Optimization Design of Nozzle Structure Inside Boiler Based on Orthogonal Design

Abstract

1. Introduction

2. Calculation Models and Methods

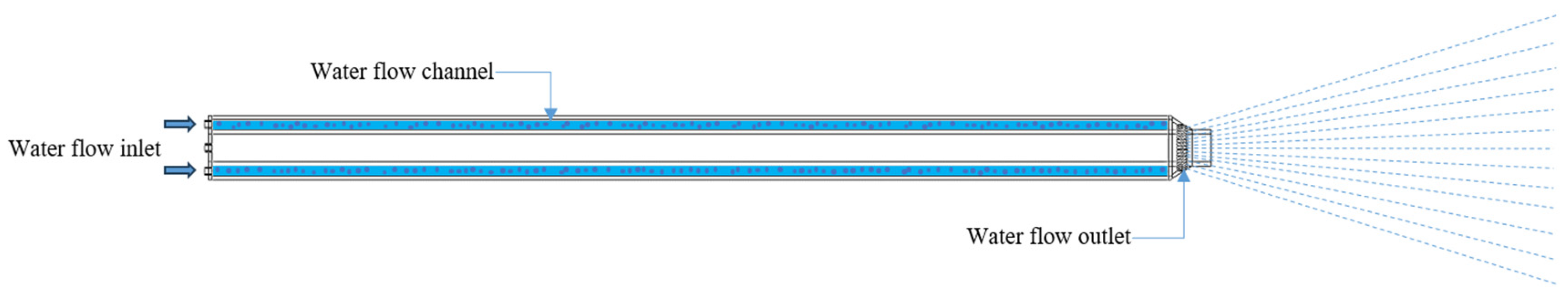

2.1. Physical Models

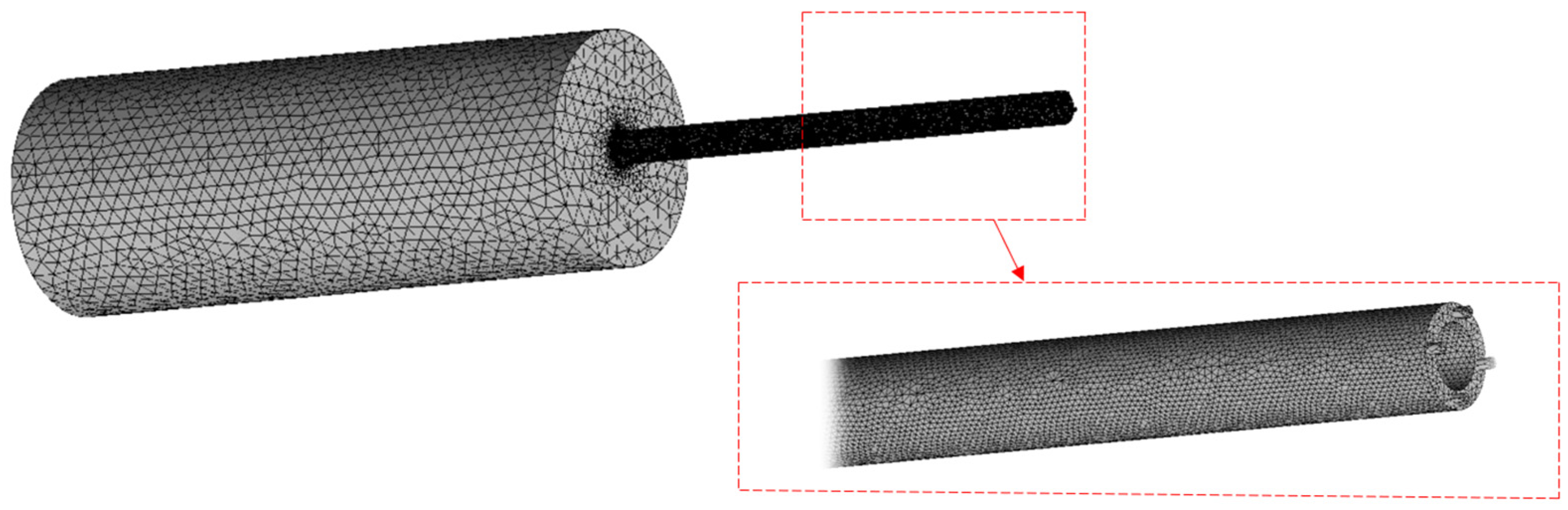

2.2. Computational Mesh

2.3. Control Equation and Boundary Conditions

2.4. Computational Scheme

3. Result Analysis

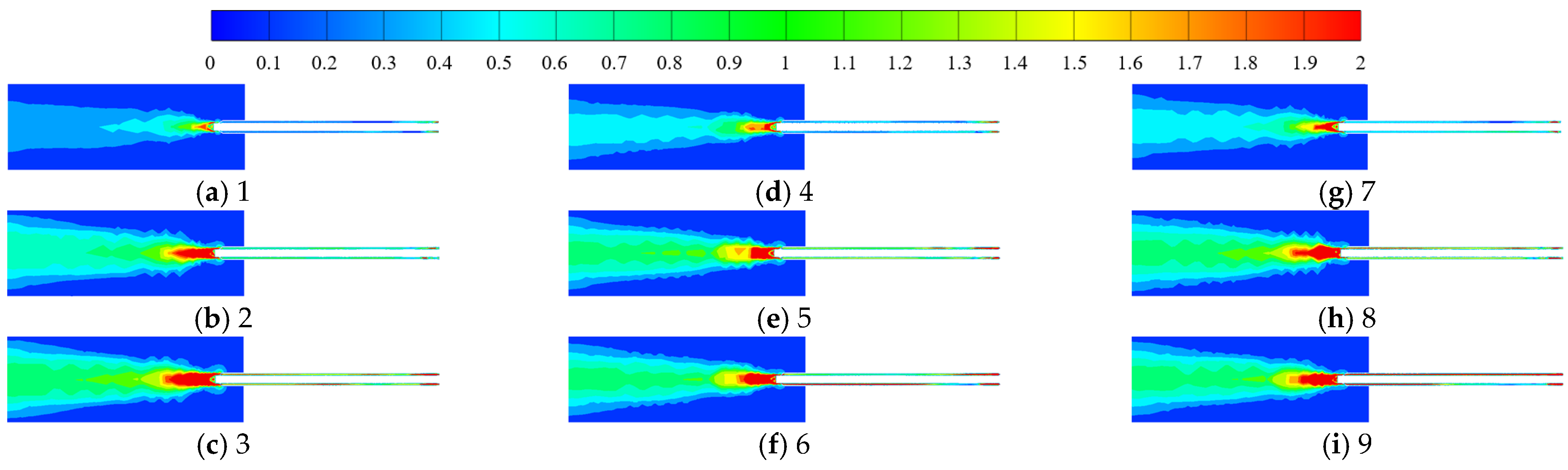

3.1. Pressure and Velocity

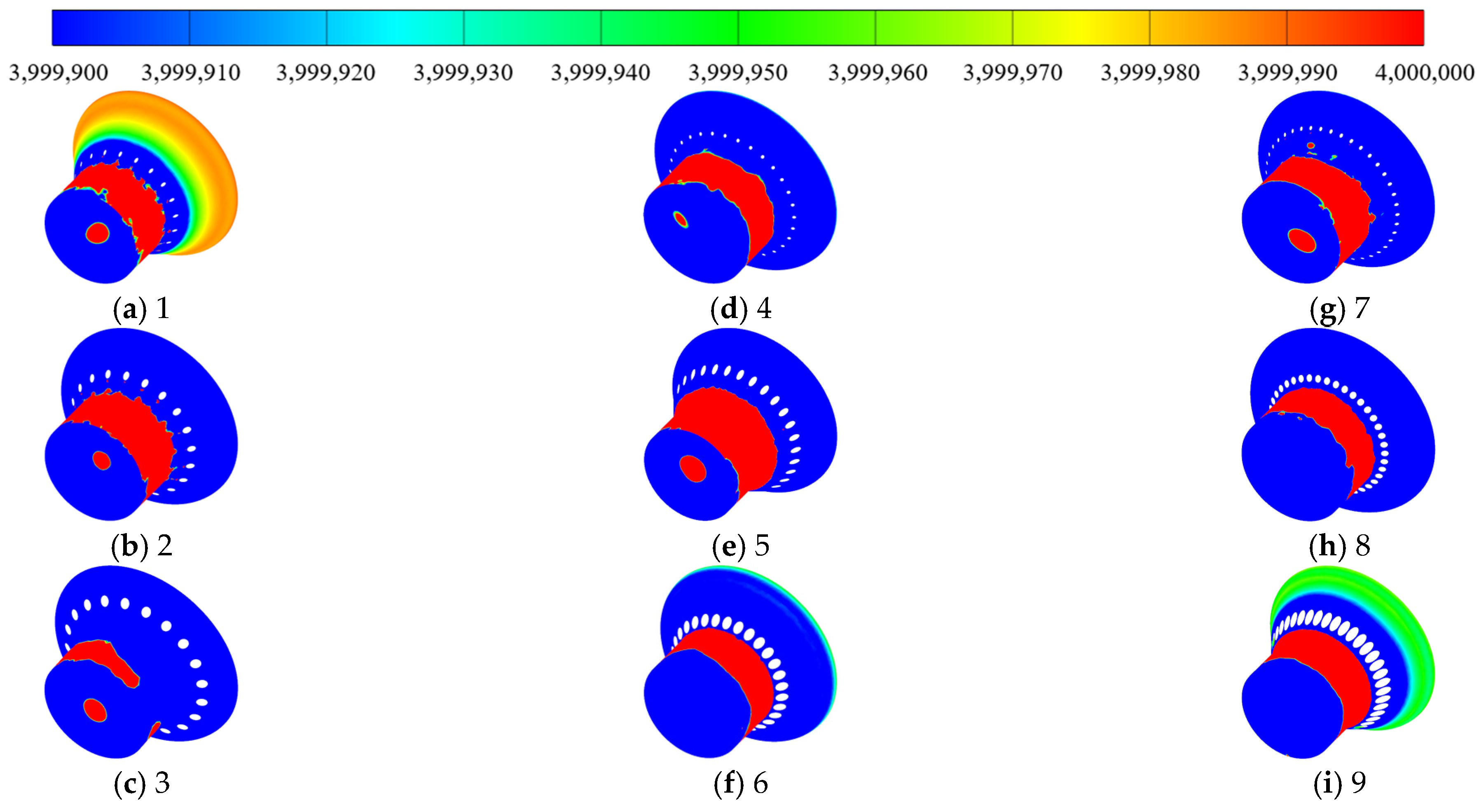

3.2. Entropy Production Distribution

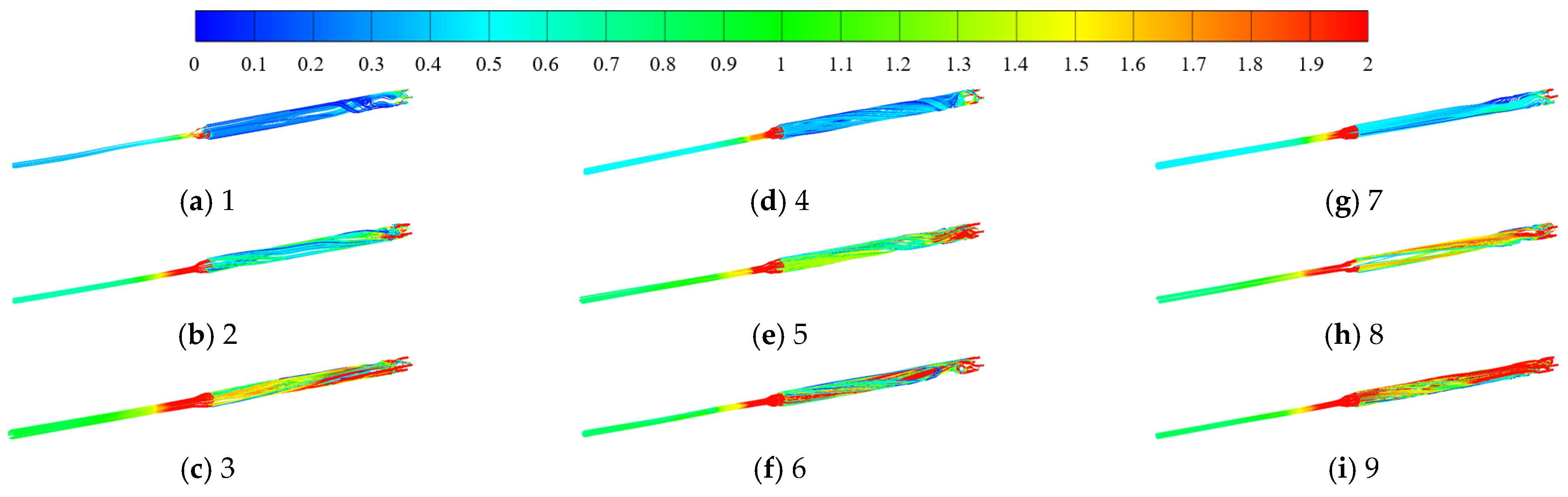

3.3. Vorticity Structure

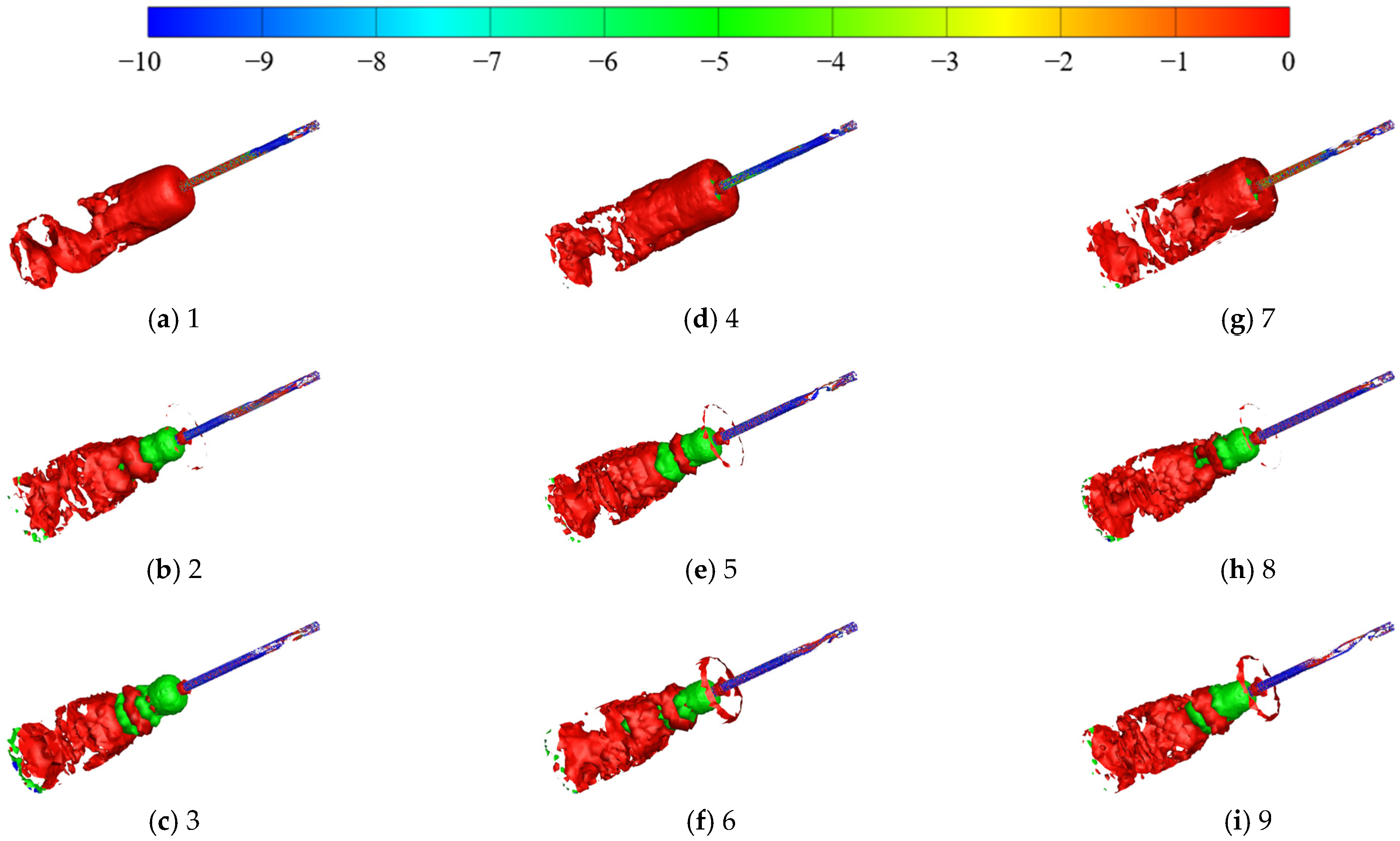

3.4. Q Criteria

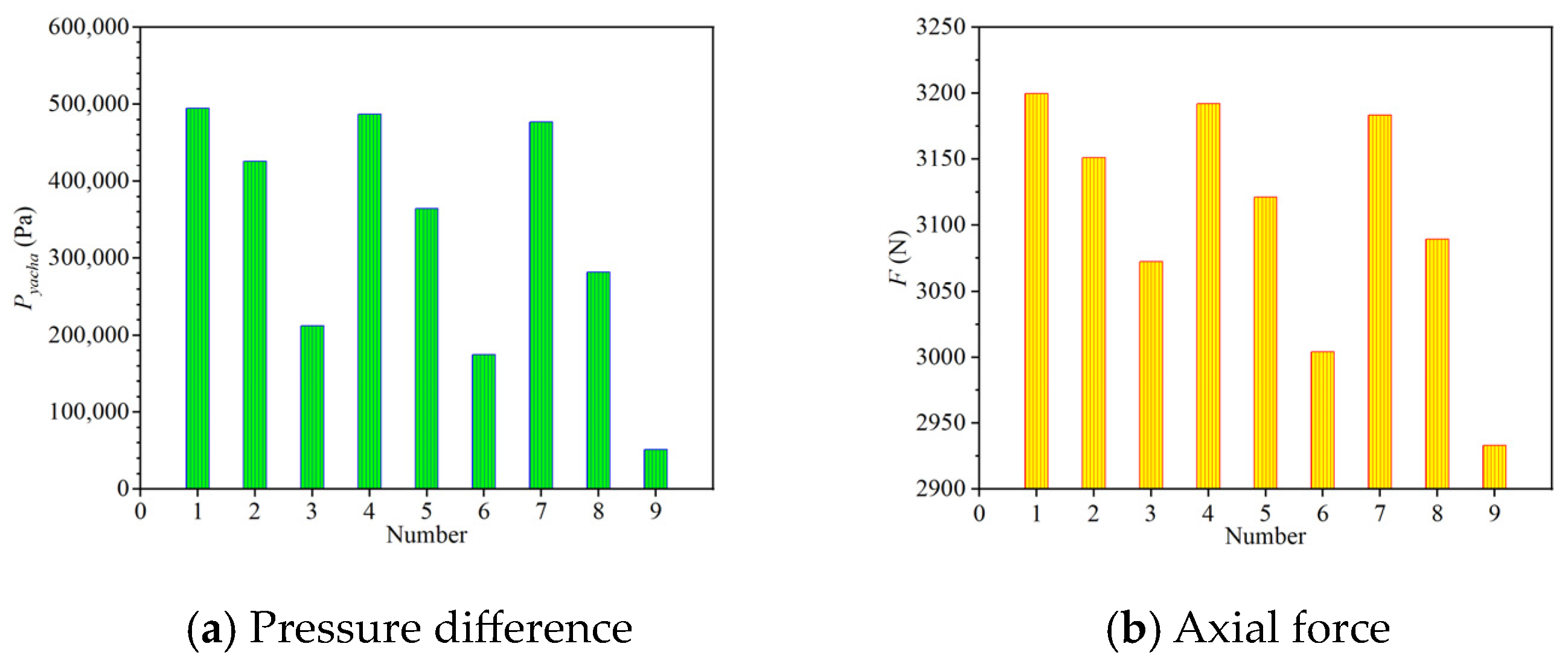

3.5. Range Analysis

3.6. Significance Test

4. Conclusions

- (1)

- According to Figure 6, it can be concluded that the maximum axial force in Experimental Group 1 is 3199.711371 N, while the minimum axial force in Experimental Group 9 is 2932.954979 N.

- (2)

- Based on entropy distribution analysis, the entropy values of monitoring bodies in Experimental Groups 3, 6, and 9 are relatively high, indicating a higher degree of disorder. On the other hand, Experimental Groups 1 and 4 have lower entropy values, indicating a lower degree of disorder.

- (3)

- According to the vortex discrimination, the monitoring body in Experimental Group 3 exhibits a higher number of vortices and greater vortex intensity. Experimental Groups 1, 6, and 9 have fewer vortices at the nozzle and lower vortex intensity compared to the other experimental groups.

- (4)

- Through range analysis and significance testing, it can be concluded that the diameter of the nozzle hole has a significant impact on the axial force experienced by the jet pipe, while the number of nozzle holes has a smaller impact. The distribution circle diameter and the tilt angle of the bottom cover have very little influence on the axial force.

- (5)

- The optimal combination of nozzle structure parameters, determined after comprehensive analysis, is as follows: the number of spray holes is 40, each with a diameter of 1.5 mm, the distribution circle diameter is 22 mm, and the incline angle of the bottom cover is 30 degrees.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| L | Outer tube length (mm) |

| Rww | Outer tube outer diameter (mm) |

| Rwn | Outer tube inner diameter (mm) |

| Rnw | Inner tube outer diameter (mm) |

| Rnn | Inner tube inner diameter (mm) |

| Rsw | Inlet outer diameter (mm) |

| Rsn | Inlet inner diameter (mm) |

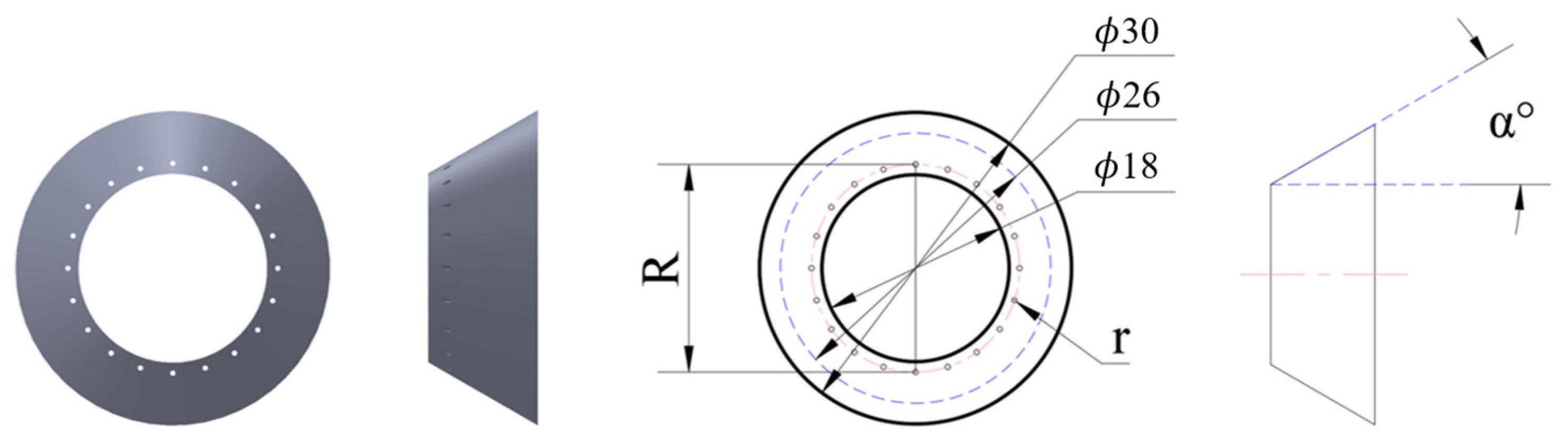

| n | Number of spray holes (pcs) |

| r | Spray hole diameter (mm) |

| R | Distribution circle diameter (mm) |

| α | Tilt angle of bottom cover (degrees) |

| Pyacha | Inlet–outlet pressure difference (Pa) |

| F | Axial force (N) |

References

- Bar, J.B.; Parashkoohi, M.G.; Zamani, D.M.; Ghafori, H. Simulation of parameters effects on fluid flow behavior in the spraying nozzle: A case study of greenhouse cultivation. Results Eng. 2023, 19, 101223. [Google Scholar]

- Pang, H.; Zhao, C.; Cheng, S.; Wang, M.; Gao, Q.; He, S.; Sun, G.; Jiang, G.; Sun, Q.; Liu, Z.; et al. Investigation on feasible zone of nozzle spray for pre-cooling the inlet air of natural draft dry cooling tower. Therm. Sci. Eng. Prog. 2023, 38, 101650. [Google Scholar] [CrossRef]

- Chen, G.; Fu, C.; Xu, B.; Wu, Y.; Lien, F.S.; Yee, E. Internal mixing air-assisted spray nozzle for large droplets: Experimental measurements and numerical simulations. J. Aerosol Sci. 2022, 165, 106035. [Google Scholar] [CrossRef]

- Ma, X.; Shi, W.; Yang, H. Study on water spraying distribution to improve the energy recovery performance of indirect evaporative coolers with nozzle arrangement optimization. Appl. Energy 2022, 318, 119212. [Google Scholar] [CrossRef]

- Cui, J.; Lai, H.; Feng, K.; Ma, Y. Quantitative analysis of the minor deviations in nozzle internal geometry effect on the cavitating flow. Exp. Therm. Fluid Sci. 2018, 94, 89–98. [Google Scholar] [CrossRef]

- Griesang, F.; Spadoni, A.B.D.; Ferreira, P.H.U.; da Costa Ferreira, M. Effect of working pressure and spacing of nozzles on the quality of spraying distribution. Crop Prot. 2022, 151, 105818. [Google Scholar] [CrossRef]

- Miao, J.; Fan, Y.; Wu, W. Effects of nozzle configuration on flash boiling fuel sprays of twin-orifice nozzle with aviation kerosene. Int. J. Heat Mass Transf. 2021, 174, 121335. [Google Scholar] [CrossRef]

- Wu, S.; Gandhi, A.; Li, H.; Meinhart, M. Experimental and numerical study of the effects of nozzle taper angle on spray characteristics of GDI multi-hole injectors at cold condition. Fuel 2020, 275, 117888. [Google Scholar] [CrossRef]

- Balz, R.; von Rotz, B.; Sedarsky, D. In-nozzle flow and spray characteristics of large two-stroke marine diesel fuel injectors. Appl. Therm. Eng. 2020, 180, 115809. [Google Scholar] [CrossRef]

- Safiullah; Nishida, K.; Ogata, Y. Evaporation and mixture formation characteristics of diesel spray under various nozzle hole size and injection pressure condition employing similar injection rate profile. Int. Commun. Heat Mass Transf. 2021, 123, 105184. [Google Scholar] [CrossRef]

- Prociw, N.; Briens, C.; Berruti, F.; McMillan, J. Effect of spray nozzle attachment geometry on rate of liquid released from agglomerates produced by gas-atomized liquid injection into a fluidized bed. Powder Technol. 2018, 325, 280–288. [Google Scholar] [CrossRef]

- Dai, X.; Wang, Z.; Liu, F.; Pei, Y.; Gong, C.; Li, Z. The effect of nozzle structure and initial state on the primary breakup of diesel spray. Fuel 2020, 280, 118640. [Google Scholar] [CrossRef]

- Wang, X.-S.; Chen, B.; Zhou, Z.-F. Atomization and surface heat transfer characteristics of cryogen spray cooling with expansion-chambered nozzles. Int. J. Heat Mass Transf. 2018, 121, 15–27. [Google Scholar] [CrossRef]

- Wu, S.; Xu, M.; Hung, D.L.S.; Li, T.; Pan, H. Near-nozzle spray and spray collapse characteristics of spark-ignition direct-injection fuel injectors under sub-cooled and superheated conditions. Fuel 2016, 183, 322–334. [Google Scholar] [CrossRef]

- Varadaraajan, V.; Mohanty, P. Design and optimization of rectangular cold spray nozzle: Radial injection angle, expansion ratio and traverse speed. Surf. Coat. Technol. 2017, 316, 246–254. [Google Scholar] [CrossRef]

- Rouaix, C.; Stoukov, A.; Bury, Y.; Joubert, D.; Legendre, D. Liquid jet breakup in gaseous crossflow injected through a large diameter nozzle. Int. J. Multiph. Flow 2023, 163, 104419. [Google Scholar] [CrossRef]

- Dubey, A.; Srivastava, P.; Kumar, A. Comparative analysis of cryoablation with singlehole and multihole nozzle in cryospray. Cryobiology 2022, 109, 46. [Google Scholar] [CrossRef]

- Sun, W.; Ma, X.; Zhang, Y.; Jia, L.; Xue, H. Performance analysis and optimization of a steam ejector through streamlining of the primary nozzle. Case Stud. Therm. Eng. 2021, 27, 101356. [Google Scholar] [CrossRef]

- Tahmasebi, E.; Lucchini, T.; D’Errico, G.; Onorati, A.; Hardy, G. An investigation of the validity of a homogeneous equilibrium model for different diesel injector nozzles and flow conditions. Energy Convers. Manag. 2017, 154, 46–55. [Google Scholar] [CrossRef][Green Version]

- Zavalan, F.-L.; Rona, A. A workflow for designing contoured axisymmetric nozzles for enhancing additively manufactured cold spray deposits. Addit. Manuf. 2023, 62, 103379. [Google Scholar] [CrossRef]

- Fang, D.; Xiang, Y.; Deng, Y.; Ma, W. A numerical study of liquid film dynamics in multi-nozzle spray cooling of downward-facing surface. Int. J. Multiph. Flow 2023, 161, 104383. [Google Scholar] [CrossRef]

- Quddus, A.; Shah, A.; Qureshi, K.R.; Tahir, A.; Mustafa, R.U.; Samee, A. Numerical study on effects of nozzle hole spacing distance on steam submerged jet condensation from triangular holes spray nozzle. Appl. Therm. Eng. 2023, 233, 121203. [Google Scholar] [CrossRef]

- Lachin, K.; Niane, M.; Person, M.; Mazet, J.; Delaplace, G.; Turchiuli, C. Prediction of droplets characteristic diameters and polydispersity index induced by a bifluid spraying nozzle by the means of dimensional analysis. Chem. Eng. Sci. 2023, 265, 118187. [Google Scholar] [CrossRef]

- Zhao, J.; Ning, Z.; Lü, M.; Wang, G. Numerical simulation of flow focusing pattern and morphological changes in two-phase flow inside nozzle. Chin. J. Chem. Eng. 2019, 27, 63–71. [Google Scholar] [CrossRef]

- Vasu, G.; Sreenivasulu, B.; Sirisha, G.; Sarma, G.; Ramesh, K. Effect of spray nozzle-hole diameter on performance of 1 kw PEM fuel cell with honeycomb candle humidifier. Mater. Today Proc. 2020, 27, 410–414. [Google Scholar] [CrossRef]

- Liu, A.; Delichatsios, M.A.; Levendis, Y.A. On the trajectory and reach of fire-suppressant liquid nitrogen droplets released from a spray nozzle. Process Saf. Environ. Prot. 2022, 161, 273–284. [Google Scholar] [CrossRef]

- Siebald, H.; Hensel, O.; Kaufmann, H.-H.; Kirchner, S. Spray nozzle function control using acoustics for agricultural applications. Biosyst. Eng. 2020, 197, 149–155. [Google Scholar] [CrossRef]

- Quddus, A.; Shah, A.; Qureshi, K.R.; Ayub, M.K.; Tahir, A.; Iqbal, M.; Waheed, K.; Kaleem, M.A. Study of steam jet characteristics and regime maps for bevelled spray nozzles exhausting into quiescent water. Int. J. Heat Mass Transf. 2022, 190, 122780. [Google Scholar] [CrossRef]

- Han, F.; Wang, D.; Jiang, J.; Zhu, X. A new design of foam spray nozzle used for precise dust control in underground coal mines. Int. J. Min. Sci. Technol. 2016, 26, 241–246. [Google Scholar] [CrossRef]

- Yin, F.; Xue, L.; Liu, Z.; Li, L.; Wang, C. Structure optimization of separating nozzle for waste plastic recycling. Procedia CIRP 2019, 80, 572–577. [Google Scholar] [CrossRef]

- Roache, P.J. Quantification of uncertainty in computational fluid dynamics. Annu. Rev. Fluid Mech. 1997, 29, 123–160. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, Q.; Yan, Y.; Cai, H.; Lu, R.; Wang, B. Simulation and Optimization of Cooling Structure for Cover of Disc Separator. Mech. Electr. Equip. 2023, 40, 48–52. [Google Scholar]

- Kan, K.; Yang, H.; Zheng, Y.; Duan, H.; Cheng, H. Analysis of Hydraulic Loss Mechanism in the Reverse S Region of Pump-Turbine Based on Entropy Production Theory. J. Hydraul. 2023, 54, 323–332. [Google Scholar]

| Elements | Size |

|---|---|

| Length of the Outer Pipe, L | 500 mm |

| Outer Pipe Outer Diameter, Rww | 32 mm |

| Inner Diameter of the Outer Pipe, Rwn | 28 mm |

| Outer Diameter of the Inner Pipe, Rnw | 18 mm |

| Inner Diameter of the Inner Pipe, Rnn | 14 mm |

| Inlet Outer Diameter, Rsw | 4 mm |

| Inlet Inner Diameter, Rsn | 3 mm |

| Serial Number | GCI Value |

|---|---|

| 1–2 | 4.8339% |

| 2–3 | 2.9244% |

| 3–4 | 2.8343% |

| 4–5 | 0.8428% |

| 5–6 | 1.7750% |

| 6–7 | 3.6031% |

| 7–8 | 0.1725% |

| 8–9 | 0.9025% |

| 9–10 | 0.0006% |

| 10–11 | 0.0054% |

| Level | Nozzle Quantity (n) | Nozzle Diameter (r) | Distribution Circle Diameter (R) | Tilt Angle of the Base (α) |

|---|---|---|---|---|

| Level 1 | 20 | 0.5 | 20 | 30 |

| Level 2 | 30 | 1 | 22 | 45 |

| Level 3 | 40 | 1.5 | 24 | 60 |

| Experimental Group Number | Nozzle Quantity (n) | Nozzle Diameter (r) | Distribution Circle Diameter (R) | Tilt Angle of the Base (α) |

|---|---|---|---|---|

| 1 | 20 | 0.5 | 20 | 30 |

| 2 | 20 | 1 | 22 | 45 |

| 3 | 20 | 1.5 | 24 | 60 |

| 4 | 30 | 0.5 | 22 | 60 |

| 5 | 30 | 1 | 24 | 30 |

| 6 | 30 | 1.5 | 20 | 45 |

| 7 | 40 | 0.5 | 24 | 45 |

| 8 | 40 | 1 | 20 | 60 |

| 9 | 40 | 1.5 | 22 | 30 |

| Experimental Group | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Number of Grids | 1,088,461 | 969,019 | 995,336 | 984,778 | 1,019,117 | 977,962 | 952,363 | 1,012,962 | 1,016,458 |

| Experimental Group | Number of Spray Holes | Spray Hole Diameter | Diameter of Distribution Circle | Angle of Inclined Bottom Cover | Axial Force |

|---|---|---|---|---|---|

| Experiment 1 | 20 | 0.5 | 20 | 30 | 3199.711371 |

| Experiment 2 | 20 | 1 | 22 | 45 | 3151.199306 |

| Experiment 3 | 20 | 1.5 | 24 | 60 | 3072.255421 |

| Experiment 4 | 30 | 0.5 | 22 | 60 | 3192.280765 |

| Experiment 5 | 30 | 1 | 24 | 30 | 3121.337614 |

| Experiment 6 | 30 | 1.5 | 20 | 45 | 3003.996483 |

| Experiment 7 | 40 | 0.5 | 24 | 45 | 3183.517847 |

| Experiment 8 | 40 | 1 | 20 | 60 | 3089.347485 |

| Experiment 9 | 40 | 1.5 | 22 | 30 | 2932.954979 |

| Mean value 1 | 3141.055 | 3191.837 | 3097.685 | 3084.668 | |

| Mean value 2 | 3105.872 | 3120.628 | 3092.145 | 3112.905 | |

| Mean value 3 | 3068.607 | 3003.069 | 3125.704 | 3117.961 | |

| Range | 72.448 | 188.768 | 33.559 | 33.293 |

| Experimental Group Number | Nozzle Quantity (n) | Nozzle Diameter (r) | Distribution Circle Diameter (R) | Tilt Angle of the Base (α) |

|---|---|---|---|---|

| 10 | 40 | 1.5 | 24 | 30 |

| Test for Between-Subject Effects | |||||

|---|---|---|---|---|---|

| Dependent Variable: Axial Force | |||||

| Source | Type III Sum of Squares | Degrees of Freedom | Mean Square | F | Significance |

| Adjusted model | 92,394.986 a | 8 | 11,549.373 | 20.552 | 0.169 |

| Intercept | 91,773,633.912 | 1 | 91,773,633.912 | 163,307.155 | 0.002 |

| Number of spray holes | 10,077.237 | 2 | 5038.619 | 8.966 | 0.230 |

| Spray hole diameter | 64,310.190 | 2 | 32,155.095 | 57.219 | 0.093 |

| Distribution circular diameter | 1474.996 | 2 | 737.498 | 1.312 | 0.525 |

| Base cover tilt angle | 3011.728 | 2 | 1505.864 | 2.680 | 0.397 |

| Error | 561.969 | 1 | 561.969 | ||

| Total | 95,447,862.726 | 10 | |||

| Adjusted total | 92,956.955 | 9 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, J.-G.; Xu, S.-S.; Huang, H.-F.; Zhao, Y.-J.; Zhou, W.; Zhang, Y.-L. Optimization Design of Nozzle Structure Inside Boiler Based on Orthogonal Design. Processes 2023, 11, 2923. https://doi.org/10.3390/pr11102923

Ye J-G, Xu S-S, Huang H-F, Zhao Y-J, Zhou W, Zhang Y-L. Optimization Design of Nozzle Structure Inside Boiler Based on Orthogonal Design. Processes. 2023; 11(10):2923. https://doi.org/10.3390/pr11102923

Chicago/Turabian StyleYe, Jian-Gang, Shui-Sheng Xu, Hui-Fan Huang, Yan-Juan Zhao, Wen Zhou, and Yu-Liang Zhang. 2023. "Optimization Design of Nozzle Structure Inside Boiler Based on Orthogonal Design" Processes 11, no. 10: 2923. https://doi.org/10.3390/pr11102923

APA StyleYe, J.-G., Xu, S.-S., Huang, H.-F., Zhao, Y.-J., Zhou, W., & Zhang, Y.-L. (2023). Optimization Design of Nozzle Structure Inside Boiler Based on Orthogonal Design. Processes, 11(10), 2923. https://doi.org/10.3390/pr11102923