Experimental and Calculational Study on Effects of Flow Additive on Flowability of Fine Coating Particles

Abstract

:1. Introduction

2. Experiments and Methods

2.1. Materials

2.2. Experimental Procedure

2.2.1. Additive Preparation

2.2.2. Coating Powder Preparation and Characterization

2.3. Evaluation of Powder Flowability

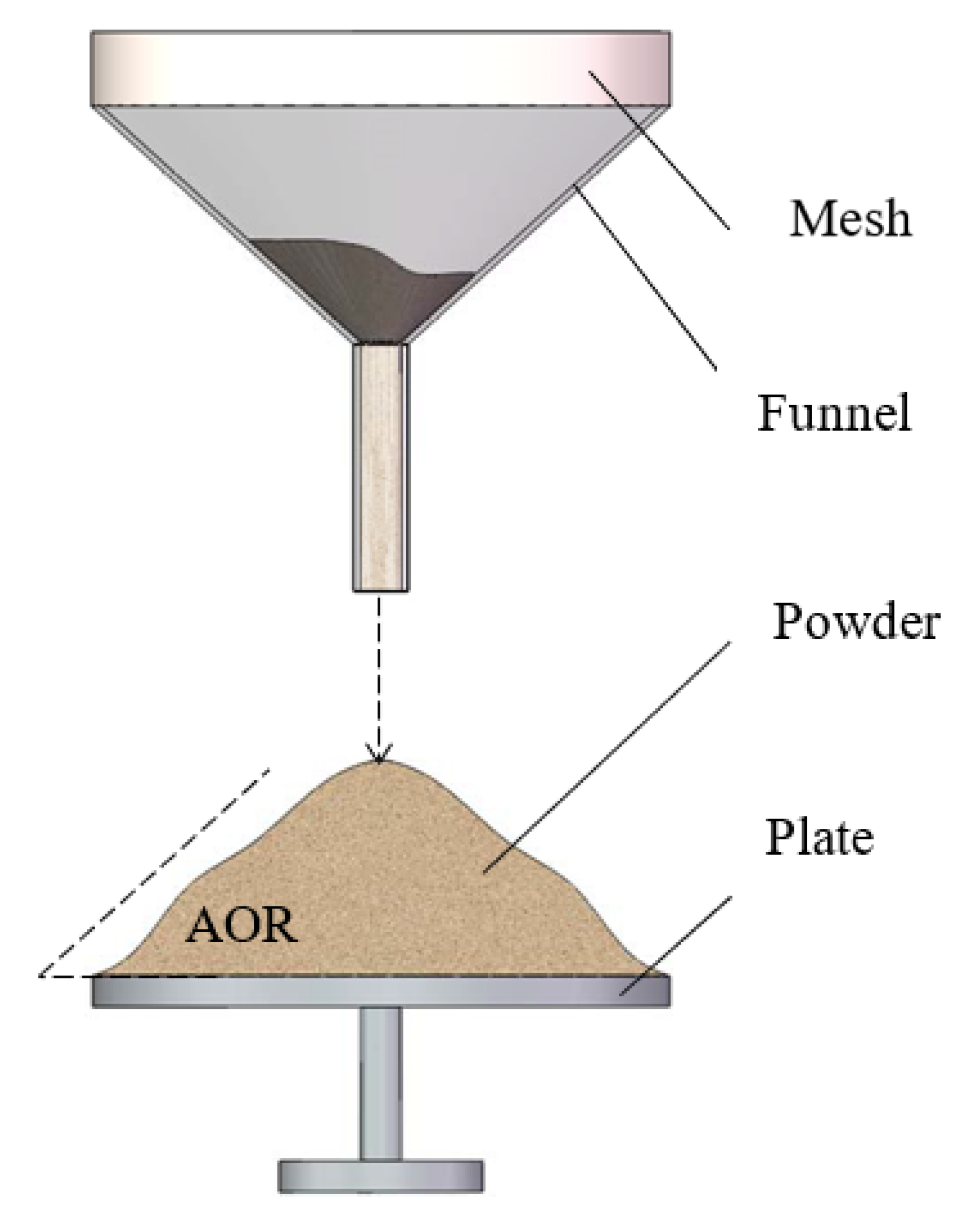

2.3.1. Angle of Repose

2.3.2. Avalanche Angle

3. Results and Discussion

3.1. Effect of Encapsulating Materials

3.2. Effect of R-E Ratio on Flowability of FPP Samples

3.3. Effect of Additive Loading Ratio on Flowability of FPP Samples

3.4. Modeling of Cohesion Force of Fine Particles with Flow Additives

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xie, J.; Zhang, H.; Shao, Y.; Bao, D.; Zhang, H.; Zhu, J. Investigation of the performance of fumed silica as flow additive in polyester powder coatings. Coatings 2020, 10, 977. [Google Scholar] [CrossRef]

- Licari, J.J. Coating Materials for Electronic Applications: Polymers, Processing, Reliability, Testing; William Andrew: Norwich, NY, USA, 2003. [Google Scholar]

- Fu, J.; Krantz, M.; Zhang, H.; Zhu, J.; Kuo, H.; Wang, Y.M.; Lis, K. Investigation of the recyclability of powder coatings. Powder Technol. 2011, 211, 38–45. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, H. Ultrafine powder coatings: An innovation. Powder Coat. 2005, 16, 39–47. [Google Scholar]

- Geldart, D. Types of gas fluidization. Powder Technol. 1973, 7, 285–292. [Google Scholar] [CrossRef]

- Dixit, K. Flow Improvement of Fine Propellant Powder Using Nano-Additives. Ph.D. Thesis, Indian Institute of Technology Gandhinagar, Palaj, Indian, 2016. [Google Scholar]

- Han, M.; Zhou, Y.; Zhu, J. Improvement on flowability and fluidization of Group C particles after nanoparticle modification. Powder Technol. 2020, 365, 208–214. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, J. Group C+ particles: Enhanced flow and fluidization of fine powders with nano-modulation. Chem. Eng. Sci. 2019, 207, 653–662. [Google Scholar] [CrossRef]

- Xu, C.C.; Zhang, H.; Zhu, J. Improving flowability of cohesive particles by partial coating on the surfaces. Can. J. Chem. Eng. 2009, 87, 403–414. [Google Scholar] [CrossRef]

- Huang, Q.; Zhang, H.; Zhu, J. Flow properties of fine powders in powder coating. Particuology 2010, 8, 19–27. [Google Scholar] [CrossRef]

- Oku, T.; Niihara, K.; Suganuma, K. Formation of carbon nanocapsules with SiC nanoparticles prepared by polymer pyrolysis. J. Mater. Chem. 1998, 8, 1323–1325. [Google Scholar] [CrossRef]

- Chen, D.; Colas, J.; Mercier, F.; Boichot, R.; Charpentier, L.; Escape, C.; Balat-Pichelin, M.; Pons, M. High temperature properties of AlN coatings deposited by chemical vapor deposition for solar central receivers. Surf. Coat. Technol. 2019, 377, 124872. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Q.; Li, Y.; Wang, N.; Zhu, J. Coating of carbon nanotubes with tungsten by physical vapor deposition. Solid State Commun. 2000, 115, 51–55. [Google Scholar] [CrossRef]

- Annat, S.; Rashtchi, H.; Atapour, M.; Golozar, M.A.; Elmkhah, H.; Zhiani, M. Preparation and performance of nanometric Ti/TiN multi-layer physical vapor deposited coating on 316L stainless steel as bipolar plate for proton exchange membrane fuel cells. J. Power Sources 2019, 435, 226818. [Google Scholar]

- Ruys, A.J.; Mai, Y.W. The nanoparticle-coating process: A potential sol-gel route to homogeneous nanocomposites. Mater. Sci. Eng. A 1999, 265, 202–207. [Google Scholar] [CrossRef]

- Bitaraf, M.; Ghazi, M.E.; Izadifard, M. Studying Structural and Optical Properties of TiO2 -SnO2 Core-Shell Synthesized by Sol-Gel Route. Cryst. Res. Technol. 2020, 55, 1900145. [Google Scholar] [CrossRef]

- Wang, Y.; Dave, R.N.; Pfeffer, R. Polymer coating/encapsulation of nanoparticles using a supercritical anti-solvent process. J. Supercrit. Fluid. 2004, 28, 85–99. [Google Scholar] [CrossRef]

- Wang, M.; Fu, Y.; Chen, G.; Shi, Y.; Li, X.; Zhang, H.; Shen, Y. Fabrication and characterization of carboxymethyl chitosan and tea polyphenols coating on zein nanoparticles to encapsulate β-carotene by anti-solvent precipitation method. Food Hydrocoll. 2018, 77, 577–587. [Google Scholar] [CrossRef]

- Johnson, K.L.; Kendall, K.; Roberts, A.D. Surface energy and the contact of elastic solids. Proc. R. Soc. London. A Math. Phys. Sci. 1971, 324, 301–313. [Google Scholar]

- Derjaguin, B.V.; Muller, V.M.; Toporov, Y.P. Effect of contact deformations on the adhesion of particles. J. Colloid Interface Sci. 1975, 53, 314–326. [Google Scholar] [CrossRef]

- Podczeck, F. Particle-Particle Adhesion in Pharmaceutical Powder Handling; World Scientific: London, UK, 1998. [Google Scholar]

- Peng, M.; Han, X.; Xiao, G.-Z.; Chen, X.-L.; Xiong, W.; Yang, K.-Y.; Luo, H. Spherical volume elements scheme for calculating van der Waals force between irregular particles and rough surfaces. Chin. J. Phys. 2021, 72, 645–654. [Google Scholar] [CrossRef]

- Shang, X.-Y.; Zhao, K.; Qian, W.-X.; Zhu, Q.-Y.; Zhou, G.-Q. On the Calculation of Van der Waals Force between Clay Particles. Minerals 2020, 10, 993. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, J.; Dave, R.N.; Pfeffer, R. Fluidization of coated group C powders. AIChE J. 2008, 54, 104–121. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, H. Fluidization Additives to Fine Powders. U.S. Patent WO2004007594A1, 22 January 2004. [Google Scholar]

- Hamaker, H.C. The London—Van der Waals attraction between spherical particles. Physica 1937, 4, 1058–1072. [Google Scholar] [CrossRef]

| Materials | Type | Suppliers | |

|---|---|---|---|

| Powder coatings | Polyurethane | -- | Seibert |

| Commercial Additive | Nano-Silica | AEROSIL®R972 | Degussa |

| Modification Materials | Epoxy | D.E.R.™ 661 | Dow |

| Polyester | CRYLCOAT®2689-0 | Cytec | |

| Hybrid | CRYLCOAT 316 | Cytec | |

| D.E.R.™ 672U | Dow |

| Additive Name | Encapsulating Resin | Resin-to-Encapsulated Additive Ratio (R-E Ratio) |

|---|---|---|

| EY-5% | Epoxy | 5% |

| EY-10% | Epoxy | 10% |

| EY-15% | Epoxy | 15% |

| EY-20% | Epoxy | 20% |

| PE-5% | Polyester | 5% |

| PE-10% | Polyester | 10% |

| PE-15% | Polyester | 15% |

| PE-20% | Polyester | 20% |

| HY-5% | Hybrid | 5% |

| HY-10% | Hybrid | 10% |

| HY-15% | Hybrid | 15% |

| HY-20% | Hybrid | 20% |

| Encapsulating Resin | Resin Ratio in Encapsulated Additive (R-E Ratio) | Loading Ratio of Additive (LOA) | |||||

|---|---|---|---|---|---|---|---|

| Control Samples | 0 | 0 | 0.3% | 0.5% | 0.8% | 1.0% | 1.2% |

| Epoxy | 5% | - | 0.3% | 0.5% | 0.8% | 1.0% | 1.2% |

| 10% | - | 0.3% | 0.5% | 0.8% | 1.0% | 1.2% | |

| 15% | - | 0.3% | 0.5% | 0.8% | 1.0% | 1.2% | |

| 20% | - | 0.3% | 0.5% | 0.8% | 1.0% | 1.2% | |

| Polyester | 5% | - | 0.3% | 0.5% | 0.8% | 1.0% | 1.2% |

| 10% | - | 0.3% | 0.5% | 0.8% | 1.0% | 1.2% | |

| 15% | - | 0.3% | 0.5% | 0.8% | 1.0% | 1.2% | |

| 20% | - | 0.3% | 0.5% | 0.8% | 1.0% | 1.2% | |

| Hybrid | 5% | - | 0.3% | 0.5% | 0.8% | 1.0% | 1.2% |

| 10% | - | 0.3% | 0.5% | 0.8% | 1.0% | 1.2% | |

| 15% | - | 0.3% | 0.5% | 0.8% | 1.0% | 1.2% | |

| 20% | - | 0.3% | 0.5% | 0.8% | 1.0% | 1.2% | |

| Loading Ratio | SAC | SHG (×1010 m2) |

|---|---|---|

| 0.01% | 1.4% | 15.08 |

| 0.3% | 42.9% | 11.28 |

| 0.5% | 71.7% | 8.64 |

| 0.7% | 100% | 6.04 |

| 0.8% | 100% | 6.94 |

| 1.0% | 100% | 8.68 |

| 1.2% | 100% | 10.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, D.; Sang, L.; Xie, J.; Zhang, H.; Zhang, H.; Zhu, J. Experimental and Calculational Study on Effects of Flow Additive on Flowability of Fine Coating Particles. Processes 2023, 11, 2. https://doi.org/10.3390/pr11010002

Bao D, Sang L, Xie J, Zhang H, Zhang H, Zhu J. Experimental and Calculational Study on Effects of Flow Additive on Flowability of Fine Coating Particles. Processes. 2023; 11(1):2. https://doi.org/10.3390/pr11010002

Chicago/Turabian StyleBao, Danni, Long Sang, Junqing Xie, Haiping Zhang, Hui Zhang, and Jesse Zhu. 2023. "Experimental and Calculational Study on Effects of Flow Additive on Flowability of Fine Coating Particles" Processes 11, no. 1: 2. https://doi.org/10.3390/pr11010002

APA StyleBao, D., Sang, L., Xie, J., Zhang, H., Zhang, H., & Zhu, J. (2023). Experimental and Calculational Study on Effects of Flow Additive on Flowability of Fine Coating Particles. Processes, 11(1), 2. https://doi.org/10.3390/pr11010002