A Hybrid Evolutionary Algorithm for Multi-Stage Workshop Sequencing in Car Production

Abstract

:1. Introduction

2. Related Works

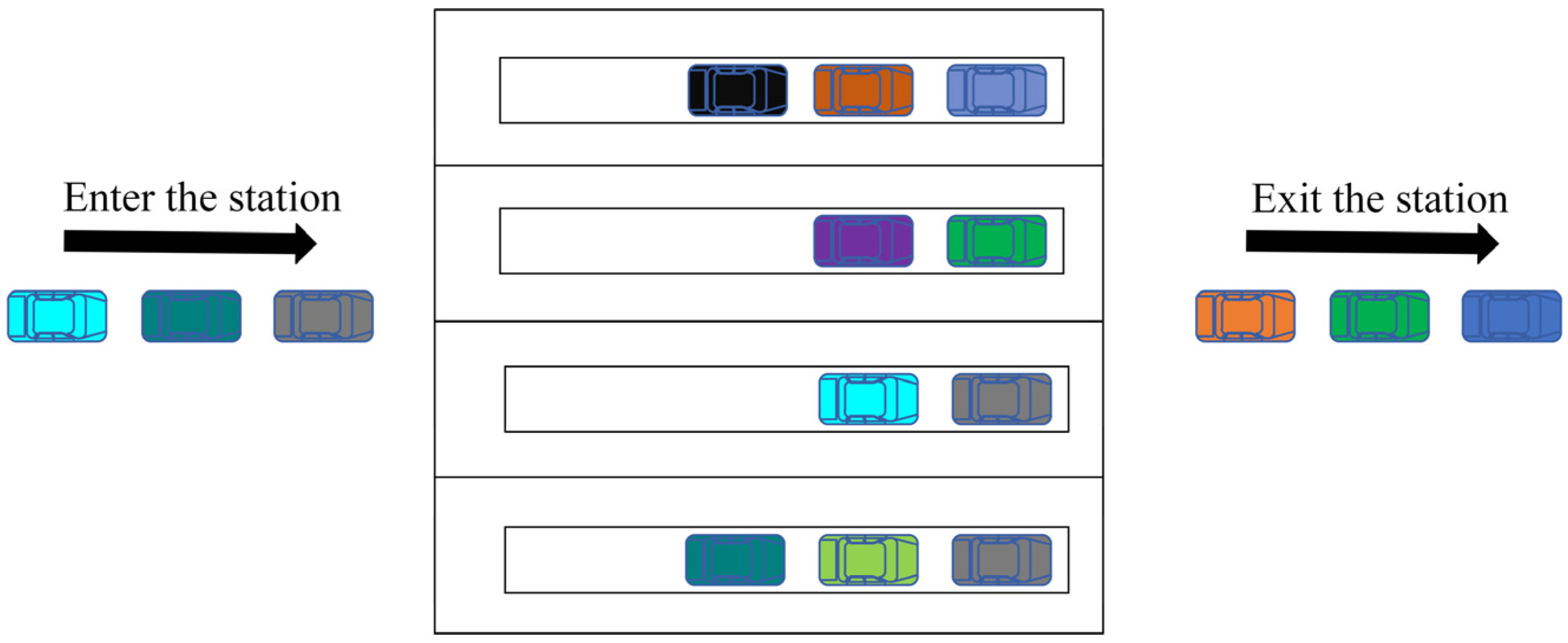

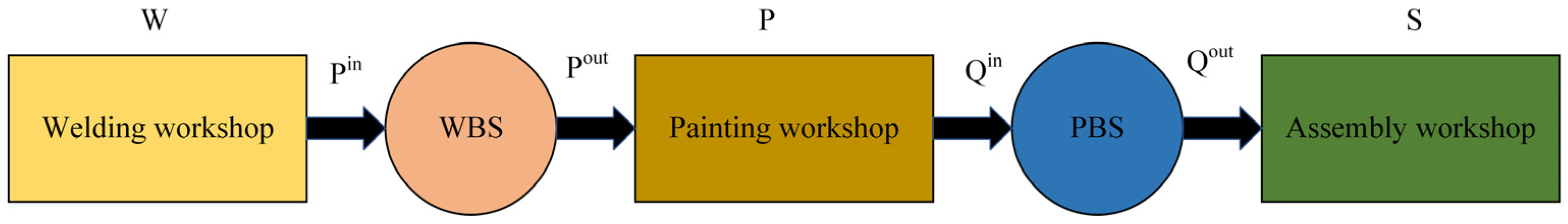

3. Problem Description and Assumptions

- (1)

- Within a single lane of a selectivity bank, the positioning of neighboring vehicles cannot be interchanged, and all vehicles in the same lane adhere to a first-in-first-out principle;

- (2)

- This paper investigates the sequencing problem of production tasks within a short timeframe (such as a single day production cycle) and does not take into account delivery time. Here, it is assumed that all orders can be delivered punctually as planned;

- (3)

- All vehicles have the same priority;

- (4)

- All workshops follow the production sequence entered into the workshop while manufacturing vehicles, without any occurrences of queue jumping.

4. The Proposed Hybrid Evolutionary Algorithm

4.1. W. Optimization Method Based on Genetic Algorithm

| Algorithm 1. Pseudocode of the crossover operation |

| 01. . 02. . 03. Randomly generate an integer D between [1, n]. 04. into two parts, mark the first D components of , find the fragments of the remaining n-D components of and keep the order unchanged, mark them as . Similarly, divide into two parts, mark the first D components of , find the fragments of the remaining n-D components of and keep the order unchanged, mark them as . 05. . 06. . |

| Algorithm 2. Pseudocode of the mutation operation |

| 01. . 02. . 03. between [1, n]. 04. . 05. 06. -th component. 07. else 08. -th component. 09. end |

4.2. Optimization Method of and Based on Differential Evolution

4.3. Optimization Method for and Based on Heuristic Rules

- (1)

- If there is no outbound vehicle, select the lane with the largest number of vehicles in all lanes for vehicle exit. If there are multiple lanes with the same maximum number of vehicles, randomly select one lane among these lanes for vehicle exit;

- (2)

- If there are outbound vehicles, select the vehicle with the same color as the previous vehicle to exit. If the current vehicle in more than one lane has the same color as the previous vehicle, select the lane with the largest number of vehicles in these lanes to exit the vehicle. If the current vehicle in multiple lanes has the same color as the previous vehicle, and there are multiple lanes with the same maximum number of vehicles in these lanes, the lane exit vehicle is randomly selected from the lanes with the maximum number of vehicles;

- (3)

- If there are outbound vehicles, but no vehicle with the same color as the previous vehicle can be found, select the outbound vehicle with the largest number of vehicles in all lanes. If there are multiple lanes with the same maximum number of vehicles, randomly select one lane from these lanes to exit the vehicle.

- (1)

- If there is no outbound vehicle, select the lane with the highest number of vehicles from all lanes for vehicle exit. If there are multiple lanes with the same maximum number of vehicles, randomly select one lane from these lanes for vehicle exit;

- (2)

- If there are already exiting outbound vehicles, please select the vehicle with the largest difference in optional accessories from the previous vehicle for exiting. If there are multiple lanes in which the current vehicle has the greatest difference from the optional accessories of the previous vehicle, select the lane with the maximum number of vehicles in these lanes to exit vehicle. If there are multiple lanes in which the current vehicle has the greatest difference from the optional accessories of the previous vehicle, and there are multiple lanes with the maximum number of vehicles, then randomly select one lane from these lanes with the maximum number of vehicles to exit vehicle.

4.4. Overall Implementation of the Proposed Hybrid Evolutionary Algorithm

| Algorithm 3. Population initialization method based on heuristic rules |

| 01. . 02. . 03. Sort according to the model of each vehicle, and then sort according to the color of the vehicles within the same model to obtain a production sequence for the welding workshop . 04. Sort the vehicles based on their color, and then sort them by vehicle model within vehicles of the same color to obtain a production sequence for the welding workshop . 05. for 06. 07. to the first n components of the i-th individual in the population. 08. If two consecutive vehicles in are of the same color, find the corresponding vehicles in the components of the i-th individual, and assign the same value (the same lane) to these vehicles. 09. of the i-th individual of the population (select a lane at random in PBS). 10. end 11. 12. to the first n components of the i-th individual of the population. 13. of the i-th individual of the population (randomly select a lane in WBS). 14. of the i-th individual of the population (select a lane at random in PBS). 15. end 16. 17. ). 18. of the i-th individual of the population (randomly select a lane in WBS). 19. of the i-th individual of the population (select a lane at random in PBS). 20. end 21. end |

| Algorithm 4. Pseudocode of HDEGA |

| 01. Set the population size to ; initialize population using Algorithm 3; calculate the fitness value for each individual and the degree of constraint violation for each individual, where represents the number of vehicle model changes, represents the number of color changes, and represents the total number of overloads. 02. Set the maximum number of function evaluations to , set the current number of function evaluation , set the offspring population , and set . 03. 04. . 05. 06. Based on the values of , and (first , then , and finally ), use the tournament selection to select two individuals. 07. Use Algorithm 1 to perform a crossover operation on the first n components of the selected two individuals, and then use Algorithm 2 to perform a mutation operation. Assign two new individuals to the first n components of the t-th individual and the of the offspring respectively. 08. . 09. end 10. 11. Randomly select a value from [0.6, 0.8, 1.0] to assign to F, and randomly select a value from [0.1, 0.2, 1.0] to assign to CR. 12. 13. Using Formula (7) to perform mutation operation on the components between n + 1 and 3n of the current individual to obtain a mutation vector. 14. else 15. Using Formula (8) to perform mutation operation on the components between n + 1 and 3n of the current individual to obtain a mutation vector. 16. end 17. Using Formula (9) to perform crossover operation on the components between n + 1 and 3n of the mutation vector to obtain a trial vector. 18. Use Formula (10) to select a survivor and assign it to the in the offspring population. 19. end 20. . 21. Merge the offspring population and the parent population , and sort the merged population based on constraint domination principle and crowding distance. Select the first n individuals to form a new generation population . 22. . 23. end |

5. Experiment

5.1. Experimental Data

5.2. Parameter Setting and Performance Evaluation Indicators

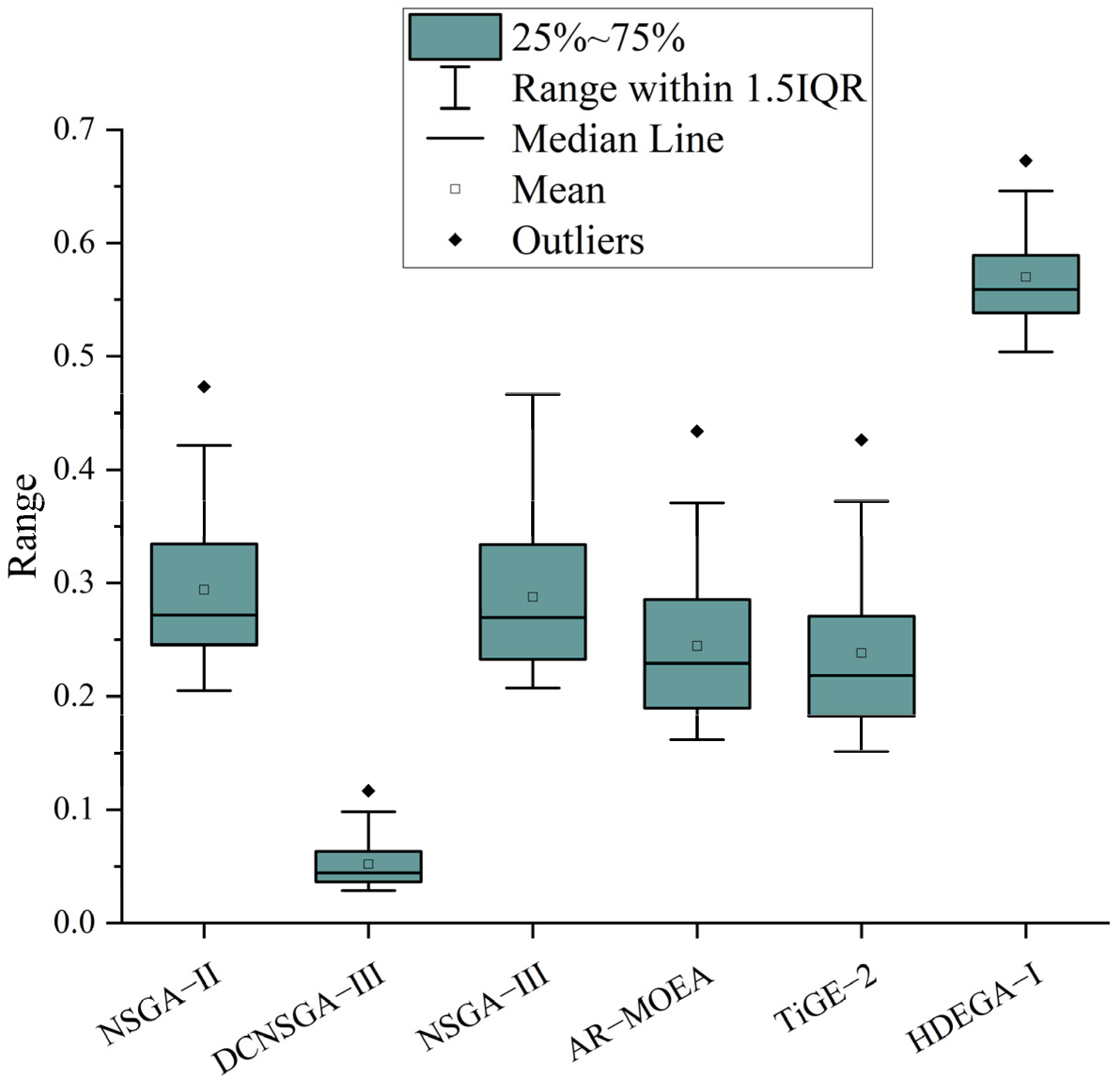

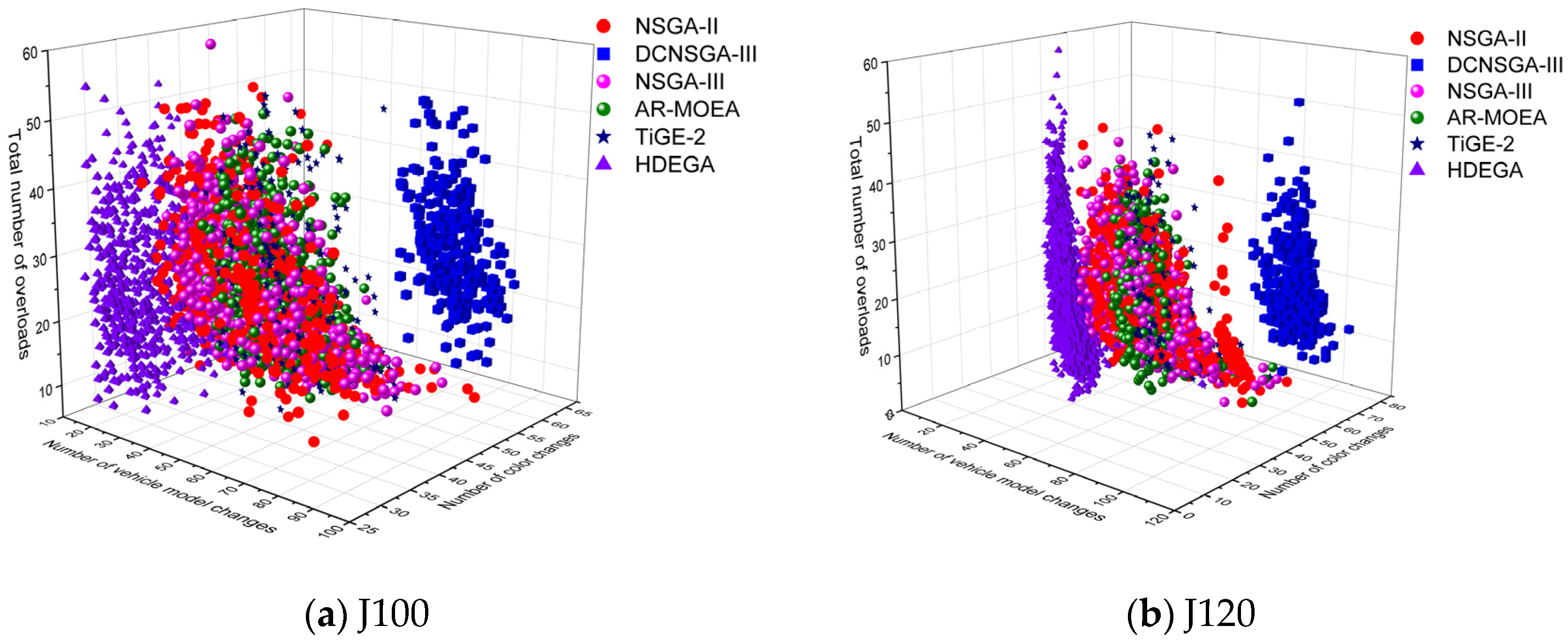

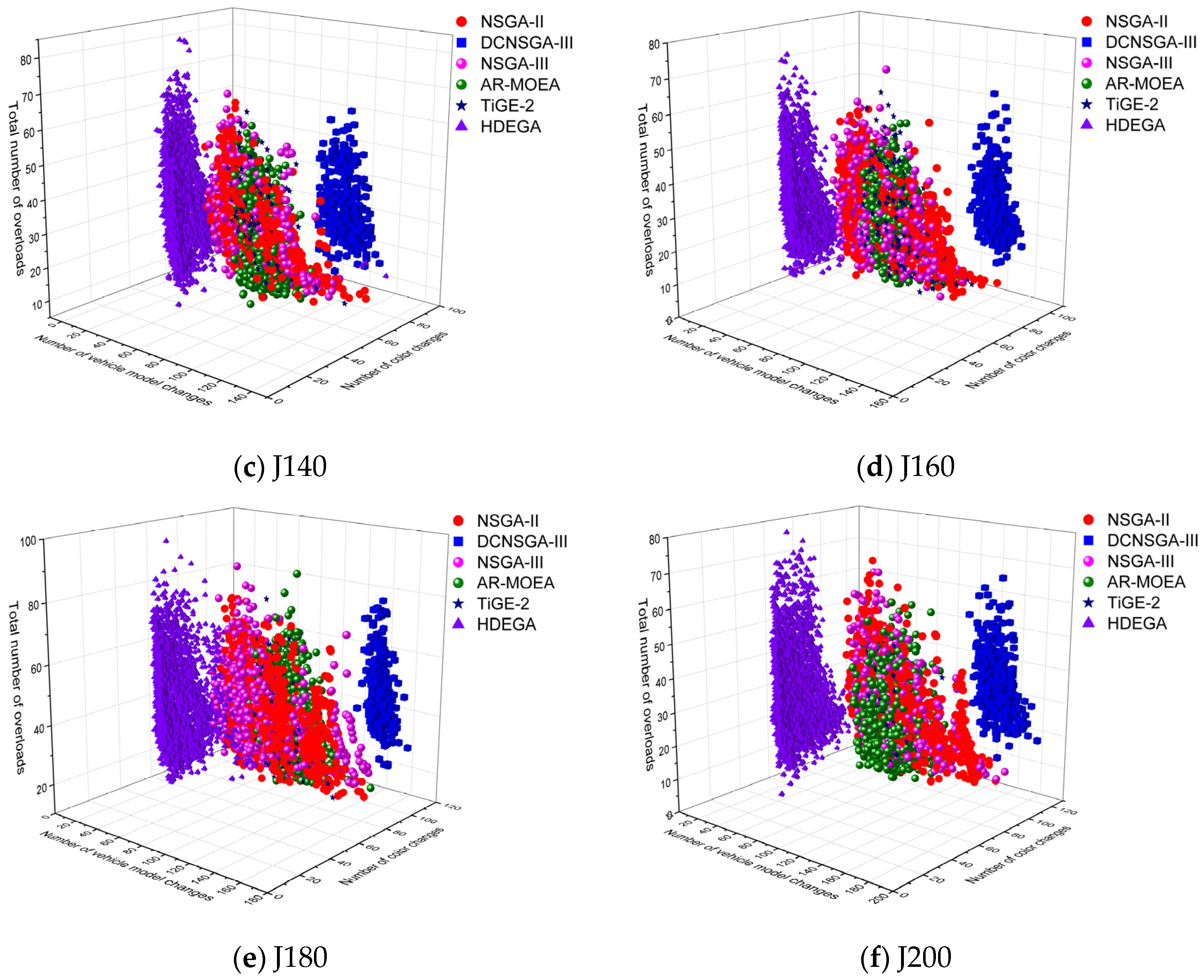

5.3. Analysis of Comparison Results

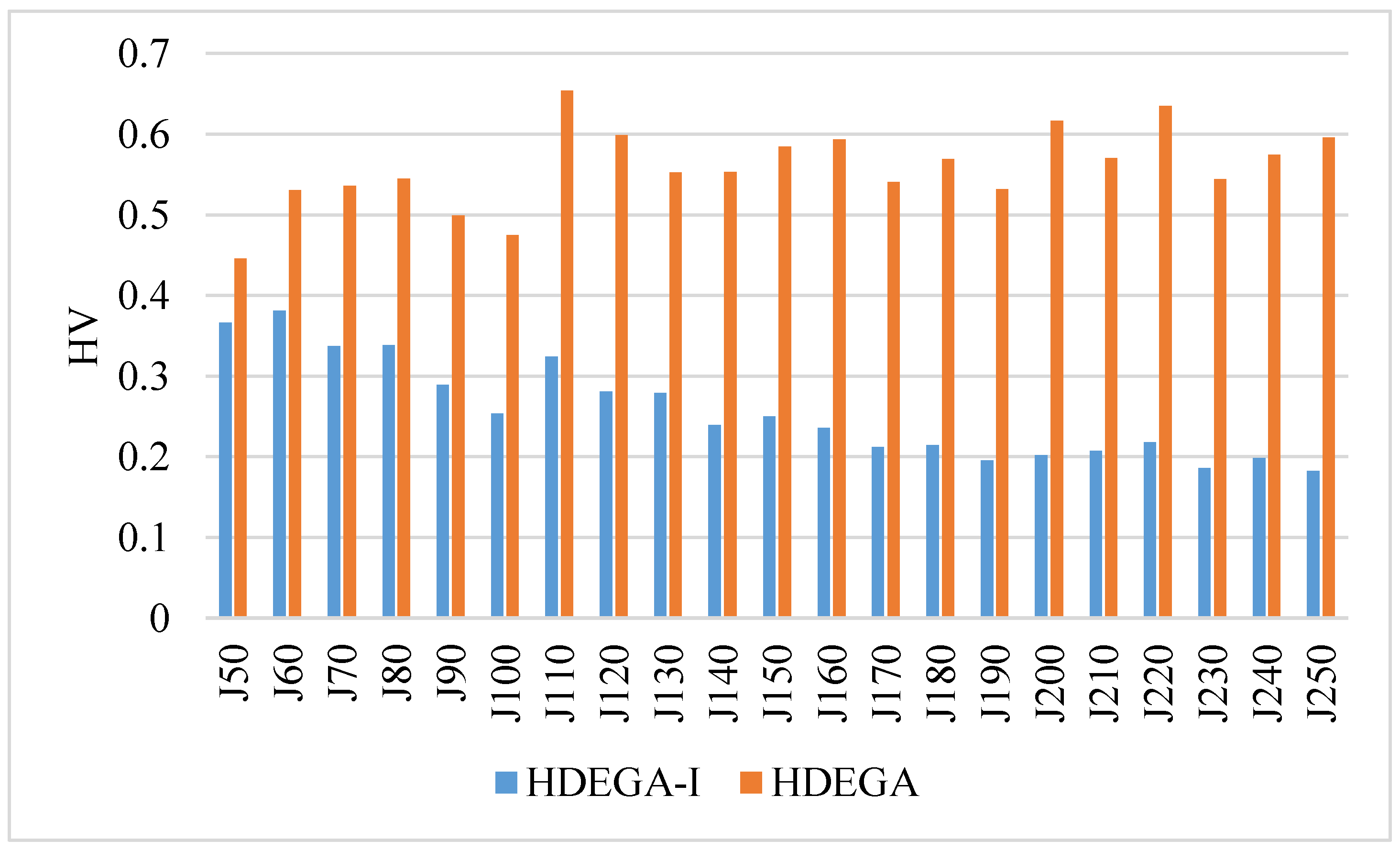

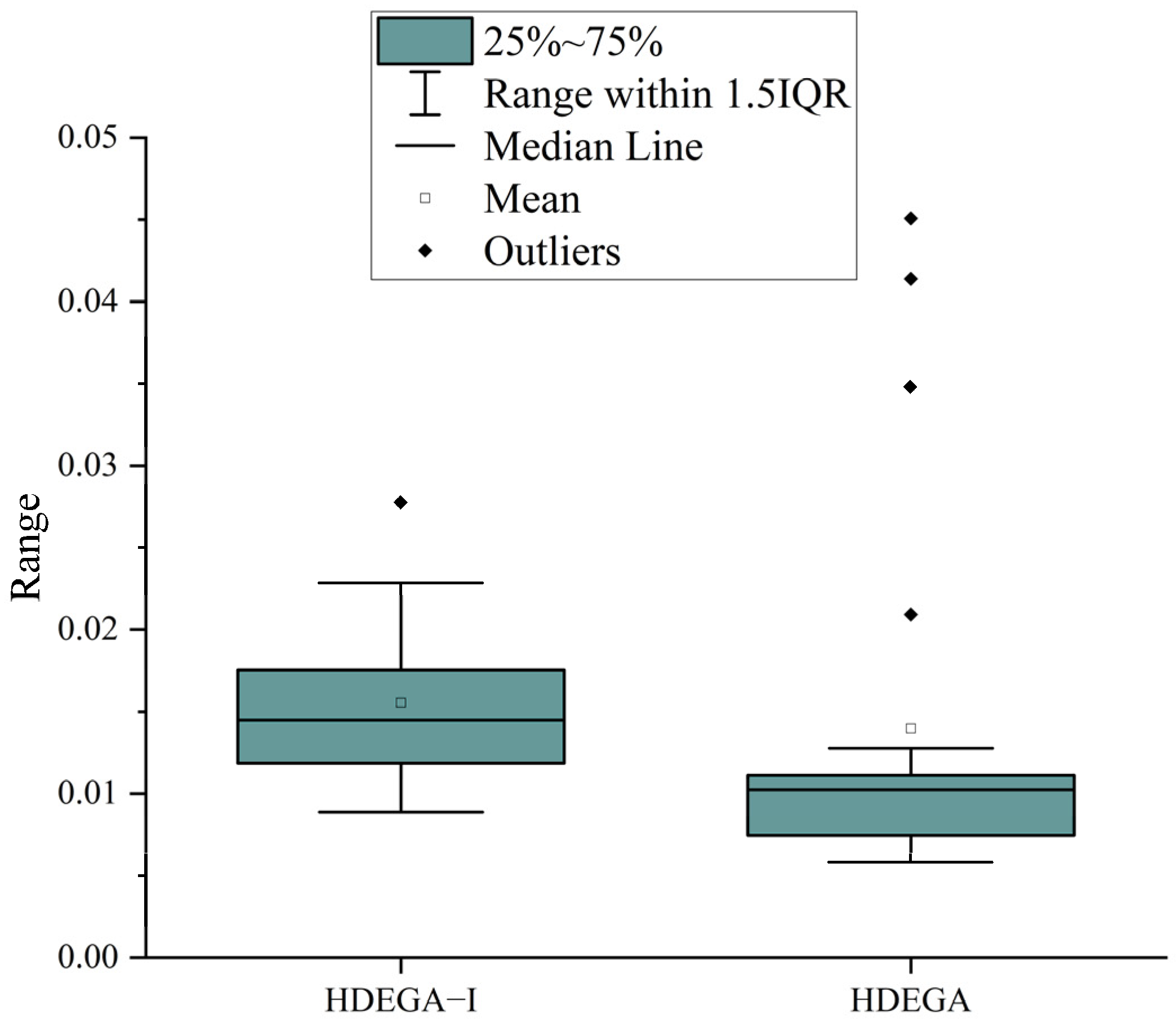

5.4. Ablation Experiment

5.5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, M.; Li, C.; Tang, Y.; Wu, W.; Zhang, X. A Collaborative Resequencing Approach Enabled by Multi-Core Prea for a Multi-Stage Automotive Flow Shop. Expert Syst. Appl. 2023, 237, 121825. [Google Scholar] [CrossRef]

- Ribeiro, C.C.; Aloise, D.; Noronha, T.F.; Rocha, C.; Urrutia, S. A hybrid heuristic for a multi-objective real-life car sequencing problem with painting and assembly line constraints. Eur. J. Oper. Res. 2008, 191, 981–992. [Google Scholar] [CrossRef]

- Kampker, A.; Kreisköther, K.; Schumacher, M. Mathematical model for proactive resequencing of mixed model assembly lines. Procedia Manuf. 2019, 33, 438–445. [Google Scholar] [CrossRef]

- Manzini, M.; Demeulemeester, E.; Urgo, M. A predictive–reactive approach for the sequencing of assembly operations in an automated assembly line. Robot. Comput.-Integr. Manuf. 2022, 73, 102201. [Google Scholar] [CrossRef]

- Müllerklein, D.; Fontaine, P.; Ostermeier, F. Integrated consideration of assembly line scheduling and feeding: A new model and case study from the automotive industry. Comput. Ind. Eng. 2022, 170, 108288. [Google Scholar] [CrossRef]

- Denizhan, B.; Özçelik, S.; Havuç, T. Minimizing deviations of car sequencing in a JIT production painting line. Assem. Autom. 2021, 41, 589–600. [Google Scholar] [CrossRef]

- Leng, J.; Jin, C.; Vogl, A.; Liu, H. Deep reinforcement learning for a color-batching resequencing problem. J. Manuf. Syst. 2020, 56, 175–187. [Google Scholar] [CrossRef]

- Winter, F.; Musliu, N. A large neighborhood search approach for the paint shop scheduling problem. J. Sched. 2022, 25, 453–475. [Google Scholar] [CrossRef]

- Sadeghi Tabar, R.; Wärmefjord, K.; Söderberg, R.; Lindkvist, L. A novel rule-based method for individualized spot welding sequence optimization with respect to geometrical quality. J. Manuf. Sci. Eng. 2019, 141, 111013. [Google Scholar] [CrossRef]

- Tabar, R.S.; Wärmefjord, K.; Söderberg, R. A method for identification and sequence optimisation of geometry spot welds in a digital twin context. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 5610–5621. [Google Scholar] [CrossRef]

- Zhipeng, T.; Xinyu, S.; Haiping, Z.; Hui, Y.; Fei, H. Small-world optimization algorithm and its application in a sequencing problem of painted body storage in a car company. Math. Probl. Eng. 2015, 2015, 932502. [Google Scholar] [CrossRef]

- Yilmazlar, I.O.; Kurz, M.E. Adaptive local search algorithm for solving car sequencing problem. J. Manuf. Syst. 2023, 68, 635–643. [Google Scholar] [CrossRef]

- Thiruvady, D.; Morgan, K.; Amir, A.; Ernst, A.T. Large neighbourhood search based on mixed integer programming and ant colony optimisation for car sequencing. Int. J. Prod. Res. 2020, 58, 2696–2711. [Google Scholar] [CrossRef]

- Hottenrott, A.; Waidner, L.; Grunow, M. Robust car sequencing for automotive assembly. Eur. J. Oper. Res. 2021, 291, 983–994. [Google Scholar] [CrossRef]

- Sun, H. Solving a virtual resequencing problem in automotive paint shops with ant colony optimization. In Proceedings of the 2021 IEEE 8th International Conference on Industrial Engineering and Applications (ICIEA), Kyoto, Japan, 23–26 April 2021; IEEE: Piscataway, NJ, USA; pp. 301–306. [Google Scholar]

- Cao, C.; Sun, H. Virtual level rescheduling for automotive mixed-model assembly lines with beam search algorithms. In Proceedings of the 2019 IEEE 6th International Conference on Industrial Engineering and Applications (ICIEA), Tokyo, Japan, 12–15 April 2019; IEEE: Piscataway, NJ, USA; pp. 225–229. [Google Scholar]

- Lübben, M.; Pries, S.; Sikora, C.G.S. Online resequencing of buffers for automotive assembly lines. Comput. Ind. Eng. 2023, 175, 108857. [Google Scholar] [CrossRef]

- Xu, Y.; Zhou, J.G. A virtual resequencing problem in automobile paint shops. In Proceedings of the 22nd International Conference on Industrial Engineering and Engineering Management 2015: Core Theory and Applications of Industrial Engineering; Atlantis Press: Amsterdam, The Netherlands, 2016; Volume 1, pp. 71–80. [Google Scholar]

- Sun, H.; Han, J. A study on implementing color-batching with selectivity banks in automotive paint shops. J. Manuf. Syst. 2017, 44, 42–52. [Google Scholar] [CrossRef]

- Fournier, X.; Agard, B. Improvement of earliness and lateness by postponement on an automotive production line. Int. J. Flex. Manuf. Syst. 2007, 19, 107–121. [Google Scholar] [CrossRef]

- Wu, J.; Ding, Y.; Shi, L. Mathematical modeling and heuristic approaches for a multi-stage car sequencing problem. Comput. Ind. Eng. 2021, 152, 107008. [Google Scholar] [CrossRef]

- Joly, A.; Frein, Y. Heuristics for an industrial car sequencing problem considering paint and assembly shop objectives. Comput. Ind. Eng. 2008, 55, 295–310. [Google Scholar] [CrossRef]

- Deb, K.; Jain, H. An evolutionary many-objective optimization algorithm using reference-point-based nondominated sorting approach, part I: Solving problems with box constraints. IEEE Trans. Evol. Comput. 2013, 18, 577–601. [Google Scholar] [CrossRef]

- Tian, Y.; Cheng, R.; Zhang, X.; Cheng, F.; Jin, Y. An indicator-based multiobjective evolutionary algorithm with reference point adaptation for better versatility. IEEE Trans. Evol. Comput. 2018, 22, 609–622. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, M.; Wang, J.; Zhang, Z.; Xiang, Y.; Zhang, J. Tri-goal evolution framework for constrained many-objective optimization. IEEE Trans. Syst. Man Cybern. Syst. 2020, 50, 3086–3099. [Google Scholar] [CrossRef]

- Jiao, R.; Zeng, S.; Li, C.; Yang, S.; Ong, Y.S. Handling constrained many-objective optimization problems via problem transformation. IEEE Trans. Cybern. 2020, 51, 4834–4847. [Google Scholar] [CrossRef] [PubMed]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T.A.M.T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Tian, Y.; Cheng, R.; Zhang, X.; Jin, Y. PlatEMO: A MATLAB platform for evolutionary multi-objective optimization [educational forum]. IEEE Comput. Intell. Mag. 2017, 12, 73–87. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Number of WBS lanes and capacity of each lane | The number of lanes is 6, and each lane has a capacity of 10 |

| Number of PBS lanes and capacity of each lane | The number of lanes is 6, and each lane has a capacity of 10 |

| Number of vehicle types in the welding workshop | 10 |

| Number of vehicle colors | 10 |

| Number of optional accessories | 5 |

| Optional Accessory | k/h Value |

|---|---|

| 1 | 4/3 |

| 2 | 5/3 |

| 3 | 5/4 |

| 4 | 6/4 |

| 5 | 6/5 |

| Problem | NSGA-II | DCNSGA-III | NSGA-III | AR-MOEA | TiGE-2 | HDEGA |

|---|---|---|---|---|---|---|

| J50 | 4.73 × 10−1 | 1.17 × 10−1 | 4.66 × 10−1 | 4.34 × 10−1 | 4.26 × 10−1 | 5.38 × 10−1 |

| 2.04 × 10−2 (+) | 2.03 × 10−2 (+) | 2.75 × 10−2 (+) | 2.88 × 10−2 (+) | 3.16 × 10−2 (+) | 6.73 × 10−3 | |

| J60 | 4.25 × 10−1 | 1.04 × 10−1 | 4.10 × 10−1 | 3.74 × 10−1 | 3.77 × 10−1 | 5.55 × 10−1 |

| 2.49 × 10−2 (+) | 1.92 × 10−2 (+) | 2.56 × 10−2 (+) | 2.77 × 10−2 (+) | 2.47 × 10−2 (+) | 6.47 × 10−3 | |

| J70 | 3.71 × 10−1 | 6.32 × 10−2 | 3.56 × 10−1 | 2.85 × 10−1 | 3.22 × 10−1 | 5.56 × 10−1 |

| 3.23 × 10−2 (+) | 1.20 × 10−2 (+) | 2.94 × 10−2 (+) | 3.68 × 10−2 (+) | 2.77 × 10−2 (+) | 8.31 × 10−3 | |

| J80 | 3.65 × 10−1 | 6.57 × 10−2 | 3.50 × 10−1 | 3.07 × 10−1 | 3.09 × 10−1 | 5.59 × 10−1 |

| 1.79 × 10−2 (+) | 1.23 × 10−2 (+) | 2.88 × 10−2 (+) | 3.25 × 10−2 (+) | 2.26 × 10−2 (+) | 1.14 × 10−2 | |

| J90 | 3.16 × 10−1 | 6.81 × 10−2 | 3.03 × 10−1 | 2.82 × 10−1 | 2.63 × 10−1 | 4.99 × 10−1 |

| 2.49 × 10−2 (+) | 1.39 × 10−2 (+) | 2.40 × 10−2 (+) | 3.20 × 10−2 (+) | 2.65 × 10−2 (+) | 6.28 × 10−3 | |

| J100 | 3.16 × 10−1 | 5.58 × 10−2 | 3.04 × 10−1 | 2.49 × 10−1 | 2.44 × 10−1 | 5.23 × 10−1 |

| 2.34 × 10−2 (+) | 7.21 × 10−3 (+) | 2.72 × 10−2 (+) | 2.45 × 10−2 (+) | 2.22 × 10−2 (+) | 1.65 × 10−2 | |

| J110 | 3.64 × 10−1 | 6.31 × 10−2 | 3.46 × 10−1 | 3.20 × 10−1 | 2.92 × 10−1 | 6.69 × 10−1 |

| 2.04 × 10−2 (+) | 1.05 × 10−2 (+) | 2.58 × 10−2 (+) | 2.99 × 10−2 (+) | 2.23 × 10−2 (+) | 6.87 × 10−3 | |

| J120 | 3.39 × 10−1 | 5.91 × 10−2 | 3.38 × 10−1 | 2.96 × 10−1 | 2.75 × 10−1 | 6.37 × 10−1 |

| 2.11 × 10−2 (+) | 1.28 × 10−2 (+) | 2.43 × 10−2 (+) | 2.07 × 10−2 (+) | 2.17 × 10−2 (+) | 6.45 × 10−3 | |

| J130 | 2.99 × 10−1 | 4.76 × 10−2 | 3.01 × 10−1 | 2.42 × 10−1 | 2.46 × 10−1 | 5.61 × 10−1 |

| 2.08 × 10−2 (+) | 6.43 × 10−3 (+) | 2.35 × 10−2 (+) | 2.14 × 10−2 (+) | 1.67 × 10−2 (+) | 9.24 × 10−3 | |

| J140 | 2.87 × 10−1 | 5.83 × 10−2 | 2.81 × 10−1 | 2.44 × 10−1 | 2.33 × 10−1 | 5.59 × 10−1 |

| 2.04 × 10−2 (+) | 1.25 × 10−2 (+) | 1.86 × 10−2 (+) | 2.29 × 10−2 (+) | 1.78 × 10−2 (+) | 4.03 × 10−2 | |

| J150 | 2.58 × 10−1 | 3.94 × 10−2 | 2.56 × 10−1 | 2.17 × 10−1 | 2.13 × 10−1 | 5.81 × 10−1 |

| 2.31 × 10−2 (+) | 6.68 × 10−3 (+) | 1.45 × 10−2 (+) | 2.51 × 10−2 (+) | 1.77 × 10−2 (+) | 7.85 × 10−3 | |

| J160 | 2.81 × 10−1 | 4.43 × 10−2 | 2.78 × 10−1 | 2.23 × 10−1 | 2.20 × 10−1 | 6.12 × 10−1 |

| 1.74 × 10−2 (+) | 6.45 × 10−3 (+) | 2.69 × 10−2 (+) | 2.15 × 10−2 (+) | 1.81 × 10−2 (+) | 7.61 × 10−3 | |

| J170 | 2.45 × 10−1 | 3.12 × 10−2 | 2.32 × 10−1 | 1.62 × 10−1 | 1.85 × 10−1 | 5.56 × 10−1 |

| 1.30 × 10−2 (+) | 2.63 × 10−3 (+) | 1.82 × 10−2 (+) | 1.49 × 10−2 (+) | 1.66 × 10−2 (+) | 1.09 × 10−2 | |

| J180 | 2.50 × 10−1 | 3.55 × 10−2 | 2.45 × 10−1 | 1.66 × 10−1 | 1.90 × 10−1 | 5.89 × 10−1 |

| 1.70 × 10−2 (+) | 3.19 × 10−3 (+) | 1.99 × 10−2 (+) | 2.35 × 10−2 (+) | 1.10 × 10−2 (+) | 3.29 × 10−2 | |

| J190 | 2.37 × 10−1 | 3.81 × 10−2 | 2.27 × 10−1 | 1.83 × 10−1 | 1.82 × 10−1 | 5.43 × 10−1 |

| 1.67 × 10−2 (+) | 7.76 × 10−3 (+) | 1.56 × 10−2 (+) | 2.44 × 10−2 (+) | 1.59 × 10−2 (+) | 2.02 × 10−2 | |

| J200 | 2.11 × 10−2 | 1.28 × 10−2 | 2.43 × 10−2 | 2.07 × 10−2 | 2.17 × 10−2 | 6.45 × 10−3 |

| 2.11 × 10−2 (+) | 1.28 × 10−2 (+) | 2.43 × 10−2 (+) | 2.07 × 10−2 (+) | 2.17 × 10−2 (+) | 6.45 × 10−3 | |

| J210 | 2.34 × 10−1 | 3.59 × 10−2 | 2.30 × 10−1 | 1.89 × 10−1 | 1.72 × 10−1 | 5.76 × 10−1 |

| 1.92 × 10−2 (+) | 5.11 × 10−3 (+) | 1.74 × 10−2 (+) | 2.96 × 10−2 (+) | 1.32 × 10−2 (+) | 1.12 × 10−2 | |

| J220 | 2.37 × 10−1 | 4.19 × 10−2 | 2.37 × 10−1 | 1.97 × 10−1 | 1.77 × 10−1 | 6.35 × 10−1 |

| 1.29 × 10−2 (+) | 9.97 × 10−3 (+) | 2.07 × 10−2 (+) | 2.76 × 10−2 (+) | 1.88 × 10−2 (+) | 1.03 × 10−2 | |

| J230 | 2.14 × 10−1 | 3.35 × 10−2 | 2.19 × 10−1 | 1.84 × 10−1 | 1.67 × 10−1 | 5.55 × 10−1 |

| 1.39 × 10−2 (+) | 6.42 × 10−3 (+) | 1.19 × 10−2 (+) | 2.18 × 10−2 (+) | 1.52 × 10−2 (+) | 1.00 × 10−2 | |

| J240 | 2.24 × 10−1 | 4.07 × 10−2 | 2.24 × 10−1 | 1.97 × 10−1 | 1.69 × 10−1 | 5.83 × 10−1 |

| 1.46 × 10−2 (+) | 1.04 × 10−2 (+) | 1.79 × 10−2 (+) | 2.35 × 10−2 (+) | 1.57 × 10−2 (+) | 4.77 × 10−2 | |

| J250 | 2.10 × 10−1 | 3.01 × 10−2 | 2.12 × 10−1 | 1.73 × 10−1 | 1.55 × 10−1 | 6.03 × 10−1 |

| 1.68 × 10−2 (+) | 6.06 × 10−3 (+) | 1.50 × 10−2 (+) | 2.19 × 10−2 (+) | 1.40 × 10−2 (+) | 1.07 × 10−2 |

| Problem | NSGA-II | DCNSGA-III | NSGA-III | AR-MOEA | TiGE-2 | HDEGA-I |

|---|---|---|---|---|---|---|

| J50 | 4.73 × 10−1 | 1.17 × 10−1 | 4.66 × 10−1 | 4.34 × 10−1 | 4.26 × 10−1 | 5.38 × 10−1 |

| 2.04 × 10−2 (+) | 2.03 × 10−2 (+) | 2.75 × 10−2 (+) | 2.88 × 10−2 (+) | 3.16 × 10−2 (+) | 6.73 × 10−3 | |

| J60 | 4.21 × 10−1 | 9.82 × 10−2 | 4.07 × 10−1 | 3.71 × 10−1 | 3.72 × 10−1 | 5.47 × 10−1 |

| 2.51 × 10−2 (+) | 1.82 × 10−2 (+) | 2.55 × 10−2 (+) | 2.80 × 10−2 (+) | 2.50 × 10−2 (+) | 6.98 × 10−3 | |

| J70 | 3.71 × 10−1 | 6.32 × 10−2 | 3.56 × 10−1 | 2.85 × 10−1 | 3.22 × 10−1 | 5.56 × 10−1 |

| 3.23 × 10−2 (+) | 1.20 × 10−2 (+) | 2.94 × 10−2 (+) | 3.68 × 10−2 (+) | 2.77 × 10−2 (+) | 8.31 × 10−3 | |

| J80 | 3.65 × 10−1 | 6.57 × 10−2 | 3.50 × 10−1 | 3.07 × 10−1 | 3.09 × 10−1 | 5.59 × 10−1 |

| 1.79 × 10−2 (+) | 1.23 × 10−2 (+) | 2.88 × 10−2 (+) | 3.25 × 10−2 (+) | 2.26 × 10−2 (+) | 1.14 × 10−2 | |

| J90 | 3.18 × 10−1 | 6.91 × 10−2 | 3.05 × 10−1 | 2.84 × 10−1 | 2.65 × 10−1 | 5.04 × 10−1 |

| 2.48 × 10−2 (+) | 1.41 × 10−2 (+) | 2.41 × 10−2 (+) | 3.20 × 10−2 (+) | 2.66 × 10−2 (+) | 6.12 × 10−3 | |

| J100 | 3.11 × 10−1 | 5.36 × 10−2 | 2.99 × 10−1 | 2.45 × 10−1 | 2.40 × 10−1 | 5.13 × 10−1 |

| 2.34 × 10−2 (+) | 7.04 × 10−3 (+) | 2.73 × 10−2 (+) | 2.44 × 10−2 (+) | 2.22 × 10−2 (+) | 1.65 × 10−2 | |

| J110 | 3.70 × 10−1 | 6.51 × 10−2 | 3.52 × 10−1 | 3.25 × 10−1 | 2.97 × 10−1 | 6.73 × 10−1 |

| 2.03 × 10−2 (+) | 1.07 × 10−2 (+) | 2.55 × 10−2 (+) | 2.99 × 10−2 (+) | 2.23 × 10−2 (+) | 6.86 × 10−3 | |

| J120 | 3.35 × 10−1 | 5.67 × 10−2 | 3.34 × 10−1 | 2.92 × 10−1 | 2.71 × 10−1 | 6.27 × 10−1 |

| 2.12 × 10−2 (+) | 1.25 × 10−2 (+) | 2.41 × 10−2 (+) | 2.08 × 10−2 (+) | 2.16 × 10−2 (+) | 7.23 × 10−3 | |

| J130 | 2.84 × 10−1 | 4.24 × 10−2 | 2.86 × 10−1 | 2.30 × 10−1 | 2.34 × 10−1 | 5.37 × 10−1 |

| 2.09 × 10−2 (+) | 6.11 × 10−3 (+) | 2.37 × 10−2 (+) | 2.13 × 10−2 (+) | 1.66 × 10−2 (+) | 1.04 × 10−2 | |

| J140 | 2.71 × 10−1 | 4.86 × 10−2 | 2.65 × 10−1 | 2.31 × 10−1 | 2.18 × 10−1 | 5.17 × 10−1 |

| 2.01 × 10−2 (+) | 1.14 × 10−2 (+) | 1.84 × 10−2 (+) | 2.33 × 10−2 (+) | 1.73 × 10−2 (+) | 3.90 × 10−2 | |

| J150 | 2.72 × 10−1 | 4.35 × 10−2 | 2.70 × 10−1 | 2.29 × 10−1 | 2.24 × 10−1 | 5.89 × 10−1 |

| 2.31 × 10−2 (+) | 7.22 × 10−3 (+) | 1.46 × 10−2 (+) | 2.52 × 10−2 (+) | 1.77 × 10−2 (+) | 7.92 × 10−3 | |

| J160 | 2.78 × 10−1 | 4.28 × 10−2 | 2.75 × 10−1 | 2.20 × 10−1 | 2.17 × 10−1 | 6.01 × 10−1 |

| 1.74 × 10−2 (+) | 6.37 × 10−3 (+) | 2.68 × 10−2 (+) | 2.15 × 10−2 (+) | 1.79 × 10−2 (+) | 8.12 × 10−3 | |

| J170 | 2.45 × 10−1 | 3.12 × 10−2 | 2.32 × 10−1 | 1.62 × 10−1 | 1.85 × 10−1 | 5.56 × 10−1 |

| 1.30 × 10−2 (+) | 2.63 × 10−3 (+) | 1.82 × 10−2 (+) | 1.49 × 10−2 (+) | 1.66 × 10−2 (+) | 1.09 × 10−2 | |

| J180 | 2.47 × 10−1 | 3.42 × 10−2 | 2.42 × 10−1 | 1.64 × 10−1 | 1.88 × 10−1 | 5.75 × 10−1 |

| 1.69 × 10−2 (+) | 3.22 × 10−3 (+) | 1.96 × 10−2 (+) | 2.34 × 10−2 (+) | 1.10 × 10−2 (+) | 3.17 × 10−2 | |

| J190 | 2.32 × 10−1 | 3.65 × 10−2 | 2.22 × 10−1 | 1.80 × 10−1 | 1.78 × 10−1 | 5.30 × 10−1 |

| 1.67 × 10−2 (+) | 7.57 × 10−3 (+) | 1.55 × 10−2 (+) | 2.43 × 10−2 (+) | 1.59 × 10−2 (+) | 1.99 × 10−2 | |

| J200 | 2.58 × 10−1 | 4.42 × 10−2 | 2.56 × 10−1 | 2.28 × 10−1 | 2.14 × 10−1 | 6.46 × 10−1 |

| 1.84 × 10−2 (+) | 8.86 × 10−3 (+) | 1.71 × 10−2 (+) | 3.47 × 10−2 (+) | 1.61 × 10−2 (+) | 1.18 × 10−2 | |

| J210 | 2.35 × 10−1 | 3.61 × 10−2 | 2.31 × 10−1 | 1.89 × 10−1 | 1.72 × 10−1 | 5.72 × 10−1 |

| 1.91 × 10−2 (+) | 5.14 × 10−3 (+) | 1.73 × 10−2 (+) | 2.98 × 10−2 (+) | 1.32 × 10−2 (+) | 1.14 × 10−2 | |

| J220 | 2.46 × 10−1 | 4.42 × 10−2 | 2.45 × 10−1 | 2.04 × 10−1 | 1.82 × 10−1 | 6.23 × 10−1 |

| 1.31 × 10−2 (+) | 1.06 × 10−2 (+) | 2.06 × 10−2 (+) | 2.82 × 10−2 (+) | 1.89 × 10−2 (+) | 1.13 × 10−2 | |

| J230 | 2.12 × 10−1 | 3.28 × 10−2 | 2.17 × 10−1 | 1.83 × 10−1 | 1.65 × 10−1 | 5.48 × 10−1 |

| 1.39 × 10−2 (+) | 6.34 × 10−3 (+) | 1.18 × 10−2 (+) | 2.18 × 10−2 (+) | 1.52 × 10−2 (+) | 1.03 × 10−2 | |

| J240 | 2.28 × 10−1 | 4.17 × 10−2 | 2.27 × 10−1 | 2.01 × 10−1 | 1.72 × 10−1 | 5.74 × 10−1 |

| 1.47 × 10−2 (+) | 1.05 × 10−2 (+) | 1.79 × 10−2 (+) | 2.36 × 10−2 (+) | 1.59 × 10−2 (+) | 4.66 × 10−2 | |

| J250 | 2.05 × 10−1 | 2.85 × 10−2 | 2.07 × 10−1 | 1.69 × 10−1 | 1.51 × 10−1 | 5.85 × 10−1 |

| 1.69 × 10−2 (+) | 5.80 × 10−3 (+) | 1.49 × 10−2 (+) | 2.19 × 10−2 (+) | 1.38 × 10−2 (+) | 1.16 × 10−2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Liu, J.; Liu, J. A Hybrid Evolutionary Algorithm for Multi-Stage Workshop Sequencing in Car Production. Processes 2023, 11, 2990. https://doi.org/10.3390/pr11102990

Chen C, Liu J, Liu J. A Hybrid Evolutionary Algorithm for Multi-Stage Workshop Sequencing in Car Production. Processes. 2023; 11(10):2990. https://doi.org/10.3390/pr11102990

Chicago/Turabian StyleChen, Cuimei, Jun Liu, and Jia Liu. 2023. "A Hybrid Evolutionary Algorithm for Multi-Stage Workshop Sequencing in Car Production" Processes 11, no. 10: 2990. https://doi.org/10.3390/pr11102990

APA StyleChen, C., Liu, J., & Liu, J. (2023). A Hybrid Evolutionary Algorithm for Multi-Stage Workshop Sequencing in Car Production. Processes, 11(10), 2990. https://doi.org/10.3390/pr11102990