Research Progress on Processing Technology of Refined Betel Nut in China: A Review

Abstract

:1. Introduction

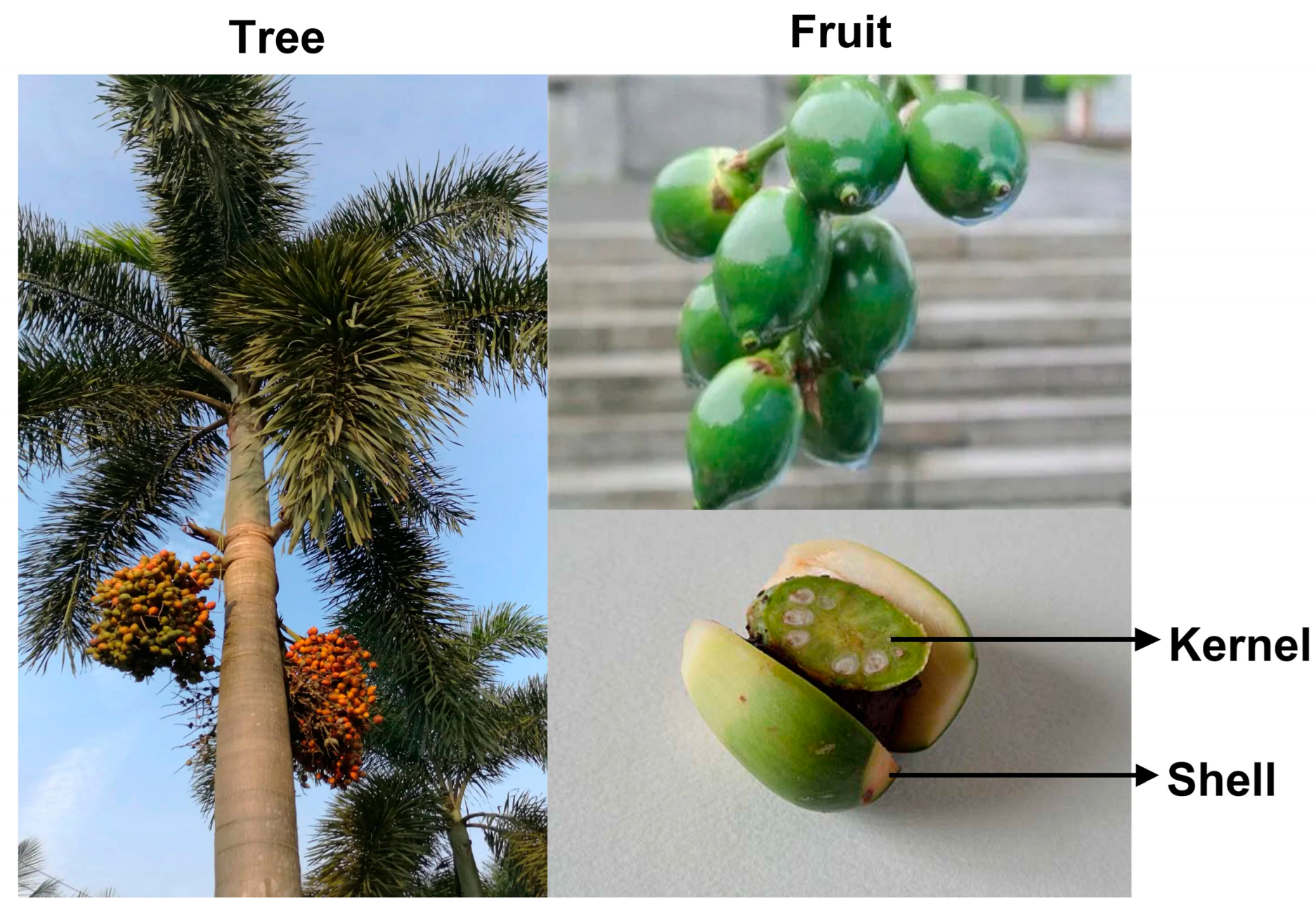

2. Betel Nut Fruit and Its Products in China

3. Process of Refined Betel Nut Production

3.1. Initial Processing in Planting Area

3.2. Cooking of the Dried Betel Nuts

3.3. Fermentation of the Betel Nuts

3.4. Roasting and Fragrance Fixing

3.5. Compressing and Top Coating

3.6. Cutting, Denucleation and Brine Dipping

4. Processing Technology of Refined Betel Nut

4.1. Fiber-Softening Technology

4.1.1. Chemical Softening Technology

4.1.2. Biological Softening Technology

4.1.3. Physical Softening Technology

| Methods | Conditions | Advantages | Disadvantages | Reference |

|---|---|---|---|---|

| Chemical | Alkali treatment: 1.25% sodium hydroxide, 90 °C, 7 min. | Low investment cost and simple operation, reduced astringency. | Color change in products, low efficiency, formation of unpleasant flavors. | [28] |

| Biological | Pectinase II, cellulase and xylanase: 55 °C, pH 5.5, 1:4 (g/mL) bath ratio, 0.5 h. | Enhanced efficiency and specificity, milder operation condition, environmental friendliness. | High cost of enzymes, formation of unpleasant flavors, uneven texture of products. | [47] |

| High-pressure pretreatment: 0.1 MPa, 121 °C, 30 min; enzyme treatment: 50 °C, 5 h, 30 FPU/g enzyme, pH 4.8. | [48] | |||

| Blanching treatment: boiling water, 25 min; enzyme treatment: 50 °C, 0.5 h, 0.08% enzyme, pH 4.8. | [49] | |||

| Physical | Microwave puffing: 915 or 2450 MHz, 2 min, 60 mm height of raw materials. | Better chewiness quality, reduced processing time and solvent use, environmental friendliness. | Increased pressure, high capital and operating cost, additional safety management. | [50] |

| Ultrasonic treatment: 560 W, 45 °C, 32 h, 0.4% enzyme, pH 4.8, 1:2.5 (g/mL) bath ratio. | [51] | |||

| Steam explosion: 80 s, 0.75 MPa, 8.51–17.65% moisture content of betel nuts. | [53] | |||

| Steam explosion: 0.25 MPa, 180 s. | [54] | |||

| Steam explosion: 180 s, 130 °C, 0.23 MPa. | [55] |

4.1.4. Composite Softening Technology

4.2. Microbial Control Technology

4.2.1. Microbial Contamination of Refined Betel Nut

4.2.2. Principle of Microbial Control Technology for Betel Nut

4.2.3. Physical and Chemical Technologies for Microbial Control

4.2.4. Automated Production Technologies for Microbial Control

4.3. Brine Quality Control Technology

4.3.1. Brine Whitening and Brine Returning

4.3.2. Improvement in Brine Reaction

4.3.3. Incorporating Compound Additives

4.3.4. Processing Environment Control

4.4. Fresh Fruit Storage Technology

4.4.1. The Problems of Fresh Betel Nut Storage

4.4.2. Chemical Preservation Technology

4.4.3. Cold Storage and Chilling-Injury-Prevention Technology

4.4.4. Modified Atmosphere Packaging (MAP) Technology

4.4.5. Coating Preservation Technology

4.4.6. Plant-Based Preservatives

| Methods | Conditions | Advantages | Disadvantages | Reference |

|---|---|---|---|---|

| Chemical-processing technology | Treatment condition: 0.27 mg/L TBZ, 16 °C, 24 min; preservation condition: 14 °C, RH 80–90%, 40 days. | Eliminating microorganisms, stable treatment effect, simple process. | Secondary pollution. | [84] |

| Preservation condition: solid sulfur-dioxide-release preservatives, 0.03 mm PVC bag, 3.0 kg fruit per bag, 8 °C, RH 70–80%, 40 days. | [85] | |||

| Cold storage and chilling-injury-prevention technology | Treatment condition: 100 µmol/L MeJA, 15 °C, 24 min; preservation condition: 11 °C, RH 90–95%, 30 days. | Reduced metabolism, inhibited microorganism growth, no chemical residues, high safety, simplicity. | Specific operations needed for chilling-injury prevention. | [90] |

| Treatment condition: 45 or 50 °C hot water, 5 min; preservation condition: 13 °C, RH 90%, 60 days. | [91] | |||

| Modified atmosphere packaging technology | 3% oxygen, 20% carbon dioxide, 11 °C, 30 days. | Reduced metabolism, retained flavor, decreased organic matter consumption, inhibited microorganism growth. | Increased capital and material cost, complicated operation. | [68] |

| 2% oxygen, 5% carbon dioxide, 93% nitrogen, 6 °C, RH 75%, 40 days. | [85] | |||

| Coating preservation technology | Treatment condition: 0.5% chitosan, 50 mg/L sodium dehydroacetate. Preservation condition: 4% oxygen, 4% carbon dioxide, 92% nitrogen, 13 °C, RH 90%, 30 days. | Reduced metabolism, decreased organic matter consumption, inhibited microorganism growth. | Reagent residue. | [95] |

| Treatment condition: 100 mg/L 6-BA, 100 mg/L GA3, 50% fruit wax. Preservation condition: 7 °C, RH 90%, 21 days. | [96] | |||

| Treatment condition: fruit wax for 30 s, fumigated with 2500 μL/L SO2, 0.5 h for every 15 days. | [97] | |||

| Plant-based preservatives | 1% Magnolia ethanol-extracting solution, 2% Perilla water-extracting solution, 1% Centella asiatica water-extracting solution, 0.3% pine needle essential oil. | Nontoxic, harmless, low residue, environmentally friendly. | Higher cost, average performance. | [99] |

| 3.56 g/L tea polyphenols, 1.75 g/L thymol, 11.83 g/L chitosan. | [100] |

4.5. Chemical Pollution of Betel Nut and Its Control Technology

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chao, Y.Z.; Liu, Y.; Chen, J.; Zhao, Z.Y.; Xia, Y.B.; Li, Y.X. Study on the Present situation of edible areca industry and development strategy in Xiangtan. Farm Prod. Process. 2019, 2, 74–77. [Google Scholar]

- Williams, S.; Malik, A.; Chowdhury, S.; Chauhan, S. Sociocultural aspects of betel nut use. Addict. Biol. 2002, 7, 147–154. [Google Scholar] [CrossRef] [PubMed]

- Jain, V.; Garg, A.; Parascandola, M.; Chaturvedi, P.; Khariwala, S.S.; Stepanov, I. Analysis of alkaloids in betel nut-containing products by Liquid Chromatography–Tandem Mass Spectrometry. J. Agric. Food Chem. 2017, 65, 1977–1983. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Pang, X.; Gu, Z.; Guo, Z.; Xin, Y.; Zhang, L. Rapidly analyzing of ingredients during chewing and processing of betel nut using feature-based molecular networking. Food Chem. 2023, 410, 135205. [Google Scholar] [CrossRef] [PubMed]

- Dalisay, F.; Buente, W.; Benitez, C.; Herzog, T.A.; Pokhrel, P. Adolescent betel nut use in Guam: Beliefs, attitudes and social norms. Addict. Res. Theory 2019, 27, 394–404. [Google Scholar] [CrossRef]

- He, X.Y. Study on the Changes in Material Basis and Biological Effects during the Roasting Process of Betel Nut; Chengdu University of TCM: Chengdu, China, 2015. [Google Scholar]

- Hu, J.; Chen, M.; Li, L.J.; Feng, C.; Zhang, D.L. Research report on the overview of betel nut cultivation and processing in Hainan. In Proceedings of the 5th National Local Mechanical Engineering Society Academic Annual Conference 2015 and Made in China 2025 Development Forum, Tengchong, China, 1 November 2015. [Google Scholar]

- Wang, D.; Pang, Y.X.; Hu, X.; Zhang, X.D.; Lin, M.X.; Yu, F.L.; Xie, X.L. Development and motivation analysis of areca planting industry in Hainan province. Guangdong Agric. Sci. 2013, 40, 207–209. [Google Scholar]

- Chen, W.L.; Wang, C. Promoting the healthy and sustainable development of the betel nut industry in Hainan. Hainan Daily, 13 October 2019; p. 1. [Google Scholar]

- Yuan, J.; Zhang, H.; Zhao, H.; Ren, H.; Zhai, H. Study on dissociation and chemical structural characteristics of betel nut husk. Molecules 2023, 28, 1513. [Google Scholar] [CrossRef]

- Huang, H.D. 2015 betel nut industry development report and forecast. World Trop. Agric. Inf. 2017, 1, 31–39. [Google Scholar]

- Xie, H. Accelerating the rule of law: A fundamental measure to solve the dilemma of the betel nut industry in our province. People’s Friend 2022, 9, 49–50. [Google Scholar]

- Betel nut market monitoring analysis in June. World Trop. Agric. Inf. 2019, 7, 40–42.

- International Agency for Research on Cancer. Personal habits and indoor combustions. A review of human carcinogens. IARC Monogr. Eval. Carcinog. Risks Hum. 2012, 100, 1–538. [Google Scholar]

- Marques, M.M.; Beland, F.A.; Lachenmeier, D.W.; Phillips, D.H.; Chung, F.L.; Dorman, D.C.; Guyton, K.Z. Carcinogenicity of acrolein, crotonaldehyde, and arecoline. Lancet Oncol. 2021, 22, 19–20. [Google Scholar] [CrossRef] [PubMed]

- Jing, Y.S.; Ma, Y.F.; Pan, F.B.; Kuang, F.J.; Zhang, D.S.; Guo, X.D.; Wu, L.F. Research Progress on Herbal Textual Research, Chemical Constituents and Pharmacological Effects of Areca Catechu. Asia-Pac. Tradit. Med. 2022, 18, 232–239. [Google Scholar]

- Chen, X.X.; He, Y.Z.; Deng, Y. Chemical composition, pharmacological, and toxicological effects of betel nut. Evid. Based Complement. Altern. Med. 2021, 2021, 1808081. [Google Scholar] [CrossRef] [PubMed]

- Yi, S.; Zou, L.; Li, Z.; Sakao, K.; Wang, Y.; Hou, D.X. In vitro antioxidant activity of betel nut polyphenol extracts on RAW264.7 Cells. Foods 2022, 11, 3607. [Google Scholar] [CrossRef]

- Peng, W.; Liu, Y.J.; Wu, N.; Sun, T.; He, X.Y.; Gao, Y.X.; Wu, C.J. Areca catechu L. (Arecaceae): A review of its traditional uses, botany, phytochemistry, pharmacology and toxicology. J. Ethnopharmacol. 2015, 164, 340–356. [Google Scholar] [CrossRef]

- Peng, Y.M.; Gong, N.C.; Li, P.H.; Tan, D.B. Compositional changes and multivariate statistical analysis of edible betel nut during processing. Food Ind. 2021, 3, 96–101. [Google Scholar]

- Zhu, L.; Zhang, H.D. Current situation and prospect of betel nut processing. Farm Prod. Process. 2011, 8, 68–69+73. [Google Scholar]

- Chen, W.X.; Dou, H.G.; Li, C.F.; Wang, Z.N.; Fu, X. Study on the processing technique of edible areca. Food Sci. Technol. 2007, 32, 57–59. [Google Scholar]

- Yan, D.; Li, Y. Study on the processing technique of edible areca. Food Mach. 2003, 19, 34–35. [Google Scholar]

- Rasheed, S.; Dasti, A.A. Quality and mechanical properties of plant commercial fibers. Pak. J. Biol. Sci. 2003, 6, 840–843. [Google Scholar] [CrossRef]

- Chen, G.; Liu, Z.Y. Study on the processing technique of edible areca with green areca fruit. Food Sci. Technol. 2009, 34, 80–83. [Google Scholar]

- Zhon, Q.D. Hainan Qionghai will ban some traditional betel nut processing sites. World Trop. Agric. Inf. 2013, 12, 9–10. [Google Scholar]

- Li, D.X. Techniques of smoking meat product. Meat Ind. 2006, 7, 18–20. [Google Scholar]

- Xiao, X.Y. Optimization of Alkali Boiling Process for Edible Betel Nut Soften and Analysis Changing during Chewing; Agricultural University of Hunan: Changsha, China, 2020. [Google Scholar]

- Li, Z.; Xu, H.H.; Deng, J.Y.; Jiang, X.W.; Li, H. Study on inteneration and sterilization of areca by high-temperature dry steam treatment. Food Mach. 2015, 31, 194–197. [Google Scholar]

- Dai, J.H.; Kang, X.N.; Ji, J.B.; Dai, W.T.; Wang, S.P.; Ma, J.S. Research and optimization of alkali deastringency technology for dried Areca nut. Storage Process. 2021, 21, 88–95. [Google Scholar]

- Song, X.H.; Zhu, J.D.; Li, Z.; Ma, C.Y.; Wang, H.X. Study on the influence of processing steps and storage conditions on the physicochemical properties of betel nut. Food Ferment. Ind. 2023, 1, 1–8. [Google Scholar]

- Hunan Huangye Food Co., Ltd. A High-Pressure Rapid Fermentation Method for Betel Nut. China Patent CN201510349525.0, 21 October 2015. [Google Scholar]

- Huang, Q.; Liu, K.K.; Chen, K.; Jian, X.P. Effect of processing technology on the content of arecoline in areca product. Food Ind. 2021, 42, 57–60. [Google Scholar]

- Xie, L.L.; Zhang, H.J.; Fang, J. Research progress of betel nut processing in China. Guangdong Agric. Sci. 2011, 38, 96–98. [Google Scholar]

- Duan, W.F. Vacuum Fermentation and Immersion Processing Method for Betel Nut: China. China Patent 1554248A, 29 December 2003. [Google Scholar]

- Jian, X.P.; He, J.W.; Chen, K. Preparation of emulsified coating agent and its application in Areca nut coating. Food Ind. 2021, 42, 22–25. [Google Scholar]

- Li, L.Y. Study on the Quality Changes and Characteristics of Edible Betel Nut Pickled Water during Shelf Life; Central South University of Forestry and Technology: Changsha, China, 2022. [Google Scholar]

- Shi, Y. Structure Design of Edible Betel Nut Cutting Machine; Xidian University: Xi’an, China, 2014; pp. 20–23. [Google Scholar]

- Zhou, C.L. Research and Design of Areca-Nut Cutting Machine; Guangdong University of Technology: Guangzhou, China, 2015; pp. 27–29. [Google Scholar]

- Yin, X.M.; Peng, J.Y.; Gao, Y.J. Clinical study on the relationship between tooth abrasion and the habits of chewing betel nut. Hunan Yi Ke Da Xue Xue Bao 2003, 28, 171–173. [Google Scholar]

- Shirzaiy, M.; Neshat, F. Effect of areca nut on oral health. A review. J. Res. Dent. Maxillofac. Sci. 2020, 5, 1–6. [Google Scholar] [CrossRef]

- Li, W.C.; Lee, P.L.; Chou, I.C.; Chang, W.J.; Lin, S.C.; Chang, K.W. Molecular and cellular cues of diet-associated oral carcinogenesis-with an emphasis on areca-nut-induced oral cancer development. J. Oral Pathol. Med. 2014, 44, 167–177. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, X.H.; Reichart, P.A. Betel quid chewing, oral cancer and other oral mucosal diseases in Vietnam. A review. J. Oral Pathol. Med. 2010, 37, 511–514. [Google Scholar]

- Song, P.D. A review of the habit of chewing betel nut and oral health research in China. J. Diet. Suppl. 2021, 23, 295–296. [Google Scholar]

- Zhao, Z.Y.; Chao, Y.Z.; Yuan, S.S.; Liu, Y.Y.; Xiao, D.; Xia, Y.B. Effects of different softening methods on quality of edible areca. Food Mach. 2017, 33, 189–193. [Google Scholar]

- Rajan, R.; Ajith, S.; Joshy, A.; Anita, R. Bleaching and softening of coir fiber using Averrhoa Bilimbi extract. J. Nat. Fibers. 2022, 19, 4477–4484. [Google Scholar] [CrossRef]

- Cheng, L.F.; Li, Q.; Ji, J.B.; Duan, S.W.; Feng, X.Y.; Zeng, J.; Yang, Q.; Liu, Z.Y.; Zheng, K.; Peng, Y.D. Enzymatic softening technology of Areca nut shell. J. Biobased Mater. Bioenergy 2017, 11, 644–648. [Google Scholar] [CrossRef]

- Li, W.; Zheng, C. Study on inteneration Areca hull by enzymatic hydrolysis coupled with high pressure treatment. Guangdong Chem. Ind. 2007, 5, 23–25. [Google Scholar]

- Wu, S.; Li, Z.J.; Tan, Y.; Du, S.; Huang, R.T.; Wu, J. Boiling softening effects and irradiation preservation research of dried betel nut. J. Nucl. Agric. Sci. 2017, 31, 711–718. [Google Scholar]

- Wang, X.D. Study on Key Technology of Microwave Puffing Areca; Zhengzhou University: Zhengzhou, China, 2018. [Google Scholar]

- Chao, Y.Z.; Xia, Y.B.; Zhao, Z.Y.; Ou, Y.H.; Wu, Y.X.; Li, Q. Optimization of ultrasonic enzyme softening technology for edible Areca. Farm Prod. Proces. 2016, 21, 14–17. [Google Scholar]

- Li, G.; Ma, L.; Yan, Z.; Zhu, Q.; Cai, J.T.; Wang, S.; Yuan, Y.; Chen, Y.Z.; Deng, S.W. Extraction of oils and phytochemicals from Camellia oleifera seeds: Trends, challenges, and innovations. Processes 2022, 10, 1489. [Google Scholar] [CrossRef]

- Yang, B.; Xu, Y.P.; Chen, W.J.; Chen, W.X.; Zhong, Q.P.; Zhang, M.; Pei, J.F.; Chen, H.M. Effect of steam explosion on the morphological, textural and chemical composition characteristics of betel nut. Res. Sq. 2023. [Google Scholar] [CrossRef]

- Huang, Q.; Xiao, W.D.; Zhang, X.J.; Li, Z.; Yang, S.L.; Gao, X.T. Research and application of steam explosion on the quality of Areca Product. Food Ind. 2019, 40, 73–77. [Google Scholar]

- Sun, Z.Q.; Tan, H.H.; Song, J.Q.; Hou, Y.B.; Huang, J.X. Orthogonal experimental study on steam explosion treatment technology of Areca nut. Adv. Eng. Technol. Res. 2022, 1, 70. [Google Scholar] [CrossRef]

- Deng, J.Y.; Li, H.; Jiang, X.W.; Yao, L.; Xu, Y.T.; Lu, K.Q. Research progress on processing technology, chemical, and microbial contamination of edible betel nut. Food Mach. 2018, 34, 173–176. [Google Scholar]

- Bhat, S.K.; Ashwin, D.; Sarpangala, M. Contamination and adulteration in arecanut (Areca catechu L.) and its chewing foms: The less focused subject by health researchers. IOSR J. Environ. Sci. Toxicol. Food Tech. 2017, 11, 7–12. [Google Scholar] [CrossRef]

- Xu, D. Safety Risk Analysis of Edible Betel Nut; Central South University of Forestry and Technology: Changsha, China, 2012. [Google Scholar]

- Yin, B.; Yu, J.; Sheng, C.M.; Cheng, Y.H. Betel nut mold of the advantages of raw materials and the development of fungicide. Food Mach. 2008, 24, 24–28. [Google Scholar]

- Kang, X.N.; Ji, J.B.; Xia, B.; Wang, H.C. Preliminary identification of storage period diseases in betel nut fruits. China Trop. Agric. 2011, 6, 61–63. [Google Scholar]

- Ruan, Z.Q.; Deng, J.Y.; Jiang, X.W.; Yao, L.; Li, H.; Luo, X.M.; Lu, K.Q. Variations of bacterial community structure during storage and processing of the betel nut. Food Mach. 2021, 8, 146–152. [Google Scholar]

- Zhang, Q.L.; Peng, L.; Cheng, X.M.; Xu, Y.F.; Zhou, Y.J.; Feng, Y.Y.; Li, W.G. The composition and changes of fungi community during processing of edible betel nut. J. Nucl. Agric. Sci. 2020, 34, 2541–2550. [Google Scholar]

- Wan, X.; Wan, J.Z.; Ai, C.X. Research and development of the fresh-keeping Areca catechu. Food Sci. Technol. 2003, 6, 19–22. [Google Scholar]

- Du, D.L.; Gan, B.C.; Wang, Y.S.; Feng, J.D.; Chen, W.P. Study on sterilization by microwaves on edible Areca catechu. Food Sci. Technol. 2005, 7, 86–88. [Google Scholar]

- Xu, Y.F.; Deng, G.Q.; Peng, L.; Li, W.G.; Zou, C.H.; Mao, Q.X.; Hu, J.S.; Cheng, W. Effect of irradiation on sterilization and quality of edible Areca nut. J. Nucl. Agric. Sci. 2014, 28, 240–244. [Google Scholar]

- Jin, H.Y.; Fu, C.R. Effect of complex preservative on betel nut. China Food Addit. 2014, 23, 128–133. [Google Scholar]

- Li, Z.; Xu, H.H.; Hu, H.; Chen, J. Study on technology of reducing water activity of Areca production. Farm Prod. Process. 2015, 5, 11–13. [Google Scholar]

- Li, Y.Y.; Yang, X.Z.; Li, S.H. Effects of different storage conditions on quality of Areca catechu L. China Fruit Veg. 2015, 36, 11–13. [Google Scholar]

- Li, W.X.; Li, F.; Zhou, S.H.; Yuan, X.; Huang, X.W.; Xu, B.C.; Luo, J. Monitoring and analysis on microbes in edible areca processing. Food Mach. 2020, 36, 58–62. [Google Scholar]

- China Consumer Reports Home Page. Available online: https://www.ccreports.com.cn/food/41534.html (accessed on 24 October 2023).

- Chen, Q.H.; Jian, X.P.; Chen, S.; Kang, M.X.; Liu, K.K. Study on edible areca nut brine whitening and its inhibition. China Food Addit. 2020, 31, 83–88. [Google Scholar]

- Ma, J.S.; Kang, X.N.; Wang, S.P.; Dai, W.T.; Dai, J.H.; Ji, J.B. Composition analysis of white substances on the surface of edible Areca brine. Food Ind. 2021, 42, 261–264. [Google Scholar]

- Fu, C.R.; Chen, Y.H.; Li, Y.S. A Brine of Edible Betel Nut and an Inhibitor of Brine Whitening: China. China Patent 104304846A, 28 January 2015. [Google Scholar]

- Guo, Z.G.; Kuang, F.J.; Kuang, F.J.; Zhang, Q.L. An Edible Betel Nut Brine and Its Production Method: China. China Patent 101843305A, 29 September 2010. [Google Scholar]

- Li, L.Y. Study on the Quality Changes of Edible Betel Nut in Brine Solution during Shelf Life; Central South University of Forestry and Technology: Changsha, China, 2022. [Google Scholar]

- Tang, M.X. An Automated Betel Nut Brine Reactor: China. China Patent 213881673U, 6 August 2021. [Google Scholar]

- Wang, W.; Chen, X.P.; Wang, J.W. Automatic Betel Nut Brining Machine: China. China Patent 304600498S, 27 April 2018. [Google Scholar]

- Kang, X.N.; Ji, J.B.; Dai, W.T.; Wang, S.P.; Ma, J.S.; Dai, J.H. A Method for Evaluating the Brine of Edible Betel Nut: China. China Patent 112179938, 5 January 2012. [Google Scholar]

- Li, L.Y.; Pan, F.B.; Zhou, W.H.; Qian, X.; Wang, Y.R.; Mo, H. Study on quality control of edible areca during shelf life. Food Mach. 2021, 37, 188–193, 218. [Google Scholar]

- Xiao, D.; Zhao, Z.Y.; Wu, Y.X. Edible Betel Nut Brine with the Ability to Inhibit Returning of Betel Nut and Its Preparation Method: China. China Patent 106551365B, 17 November 2020. [Google Scholar]

- Huang, Q.; Gao, X.; Jian, X. Research progress on preservation and deep processing technology of areca nut. Food Ind. 2021, 42, 251–254. [Google Scholar]

- Jiang, Y.M.; Chen, F.; Zhang, D.L.; Liu, S.X.; Li, Y.B. Browning substrates of betelnut. Chin. J. Trop. Crops 1992, 2, 93–96. [Google Scholar]

- Guo, Y.; Pan, Y.; Zhang, Z.; Zhang, W. Study on the browning mechanism of betel nut (Betel catechu L.) kernel. Food Sci. Nutr. 2020, 8, 1818–1827. [Google Scholar] [CrossRef]

- Zhang, J.J.; Hao, X.L.; Li, H.X.; Liu, J.; Li, M.; Zhang, W.T.; Du, Y.R. Effects of different preservation treatments on storage quality of betel nut. Stor. Process. 2016, 16, 16–20. [Google Scholar]

- Xia, B. Study on the Respiratory Mechanism and Key Technologies of Storage and Preservation for Betel Nuts; Hainan University: Haikou, China, 2010. [Google Scholar]

- Pan, Y.; Guo, Y.; Huang, Q.; Zhang, W.; Zhang, Z. Enzymatic browning in relation to permeation of oxygen into the kernel of postharvest areca nut under different storage temperatures. J. Food Sci. Technol. 2021, 9, 3768–3776. [Google Scholar] [CrossRef]

- Gu, W.L. Effects of Fresh Keeping and Processing of Areca catechu on Its Active Components; South China University of Technology: Guangzhou, China, 2017. [Google Scholar]

- Yao, X.L. Postharvest Storage and Packaging Preserving Process of Betel Nut; Jiangnan University: Wuxi, China, 2018. [Google Scholar]

- Li, W.; Shao, Y.Z.; Gan, X.L.; Wu, S.F. The preliminary study on storage and fresh-keeping methods of arecatechu fruit. Guizhou Sci. 2005, 23, 69–72. [Google Scholar]

- Li, X.H.; Zhang, J.J.; Hao, X.L.; Liu, J.; Li, M.; Zhang, W.T.; Du, Y.R. Effect of Methyl Jasmonate on chilling injury regulation in fresh betel nut. Mod. Food Sci. Technol. 2016, 32, 260–265. [Google Scholar]

- Pan, Y.F.; Xu, M.J.; Guo, Y.L.; Zhang, J.J.; Li, X.H. Effect of hot water treatment on chilling injury and lignification of cold-stored fresh areca nut (Areca catechu L.). J. Food Sci. Technol. 2020, 57, 4337–4344. [Google Scholar] [CrossRef]

- Wilson, M.D.; Stanley, R.A.; Eyles, A.; Ross, T. Innovative processes and technologies for modified atmosphere packaging of fresh and fresh-cut fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2019, 59, 411–422. [Google Scholar] [CrossRef]

- Huang, S.S.; Qiu, Z.N.; Zhang, Z.Q.; Huang, X.M. Study on postharvest managements of Areca catechu fruits. Guangdong Agric. Sci. 2012, 39, 114–116. [Google Scholar]

- Elsa, D.M.; Roberto, C.M. Edible films and coatings as food-quality preservers: An overview. Foods 2021, 10, 249. [Google Scholar]

- Pan, L.; Yao, X.L.; Lu, L.X.; Zhang, D.H. Effect of chitosan and sodium dehydroacetate coating on the quality of betel nuts. Packag. Eng. 2019, 40, 1–5. [Google Scholar]

- Li, S.B.; Zhang, W.W.; Pan, Y.G. Effects of compound with 6-BA, GA-3 and fruit wax coating on the water loss and skin color of betel nuts and its mechanism. Sci. Technol. Food Ind. 2017, 38, 319–323, 348. [Google Scholar]

- Zhang, J.J.; Li, X.H.; Hao, X.L.; Liu, J.; Li, M.; Zhang, W.T.; Du, Y.R. Application of fruit wax coating and SO2 fumigation in preservation of fresh betel nut. Food Sci. Technol. 2015, 40, 356–359. [Google Scholar]

- Michel, M.B.; Michael, E.N.; Yasmina, S.; Heather, S.; Louwrens, C.H. Plant-based phenolic molecules as natural preservatives in comminuted meats: A review. Antioxidants 2021, 10, 263. [Google Scholar]

- Cheng, H.B.; Pan, X.C.; Wang, F.L.; Jia, X.Y.; Li, J.H.; Wang, D.J. Effect of compound natural antistaling agent on cold storage of betel nut. Food Ind. 2022, 43, 1–5. [Google Scholar]

- Liu, C. Effects of Electron Beam Irradiation on the Quality of Fresh Betel Nut in Coated and Packaged; Huazhong Agricultural University: Wuhan, China, 2022. [Google Scholar]

- Kang, X.N.; Ji, J.B.; Li, L. Analysis of unsafe factors in baked craft of betel nuts. Food Mach. 2015, 31, 68–70. [Google Scholar]

- Lin, L.; Cheng, L.H.; Zhang, P. Determination of copper content in betel nut and study on methods to reduce its content causing submucous fibrosis of oral mucosa. Exp. Lab. Med. 2015, 33, 264–265. [Google Scholar]

- GB 2760-2014; National Food Safety Standard for Uses of Food Additives. National Health and Family Planning: Beijing, China, 2014.

- 59 Batches of Food Products Fail Quality Inspection. Guangxi Qual. Superv. Guide Period. 2013, 2, 37.

- Witkowski, M.; Nemet, I.; Alamri, H.; Wilcox, J.; Gupta, N.; Nimer, N.; Haghikia, A.; Li, X.S.; Wu, Y.; Saha, P.P.; et al. The artificial sweetener erythritol and cardiovascular event risk. Nat. Med. 2023, 29, 710–718. [Google Scholar] [CrossRef] [PubMed]

- DB43/132-2004; Local standard for edible betel nut in Hunan. Hunan Provincial Bureau of Quality and Technical Supervision: Changsha, China, 2004.

- DB46/T75-2007; Local Standard for Edible Betel Nut in Hainan. Hainan Provincial Bureau of Quality and Technical Supervision: Haikou, China, 2007.

| Procedures | Operation Methods | Major Objective |

|---|---|---|

| Initial processing | Cooking in boiling water for 30–50 min followed by drying and roasting with electric or steam ovens. | Conservation of betel nut fruit. |

| Cooking | Cooking in boiling water for 20 min or exposure to steam (110 °C and 0.05 MPa) for 15 min. | Cleaning, rehydration, softening and sterilization. |

| Fermentation | Soaking in solution containing plant extract, sweeteners, flavors and fragrances at 40–50 °C for one day and at room temperature for the next couple of days. | Enhancing the flavor and aroma. |

| Roasting | Drying with hot-air baking machines. | Reducing the water content. |

| Fragrance fixing | Soaking in a solution containing various flavors and fragrances. | Stabilizing and enhancing the aroma. |

| Compressing | Flattening using hydraulic equipment. | Loosening the fibers and creating specific patterns on the surface. |

| Top coating | Spraying gelatin film onto the surface of the betel nuts. | Increasing brightness. |

| Cutting and denucleation | Cutting betel nuts into two pieces manually or mechanically and picking out the kernel. | Denucleation. |

| Brine dipping | Adding the brine to the middle point of the betel nut shell. | Flavoring and beautifying. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Q.; Deng, S.; Ma, L.; Li, Q.; Tan, S.; Zheng, Y.; Xu, A.; Wang, H. Research Progress on Processing Technology of Refined Betel Nut in China: A Review. Processes 2023, 11, 3199. https://doi.org/10.3390/pr11113199

Zhu Q, Deng S, Ma L, Li Q, Tan S, Zheng Y, Xu A, Wang H. Research Progress on Processing Technology of Refined Betel Nut in China: A Review. Processes. 2023; 11(11):3199. https://doi.org/10.3390/pr11113199

Chicago/Turabian StyleZhu, Qinhe, Senwen Deng, Li Ma, Qi Li, Shuhua Tan, Yuojun Zheng, Aiqing Xu, and Haihua Wang. 2023. "Research Progress on Processing Technology of Refined Betel Nut in China: A Review" Processes 11, no. 11: 3199. https://doi.org/10.3390/pr11113199

APA StyleZhu, Q., Deng, S., Ma, L., Li, Q., Tan, S., Zheng, Y., Xu, A., & Wang, H. (2023). Research Progress on Processing Technology of Refined Betel Nut in China: A Review. Processes, 11(11), 3199. https://doi.org/10.3390/pr11113199