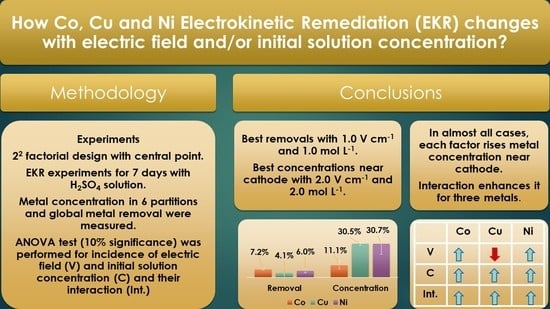

Incidence of Electric Field and Sulfuric Acid Concentration in Electrokinetic Remediation of Cobalt, Copper, and Nickel in Fresh Copper Mine Tailings

Abstract

1. Introduction

2. Materials and Methods

2.1. Tailing Samples and Reagents

2.2. Experimental Disposal and Measuring

2.3. Calculations

2.3.1. Process Indicators

2.3.2. Statistical Indicators

3. Results and Discussion

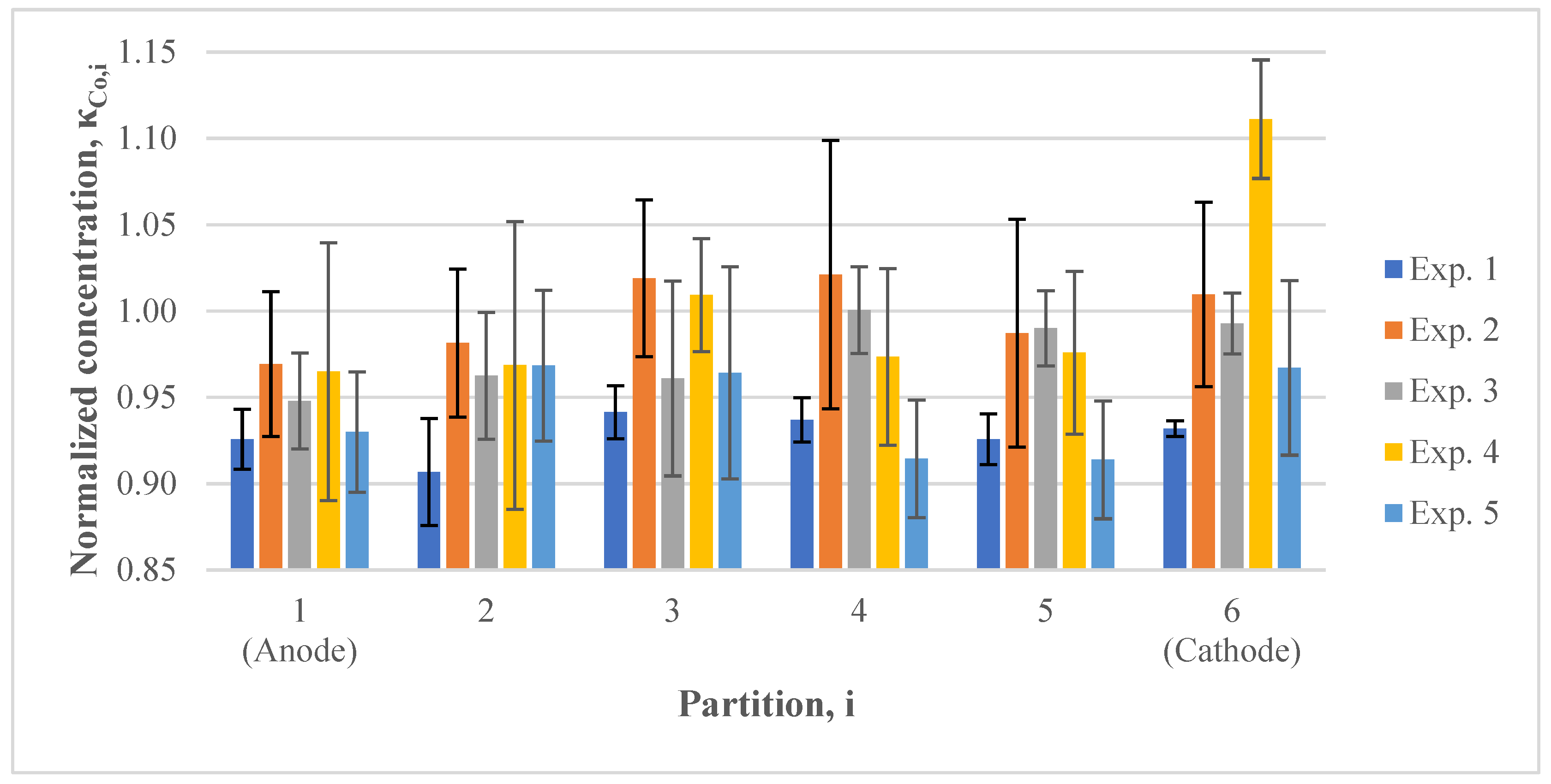

3.1. Cobalt

3.2. Copper

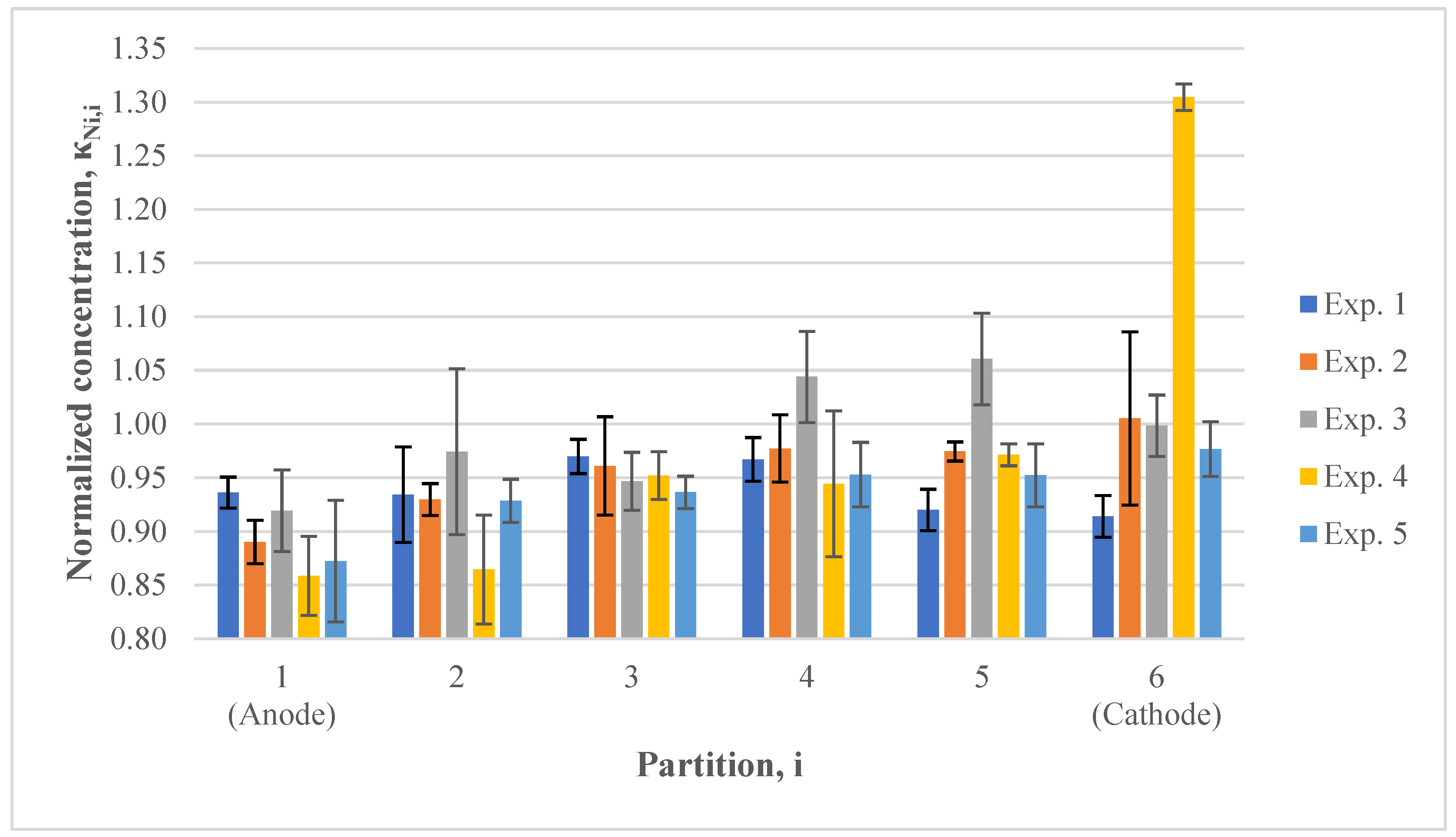

3.3. Nickel

3.4. Metal Removal

3.5. Interaction Proof

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lacasa, E.; Cotillas, S.; Saez, C.; Lobato, J.; Canizares, P.; Rodrigo, M.A. Environmental applications of electrochemical technology. What is needed to enable full-scale applications? Curr. Opin. Electrochem. 2019, 16, 149–156. [Google Scholar] [CrossRef]

- Kelm, U.; Helle, S.; Matthies, R.; Morales, A. Distribution of trace elements in soils surrounding the El Teniente porphyry copper deposit, Chile: The influence of smelter emissions and a tailings deposit. Environ. Geol. 2009, 57, 365–376. [Google Scholar] [CrossRef]

- Ramirez, M.; Massolo, S.; Frache, R.; Correa, J.A. Metal speciation and environmental impact in Sandy beaches due to El Salvador copper mine, Chile. Mar. Pollut. Bull. 2005, 50, 62–72. [Google Scholar] [CrossRef]

- Fernández-Marchante, C.M.; Souza, F.L.; Millán, M.; Lobato, J.; Rodrigo, M.A. Can the green energies improve the sustainability of electrochemically-assisted soil remediation processes? Sci. Total Environ. 2022, 803, 149991–149999. [Google Scholar] [CrossRef] [PubMed]

- Figueroa, A.; Cameselle, C.; Gouveia, S.; Hansen, H.K. Electrokinetic treatment of an agricultural soil contaminated with heavy metals. J. Environ. Sci. Health A Tox. Hazard. Subst. Environ. Eng. 2016, 51, 691–700. [Google Scholar] [CrossRef] [PubMed]

- Correa, J.A.; Castilla, J.C.; Ramirez, M.; Varas, M.; Lagos, N.; Vergara, S.; Moenne, A.; Roman, D.; Brown, M.T. Copper, copper mine tailings and their effect on marine algae in northern Chile. J. Appl. Physiol. 1999, 11, 57–67. [Google Scholar] [CrossRef]

- Leyssens, L.; Vinck, B.; Van Der Straeten, C.; Wuyts, F.; Maes, L. Cobalt toxicity in humans—A review of the potential sources and systemic health effects. Toxicology 2017, 387, 43–56. [Google Scholar] [CrossRef] [PubMed]

- Schaumlöffel, D. Nickel species: Analysis and toxic effects. J. Trace Elem. Med. Biol. 2012, 26, 1–6. [Google Scholar] [CrossRef]

- Vardhan, K.H.; Kumar, P.S.; Panda, R.C. A review on heavy metal pollution, toxicity and remedial measures: Current trends and future perspectives. J. Mol. Liq. 2019, 290, 111197–111218. [Google Scholar] [CrossRef]

- Araya, N.; Mamani Quiñonez, O.; Cisternas, L.A.; Kraslawski, A. Sustainable Development Goals in Mine Tailings Management: Targets and Indicators. Mater. Proc. 2021, 5, 82. [Google Scholar] [CrossRef]

- Aznar-Sánchez, J.A.; García-Gómez, J.J.; Velasco-Muñoz, J.F.; Carretero-Gómez, A. Mining Waste and Its Sustainable Management: Advances in Worldwide Research. Minerals 2018, 8, 284. [Google Scholar] [CrossRef]

- Qin, J.; Zhao, H.; Dai, M.; Zhao, P.; Chen, X.; Liu, H.; Lu, B. Speciation Distribution and Influencing Factors of Heavy Metals in Rhizosphere Soil of Miscanthus Floridulus in the Tailing Reservoir Area of Dabaoshan Iron Polymetallic Mine in Northern Guangdong. Processes 2022, 10, 1217. [Google Scholar] [CrossRef]

- Tarfeen, N.; Nisa, K.U.; Hamid, B.; Bashir, Z.; Yatoo, A.M.; Dar, M.A.; Mohiddin, F.A.; Amin, Z.; Ahmad, R.A.; Sayyed, R.Z. Microbial Remediation: A Promising Tool for Reclamation of Contaminated Sites with Special Emphasis on Heavy Metal and Pesticide Pollution: A Review. Processes 2022, 10, 1358. [Google Scholar] [CrossRef]

- Liu, L.; Li, W.; Song, W.; Guo, M. Remediation techniques for heavy metal-contaminated soils: Principles and applicability. Sci. Total Environ. 2018, 633, 206–219. [Google Scholar] [CrossRef]

- Acar, Y.B.; Gale, R.J.; Alshawabkeh, A.N.; Marks, R.E.; Puppala, S.; Bricka, M.; Parker, R. Electrokinetic remediation: Basics and technology status. J. Hazard. Mater. 1995, 40, 117–137. [Google Scholar] [CrossRef]

- Alshawabkeh, A.N. Electrokinetic soil remediation: Challenges and oportunitites. Sep. Sci. Technol. 2009, 44, 2171–2187. [Google Scholar] [CrossRef]

- Singh, A.; Kuhad, R.C.; Ward, O.P. Biological Remediation of Soil: An Overview of Global Market and Available Technologies. In Advances in Applied Bioremediation; Soil Biology; Singh, A., Kuhad, R., Ward, O., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; Volume 17, ISBN 978-3-540-89621-0. [Google Scholar]

- Boonmeerati, U.; Sampanpanish, P. Enhancing Arsenic Phytoextraction of Dwarf Napier Grass (Pennisetum purpureum cv. Mott) from Gold Mine Tailings by Electrokinetics Remediation with Phosphate and EDTA. J. Hazard. Toxic Radioact. Waste 2021, 25, 04021027. [Google Scholar] [CrossRef]

- Torabi, M.S.; Asadollahfardi, G.; Rezaee, M.; Panah, N.B. Electrokinetic Removal of Cd and Cu from Mine Tailing: EDTA Enhancement and Voltage Intensity Effects. J. Hazard. Toxic Radioact. Waste 2021, 25, 05020007. [Google Scholar] [CrossRef]

- Asadollahfardi, G.; Sarmadi, M.S.; Rezaee, M.; Khodadadi-Darban, A.; Yazdani, M.; Paz-Garcia, J.M. Comparison if different extracting agents for the recovery of Pb and Zn through electrokinetic remediation of mine tailings. J. Environ. Manag. 2021, 279, 111728–111739. [Google Scholar] [CrossRef]

- Boonmeerati, U.; Sampanpanish, P. Application of Phosphate and EDTA on As(V) Removal in Gold Mine Tailings by Electrokinetic Remediation. EnvironmentAsia 2020, 13, 1–12. [Google Scholar] [CrossRef]

- Kirkelund, G.M.; Jensen, P.E.; Ottosen, L.M.; Pedersen, K.B. Comparison of two- and three-compartment cells for electrodialytic of heavy metals from contaminated material suspensions. J. Hazard. Mater. 2019, 367, 68–76. [Google Scholar] [CrossRef] [PubMed]

- Rosa, M.A.; Egido, J.A.; Márquez, M.C. Enhanced electrochemical removal of arsenic and heavy metals from mine tailings. J. Taiwan. Inst. Chem. E. 2017, 78, 409–415. [Google Scholar] [CrossRef]

- Demir, A.; Pamukcu, S.; Shrestha, R.A. Simultaneous Removal of Pb, Cd, and Zn from Heavily Contaminated Mine Tailing Soil Using Enhanced Electrochemical Process. Environ. Eng. Sci. 2015, 32, 416–424. [Google Scholar] [CrossRef]

- Hansen, H.K.; Lamas, V.; Gutiérrez, C.; Nuñez, P.; Rojo, A.; Cameselle, C.; Ottosen, L.M. Electro-remediation of copper mine tailings. Comparing copper removal efficiencies for two tailings of different age. Miner. Eng. 2013, 41, 1–8. [Google Scholar] [CrossRef]

- Hansen, H.K.; Rojo, A.; Ottosen, L.M. Electrokinetic remediation of copper mine tailings—Implementing bipolar electrodes. Electrochim. Acta 2007, 52, 3355–3359. [Google Scholar] [CrossRef]

- Hansen, H.K.; Rojo, A. Testing pulsed electric fields in electroremediation of copper mine tailings. Electrochim. Acta 2007, 52, 3399–3405. [Google Scholar] [CrossRef]

- Jensen, P.E.; Ottosen, L.M.; Hansen, H.K.; Bollwerk, S.; Belmonte, L.J.; Kirkelund, G.M. Suspended electrodialytic extraction of toxic elements for detoxification of three different mine tailings. Int. J. Sustain. Dev. Plan. 2016, 11, 119–127. [Google Scholar] [CrossRef]

- Hansen, H.K.; Rojo, A.; Ottosen, L.M. Electrodialytic remediation of copper mine tailings. J. Hazard. Mater. 2005, 117, 179–183. [Google Scholar] [CrossRef]

- Rojo, A.; Hansen, H.K.; Ottosen, L.M. Electrodialytic remediation of copper mine tailings: Comparing different operational conditions. Miner. Eng. 2006, 19, 500–504. [Google Scholar] [CrossRef]

- Ortiz-Soto, R.; Leal, D.; Gutierrez, C.; Aracena, A.; Rojo, A.; Hansen, H.K. Electrokinetic remediation of manganese and zinc in copper mine tailings. J. Hazard. Mater. 2019, 365, 905–911. [Google Scholar] [CrossRef]

- Del Real, I.; Thompson, J.F.H.; Simon, A.C.; Reich, M. Geochemical and Isotopic Signature of Pyrite as a Proxy for Fluid Source and Evolution in the Candelaria-Punta del Cobre Iron Oxide Copper-Gold District, Chile. Econ. Geol. 2020, 115, 1493–1518. [Google Scholar] [CrossRef]

- Montgomery, D.C.; Runger, G.C. Applied Statistics and Probability for Engineers, 7th ed.; Wiley: Hoboken, NJ, USA, 2018; ISBN 978-1-119-40036-3. [Google Scholar]

- Papadopoulos, C.E.; Yeung, H. Uncertainty estimation and Monte Carlo method. Flow Meas. Instrum. 2001, 12, 291–298. [Google Scholar] [CrossRef]

- Lewis, A.E. Review of metal sulphide precipitation. Hydrometallurgy 2010, 104, 222–234. [Google Scholar] [CrossRef]

- Córdoba, E.M.; Muñoz, J.A.; Blázquez, M.L.; González, F.; Ballester, A. Leaching of chalcopyrite with ferric ion. Part I: General aspects. Hydrometallurgy 2008, 93, 81–87. [Google Scholar] [CrossRef]

- Chen, R.; Zhou, L.; Wang, W.; Cui, D.; Hao, D.; Guo, J. Enhanced Electrokinetic Remediation of Copper-Contaminated Soil by Combining Steel Slag and a Permeable Reactive Barrier. Appl. Sci. 2022, 12, 7981. [Google Scholar] [CrossRef]

- Ge, X.; Xie, J.; Song, X.; Cao, X.; Wang, Y.; Xu, Z. Electrokinetic Remediation of Cadmiun (Cd), Copper (Cu) and Nickel (Ni) Co-contaminated soil with Oxalic Acid, Acetic Acid or Citric Acid as a Catholyte. Int. J. Electrochem. Sci. 2022, 17, 220444. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| pH | 8.04 ± 0.06 |

| Particle diameter, μm | 212–350 |

| Cu total concentration, mg kg−1 | 486.50 ± 5.50 |

| Co total concentration, mg kg−1 | 89.10 ± 5.50 |

| Ni total concentration, mg kg−1 | 31.00 ± 1.40 |

| Experimental Number | Electric Field V cm−1 | H2SO4 Concentration mol L−1 | Sample pH at Beginning of Trial | Average Electrical Current mA | Effective Operation Time Days |

|---|---|---|---|---|---|

| 1 | 1.0 | 1.0 | 6.93 ± 0.04 | 45.21 | 7.0 |

| 2 | 1.0 | 2.0 | 3.91 ± 0.02 | 157.48 | 7.0 |

| 3 | 2.0 | 1.0 | 7.04 ± 0.01 | 85.57 | 6.1 |

| 4 | 2.0 | 2.0 | 3.79 ± 0.03 | 339.63 | 7.0 |

| 5 | 1.5 | 1.5 | 4.51 ± 0.03 | 107.12 | 4.7 |

| Experiments | |||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Total removalCo | 7.19% ± 0.74% | 0.15% ± 4.49% | 2.38% ± 2.09% | −0.57% ± 3.53% | 5.40% ± 0.74% |

| Total removalCu | 4.05% ± 5.22% | 1.82% ± 5.60% | 2.27% ± 2.46% | −0.32% ± 6.80% | 2.57% ± 0.74% |

| Total removalNi | 5.95% ± 1.65% | 4.07% ± 2.40% | 0.84% ± 3.08% | 0.39% ± 1.81% | 6.33% ± 0.74% |

| Metal | Variability Source | Partition | |||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | ||

| Cobalt | Electric Field | 60.70% | 31.95% | 71.70% | 66.52% | 13.35% | 0.03% |

| Initial Acidity | 13.13% | 10.09% | 0.74% | 16.93% | 16.77% | 0.02% | |

| Interaction | 45.10% | 14.54% | 30.79% | 3.09% | 5.48% | 4.80% | |

| Total Copper | Electric Field | 15.51% | 6.95% | 30.05% | 48.71% | 12.38% | 0.33% |

| Initial Acidity | 46.24% | 0.10% | 1.33% | 1.66% | 1.33% | 0.01% | |

| Interaction | 27.77% | 60.64% | 81.29% | 4.42% | 8.02% | 0.20% | |

| Soluble Copper | Electric Field | 0.02% | 0.00% | 0.52% | 78.25% | 0.01% | 0.00% |

| Initial Acidity | 0.41% | 0.00% | 0.05% | 15.86% | 0.02% | 0.00% | |

| Interaction | 0.03% | 0.00% | 0.03% | 0.09% | 0.00% | 0.00% | |

| Nickel | Electric Field | 8.37% | 58.22% | 20.50% | 27.25% | 0.08% | 0.35% |

| Initial Acidity | 0.71% | 5.27% | 87.38% | 6.20% | 7.87% | 0.03% | |

| Interaction | 52.58% | 6.60% | 54.89% | 3.40% | 0.06% | 0.04% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortiz-Soto, R.; Leal, D.; Gutierrez, C.; Aracena, A.; León, M.; Lazo, A.; Lazo, P.; Ottosen, L.; Hansen, H. Incidence of Electric Field and Sulfuric Acid Concentration in Electrokinetic Remediation of Cobalt, Copper, and Nickel in Fresh Copper Mine Tailings. Processes 2023, 11, 108. https://doi.org/10.3390/pr11010108

Ortiz-Soto R, Leal D, Gutierrez C, Aracena A, León M, Lazo A, Lazo P, Ottosen L, Hansen H. Incidence of Electric Field and Sulfuric Acid Concentration in Electrokinetic Remediation of Cobalt, Copper, and Nickel in Fresh Copper Mine Tailings. Processes. 2023; 11(1):108. https://doi.org/10.3390/pr11010108

Chicago/Turabian StyleOrtiz-Soto, Rodrigo, Daniela Leal, Claudia Gutierrez, Alvaro Aracena, Marcelo León, Andrea Lazo, Pamela Lazo, Lisbeth Ottosen, and Henrik Hansen. 2023. "Incidence of Electric Field and Sulfuric Acid Concentration in Electrokinetic Remediation of Cobalt, Copper, and Nickel in Fresh Copper Mine Tailings" Processes 11, no. 1: 108. https://doi.org/10.3390/pr11010108

APA StyleOrtiz-Soto, R., Leal, D., Gutierrez, C., Aracena, A., León, M., Lazo, A., Lazo, P., Ottosen, L., & Hansen, H. (2023). Incidence of Electric Field and Sulfuric Acid Concentration in Electrokinetic Remediation of Cobalt, Copper, and Nickel in Fresh Copper Mine Tailings. Processes, 11(1), 108. https://doi.org/10.3390/pr11010108