Abstract

Water-efficient products, a key component of water-saving technology, are widely installed and utilized in all sectors of society. Due to China’s extensive and varied use of this product, advancements in effectiveness and quality will significantly enhance people’s standard of living. In recent years, manufacturers, corporate purchasers, and individual customers have given more attention to the quality of these items due to the spike in local market and export demands for water-efficient products in China. It has been a pressing problem to find a practical solution for increasing product quality in a reasonable and scientific manner. In order to build a DECIA quality improvement model for water-efficient product quality that is quantifiable and technically practical, this paper investigates how to improve the quality of smart water closets based on six-sigma management. Thus, the development of a water-efficient industry can be green and sustainable.

1. Introduction

Water-efficient products refer to a type of daily-used device that meets certain water conservation requirements, including regular water closets, smart water closets, squat toilets, water nozzles, showers, and water purifiers. China has been the largest producer and consumer of water-efficient products in the world. Since 2010, the industry of water-efficient products has experienced rapid development, with an average annual growth rate of 10%. In 2021, the sales volume of water-efficient products in China reached 500 million units. Water-efficient products are daily necessities, so their quality directly affects water use efficiency, environmental protection, and safety. The Chinese people are better off due to the rapid economic development, which stimulates the demand for water-efficient products. As traditional production methods cannot meet the needs of energy and resource conservation and environmental protection, there is an urgent need for high-quality water-efficient products that are green and low-carbon. There will be opportunities and difficulties for the water-conservation device market as a result of the trend toward utilizing high-quality, water-efficient products and a healthy lifestyle. However, there is little research conducted in this area, especially concerning the theory and technology of water-efficient upgrades, and therefore they are unable to influence the process of product development.

Smart water closets were introduced in China in the 1990s, and their popularity has exploded over the past decade. China is currently the world’s largest manufacturer and distributor of smart water closets. As living standards continue to rise, so do consumer demands and requirements for items that use less water. Consumers readily accept and buy smart water closets with humanized and personalized features, such as warm water cleansing, warm air drying, automatic deodorization, music, and health monitoring. These features have made smart water closets an integral part of home furnishing. Roughly 10 million sets of smart water closets were sold in China in 2021, a nearly 130% increase from 2016. Along with the fast spread of smart water closets, quality has been widely concerned by consumers. A smart water closet is a high-power wading electrical product that is powered by highly complicated technology that spans a variety of industries and specialties, including water, electricity, heating, machinery, sensing, injection molding, welding, etc. When using, it is common to have issues with controlling the temperature of warm air, water efficiency, input power and current, and grounding procedures. For the steady and quick development of the industry, it is imperative to create a quality model that analyzes the influencing and evaluating variables of the quality of smart water closets over the entire life cycle.

The first section of this paper examines the current research findings on Six Sigma management. The DECIA model of water-efficient product quality improvement, which is based on the DMAIC model in the Six Sigma framework, is studied in the second section. The five dimensions of the model’s construction are definition, assessment, inspection, improvement, and application. On the basis of a case study involving smart water closets, the contents of each dimension were then introduced. Finally, a few ideas and actions were put out to raise the standard of water-efficient products in accordance with the DECIA model.

2. Research Status

Motorola was the first company to embrace Six Sigma, and it has since gained widespread acceptance throughout the world, particularly in the manufacturing, service, government, and other institutions or enterprise management sectors. It has developed into a sophisticated management style that offers businesses significant financial advantages [1]. Through business process re-engineering and procedure optimization, Six Sigma management is intended to increase the effectiveness of enterprise management in a scientific and efficient manner. It is also known as the DMAIC model for short since it comprises the five stages of Define, Measure, Analyze, Improve, and Control in its application to quality improvement [2]. DMAIC is a cycle of continuous improvement and promotion that combines project management, schedule management, and statistical analysis. Table 1 shows the processes, techniques, and technologies under the DMAIC process, which provides a solution to intricate and systematic issues [3].

Table 1.

Key points and tools of DMAIC process activities.

Six Sigma management starts with D for Define, which stands for the definition of a problem and boundaries. The definition of the issues to be resolved and the goals to be attained is necessary for this demand analysis step, setting the fundamental groundwork for project implementation [4,5,6]. The purpose of M for Measure, also known as the assessment of project improvement, is to identify the measurement indicators that demand improvement with a focus on detecting issues. To assist the reflection of shortcomings and process obstacles, it is necessary to gather a sizable amount of data from the project’s operational phases [7]. In order to accurately reveal the project’s causality, A for Analysis is the key to identifying problems that require transformation and examining their internal logical relationships in light of feedback returns from the measured data. I for Improve refers to the process of problem-solving through iteration and bridging the gap between the measurement indicator and the goal by adhering to the technical path and solution designed for project improvement based on the analysis results and the thorough consideration of factors like cost. The final stage of the model, C for Control, which stands for controlling the project, is crucial to sustaining the project’s ability to improve in order to support continuous improvement. The entire process of creating improvements needs to be monitored to ensure that they are resolved permanently [8,9].

The DMAIC approach has been widely employed in industrial manufacturing [10,11,12] to effectively decrease defects or errors resulting from manual handling, materials, processes, machinery, or environment [13,14]. In addition, the DMAIC approach can be implemented in the urban service sector, government agencies, and other regulatory departments [4] in order to minimize handling errors caused by people or systems. Successful DMAIC applications have been made in service sectors including banking [15,16], education [17,18], hospitals [19,20], etc. The following are benefits of the DMAIC model. First, it is a data-driven model. As the project is completed, statistics are gathered to identify difficulties with an emphasis on a data-driven strategy. Secondly, it focuses on continuous improvement. The DMAIC is a model that is continuously optimized and iterated until the measurement index reaches the target [18,21]. Thirdly, it emphasizes the shift in thinking style. Since DMAIC optimizes company culture beyond a mere instrument, it adds fresh significance to the initial project for improvement by altering employees’ thinking and behavior [22]. However, DMAIC has inherited drawbacks. First, the reasonability of the boundary and problem definition in the DMAIC model will directly affect the subsequent measurement, analysis, improvement, and control links. Definition errors could lead to project delays or even project failure. Second, it is unclear how the improvement cycle works. The DMAIC model places an emphasis on studying the process of quality improvement, but disregards the completion of the improvement cycle, leading to unmanageable expenses and service quality. Third, it discourages innovation. The DMAIC model streamlines the procedure, emphasizes its uniformity, and lowers the dynamic of innovation.

The boundary issues for items that conserve water are defined by the green, leader, and green indicator systems. The evaluation system for water-efficient products is formed by national, industrial, or association standards with distinct cycles for change and review. Such standards also provide technical support for policies that have been issued relating to water-efficient products. In addition, innovative procedures and product lines will drive the development of water-efficient products in order to meet assessment requirements. In conclusion, the DMAIC model’s advantages can be utilized while avoiding its drawbacks by taking into account the industry’s current features when improving water-efficient products.

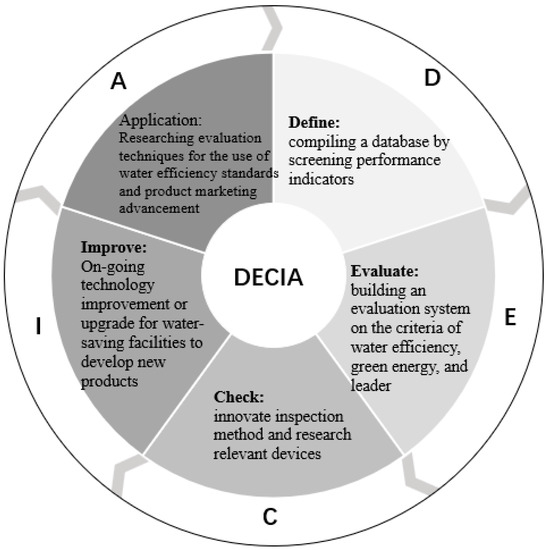

3. Construction of Water-Efficient Product Quality Improvement Model

Taking into consideration the features of water-efficient products and based on the internal quality control of water-efficient products and external policy market promotion, we developed a DECIA improvement model (Define, Evaluate, Check, Improve, and Application) based on the six-sigma DMAIC quality management model for performance evaluation and quality improvement under the novel use scenario of water-saving appliances. Define: compiling a database by screening performance indicators. Evaluate: building an evaluation system on the criteria of water efficiency, green energy, and leader. Check: innovate inspection method and research relevant devices. Improve: On-going technology improvement or upgrade for water-saving facilities to develop new products. Application: Researching evaluation techniques for the use of water efficiency standards and product marketing advancement to tap the water-saving potential of the product, form marketing policies to publicize and promote products. The DECIA model’s details are shown in Figure 1, which can determine the quality evaluation index system of water-efficient products and guide the collection of corresponding data, through objective index data analysis to find the existence of quality problems. Moreover, the evaluation system established will effectively promote the quality of water-efficient products via iterative upgrade, clear quality improvement goals, and innovative water-saving technologies, thus solving the problem of unclear transformation cycle and insufficient innovation momentum in the DMAIC model. In summary, the DECIA model provides theoretical and technical support for the quality evaluation and improvement of water-efficient products, respectively, and enriches the application scenarios of the DMAIC quality management model.

Figure 1.

Schematic diagram of DECIA model.

3.1. Definition

For water-efficient products, e.g., water nozzle, toilet, and water purifier, the Definition represents the boundary featuring the quality of water-saving appliances and the indicators reflecting the quality attributes over the product life cycle [23]. The water efficiency indicator is a necessary performance criterion in order to reflect the characteristics of water conservation. The entire process, including the acquisition of raw materials, manufacturing, circulation, usage, and recovery, should be covered in the selection of indicators, along with economy, feasibility, and operability.

The defined indicator database of smart water closet is shown in Table 2.

Table 2.

Indicator database of smart water closets.

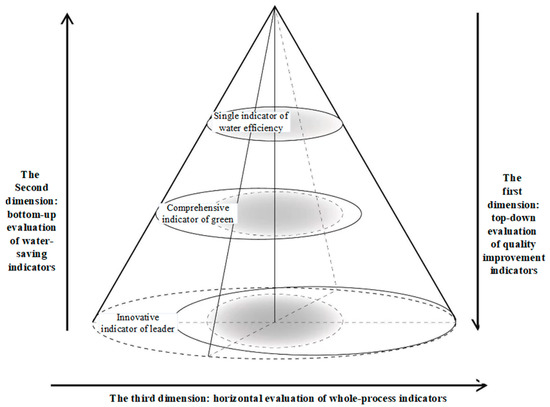

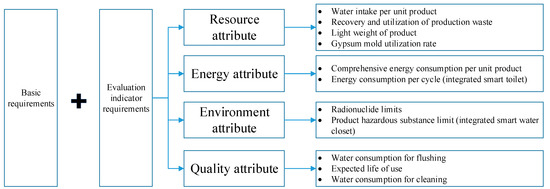

3.2. Evaluation

Indicators are classified into three groups: water efficiency evaluation, green evaluation, and leader to build a quality assessment system for water conservation evaluation, as shown in Figure 2. Three tiers and three dimensions make up the system. The three-level evaluation framework combines leading, comprehensive, and independent indicators. The independent indicators specifically refer to the ratings for water efficiency for appliances applied throughout the entire evaluation system. Comprehensive evaluation incorporates green evaluation indicators, as shown in Figure 3, including resource attributes (water intake per unit product, recycling, and utilization of production wastes), energy attributes, environmental attributes, quality attributes, etc. Leader evaluations refer to a series of evaluation indicators for standard enterprise leaders. For the three dimensions, the first dimension consists of top-down evaluation indicators that enrich assessment criteria and technical requirements to gradually improve the overall quality and production level. The second dimension includes bottom-up evaluation indicators that allocate from the basic to the premier level based on water-saving capability, green, and leader, highlighting the core function of water efficiency evaluation. A horizontal evaluation model covering the complete life cycle of appliances makes up the third dimension.

Figure 2.

“3 + 3” performance evaluation system.

Figure 3.

Construction of green evaluation system.

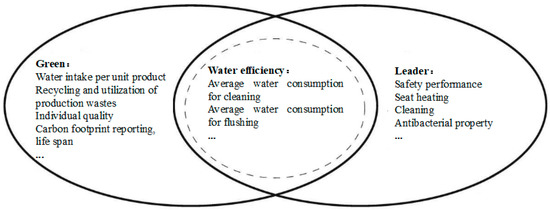

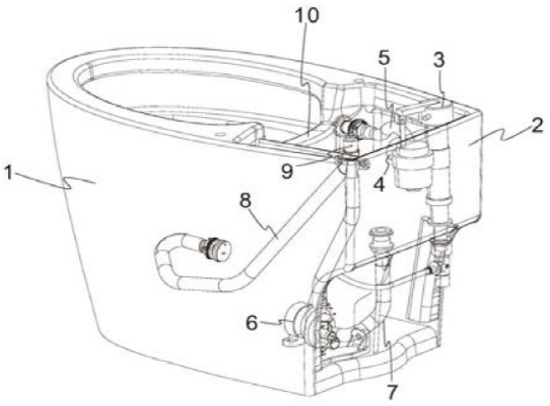

Take smart water closet for example, as shown in Figure 4. Its water efficiency evaluation dimension includes the average water consumption for cleaning and flushing. The green evaluation dimension incorporates water intake per unit, recycling rate of waste water, unit quality, a carbon footprint report, and the expected life of use. Leader evaluation dimensions cover safety performance, cleaning performance, antibacterial activity, and other indicators.

Figure 4.

Example of evaluation system of smart water closets.

3.3. Checking

The checking procedures and facilities are improved based on the evaluation system that satisfies market expectations and achieves the indication value. When testing the smart water closet, leader evaluation indicators for water efficiency, environmental friendliness, and other factors were taken into consideration.

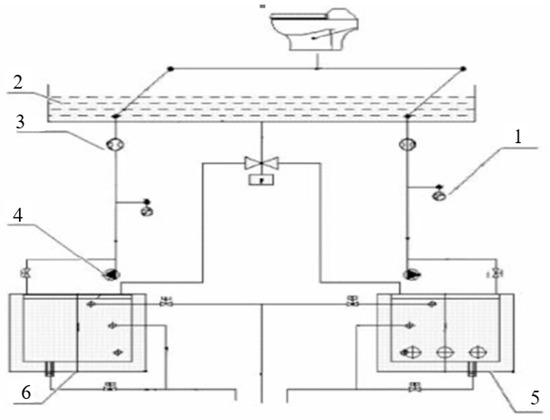

Improving detection methods: Targeting existing smart water closets’ problems of technical weakness, low precision, and big testing errors from the aspects of average flushing water consumption and heating temperature, we modified the checking method and redesigned the checking devices (Figure 5). In view of the rapid change of the water temperature, the detection device with a fast thermocouple as the main element was developed to realize fast, accurate, and dynamic temperature checking. At the same time, the new method also satisfies data statistical analysis by tracing the changing pattern of test parameters, such as water temperature and power. The improved checking method and device meet the indicator requirements in the evaluation system, provide technical support, and improve the checking efficiency.

Figure 5.

Schematic diagram of detection for a smart water closet. Note: 1—Pressure gauge; 2—Weight scale; 3—Flow meter; 4—Water pump; 5—Cold water tank; 6—Hot water tank.

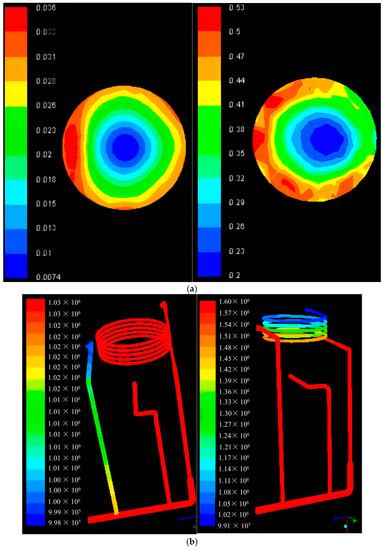

Developing smart monitor: A comprehensive smart water closet monitoring platform is built for the safety attribute in the leader indicators by integrating the smart water supply control system, the electrical control system, the data acquisition and analysis system, and a test bench. The smart monitoring platform can also effectively acquire and process data such as pressure and temperature. The platform is an embedded system based on the Internet of Things. It adopts high-power switching technology and realizes stable water source temperature and pressure testing through a constant temperature and pressure water supply system controlled by an adaptive tuning controller driven by DAQmx. As a result, the smart water closet is guaranteed to operate safely under various conditions. Meanwhile, the pipeline water supply system and the platform of the testing equipment were scientifically designed based on fluid mechanics and ergonomics to achieve the functions of human-computer interface interaction parameter setting. Other functions, such as automatic storage of test data and remote data transmission, also standardize the test conditions for flushing and cleaning water volume and provide technical support for performance parameter detection (Figure 6).

Figure 6.

Determination of the standardized piping system through test verification. (a) Analysis of influence of pipe diameter on turbulence intensity; (b) Nephogram of overall pressure distribution in pipeline; (c) Analysis of pipe diameter velocity and pressure.

3.4. Improvement

This stage is designed to encourage enterprises to invest in R&D, technology innovation, and market competitiveness under the guidance of the evaluation indicators and testing results, so as to continuously improve/upgrade water-efficient technology and create new products [28].

For example, the evaluation system of the smart water closets will specify the value of the indicators, including water efficiency indicators of the average cleaning water consumption level 1 indicator value of 0.3 L, level 2 for 0.5 L, level 3 for 0.7 L; with seat heating function of energy consumption indicators level 1 for 0.03 kW·h, level 2 for 0.04 kW·h, level 3 for 0.06 kW·h, which are mandatory in China, and products that do not meet the relevant standards will no longer be allowed to be sold. Therefore, in order to meet the water efficiency index and the requirements of the frontrunner, manufacturers will increase investment in new technology research and development and develop new products. In particular, energy-saving water efficiency of more than two levels of products in the market is very popular with consumers. The entry of new products will drive positive growth in product sales, feeding the investment in technology research and development. In order to meet the requirements of water efficiency and leader indicators, manufacturers have been optimizing their technologies to strengthen the producing process as well as innovating new products. In particular, China’s water efficiency level 2 and above products are very popular with consumers in the market, and the entry of new products will drive positive growth in product sales and promote investment in technology research and development.

Optimizing the process: Due to the limitations of the process, many manufacturers of smart water closet products cannot meet the requirements of the leader indicators. In light of the leader indicator that requires top water efficiency, a certain Chinese smart water closet design represents a first-of-its-kind inner water retaining structure, breaking through the traditional water diversion structure. The new design solves the water wasting problem caused by the baffle plate of the flush toilet with a waterless ring structure, and the water efficiency reaches the first class level. By fixing the baffle plate and the flow division plate behind it but at the front end of the main water outlet of the toilet body, the new product installs a water blocking bump in the interior of the baffle plate, so the flushing water will only flow down in the middle of the plate and save water. The water retaining design utilizes the flushing water more efficiently and prevents water from flowing on both sides of the water baffle.

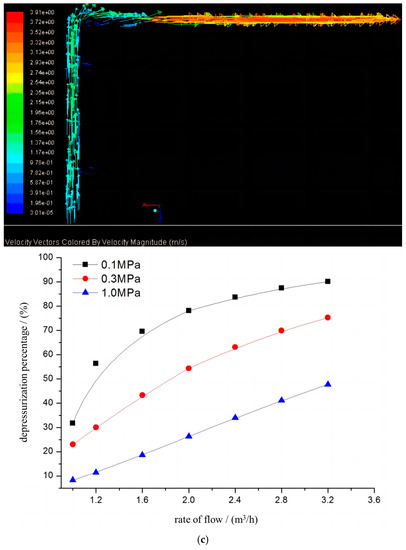

New product R&D: In order to occupy the highly smart water closet market, a manufacturer has developed a height adjusting component for the defects in the original water seal, so that the new smart water closet can reach the limit of first-class water efficiency. The height of the water seal point in the sewage discharge pipeline, which will lower when flushing. The height difference between the water surface in the toilet and the water seal point increases the pressure difference, pushing the sewage up into the upper pipeline faster to trigger the siphon effect. As a result, when maintaining the water seal height unchanged, the water volume used for replacing the storage water is rather low, thus enhancing its flushing and water-saving capabilities. At the same time, the siphon pipe structure, water tank structure, water spray hole, and water distribution hole of the smart water closets were optimized. A double-pump toilet flushing structure was designed and developed to solve problems such as backwater or reverse suction by installing an air isolation valve on the spray water outlet pipe. Meanwhile, the structure of pump flushing + air isolation valve was adopted to reduce the average water consumption to less than 4 L, reaching the requirement of the water efficiency indicator. The design is shown in Figure 7. Due to the greatly improved water-saving performance and better product quality, the product became the main brand of the enterprise after entering the market, with annual sales volume greater than 100,000 sets, and soon occupied the high-end market and achieved greater economic benefits.

Figure 7.

Schematic diagram of the R&D process of smart water closet. Note: 1—Toilet body; 2—Water tank; 3—Water inlet valve; 4—Swipe circle pump; 5—Arch bridge-shaped bend; 6—Jet pump; 7—Jet inlet pipe; 8—Injection water pipe; 9—Air isolation valve; 10—Overflow hole.

In addition, the water purifier products, for example, in order to achieve the water efficiency requirements of the water purifier, a manufacturer developed a new product to achieve the water purifier rinse water does not need to be discharged, reducing water consumption and achieving water efficiency level 2 requirements. This product solves the problem of large discharge of rinse water from water purifiers and the inability to utilize rinse water by developing a small flow throttle device. The inlet of the low-flow throttle valve is connected to the inlet pipe of the reverse osmosis processor or the outlet pipe of the concentrated water to realize the recycling of concentrated water and limit the concentration of water in the circulating pipeline of the reverse osmosis system through the regulation technology to reduce the blockage of the inlet pipe, and to extend the service life of the membrane, improve the water efficiency, and enhance the product quality.

3.5. Application

Marketing strategies help promote the application of water-efficient products while the product evaluation model will tap water-saving potential and continuously stimulate the updating of Definition indicators. Such effort enables continuous water-efficient products’ quality iteration and improvement.

For instance, the water efficiency labeling system, water efficiency pioneering system, green product system and leader system have been formulated in the field of smart water closet for wider promotion and application. The pioneering system water efficiency is based on China’s National Development and Reform Commission, the Ministry of Water Resources, the Ministry of Housing and Urban-Rural Development, and other departments issuing Measures for the Administration of Water Efficiency Labels and Implementation Rules for Water Efficiency Labeling of smart water closets and other policies, which clearly put forward the average water consumption of cleaning, average water consumption of flushing, flushing full flush water consumption, and unit cycle energy consumption should be based on GB 38,448 intelligent toilet energy efficiency water efficiency limit value and level for the determination of evaluation indicators. The system has become compulsory in China where products without these labels are not allowed to be sold in the market. The leader system is based on the Implementation Plan for Leader Action by Water Efficiency Leaders issued by China’s National Development and Reform Commission, Ministry of Water Resources, State Administration of Market Regulation and other departments, and the Implementation Plan for Energy Efficiency Leader Systems (Trial), which clearly proposed to meet the requirements of the relevant indicators to be named “frontrunner” products, such as water efficiency level to meet the average flush water consumption ≤4.0 L, wash function without residue, mixed media emissions for the first flush number of 28. The system of selection of the best, to establish the benchmark in the field of intelligent toilets, the formation of benchmarking effect, to promote new product updates and technical upgrades in the field of intelligent toilets. The system selects the best among the best, sets up a benchmark in the smart water closets industry, and promotes the new product and technology upgrade. The green product system is based on Certification and Accreditation Administration of the People’s Republic of China issue of the Announcement of Certification and Accreditation Administration on Issuing the Qualification Conditions of Green Product Certification Organizations and the First Batch of Certification Implementation Rules, which proposed that water closets’ resource attributes, energy attributes, environmental attributes, and quality attributes need to meet the relevant indicators to be recognized as green products. The system promotes the green certification of smart water closet products and promotes the improvement of product quality.

4. Conclusions

This paper proposes a DMAIC model for water-efficient product quality improvement based on the DECIA of six sigma management, providing a theoretical guideline for manufacturers to improve product quality. Based on the DECIA model, water-saving appliance manufacturers, through the construction of evaluation systems and the formation of relevant policy support, etc., can promote the upgrading of production processes or technologies, forming a virtuous cyclical circulation, and ultimately achieve the goal of improving product quality and increasing market penetration. In addition, the means of pasting the water efficiency label will influence the consumer’s purchase decision, promote a positive relationship between marketing and enterprise innovation, and achieve a cycle of quality improvement.

The DECIA model suggests improving the quality of water-efficient products in the following aspects. First, strengthen enterprises’ awareness of quality enhancement. Quality is the soul of a product, so higher quality will increase the sales volume while improving the user experience, which further translates into economic benefits for enterprises. In light of this, enterprises should focus on the quality of their product through strategy, ideology, and business practices. Second, enhance R&D. Technology is the driving force behind product upgrades and iterations. Only through constant R&D and innovation can manufacturers be self-motivated to improve the quality of their products. Third, improve the checking methods and equipment. The checking accuracy and precision should be improved to push the quality improvement of water-efficient products. Fourth, improve the product evaluation system. The evaluation system for water efficiency, green, and leader should be continuously improved, and relevant standards should be revised from time to time to remain effective in the long term. Fifth, build a top-level design for quality improvement. Top-level policies and norms should be formulated to give full play to the efforts of the government and the market, promote the wide application of water-efficient products, enhance the market penetration of high-quality water-efficient products, and stimulate the production and R&D enthusiasm of manufacturers.

Author Contributions

Conceptualization, Y.B. and J.L.; methodology, R.Z.; formal analysis, Y.B.; writing—original draft preparation, Y.B.; writing—review and editing, X.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kaushik, P.; Khanduja, D. Developing a Six Sigma Methodology to Increase the Passing Rate of Student in Engineering Education. J. Eng. 2006, 20, 23–30. [Google Scholar]

- Amrina, U.; Firmansyah, H. Analysis of defect and quality improvement for o ring product through applying DMAIC methodology. Penelit. Dan Apl. Sist. Dan Tek. Ind. 2019, 13, 136–148. [Google Scholar] [CrossRef]

- Trimarjoko, A.; Hardi Purba, H.; Nindiani, A. Consistency of DMAIC phases implementation on Six Sigma method in manufacturingand service industry: A literature review. Manag. Prod. Eng. Rev. 2020, 11, 34–45. [Google Scholar]

- Nagi, K.; Charmonman, S. Applying Six Sigma techniques to improving the quality of eLearning courseware components-A case study. In Proceedings of the 2010 IEEE International Conference on Management of Innovation & Technology, Singapore, 2–5 June 2010. [Google Scholar]

- Chakraborty, A.; Tan, K.C. Case study analysis of Six Sigma implementation in service organisations. Bus. Process Manag. J. 2012, 18, 992–1019. [Google Scholar] [CrossRef]

- Lynch, D.P.; Bertolino, S.; Cloutier, E. How to scope DMAIC projects. Qual. Prog. 2003, 36, 37–41. [Google Scholar]

- Rana, P.; Kaushik, P. Initiatives of six-sigma in an automotive ancillary unit: A case study. Manag. Sci. Lett. 2018, 8, 569–580. [Google Scholar] [CrossRef]

- Jaffal, M.S.; Korkmaz, I.; Özceylan, E. Critical success factors for Six Sigma implementation in Gaziantep carpet companies. Ind. Eng. Lett. 2017, 7, 83–92. [Google Scholar]

- ALmasarweh, M.S.Y.; Rawashdeh, A.M. The effect of using Six Sigma methodologies on the quality of health service: A field study at Prince Hashem hospital/city of Aqaba. J. Soc. Sci. (COESRJ-JSS) 2016, 5, 396–407. [Google Scholar] [CrossRef]

- Smętkowska, M.; Mrugalska, B. Using Six Sigma DMAIC to improve the quality of the production process: A case study. Procedia-Soc. Behav. Sci. 2018, 238, 590–596. [Google Scholar] [CrossRef]

- Godina, R.; Silva, B.G.R.; Espadinha-Cruz, P. A DMAIC integrated fuzzy FMEA model: A case study in the Automotive Industry. Appl. Sci. 2021, 11, 3726. [Google Scholar] [CrossRef]

- Abhilash, C.; Thakkar, J.J. Application of Six Sigma DMAIC methodology to reduce the defects in a telecommunication cabinet door manufacturing process: A case study. Int. J. Qual. Reliab. Manag. 2019, 36, 1540–1555. [Google Scholar]

- Rahman, M.A.; Talapatra, S. Defects reduction in casting process by applying Six Sigma principles and DMAIC problem solving methodology (a case study). In Proceedings of the International Conference on Mechanical, Industrial and Materials Engineering 2015 (ICMIME2015), Rajshahi, Bangladesh, 11–13 December 2015. [Google Scholar]

- More, C.S.; Nerkarm, A.A.; Khonde, R.V.; Tilekar, S. Study of application of six sigma of DMAIC in dent minimization in gear manufacturing. Glob. Res. Dev. J. Eng. 2017, 2, 82–87. [Google Scholar]

- Qutait, M. The role of six sigma approach by applying (DMAIC) model and forming work team in improving banks performance: A survey study in syrian banks in damascus. J. Soc. Sci. (COESRJ-JSS) 2018, 14, 169–180. [Google Scholar] [CrossRef]

- Aditya, G.M.; Irawan, H. Application of the six sigma method as a tool for management to improve quality of services (case Study On Bank Bni Syariah Bandung). eProc. Manag. 2020, 7, 1046–1056. [Google Scholar]

- Antony, J.; Scheumann, T.; M., V.S.; Cudney, E.; Rodgers, B.; Grigg, N.P. Using Six Sigma DMAIC for Lean project management in education: A case study in a German kindergarten. Total Qual. Manag. Bus. Excell. 2021, 33, 1489–1509. [Google Scholar] [CrossRef]

- Qureshi, M.I.; Janjua, S.Y.; Zaman, K.; Lodhi, M.S.; Tariq, Y.B. Internationalization of higher education institutions: Implementation of DMAIC cycle. Scientometrics 2014, 98, 2295–2310. [Google Scholar] [CrossRef]

- Al Kuwaiti, A.; Subbarayalu, A.V. Reducing hospital-acquired infection rate using the Six Sigma DMAIC approach. Saudi J. Med. Med. Sci. 2017, 5, 260. [Google Scholar] [CrossRef]

- Vijay, S.A. Reducing and optimizing the cycle time of patients discharge process in a hospital using six sigma dmaic approach. Int. J. Qual. Res. 2014, 8, 169–182. [Google Scholar]

- Franchetti, M.; Yanik, M. Continuous improvement and value stream analysis through the lean DMAIC Six Sigma approach: A manufacturing case study from Ohio, USA. Int. J. Six Sigma Compet. Advant. 2011, 6, 278–300. [Google Scholar] [CrossRef]

- He, Z.; Hu, H.; Liu, H.L.; Wang, W. A review on the theoretical research and application of lean six sigma. Ind. Eng. J. 2021, 24, 1–8, 54. [Google Scholar]

- Schulz, M.; Short, M.D.; Peters, G.M. A streamlined sustainability assessment tool for improved decision making in the urban water industry. Integr. Environ. Assess. Manag. 2012, 8, 183–193. [Google Scholar] [CrossRef] [PubMed]

- Todt, D.; Bisschops, I.; Chatzopoulos, P.; van Eekert, M.H.A. Practical performance and user experience of novel DUAL-Flush vacuum toilets. Water 2021, 13, 2228. [Google Scholar] [CrossRef]

- Iyo, T.; Asakura, K.; Nakano, M.; Yamada, M.; Omae, K. BBidet toilet seats with warm-water tanks: Residual chlorine, microbial community, and structural analyses. J. Water Health 2016, 14, 68–80. [Google Scholar] [CrossRef]

- Bao, K.; Shen, Q. Research and development of intelligent controller for high-grade sanitary ware//International Conference on Graphic and Image Processing (ICGIP 2012). SPIE 2013, 8768, 146–150. [Google Scholar]

- Yuan, Q.; Mohajerani, A.; Kurmus, H.; Smith, J.V. Possible recycling options of waste materials in manufacturing ceramic tiles. GEOMATE J. 2021, 20, 73–80. [Google Scholar] [CrossRef]

- Hoecker, J.; Bracciano, D. Passive conservation: Codifying the use of water-efficient technologies. J.-Am. Water Work. Assoc. 2012, 104, 93–99. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).