Predefined-Time Fuzzy Neural Network Control for Omnidirectional Mobile Robot

Abstract

1. Introduction

- (1)

- Considering the requirement of control time, the predefined-time stability is introduced into the design of trajectory tracking controller for FM-OMR. Compared with the traditional feedforward proportional controller, the parameters of the controller can not only explicitly specify the minimum upper bound of the convergence time, but also adjust the convergence process of the error within the upper bound, which improves the flexibility of the tracking control.

- (2)

- There is still a gap in the research of the combination of predefined-time theory and fuzzy neural network, and there is no exploration of relevant methods in the field of FM-OMR trajectory tracking control. The predefined-time controller combined with fuzzy neural network is proposed. The approximation of fuzzy neural network is used to reduce the influence of uncertainty and improve the tracking performance of angular velocity. The method verifies the feasibility of the combination of the two and its application in the trajectory tracking control of FM-OMR.

- (3)

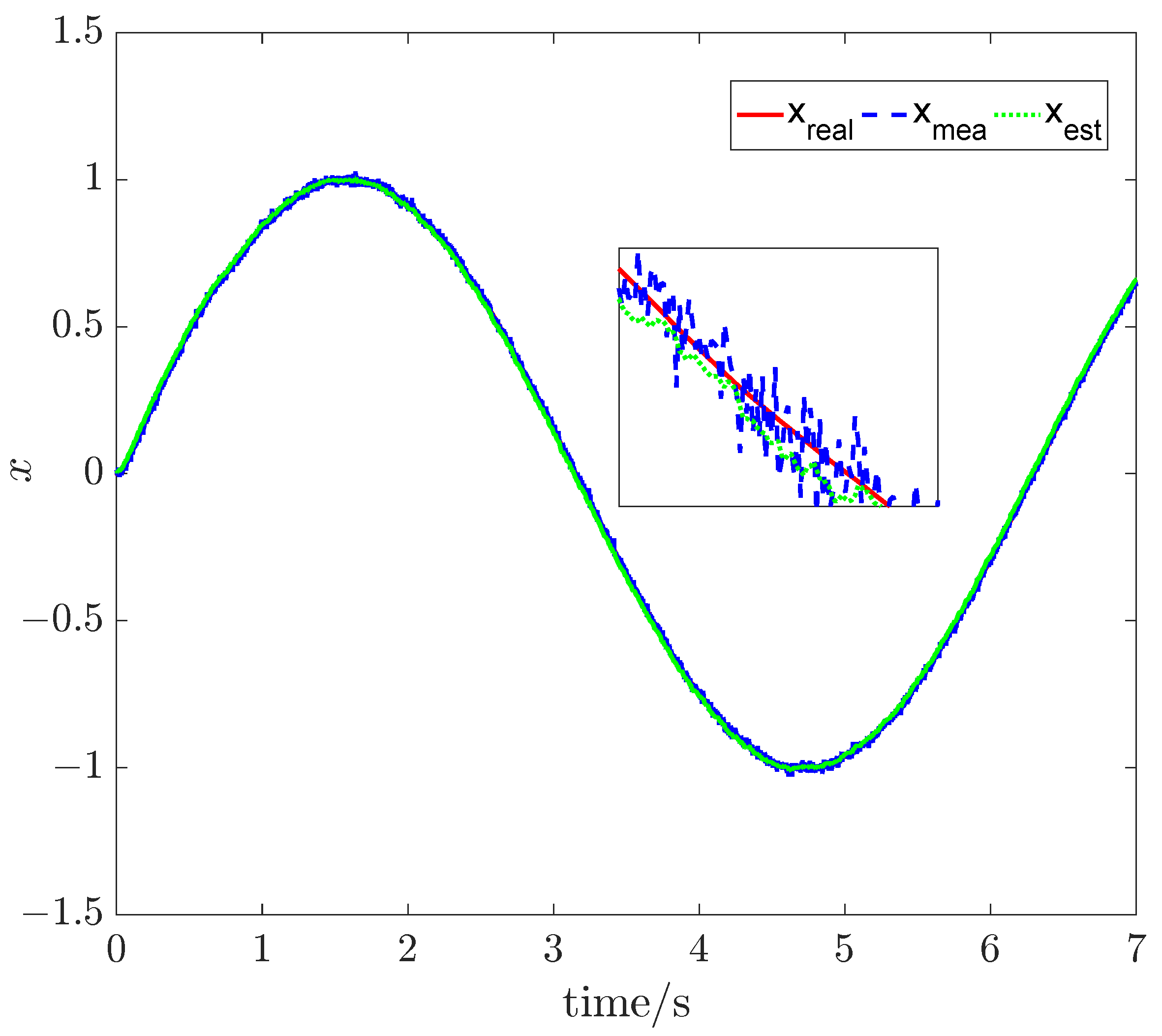

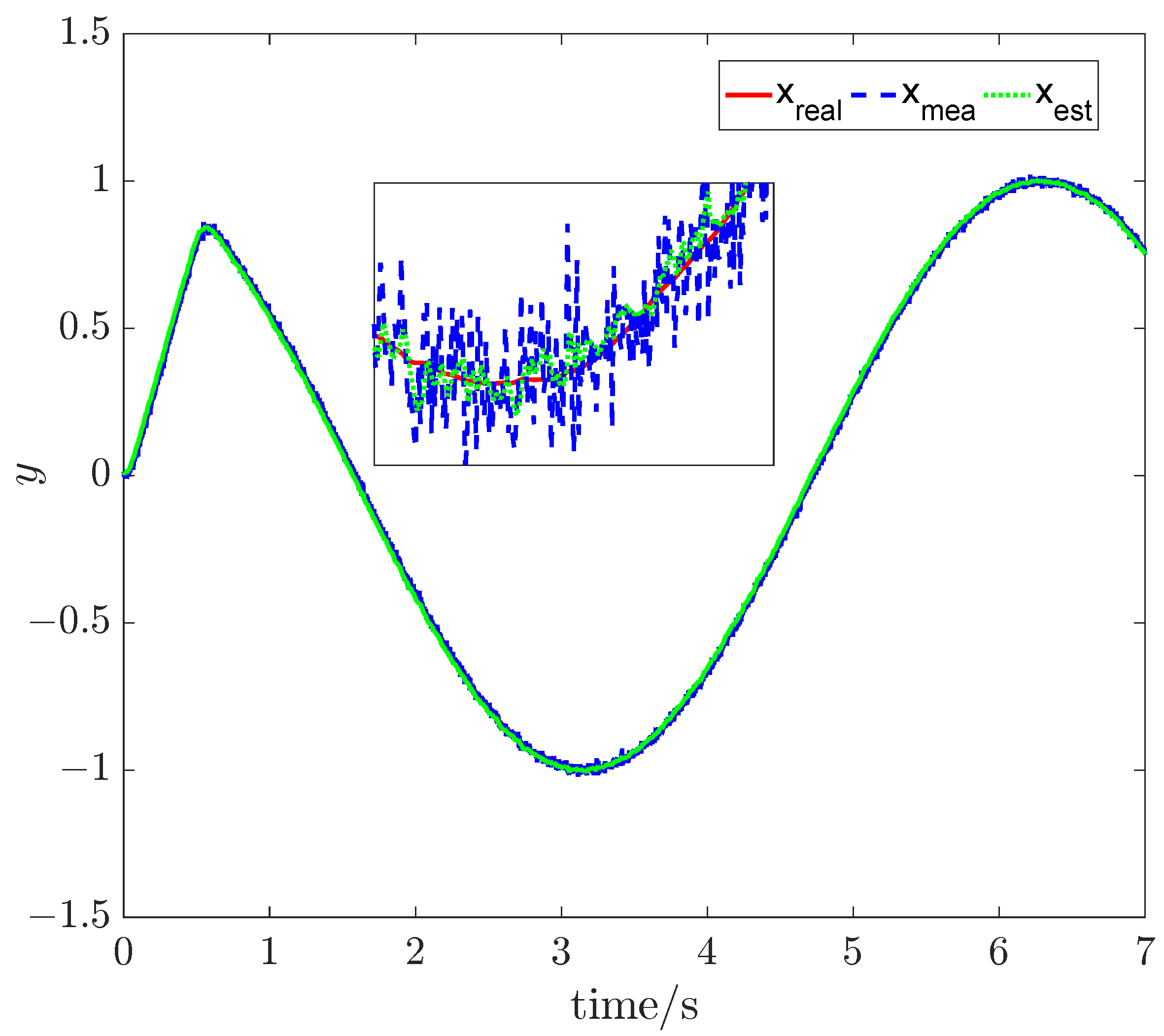

- Considering the influence of feedback noise on the system, a Kalman filter is designed to improve the quality of feedback signal.

2. Preliminaries

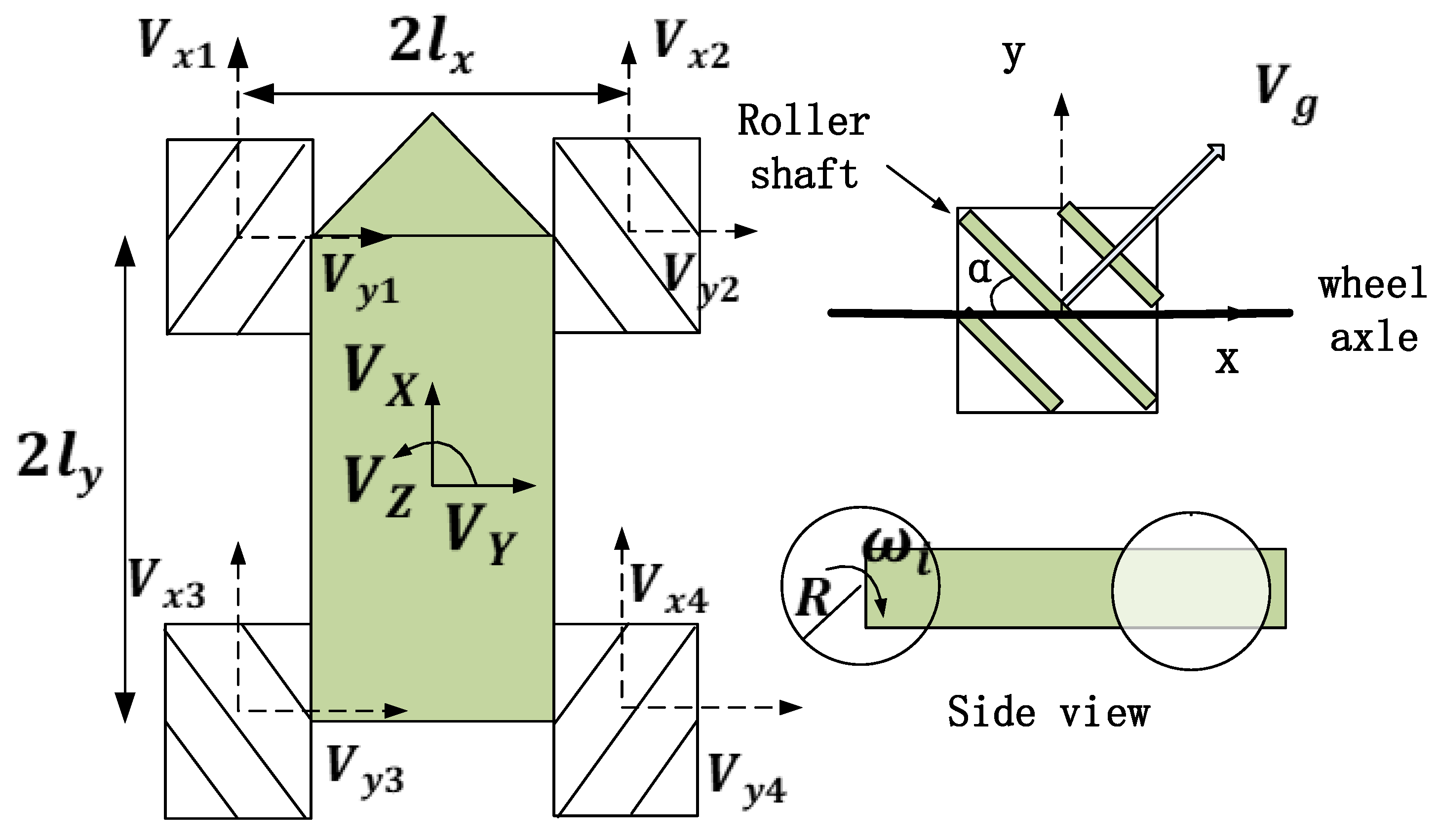

2.1. Model

2.2. Predefined Time Stability Theory

- (a)

- .

- (b)

- is bounded.

- (c)

- .

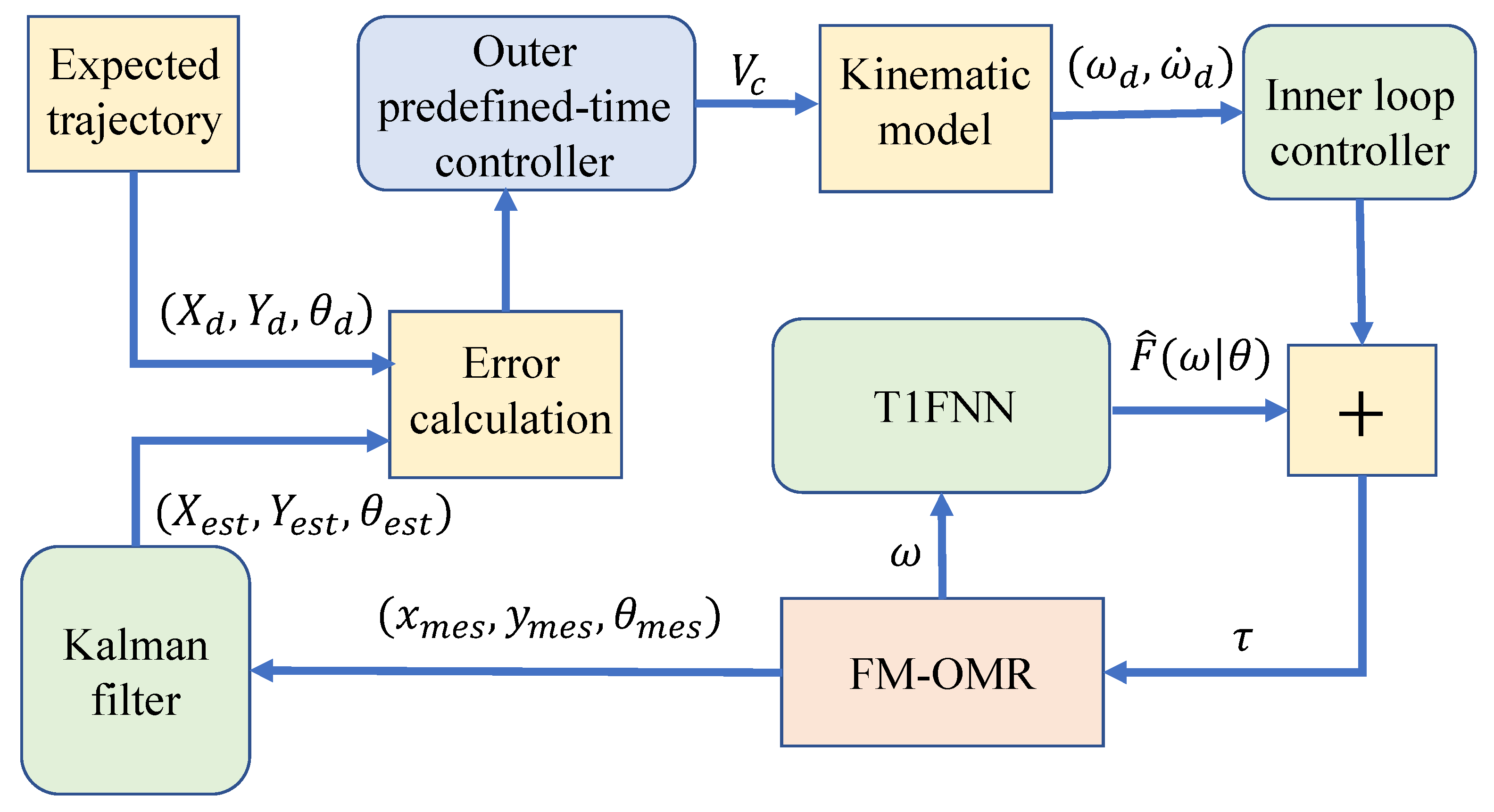

3. Control Method Design

3.1. Overall Structure of Method

3.2. Outer Loop Controller

3.3. Inner Loop Controller

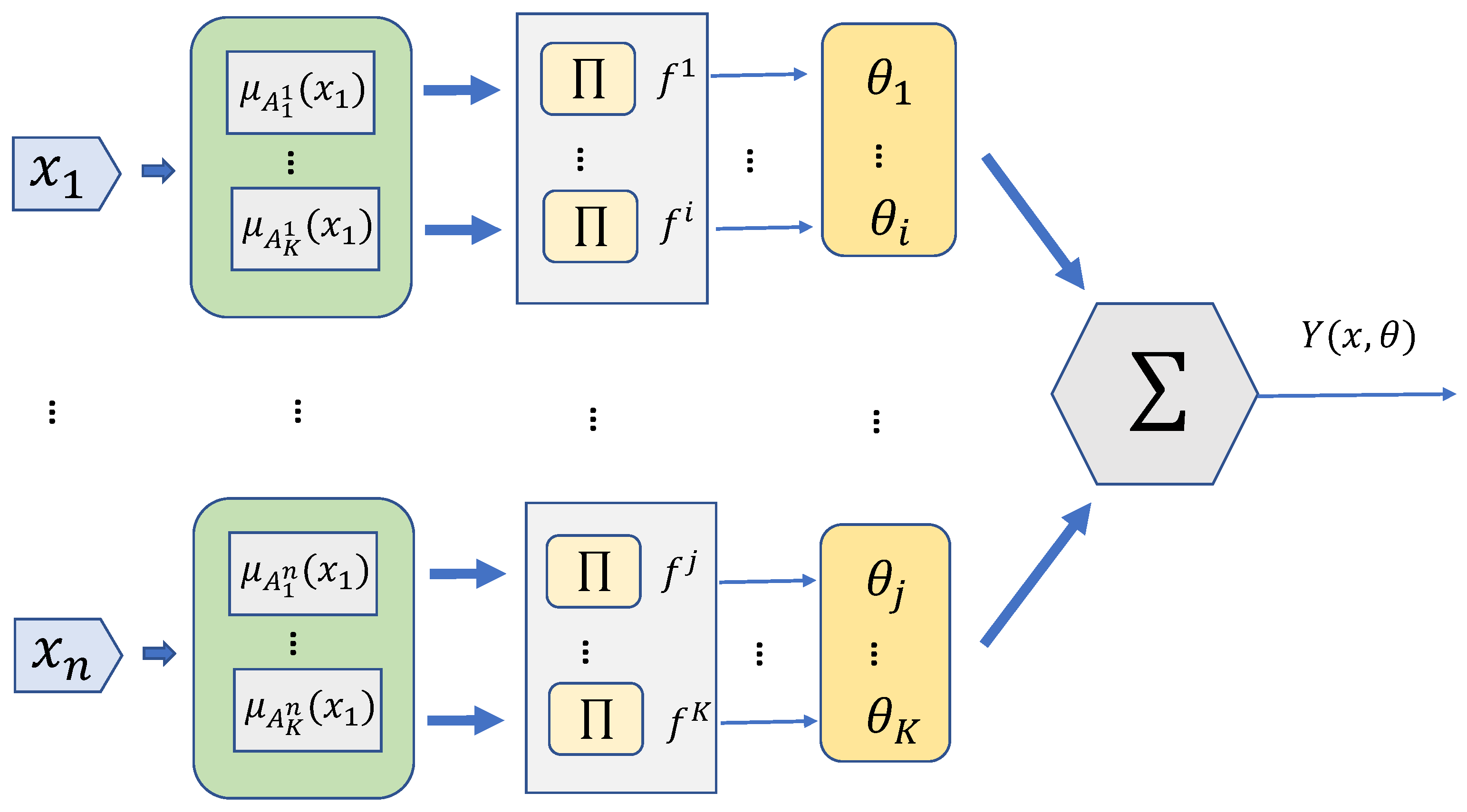

3.4. Design of T1FNN

3.5. Filter Design

4. Stability Analysis

5. Simulation

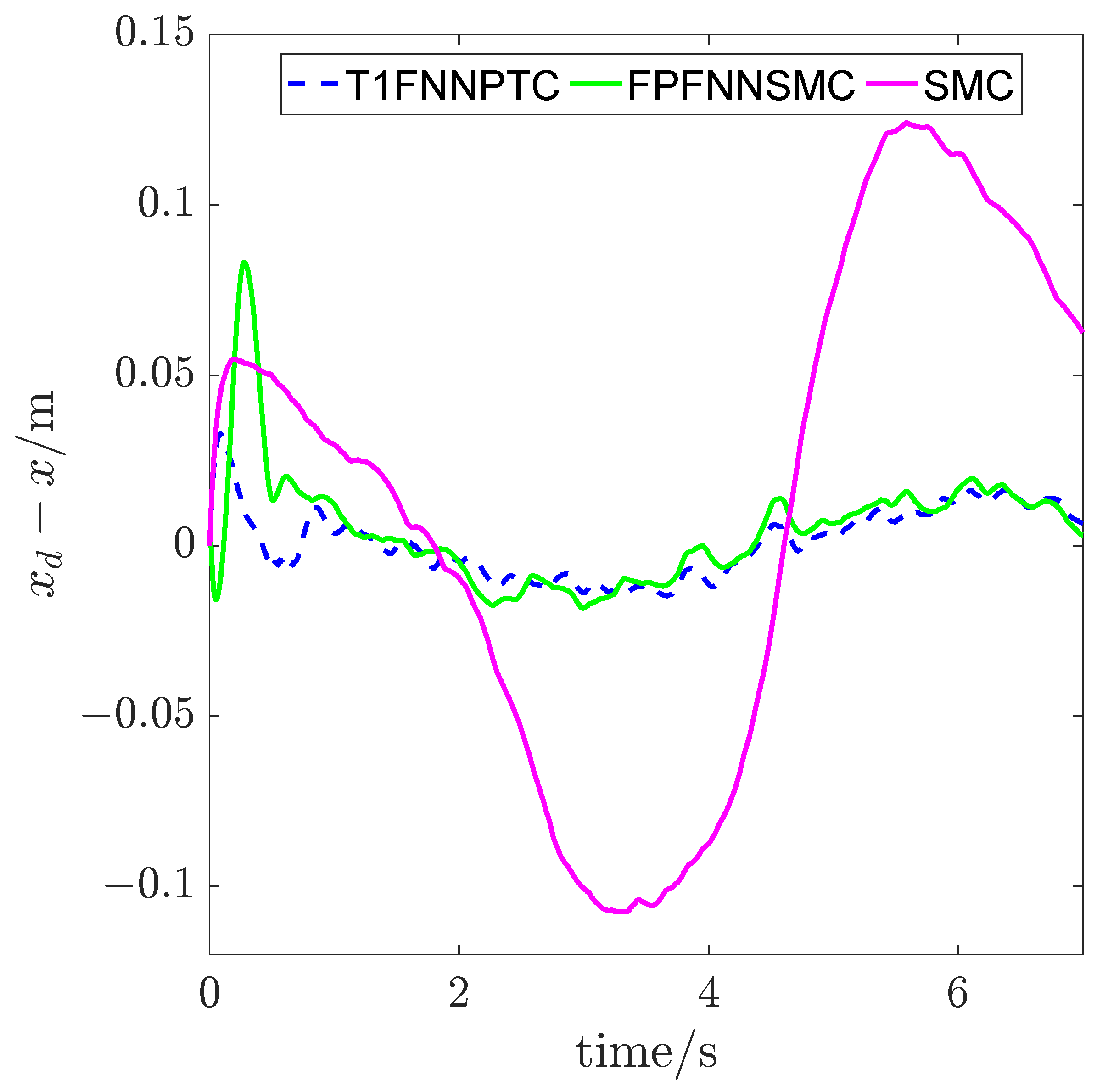

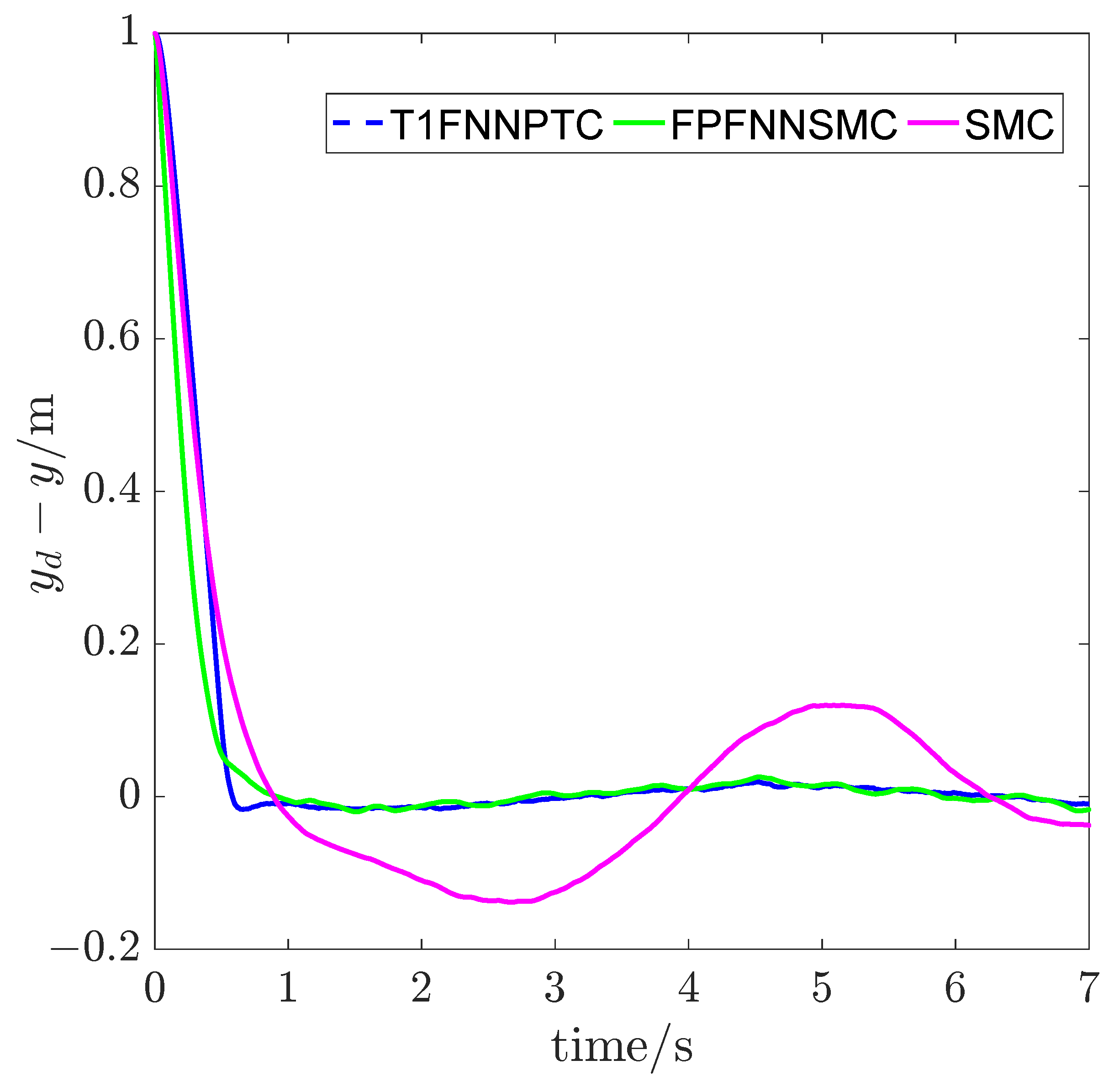

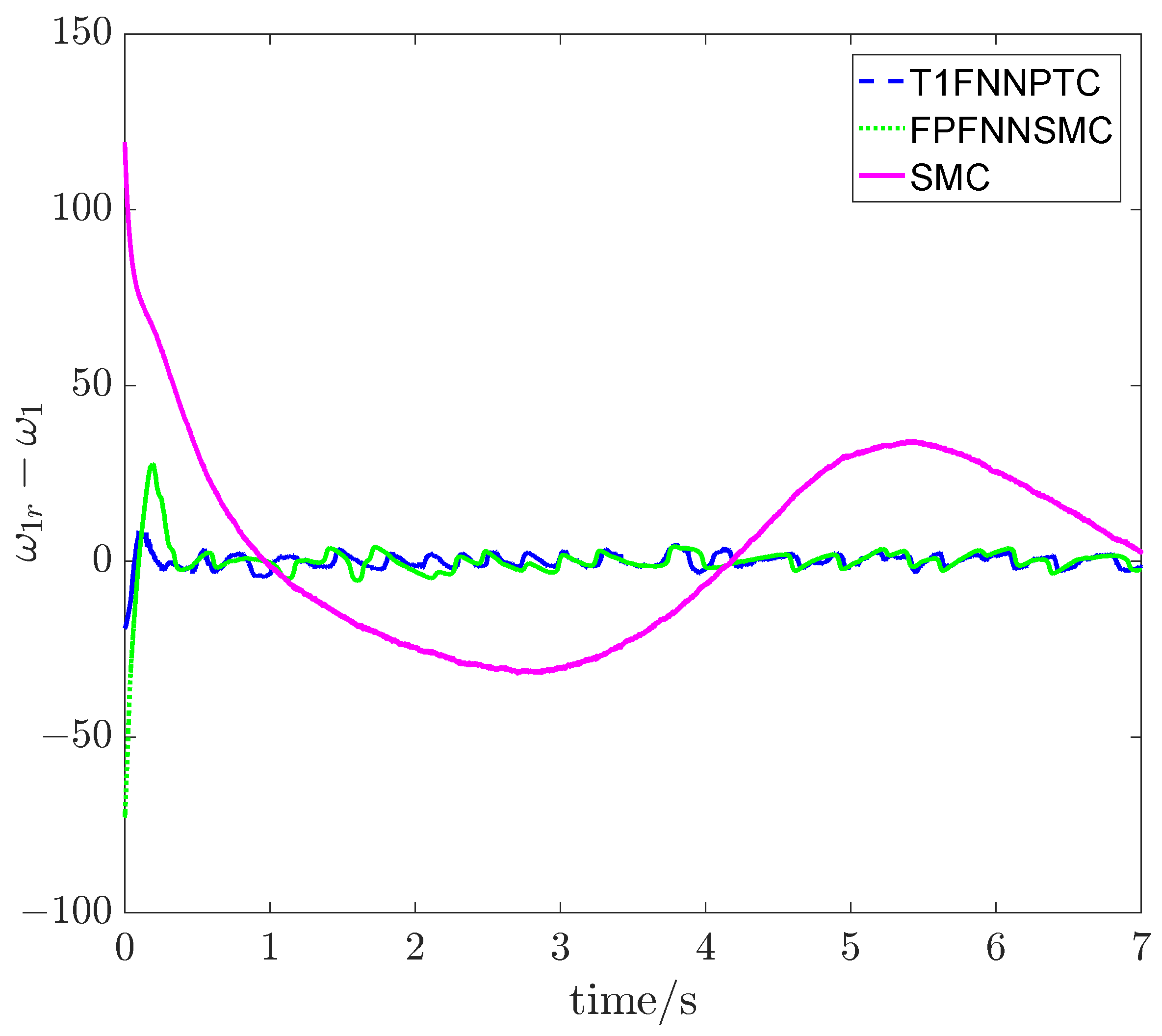

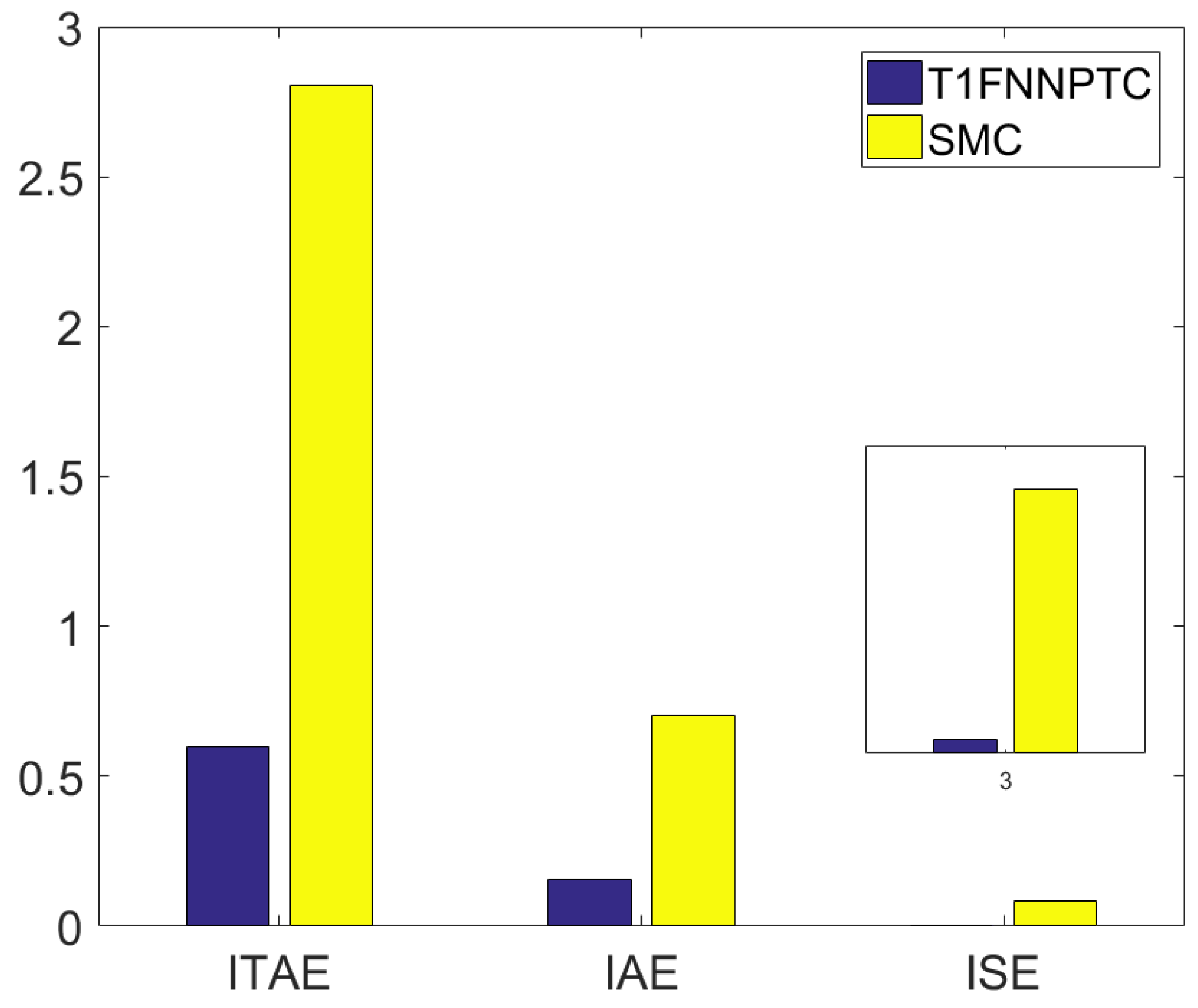

5.1. Tracking Effect

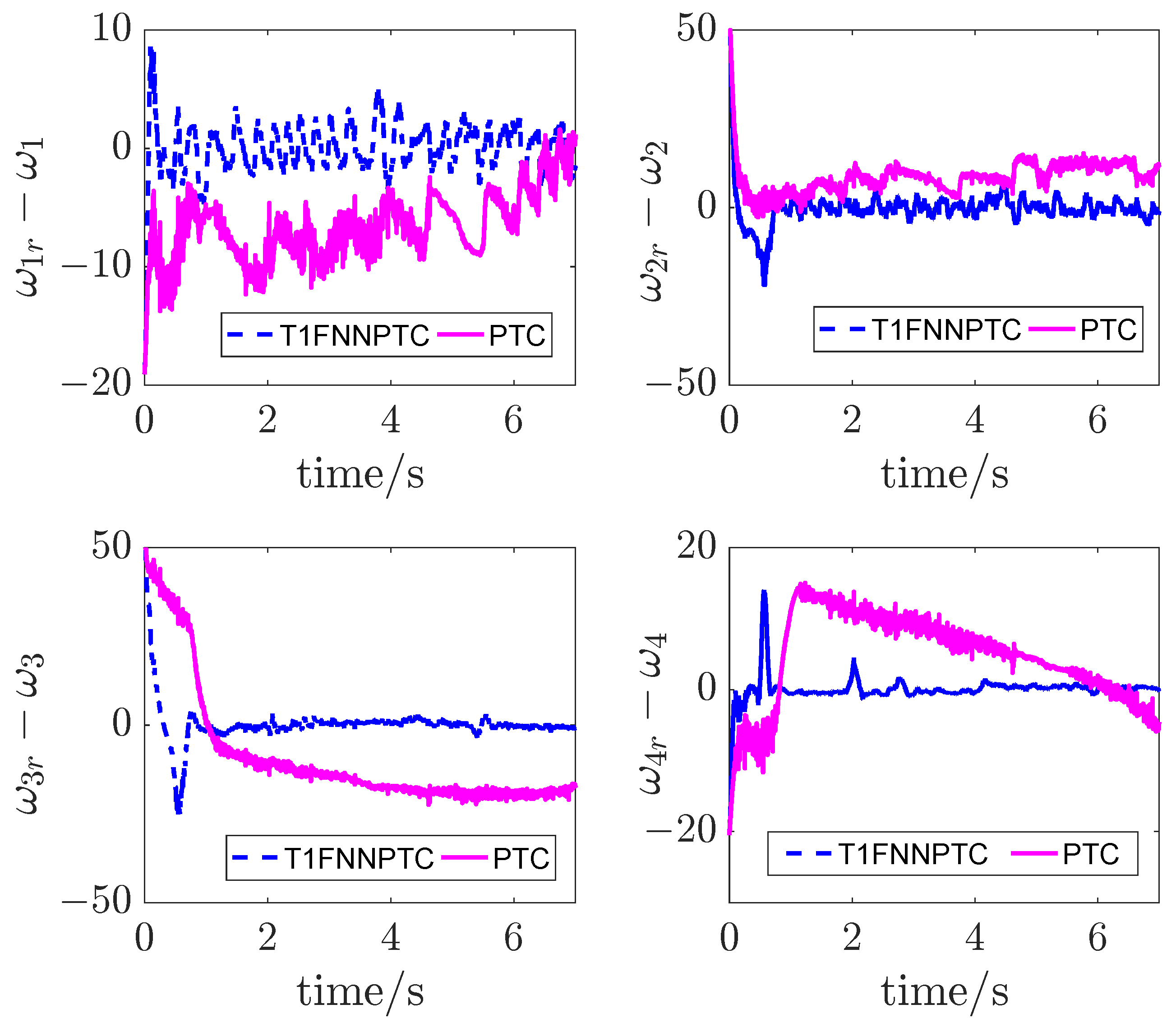

5.2. The Role of T1FNN

5.3. Filtering Effect

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guettari, M.; Gharbi, I.; Hamza, S. UVC disinfection robot. Environ. Sci. Pollut. Res. 2021, 28, 40394–40399. [Google Scholar] [CrossRef] [PubMed]

- Murphy, R.R. By the time we build robots that care for us, will we be able to care for them? Sci. Robot. 2021, 6, eabj9789. [Google Scholar] [CrossRef] [PubMed]

- Schilling, K.; Jungius, C. Mobile robots for planetary exploration. Control Eng. Pract. 1996, 4, 513–524. [Google Scholar] [CrossRef]

- Baudoin, Y.; Habib, M.; Doroftei, I. Introduction: Mobile robotics systems for humanitarian de-mining and risky interventions. In Using Robots in Hazardous Environments; Elsevier: Amsterdam, The Netherlands, 2011; pp. 3–31. [Google Scholar]

- Ruangpayoongsak, N.; Roth, H.; Chudoba, J. Mobile robots for search and rescue. In Proceedings of the IEEE International Safety, Security and Rescue Rototics, Workshop, Kobe, Japan, 6–9 June 2005; pp. 212–217. [Google Scholar]

- Schneier, M.; Schneier, M.; Bostelman, R. Literature Review of Mobile Robots for Manufacturing; US Department of Commerce, National Institute of Standards and Technology: Gaithersburg, MD, USA, 2015. [Google Scholar]

- Aravind, K.R.; Raja, P.; Pérez-Ruiz, M. Task-based agricultural mobile robots in arable farming: A review. Span. J. Agric. Res. 2017, 15, e02R01. [Google Scholar] [CrossRef]

- Gao, X.; Li, J.; Fan, L.; Zhou, Q.; Yin, K.; Wang, J.; Song, C.; Huang, L.; Wang, Z. Review of wheeled mobile robots’ navigation problems and application prospects in agriculture. IEEE Access 2018, 6, 49248–49268. [Google Scholar] [CrossRef]

- Rotondo, D.; Puig, V.; Nejjari, F.; Romera, J. A fault-hiding approach for the switching quasi-LPV fault-tolerant control of a four-wheeled omnidirectional mobile robot. IEEE Trans. Ind. Electron. 2014, 62, 3932–3944. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, X.; Zhang, G.; Jia, S. Design of adaptive sliding mode controller for four-Mecanum wheel mobile robot. In Proceedings of the 2018 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; pp. 3983–3987. [Google Scholar]

- Cao, G.; Zhao, X.; Ye, C.; Yu, S.; Li, B.; Jiang, C. Fuzzy adaptive PID control method for multi-mecanum-wheeled mobile robot. J. Mech. Sci. Technol. 2022, 36, 2019–2029. [Google Scholar] [CrossRef]

- Chen, C.P.; Ren, C.E.; Du, T. Fuzzy observed-based adaptive consensus tracking control for second-order multiagent systems with heterogeneous nonlinear dynamics. IEEE Trans. Fuzzy Syst. 2015, 24, 906–915. [Google Scholar] [CrossRef]

- Alakshendra, V.; Chiddarwar, S.S. Adaptive robust control of Mecanum-wheeled mobile robot with uncertainties. Nonlinear Dyn. 2017, 87, 2147–2169. [Google Scholar] [CrossRef]

- Wang, C.; Liu, X.; Yang, X.; Hu, F.; Jiang, A.; Yang, C. Trajectory tracking of an omni-directional wheeled mobile robot using a model predictive control strategy. Appl. Sci. 2018, 8, 231. [Google Scholar] [CrossRef]

- Yuan, Z.; Tian, Y.; Yin, Y.; Wang, S.; Liu, J.; Wu, L. Trajectory tracking control of a four mecanum wheeled mobile platform: An extended state observer-based sliding mode approach. IET Control Theory Appl. 2020, 14, 415–426. [Google Scholar] [CrossRef]

- Kwon, H.; Kim, Y. Toward Selective Membership Inference Attack against Deep Learning Model. IEICE Trans. Inf. Syst. 2022, 105, 1911–1915. [Google Scholar] [CrossRef]

- Kwon, H.; Cho, C.; Lee, J. Priority Evasion Attack: An Adversarial Example That Considers the Priority of Attack on Each Classifier. IEICE Trans. Inf. Syst. 2022, 105, 1880–1889. [Google Scholar] [CrossRef]

- Kwon, H. Defending Deep Neural Networks against Backdoor Attack by Using De-trigger Autoencoder. IEEE Access 2021, early access. [Google Scholar] [CrossRef]

- Ma, C.; Li, X.; Xiang, G.; Dian, S. A TS Fuzzy Quaternion-Value Neural Network-Based Data-Driven Generalized Predictive Control Scheme for Mecanum Mobile Robot. Processes 2022, 10, 1964. [Google Scholar] [CrossRef]

- Li, J.; Wang, J.; Peng, H.; Zhang, L.; Su, H. Neural fuzzy approximation enhanced autonomous tracking control of the wheel-legged robot under uncertain physical interaction. Neurocomputing 2020, 410, 342–353. [Google Scholar] [CrossRef]

- Zhang, Y.; Niu, B.; Zhao, X.; Duan, P.; Wang, H.; Gao, B. Global Predefined-Time Adaptive Neural Network Control for Disturbed Pure-Feedback Nonlinear Systems With Zero Tracking Error. IEEE Trans. Neural Netw. Learn. Syst. 2021, early access. [Google Scholar] [CrossRef]

- Liu, Y.; Yan, W.; Zhang, T.; Yu, C.; Tu, H. Trajectory tracking for a dual-arm free-floating space robot with a class of general nonsingular predefined-time terminal sliding mode. IEEE Trans. Syst. Man Cybern. Syst. 2021, 52, 3273–3286. [Google Scholar] [CrossRef]

- Wu, C.; Yan, J.; Shen, J.; Wu, X.; Xiao, B. Predefined-time attitude stabilization of receiver aircraft in aerial refueling. IEEE Trans. Circuits Syst. II Express Briefs 2021, 68, 3321–3325. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.W.; Xiao, J.W.; Liu, X.K. Predefined-time secondary control for DC microgrid. IEEE Trans. Ind. Electron. 2021, 69, 13504–13513. [Google Scholar] [CrossRef]

- Zhao, T.; Tong, W.; Mao, Y. Hybrid Non-singleton Fuzzy Strong Tracking Kalman Filtering for High Precision Photoelectric Tracking System. IEEE Trans. Ind. Inform. 2022, early access. [Google Scholar] [CrossRef]

- Zhao, T.; Chen, C.; Cao, H. Evolutionary self-organizing fuzzy system using fuzzy-classification-based social learning particle swarm optimization. Inf. Sci. 2022, 606, 92–111. [Google Scholar] [CrossRef]

- Zhao, T.; Cao, H.; Dian, S. A Self-Organized Method for a Hierarchical Fuzzy Logic System based on a Fuzzy Autoencoder. IEEE Trans. Fuzzy Syst. 2022, 30, 5104–5115. [Google Scholar] [CrossRef]

- Mei, Z.; Zhao, T.; Liu, N. Deep Hierarchical Interval Type 2 Self-Organizing Fuzzy System for Data-Driven Robot Control. Processes 2022, 10, 2091. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, T.; Liu, N. Fractional-Order Active Disturbance Rejection Control with Fuzzy Self-Tuning for Precision Stabilized Platform. Entropy 2022, 24, 1681. [Google Scholar] [CrossRef]

- Zhao, T.; Chen, C.; Cao, H.; Dian, S.; Xie, X. Multiobjective Optimization Design of Interpretable Evolutionary Fuzzy Systems With Type Self-Organizing Learning of Fuzzy Sets. IEEE Trans. Fuzzy Syst. 2022; early access. [Google Scholar] [CrossRef]

- Sun, Z.; Hu, S.; Li, N.; He, D. Trajectory-Following Control of Mecanum-Wheeled AGV Using Fuzzy Nonsingular Terminal Sliding Mode. In Proceedings of the 2020 4th CAA International Conference on Vehicular Control and Intelligence (CVCI), Hangzhou, China, 18–20 December 2020; pp. 342–347. [Google Scholar]

- Liang, C.D.; Ge, M.F.; Liu, Z.W.; Zhan, X.S.; Park, J.H. Predefined-time stabilization of TS fuzzy systems: A novel integral sliding mode based approach. IEEE Trans. Fuzzy Syst. 2022, 30, 4423–4433. [Google Scholar] [CrossRef]

- Alshorman, A.M.; Alshorman, O.; Irfan, M.; Glowacz, A.; Muhammad, F.; Caesarendra, W. Fuzzy-based fault-tolerant control for omnidirectional mobile robot. Machines 2020, 8, 55. [Google Scholar] [CrossRef]

- Pizá, R.; Carbonell, R.; Casanova, V.; Cuenca, Á.; Salt Llobregat, J.J. Nonuniform Dual-Rate Extended Kalman-Filter-Based Sensor Fusion for Path-Following Control of a Holonomic Mobile Robot with Four Mecanum Wheels. Appl. Sci. 2022, 12, 3560. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, T.; Sun, B.; Zhang, Y.; Khatibi, S.; Sun, M. Indoor Vision/INS Integrated Mobile Robot Navigation Using Multimodel-Based Multifrequency Kalman Filter. Math. Probl. Eng. 2021, 2021, 6694084. [Google Scholar] [CrossRef]

- Tsai, C.C.; Tai, F.C.; Lee, Y.R. Motion controller design and embedded realization for Mecanum wheeled omnidirectional robots. In Proceedings of the 2011 9th World Congress on Intelligent Control and Automation, Taipei, Taiwan, 21–25 June 2011; pp. 546–551. [Google Scholar] [CrossRef]

- Razzaghian, A. A fuzzy neural network-based fractional-order Lyapunov-based robust control strategy for exoskeleton robots: Application in upper-limb rehabilitation. Math. Comput. Simul. 2022, 193, 567–583. [Google Scholar] [CrossRef]

| Parameter | Definition |

|---|---|

| M | Inertial matrix |

| Viscous friction coefficient matrix | |

| The angular acceleration | |

| The coefficient of viscous friction | |

| The input torque | |

| The rotational inertia of the wheel | |

| The quality of robot |

| Parameters | |

|---|---|

| m | m |

| kg | m |

| Parameters | |

|---|---|

| Outerloop | , , |

| Inner loop | , |

| fuzzy set | c = [−100, −50, 0, 50, 100] |

| Kalman filter | , |

| T1FNNPTC | FPFNNSMC | |

|---|---|---|

| Overshoot peak = 0.03279 Settling time = 0.2 s | Overshoot peak = 0.08314 Settling time = 0.4654 s | |

| Overshoot peak = −0.01 Settling time = 0.554 s | Overshoot peak = 0 Settling time = 0.714 s | |

| Overshoot peak = 0.03 Settling time = 0.14 s | Overshoot peak = −0.246 Settling time = 0.404 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, P.; Zhao, T.; Liu, N.; Mei, Z.; Yan, W. Predefined-Time Fuzzy Neural Network Control for Omnidirectional Mobile Robot. Processes 2023, 11, 23. https://doi.org/10.3390/pr11010023

Qin P, Zhao T, Liu N, Mei Z, Yan W. Predefined-Time Fuzzy Neural Network Control for Omnidirectional Mobile Robot. Processes. 2023; 11(1):23. https://doi.org/10.3390/pr11010023

Chicago/Turabian StyleQin, Peng, Tao Zhao, Nian Liu, Zhen Mei, and Wen Yan. 2023. "Predefined-Time Fuzzy Neural Network Control for Omnidirectional Mobile Robot" Processes 11, no. 1: 23. https://doi.org/10.3390/pr11010023

APA StyleQin, P., Zhao, T., Liu, N., Mei, Z., & Yan, W. (2023). Predefined-Time Fuzzy Neural Network Control for Omnidirectional Mobile Robot. Processes, 11(1), 23. https://doi.org/10.3390/pr11010023