Study of the Grinding Process by Friction of Cereal Grains in Stone Mills

Abstract

:1. Introduction

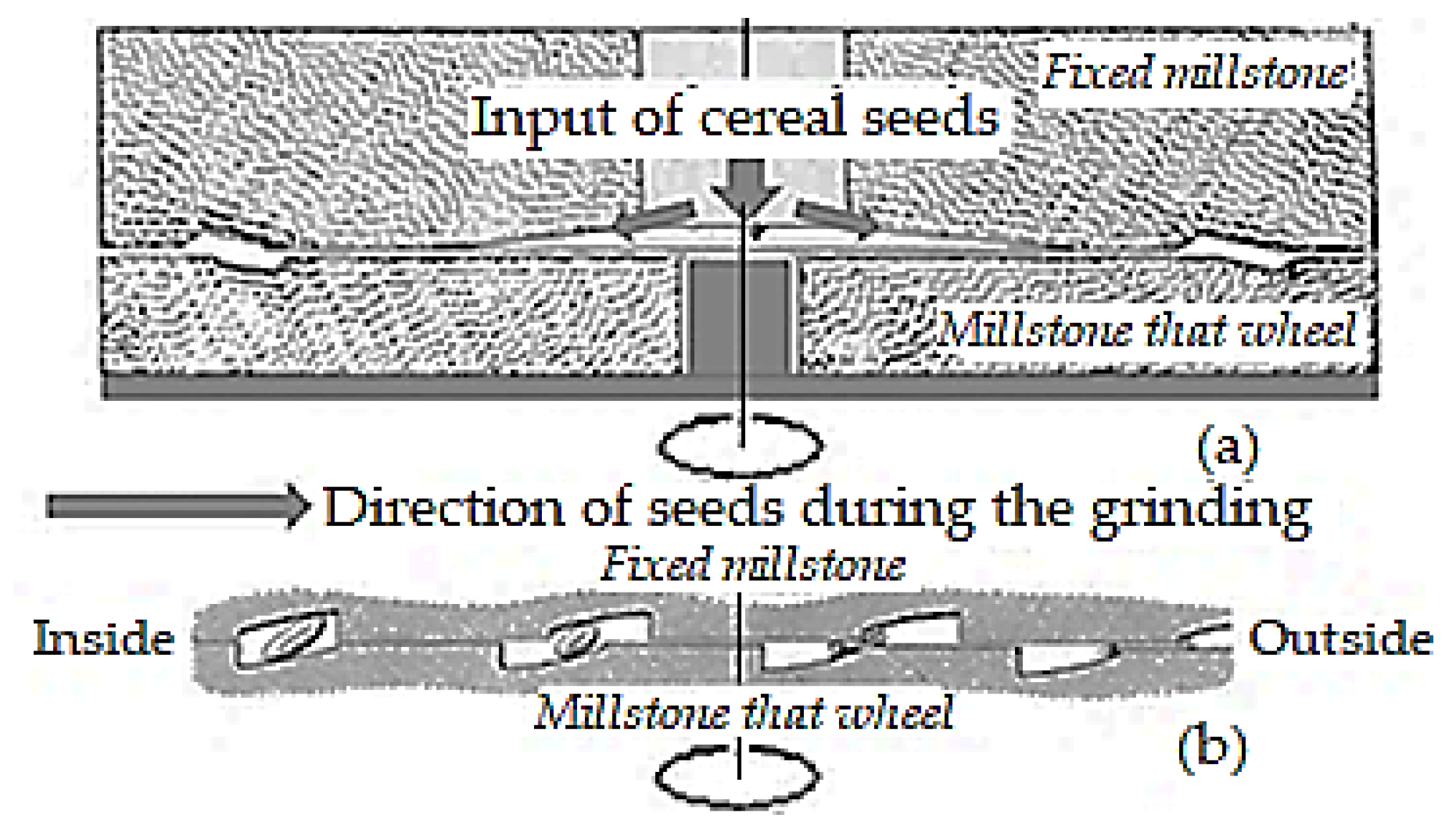

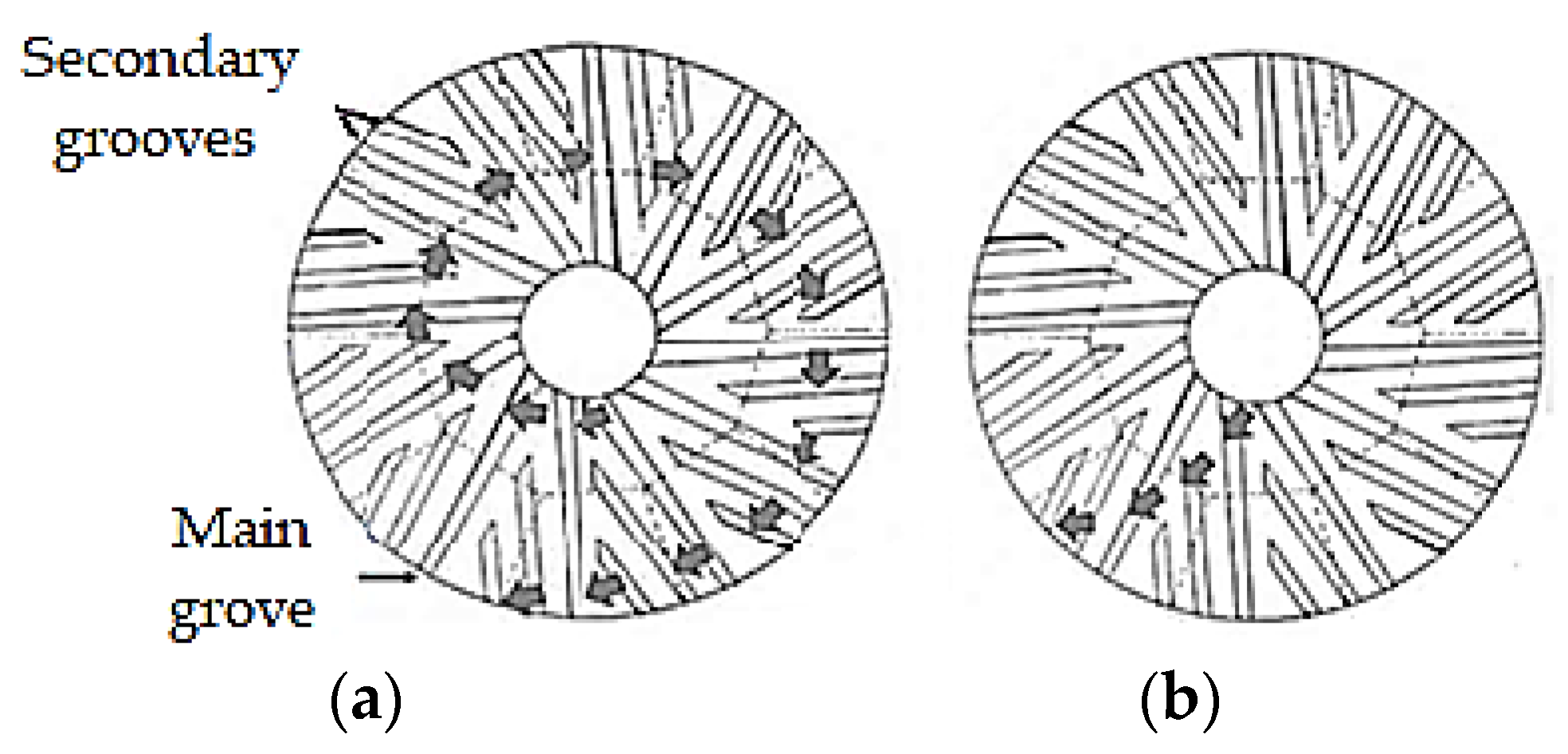

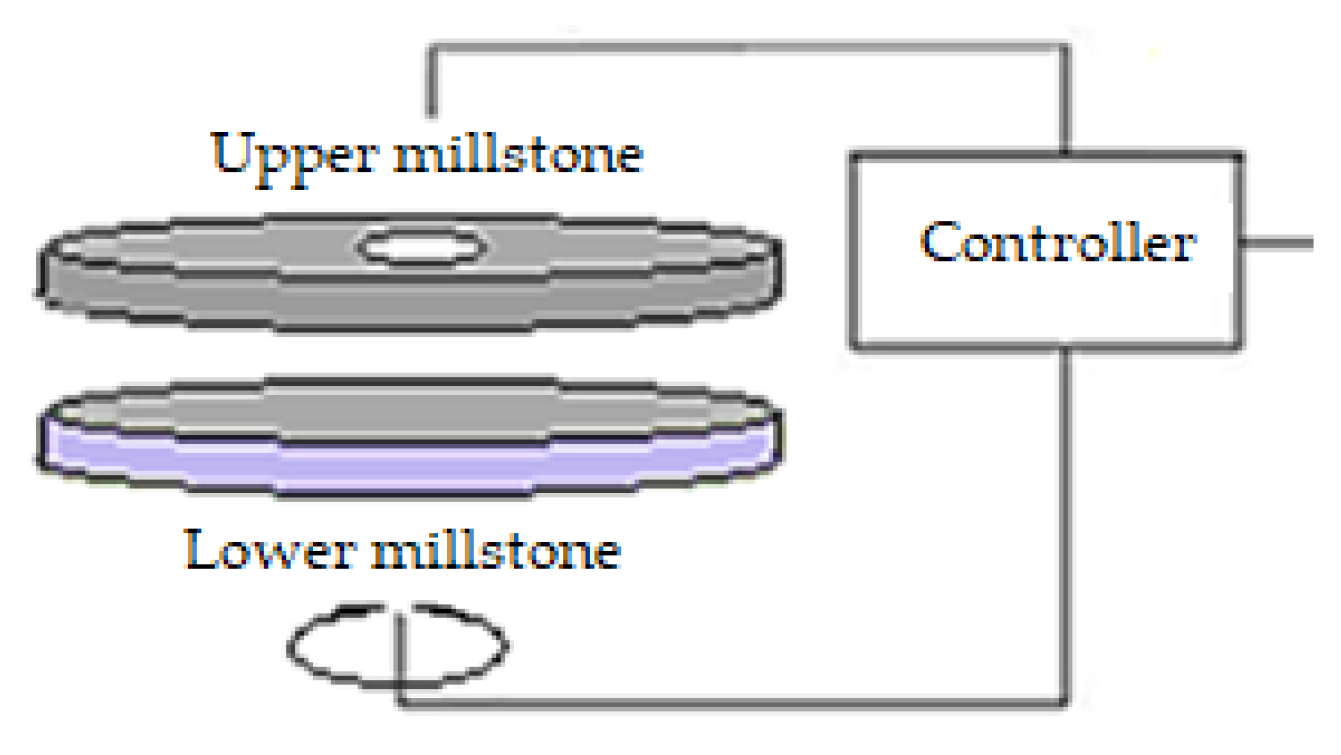

2. Materials and Methods

3. Results and Discussion

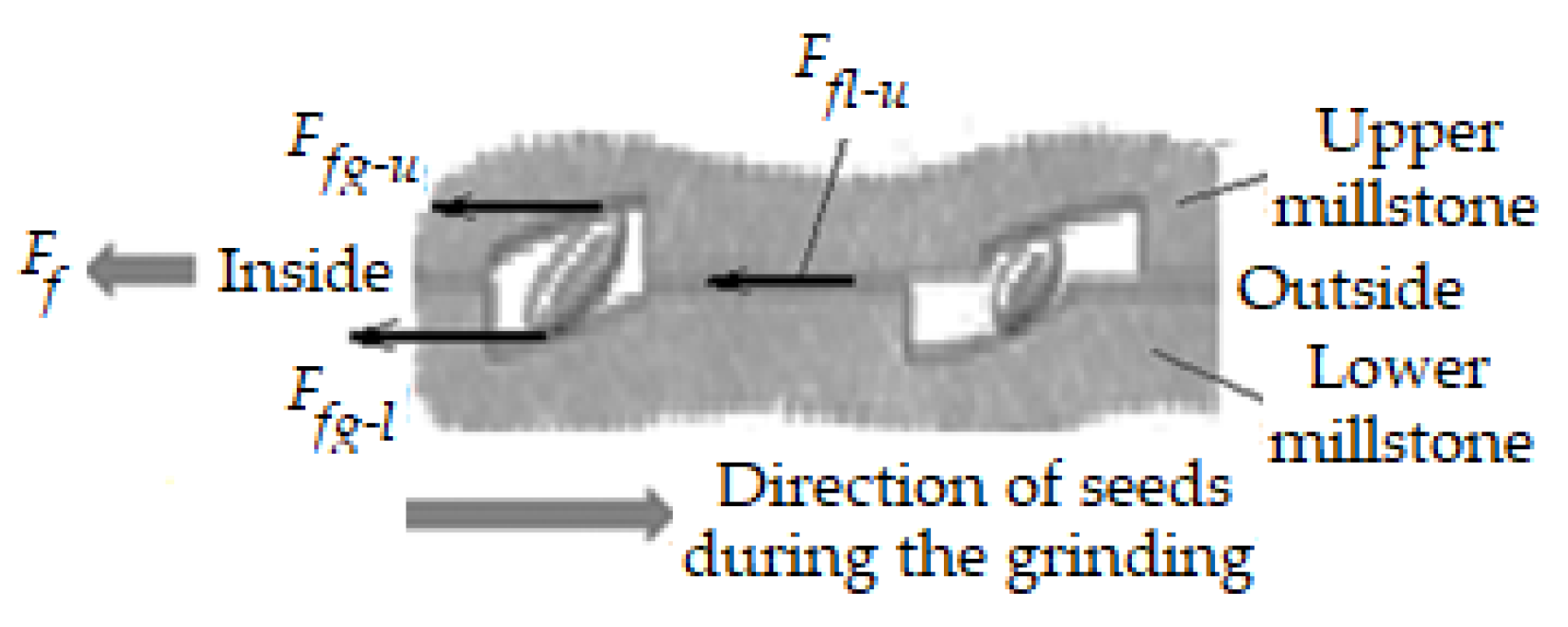

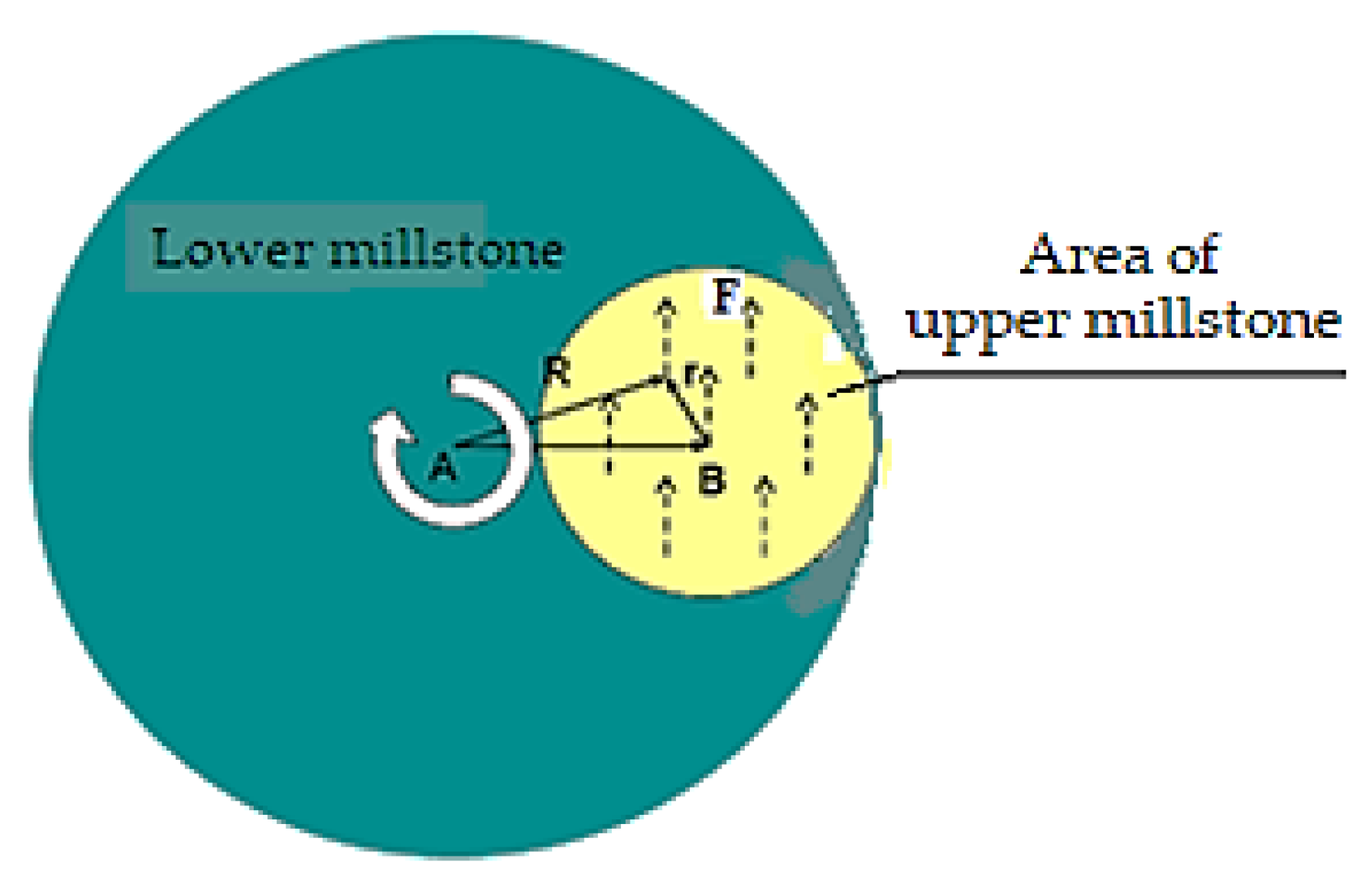

3.1. Friction Modeling

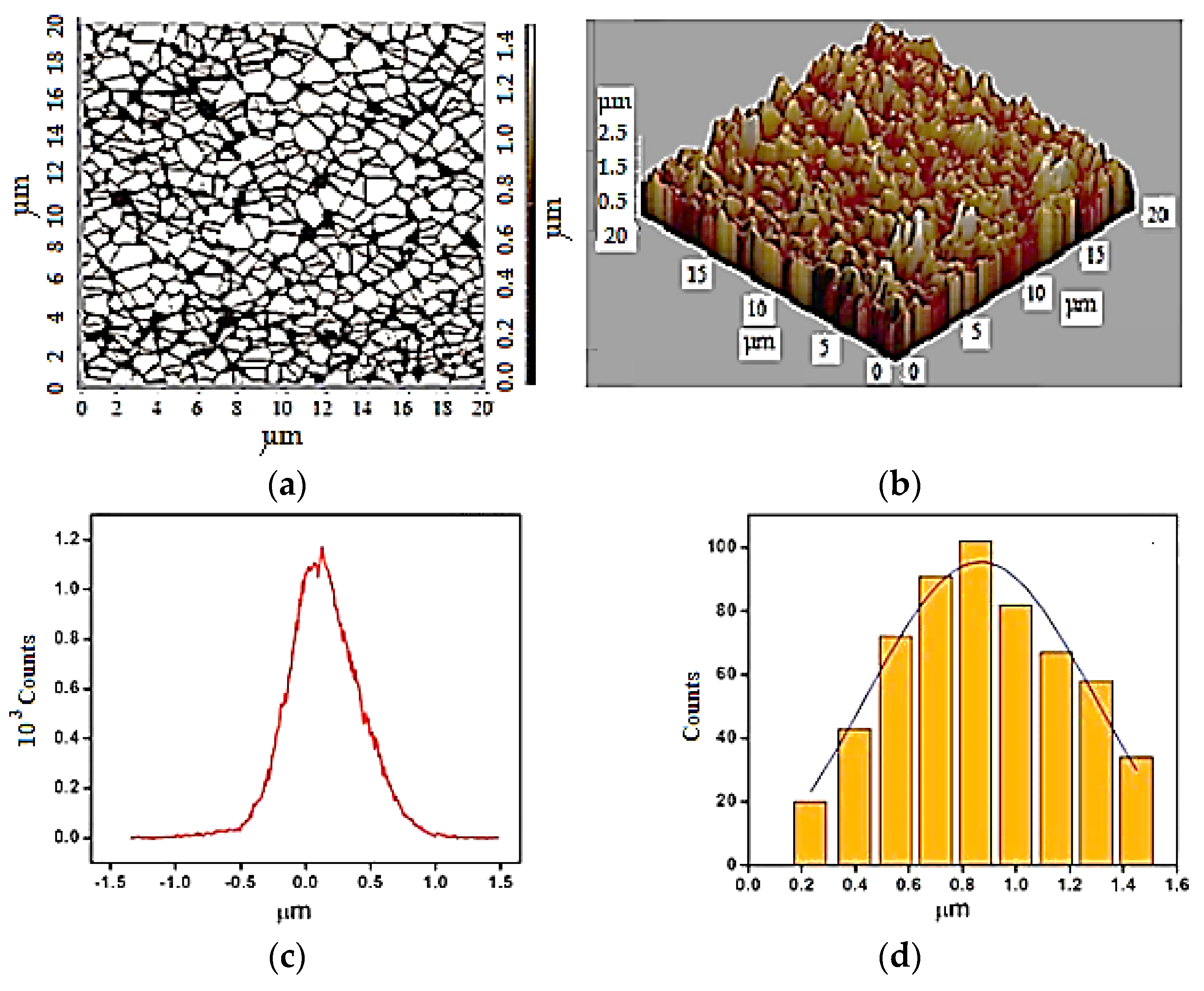

3.2. Experimental Procedure

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Thielecke, F.; Lecerf, J.-M.; Nugent, A. Processing in the food chain: Do cereals have to be processed to add value to the human diet? Nutr. Res. Rev. 2020, 34, 159–173. [Google Scholar] [CrossRef] [PubMed]

- Papageorgiou, M.; Skendi, A. Chapter 1—Introduction to cereal processing and by-products. In Sustainable Recovery and Reutilization of Cereal Processing By-Products; Woodhead Publishing: Sawston, UK, 2018. [Google Scholar] [CrossRef]

- Rana, R.; Tricase, C.; Padalino, L.; Mastromatteo, M.; Del Nobile, M.; Conte, A. Milling Process of Cereal Grains and Quality of Flours. Int. J. Sci. 2014, 3. Available online: https://www.ijSciences.com (accessed on 10 January 2023).

- Chondrou, D.; Bofill, M.; Procopiou, H.; Vargiolu, R.; Zahouani, H.; Valamoti, S.M. How do you like your cereal? A qualitative and quantitative use-wear analysis on archaeological grinding tools from prehistoric Greek sites. Wear 2021, 476, 203636. [Google Scholar] [CrossRef]

- Li, A.; Han, Y.; Jia, F.; Zhang, J.; Meng, X.; Chen, P.; Xiao, Y.; Zhao, H. Examination milling non-uniformity in friction rice mills using by discrete element method and experiment. Biosyst. Eng. 2021, 211, 247–259. [Google Scholar] [CrossRef]

- Jung, H.; Lee, Y.J.; Yoon, W.B. Effect of Moisture Content on the Grinding Process and Powder Properties in Food: A Review. Processes 2018, 6, 69. [Google Scholar] [CrossRef]

- Zeng, Y.; Jia, F.; Meng, X.; Han, Y.; Xiao, Y. The effects of friction characteristic of particle on milling process in a horizontal rice mill. Adv. Powder Technol. 2018, 29, 1280–1291. [Google Scholar] [CrossRef]

- Li, A.; Jia, F.; Zhang, J.; Han, Y.; Meng, X.; Chen, P.; Wang, Y.; Zhao, H. The effects of filling level on the milling accuracy of rice in the friction rice mill. Powder Technol. 2022, 398, 117052. [Google Scholar] [CrossRef]

- Almessiere, M.A.; Algarou, N.A.; Slimani, Y.; Sadaqat, A.; Baykal, A.; Manikandan, A.; Trukhanov, S.V.; Trukhanov, A.V.; Ercan, I. Investigation of exchange coupling and microwave properties of hard/soft (SrNi0.02Zr0.01Fe11.96O19)/(CoFe2O4)x nanocomposites. Mater. Today Nano 2022, 18, 100186. [Google Scholar] [CrossRef]

- Kaliniewicz, Z.; Jadwisieńczak, K.; Żuk, Z.; Konopka, S.; Frączyk, A.; Krzysiak, Z. Effects of Friction Plate Hardness and Surface Orientation on the Frictional Properties of Cereal Grain. Int. J. Food Sci. 2020, 2020, 6639233. [Google Scholar] [CrossRef]

- Khozyaev, I.; Savenkov, D.; Kirischiev, O.; Kirischieva, Y.; Tupolskikh, T. Study of the dynamics of the coefficient of external friction of seeds crops with shell. E3S Web Conf. Interagromash 2021, 273, 01032. [Google Scholar] [CrossRef]

- Gierz, Ł.; Kolankowska, E.; Markowski, P.; Koszela, K. Measurements and Analysis of the Physical Properties of Cereal Seeds Depending on Their Moisture Content to Improve the Accuracy of DEM Simulation. Appl. Sci. 2022, 12, 549. [Google Scholar] [CrossRef]

- Lupu, M.I.; Pădureanu, V.; Canja, C.M.; Măzărel, A. The effect of moisture content on grinding process of wheat and maize single kernel. IOP Conf. Ser. Mater. Sci. Eng. 2016, 145, 022024. [Google Scholar] [CrossRef]

- Moon, J.H.; Yoon, W.B. Effect of moisture content and particle size on grinding kinetics and flowability ofballoon flower (Platycodon grandiflorum). Food Sci. Biotechnol. 2017, 1–10. [Google Scholar] [CrossRef]

- Hassoon, W.H.; Dziki, D.; Mis, A.; Biernacka, B. Wheat Grinding Process with Low Moisture Content: A New Approach for Wholemeal Flour Production. Processes 2021, 9, 32. [Google Scholar] [CrossRef]

- Savenkov, D.; Kirischiev, O.; Kirischieva, Y.; Tupolskikh, T.; Tatiana Maltseva, T.; Magomedov, M.; Chistyakov, A. Study of the nature of the dynamic coefficient of internal friction of grain materials. E3S Web Conf. 2019, 135, 01102. [Google Scholar] [CrossRef]

- Kozlovskiy, A.L.; Zdorovets, M.V. Study of hydrogenation processes in radiation-resistant nitride ceramics. J. Mater. Sci. Mater. Electron 2020, 31, 11227–11237. [Google Scholar] [CrossRef]

- Available online: https://www.twi-global.com/ (accessed on 10 August 2023).

- Available online: https://www.laboratuar.com/ro/ (accessed on 10 August 2023).

- Popok, V.N.; Vučković, S.; Campbell, E.E.B.; Jensen, J.; Samela, J. Nordlund, Energetic Cluster-urface Interactions. In Proceedings of the Ion-Surface Interactions, Proceedings of XIX International Conference, Zvenigorod, Russia, 21–25 August 2009; Volume 1, pp. 49–54. [Google Scholar]

- Sweatman, M.; Afify, N.; Ferreiro-Rangel, C.; Jorge, M.; Sefcik, J. Molecular Dynamics Investigation of Clustering in Aqueous Glycine Solutions. J. Phys. Chem. B 2022, 126, 4711–4722. [Google Scholar] [CrossRef]

- Afify, N.; Ferreiro-Rangel, C.; Sweatman, M. Molecular Dynamics Investigation of Giant Clustering in Small-Molecule Solutions: The Case of Aqueous PEHA. J. Phys. Chem. B 2022, 126, 8882–8891. [Google Scholar] [CrossRef]

- Ilie, F. Movement, and collision of nanoparticles in the process of chemical mechanical polishing (CMP). INMATEH—Agric. Eng. 2013, 39, 85–90. [Google Scholar]

- Ilie, F.; Ipate, G. Chemical-Mechanical Impact of Nanoparticles and pH Effect of the Slurry on the CMP of the Selective Layer Surfaces. Lubricants 2017, 5, 15. [Google Scholar] [CrossRef]

- Sand Blasting Aluminium Oxide/Brown Fused Alumina—Products—Dengfeng Sweet Abrasives Co., Ltd.—Ruixiangmc.com. Available online: http://dfsweet.ruixiangmc.com/sell/itemid-950.shtml (accessed on 15 November 2023).

- Wassilkowska, A.; Czaplicka-Kotas, A.; Zielina, M.; Bielski, A. An analysis of the elemental composition of micro-samples using eds technique. Tech. Trans. Chem. 2014, 1-Ch/2014, 133–148. [Google Scholar]

- Belderok, B. Milling of wheat. Plant Foods Hum. Nutr. 2000, 55, 21–29. [Google Scholar] [CrossRef] [PubMed]

- Madureri, E. Storia della Macinazione dei Cereali; Edizioni Chiriotti: Torino, Italy, 1995; ISBN 9788885022546. [Google Scholar]

- Perec, A. Research into the Disintegration of Abrasive Materials in the Abrasive Water Jet Machining Process. Materials 2021, 14, 3940. [Google Scholar] [CrossRef] [PubMed]

- Maletsky, A.V.; Belichko, D.R.; Konstantinova, T.E.; Volkova, G.K.; Doroshkevich, A.S.; Lyubchyk, A.I.; Burkhovetskiy, V.V.; Aleksandrov, V.A.; Mardare, D.; Mita, C.; et al. Structure formation and properties of corundum ceramics based on metastable aluminium oxide doped with stabilized zirconium dioxide. Ceram. Int. 2021, 47, 19489–19495. [Google Scholar] [CrossRef]

- Xia, J.; Yu, J.; Lu, S.; Huang, Q.; Xie, C.; Wang, Z. Surface Morphology Evolution during Chemical Mechanical Polishing Based on Microscale Material Removal Modeling for Monocrystalline Silicon. Materials 2022, 15, 5641. [Google Scholar] [CrossRef] [PubMed]

- Salerno, E.; Casotti, D.; Paolicelli, G.; Gualtieri, E.; Ballestrazzi, A.; Gazzadi, G.C.; Bolelli, G.; Lusvarghi, L.; Valeri, S.; Rota, A. Friction and wear of DLC films deposited on additive manufactured AlSi10Mg: The role of surface finishing. Surf. Coat. Technol. 2023, 463, 129531. [Google Scholar] [CrossRef]

- Albahrani, S.M.B.; Alves, J.T.; Duval, A.; Chaise, T.; De Vaujany, J.-P.; Michèle Guingand, M. Modelling of elastoplastic, multi-scale and multi-contact problems: Application to worm gears. Mech. Ind. 2022, 23, 6. [Google Scholar] [CrossRef]

- Boning, D.; Xie, X.; Sorooshian, J.; Philipossian, A.; Stein, D.; Hetherington, D. Relationship between patterned wafer topography evolution and STI CMP motor current endpoint signals. In Proceedings of the 9th International CMP-MIC Conference, Marina Beach, Dubai, United Arab Emirates, 16–18 November 2021; Volume 341. [Google Scholar]

- Zake-Tiluga, I.; Svinka, R.; Svinka, V. Highly porous corundum–mullite ceramics—Structure and properties. Ceram. Int. 2014, 40, 3071–3077. [Google Scholar] [CrossRef]

- Kaliniewicz, Z. Analysis of frictional properties of cereal seeds. Afr. J. Agric. Res. 2013, 8, 5611–5621. [Google Scholar]

- Matouk, A.M.; El-Kholy, M.M.; Radwan, S.M. Determination of friction coefficients for different varieties of some cereal crops. J. Agric. Sci. Mansoura Univ. 2003, 28, 6939–6955. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ilie, F.; Cotici, C.D.; Hristache, A.-F. Study of the Grinding Process by Friction of Cereal Grains in Stone Mills. Processes 2023, 11, 3376. https://doi.org/10.3390/pr11123376

Ilie F, Cotici CD, Hristache A-F. Study of the Grinding Process by Friction of Cereal Grains in Stone Mills. Processes. 2023; 11(12):3376. https://doi.org/10.3390/pr11123376

Chicago/Turabian StyleIlie, Filip, Constantin Daniel Cotici, and Andrei-Florin Hristache. 2023. "Study of the Grinding Process by Friction of Cereal Grains in Stone Mills" Processes 11, no. 12: 3376. https://doi.org/10.3390/pr11123376

APA StyleIlie, F., Cotici, C. D., & Hristache, A.-F. (2023). Study of the Grinding Process by Friction of Cereal Grains in Stone Mills. Processes, 11(12), 3376. https://doi.org/10.3390/pr11123376