1. Introduction

Currently, China possesses billions of tons of coal resources in need of extraction. Coal resources have made a significant contribution to China’s economic and social development. However, as the depth of mining increases year by year, reaching from several hundred meters to a thousand meters, the temperature in mines is also rising. It can reach up to 40 °C, which greatly impacts the miners [

1]. Due to limited space underground, the heat generated by surrounding rocks, compressed air, and mechanical and electrical equipment cannot be dissipated, resulting in a gradual deterioration of the thermal environment in mines. Thermal hazards in mines are widespread. Therefore, it is crucial to lower the temperature in the mining environment.

Methods for preventing and controlling heat hazards in mines can be broadly categorized into two main types: traditional cooling techniques and individual cooling suits. Traditional cooling techniques primarily rely on ventilation to achieve lower temperatures. This is achieved by controlling parameters such as the airflow speed, volume, and temperature underground to achieve the desired cooling effect [

2]. However, this method has certain limitations, and the cooling effect may not be very pronounced. To meet the demand for thermal comfort of personnel working in high-temperature mine environments, improve their work efficiency, and ensure work quality, the development of individual cooling suits has come into the view of researchers [

3]. Individual cooling suits have the capability to regulate the microclimate temperature between the human body and the clothing. They exhibit high cooling efficiency, leading to effective temperature reduction and ultimately enhancing the thermal comfort of mine workers. Therefore, herein existing individual cooling suits have been classified and summarized. Initially, from a structural perspective, they are divided into vest-type cooling suits and full-body cooling suits. Upon analysis and comparison, it is evident that vest-type cooling suits are more suitable for wearing in mining operations. They are easy to put on and take off, facilitate movement, and provide good cooling effects. Based on their different cooling principles, the cooling suits are further categorized into gas-based cooling suits [

4], liquid-based cooling suits [

5], phase change cooling suits [

6], and hybrid cooling suits [

7]. This paper concludes and summarizes the working principles, advantages, disadvantages, and feasibility of using various types of cooling suits in underground mines. The strengths and weaknesses of different cooling suits are analyzed. Finally, recommendations are made for the future development of cooling suits for mining applications.

2. Human Thermal Comfort

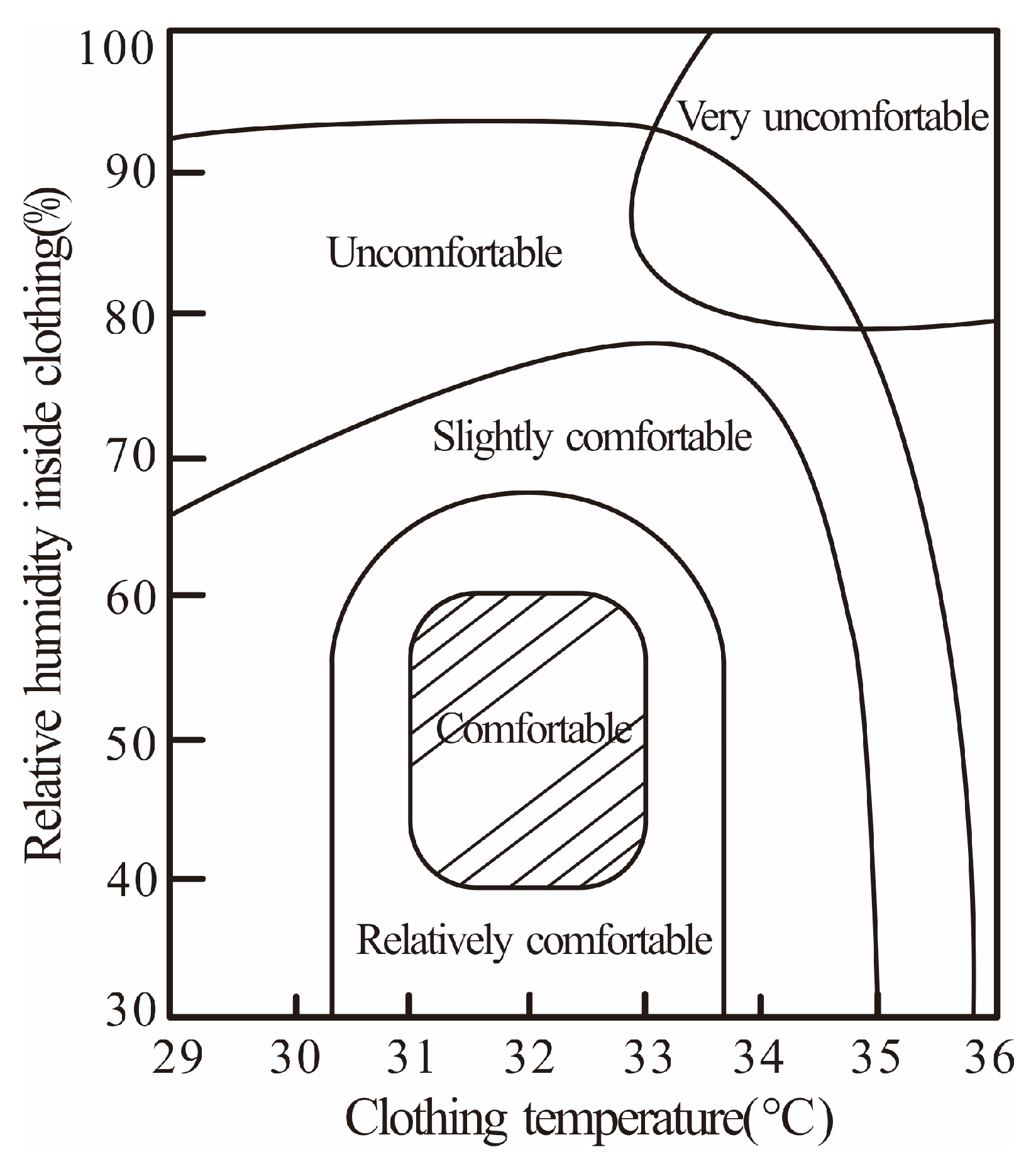

After a person puts on clothing, a small climate is formed between the surface of the body and the outermost layer of clothing, known as the clothing microclimate. The comfort of this microclimate is closely related to human comfort. Temperature and humidity are important indicators for evaluating thermal comfort. The relationship between the clothing microclimate and human thermal comfort is shown in

Figure 1. As shown in the figure, when the temperature of the clothing microclimate is between 31 °C and 33 °C, and the relative humidity is between 40% and 60%, the person feels comfortable. According to the ISO 7730-2005 “Ergonomics of the Thermal Environment” standard, human thermal comfort is defined as the subjective thermal environment evaluation made by a person in the surrounding environment. Thermal comfort occurs when the heat production and dissipation of the human body are in balance. However, in mining environments, the airflow between the underground environment and the outside world is weak, which severely affects evaporative and convective heat dissipation. Therefore, heat-related issues in mines significantly impact the thermal stability of mine workers, posing a threat to their health. To address the issue of cooling the human body in a hot environment, a method is proposed for mine workers to wear cooling suits in high-temperature mining environments. By regulating the heat in the clothing microclimate, the goal is to achieve thermal balance and thermal comfort for the human body. Factors affecting human thermal comfort include aspects related to the human body, clothing, and the environment [

8]. The relationships between the human body, the environment, and the cooling suit during wearing are illustrated in

Figure 2. For mine workers, it is challenging to control the intensity of activities and the environmental temperature underground. However, utilizing cooling suits to reduce the generation of body heat and facilitate heat dissipation is an effective approach.

3. Working Principle of Cooling Clothes

The heat generated during the human body’s metabolic processes is dissipated to the surrounding environment through the skin. When the surrounding temperature is too high or heat cannot be effectively dissipated, heat accumulates in the microclimate zone on the surface of the skin, causing discomfort. Therefore, the primary purpose of cooling garments is to regulate the temperature in the microclimate zone on the surface of the skin. The human body dissipates heat through various methods, including convective heat dissipation, radiative heat dissipation, conductive heat dissipation, and evaporative heat dissipation. The cooling effect of cooling garments on the human body primarily involves the transfer of heat between the skin surface, clothing, and the environment, as illustrated in

Figure 3.

As seen in

Figure 3, when the heat exchange between the human body and the environment reaches dynamic equilibrium, the production and dissipation of heat by the body are balanced. Wearing cooling garments involves two main paths of heat transfer between the human body and the external environment: the first path involves the transfer of heat generated by metabolic processes through the skin surface to the cooling garment in a process of thermal equilibrium; the second path involves the transfer of heat between the external environment and the cooling garment. In harsh mining environments, where the heat generated by the body’s metabolism is constant, the cooling effect of cooling garments directly influences the heat transfer between the body and the environment. When the body is in a high-temperature environment, cooling garments absorb excess heat produced by the body to maintain thermal comfort.

4. Research Status of Cooling Clothing

Utilizing the Web of Science database for retrieval, we gathered 118 articles on cooling garments from the past 20 years, as depicted in

Figure 4. The linear trend chart indicates an increasing focus by researchers on the innovation and application of cooling garments. The prominent areas of interest include liquid-cooled garments, evaporative cooling, cooling performance, cooling textiles, protective devices, phase-change materials, and others.

The effectiveness of cooling suits is influenced by factors such as environmental temperature and humidity, cool fabric, cooling clothing structure, cooling clothing design, and level of physical activity, as shown in

Figure 5. Among these, factors that can be improved to enhance the cooling effect of cooling suits include the cool fabric, cooling clothing structure, and cooling clothing design.

4.1. Cool Fabric

In the high-temperature environment of mines, the use of cooling fabrics can enhance heat conduction and facilitate more effective convective evaporation, thus increasing comfort when the fabric is in close contact with the body. By increasing the thermal conductivity of fibers, regulating fiber cross-sectional structures, introducing phase-change materials, and employing post-fabric processing techniques, the fabric can rapidly transfer heat and accelerate perspiration, resulting in a cooling effect. This, in turn, enhances the thermal comfort of the human body. In recent years, experts and scholars have paid considerable attention to research on fiber thermal conductivity and the introduction of phase-change materials. Elevating thermal conductivity can enhance the fabric’s ability to dissipate heat to the environment. Among these, phase-change fibers utilize the properties of phase-change materials to absorb and store body heat, thereby achieving a cooling effect [

9].

Thermal conductivity is a metric used to assess the ability of clothing fibers to conduct heat. The thermal conductivity of fibers primarily depends on factors such as the internal molecular arrangement of the material, fiber morphology, and the microstructure within the fibers. Research conducted by You B et al. [

10] through experimental comparative analysis indicates that modal fibers are better suited for mining clothing due to their high thermal conductivity, leading to enhanced cooling effects. To increase fiber thermal conductivity, Gao et al. [

11] prepared boron nitride/polyvinyl alcohol composite fiber fabrics. The high thermal conductivity of the boron nitride nanosheets resulted in a thermal conductivity coefficient of the composite fiber fabric that was 2.22 times that of cotton fabric. Yuan et al. [

12] utilized copper nanowires coated with polydopamine to prepare electrically insulating epoxy resin nanocomposite fibers with a thermal conductivity of up to 2.87 W/(m K). Wu et al. [

13] developed a regenerated cellulose/BNNS (boron nitride nanosheets) composite fiber with a high BNNS content of up to 60% (by weight percentage). The thin and transparent two-dimensional structure of BNNS was particularly conducive to heat conduction. Chien et al. [

14] fabricated a semi-crystalline polyamide (nylon) nanofiber. Annealing treatment was employed to enhance the configuration orderliness of the polymer, resulting in a high thermal conductivity of 59.1 W/(m K). This fiber can be employed to enhance the human thermal comfort performance.

Phase-change cooling fabrics integrate fibers with phase-change materials, leveraging the capacity of these materials to absorb, store, and release heat during phase transitions. This enables the regulation of skin temperature. In order to achieve an optimal thermal regulation response with phase-change fibers, it is important to enhance the thermal conductivity of both the phase-change material and the polymer substrate. Liu et al. [

15] utilized wet spinning and freeze-drying processes to prepare Kevlar aerogel fibers with high porosity and surface area. After filling them with phase-change material, they obtained phase-change fibers with a phase-change enthalpy of 162 J/g. Wu et al. [

16] used silk fibroin as a raw material and employed a freeze-spinning method to create microstructured fibers with high porosity. They then filled these fibers with polyethylene glycol (PEG) and coated them with polydimethylsiloxane (PDMS) to prevent leakage. The phase-change enthalpy of these fibers was approximately 118.1 J/g.

With the development of smart fibers, material intelligence has gradually come into the view of researchers. Wang Wen et al. [

17] used deformable bacteria on fabrics to make them sensitive to humidity. They placed the bacteria on both sides of latex and kept them stable at room temperature. When one side was exposed to high temperatures, the expansion of the bacteria caused the latex to bend outward. Sweat evaporates through the opened ventilation port, achieving the goal of cooling. Lao S et al. [

18] developed a solar cooling suit. They installed a semi-flexible solar panel on the back of the suit and supplied power to two battery packs through a controller. This provided a continuous power source for a fan, enabling sustained cooling. This cooling suit is environmentally friendly. Ke et al. [

19] designed a ladies’ blouse made from nano-porous polyethylene material. The study found that when using this cooling suit, increasing the set air conditioning temperature from 25.5 °C to 27.0 °C could save 9% to 15% of cooling energy. Wei et al. [

20] applied a layer of Al

2O

3-dispersed cellulose acetate on the textile. This increased the textile’s solar reflectance from 62.6% to 80.1%. As a result, the wearer absorbs less radiant heat, achieving the goal of cooling.

4.2. Cooling Clothing Structure

Experimental measurements have revealed that different parts of the human body exhibit varying microclimates within clothing, and their relationship and response to the external environment are distinct. Areas such as the armpits, sides, and waist have relatively little correlation with environmental climate variations (changing by approximately 5 °C over the course of a year). Conversely, regions like the chest, back, shoulders, upper and lower limbs, including the forearms and thighs, have a closer relationship with external climate changes (varying by 5 °C to 10 °C for the forearms and thighs, and by 10 °C to 15 °C for the calves). Additionally, during physical activity, the trunk of the body has the highest basal metabolic rate and heat capacity [

4]. Based on the relationship between different parts of the human body and environmental variations, various types of cooling suits with different structural designs have been developed.

Figure 6a depicts a vest-type cooling suit. Vest-type cooling suits are widely used in various fields of production and daily life due to their simple structure, ease of wear, effective cooling, and high practicality.

Figure 6b shows a full-body cooling suit. The advantage of a full-body cooling suit lies in its ability to comprehensively cool the trunk, limbs, and other areas, ensuring that the entire body remains in a relatively comfortable state. Gerrett et al. [

21] conducted a study analyzing the thermal sensitivity of different areas on the human body. They found that the abdominal area and the sides of the lower back are more sensitive to cold sensations. Therefore, cooling the lower half of the body is more conducive to enhancing thermal comfort. In comparison to the upper body, the legs generate more heat during walking. Cooling suits need to absorb a significant amount of heat. As a result, the legs may not achieve the desired cooling effect in the later stages of exercise and during periods of rest [

22]. However, for workers in high-temperature mines with extensive work areas and high intensity, it may affect their work efficiency and overall comfort of wearing.

4.3. Cooling Clothing Design

To date, researchers have conducted extensive studies on different types of cooling suits and their performance. Based on different cooling media, cooling suits can be categorized as gas-based cooling suits, liquid-based cooling suits, phase-change cooling suits, and hybrid cooling suits. According to the source of the cooling power, they can be classified as active cooling suits or passive cooling suits. Additionally, based on different cooling methods, they can further be divided into cold storage cooling suits, vapor compression cooling suits, vortex tube cooling suits, and thermoelectric refrigeration cooling suits [

23,

24,

25].

4.3.1. Gas Cooling Suit

Gas-based cooling suits blow air into the microclimate of the clothing, dissipating heat through evaporation and convection. This falls under the category of active cooling [

26]. The principle of heat dissipation involves accelerating the evaporation of sweat and enhancing air convection, thereby achieving the goal of cooling. Depending on the different methods of heat dissipation, gas-based cooling suits can be further divided into convective gas-based cooling suits and evaporative gas-based cooling suits. Additionally, based on different structural designs, gas-based cooling suits can be categorized as fan-type cooling suits and duct-type cooling suits [

27].

Fan-based cooling suits primarily operate by using an external power source to drive a fan or blower device, creating a flow of air between the clothing and the skin surface. This accelerates the evaporation of sweat, thereby cooling the microclimate, as illustrated in

Figure 7. Currently, some construction workers and traffic control personnel have adopted these suits. Mengmeng Zhao [

4] conducted experiments under different fan placement configurations and found that placing fans along the spine and lower back yielded the best results. Yi et al. [

28] added multiple settings to the fan in the cooling suit to ensure a stable airflow. Each setting provided a relatively consistent volume of air. Gas-based cooling suits offer excellent cooling effects. Underground environments are rich in gas resources, allowing for extended cooling durations. These suits are compact, lightweight, and can alleviate the burden on workers. However, fan-based cooling suits can be cumbersome to wear, potentially hindering the wearer’s mobility. Moreover, there may be risks of explosion in underground mines due to the presence of hazardous gases like methane. And its cooling effect is not significant in high humidity or extremely hot environments [

29].

In 2005, Zheng Xiang Pu [

30] introduced the duct-type gas-based cooling suit. In this design, an air compressor compresses air and pre-cools it through a vortex tube. The compressed air is then routed through a system of tubes distributed throughout the suit. This promotes heat dissipation on the body surface through the evaporation of sweat and air convection. The gas, having completed its heat exchange, is expelled through the exhaust port. This technology applies the cooling effect of the vortex tube to provide cooling protection for mine workers. During use, temperature output within the range of human thermal comfort can be ensured simply by controlling the adjustment valve. The suit features a straightforward structure, convenient operation, and occupies minimal space, making it suitable for the complex environments found in mines. Compared to traditional fan-based cooling suits, vortex-based cooling suits do not require power sources or refrigerants and can operate continuously for extended periods. However, their cooling effect is relatively weaker and is influenced by the intake pressure and flow rate. Guo et al. [

31] developed a tubular ventilation suit with an open front and unsealed ventilation. The ventilation device introduces natural air or cool air into the duct, which is then blown onto the inner clothing through holes. This design offers characteristics such as ease of wear, being lightweight, and low resistance.

4.3.2. Liquid Cooling Suit

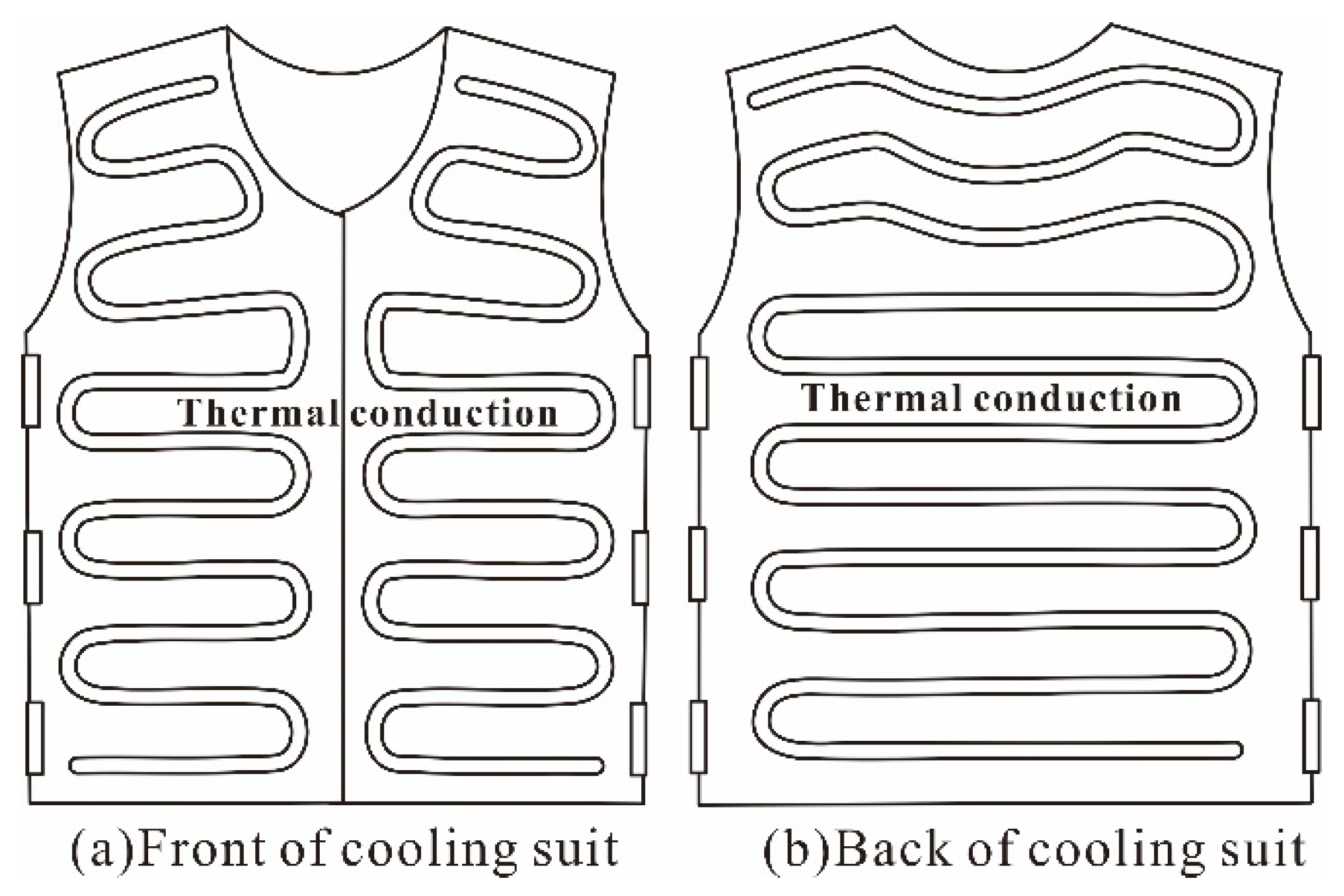

Liquid-based cooling suits circulate a cooling liquid within the microclimate, dissipating the body’s metabolic heat to maintain thermal balance. This falls under active cooling. The cooling mediums for liquid cooling suits mainly include water, a mixture of water and ice, phase-change emulsions, and microcapsule emulsions. The design styles are depicted in

Figure 8. Since liquid cooling suits rely on conductive heat dissipation, they are typically designed in a form-fitting style to ensure effective heat conduction by keeping the clothing close to the skin [

32]. However, to reduce the initial discomfort when the skin surface comes into direct contact with the low-temperature pipes, McLellan [

33] suggests wearing a T-shirt or long-sleeved shirt underneath the liquid cooling suit. Guo et al. [

5] developed a detailed theoretical model for heat transfer from the liquid cooling suit to the environment and determined its maximum working duration to be 3.36 h, which is relatively short. Liquid cooling suits generally require additional equipment such as power sources, water pumps, and refrigeration devices, making them heavy and less portable. To address these issues, Rahman et al. [

34] designed an active cooling system that uses non-toxic gallium-based liquid metal (Galinstan) as the coolant. Compared to other active cooling systems, the liquid-metal cooling system extended the cooling time by four times, reduced the weight to one-third of the original weight, and lowered the cost to one-eighth of the original cost, significantly improving upon the drawbacks of traditional liquid cooling suits. However, further research is needed to address issues such as preventing leaks in liquid cooling suits and improving freedom of movement while wearing them.

4.3.3. Phase-Change Cooling Suit

According to the cooling principle, phase-change cooling suits fall under passive cooling technology. Due to their simple system, user-friendly operation, lack of power requirements, absence of explosion-proof demands, wide range of phase-change materials, effective cooling performance, and reusability, phase-change cooling suits possess extensive application prospects. They have become a focal point of research for international scholars.

Phase-change cooling suits operate on a passive cooling principle [

35]. Typically, multiple pockets are incorporated into the clothing to hold phase-change materials. Through the phase transition of these materials, they absorb heat from the body, achieving the cooling effect. Common phase-change materials include ice, dry ice, gels, crystalline salts, and phase-change material capsules [

36]. Ali et al. [

37] explored the melting points of different phase-change materials, ultimately choosing hexadecane, with a melting point of 18-20 °C, as the phase-change material to develop a phase-change cooling suit. Itani et al. [

38] tested the metabolic rate of individuals wearing three different cooling vests at different environmental temperatures to evaluate their respective cooling performance. The study found that using a mixed-phase-change cooling suit with a desiccant vest had a good effect on maintaining a stable metabolic rate. Ji Changfa et al. [

39] conducted experimental research on the characteristics of phase-change storage materials in cooling suits. They found that inorganic salts have good storage effects when used as coolants, demonstrating that an inorganic salt solution with a certain concentration ratio can be used as a phase-change refrigerant to fill the cooling suit.

However, phase-change cooling suits do have some drawbacks, such as a non-adjustable temperature, heavy weight, limited duration, and potential for leakage. To address these issues, Yuan Pei et al. selected a phase-change material with a transition temperature close to body temperature and used a vortex tube as a cold source to cool the phase-change material, resolving the problem of repeated cooling. Sun Wenjuan et al. [

40] proposed a composite phase-change latent heat storage material based on paraffin, which was blended with a polymer material in a proportionate melt. When the paraffin-based phase-change material underwent solid–liquid phase transition, the surface of the composite phase-change material remained unchanged, effectively solving the issues of leakage and the encapsulation of phase-change latent heat storage materials in individual cooling in mining. Liang Y et al. [

41] selected the TH-SL-23 hybrid solid–liquid phase-change material, which has a high latent heat of fusion for an organic phase-change material, low undercooling ability in the liquid phase, and stable thermal and chemical properties without reaction or corrosion. The total mass of the working material was only 618 g. Today, various critical issues in phase-change cooling suits have been resolved. However, the future focus of research lies in how to integrate and apply these key technologies. This includes the development of a new type of comprehensive cooling suit based on phase-change materials that not only provides effective cooling but also offers temperature control. Additionally, there is a need for improved encapsulation materials and methods, enhanced thermal conductivity of phase-change materials, the development of composite phase-change materials with excellent heat dissipation and long endurance, as well as the creation of new materials or devices for rapid activation of phase-change materials, all of which will drive the advancement of phase-change cooling suits.

4.3.4. Hybrid Cooling Suit

A hybrid cooling suit refers to a cooling suit that combines two or more cooling methods, taking advantage of their respective strengths and compensating for their weaknesses. Song et al. [

42] developed a hybrid cooling suit equipped with both a ventilation fan and phase-change materials. Their research results indicate that compared to a single cooling suit, wearing this hybrid cooling suit during indoor work for 90 min demonstrates better cooling effects and a longer cooling duration. Kang et al. [

43], on the basis of a hybrid cooling suit combining phase-change materials and a fan, added an insulating layer to the outer surface of the phase-change cooling suit to reduce the absorption of heat from the external environment, significantly enhancing the cooling effectiveness and the duration of effective cooling for the hybrid cooling suit.

5. The Application of Cooling Clothes in Mine Environments

In hot underground mining environments, the initial investment for cooling suits is only 1/25 of that for traditional cooling methods, and the operational maintenance costs are 1/16 of the original. Mining cooling suits are flexible and convenient to use, not limited by the workplace, and can be moved according to changes in the mining face. It can be foreseen that in the hot environment of mines, cooling suits have a broad application prospect. The characteristics of various types of cooling suits are compared in

Table 1.

Based on the above comparative analysis, it is evident that existing cooling suits still face challenges when applied in high-temperature mines, including limited cooling duration, material leakage, and inconvenience in wearability. When selecting cooling suits for use in high-temperature mines, various factors must be taken into consideration, such as the hot and humid working environment, underground safety conditions, permitted battery types and CO2 volume fractions, comfort and flexibility in wear, as well as overall cost-effectiveness. Therefore, the issues that need to be addressed for different types of cooling suits in mining applications include:

- (1)

The use of fan-cooled suits carries a risk of electrical leakage and explosion. Phase-change cooling suits are susceptible to deformation and potential leakage of phase-change materials when miners engage in high-intensity physical labor, which can lead to skin corrosion, resulting in lower safety levels.

- (2)

While gas cooling and liquid cooling suits provide effective cooling, they rely on refrigeration units to supply the cooling medium. This results in suits with a large size and weight, which may impede the movement of underground workers.

- (3)

Gas cooling suits are suitable for mines with low pollution levels, low cooling requirements, low humidity, and no electrical explosion-proof requirements. Liquid cooling suits are suitable for large spaces in high-temperature mines. Phase-change cooling suits are suitable for short-duration work in high-temperature mines.

6. Conclusions and Outlook

The fabric of the suit and the design of the cooling suit structure both impact the cooling effectiveness of the cooling suit. Cooling suits have already been applied in high-temperature mining environments to improve human thermal comfort.

With the advancement of technology, cooling fibers have emerged. Cooling suits are no longer limited to conventional materials. Cooling-fabric-based cooling suits are comfortable to wear and environmentally friendly. The development of new cooling fabrics has improved the thermal conductivity and convective evaporation of cooling suits, enhancing comfort when the suit is in close contact with the body. In the future, interdisciplinary collaboration in fields such as textiles, materials, optics, thermodynamics, and mechanics could lead to the development of intelligent cooling suits with new materials that meet the basis of human thermal comfort.

Gas cooling suits, liquid cooling suits, phase-change cooling suits, and hybrid cooling suits each have their own strengths and weaknesses. To be effectively used in mining environments, further improvements are needed. In addition to ensuring safety and comfort, factors such as cooling duration, weight, leakage issues, ease of wearing, power requirements, and aesthetics need to be comprehensively considered. Continued optimization in design is necessary to meet the needs of mining personnel. Among them, hybrid cooling suits exhibit excellent comprehensive performance and high practicality, making them a key focus for future development.

Taking into consideration the unique environment and conditions in high-temperature mines, the future development trends of cooling suits for mining will focus on the miniaturization of components, intelligent temperature control, optimization of new phase-change materials, development of cooling fabrics, and research in smart fibers. Among these, phase-change cooling suits and composite cooling suits show significant potential and are likely to be the best-suited cooling solutions for miners.