2.1. Geological Characteristics of the Study Area

The reservoir of Triassic Baikouquan Formation in Mahu Sag is located on the Madong slope of Mahu Sag in the central depression of Junggar Basin, belonging to Xinjiang Uygur Autonomous Region and Bukeser Mongolian Autonomous County, adjacent to Manas Lake, 20 km east of Hefeng Yanchi, and is an important oil and gas exploration and development zone in China. The structure of the study area is gentle and inclined to the south, and the reservoir thickness is about 200 m, which is divided into the third member (T1b3), the second member (T1b1) and the first member (T1b1) of Baikouquan Formation from top to bottom, mainly composed of glutenite mixed with mudstone; the thickness of glutenite is relatively large [

11].

The reservoir studied belongs to continental sedimentary rocks, which is mainly composed of sandstone, mudstone and shale [

12]. The fine grain size of sandstone leads to extremely low reservoir porosity, and, at the same time, many pore structures such as dissolution pores, cementation pores and intergranular gaps are formed [

13]. Through the observation of core microscope and the analysis of whole rock composition, it is considered that the lithology of the studied reservoir is mainly glutenite, followed by medium-fine sandstone [

13]. The maximum particle size of gravel is more than 8 cm, mostly 1~2 cm, and the particles keep line contact and point-line contact, which is characterized by pressure-embedding pore cementation.

Table 1 shows the composition of reservoir glutenite. It can be seen that the main glutenite is mainly composed of tuff and metamorphic mudstone, and the maturity of reservoir composition and structure is low. Through core measurement and mercury injection test, it is concluded that the average porosity of this reservoir is 10.5%, the average permeability is 9 × 10

−4 μ m

2, the average displacement pressure is 0.58 MPa, the average capillary radius is 0.58’m, and the average mercury removal efficiency is 38.3% [

13]. Therefore, it can be considered that this reservoir has low porosity and low permeability and poor pore structure.

Reservoir sensitivity is mainly related to the kinds of clay minerals [

14]. X-ray diffraction analysis of reservoir characteristics first requires sample preparation, collection and fine grinding of reservoir rock samples to turn them into powder for easy analysis of reservoir characteristics. Then, the sample powder is placed in an X-ray diffraction instrument, and diffraction patterns are obtained by scanning X-rays from different angles and ranges. Then, standard spectra of known minerals are compared to obtain information about rock composition, including crystal structure and composition. The composition and proportion of clay minerals in the reservoir are obtained by X-ray diffraction (

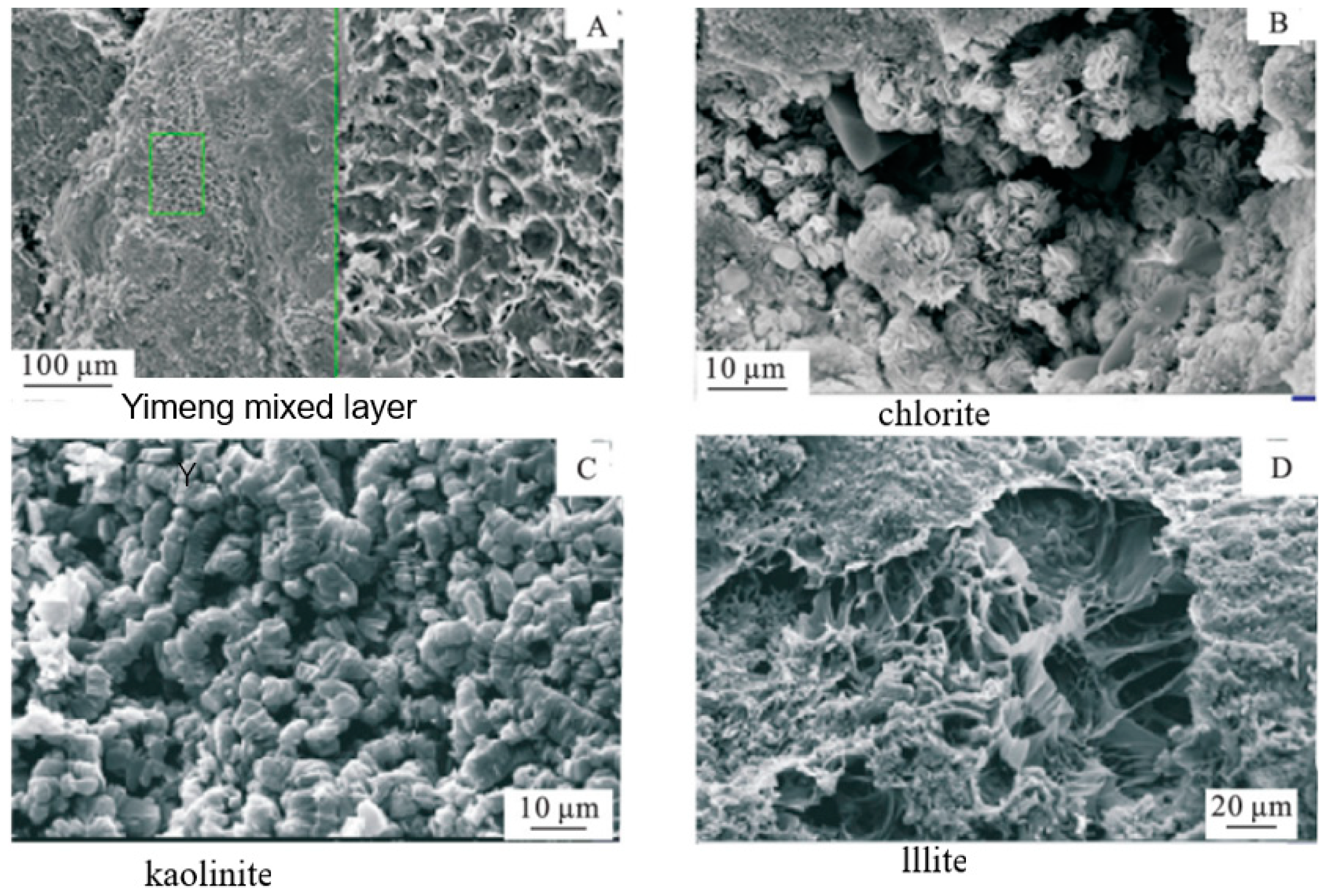

Table 2). Clay minerals in Yimeng mixed layer in the study area are mainly clay minerals, followed by chlorite and kaolinite, with a small amount of illite. Montmorillonite accounts for more than 60% in Yimeng mixed layer, so the mixed-layer minerals mainly show the physical and chemical properties of montmorillonite, so the reservoir is water-sensitive and salt-sensitive, kaolinite is speed-sensitive, and chlorite is acid-sensitive, which makes the reservoir have speed-sensitive and acid-sensitive properties. To obtain reservoir characteristics using a scanning electron microscope, it is necessary to first slice the sample to obtain thin or blocky samples for SEM observation. Then, the sample is placed in an SEM instrument and the surface of the sample is scanned by an electron beam to obtain a high magnification image. These images can display the microstructure, pore distribution, and particle characteristics of rocks. Scanning electron microscopy (SEM) was used to observe the cores. It was found that the mixed layer of illite and montmorillonite was mainly irregular flake, chlorite was a foliated or fluffy aggregate, kaolinite filled the reservoir pores with worms, and illite filled the pores with clay bridges (

Figure 1).

The study of reservoir geological characteristics is mainly affected by depression structure and sedimentation. The sag structure experienced multiple periods of uplift and subsidence, forming multiple structural zones and uneven topography, which affected the distribution and connectivity of reservoirs. Under the deposition of terrestrial clastic rocks such as rivers, lakes and sedimentary fans, it has a great influence on the physical properties and pore structure of reservoirs. For example, the porosity of sandstone reservoirs is generally higher under lake deposition and lower related to the kinds of clay minerals [

15].

2.2. Research Methods and Test Steps

In order to simulate the dynamic damage of different fluids to the reservoir and evaluate the damage degree of different sensitivities to the reservoir, different types of fluids are configured in this paper to carry out core mobility tests. By using the method of reservoir sensitive flow test and evaluation, the reservoir sensitive flow test is carried out.

Preparation of the rock sample: A flat cylindrical sample with a diameter of 2.5 cm and a length of 5 cm was obtained by drilling and coring (

Figure 2). Before the test began, the core was cleaned with toluene to clean the liquid (oil) inside the core. The core was placed in a dryer at 70 °C and dried for more than 24 h, while the clay mineral properties of the core were kept unchanged [

16].

According to the physical parameters of the sample, the seepage pressure of gas in the core was determined, and the gas permeability of the sample was obtained according to Darcy’s law. According to the ion concentration in reservoir formation water measured by logging, the dosage of chemical reagents in the testing process was calculated and different types of formation water are prepared. Standard saline with 8% salinity can also be tested via this method. The core was then immersed in the prepared formation water, and was kept in this vacuum-saturated state for more than 4 h. Afterwards, it was let to stand for one day, and the core was placed into the core holder, and the reservoir sensitive flow test was started (

Figure 3).

Velocity sensitivity test: Set the flow rates of formation water to be 0.1, 0.25, 0.50, 0.75, 1.0, 2.0, 3.0, 4.0, 5.0 and 6.0 cm 3/min, then calculate the displacement time according to the pore size of the test, record the displacement pressure and environmental temperature, and obtain the core permeability corresponding to each flow rate, thus obtaining the formation water.

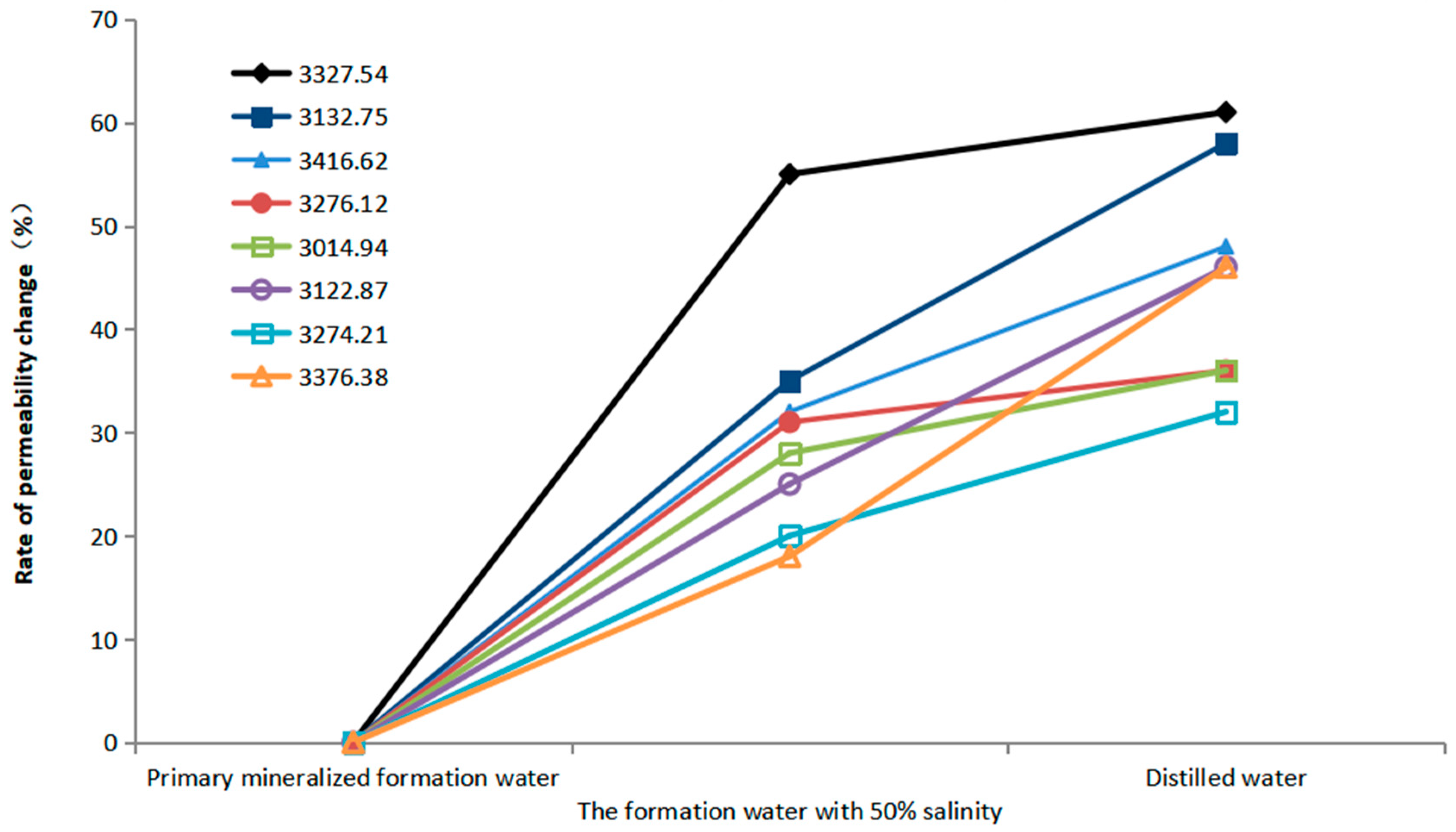

Water sensitivity test: Set the flow rate as the critical flow rate, conduct core displacement test with formation water with original salinity, formation water with salinity of 50% and distilled water, set the pore volume of the core to be 10 times, calculate the displacement time, and record the displacement pressure and environmental temperature of formation water with original salinity. Then, continue to fully carry out displacement experiments with formation water with salinity of 50%, and make the fluid fully react with rock minerals under the condition of constant confining pressure, and calculate the permeability of samples with different salinity and the water-sensitive damage rate. The core displacement test of distilled water is the same as that of formation water with 50% salinity.

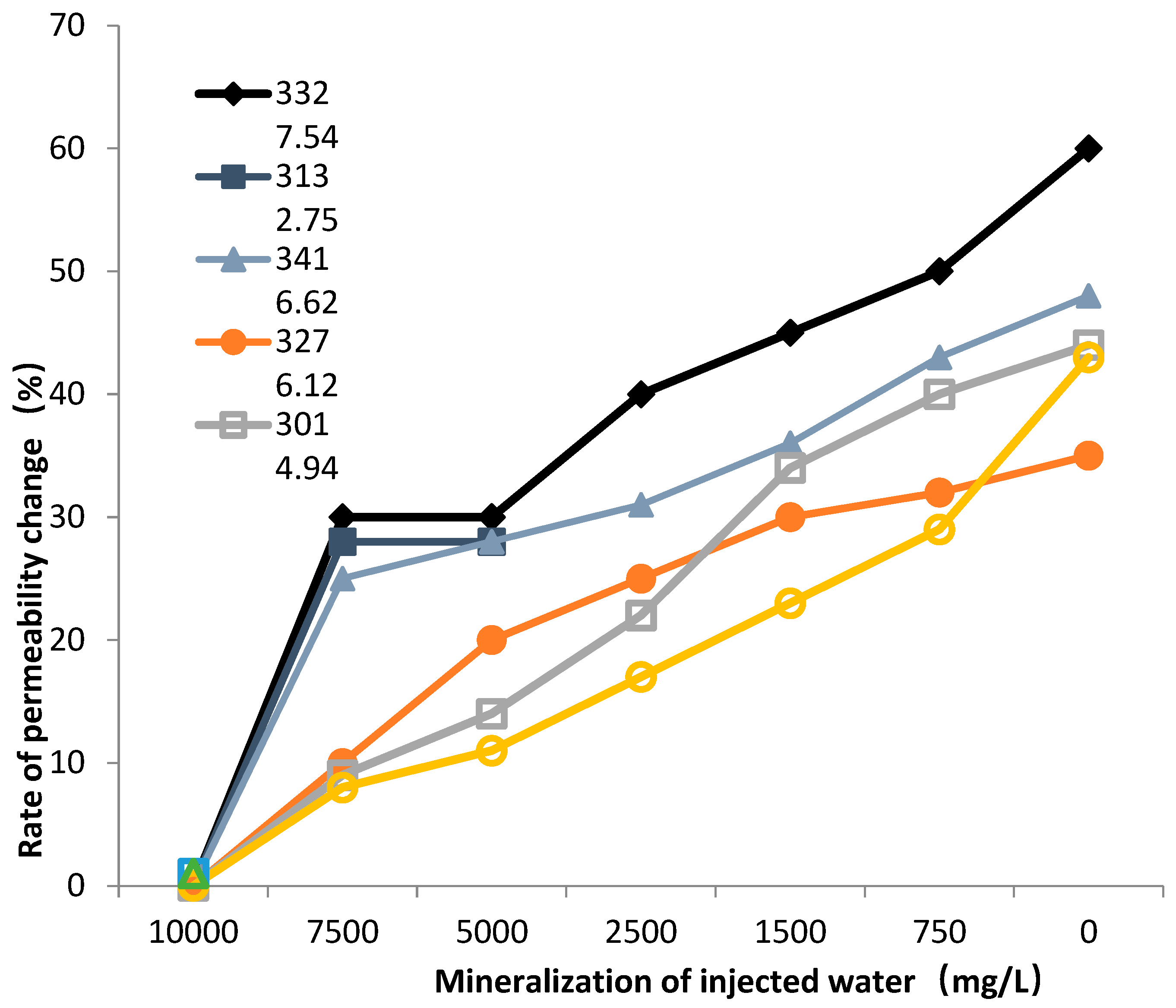

Salt sensitivity test: Set the flow rate as the critical flow rate, add formation water and distilled water with salinity levels of 10,000 mg/L, 7500 mg/L, 5000 mg/L, 2500 mg/L, 1500 mg/L and 750 mg/L, then conduct displacement test on the core, set the pore volume to 5, calculate the displacement time and record it. Continue to use formation water with salinity levels of 7500 mg/L to carry out displacement experiments on the core, and make the fluid fully react with rock minerals under the condition of constant confining pressure, and calculate the permeability of samples with different salinities to obtain the critical salinity. The displacement test of other mineralized formation water and distilled water are the same as those of formation water with salinity of 7500mg/L.

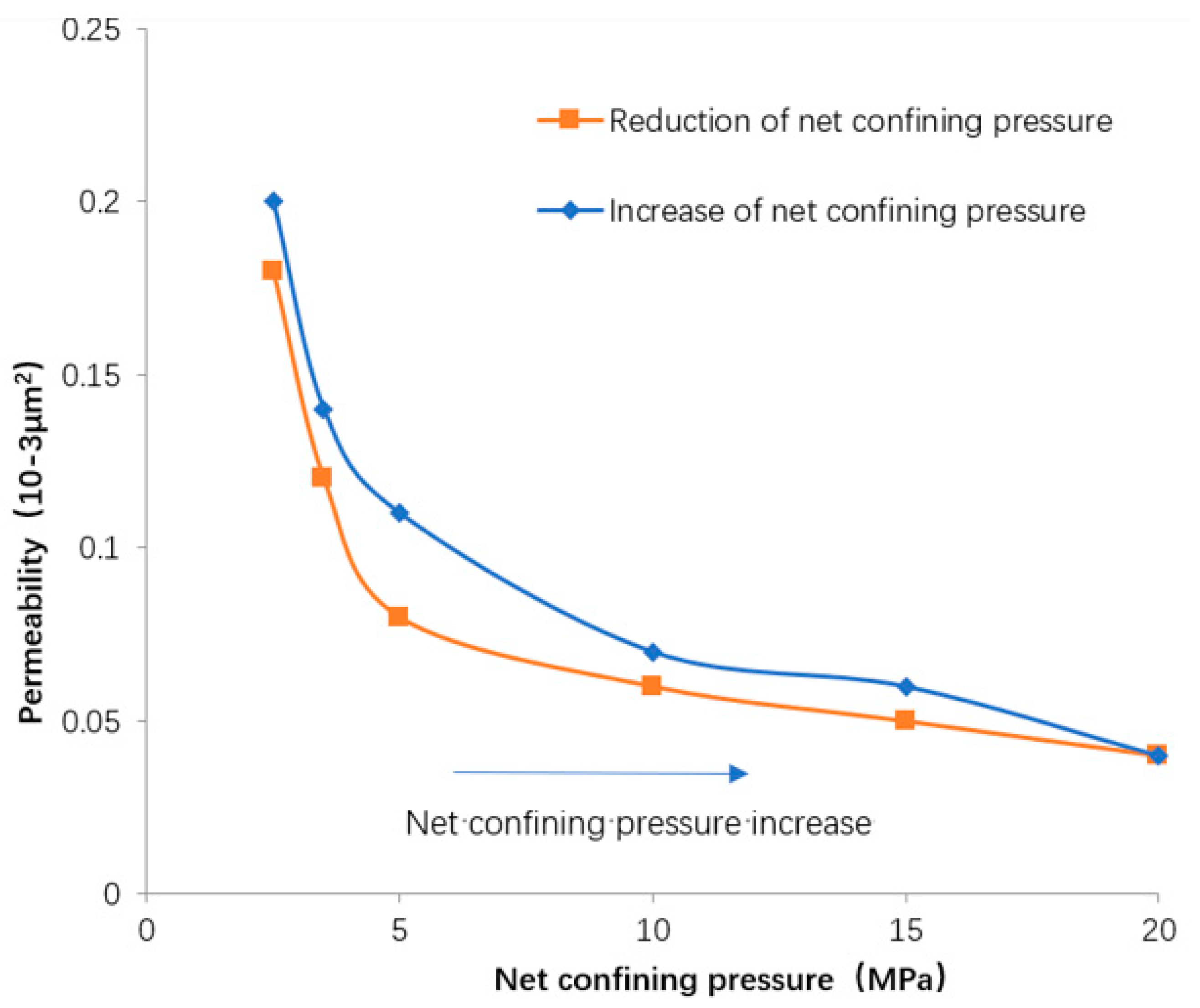

Stress sensitivity test: The flow rate is set as the critical flow rate, the initial net stress is set as 0 Mpa, and the net stress increases gradually according to 2.5 MPa, 3.5 MPa, 5.0 MPa, 10 MPa, 15 MPa and 20 MPa. According to the actual situation of the reservoir, the net stress interval is at least 5, and it increases to the maximum net stress continuously, and the displacement time of each pressure point is maintained for 0.5 h, and then it slowly decreases to the initial net stress. The displacement time of each pressure point is 1h, and the displacement pressure and environmental temperature during the change of net stress are recorded, and the permeability of samples under different stresses is calculated to determine the maximum permeability damage rate and irreversible permeability damage rate.