Permeability Evolution of Intact and Fractured Coal during Progressive Deformation Subjected to True Triaxial Stresses

Abstract

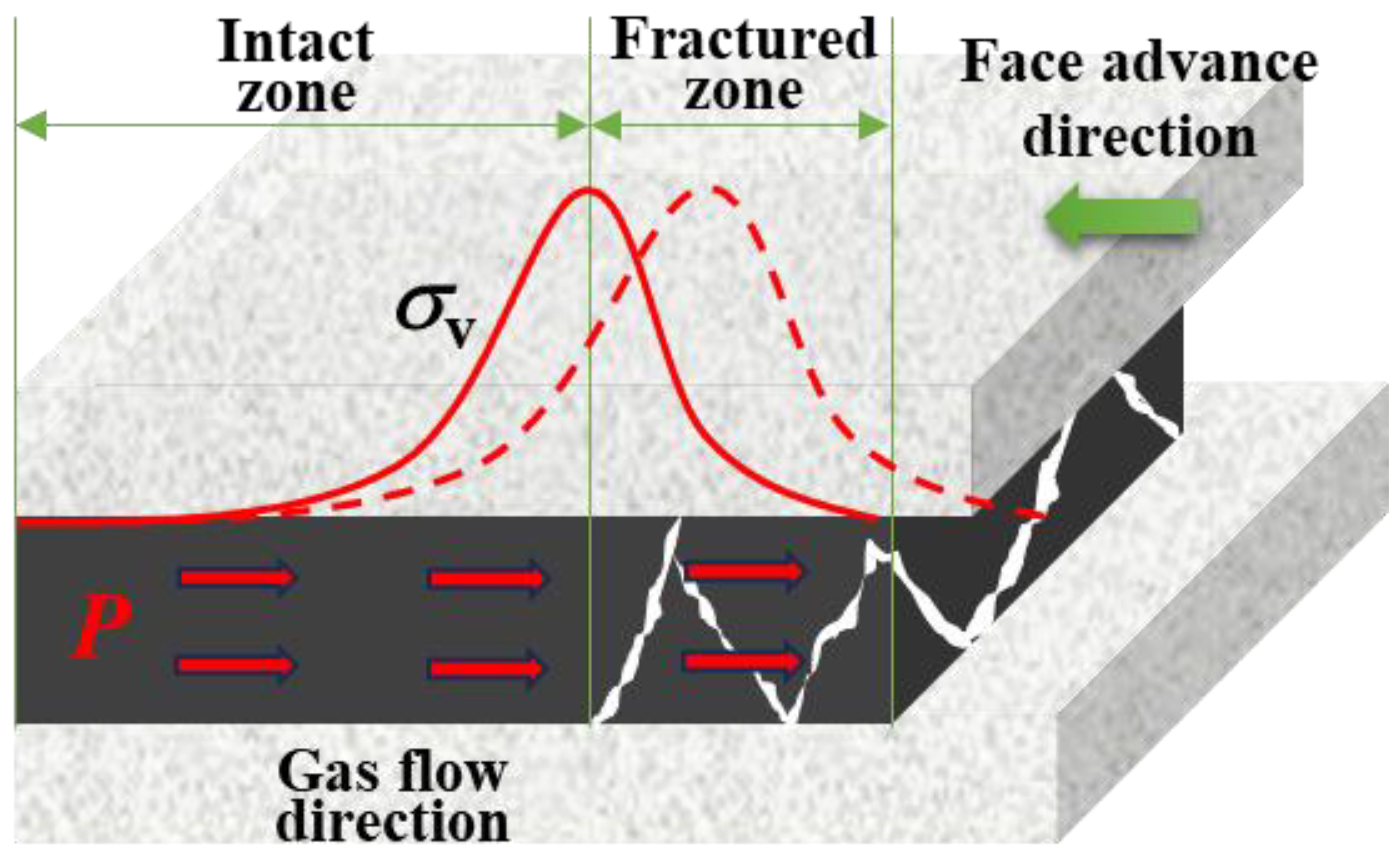

:1. Introduction

2. Material and Experimental Procedure

2.1. Experimental Materials

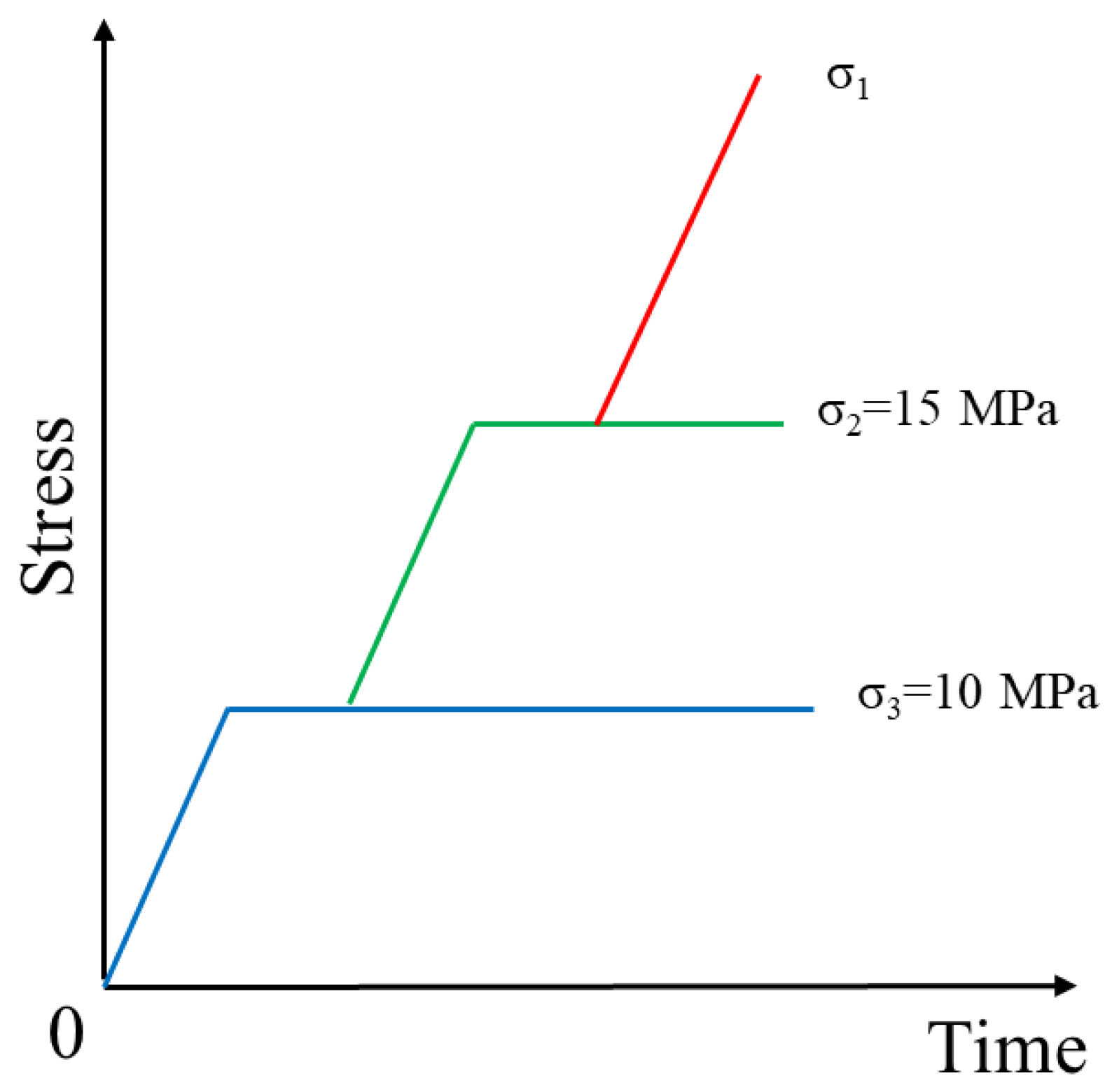

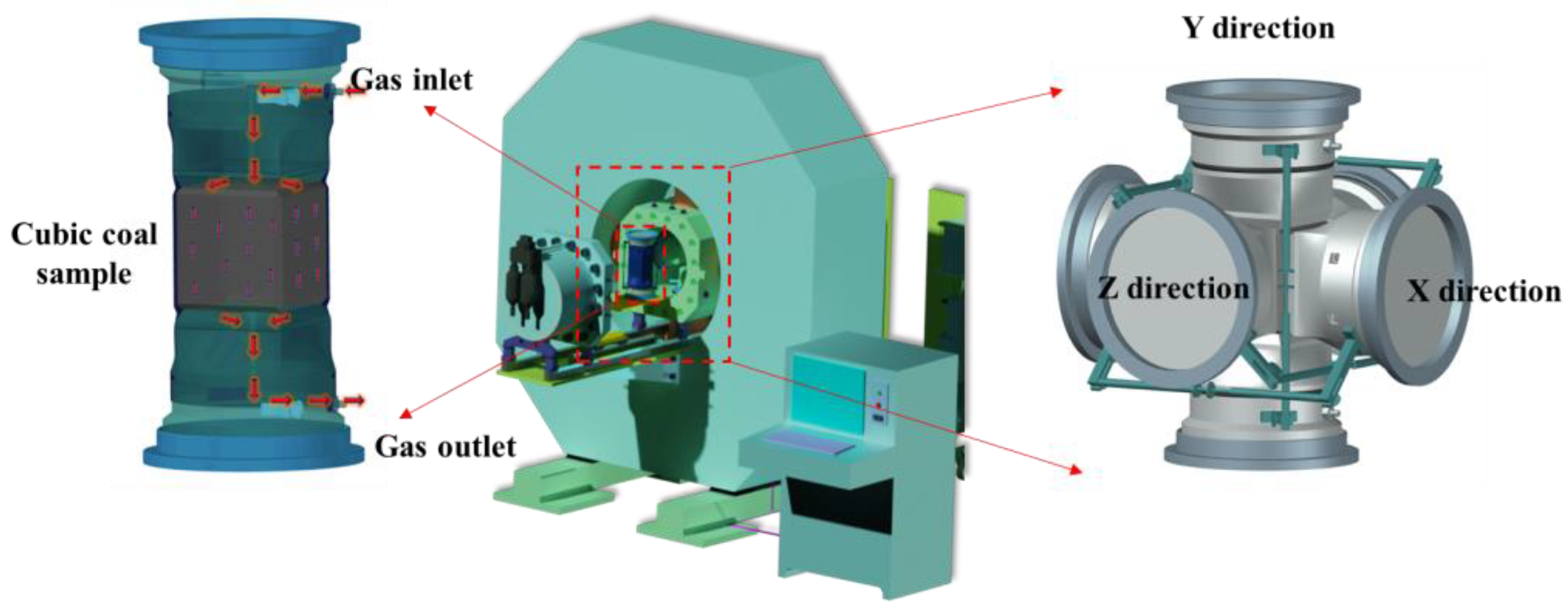

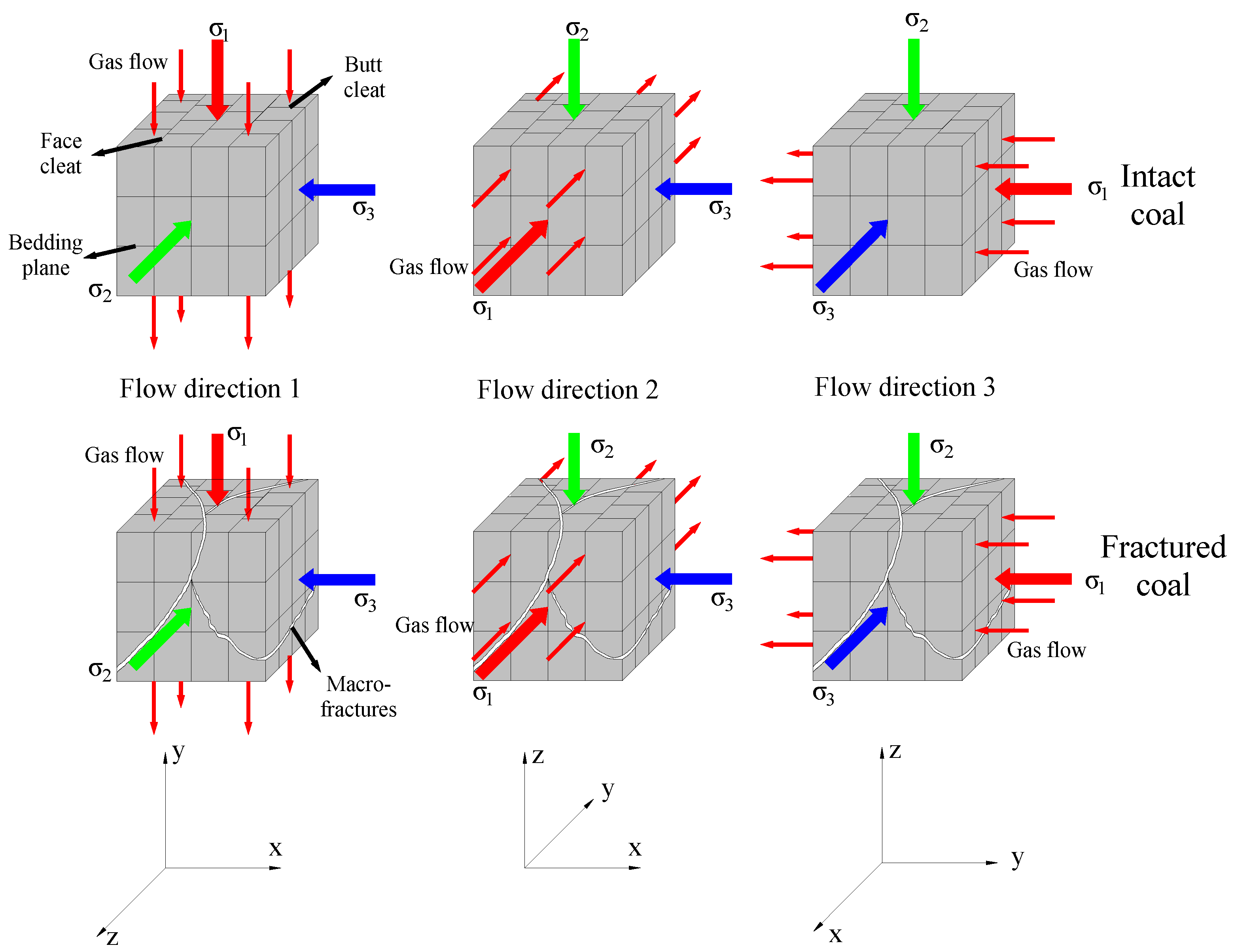

2.2. Experimental Procedure and Setup

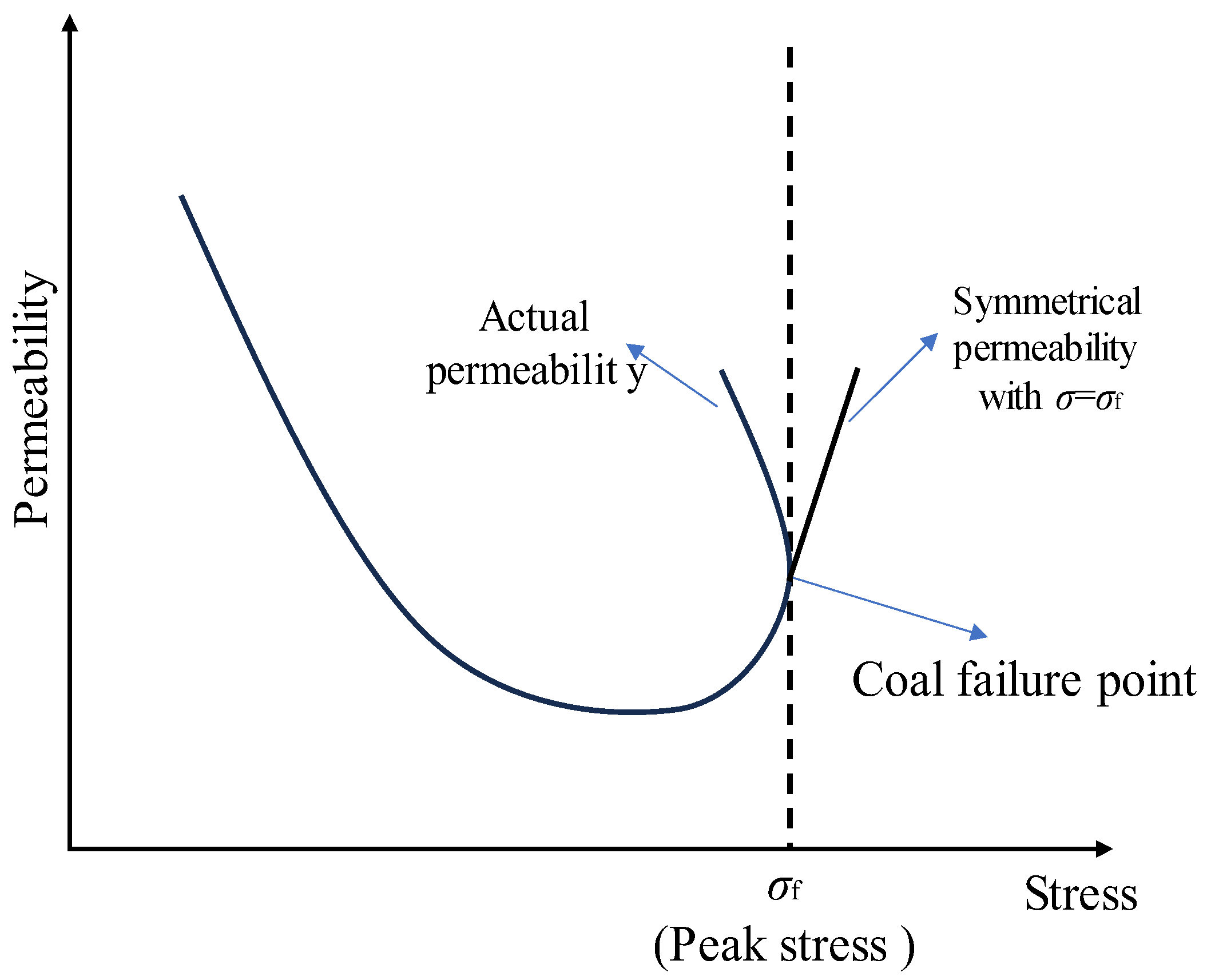

2.3. Permeability Model

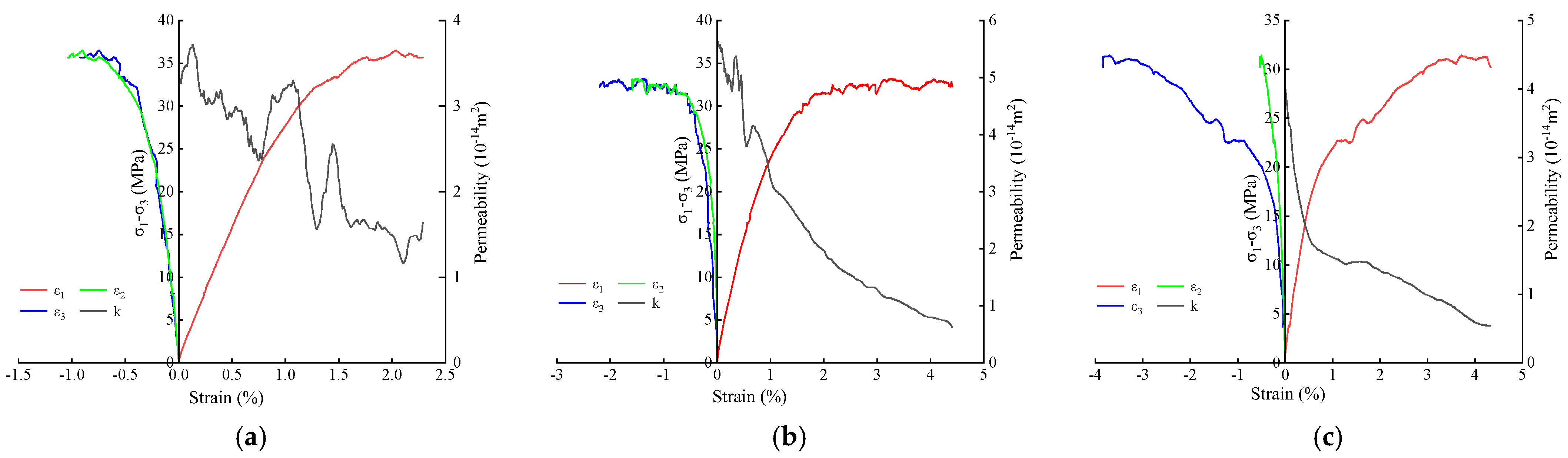

3. Results and Analysis

4. Discussion

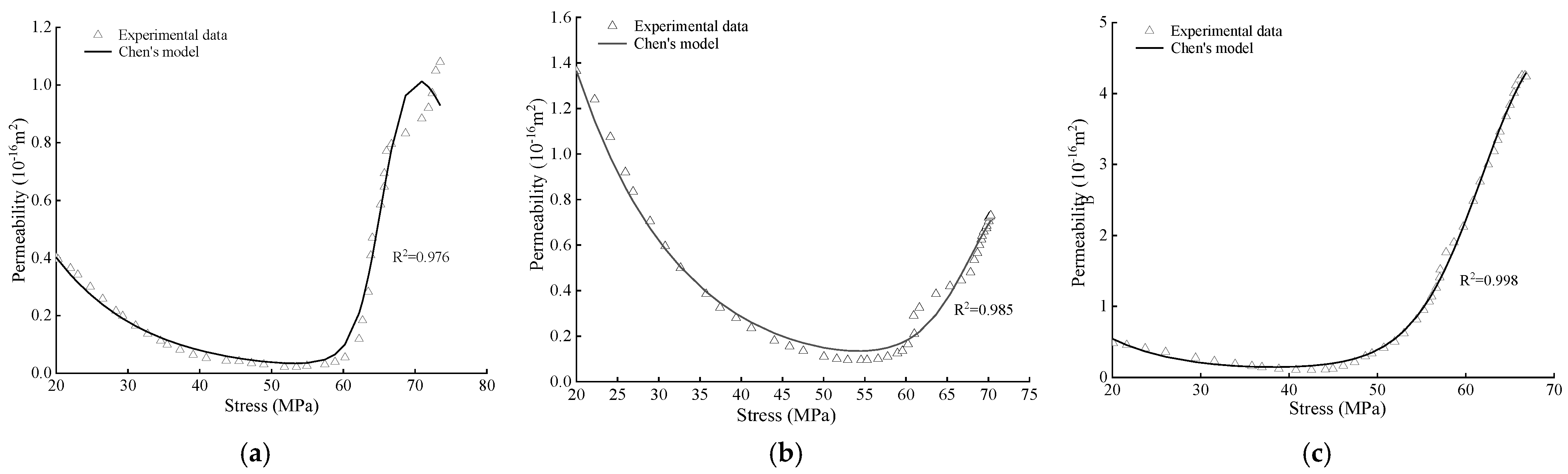

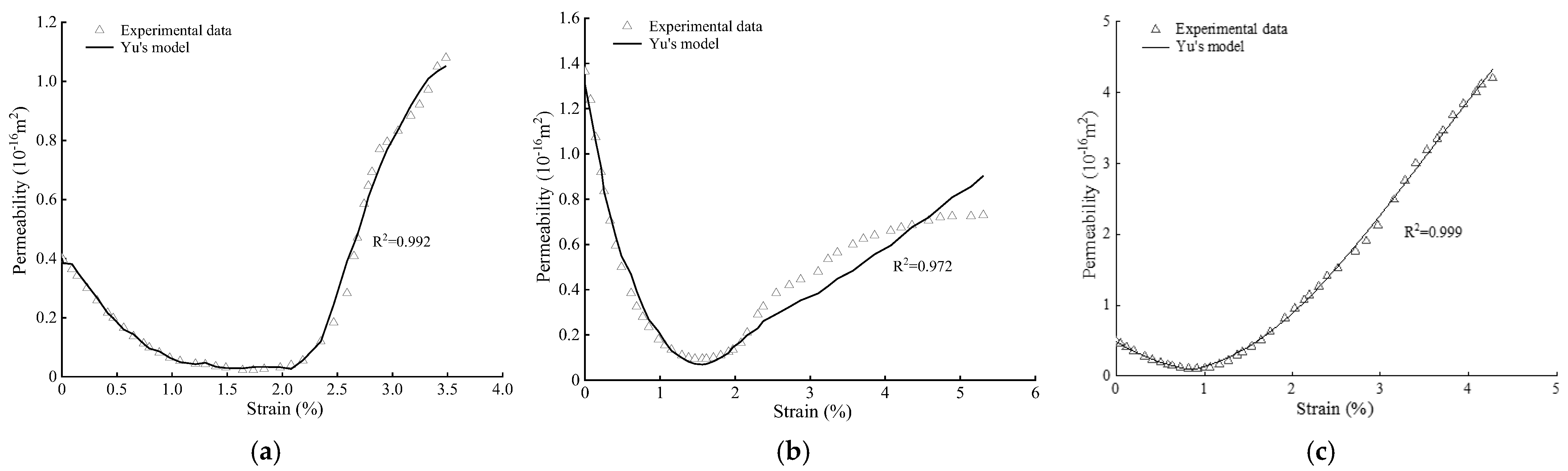

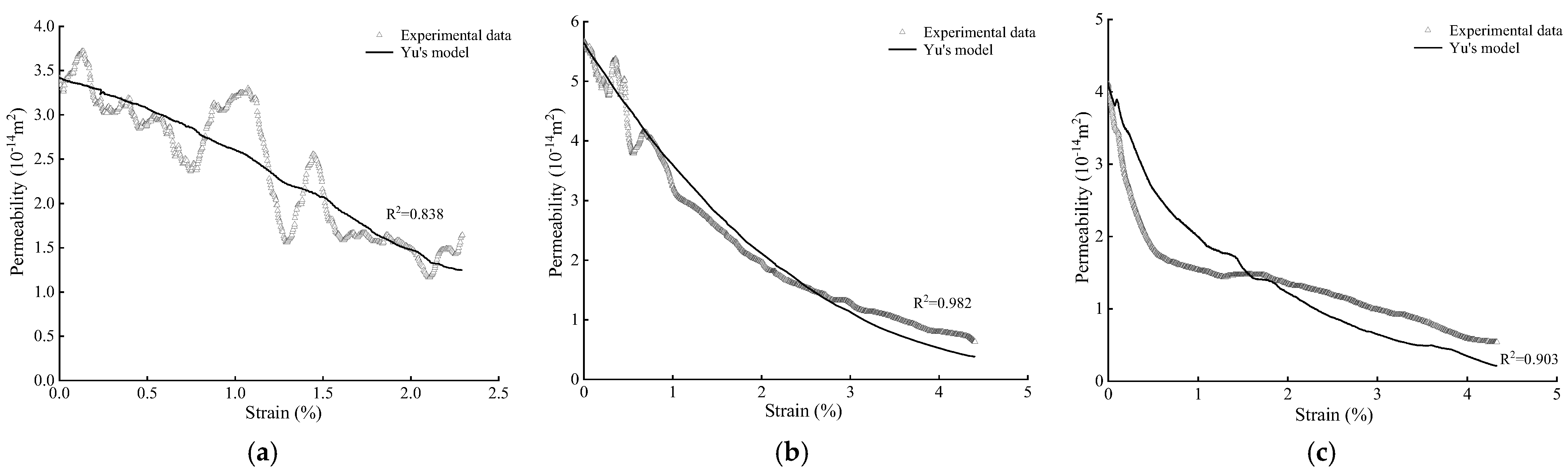

4.1. Validation of the Permeability Model

4.2. Permeability Evolution of Intact and Fractured Coal Samples

4.3. Analysis of Permeability Model Parameters in Different Flow Directions

5. Conclusions

- (1)

- The permeability of intact coal first decreased, then remained stable, then rose slowly, and finally increased rapidly after the failure strain during progressive deformation, which presented an L-shaped trend. Most of the fractured coal showed failure during progressive deformation. The permeability of fractured coal remained gradually stable after the first drop, and the overall trend was L-shaped. The permeability of intact and fractured coal exhibited anisotropy.

- (2)

- The permeability exponential and cubic models had a good fit for most of the intact and fractured coal samples in different flow directions. The mean fitting degree of permeability based on Chen’s model was 0.973, and the result based on Yu’s model was 0.948. Chen’s model had a higher fitting degree than Yu’s model in the case of permeability fluctuations.

- (3)

- The existence of macroscopic fractures increased the permeability of coal samples by 1–3 orders of magnitude. During the progressive deformation of fractured coal, the surface slips between the macroscopic fractures, resulting in permeability fluctuations. There were no permeability fluctuations in intact coal during progressive deformation. The presence of macroscopic fractures increased the slope of the curve after post-peak stress and reduced the coal compressibility and coal strength resistant to shear failure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xie, H. Research framework and anticipated results of deep rock mechanics and mining theory. Gongcheng Kexue Yu Jishu/Adv. Eng. Sci. 2017, 49, 1–16. [Google Scholar]

- Ranjith, P.G.; Zhao, J.; Ju, M.H.; De Silva, R.V.S.; Rathnaweera, T.D.; Bandara, A. Opportunities and challenges in deep mining: A brief review. Engineering 2017, 3, 546–551. [Google Scholar] [CrossRef]

- Shen, J.; Wan, L.; Zuo, J. Non-linear shear strength model for coal rocks. Rock Mech. Rock Eng. 2019, 52, 4123–4132. [Google Scholar] [CrossRef]

- Tan, Y.; Pan, Z.; Liu, J.; Zhou, F.; Connell, L.D.; Sun, W.; Haque, A. Experimental study of impact of anisotropy and heterogeneity on gas flow in coal. Part II: Permeability. Fuel 2018, 230, 397–409. [Google Scholar] [CrossRef]

- Zou, Q.; Liu, H.; Jiang, Z.; Wu, X. Gas flow laws in coal subjected to hydraulic slotting and a prediction model for its permeability-enhancing effect. Energ. Source. Part A 2021, 1–15. [Google Scholar] [CrossRef]

- Lu, S.Q.; Li, M.J.; Ma, Y.K.; Wang, S.C.; Zhao, W. Permeability changes in mining-damaged coal: A review of mathematical models. J. Nat. Gas Sci. Eng. 2022, 106, 30. [Google Scholar] [CrossRef]

- Vishal, V.; Ranjith, P.G.; Singh, T.N. CO2 permeability of Indian bituminous coals: Implications for carbon sequestration. Int. J. Coal Geol. 2013, 105, 36–47. [Google Scholar] [CrossRef]

- Viete, D.R.; Ranjith, P.G. The effect of CO2 on the geomechanical and permeability behaviour of brown coal: Implications for coal seam CO2 sequestration. Int. J. Coal Geol. 2006, 66, 204–216. [Google Scholar] [CrossRef]

- Xie, H.; Gao, F.; Ju, Y.; Gao, M.; Ru, Z.; Gao, Y.; Liu, J.; Xie, L.Z. Quantitative definition and investigation of deep mining. Meitan Xuebao/J. China Coal Soc. 2015, 40, 1–10. [Google Scholar]

- Chen, X.; Li, L.; Wang, L.; Qi, L. The current situation and prevention and control countermeasures for typical dynamic disasters in kilometer-deep mines in China. Saf. Sci. 2019, 115, 229–236. [Google Scholar] [CrossRef]

- Fairhurst, C. Some challenges of deep mining. Engineering 2017, 3, 527–537. [Google Scholar] [CrossRef]

- Ghorbani, Y.; Nwaila, G.T.; Zhang, S.E.; Bourdeau, J.E.; Canovas, M.; Arzua, J.; Nikadat, N. Moving towards deep underground mineral resources: Drivers, challenges and potential solutions. Resour. Policy 2023, 80, 15. [Google Scholar] [CrossRef]

- Wang, F.; Xiao, Z.; Liu, X.; Ren, J.; Xing, T.; Li, Z.; Li, X.; Chen, Y. Strategic design of cellulose nanofibers@zeolitic imidazolate frameworks derived mesoporous carbon-supported nanoscale CoFe2O4/CoFe hybrid composition as trifunctional electrocatalyst for Zn-air battery and self-powered overall water-splitting. J. Power Sources 2022, 521, 230925. [Google Scholar] [CrossRef]

- Li, Q.; Han, Y.; Liu, X.; Ansari, U.; Cheng, Y.; Yan, C. Hydrate as a by-product in CO2 leakage during the long-term sub-seabed sequestration and its role in preventing further leakage. Environ. Sci. Pollut. R 2022, 29, 77737–77754. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Wang, Y.; Forson, K.; Cao, L.; Zhang, C.; Zhou, C.; Zhao, B.; Chen, J. Experimental investigation on the high-pressure sand suspension and adsorption capacity of guar gum fracturing fluid in low-permeability shale reservoirs: Factor analysis and mechanism disclosure. Environ. Sci. Pollut. R 2022, 29, 53050–53062. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, E.; Li, M.; Song, Z.; Zhang, L.; Zhao, D. Mechanical response and gas flow characteristics of pre-drilled coal subjected to true triaxial stresses. Gas Sci. Eng. 2023, 111, 204927. [Google Scholar] [CrossRef]

- Yang, X.L.; Cao, J.; Cheng, X.Y.; Liu, Y.H.; Li, X.L.; Sun, Z.G.; Guo, J.J. Mechanical response characteristics and permeability evolution of coal samples under cyclic loading. Energy Sci. Eng. 2019, 7, 1588–1604. [Google Scholar] [CrossRef]

- Pan, R.K.; Cheng, Y.P.; Yuan, L.; Yu, M.G.; Dong, J. Effect of bedding structural diversity of coal on permeability evolution and gas disasters control with coal mining. Nat. Hazards 2014, 73, 531–546. [Google Scholar] [CrossRef]

- Chen, Z.Y.; Li, G.F.; Wang, Y.; Li, Z.M.; Chi, M.B.; Zhang, H.W.; Tian, Q.L.; Wang, J.H. An experimental investigation of the gas permeability of tectonic coal mineral under triaxial loading conditions. Minerals 2022, 12, 70. [Google Scholar] [CrossRef]

- Somerton, W.H.; Söylemezoḡlu, I.M.; Dudley, R.C. Effect of stress on permeability of coal. Int. J. Rock Mech. Min. 1975, 12, 129–145. [Google Scholar] [CrossRef]

- Siriwardane, H.; Haljasmaa, I.; McLendon, R.; Irdi, G.; Soong, Y.; Bromhal, G. Influence of carbon dioxide on coal permeability determined by pressure transient methods. Int. J. Coal Geol. 2009, 77, 109–118. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, E.; Zhao, D.; Zhang, L.J.S. Energy evolution characteristics of water-saturated and dry anisotropic coal under true triaxial stresses. Sustainabilitiy 2023, 15, 1431. [Google Scholar] [CrossRef]

- Kudasik, M. Investigating permeability of coal samples of various porosities under stress conditions. Energies 2019, 12, 762. [Google Scholar] [CrossRef]

- Prusty, B.K.; Pal, S.K.; Kumar, J.H. Study of porosity and permeability of coal and coal measure rocks from raniganj coalfield of India. In Proceedings of the 24th International Mining Congress of Turkey, Antalya, Turkey, 14–17 April 2015. [Google Scholar]

- Wang, G.; Qin, Y.; Shen, J.; Chen, S.Y.; Han, B.B.; Zhou, X.T. Dynamic-change laws of the porosity and permeability of low-to medium-rank coals under heating and pressurization treatments in the eastern junggar basin, China. J. Earth Sci. 2018, 29, 607–615. [Google Scholar] [CrossRef]

- Liu, Y.; Lebedev, M.; Zhang, Y.; Wang, E.; Li, W.; Liang, J.; Feng, R.; Ma, R. Micro-cleat and permeability evolution of anisotropic coal during directional CO2 flooding: An in situ micro-CT study. Nat. Resour. Res. 2022, 31, 2805–2818. [Google Scholar] [CrossRef]

- Liu, Y.B.; Wang, E.Y.; Jiang, C.B.; Zhang, D.M.; Li, M.H.; Yu, B.C.; Zhao, D. True triaxial experimental study of anisotropic mechanical behavior and permeability evolution of initially fractured coal. Nat. Resour. Res. 2023, 32, 567–585. [Google Scholar] [CrossRef]

- Ju, Y.; Zhang, Q.G.; Zheng, J.T.; Wang, J.G.; Chang, C.; Gao, F. Experimental study on CH4 permeability and its dependence on interior fracture networks of fractured coal under different excavation stress paths. Fuel 2017, 202, 483–493. [Google Scholar] [CrossRef]

- Pan, R.K.; Chen, L.; Li, Z.F.; Yu, M.G. The characteristic of micro-fracture evolution and gas permeability effect in the different bedding structure of coal. J. Nanosci. Nanotechnol. 2017, 17, 6670–6676. [Google Scholar] [CrossRef]

- Purl, R.; Evanoff, J.; Brugler, M. Measurement of coal cleat porosity and relative permeability characteristics. In Proceedings of the SPE Gas Technology Symposium, Houston, TX, USA, 22 January 1991. [Google Scholar]

- Guo, H.J.; Wang, K.; Cheng, Y.P.; Yuan, L.; Xu, C. Model development and analysis of coal permeability based on the equivalent characteristics of dual-porosity structure. J. Geophys. Eng. 2020, 17, 313–327. [Google Scholar] [CrossRef]

- Gao, Q.; Liu, J.; Huang, Y.; Li, W.; Shi, R.; Leong, Y.-K.; Elsworth, D. A critical review of coal permeability models. Fuel 2022, 326, 125124. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, J.; Elsworth, D.; Chen, Z.; Connell, L.; Pan, Z. Dual poroelastic response of a coal seam to CO2 injection. Int. J. Greenh. Gas Con. 2010, 4, 668–678. [Google Scholar] [CrossRef]

- Kumar, H.; Elsworth, D.; Mathews, J.; Marone, C.J.G. Permeability evolution in sorbing media: Analogies between organic-rich shale and coal. Geofluids 2016, 16, 43–55. [Google Scholar] [CrossRef]

- Nazarova, L.A.; Nazarov, L.A. Evolution of stresses and permeability of fractured-and-porous rock mass around a production well. J. Min. Sci. 2016, 52, 424–431. [Google Scholar] [CrossRef]

- Chen, D.; Pan, Z.J.; Shi, J.Q.; Si, G.Y.; Ye, Z.H.; Zhang, J.L. A novel approach for modelling coal permeability during transition from elastic to post-failure state using a modified logistic growth function. Int. J. Coal Geol. 2016, 163, 132–139. [Google Scholar] [CrossRef]

- Shi, J.Q.; Durucan, S. Drawdown induced changes in permeability of coalbeds: A new interpretation of the reservoir response to primary recovery. Transp. Porous Media 2004, 56, 1–16. [Google Scholar] [CrossRef]

- Palmer, I.; Mansoori, J. How permeability depends on stress and pore pressure in coalbeds: A new model. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 6–9 October 1996. [Google Scholar]

- Wang, G.; Ren, T.; Wang, K.; Zhou, A. Improved apparent permeability models of gas flow in coal with Klinkenberg effect. Fuel 2014, 128, 53–61. [Google Scholar] [CrossRef]

- Pan, Z.; Connell, L.D. Modelling permeability for coal reservoirs: A review of analytical models and testing data. Int. J. Coal Geol. 2012, 92, 1–44. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.; Yang, W. Impact of matrix–fracture interactions on coal permeability: Model development and analysis. Fuel 2017, 207, 522–532. [Google Scholar] [CrossRef]

- Zhou, H.W.; Zhao, J.W.; Su, T.; Zhang, L.; Zhong, J.C.; Liu, Z.L. Characterization of gas flow in backfill mining-induced coal seam using a fractional derivative-based permeability model. Int. J. Rock Mech. Min. 2021, 138, 104571. [Google Scholar] [CrossRef]

- Yu, B.C.; Zhang, D.M.; Li, S.J.; Xu, B.; Liu, C.; Liu, Y.B. Biot’s coefficient and permeability evolution of damaged anisotropic coal subjected to true triaxial stress. Rock Mech. Rock Eng. 2023, 56, 237–260. [Google Scholar] [CrossRef]

- Zhu, W.C.; Wei, C.H. Numerical simulation on mining-induced water inrushes related to geologic structures using a damage-based hydromechanical model. Environ. Earth Sci. 2011, 62, 43–54. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, Y.; Ning, L.; Bi, J. Permeability evolution of coal subjected to triaxial compression based on in-situ nuclear magnetic resonance. Int. J. Rock Mech. Min. 2022, 159, 105213. [Google Scholar] [CrossRef]

- Li, M.; Yin, G.; Xu, J.; Cao, J.; Song, Z. Permeability evolution of shale under anisotropic true triaxial stress conditions. Int. J. Coal Geol. 2016, 165, 142–148. [Google Scholar] [CrossRef]

- Phillips, T.; Kampman, N.; Bisdom, K.; Forbes Inskip, N.D.; den Hartog, S.A.M.; Cnudde, V.; Busch, A. Controls on the intrinsic flow properties of mudrock fractures: A review of their importance in subsurface storage. Earth-Sci. Rev. 2020, 211, 103390. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, D.; Mathews, J.P.; Pan, Z.; Elsworth, D.; Yao, Y.; Li, J.; Guo, X. Permeability evolution in fractured coal—Combining triaxial confinement with X-ray computed tomography, acoustic emission and ultrasonic techniques. Int. J. Coal Geol. 2014, 122, 91–104. [Google Scholar] [CrossRef]

- Zoback, M.D.; Byerlee, J.D. Permeability and Effective Stress1. AAPG Bull. 1975, 59, 154–158. [Google Scholar]

- Lee, K.; Advani, S. In Stress and displacement responses of porous-permeable media under thermo-mechanical loading. In Proceedings of the Arma Us Rock Mechanics/Geomechanics Symposium, Reno, NV, USA, 1–3 May 1978. [Google Scholar]

- Zhao, Y.; Wang, Z.; Ye, J.; Sun, H.; Gu, J. Lattice Boltzmann simulation of gas flow and permeability prediction in coal fracture networks. J. Nat. Gas Sci. Eng. 2018, 53, 153–162. [Google Scholar] [CrossRef]

| Direction | Elastic Modulus (GPa) | Uniaxial Compressive Strength (MPa) |

|---|---|---|

| parallel to bedding plane | 3.42 | 20.03 |

| normal to bedding plane | 2.95 | 25.28 |

| Sample ID | Elastic Modulus (GPa) | Peak Strength (MPa) | Strain at the Time of Failure (%) | Initial Permeability (×10−16 m2) | Minimum Permeability (×10−16 m2) | The Maximum Rebound Permeability (×10−16 m2) |

|---|---|---|---|---|---|---|

| Coal-int-1 | 1.89 | 62.68 | 2.47 | 0.402 | 0.022 | 1.080 |

| Coal-int-2 | 2.32 | 61.01 | 2.16 | 1.365 | 0.095 | 0.905 |

| Coal-int-3 | 2.40 | 57.11 | 2.52 | 0.484 | 0.104 | 4.256 |

| Sample ID | Initial Permeability (×10−14 m2) | Minimum Permeability (×10−14 m2) | Strain at the Time of Peak Stress (%) | Peak Stress (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|

| Coal-fra-1 | 3.419 | 1.644 | 2.29 | 34.82 | 2.99 |

| Coal-fra-2 | 5.643 | 0.630 | 4.41 | 38.19 | 3.26 |

| Coal-fra-3 | 4.109 | 1.314 | 5.55 | 41.51 | 2.48 |

| Parameter | Value |

|---|---|

| φ0 | 6.42% |

| E (GPa) | 2.1 |

| K (GPa) | 1.75 |

| Km (GPa) | 11.841 |

| Kp (GPa) | 0.597 |

| s1, s2, s3 (m) | 0.095, 0.097, 0.094 |

| b1, b2, b3 (m) | 0.005, 0.003, 0.006 |

| l (m) | 0.1 |

| Sample ID | Cf (MPa−1) | α (MPa−1) | β (MPa) | γ | R2 |

|---|---|---|---|---|---|

| Coal-int-1 | 0.0817 | 0.927 | 52.160 | 4.329 | 0.976 |

| Coal-int-2 | 0.0795 | 0.206 | 55.217 | 4.511 | 0.985 |

| Coal-int-3 | 0.1273 | 0.128 | 44.195 | 9.751 | 0.998 |

| Coal-fra-1 | 0.0111 | 1.047 | 25.973 | 0.722 | 0.992 |

| Coal-fra-2 | 0.0194 | 1.113 | 28.704 | 1.858 | 0.972 |

| Coal-fra-3 | 0.0475 | 0.787 | 25.192 | 1.074 | 0.999 |

| Sample ID | αh | R2 | Mean Slope before Failure Strain (10−14 m2) |

|---|---|---|---|

| Coal-int-1 | 0.665 | 0.924 | 0.361 |

| Coal-int-2 | 0.596 | 0.969 | 1.141 |

| Coal-int-3 | 0.629 | 0.985 | 0.477 |

| Coal-fra-1 | 0.869 | 0.838 | 1.443 × 102 |

| Coal-fra-2 | 0.756 | 0.982 | 2.277 × 102 |

| Coal-fra-3 | 0.804 | 0.903 | 1.536 × 102 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Zhao, D.; Li, Y.; Zhang, L. Permeability Evolution of Intact and Fractured Coal during Progressive Deformation Subjected to True Triaxial Stresses. Processes 2023, 11, 2826. https://doi.org/10.3390/pr11102826

Liu Y, Zhao D, Li Y, Zhang L. Permeability Evolution of Intact and Fractured Coal during Progressive Deformation Subjected to True Triaxial Stresses. Processes. 2023; 11(10):2826. https://doi.org/10.3390/pr11102826

Chicago/Turabian StyleLiu, Yubing, Dong Zhao, Yiteng Li, and Li Zhang. 2023. "Permeability Evolution of Intact and Fractured Coal during Progressive Deformation Subjected to True Triaxial Stresses" Processes 11, no. 10: 2826. https://doi.org/10.3390/pr11102826

APA StyleLiu, Y., Zhao, D., Li, Y., & Zhang, L. (2023). Permeability Evolution of Intact and Fractured Coal during Progressive Deformation Subjected to True Triaxial Stresses. Processes, 11(10), 2826. https://doi.org/10.3390/pr11102826