Study on the Medium-Temperature Reduction Behavior of Methane and Laterite Nickel Ore

Abstract

:1. Introduction

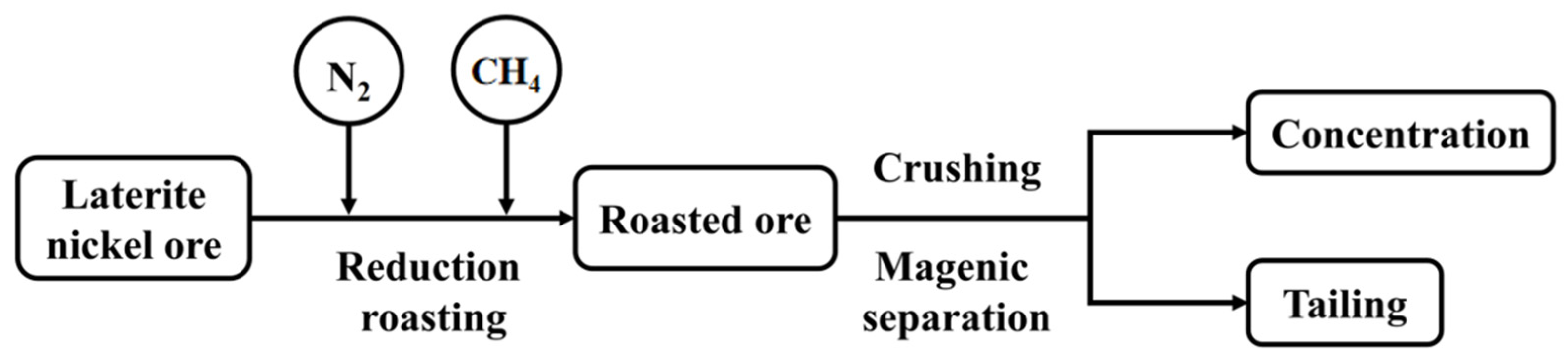

2. Experimental

2.1. Experimental Materials

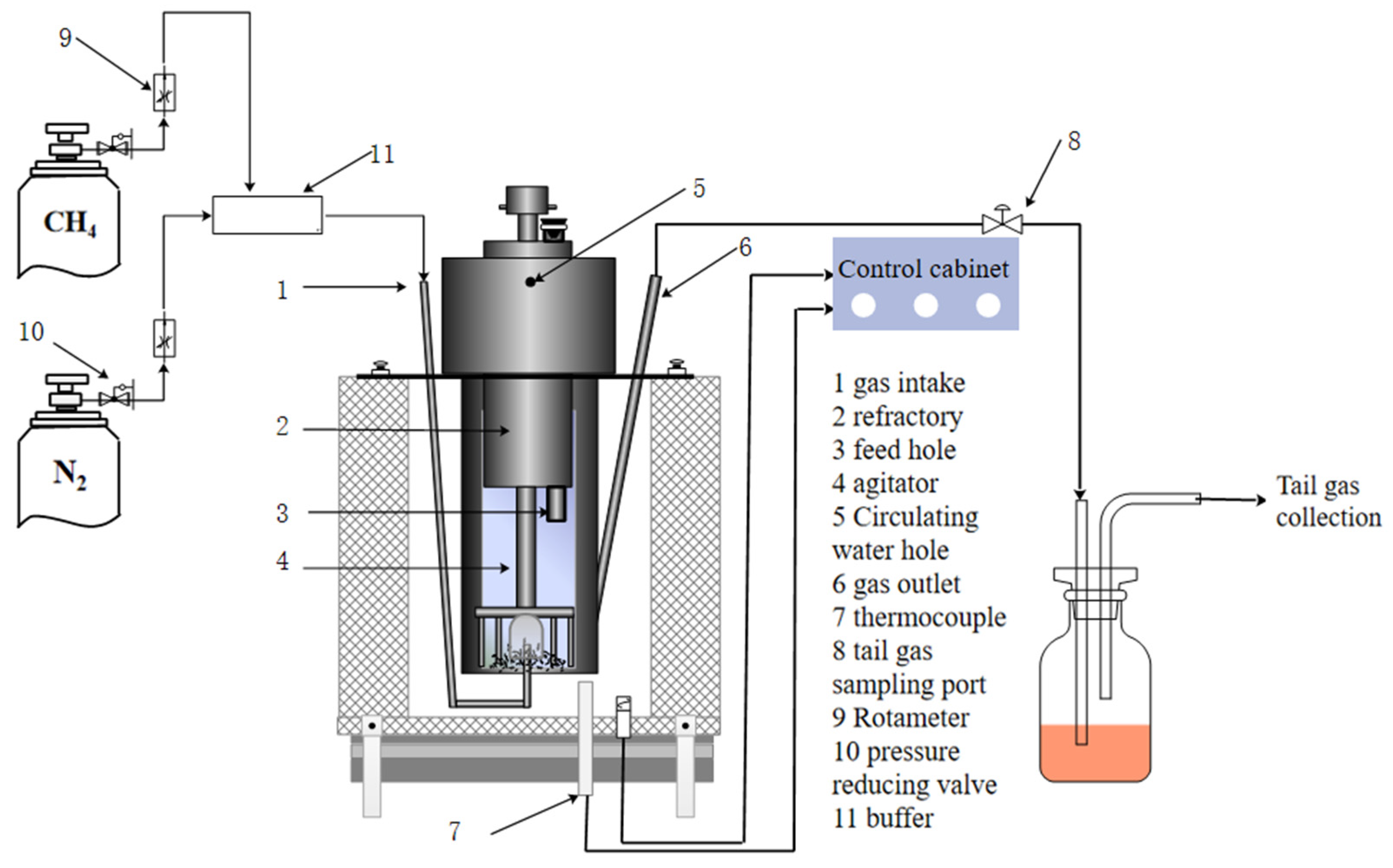

2.2. Experimental Methods

2.3. Characterization and Analysis

3. Results and Discussion

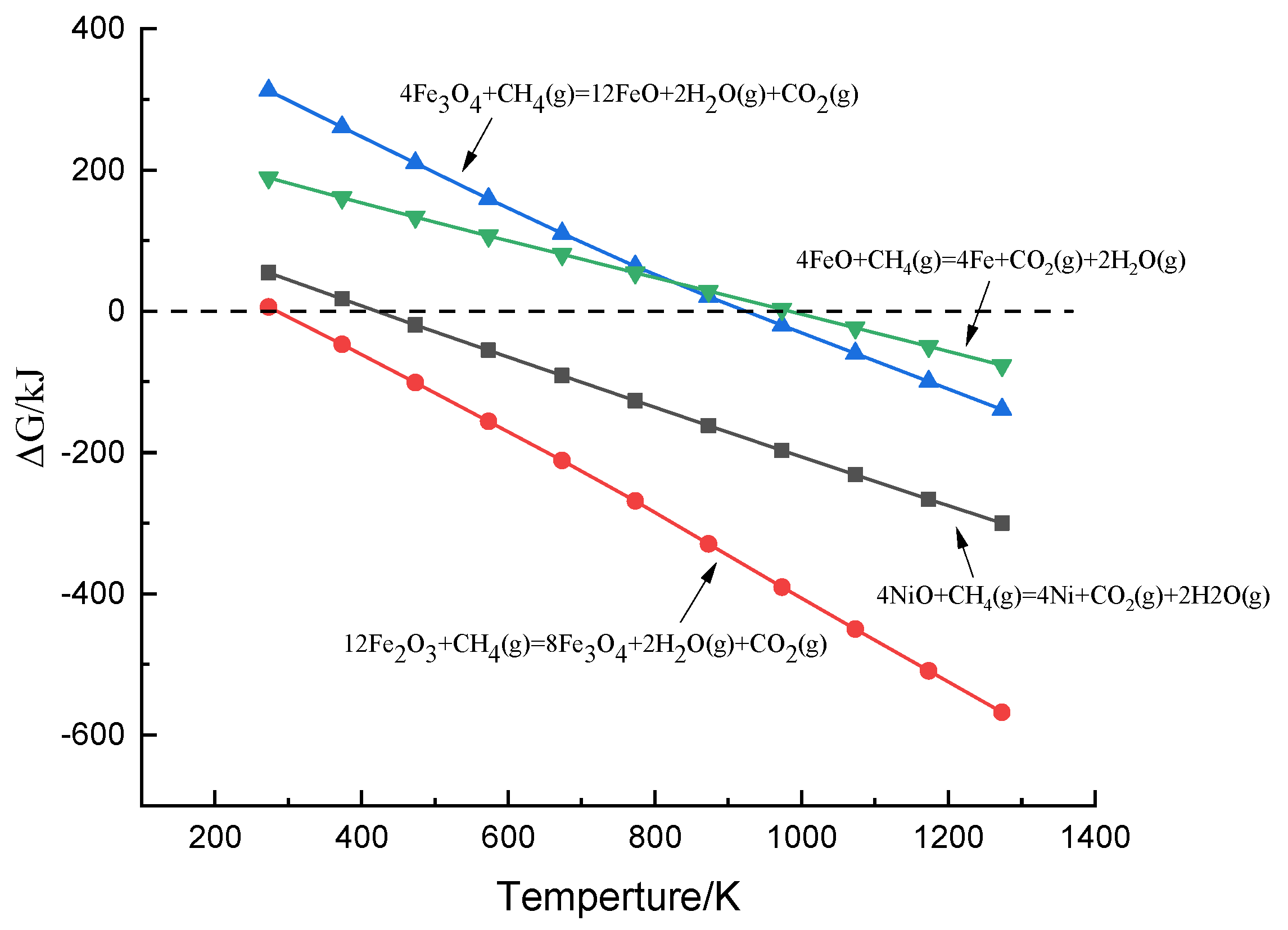

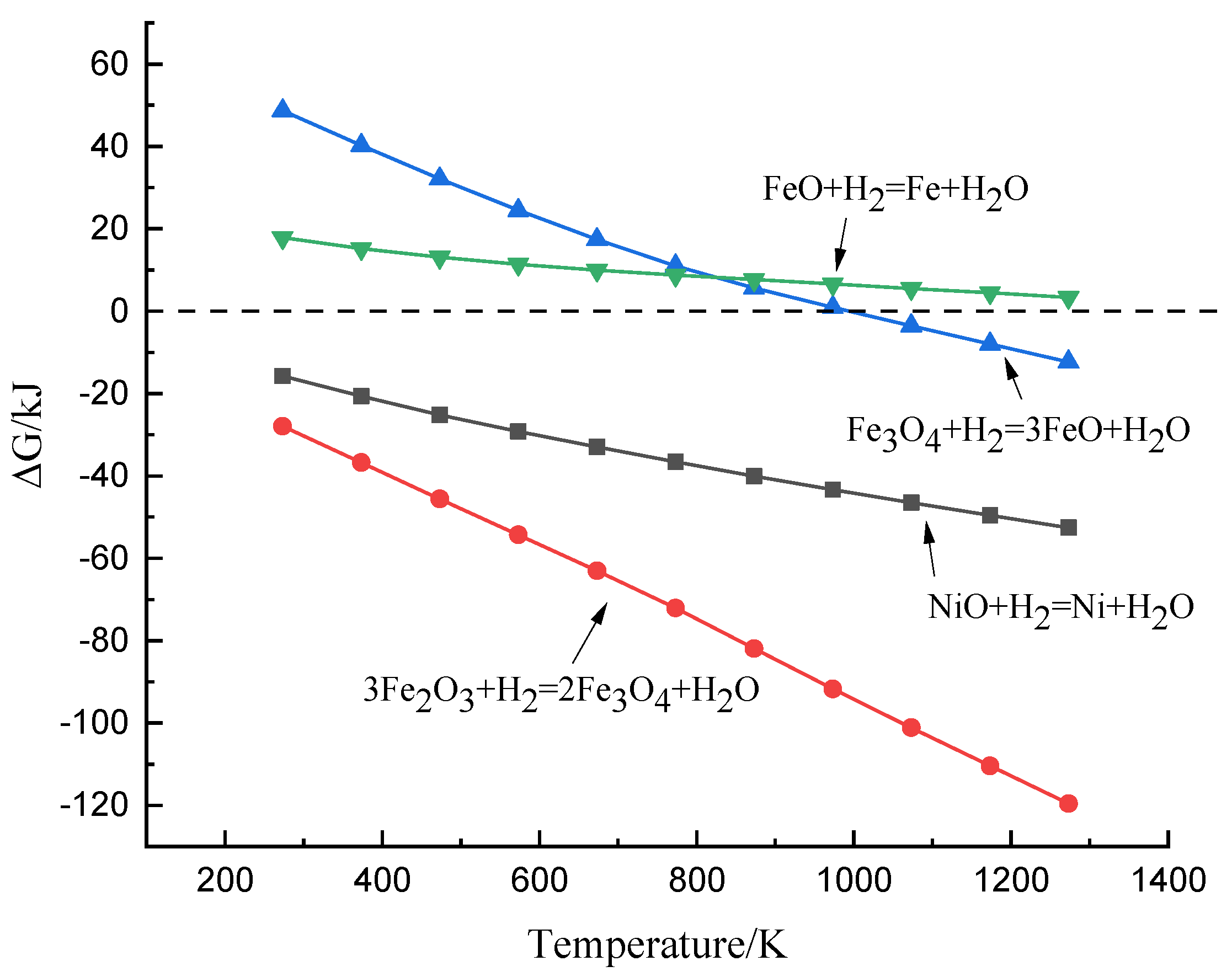

3.1. Thermodynamic Study on the Reduction Reaction between Methane and Laterite Nickel Ore

3.2. Reduction Reaction Conditions of Methane with Laterite Nickel Ore

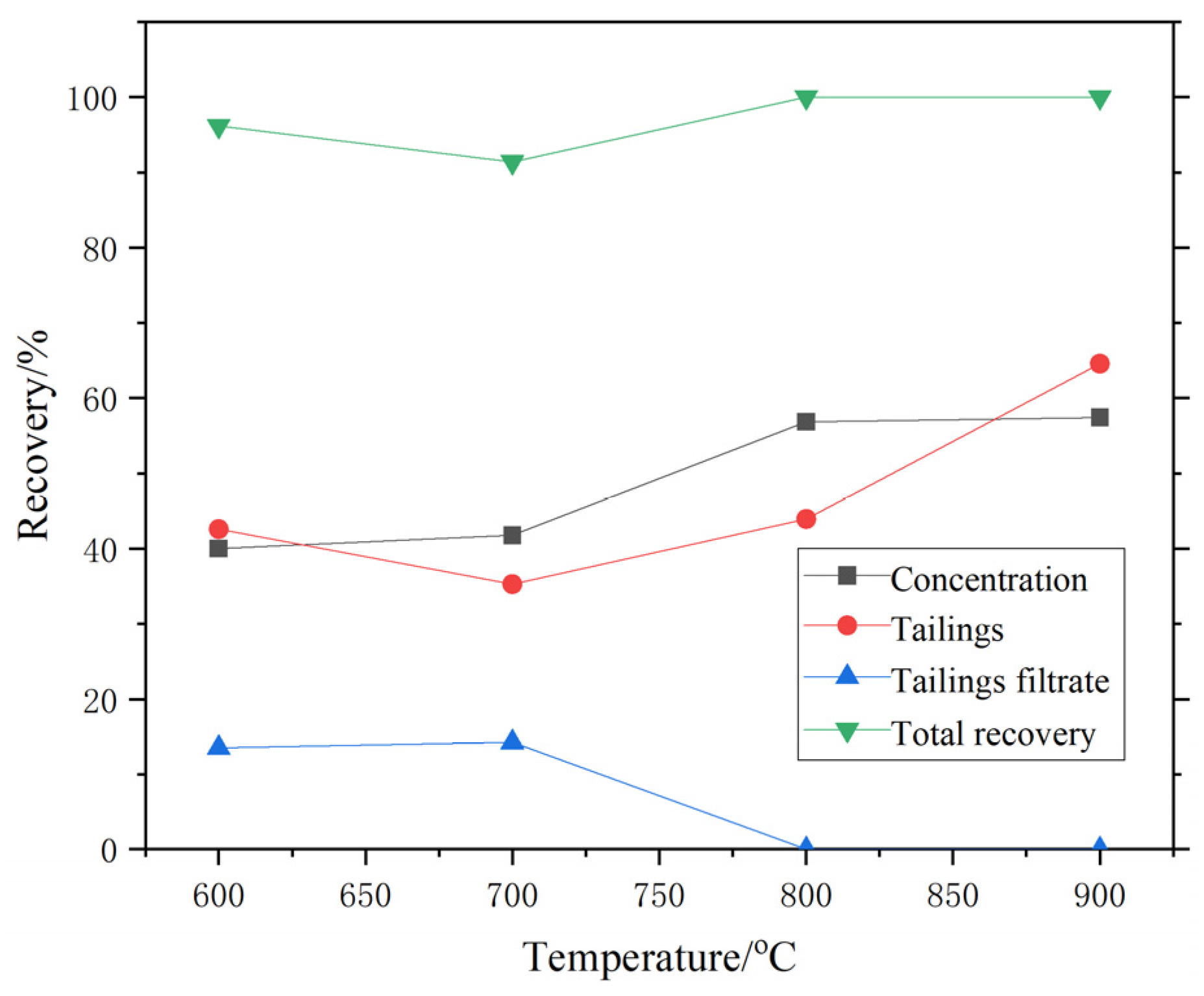

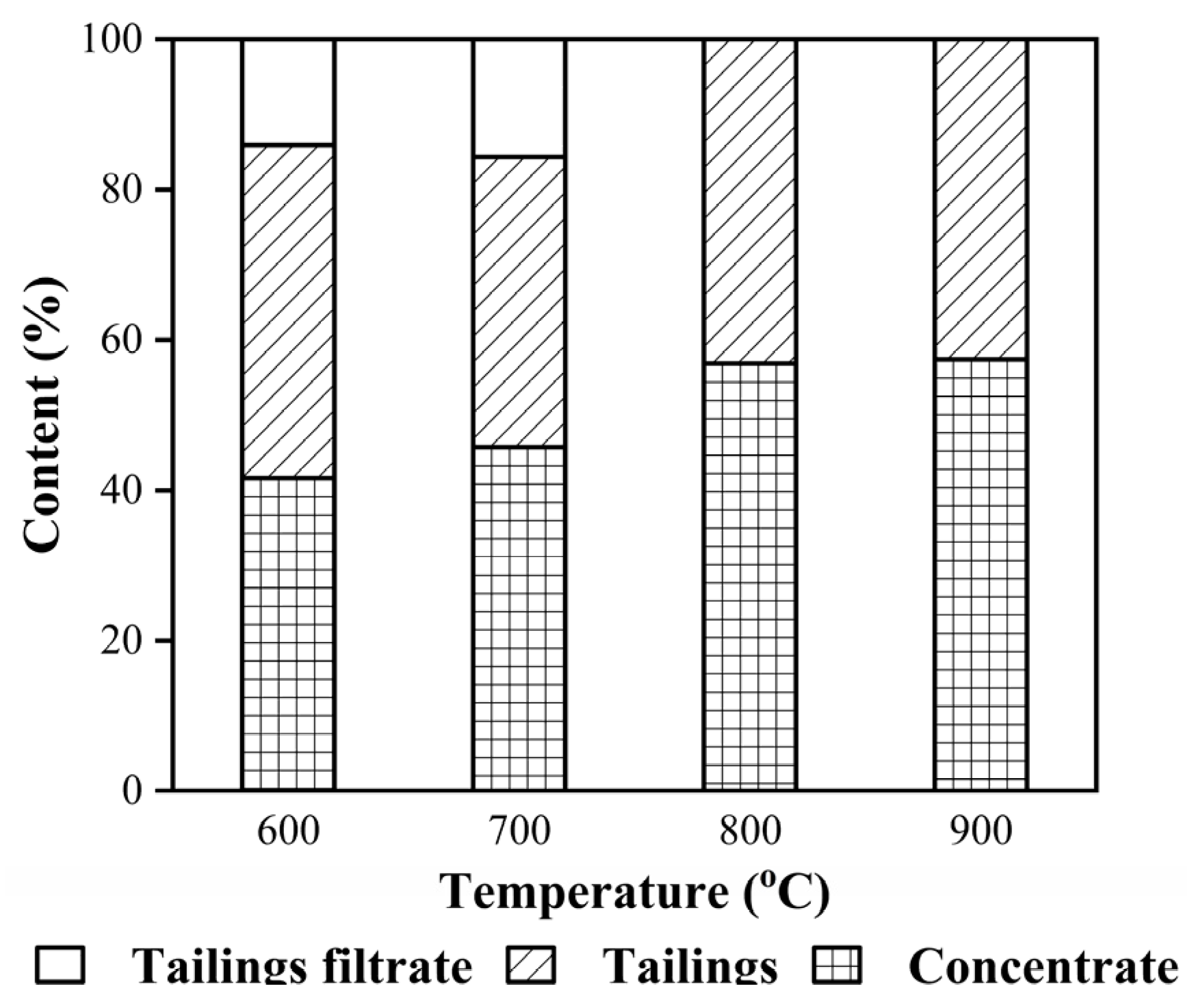

3.2.1. The Effect of Reduction Reaction Temperature on the Grade and Recovery Rate of Nickel Iron

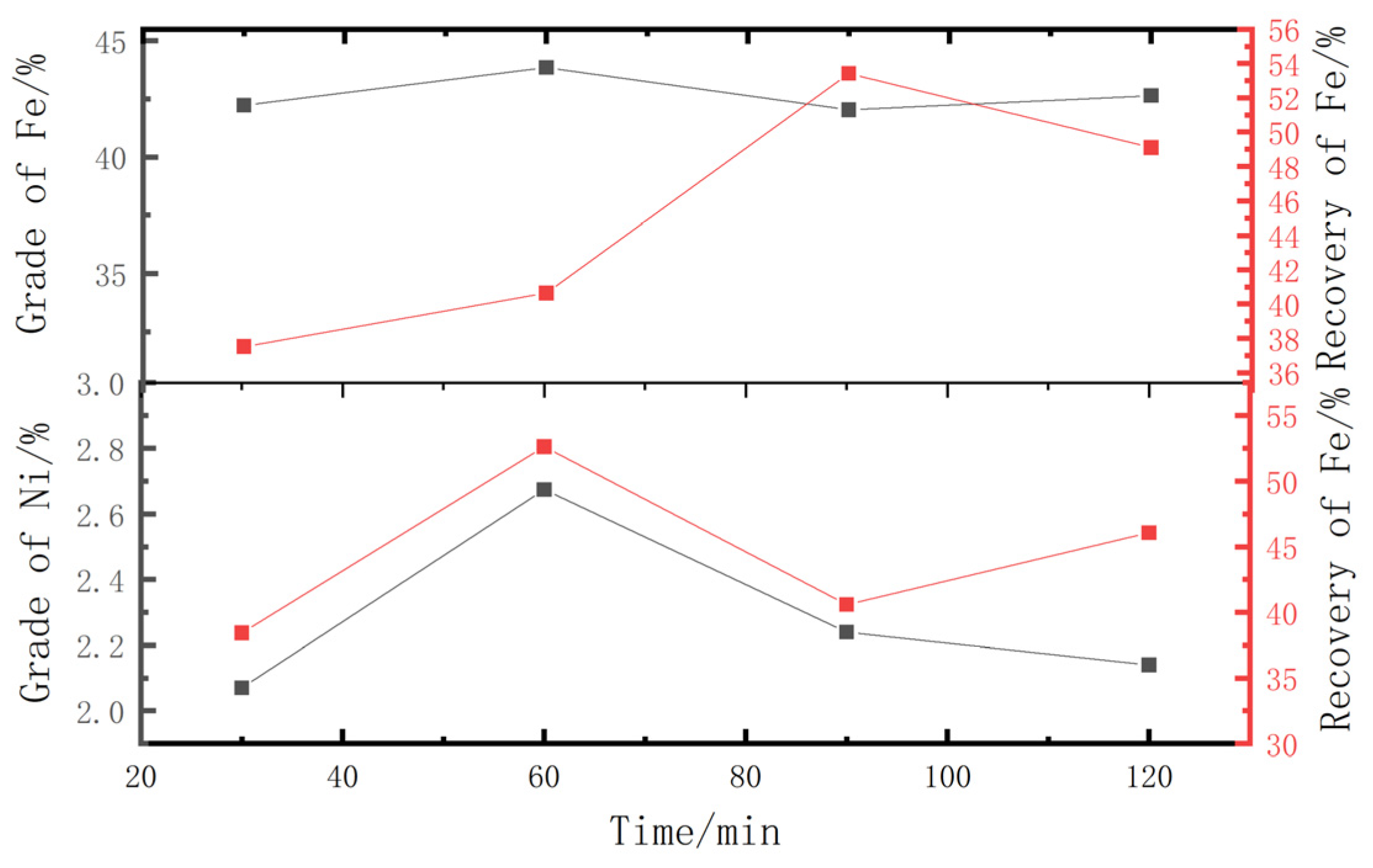

3.2.2. The Effect of Reduction Reaction Time on the Grade and Recovery Rate of Nickel Iron

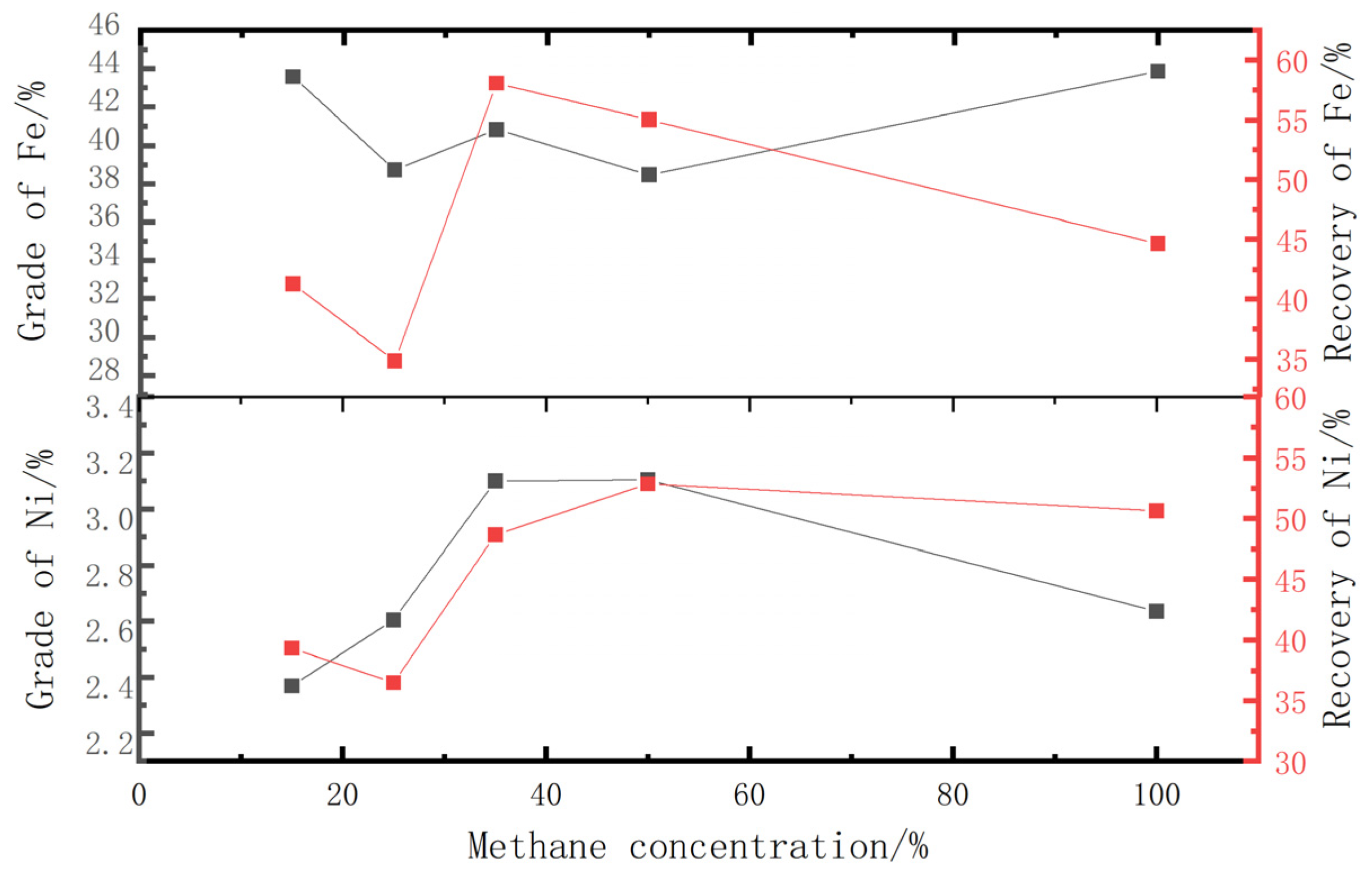

3.2.3. The Effect of Methane Concentration on the Grade and Recovery Rate of Nickel Iron

3.3. Migration of Nickel and Iron in Laterite Nickel Ore during Methane Reduction Process

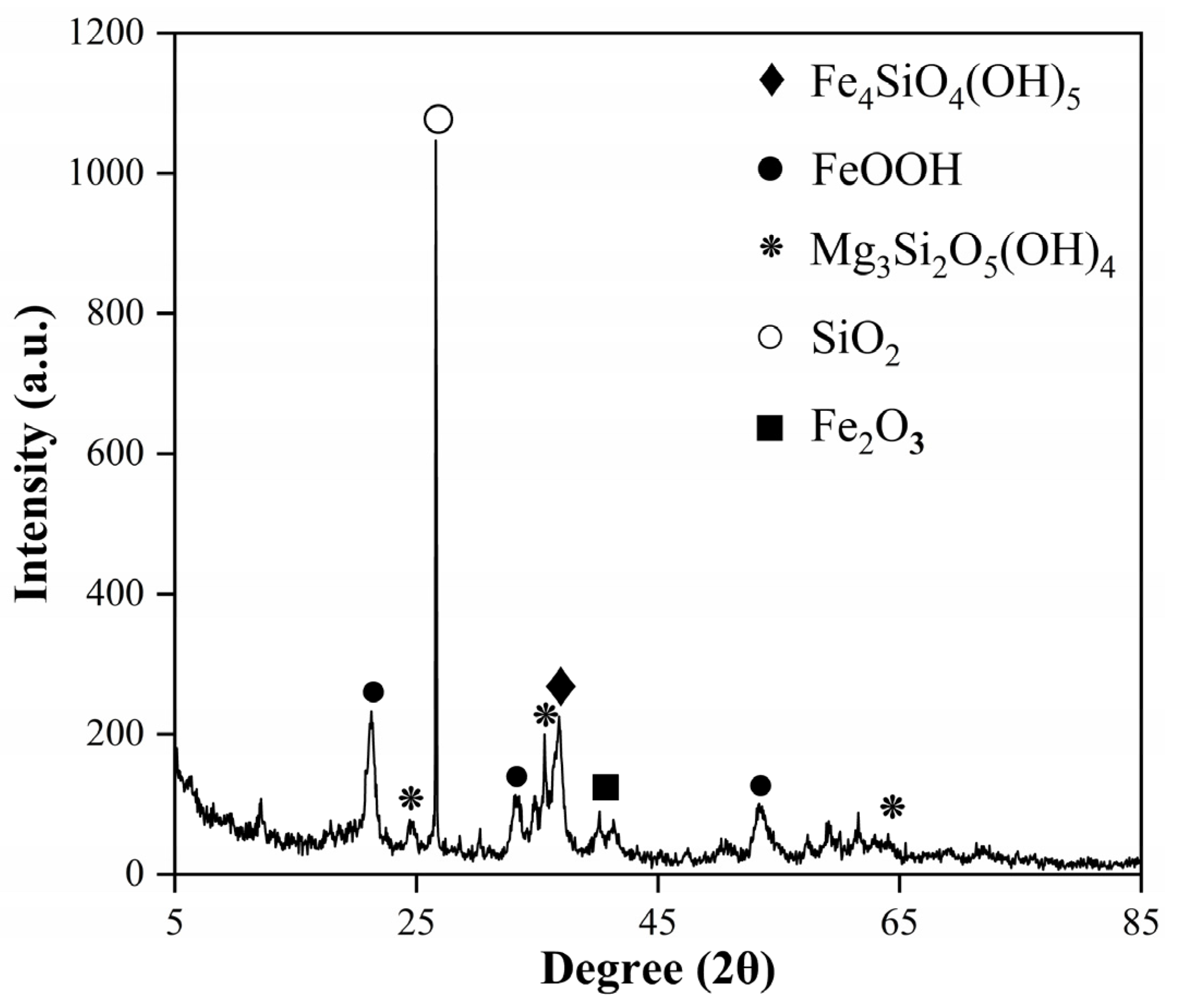

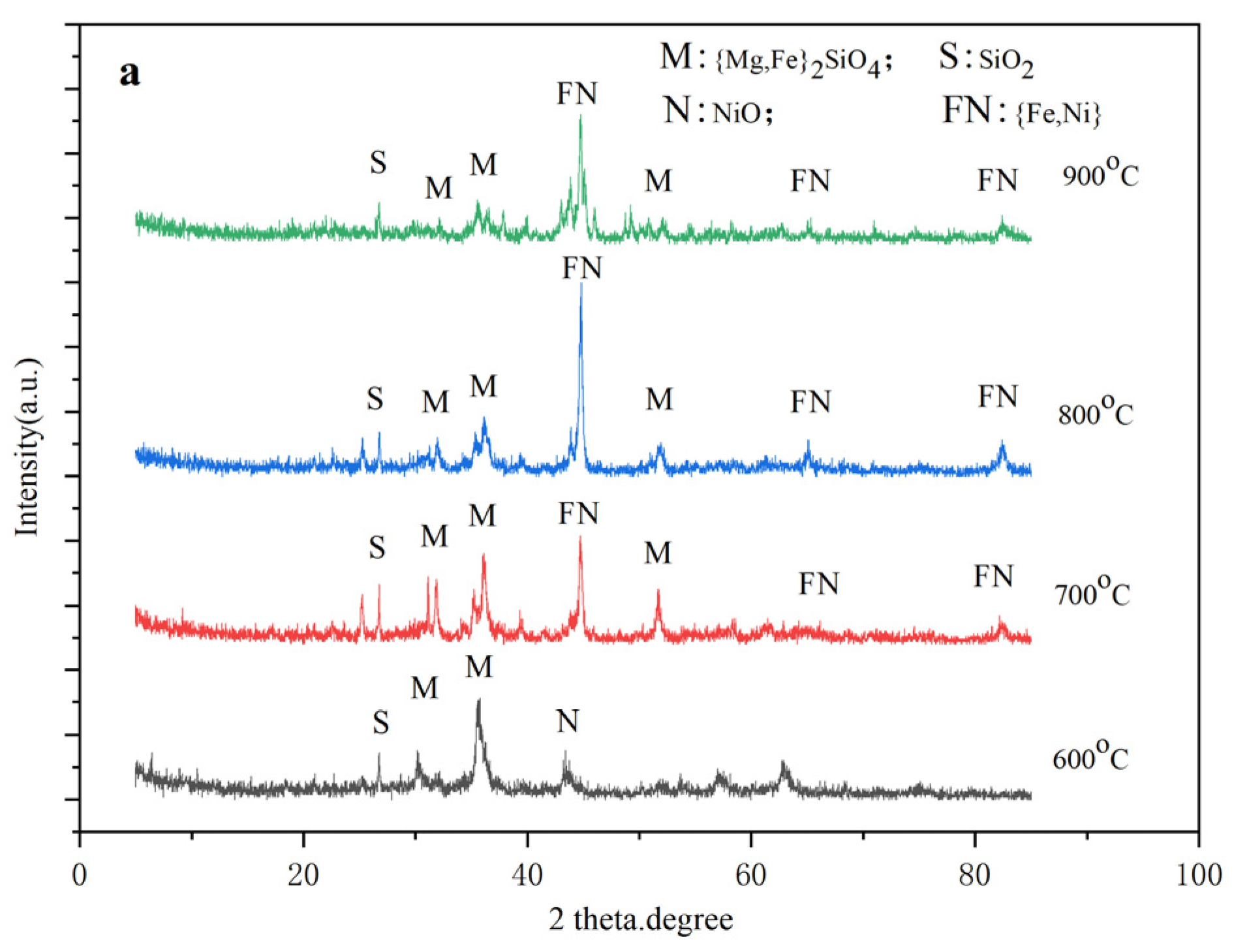

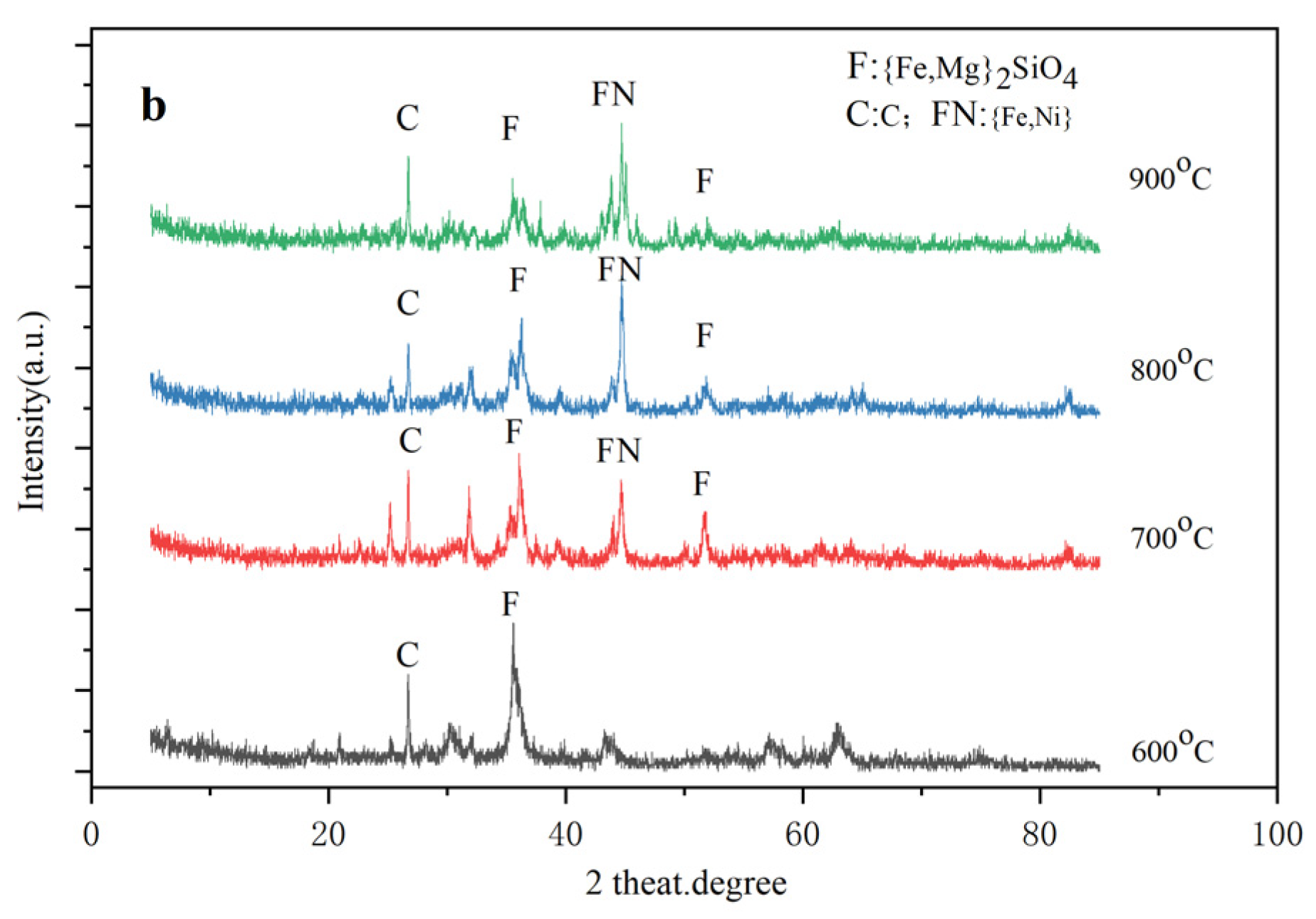

3.3.1. XRD Phase Analysis

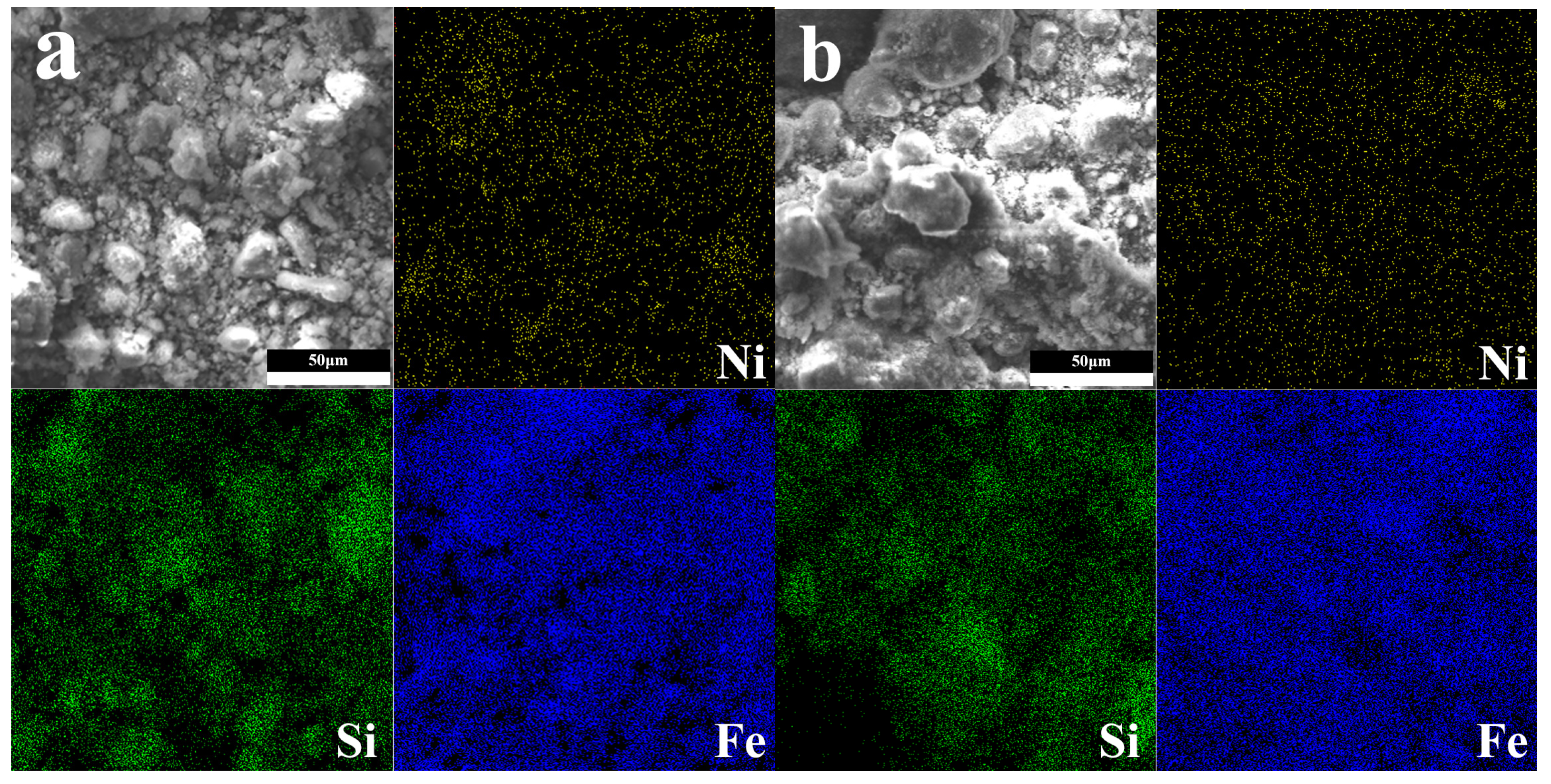

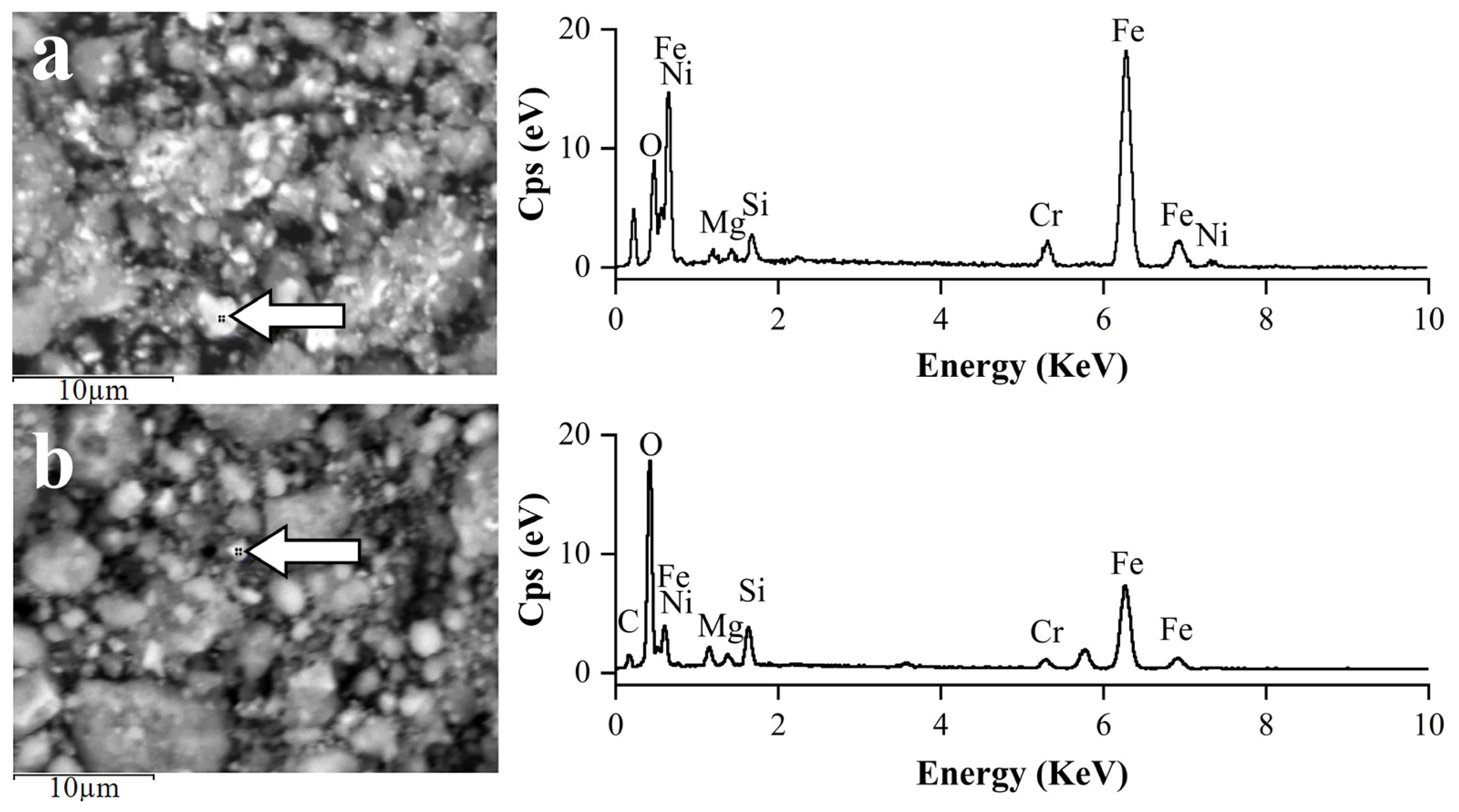

3.3.2. SEM-EDS Analysis

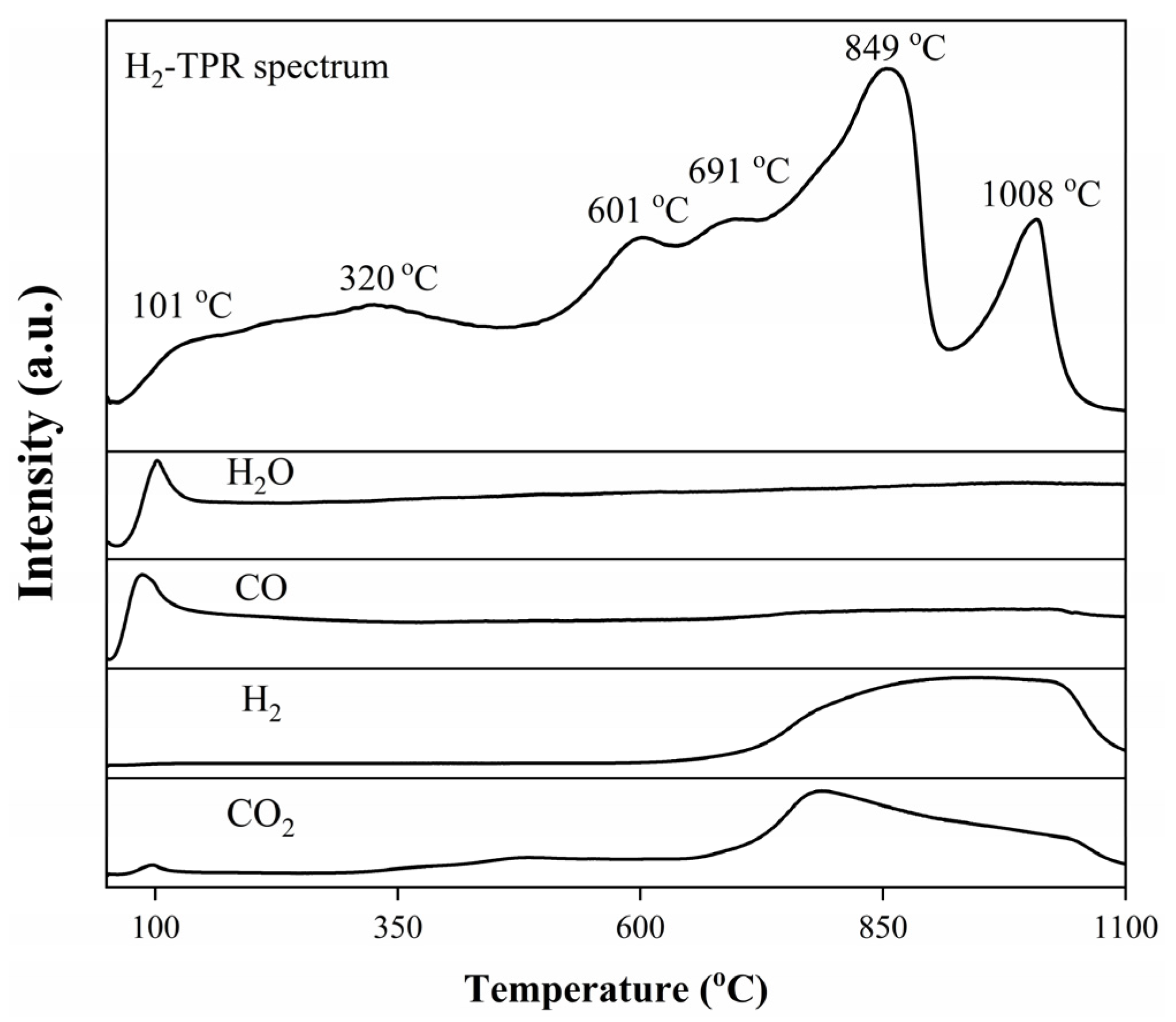

3.4. H2-TPR Testing of the Reduction Reaction between Methane and Laterite Nickel Ore

4. Conclusions

- (1)

- The optimal experimental conditions for this experiment are: a reduction temperature of 900 °C, a reduction time of 60 min, a CH4 concentration of 50%, obtained nickel concentrate with a grade of 3.06% and a recovery rate of 52.09%.

- (2)

- XRD and SEM characterization indicate that nickel in the concentrate mainly exists in the form of {Fe, Ni} alloys, while the unrecycled nickel in the tailings is mainly in the form of {Fe, Ni} alloys and occurs in {Fe,Mg}2SiO4. In addition, when the temperature is low, some nickel will be lost in the tailings filtrate, and the nickel recovery rate of this part is between 13 and 14%. The {Fe, Ni} alloys in the concentrate and tailings are relatively dispersed and do not agglomerate well. Moreover, due to the fine particle size of the {Fe,Ni} alloys in the tailings, they are not recovered into the concentrate during magnetic separation, resulting in a low grade and recovery rate of nickel.

- (3)

- When CH4 reduces laterite nickel ore at high temperatures, the H2 produced synergistically reduces laterite nickel ore with CH4, while the proportion of the carbon black-dominated carbothermal reduction reaction is very small. Thermodynamic studies have shown that CH4 has a strong reducing ability. When the temperature exceeds 420 K, the NiO phase in the mineral is completely reduced, while iron oxides are reduced in the order of Fe2O3 → Fe3O4 → FeO → Fe.

- (4)

- The reason for the low nickel grade and recovery rate in the concentrate is, on the one hand, due to the incomplete reduction of NiO, as there is still a large amount of nickel present in the silicate in the tailings; on the other hand, it is due to the fine grain size of the partially reduced nickel iron alloy, which is lost in the tailings and filtrate. In order to improve the performance of magnetic separation, in future research, additives can be considered to improve the recovery rate of nickel.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Chen, X.; Li, Y.; Gao, A.; Wang, Y.; He, X.; Wang, Q. Multipurpose Utilization Trend of Nickel Mineral Resources under the Goal of Carbon Peaking and Carbon Neutrality. Multipurp. Util. Miner. Resour. 2022, 43, 31–39. [Google Scholar]

- Wu, Q.; Cheng, C.; Ge, Z.; Ma, J. Thoughts on Ensuring the Supply Safety of Nickel Ore Resources. China Min. Mag. 2020, 29, 35–38. [Google Scholar]

- Moskalyk, R.R.; Alfantazi, A.M. Nickel sulphide smelting and electrorefining practice: A review. Miner. Process. Extr. Metall. Rev. 2002, 23, 141–180. [Google Scholar] [CrossRef]

- Ma, B.; Wu, H.; Gao, Z. Research development on treatment processes of laterite nickel ore. Refract. Lime 2022, 47, 35–40. [Google Scholar]

- Zheng, Z. Current status and research of nickel ore resources pyrosmelting technology. World Nonferrous Met. 2023, 13, 4–6. [Google Scholar]

- Zhao, D.; Ma, B.; Wang, C.; Chen, Y. Research progress of limonitic laterite hydrometallurgy. J. Cent. South Univ. Sci. Technol. 2023, 54, 401–414. [Google Scholar]

- Ma, W.; Cheng, J. Development trend of low-grade nickel-laterite resources: The integrated model of “Resources+Energy+Materials”. China Nonferrous Metall. 2019, 48, 75–78. [Google Scholar]

- Abdul, F.; Pintowantoro, S.; Maulidani, A. Analysis the Effect of Charcoal Mass Variation to Ni Content, Sinter Strength and Yield on Sintering Process of Limonitic Laterite Nickel Ore. Key Eng. Mater. 2020, 867, 25–31. [Google Scholar] [CrossRef]

- de Fátima da Silva, M.; de Sousa Oliveira, M.R.; dos Santos, I.D.; Radino-Rouse, P.; Mansur, M.B. Iron precipitation strategies from nickel laterite ore sulfuric acid leach liquor. Miner. Process. Extr. Metall. Rev. 2022, 43, 28–39. [Google Scholar] [CrossRef]

- Faris, N.; Pownceby, M.I.; Bruckard, W.J.; Chen, M. The Direct Leaching of Nickel Sulfide Flotation Concentrates-A Historic and State-of-the-Art Review Part I: Piloted Processes and Commercial Operations. Miner. Process. Extr. Metall. Rev. 2022, 44, 407–435. [Google Scholar] [CrossRef]

- Jiang, M.; Sun, T.; Liu, Z.; Kou, J.; Liu, N.; Zhang, S. Mechanism of sodium sulfate in promoting selective reduction of nickel laterite ore during reduction roasting process. Int. J. Miner. Process. 2013, 123, 32–38. [Google Scholar] [CrossRef]

- Hu, C.; Jia, Y.; Liang, D.; Zhang, L.; Wang, X.; Li, S. Stduying on reductive roasting mechanism about nickel laterite. China Nonferrous Metall. 2012, 41, 72–75. [Google Scholar]

- Sudagar, J.; Lian, J.; Sha, W. Electroless nickel, alloy, composite and nano coatings—A critical review. J. Alloys Compd. 2013, 571, 183–204. [Google Scholar] [CrossRef]

- Mohanty, S.; Roy, S.K.; Sen, P.K. Thermodynamic considerations in reduction of nickeliferrous laterite by methane. Metall. Mater. Trans. B 2008, 39, 639–642. [Google Scholar] [CrossRef]

- Su, K.; Wang, F.; Parianos, J.; Cui, Z.; Zhao, B.; Ma, X. Alternative Resources for Producing Nickel Matte-Laterite Ores and Polymetallic Nodules. Miner. Process. Extr. Metall. Rev. 2022, 43, 584–597. [Google Scholar] [CrossRef]

- Liu, X.; Liu, S.; Yang, S. Reaction behavior of iron and nickel oxides in laterite nickel ore under action of methane. Chin. J. Nonferrous Met. 2022, 32, 1759–1771. [Google Scholar]

- Li, B.; Ding, Z.; Wei, Y.; Zhou, S.; Wang, H. Reduction of nickel and iron from low-grade nickel laterite ore via a solid-state deoxidization method using methane. Mater. Trans. 2018, 59, 1180–1185. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Z.; Guo, Z. Water electrolysis enhanced by super gravity field for hydrogen production. Int. J. Hydrogen Energy 2010, 35, 3198–3205. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, H.; Ding, Z. Reduction roasting test of silicon-magnesium-type laterite-nickel ore under the action of methane. J. Henan Univ. Sci. Technol. Nat. Sci. Ed. 2018, 39, 6. [Google Scholar]

- Pickles, C.; Anthony, W. Thermodynamic modelling of the reduction of a saprolitic laterite ore by methane. Miner. Eng. 2018, 120, 47–59. [Google Scholar] [CrossRef]

- Kolmachikhina, O.; Polygalov, S.; Vakula, K. The study of physicochemical features of laterite ores of the buruktalsky deposit. Solid State Phenom. 2021, 316, 694–698. [Google Scholar] [CrossRef]

- Al-Khirbash, S.A. Mineralogical characterization of low-grade nickel laterites from the North Oman Mountains: Using mineral liberation analyses-Scanning electron microscopy-based automated quantitative mineralogy. Ore Geol. Rev. 2020, 120, 103429. [Google Scholar] [CrossRef]

- Tian, H.; Pan, J.; Zhu, D.; Yang, C.; Guo, Z.; Xue, Y. Improved beneficiation of nickel and iron from a low-grade saprolite laterite by addition of limonitic laterite ore and CaCO3. J. Mater. Res. Technol. 2020, 9, 2578–2589. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Zhou, Y.H.; Li, Z.Y.; Li, W.G. Characteristics of laterite resource and analysis on its pyrometallurgy process. Ferro-Alloys 2007, 6, 18–21. [Google Scholar]

- Quast, K.; Connor, J.N.; Skinner, W.; Robinson, D.J.; Addai-Mensah, J. Preconcentration strategies in the processing of nickel laterite ores Part 4: Preliminary dewatering studies. Miner. Eng. 2015, 79, 287–294. [Google Scholar] [CrossRef]

- Wang, L.W.; Lü, X.M.; Liu, M.; You, Z.X.; Lü, X.W.; Bai, C.G. Preparation of ferronickel from nickel laterite via coal-based reduction followed by magnetic separation. Int. J. Miner. Metall. Mater. 2018, 25, 744–751. [Google Scholar] [CrossRef]

- Yuan, S.; Zhou, W.-T.; Li, Y.-J.; Han, Y.-X. Efficient enrichment of nickel and iron in laterite nickel ore by deep reduction and magnetic separation. Trans. Nonferrous Met. Soc. China 2020, 30, 812–822. [Google Scholar] [CrossRef]

- He, L.; Shen, Z. Methane Conversion and Utilization; Chemical Industry Press: Beijing, China, 2005. [Google Scholar]

- Lu, J. Study on the Reduction of Sodium Sulfate to Laterite Nickel Ore Under Hydrogen and Methane Atmosphere. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2013. [Google Scholar]

| Fe | Ni | Al | Ca | Mg | Cr | Si | O | Mn | Co |

|---|---|---|---|---|---|---|---|---|---|

| 25.37 | 1.65 | 2.57 | 0.12 | 7.06 | 0.89 | 6.71 | 47.10 | 0.62 | 0.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Y.; Qi, S.; Liu, X.; Liu, S.; Yan, J.; Yang, S. Study on the Medium-Temperature Reduction Behavior of Methane and Laterite Nickel Ore. Processes 2023, 11, 3291. https://doi.org/10.3390/pr11123291

Shi Y, Qi S, Liu X, Liu S, Yan J, Yang S. Study on the Medium-Temperature Reduction Behavior of Methane and Laterite Nickel Ore. Processes. 2023; 11(12):3291. https://doi.org/10.3390/pr11123291

Chicago/Turabian StyleShi, Ying, Sheng Qi, Xingyang Liu, Shoujun Liu, Jinyao Yan, and Song Yang. 2023. "Study on the Medium-Temperature Reduction Behavior of Methane and Laterite Nickel Ore" Processes 11, no. 12: 3291. https://doi.org/10.3390/pr11123291

APA StyleShi, Y., Qi, S., Liu, X., Liu, S., Yan, J., & Yang, S. (2023). Study on the Medium-Temperature Reduction Behavior of Methane and Laterite Nickel Ore. Processes, 11(12), 3291. https://doi.org/10.3390/pr11123291