New Generation of SF6-Free Medium-Voltage Switchgear for the Electrical Network: Stability and Toxicity Studies of Trans-1,1,1,4,4,4-Hexafluorobut-2-ene with N2 Gas Mixture

Abstract

1. Introduction

2. Materials and Methods

2.1. Reagents

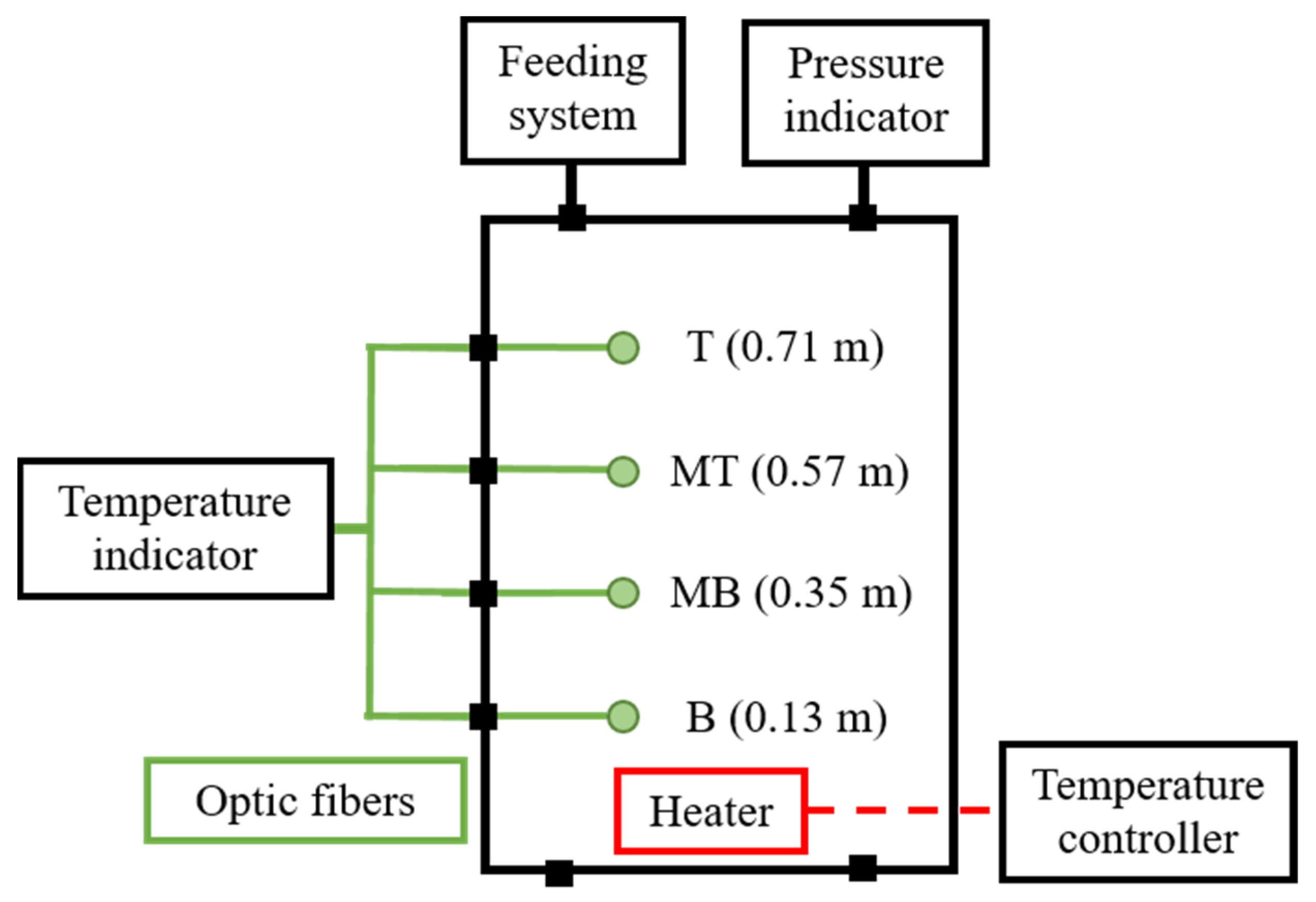

2.2. Instrumentation

2.3. Chromatographic Conditions

2.4. Characterization of HFO4E Standard

2.5. Behavior of the HFO4E and N2 Gas Mixture in the Medium-Voltage Electrical Switchgear

2.5.1. Permanent Voltage of 30 kV

2.5.2. Making Operations

2.5.3. Dielectric Tests

2.5.4. Electrical Arc Tests

2.6. Comparison of HFO4E and N2 Gas Mixture Behavior versus SF6

2.6.1. Physical Properties

2.6.2. Breakdown Voltage

2.7. OECD TG 403 Acute Toxicity Test

2.8. Influence of Temperature on HFO4E and N2 Gas Mixture Behavior in the Switchgear

3. Results and Discussion

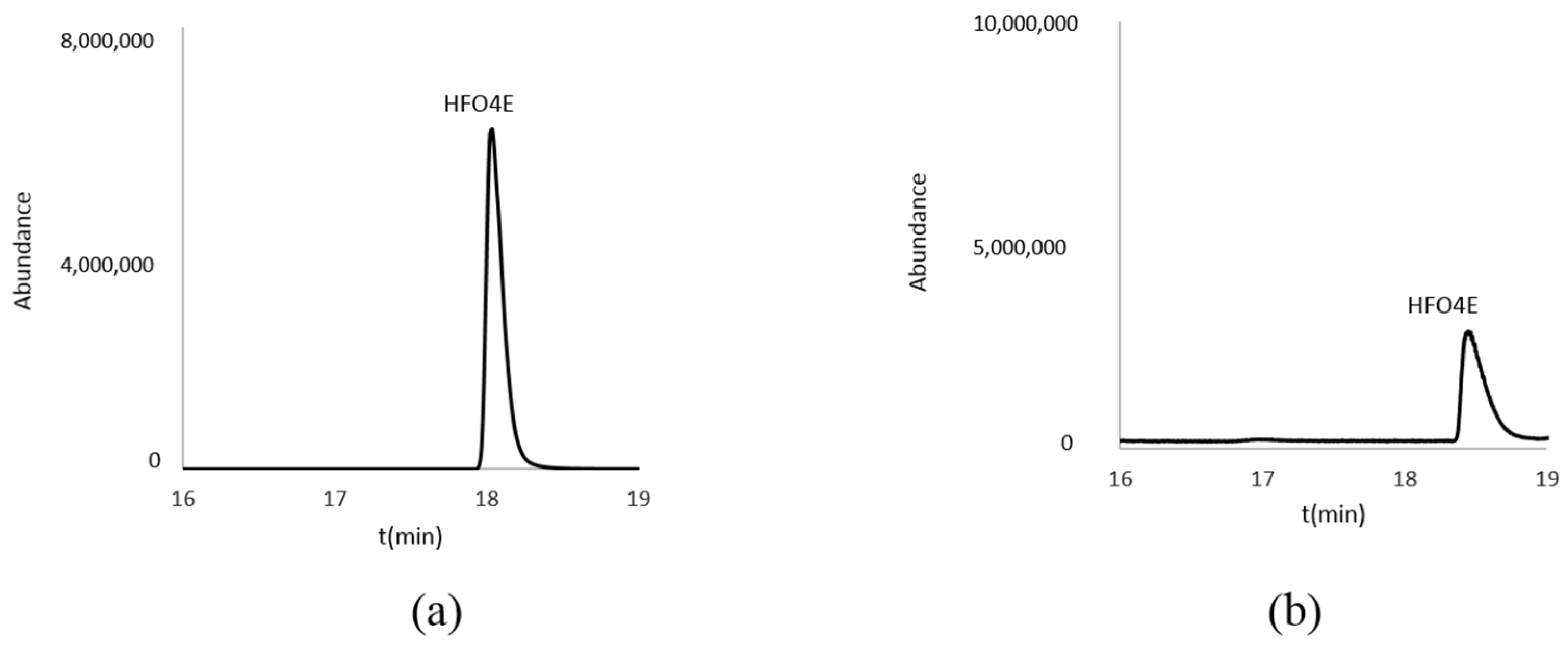

3.1. Characterization of the HFO4E Standard

3.2. GC/MS-TCD Method Validation for HFO4E

3.3. Behavior of the HFO4E and N2 Gas Mixture in the Medium-Voltage Electrical Switchgear

3.3.1. Permanent Voltage of 30 kV

3.3.2. Making Operations

3.3.3. Dielectric Tests

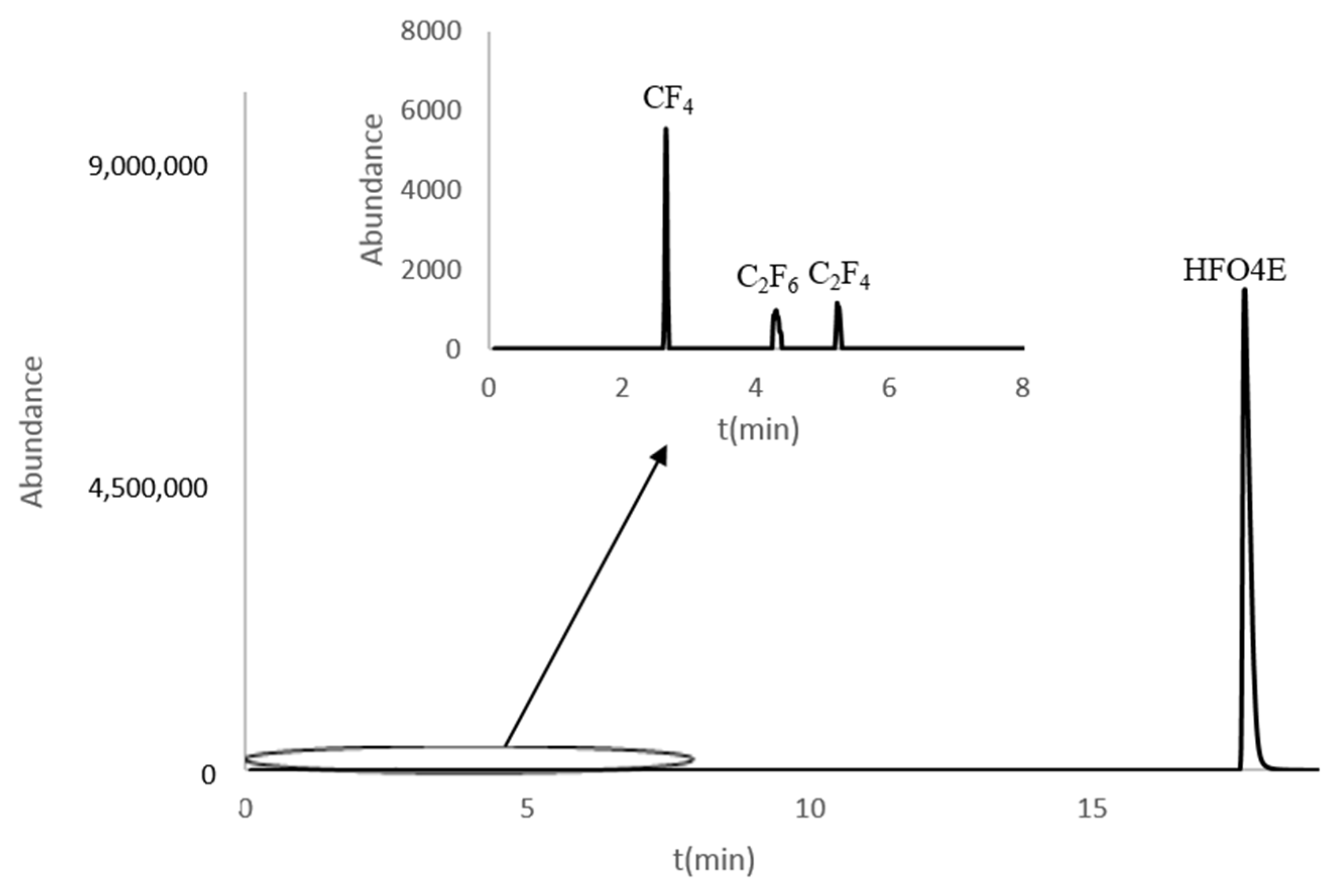

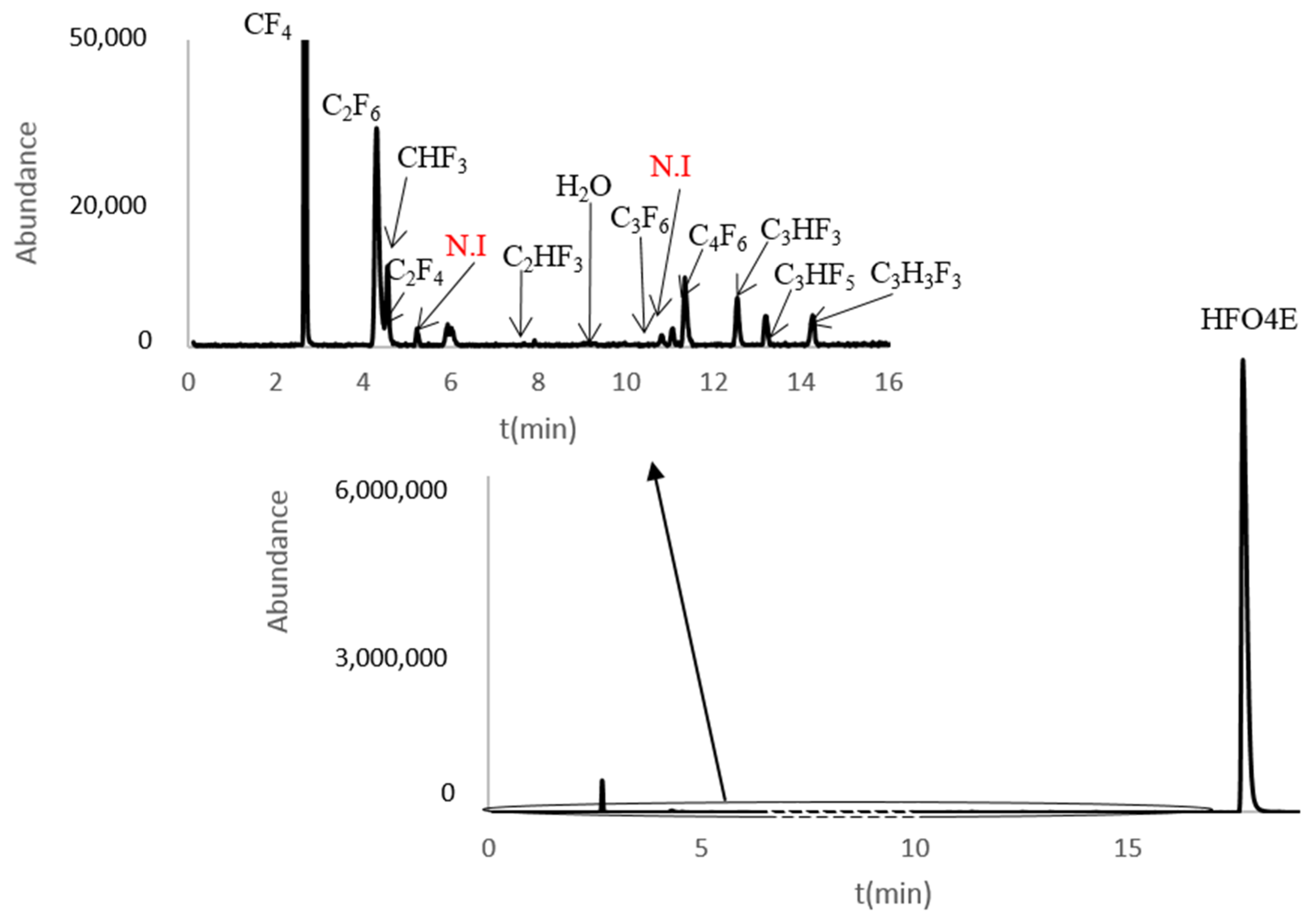

3.3.4. Electrical Arc Tests

3.4. Comparison of HFO4E and N2 Gas Mixture Behavior versus SF6

3.4.1. Physical Properties

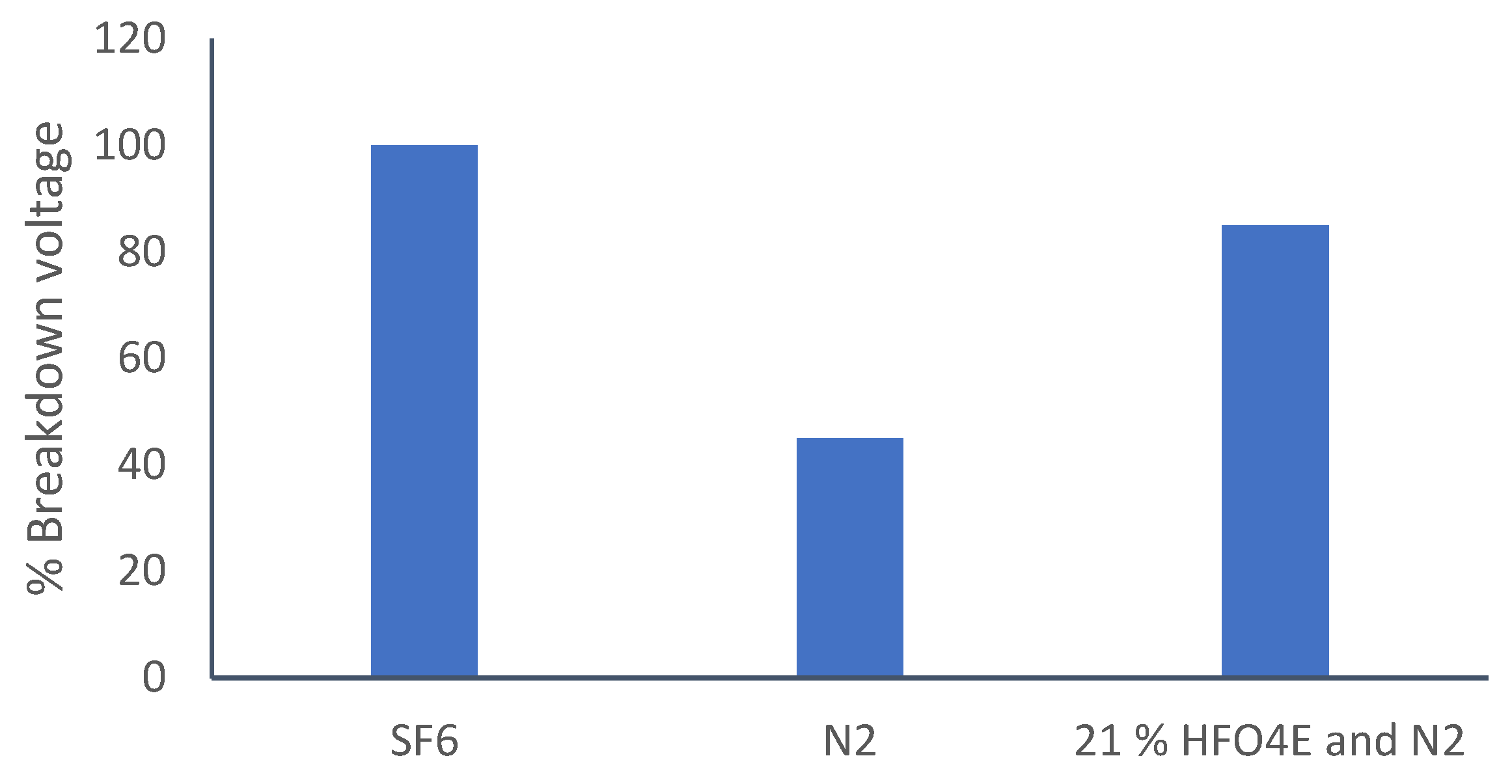

3.4.2. Breakdown Voltage

3.5. OECD TG 403 Acute Toxicity Test

3.6. Influence of Temperature on HFO4E and N2 Gas Mixture Behavior in the Switchgear

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- The Intergovernmental Panel on Climate Change. Available online: https://www.ipcc.ch (accessed on 1 September 2022).

- Tsai, W. The decomposition products of sulfur hexafluoride (SF6): Rewiews of environmental and health risk analysis. J. Fluor. Chem. 2007, 128, 1345–1352. [Google Scholar] [CrossRef]

- Regulation of the European Parliament and of the Council on Fluorinated Greenhouse Gases. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:ecf2b875-b59f-11ec-b6f4-01aa75ed71a1.0001.02/DOC_2&format=PDF (accessed on 15 December 2022).

- Tatarinov, A.V.; Bilera, I.V.; Avtaeva, S.V.; Shakhatov, V.A.; Solomakhin, P.V.; Maladen, R.; Prévé, C.; Piccoz, D. Dielectric barrier discharge processing of trans-CF3CH=CHF and CF3C(O)CF(CF3)2, their mixtures with air, N2, CO2 and analysis of their decomposition products. Plasma Chem. Plasma Process. 2015, 35, 845–862. [Google Scholar] [CrossRef]

- Seeger, M.; Smeets, R.; Yan, J.; Itod, H.; Claessens, M.; Dullni, E.; Falkingham, L.; Franck, C.M.; Gentils, F.; Hartmann, W.; et al. Recent trends in development of high voltage circuit breakers with SF6 alternative gases. Plasma Phys. Technol. 2017, 4, 8–12. [Google Scholar] [CrossRef]

- CSO. Available online: https://www.cso.go.cr/temas_de_interes/seguridad/enciclopedia/104-06.pdf (accessed on 1 July 2022).

- GAB Neumann. Available online: https://www.gab-neumann.com/Aplicaciones/$/Hydrofluoroolefins/201 (accessed on 1 July 2022).

- Alonso, M.L.; Alonso, R.M.; Lombraña, J.I.; Izcara, J.; Izagirre, J. Exploring the Decomposition Products of 1,3,3,3-Tetrafluoropropene and Perfluoro-(3-methylbutan-2-one) GasMixtures in Medium-Voltage Electrical Switchgear as Alternatives to SF6. ACS Omega 2021, 12, 21534–21542. [Google Scholar] [CrossRef] [PubMed]

- Pubchem. Available online: https://pubchem.ncbi.nlm.nih.gov (accessed on 1 September 2022).

- EP3671764A1; Low Environmental Impact Electrical Insulation System for Medium and High Voltage Electrical Switchgear. Oficina Española de Patentes y Marcas: Madrid, Spain, 2019.

- Chemours Company. Available online: https://www.chemours.com/es (accessed on 1 September 2022).

- Preve, C.; Piccoz, D.; Maladen, R. Measurements of primary and secondary emission in the supraharmonic frequency range 2–150 kHz. In Proceedings of the 23rd International Conference on Electricity Distribution, Lyon, France, 15–18 June 2015. [Google Scholar]

- Liu, J.; Wang, F.; Zhong, L.; Gan, H.; Hai, B.; Tang, N.; Li, L.; Zhou, Y. Theoretical study of the decomposition mechanism of a novel eco-friendly insulation medium HFO-1336mzz(E) considering the effect of trace humidity. J. Phys. D Appl. Phys. 2022, 55, 045201. [Google Scholar] [CrossRef]

- Li, X.-Y. (Charles River, Laboratories Preclinical Services, Montreal, QC, Canada). Personal communication, 2010.

- Beroual, A.; Haddad, A. Recent Advances in the Quest for a New Insulation Gas with a Low Impact on the Environment to Replace Sulfur Hexafluoride (SF6) Gas in High-Voltage Power Network Applications. Energies 2017, 10, 1216. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, Z.; Wang, B.; Zhou, W.; Yu, P.; Luo, Y. Synthesis and Dielectric Properties of Trifluoromethanesulfonyl Fluoride: An Alternative Gas to SF6. Ind. Eng. Chem. Res. 2019, 58, 21913–21920. [Google Scholar] [CrossRef]

- IEC 62271-200:2011. Available online: https://webstore.iec.ch/publication/6716 (accessed on 1 September 2022).

- IEC 62271-1:20. Available online: https://webstore.iec.ch/publication/32982 (accessed on 1 September 2022).

- Preve, C.; Maladen, R.; Trichon, F.; Piccoz, D. Comparison of alternatives to SF6 regarding EHS criteria. In Proceedings of the MATPOST conference, Lyon, France, 20–22 June 2019. [Google Scholar]

- EPA. Available online: https://www.epa.gov (accessed on 1 September 2022).

- U.S. National Archives and Records Administration’s Electronic Code of Federal Regulations. Available online: http://www.ecfr.gov (accessed on 1 September 2022).

- Tanaka, T.; Okamoto, H.; Ueno, K.; Irisawa, J.; Otsuka, T.; Nogami, T.; Dobashi, R. Development of a New Low-GWP Refrigerant Composed of HFO-1123 (trifluoroethylene). In Proceedings of the AIChE Annual Meeting Fundamentals of Environmental Kinetics and Reaction Engineering, Atlanta, GA, USA, 18 November 2014. [Google Scholar]

- Yuji Tech. Available online: http://www.beijingyuji.com/english/product/fluorine/Cryogen1/Hexafluoro-1-3-butadiene-C4F6.html (accessed on 1 September 2022).

- Airgas. Available online: https://www.airgas.com/msds/001138.pdf (accessed on 1 September 2022).

- McLinden, M.O.; Brown, J.S.; Brignoli, R.; Kazakov, A.F.; Domanski, P.A. Limited options for low-global-warming-potential refrigerants. Nat. Commun. 2017, 8, 14476. [Google Scholar] [CrossRef]

- EPA. Available online: https://19january2017snapshot.epa.gov/sites/production/files/2015-07/documents/f-ghg-gwp-rule_072414.pdf (accessed on 1 September 2022).

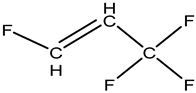

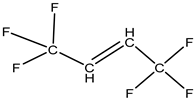

| Physicochemical Properties | SF6 [9] | HFO3E [9,10,11] Trans-1,3,3,3-Tetrafluoropropene R-1234ze(E) | HFO4E [9,12,13,14] Trans-1,1,1,4,4,4-Hexafluorobut-2-ene R-1336mzz(E) |

|---|---|---|---|

| Molecular structure |  |  |  |

| Molecular weight (g/mol) | 146 | 114 | 164.05 |

| Boiling Point (°C) | −63 | −19.4 | 7.5 |

| Dielectric strength (%SF6) | 100 | 85 | 159 |

| GWP (100 years) [1] | 25,200 | 1.37 | 17.9 |

| AcuteToxicity (LC50 4 h/rat, ppmv) | >500,000 | >200,000 | >25,400 |

| Chronic Toxicity (TWA, ppmv) | 1000 | 800 | 400 |

| Flammability | Nonflammable | Midly-flammable | Nonflammable |

| Analyte | LOD/LOQ (%)(v/v) | |

|---|---|---|

| GC/TCD | GC/MS | |

| HFO4E | 1.00/1.50 | 0.15/0.25 |

| Concentration HFO4E (%) (v/v) | Accuracy Intraday/Interday (% R) | Repeatability Intraday/Interday (% RSD) | |

|---|---|---|---|

| GC/MS | 3 | 99/98 | 5.0/6.1 |

| 20 | 101/99 | 4.2/5.0 | |

| GC/TCD | 3 | 98/98 | 4.1/5.5 |

| 20 | 99/98 | 3.7/4.3 |

| Decomposition Products under Electric Arc | Chemical Formula | tr (min) | Chromatographic Area Relative to HFO4E (%) | Molecular Weight (g/mol) | GWP (100 Years) | Toxicity (LC50 4 h/rat, ppmv) | Flammability |

|---|---|---|---|---|---|---|---|

| CF4 [4,9,21,22,23,24,25] PFC-14 Tetrafluoromethane |  | 2.7 | 1.92 | 88.04 | 7390 | 89,500 * | Nonflammable |

| C2F6 [9,22,26] PFC-116 Hexafluoroethane |  | 4.3 | 0.33 | 138.01 | 12,200 | 40,000 | Nonflammable |

| CHF3 [9] HFC-23 Trifluoromethane |  | 4.5 | 0.08 | 70.01 | 14,800 | N.A | Nonflammable |

| C2F4 [8] PFC-1114 Tetrafluoroethylene |  | 5.2 | 0.01 | 100.01 | 4 [26] | 40,000 | Flammable |

| C2HF3 [9] HFO-1123 Trifluoroethylene |  | 7.5 | 0.04 | 82.02 | 0.3 [24] | N.A | Flammable |

| C3F6 [3,9,22,25] Hexafluoropropylene |  | 10.8 | 0.01 | 150 | <5 | 1672 | Nonflammable |

| C4F6 [9,23] Hexafluoro-1,3-butadiene |  | 11.4 | 0.08 | 162.03 | <1 [24] | 1334 ** [25] | Flammable |

| C3HF3 [9] 3,3,3-trifluoroprop-1-yne |  | 12.5 | 0.05 | 94.04 | 1.4 [26] | N.A | Flammable |

| C3HF5 [9] FC-1223zc 1,1,3,3,3-Pentafluoropropene |  | 13.2 | 0.03 | 132.03 | <1 [26] | N.A | Flammable |

| C3H3F3 [9] Trifluoropropene |  | 14.2 | 0.04 | 96.05 | 0.12 [26] | 1750 ** | Flammable |

| Physicochemical Properties | Dielectric Strength (%SF6) | Dynamic Viscosity (cPoise) | Thermal Conductivity at 25 °C, 1 bar (W/mK) | Specific Heat at 25 °C, 1 bar (J/kg·K) |

|---|---|---|---|---|

| SF6 | 100 | 0.0145 | 0.0134 | 666 |

| N2 | 45 | 0.0158 | 0.0260 | 1040 |

| 21.7% HFO4E and N2 | 85 | 0.0154 | 0.0196 | 903 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alonso, M.L.; Espinazo, A.; Alonso, R.M.; Lombraña, J.I.; Izcara, J.; Izaguirre, J. New Generation of SF6-Free Medium-Voltage Switchgear for the Electrical Network: Stability and Toxicity Studies of Trans-1,1,1,4,4,4-Hexafluorobut-2-ene with N2 Gas Mixture. Processes 2023, 11, 136. https://doi.org/10.3390/pr11010136

Alonso ML, Espinazo A, Alonso RM, Lombraña JI, Izcara J, Izaguirre J. New Generation of SF6-Free Medium-Voltage Switchgear for the Electrical Network: Stability and Toxicity Studies of Trans-1,1,1,4,4,4-Hexafluorobut-2-ene with N2 Gas Mixture. Processes. 2023; 11(1):136. https://doi.org/10.3390/pr11010136

Chicago/Turabian StyleAlonso, Maria Luz, Ane Espinazo, Rosa Maria Alonso, Jose Ignacio Lombraña, Jesús Izcara, and Josu Izaguirre. 2023. "New Generation of SF6-Free Medium-Voltage Switchgear for the Electrical Network: Stability and Toxicity Studies of Trans-1,1,1,4,4,4-Hexafluorobut-2-ene with N2 Gas Mixture" Processes 11, no. 1: 136. https://doi.org/10.3390/pr11010136

APA StyleAlonso, M. L., Espinazo, A., Alonso, R. M., Lombraña, J. I., Izcara, J., & Izaguirre, J. (2023). New Generation of SF6-Free Medium-Voltage Switchgear for the Electrical Network: Stability and Toxicity Studies of Trans-1,1,1,4,4,4-Hexafluorobut-2-ene with N2 Gas Mixture. Processes, 11(1), 136. https://doi.org/10.3390/pr11010136