Experimental Study of the Influences of Operating Parameters on the Performance, Energy and Exergy Characteristics of a Turbocharged Marine Low-Speed Engine

Abstract

1. Introduction

2. Methodology

2.1. Experimental Setup

2.2. Energy Analysis

2.3. Exergy Analysis

3. Results and Discussion

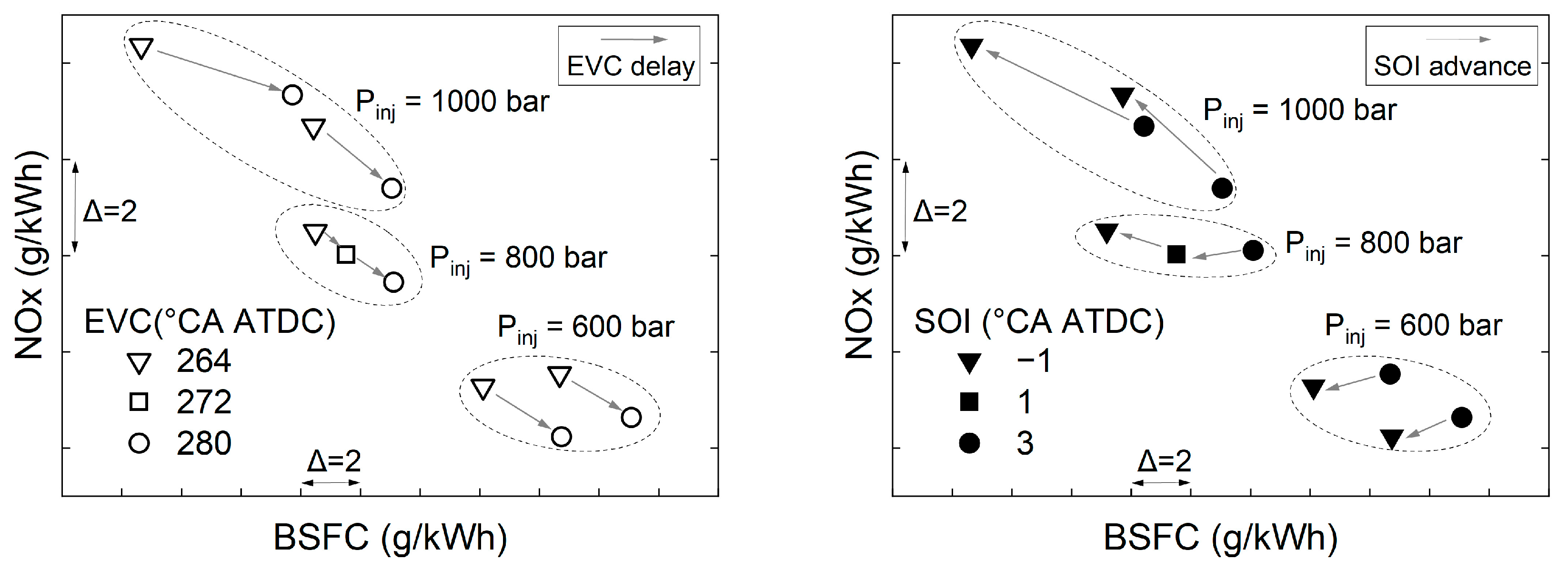

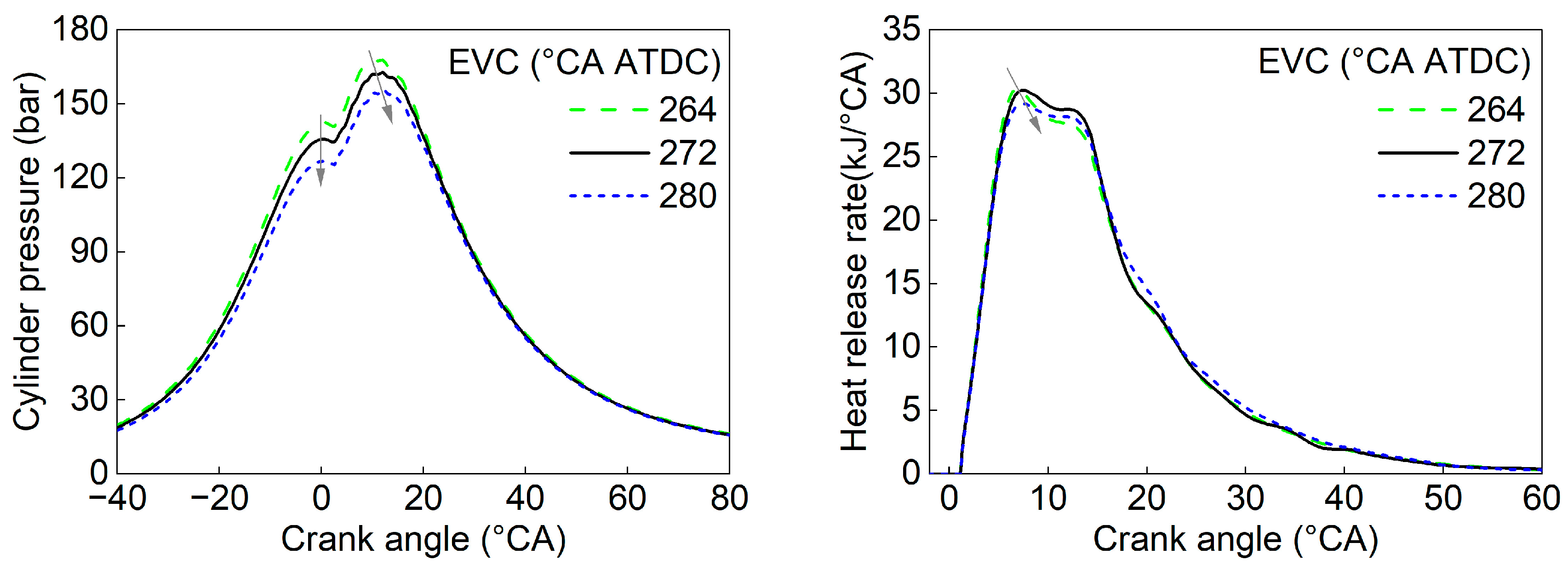

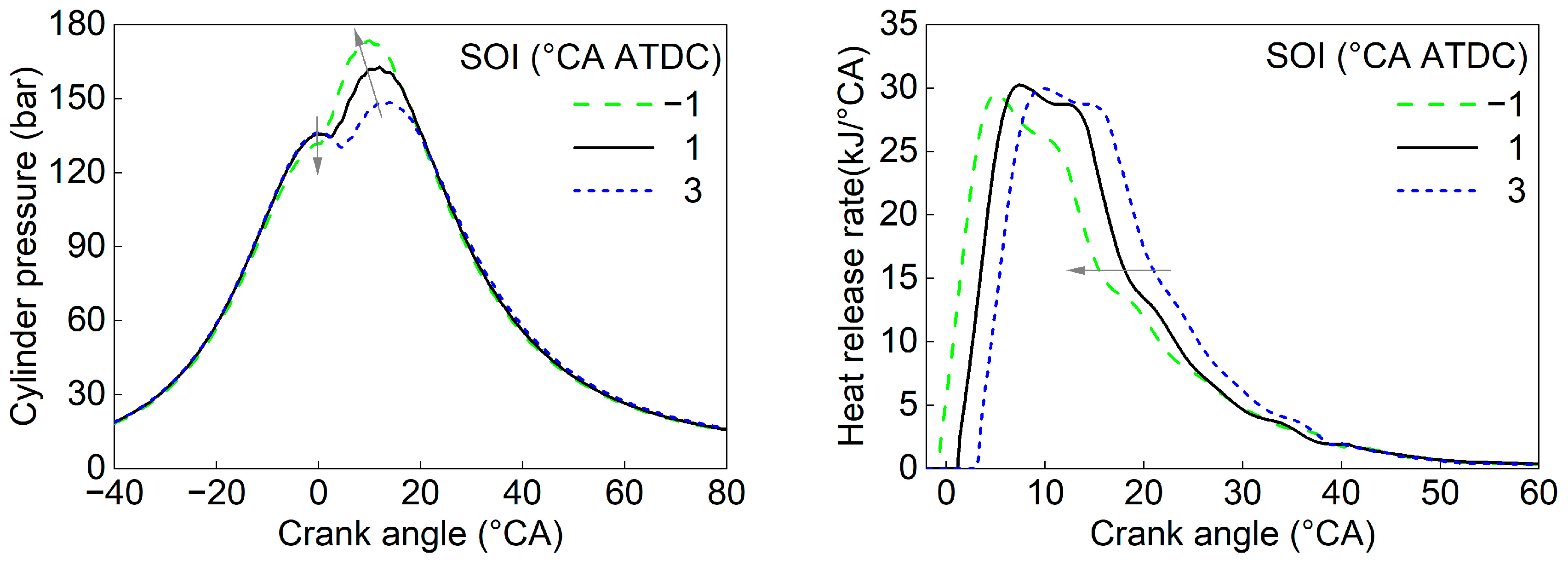

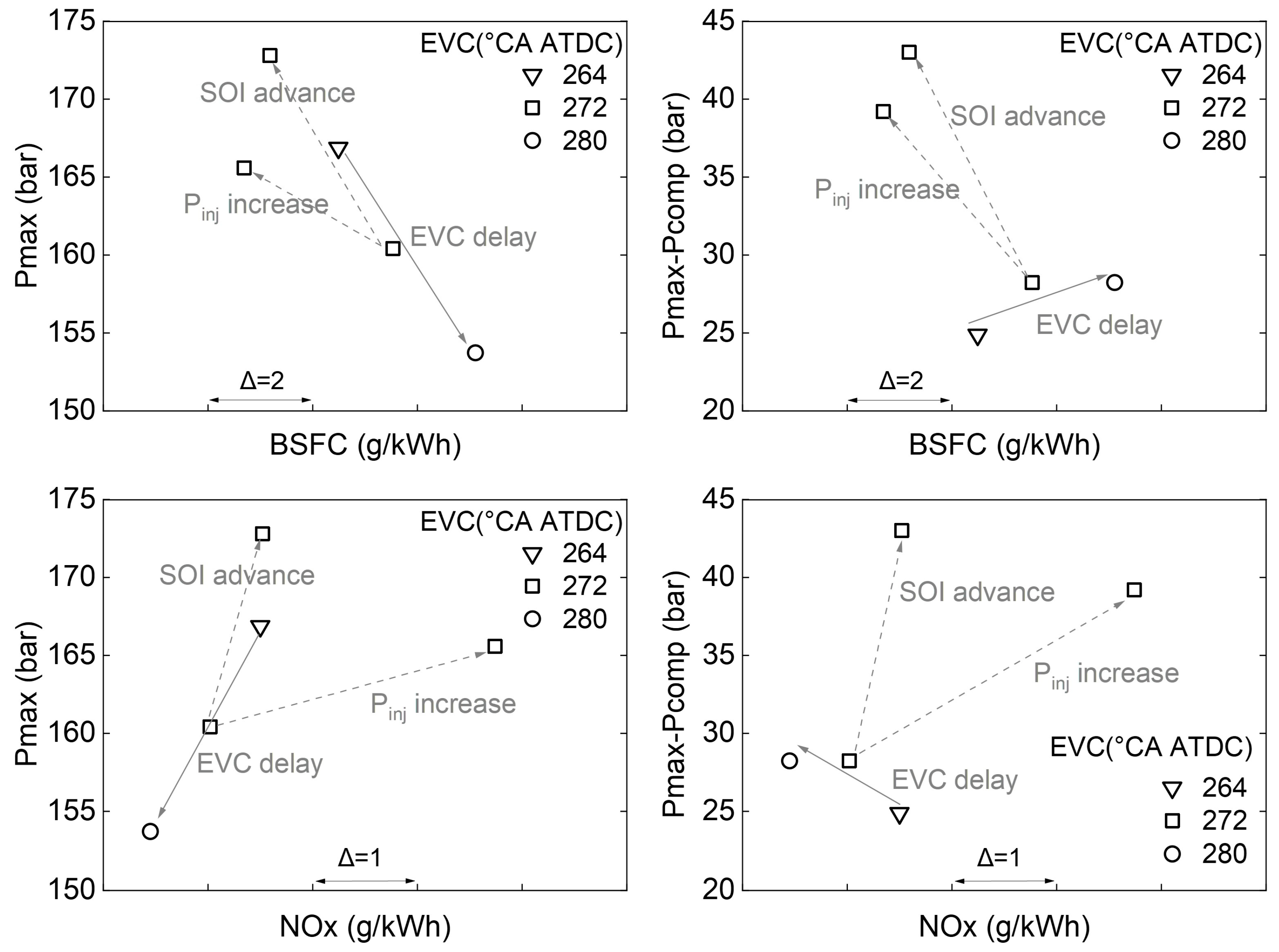

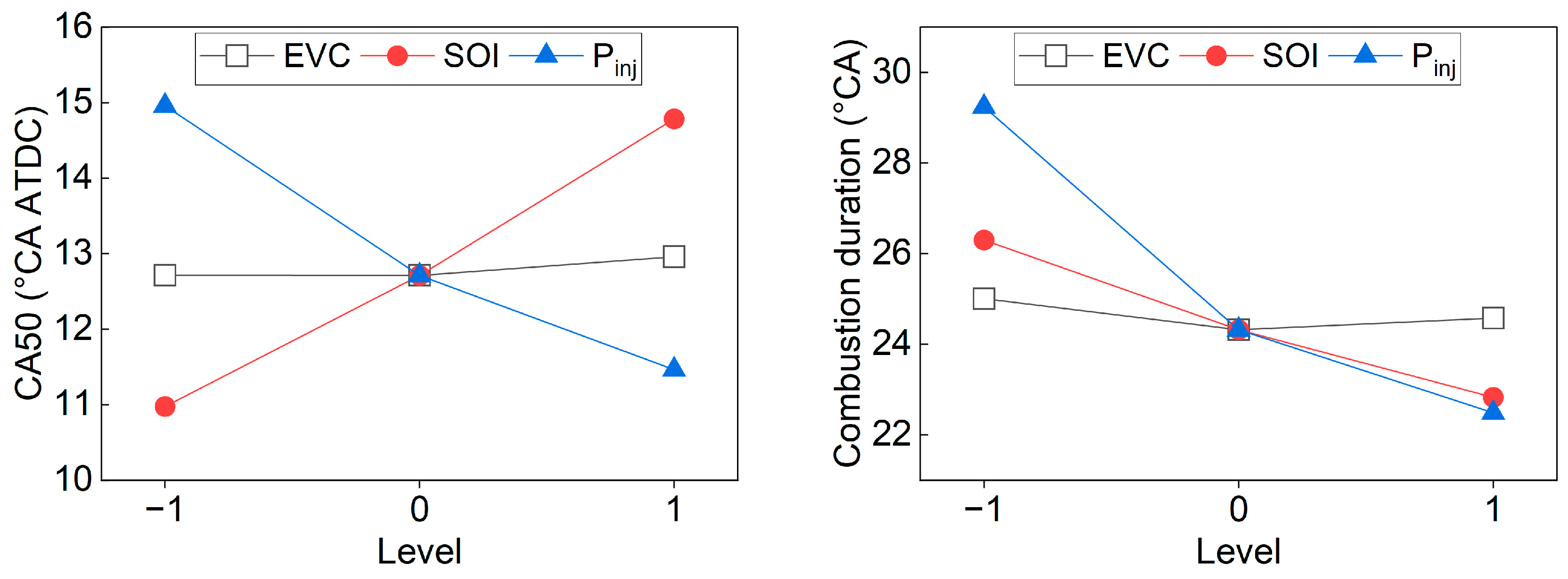

3.1. Effects of EVC and Fuel Injection Parameters

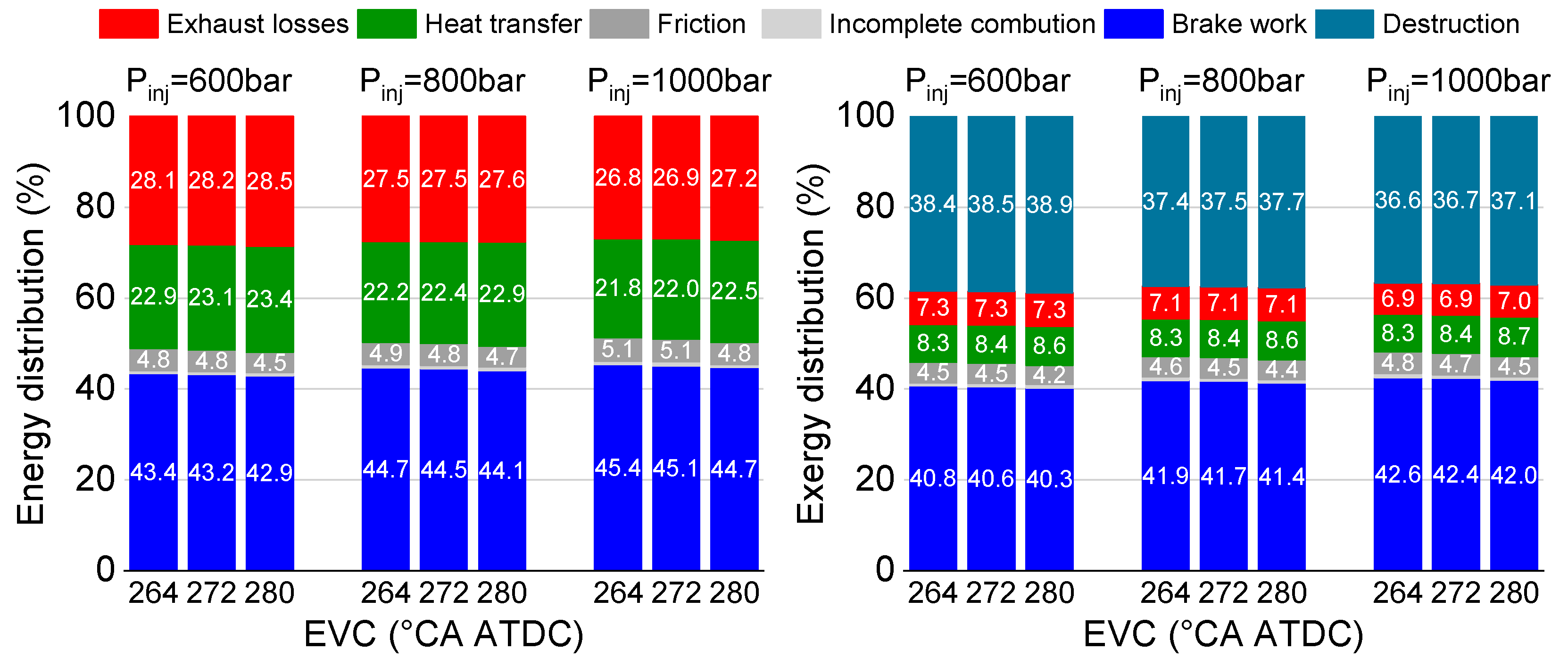

3.2. Energy and Exergy Distribution

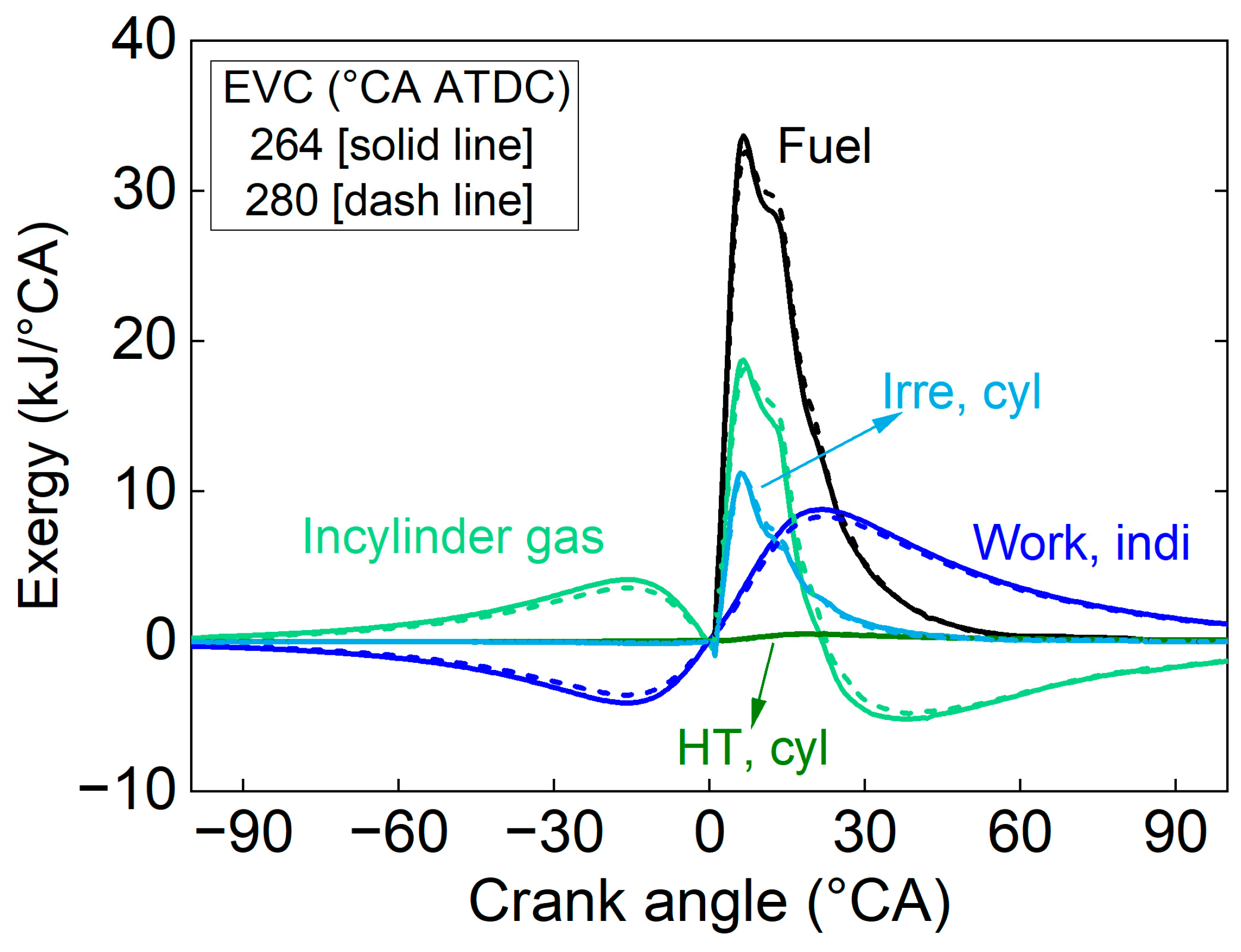

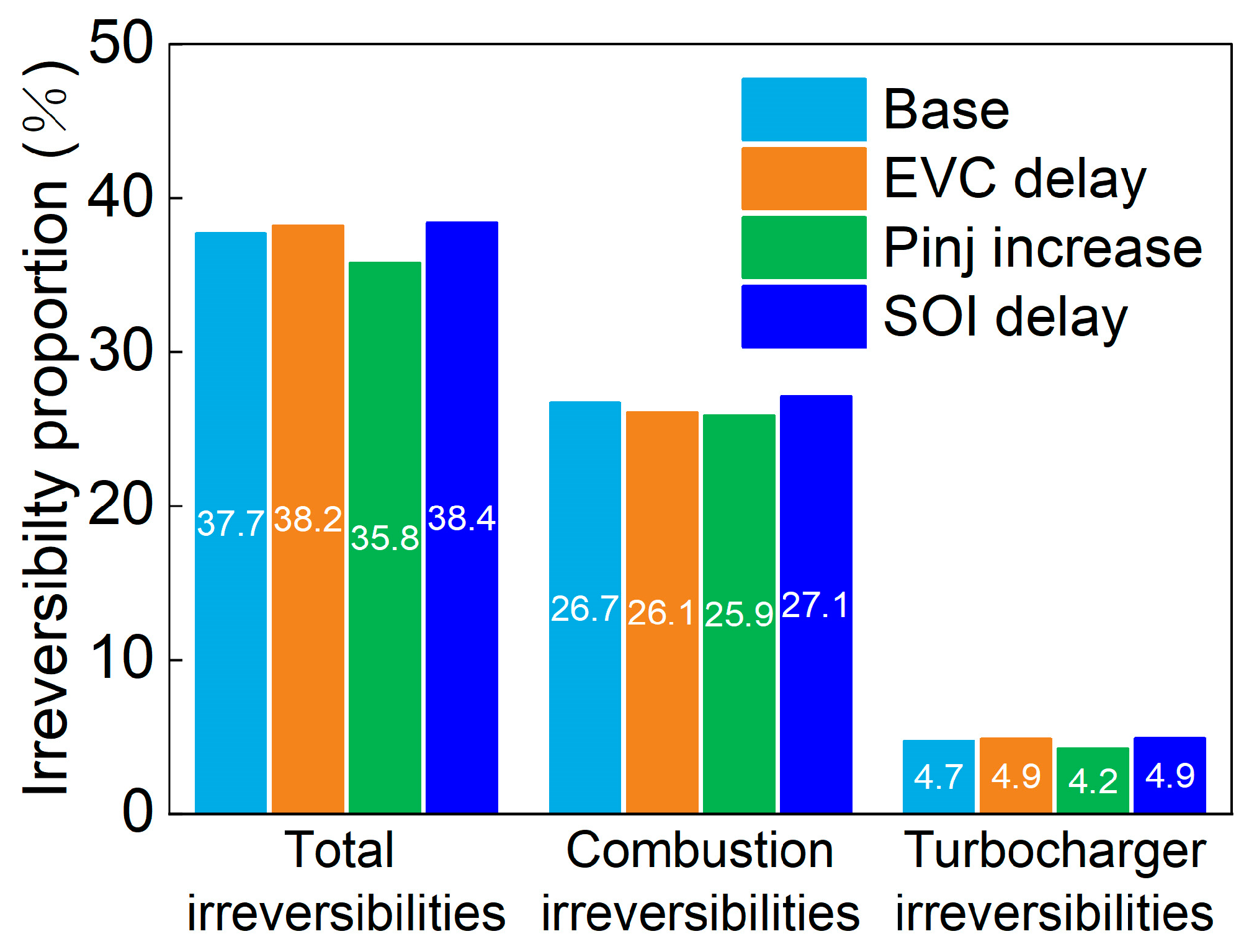

3.3. Quantification of Engine Irreversibilities

4. Conclusions

- Experimental results show that delaying EVC could reduce the NOx emission by decreasing the effective compression ratio. With the same fuel injection strategy, a 16 °CA delay of EVC could achieve about 8% decrement of NOx emission.

- According to the following energy analysis based on the experimental results, the loss of heat transfer and exhaust gas both take more than 20% in proportion. Retarding the EVC and the start of injection (SOI) could raise the energy loss of heat transfer and exhaust gas. Increasing the fuel injection pressure reduces these two losses and the brake specific fuel consumption could be obviously improved, while this kind of improvement will be limited by the maximum cylinder pressure and the pressure difference of maximum and compression cylinder pressure.

- The following exergy analysis demonstrated that the exergy of heat transfer and exhaust gas are both below 9% in proportion, and the heat transfer exergy is about 1% higher than that of exhaust gas. Delaying the EVC will not change the ratio of exhaust gas exergy, but will raise the proportion of heat transfer. The main reason is that the decline of relative air/fuel ratio led to the increment of in-cylinder temperature during the combustion process. Retarding the start of injection has less influence on the exhaust gas and the heat transfer exergy. Increasing the fuel injection pressure will not change the proportion of heat transfer exergy, but could reduce that of exhaust gas, improving the exergy efficiency of marine low-speed engine.

- The total irreversibility could take about 35% to 39% of fuel exergy, the combustion process could account, roughly, 70%, and the proportion produced by turbocharger is about 12%. Delaying the EVC almost has no influence on the combustion irreversibility, and retarding the SOI could raise it while increasing the fuel injection pressure could effectively reduce the irreversibility during the combustion process.

- For future research, the combination of delaying EVC, variable compression ratio and suitable fuel-air organization will be a powerful measure to improve the fuel consumption and eliminate the NOx emission simultaneously. All the above methods, especially the suitable fuel-air organization, will be effective to achieve this target, the reason of which is mainly due to the limitation of irreversibility in cylinders.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AHRR | Apparent heat release rate |

| BSFC | Brake specific fuel consumption, g/kWh |

| ISFC | Indicated specific fuel consumption, g/kWh |

| CA | Crank angle, °CA |

| EGR | Exhaust gas recirculation |

| EVC | Exhaust valve closing, °CA |

| EVO | Exhaust valve opening, °CA |

| LHV | Lower heating value, J/kg |

| SCR | Selective catalytic reduction |

| TDC | Top dead center, °CA |

| ATDC | After top dead center, °CA |

| SOI | Start of injection |

| WMC | Water mist catcher |

References

- DieselNet. Emission Standards: IMO Marine Engine Regulations. DieselNet. 2023. Available online: https://dieselnet.com/standards/inter/imo.php (accessed on 28 August 2023).

- IMO. Prevention of Air Pollution from Ships. International Maritime Organization. 2019. Available online: https://www.imo.org/en/OurWork/Environment/Pages/Clean%20air%20in%20shipping.aspx (accessed on 4 October 2023).

- UNCTAD. Review of Maritime Transport 2021; United Nations: New York, NY, USA, 2021. [Google Scholar]

- Notteboom, T.E. Container Shipping and Ports: An Overview. Rev. Netw. Econ. 2004, 3, 1045. [Google Scholar] [CrossRef]

- Wik, C. Reducing medium-speed engine emissions. J. Mar. Eng. Technol. 2010, 9, 37–44. [Google Scholar] [CrossRef][Green Version]

- Woodyard, D. Pounder’s Marine Diesel Engines and Gas Turbines, 9th ed.; Butterworth-Heinemann: Oxford, UK, 2009. [Google Scholar]

- Wik, C. Choice of Tier III Technologies—Ship Owners’ Viewpoints; CIMAC: Helsinki, Finland, 2016. [Google Scholar]

- Elkelawy, M.; El Shenawy, E.A.; Mohamed, S.A.; Elarabi, M.M.; Alm-Eldin Bastawissi, H. Impacts of EGR on RCCI engines management: A comprehensive review. Energy Convers. Manag. X 2022, 14, 100216. [Google Scholar] [CrossRef]

- Zhou, L.; Song, Y.; Hua, J.; Liu, F.; Wei, H. Effects of miller cycle strategies on combustion characteristics and knock resistance in a spark assisted compression ignition (SACI) engine. Energy 2020, 206, 118119. [Google Scholar] [CrossRef]

- Zhu, S.; Deng, K.; Liu, S.; Qu, S. Comparative analysis and evaluation of turbocharged Dual and Miller cycles under different operating conditions. Energy 2015, 93, 75–87. [Google Scholar] [CrossRef]

- Gonca, G.; Sahin, B.; Parlak, A.; Ayhan, V.; Cesur, İ.; Koksal, S. Application of the Miller cycle and turbo charging into a diesel engine to improve performance and decrease NO emissions. Energy 2015, 93, 795–800. [Google Scholar] [CrossRef]

- Verschaeren, R.; Schaepdryver, W.; Serruys, T.; Bastiaen, M.; Vervaeke, L.; Verhelst, S. Experimental study of NOx reduction on a medium speed heavy duty diesel engine by the application of EGR (exhaust gas recirculation) and Miller timing. Energy 2014, 76, 614–621. [Google Scholar] [CrossRef]

- Guan, W.; Pedrozo, V.; Zhao, H.; Ban, Z.; Lin, T. Investigation of EGR and Miller Cycle for NOx Emissions and Exhaust Temperature Control of a Heavy-Duty Diesel Engine. SAE Tech. Pap. 2017. [Google Scholar] [CrossRef]

- Pedrozo, V.B.; Zhao, H. Improvement in high load ethanol-diesel dual-fuel combustion by Miller cycle and charge air cooling. Appl. Energy 2018, 210, 138–151. [Google Scholar] [CrossRef]

- Ji, W.; Li, A.; Lu, X.; Huang, Z.; Zhu, L. Numerical study on NOx and ISFC co-optimization for a low-speed two-stroke engine via Miller cycle, EGR, intake air humidification, and injection strategy implementation. Appl. Therm. Eng. 2019, 153, 398–408. [Google Scholar] [CrossRef]

- Zhou, S.; Gao, R.; Feng, Y.; Zhu, Y. Evaluation of Miller cycle and fuel injection direction strategies for low NOx emission in marine two-stroke engine. Int. J. Hydrog. Energy 2017, 42, 20351–20360. [Google Scholar] [CrossRef]

- Feng, L.; Tian, J.; Long, W.; Gong, W.; Du, B.; Li, D.; Chen, L. Decreasing NOx of a Low-Speed Two-Stroke Marine Diesel Engine by Using In-Cylinder Emission Control Measures. Energies 2016, 9, 304. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, H.; Wang, H.; Zou, X.; Yao, M. A Numerical Study on Combustion and Emission Characteristics of Marine Engine through Miller Cycle Coupled with EGR and Water Emulsified Fuel. SAE Tech. Pap. 2016. [Google Scholar] [CrossRef]

- Pugnali, L.D.; Chen, R. Feasibility Study of Operating 2-Stroke Miller Cycles on a 4-Stroke Platform through Variable Valve Train; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Bejan, A.; Tsatsaronis, G.; Moran, M. Thermal Design and Optimization; John Wiley and Sons Inc.: New York, NY, USA, 1996. [Google Scholar]

- Azoumah, Y.; Blin, J.; Daho, T. Exergy efficiency applied for the performance optimization of a direct injection compression ignition (CI) engine using biofuels. Renew. Energy 2009, 34, 1494–1500. [Google Scholar] [CrossRef]

- Wang, P.; Tang, X.; Shi, L.; Ni, X.; Hu, Z.; Deng, K. Experimental investigation of the influences of Miller cycle combined with EGR on performance, energy and exergy characteristics of a four-stroke marine regulated two-stage turbocharged diesel engine. Fuel 2021, 300, 120940. [Google Scholar] [CrossRef]

- Fu, J.; Liu, J.; Feng, R.; Yang, Y.; Wang, L.; Wang, Y. Energy and exergy analysis on gasoline engine based on mapping characteristics experiment. Appl. Energy 2013, 102, 622–630. [Google Scholar] [CrossRef]

- Hong, B.; Mahendar, S.K.; Hyvönen, J.; Cronhjort, A.; Erlandsson, A.C. Quantification of Losses and Irreversibilities in a Marine Engine for Gas and Diesel Fuelled Operation Using an Exergy Analysis Approach. American Society of Mechanical Engineers Digital Collection. In Proceedings of the ASME 2020 Internal Combustion Engine Division Fall Technical Conference, Virtual, 4–6 November 2020. [Google Scholar]

- Zhu, S.; Ma, Z.; Zhang, K.; Deng, K. Energy and exergy analysis of a novel steam injected turbocompounding system applied on the marine two-stroke diesel engine. Energy Convers. Manag. 2020, 221, 113207. [Google Scholar] [CrossRef]

- Zhu, S.; Ma, Z.; Zhang, K.; Deng, K. Energy and exergy analysis of the combined cycle power plant recovering waste heat from the marine two-stroke engine under design and off-design conditions. Energy 2020, 210, 118558. [Google Scholar] [CrossRef]

- Yoshida, S.; Yamamoto, H. Exergy analysis of a diesel engine cycle and its performance improvement. Int. J. Exergy 2005, 2, 284–298. [Google Scholar] [CrossRef]

- Marty, P.; Hétet, J.-F.; Chalet, D.; Corrignan, P. Exergy analysis of complex ship energy systems. Entropy 2016, 18, 127. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, D.; Long, W.; Qian, Y. Analysis of Energy and Exergy Distribution for Improving Fuel Economy of Marine Low-speed Two-stroke Diesel Engine. SAE Tech. Pap. 2022. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, H.; Qian, Y.; Deng, K. Experimental energy and exergy analysis of turbocharged marine low-speed engine with high pressure exhaust gas recirculation. Fuel 2022, 323, 124360. [Google Scholar] [CrossRef]

- Caton, J.A. A Review of Investigations Using the Second Law of Thermodynamics to Study Internal-Combustion Engines. SAE Tech. Pap. 2000. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Giakoumis, E.G. Second-law analyses applied to internal combustion engines operation. Prog. Energy Combust. Sci. 2006, 32, 2–47. [Google Scholar] [CrossRef]

- Zehe, M.J.; McBride, B.J.; Gordon, S. CAP: A Computer Code for Generating Tabular Thermodynamic Functions from NASA Lewis Coefficients. 2002. Available online: https://ntrs.nasa.gov/citations/20020012428 (accessed on 4 October 2023).

- Mayer, S.; Elena, T.A.; Andreasen, A. Design of Experiments Analysis of the NOx-SFOC Trade-Off in Two-Stroke Marine Engine; CIMAC: Bergen, Norway, 2010. [Google Scholar]

| Engine Parameter | Value |

|---|---|

| Bore (mm) | 340 |

| Number of cylinders | 6 |

| Stroke (mm) | 1600 |

| Geometric compression ratio | 19.8 |

| Connecting rod length (mm) | 1600 |

| Rated rotation speed (revolutions per minute, RPM) | 157 |

| Rated power (kW) | 4896 |

| Parameters | Value |

|---|---|

| Engine load (%) | 75 |

| Speed (RPM) | 142.6 |

| Power (kW) | 3679 |

| EVC (°CA ATDC) | 264, 272, 280 |

| Fuel injection pressure (bar) | 600, 800, 1000 |

| Start of injection (°CA ATDC) | −1, 1, 3 |

| Parameter | Equipment | Uncertainty |

|---|---|---|

| Speed | Nabtesco: Governor Unit | ±1% |

| Torque | JAPAN: CSFR-22.0 | 0.2% |

| Temperature | KONGSBERG: PO702457 | ±1% |

| Pressure | Tempress: 0–4 bar | ±0.5% |

| Humidity | TEST0: TESTO623 | ±3% |

| Cylinder pressure | ABB: CylMate | ±0.2% |

| Fuel flow | Endress Hauser: 80F40–10C2/0 | ±0.16% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Long, W.; Xiao, G.; Tian, J.; Li, B.; Wang, D.; Qian, Y. Experimental Study of the Influences of Operating Parameters on the Performance, Energy and Exergy Characteristics of a Turbocharged Marine Low-Speed Engine. Processes 2023, 11, 2924. https://doi.org/10.3390/pr11102924

Zhang H, Long W, Xiao G, Tian J, Li B, Wang D, Qian Y. Experimental Study of the Influences of Operating Parameters on the Performance, Energy and Exergy Characteristics of a Turbocharged Marine Low-Speed Engine. Processes. 2023; 11(10):2924. https://doi.org/10.3390/pr11102924

Chicago/Turabian StyleZhang, Heng, Wuqiang Long, Ge Xiao, Jiangping Tian, Bo Li, Dawei Wang, and Yuehua Qian. 2023. "Experimental Study of the Influences of Operating Parameters on the Performance, Energy and Exergy Characteristics of a Turbocharged Marine Low-Speed Engine" Processes 11, no. 10: 2924. https://doi.org/10.3390/pr11102924

APA StyleZhang, H., Long, W., Xiao, G., Tian, J., Li, B., Wang, D., & Qian, Y. (2023). Experimental Study of the Influences of Operating Parameters on the Performance, Energy and Exergy Characteristics of a Turbocharged Marine Low-Speed Engine. Processes, 11(10), 2924. https://doi.org/10.3390/pr11102924