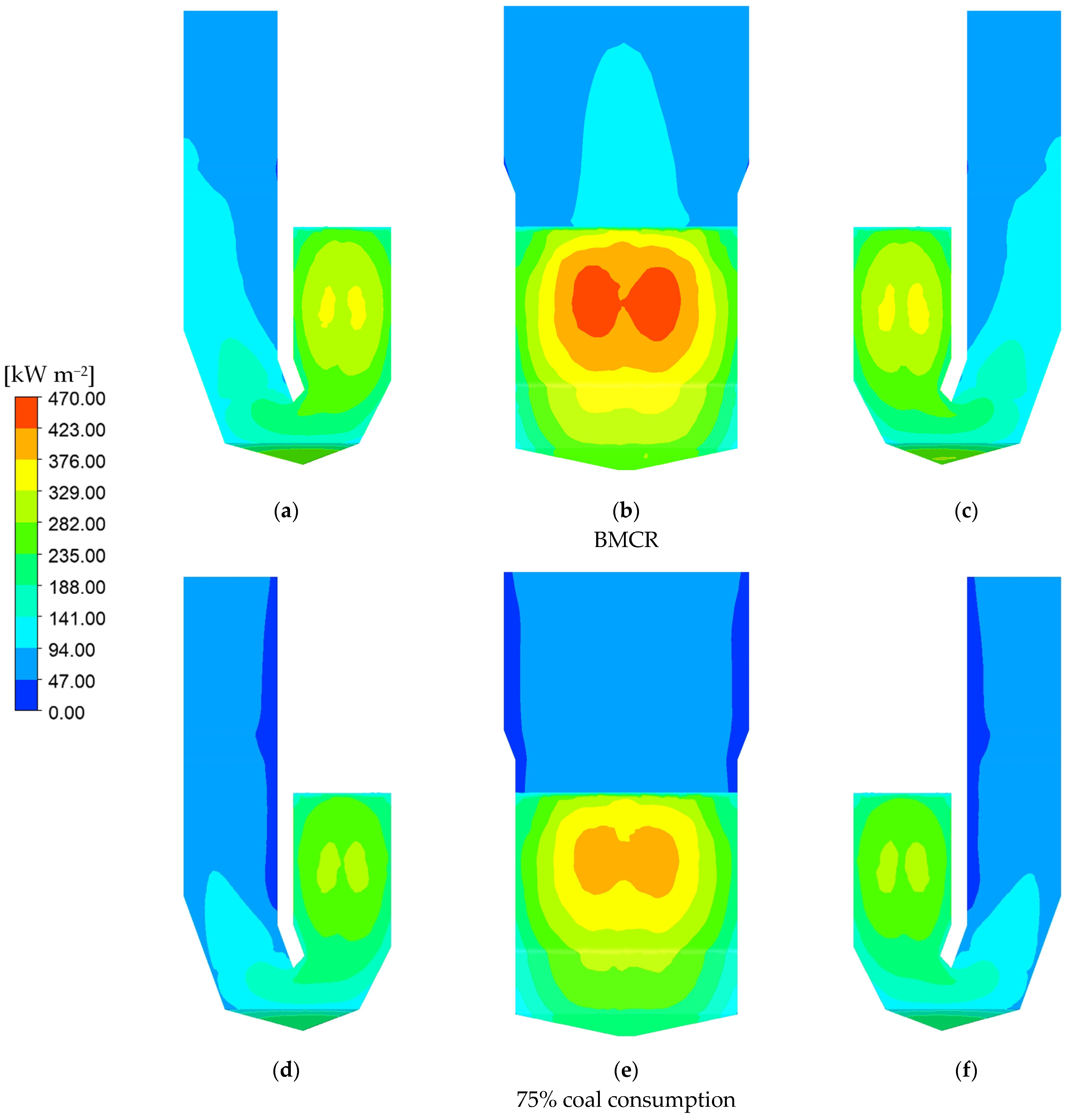

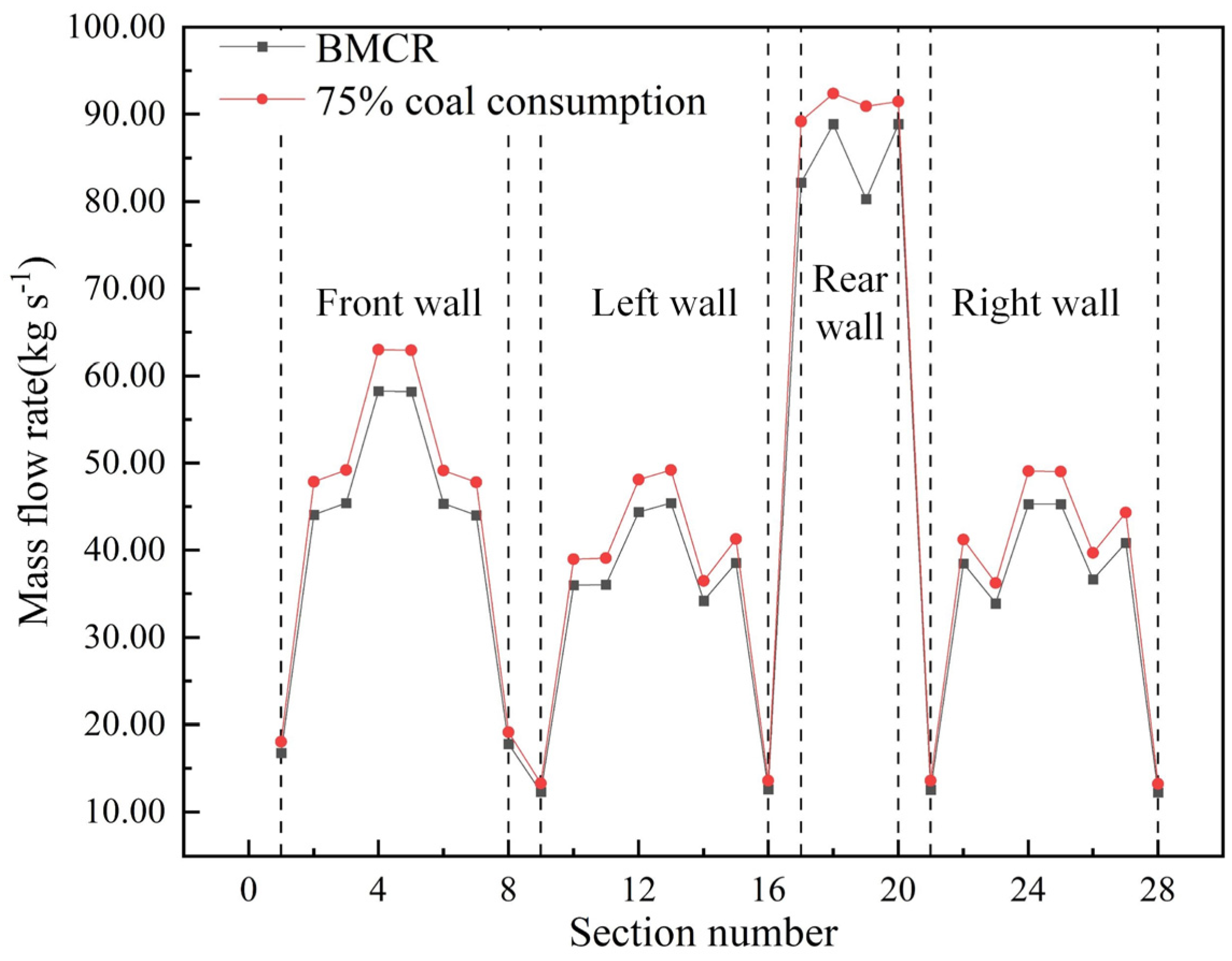

4.4. Hydrodynamic Characteristic of the Slag-Tap Boiler

5. Conclusions

- The maximum temperature in the slag-tap boiler is higher than that in the tangentially fired boiler, with values of 2095.8 and 2306.8 K, respectively. Moreover, the filling degree of high temperature flue gas is higher in the combustion chamber of the slag-tap boiler. The average temperature in the combustion chamber is 2080.3 K, ensuring that the slag can be discharged in a molten state.

- When the boiler load is decreased, the temperature level in the furnace drops obviously. When the coal consumption is halved from the BMCR condition, the maximum temperature in the furnace decreases from 2306.8 to 2220.3 K. However, the temperature distribution in the combustion chamber remains relatively uniform, which would not affect the discharge of slag.

- The slag-tap boiler exhibits reliable hydrodynamic characteristics. Under both calculated conditions, the fluid flow rate in the water-cold wall is positively correlated with the heat flux. The maximum wall temperatures under the two working conditions are 653.9 and 590.6 K, respectively, both within the safe range of the tube wall material.

- Based on the results obtained in this study, the proposed retrofit scheme demonstrates robust performance in terms of slagging and hydrodynamic safety. This retrofit approach provides a practical solution for effectively burning high-alkali coal by retrofitting tangentially fired boilers into slag-tap boilers.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, P.; Wang, C.; Zhang, M.; Cui, L.; Dong, Y. Ash problems and prevention measures in power plants burning high alkali fuel: Brief review and future perspectives. Sci. Total Environ. 2023, 901, 165985. [Google Scholar] [CrossRef] [PubMed]

- Ni, Y.; Hu, S.; Zhang, Y.; Zhang, M.; Li, H.; Zhou, H. Research on the effects of the fly ash reburning on element migration and ash deposition characteristics of high-alkali coal in a full-scale slag-tapping boiler. Fuel 2023, 335, 126952. [Google Scholar] [CrossRef]

- Tang, C.; Pan, W.; Zhang, J.; Wang, W.; Sun, X. A comprehensive review on efficient utilization methods of high-alkali coals combustion in boilers. Fuel 2022, 316, 123269. [Google Scholar] [CrossRef]

- Zhang, T.; Li, Z.; Hu, F.; Huang, X.; Liu, Z. Correlation of sodium releasing and mineral transformation characteristics with ash composition of typical high-alkali coals. Fuel Process. Technol. 2021, 224, 107035. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, M.; Yan, G.; Zhang, Z.; Zhao, P.; Guo, M.; Zhang, B. Removal of AAEMs from high alkali coal under supercritical CO2 fluid-citric acid extraction system. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 5836–5847. [Google Scholar]

- Wei, L.; Fan, Y.; Fang, F.; Guo, L.; Chen, Y.; Yang, T. Effect of sodium and mineral types on distribution of tar and BTEXN under high alkali coal fast pyrolysis. CIESC J. 2021, 72, 1702–1711. [Google Scholar]

- Jayasekara, A.S.; Brooks, B.; Steel, K.; Koshy, P.; Hockings, K.; Tahmasebi, A. Microalgae blending for sustainable metallurgical coke production—Impacts on coking behaviour and coke quality. Fuel 2023, 344, 128130. [Google Scholar] [CrossRef]

- Zhao, P.; Huang, N.; Li, J.; Cui, X. Fate of sodium and chlorine during the co-hydrothermal carbonization of high-alkali coal and polyvinyl chloride. Fuel Process. Technol. 2020, 199, 106277. [Google Scholar] [CrossRef]

- Vassilev, S.; Kitano, K.; Takeda, S.; Tsurue, T. Influence of mineral and chemical-composition of coal ashes on their fusibility. Fuel Process. Technol. 1995, 45, 27–51. [Google Scholar] [CrossRef]

- Guo, Y.; Bai, X.; Zhang, X.; Gao, G.; Wang, G.; Yao, W. Study on techniques for slagging prevention and ash deposition control in existing boilers burning high-alkali coal. Therm. Power Gener. 2022, 51, 131–140. [Google Scholar]

- Liu, Y.; Cheng, L.; Ji, J.; Zhang, W. Ash deposition behavior in co-combusting high-alkali coal and bituminous coal in a circulating fluidized bed. Appl. Therm. Eng. 2019, 149, 520–527. [Google Scholar] [CrossRef]

- Wang, Y.; Bai, Y.; Zou, L.; Liu, Y.; Li, F.; Zhao, Q. Co-combustion characteristics and ash melting behavior of sludge/high-alkali coal blends. Combust. Sci. Technol. 2024, 196, 177–194. [Google Scholar] [CrossRef]

- Hariana; Prismantoko, A.; Prabowo; Hilmawan, E.; Darmawan, A.; Aziz, M. Effectiveness of different additives on slagging and fouling tendencies of blended coal. J. Energy Inst. 2023, 107, 101192. [Google Scholar] [CrossRef]

- Prokhorov, V.; Kirichkov, V.; Chernov, S. Physical and mathematical modeling of solid fuel combustion in the application of direct-flow burners. J. Phys. Conf. Ser. 2019, 1261, 012028. [Google Scholar] [CrossRef]

- Wang, W.; Sun, Y.; Huang, Z.; Liao, Y.; Fang, F. Numerical simulation of NOx emission characteristics of a cyclone boiler with slag-tap furnace. ACS Omega 2020, 5, 29978–29987. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Huang, Z.; Fang, F.; Liao, Y. Effect of primary air blade inclination angle on combustion and NOx emission of a cyclone boiler with slag-tap furnace. J. Chin. Soc. Power Eng. 2021, 41, 8–13. [Google Scholar] [CrossRef]

- Ni, Y.; Hu, S.; Meng, H.; Wang, J.; Li, H.; Zhou, H.; Ma, X.; Zhou, H. Experimental research on fully burning high-alkali coal in a 300 MW boiler with slag-tap furnace. Asia-Pac. J. Chem. Eng. 2022, 17, e2807. [Google Scholar] [CrossRef]

- Jing, X.; Pu, Y.; Li, Z.; Tang, Q.; Yao, B.; Fu, P.; Lou, C.; Lim, M. Experimental investigation of gaseous sodium release in slag-tapping coal-fired furnaces by spontaneous emission spectroscopy. Energies 2022, 15, 4165. [Google Scholar] [CrossRef]

- Zhou, C.; Zhou, H.; Xing, Y.; Zhang, J.; Zhou, M. Effect of additives on flow characteristics and sodium capture efficiency of high alkali coal ash slag. J. Zhejiang Univ.-Sc. A 2020, 54, 623–630. [Google Scholar]

- Liu, H.; Yu, P.; Xue, J.; Deng, L.; Che, D. Research and application of double-reheat boiler in china. Processes 2021, 9, 2197. [Google Scholar] [CrossRef]

- Zhu, M.; Lu, H.; Zhao, W.; Huang, S.; Chang, X.; Dong, L.; Kong, D.; Jing, X. A numerical study of ash deposition characteristics in a 660mw supercritical tangential boiler. Adv. Theor. Simul. 2023, 6, 2300133. [Google Scholar] [CrossRef]

- Zhong, Y.; Wang, X.; Xu, G.; Ning, X.; Zhou, L.; Tang, W.; Wang, M.; Wang, T.; Xu, J.; Jiang, L.; et al. Investigation on slagging and high-temperature corrosion prevention and control of a 1000 MW ultra supercritical double tangentially fired boiler. Energy 2023, 275, 127455. [Google Scholar] [CrossRef]

- Liao, X.; Zhang, Q.; Yang, W.; Qiu, Z.; Guo, R.; Liu, J.; Li, F.; Li, Y. The role of pulverized coal drying temperature in fly ash carbon content and slagging of a tangentially coal-fired boiler. Fuel 2019, 257, 115951. [Google Scholar] [CrossRef]

- Pei, J.; Zhang, Z.; You, C. Optimizing the combustion of low-quality coal by the wall wind auxiliary combustion method in a tangentially fired utility boiler. Combust. Sci. Technol. 2019, 191, 570–589. [Google Scholar] [CrossRef]

- Lamioni, R.; Bronzoni, C.; Folli, M.; Tognotti, L.; Galletti, C. Impact of H2-enriched natural gas on pollutant emissions from domestic condensing boilers: Numerical simulations of the combustion chamber. Int. J. Hydrogen Energy 2023, 48, 19686–19699. [Google Scholar] [CrossRef]

- Nakamura, H.; Zhang, J.; Hirose, K.; Shimoyama, K.; Ito, T.; Kanaumi, T. Generating simplified ammonia reaction model using genetic algorithm and its integration into numerical combustion simulation of 1 MW test facility. Appl. Energy Combust. Sci. 2023, 15, 100187. [Google Scholar] [CrossRef]

- Medina, P.; Beltrán, A.; Núñez, J.; Ruiz-García, V.M. Transport phenomena in a biomass plancha-type cookstove: Experimental performance and numerical simulations. Energy Sustain. Dev. 2022, 71, 132–140. [Google Scholar] [CrossRef]

- Li, Z.; Miao, Z.; Shen, X.; Li, J. Effects of momentum ratio and velocity difference on combustion performance in lignite-fired pulverized boiler. Energy 2018, 165, 825–839. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, W.; Wang, H.; Zhang, Y.; Deng, L.; Che, D. Coupled combustion and hydrodynamics simulation of a 1000 MW double-reheat boiler with different FGR positions. Fuel 2020, 261, 116427. [Google Scholar] [CrossRef]

- Zhu, M.; Chen, L.; Zhou, L.; Jiang, L.; Su, S.; Hu, S.; Xu, K.; Wang, C.; Li, A.; Qing, H.; et al. Experimental test, numerical analysis and thermal calculation modeling of hundreds kWth-class supercritical CO2 fossil-fired boiler system. Energy 2023, 284, 128523. [Google Scholar] [CrossRef]

- Zima, W.; Taler, J.; Grądziel, S.; Trojan, M.; Cebula, A.; Ocłoń, P.; Dzierwa, P.; Taler, D.; Rerak, M.; Majdak, M.; et al. Thermal calculations of a natural circulation power boiler operating under a wide range of loads. Energy 2022, 261, 125357. [Google Scholar] [CrossRef]

- Zhou, J.; Zhu, M.; Su, S.; Chen, L.; Xu, J.; Hu, S.; Wang, Y.; Jiang, L.; Zhong, W.; Xiang, J. Numerical analysis and modified thermodynamic calculation methods for the furnace in the 1000 MW supercritical CO2 coal-fired boiler. Energy 2020, 212, 118735. [Google Scholar] [CrossRef]

- Karampinis, E.; Nikolopoulos, N.; Nikolopoulos, A.; Grammelis, P.; Kakaras, E. Numerical investigation Greek lignite/cardoon co-firing in a tangentially fired furnace. Appl. Energy 2012, 97, 514–524. [Google Scholar] [CrossRef]

- Chen, S.; He, B.; He, D.; Cao, Y.; Ding, G.; Liu, X.; Duan, Z.; Zhang, X.; Song, J.; Li, X. Numerical investigations on different tangential arrangements of burners for a 600 MW utility boiler. Energy 2017, 122, 287–300. [Google Scholar] [CrossRef]

- Wei, B.; Tan, H.; Wang, Y.; Wang, X.; Yang, T.; Ruan, R. Investigation of characteristics and formation mechanisms of deposits on different positions in full-scale boiler burning high alkali coal. Appl. Therm. Eng. 2017, 119, 449–458. [Google Scholar] [CrossRef]

- Li, X.; Li, G.; Cao, Z.; Xu, S. Research on flow characteristics of slag film in a slag tapping gasifier. Energy Fuels 2010, 24, 5109–5115. [Google Scholar] [CrossRef]

- Zhu, T.; Tang, C.; Ning, X.; Wang, L.; Deng, L.; Che, D. Experimental study on NOx emission characteristics of Zhundong coal in cyclone furnace. Fuel 2022, 311, 122536. [Google Scholar] [CrossRef]

- Zhu, B.; Shang, B.; Guo, X.; Wu, C.; Chen, X.; Zhao, L. Study on combustion characteristics and NOx formation in 600 MW coal-fired boiler based on numerical simulation. Energies 2023, 16, 262. [Google Scholar] [CrossRef]

- Choi, C.; Kim, C. Numerical investigation on the flow, combustion and NOx emission characteristics in a 500 MWe tangentially fired pulverized-coal boiler. Fuel 2009, 88, 1720–1731. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, W.; Xu, W. A study of the hydrodynamic characteristics of a vertical water wall in a 2953 t/h ultra-supercritical pressure boiler. Int. J. Heat Mass Trans. 2015, 86, 404–414. [Google Scholar] [CrossRef]

- Peng, D.; Xu, Y.; Lan, R. Loop analysis method for the numerical calculation of hydrodynamic characteristic of boiler with natural circulation. J. Harbin Inst. Technol. 2007, 39, 462–466. [Google Scholar]

| Parameter | Outlet Flow of Superheater (t h−1) | Superheated Steam Temperature (K) | Superheated Steam Pressure (MPa) | Feed Water Temperature (K) | Exhaust Gas Temperature (K) | Outlet Excess Air Ratio | Boiler Thermal Efficiency (%) |

|---|---|---|---|---|---|---|---|

| Value | 1025 | 814.0 | 17.5 | 555.0 | 409.0 | 1.25 | 93.24 |

| Proximate Analysis (%) | Elemental Analysis (%) | Qnet,ar (MJ kg−1) | ||||||

|---|---|---|---|---|---|---|---|---|

| Mar | Aar | Vdaf | Car | Har | Oar | Nar | Sar | |

| 17.25 | 14.72 | 32.04 | 54.31 | 2.78 | 9.84 | 0.56 | 0.54 | 19.937 |

| Proximate Analysis (%) | Elemental Analysis (%) | Qnet,ar (MJ kg−1) | ||||||

|---|---|---|---|---|---|---|---|---|

| Mar | Aar | Vdaf | Car | Har | Oar | Nar | Sar | |

| 22.60 | 11.02 | 45.42 | 50.46 | 3.32 | 11.46 | 0.67 | 0.47 | 18.800 |

| Deformation Temperature (K) | Softening Temperature (K) | Hemisphere Temperature (K) | Flow Temperature (K) |

|---|---|---|---|

| 1413 | 1433 | 1453 | 1463 |

| Working Condition | Boiler Type | Fuel Type | Excess Air Ratio | Coal Consumption (t h−1) |

|---|---|---|---|---|

| 1 | Tangentially fired boiler | Design coal | 1.25 | 143.3 |

| 2 | Slag-tap boiler | Naomaohu coal | 150.4 | |

| 3 | Slag-tap boiler | Naomaohu coal | 112.8 | |

| 4 | Slag-tap boiler | Naomaohu coal | 75.2 |

| Wall | Number | Fluid Temperature (K) | Average Tube Wall Temperature (K) | Front Point Wall Temperature (K) | Fin Center Temperature (K) |

|---|---|---|---|---|---|

| Front wall | Gf1 | 629.47 | 636.64 | 638.72 | 636.11 |

| Gf2 | 633.93 | 647.02 | 651.84 | 647.88 | |

| Gf3 | 633.39 | 643.06 | 649.02 | 647.14 | |

| Gf4 | 632.76 | 642.7 | 649.15 | 647.3 | |

| Gf5 | 632.6 | 641.19 | 646.78 | 645.18 | |

| Gf6 | 632.47 | 638.42 | 642.28 | 641.17 | |

| Left wall | Gl1 | 624.52 | 627.85 | 628.91 | 627.74 |

| Gl2 | 628.63 | 643.79 | 648.63 | 643.61 | |

| Gl3 | 633.49 | 643.63 | 649.63 | 647.59 | |

| Gl4 | 633.03 | 643.13 | 649.67 | 647.78 | |

| Gl5 | 632.69 | 641.36 | 647.04 | 645.43 | |

| Gl6 | 632.6 | 638.59 | 642.52 | 641.41 | |

| Rear wall | Gre1 | 629.01 | 635.95 | 638.03 | 635.54 |

| Gre2 | 633.4 | 649.11 | 653.87 | 648.53 | |

| Gre3 | 633.46 | 643.18 | 649.13 | 647.24 | |

| Gre4 | 633.02 | 643 | 649.45 | 647.58 | |

| Gre5 | 632.86 | 646.31 | 653.1 | 646.45 | |

| Right wall | Gr1 | 624.79 | 628.3 | 629.35 | 628.09 |

| Gr2 | 629.34 | 645.27 | 650.09 | 644.66 | |

| Gr3 | 633.37 | 643.4 | 649.41 | 647.42 | |

| Gr4 | 632.74 | 642.82 | 649.37 | 647.49 | |

| Gr5 | 632.58 | 641.27 | 646.95 | 645.34 | |

| Gr6 | 632.46 | 638.46 | 642.39 | 641.27 |

| Wall | Number | Fluid Temperature (K) | Average Tube Wall Temperature (K) | Front Point Wall Temperature (K) | Fin Center Temperature (K) |

|---|---|---|---|---|---|

| Front wall | Gf1 | 573.19 | 578.17 | 580.17 | 578.62 |

| Gf2 | 572.98 | 578.83 | 584.58 | 583.31 | |

| Gf3 | 572.47 | 579.27 | 585.98 | 584.56 | |

| Gf4 | 571.84 | 579.11 | 586.29 | 584.81 | |

| Gf5 | 571.56 | 577.85 | 584.08 | 582.8 | |

| Gf6 | 571.42 | 575.77 | 580.08 | 579.19 | |

| Left wall | Gl1 | 573.2 | 575.91 | 576.92 | 576.04 |

| Gl2 | 572.98 | 578.92 | 584.75 | 583.44 | |

| Gl3 | 572.45 | 579.35 | 586.15 | 584.71 | |

| Gl4 | 571.82 | 579.2 | 586.48 | 584.98 | |

| Gl5 | 571.55 | 577.94 | 584.25 | 582.95 | |

| Gl6 | 571.42 | 575.84 | 580.2 | 579.3 | |

| Rear wall | Gre1 | 573.25 | 578.39 | 580.38 | 578.75 |

| Gre2 | 573.05 | 578.9 | 584.65 | 583.39 | |

| Gre3 | 572.58 | 579.38 | 586.08 | 584.67 | |

| Gre4 | 572.11 | 579.38 | 586.57 | 585.08 | |

| Gre5 | 571.89 | 584.19 | 590.57 | 584.49 | |

| Right wall | Gr1 | 573.2 | 575.91 | 576.92 | 576.04 |

| Gr2 | 572.98 | 578.92 | 584.75 | 583.44 | |

| Gr3 | 572.45 | 579.35 | 586.15 | 584.71 | |

| Gr4 | 571.82 | 579.2 | 586.48 | 584.98 | |

| Gr5 | 571.55 | 577.94 | 584.25 | 582.95 | |

| Gr6 | 571.42 | 575.84 | 580.2 | 579.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Q.; Yang, J.; Zhao, Y.; Du, J.; Da, Y.; Che, D. Numerical Study and Hydrodynamic Calculation of the Feasibility of Retrofitting Tangentially Fired Boilers into Slag-Tap Boilers. Processes 2023, 11, 3442. https://doi.org/10.3390/pr11123442

Guo Q, Yang J, Zhao Y, Du J, Da Y, Che D. Numerical Study and Hydrodynamic Calculation of the Feasibility of Retrofitting Tangentially Fired Boilers into Slag-Tap Boilers. Processes. 2023; 11(12):3442. https://doi.org/10.3390/pr11123442

Chicago/Turabian StyleGuo, Qianxin, Jiahui Yang, Yonggang Zhao, Jiajun Du, Yaodong Da, and Defu Che. 2023. "Numerical Study and Hydrodynamic Calculation of the Feasibility of Retrofitting Tangentially Fired Boilers into Slag-Tap Boilers" Processes 11, no. 12: 3442. https://doi.org/10.3390/pr11123442

APA StyleGuo, Q., Yang, J., Zhao, Y., Du, J., Da, Y., & Che, D. (2023). Numerical Study and Hydrodynamic Calculation of the Feasibility of Retrofitting Tangentially Fired Boilers into Slag-Tap Boilers. Processes, 11(12), 3442. https://doi.org/10.3390/pr11123442