Numerical Study of Factors Affecting Particle Suction Efficiency of Pick-Up Head of a Regenerative Air Vacuum Sweeper

Abstract

:1. Introduction

2. Numerical Model

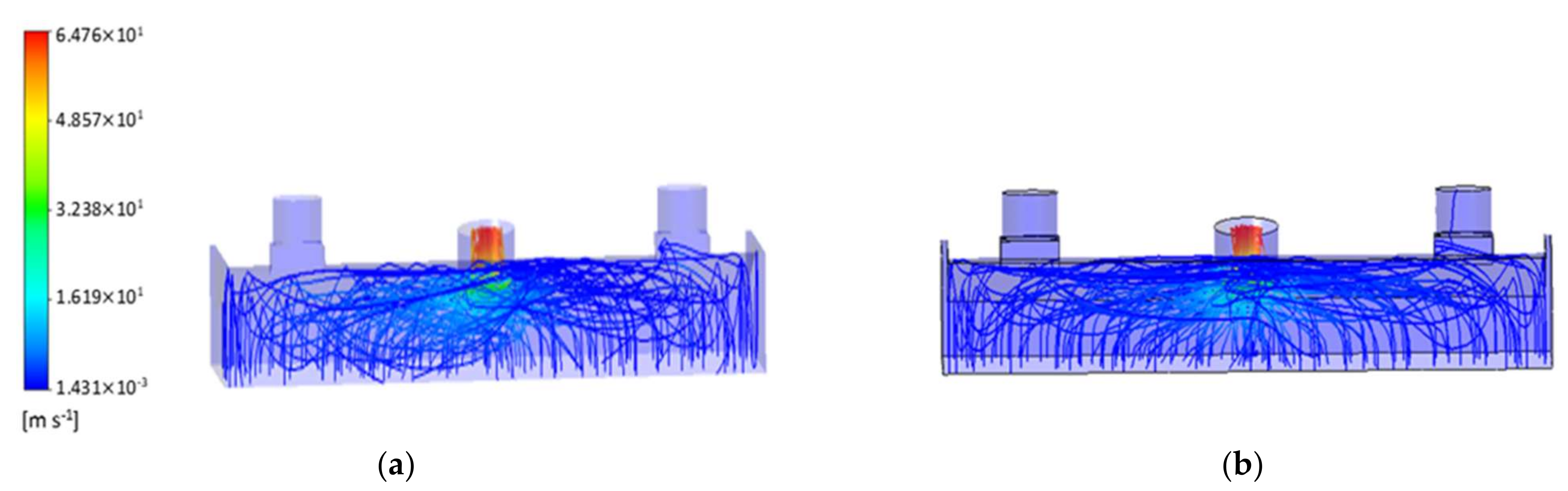

- To study the direction of particle movement by observing the particle trajectory in the suction port of the pick-up head.

- To observe the airflow direction and the factors affecting airflow through the inlet channels of the pick-up head.

- To increase the absorption efficiency of suction dust particles by detecting the movement of ambient airflow in the direction of the suction port.

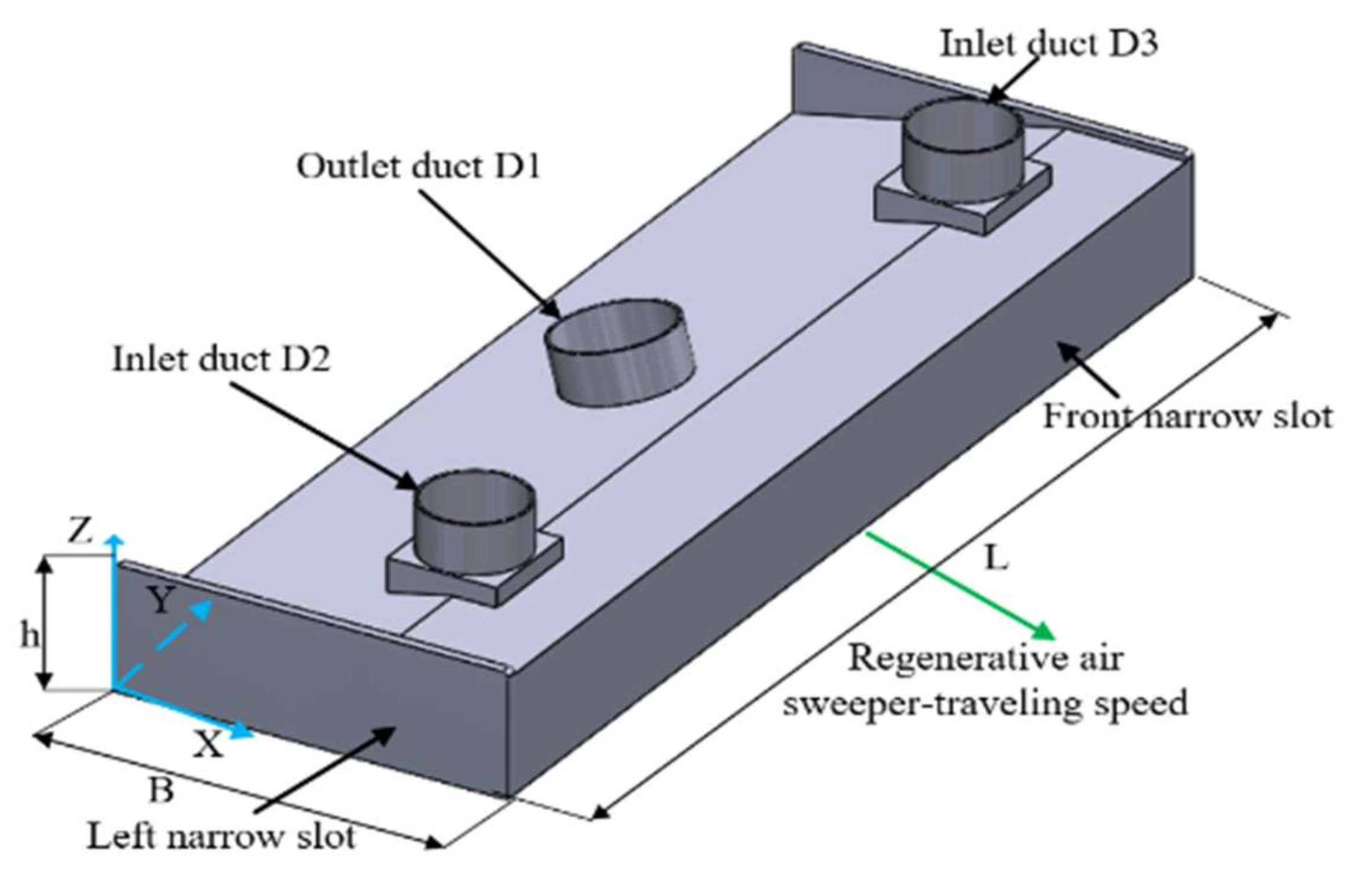

2.1. Structural Parameters of the Pick-Up Head for Dust Extraction

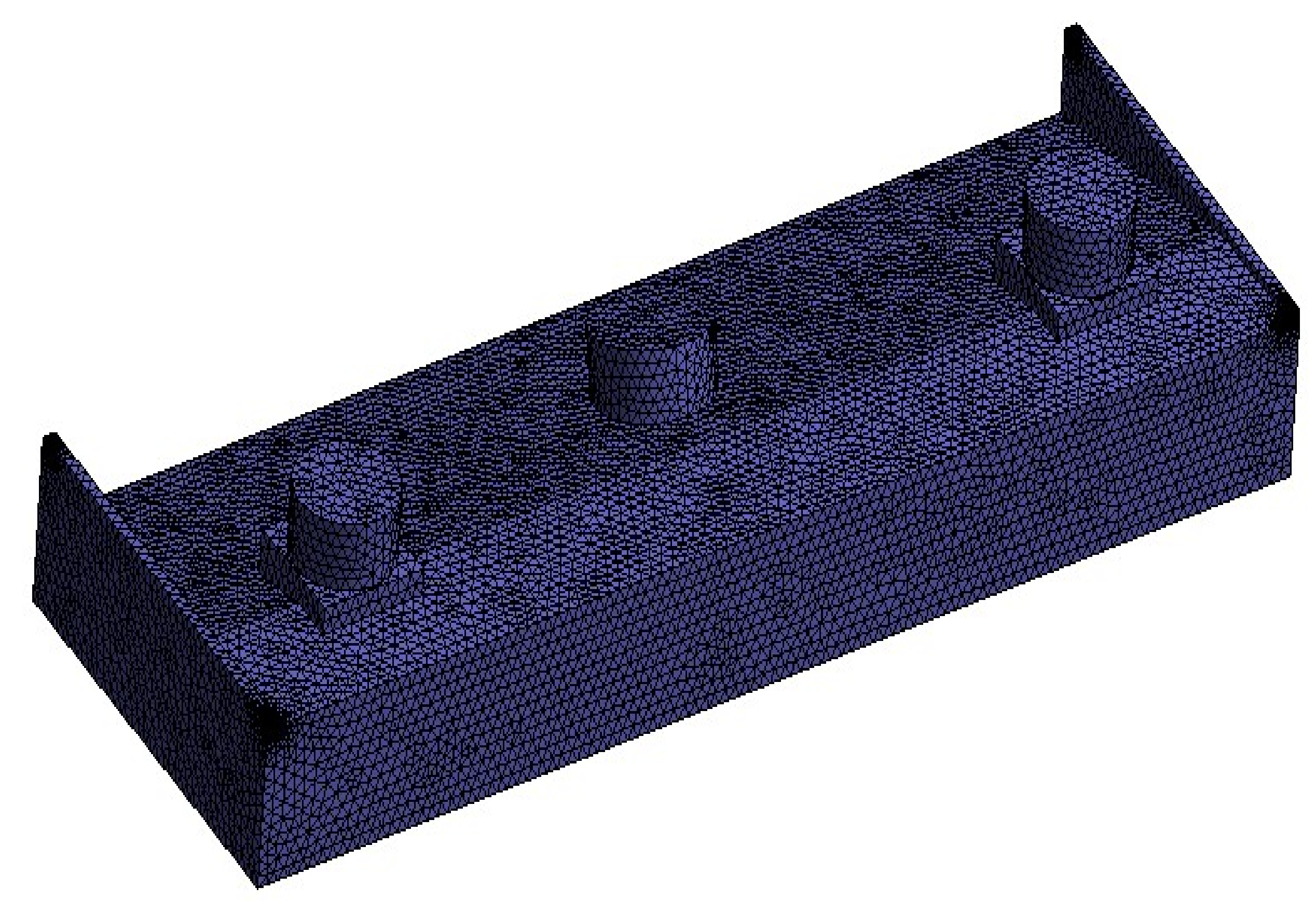

2.2. Mathematical Model

2.2.1. Equation for the Flow Field

2.2.2. Discrete Phase Modeling

2.2.3. Analysis of the Initial Velocity of Dust Particles

2.2.4. Boundary Conditions and Solution Controls

3. Experimental Setup

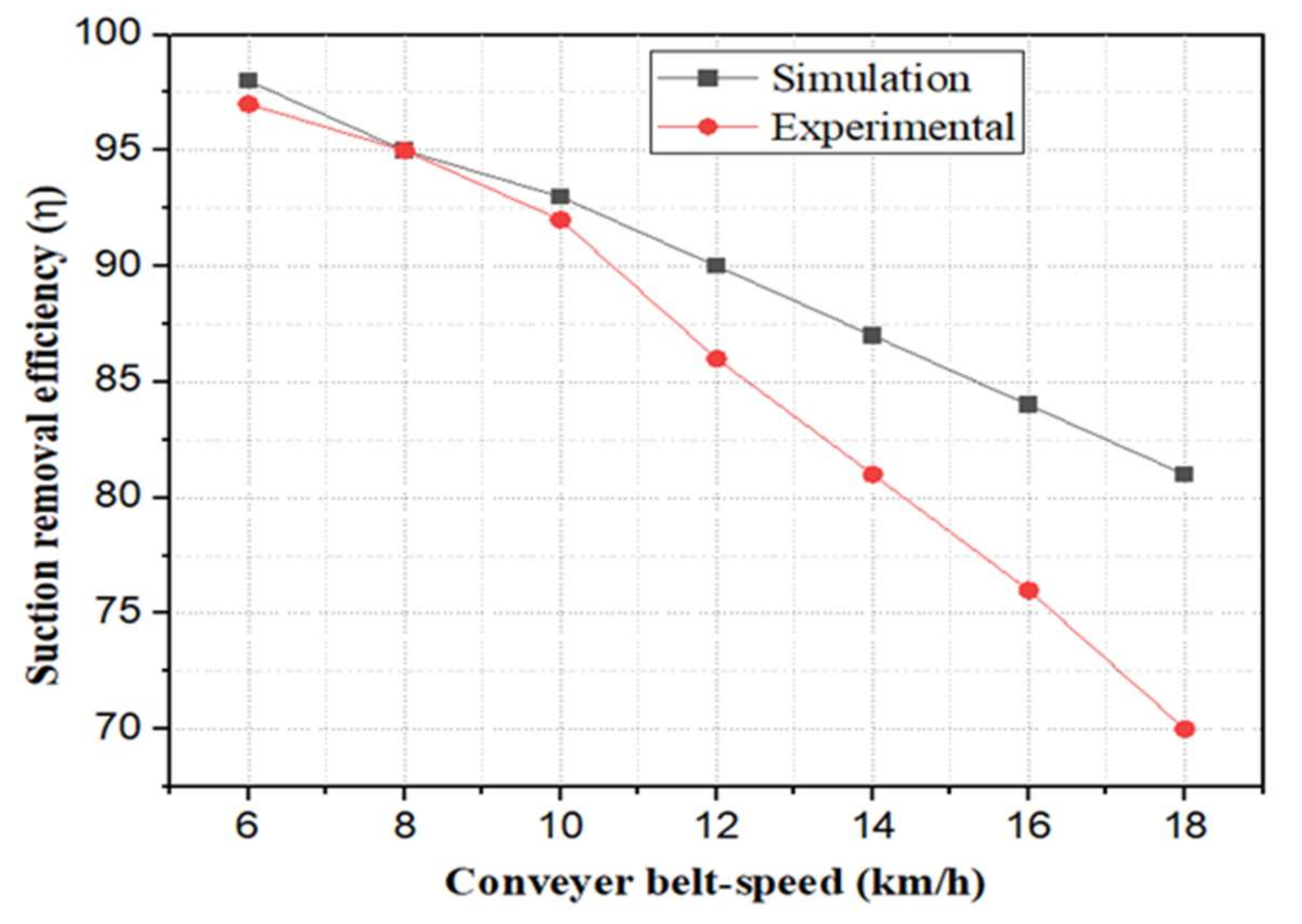

Model Validation

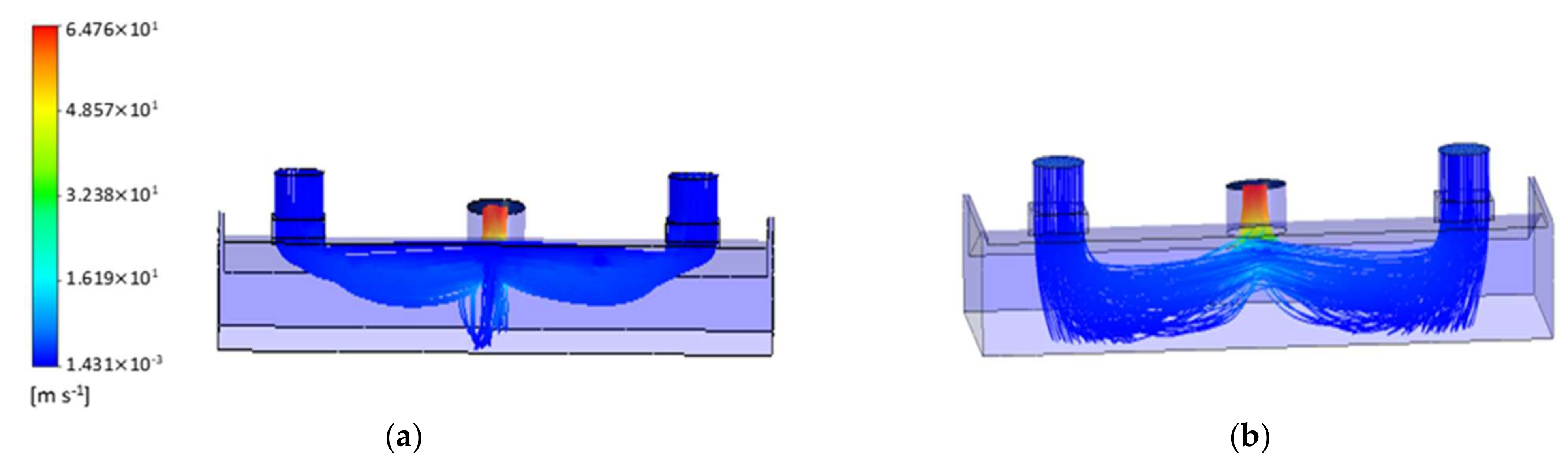

4. Results and Discussion

4.1. Initial Flow Rate of Particle Removal Efficiency

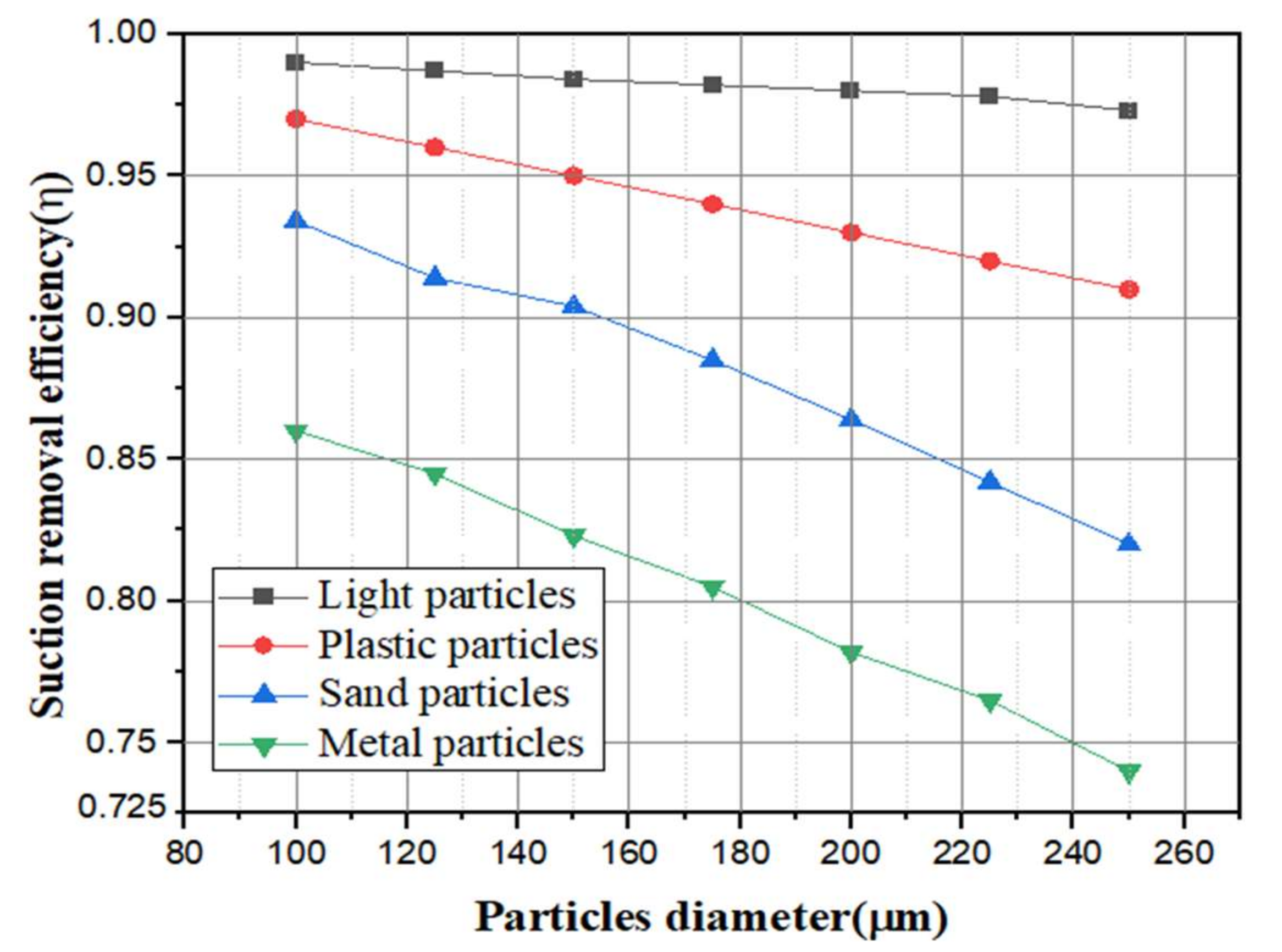

4.2. Particle Suction Removal Efficiency

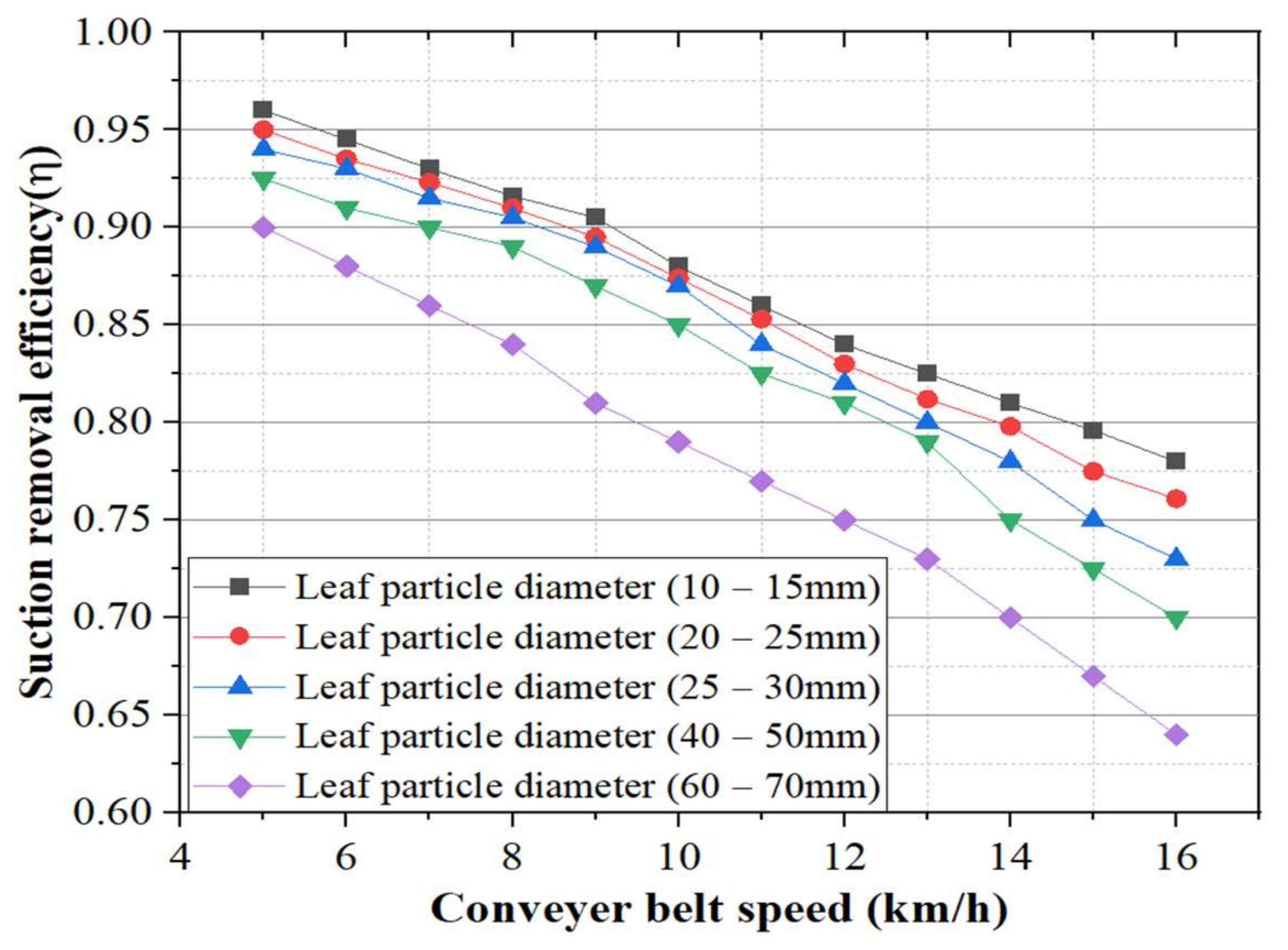

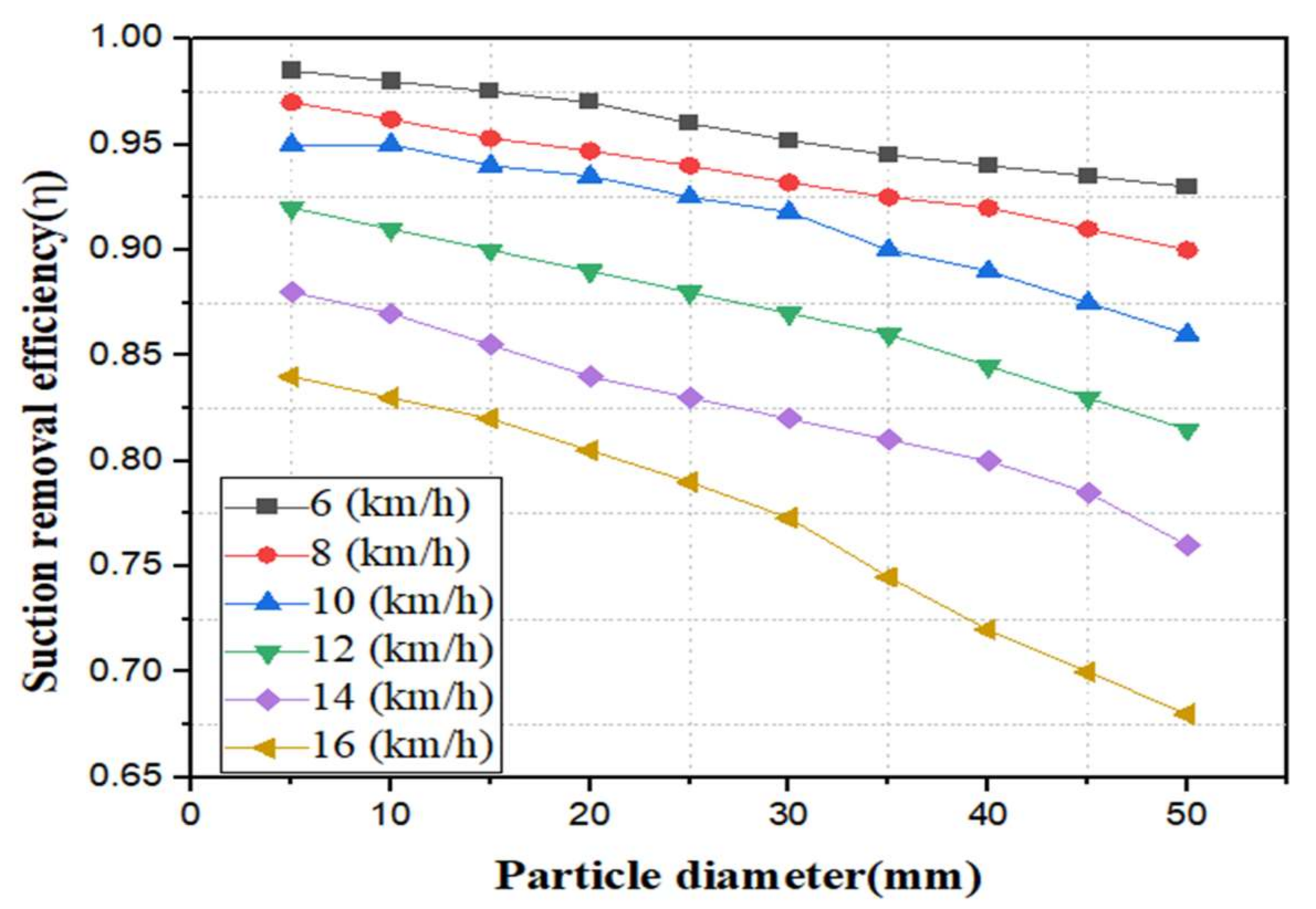

4.3. The Effect of Sweeper Movement Speed on the Suction Efficiency of Particles

4.4. Effect of Pressure Change on Particle Suction-Removal Efficiency

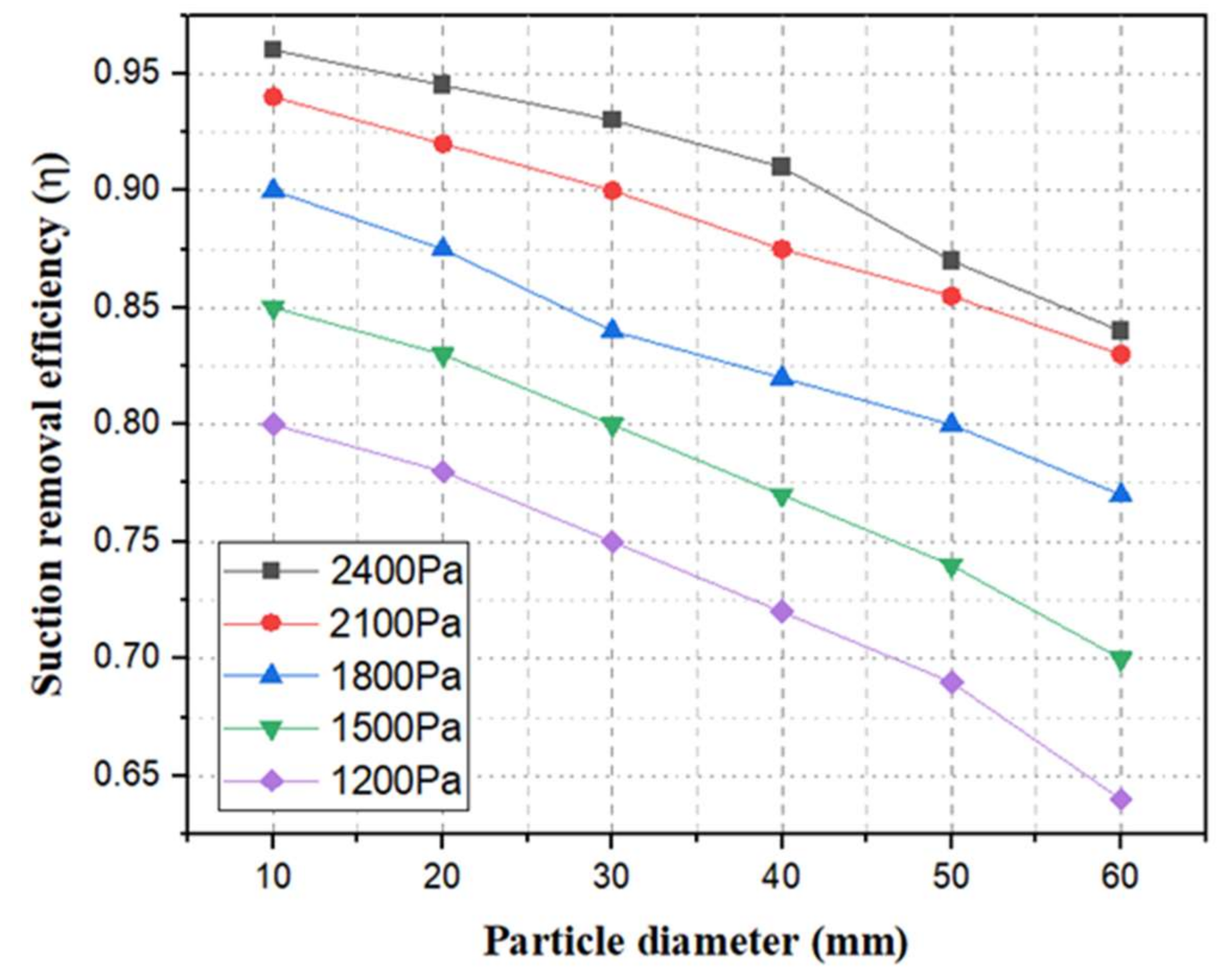

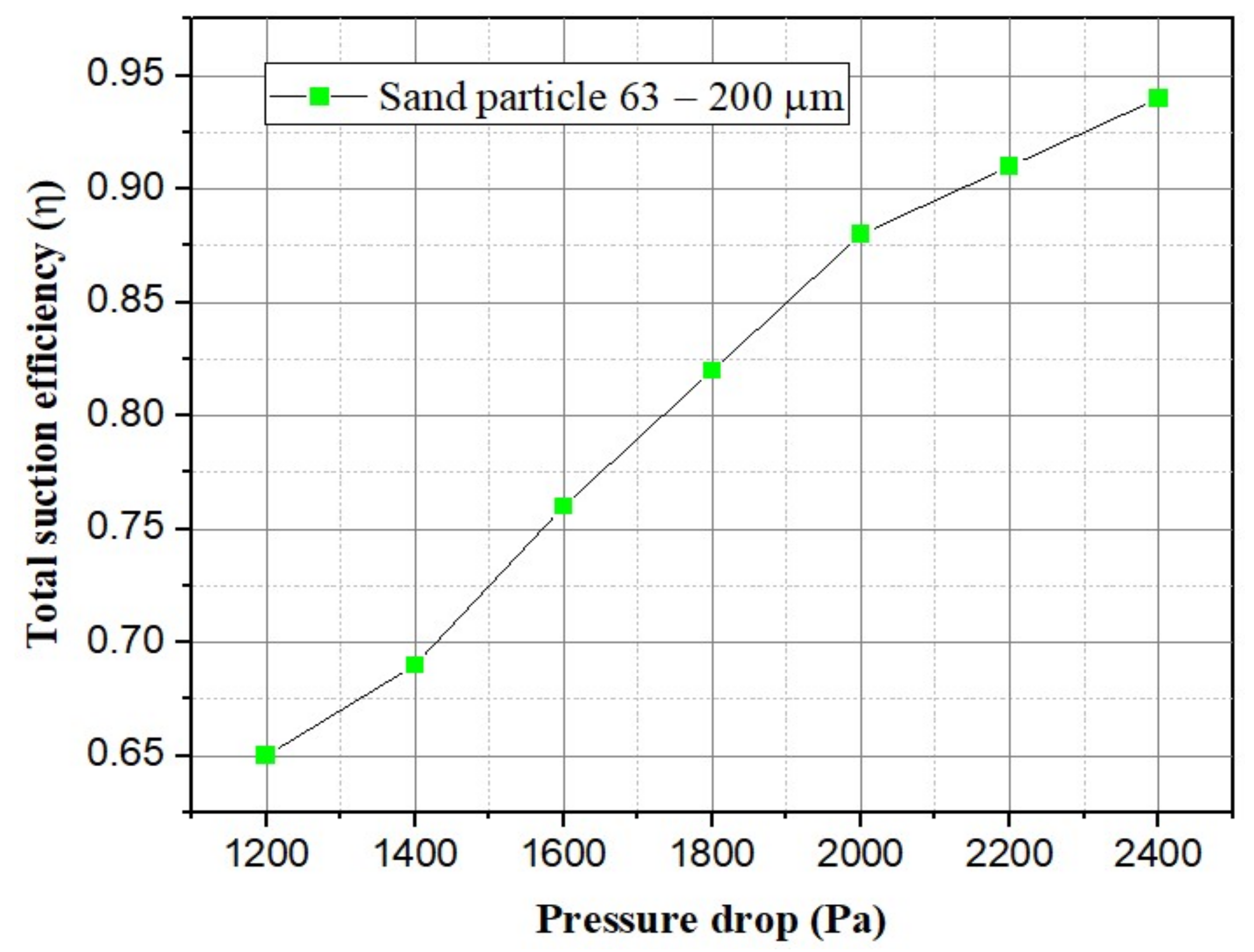

4.5. The Effect of Changes in the Distance between the Suction Port and the Road Surface on the Efficiency of Particle Removal

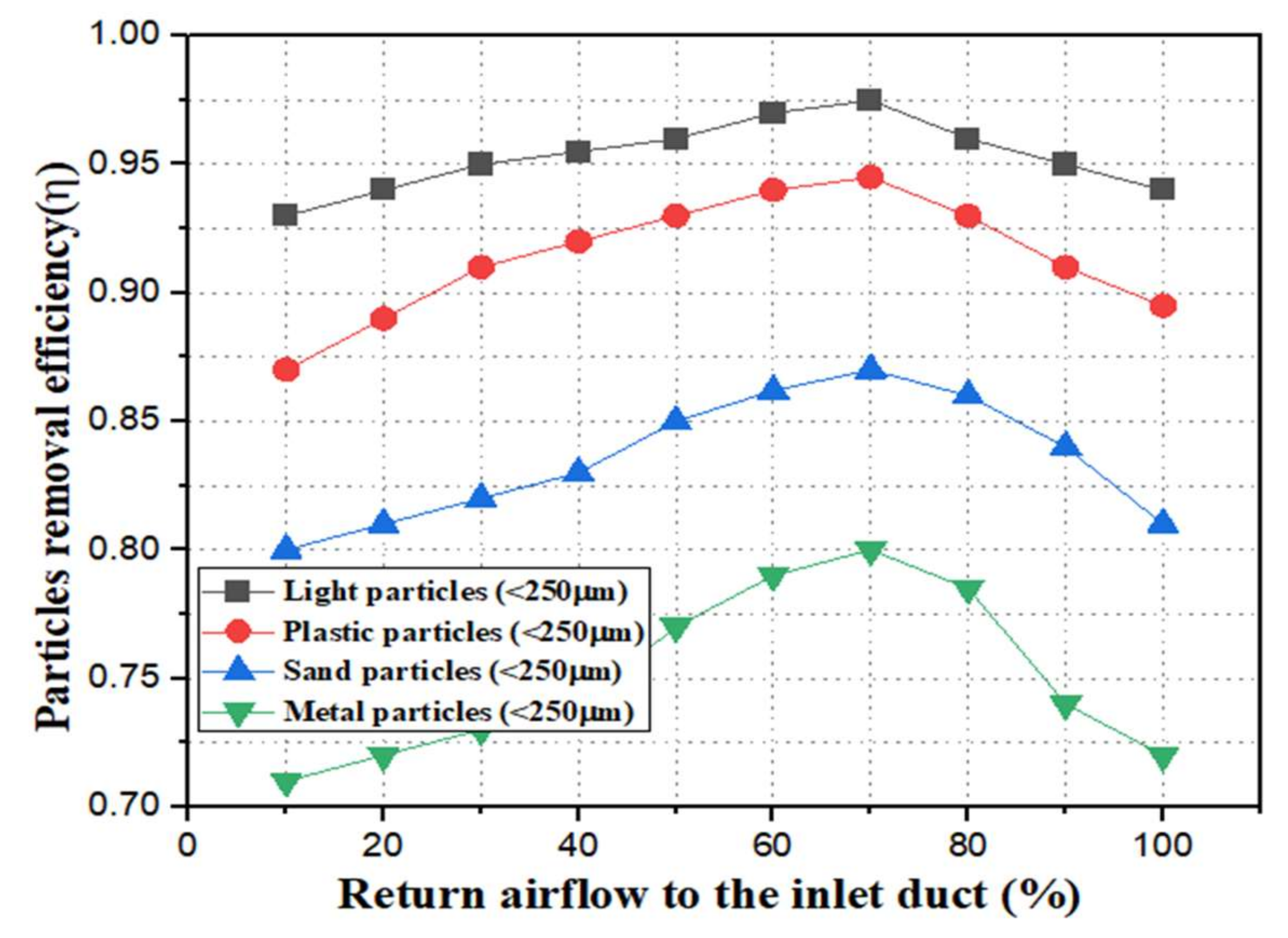

4.6. The Effect of the Recirculated Secondary Airflow in the System on the Particle Removal Efficiency

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Parameter name | Parameter meaning |

| Drag coefficient, (-) | |

| Starting velocity of the dust particles, (m/s) | |

| Incipient velocity of stratified dust particles, (m/s) | |

| D | Duct diameter, (mm) |

| L | Length, (mm) |

| B | Width, (mm) |

| h | Height, (mm) |

| H | Thickness, (mm) |

| D1 | Outlet duct, (mm) |

| D2 | Inlet duct, (mm) |

| D3 | Inlet duct, (mm) |

| ) | |

| Particle mass, (kg) | |

| Drag force, (N) | |

| Gravitational force, (N) | |

| Particle listing force, (N) | |

| Air velocity, (m/s) | |

| Pickup velocity (gas velocity when pickup from a layer of particles begins), (m/s) | |

| Pickup velocity (gas velocity when particles start to move on a surface), (m/s) | |

| Friction coefficient between dust particles and duct, (-) | |

| Gravity acceleration (m/s2) | |

| Deformation tensor | |

| Archimedes number, (-) | |

| Reynold number, (-) | |

| Fluid pressure, (Pa) | |

| Influence factor | |

| Inlet mass flow rate, (kg/s) | |

| Outlet mass flow rate, (kg/s) | |

| K | 2.594, constant |

| 1.0, constant | |

| 1.44, constant | |

| 1.92, constant | |

| 1.3 constant | |

| Particle removal efficiency, (%) | |

| Mass of total particles, (kg) | |

| Mass of residual particles after collection, (kg) | |

| Time-averaged air velocity | |

| Air fluctuating velocity, (m/s) | |

| ) | |

| Turbulent kinetic energy production | |

| Greek letters | |

| ) | |

| ) | |

| Particle removal efficiency, (%) | |

| ) | |

| Kinematic velocity, (m2/s) | |

| ) | |

| Particle shape factor, (-) | |

| k | ) |

| ) | |

| Subscripts | |

| , j | Tensor index |

References

- Bao, Y.; Zhang, Z. Development and performance analysis of a small road sweeper and dust collector. In Proceedings of the 3rd International Symposium on Robotics & Intelligent Manufacturing Technology (ISRIMT), Virtual, 25–26 September 2021. [Google Scholar]

- Avsar, E.; Hanedar, A.; Toroz, I.; Alp, K.; Kaynak, B. Investigation of PM10 concentrations and noise levels of the road sweepers operating in Istanbul-Turkey: A case study. Fresen. Environ. Bull. 2010, 9, 2033–2039. [Google Scholar]

- Nie, W.; Zhang, X.; Peng, H.; Chen, D.; Du, T.; Yang, B.; Liu, C. Research on air curtain dust control technology for environmental protection at fully mechanized working faces. Environ. Sci. Pollut. Res. 2022, 29, 43371–43384. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.M.; Chou, C.M.; Su, K.T.; Tseng, C.H. Effectiveness of street sweeping and washing for controlling ambient TSP. Atmos. Environ. 2005, 39, 1891–1902. [Google Scholar] [CrossRef]

- Calvillo, S.J.; Williams, E.S.; Brooks, B.W. Street dust: Implications for stormwater and air quality, and environmental management through street sweeping. Rev. Environ. Contam. Toxicol. 2015, 233, 71–128. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.; Men, J.; Chen, J. Improving the design of a pickup head for particle removal using computational fluid dynamics. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2011, 225, 939–948. [Google Scholar] [CrossRef]

- Xi, Y.; Dai, Y.; Zhang, X.L.; Zhang, X. Prediction of particle-collection efficiency for vacuum-blowing cleaning system based on operational conditions. Processes 2020, 8, 809. [Google Scholar] [CrossRef]

- Xi, Y.; Zhang, Y.L.; Zhang, X.L.; Dai, Y. Enhancement of particle collection efficiency considering the structural interplay: Particle motion characteristics analysis. Mech. Ind. 2020, 21, 618–634. [Google Scholar] [CrossRef]

- Wu, B.; Men, J.; Chen, J. Study of the particle separation performance of a dust-settling hopper. Chem. Prod. Process Model. 2011, 6, 2–16. [Google Scholar] [CrossRef]

- Wu, B.; Men, J.; Chen, J. Numerical study on particle removal performance of pickup head for a street vacuum sweeper. Powder Technol. 2010, 200, 16–24. [Google Scholar] [CrossRef]

- Xi, Y.; Dai, Y.; Xiao, Y.; Li, W.; Cheng, K. Numerical study on particle suction performance of reverse blowing pickup mouth. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2018. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Yang, C.Z.; Baker, C.; Chen, M.; Zou, X.; Dai, W.L. Effects of expanding zone parameters of vacuum dust suction mouth on flow simulation results. J. Cent. South Univ. 2014, 21, 2547–2552. [Google Scholar] [CrossRef]

- Cai, S.; Bao, G.; Ma, X.; Wu, W.; Bian, G.B.; Rodrigues, J.J.; de Albuquerque, V.H. Parameters optimization of the dust absorbing structure for photovoltaic panel cleaning robot based on orthogonal experiment method. J. Clean. Prod. 2019, 217, 724–731. [Google Scholar] [CrossRef]

- Du, X.; Li, Y.; Tang, Z.; Ma, Z.; Jiang, F.; Zhou, H.; Wu, C.; Ghorbel, F.H. Modeling and experimental verification of a novel vacuum dust collector for cleaning photovoltaic panels. Powder Technol. 2022, 397, 117014. [Google Scholar] [CrossRef]

- Chen, X.; Yang, M.; Deng, K.; Bai, Y. Numerical analysis of a centrifugal fan for a road sweeper. In Fluids Engineering Division Summer Meeting; American Society of Mechanical Engineers: New York, NY, USA, 2017. [Google Scholar] [CrossRef]

- Zhijiang, O.; Zhang, Y.; Jia, G.; Yang, C.; Cao, Y.; Chen, C. Flow properties of dust suction mouth with curled edges. Mech. Sci. Technol. Aerosp. Eng. 2013, 3, 363–366. [Google Scholar] [CrossRef]

- Zheng, N.; Gao, X. Research and design of the cleaning and disinfecting vehicle. In Proceedings of the 2020 International Conference on Computer Engineering and Application (ICCEA), Guangzhouo, China, 27–29 March 2020; IEEE: Wuhan, China, 2020. [Google Scholar] [CrossRef]

- Lee, S.J. Experimental analysis of flow fields inside intake heads of a vacuum cleaner. J. Mech. Sci. Technol. 2005, 19, 894–904. [Google Scholar] [CrossRef]

- He, Y.; Deen, N.G.; Annaland, M.V.; Kuipers, J.A. Gas—Solid turbulent flow in a circulating fluidized bed riser: Experimental and numerical study of monodisperse particle systems. Ind. Eng. Chem. Res. 2009, 48, 8091–8097. [Google Scholar] [CrossRef]

- Goy, S.P.; Chew, J.W.; Hadinoto, K. Effects of binary particle size distribution on minimum pick-up velocity in pneumatic conveying. Powder Technol. 2011, 208, 166–174. [Google Scholar] [CrossRef]

- Hayden, K.S.; Park, K.; Curtis, J.S. Effect of particle characteristics on particle pickup velocity. Powder Technol. 2003, 131, 7–14. [Google Scholar] [CrossRef]

- Pang, L.; Zhang, Z.; Cui, S.; Sun, S. Experimental study of the venting characteristics of dust explosion through a vent duct. J. Loss Prev. Process Ind. 2020, 65, 104144. [Google Scholar] [CrossRef]

- Kalman, H.; Satran, A.; Meir, D.; Rabinovich, E. Pickup (critical) velocity of particles. Powder Technol. 2005, 160, 103–113. [Google Scholar] [CrossRef]

- Hu, S.; Gao, Y.; Feng, G.; Hu, F.; Liu, C.; Li, J. Experimental study of the dust-removal performance of a wet scrubber. Int. J. Coal Sci. Technol. 2021, 8, 228–239. [Google Scholar] [CrossRef]

- Cabrejos, F.J.; Klinzing, G. Incipient motion of solid particles in horizontal pneumatic conveying. Powder Technol. 1992, 72, 51–61. [Google Scholar] [CrossRef]

- Cabrejos, F.J.; Klinzing, G.E. Pickup and saltation mechanisms of solid particles in horizontal pneumatic transport. Powder Technol. 1994, 79, 173–186. [Google Scholar] [CrossRef]

- Neilson, J.H.; Gilchrist, A. An analytical and experimental investigation of the velocities of particles entrained by the gas flow in nozzles. J. Fluid Mech. 1968, 33, 131–149. [Google Scholar] [CrossRef]

- Neilson, J.H.; Gilchrist, A. An analytical and experimental investigation of the trajectories of particles entrained by the gas flow in nozzles. J. Fluid Mech. 1969, 35, 549–559. [Google Scholar] [CrossRef]

- Li, A.; Ahmadi, G. Dispersion and deposition of spherical particles from point sources in a turbulent channel flow. Aerosol Sci. Technol. 1992, 16, 209–226. [Google Scholar] [CrossRef]

- Park, I.S.; Sohn, C.H.; Lee, S.; Song, H.; Oh, J. Flow-induced noise in a suction nozzle with a centrifugal fan of a vacuum cleaner and its reduction. Appl. Acoust. 2010, 71, 460–469. [Google Scholar] [CrossRef]

- Rogoziński, T.; Trofimov, S. Principles of pulse-jet filters used in the woodworking industry. Ann. WULS For. Wood Technol. 2019, 105, 98–101. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Liu, T.; Zuo, W.; Huang, Y. Simulation on entrainment process of suction mouth under negative pressure in the medium dry sanitation trucks. Appl. Mech. Mater. 2014, 711, 86–90. [Google Scholar]

- Jiaqiang, E.; Peng, Q.; Liu, T.; Zuo, W.; Huang, Y. Simulation optimization on sucking up dust particle by suction mouth in sanitation sweepers under the negative pressure. In Proceedings of the 2015 International Forum on Energy, Environment Science and Materials, Guangzhou, China, 25–26 August 2015. [Google Scholar]

- Yang, C.Z.; Zhang, Y.C.; Ouyang, Z.J.; Zhang, J.; Yang, S.Z.; Zhang, R.Z. Parametric design of dust collection port of vacuum sweeper based on flow simulation. J. Cent. South Univ. Sci. Technol. 2012, 43, 3704–3709. [Google Scholar]

- Zhu, H.P.; Zhou, Z.Y.; Yang, R.Y.; Yu, A.B. Discrete particle simulation of particulate systems: A review of major applications and findings. Chem. Eng. Sci. 2008, 63, 5728–5770. [Google Scholar] [CrossRef]

- Jin, Y.; Jiabao, P.; Hejin, A.; Lujun, Z. Relationship between flow field characteristics and dust collection efficiency of sweeper suction port. J. Eng. 2022, 2022, 389–400. [Google Scholar] [CrossRef]

- Alderliesten, M. Mean particle diameters. Part VII. The rosin-rammler size distribution: Physical and mathematical properties and relationships to moment-ratio defined mean particle diameters. Part. Syst. Charact. 2013, 30, 244–257. [Google Scholar] [CrossRef]

- Gul, H.; Alrabaiah, H.; Ali, S.; Shah, K.; Muhammad, S. Computation of solution to fractional order partial reaction diffusion equations. J. Adv. Res. 2020, 25, 31–38. [Google Scholar] [CrossRef] [PubMed]

- Pang, L.; Cao, J.; Xiao, Q.; Yang, K.; Shi, L. Explosion propagation in a dust removal pipeline under dust collector explosion. J. Loss Prev. Process Ind. 2022, 74, 104662. [Google Scholar] [CrossRef]

- Zhaowen, J.; Kai, C.; Yuming, G. Nozzle system performance analysis for suction broom road sweeper. Spec. Purp. Veh. 2012, 6, 92–97. [Google Scholar]

- Gilbert, M.; Davis, L.; Altman, D. Velocity lag of particles in linearly accelerated combustion gases. J. Jet Propuls. 1955, 25, 26–30. [Google Scholar] [CrossRef]

- Ye, J.; Jiabao, P.; Hejin, A.; and Jiamei, W. Pure electric sweeper performance analysis and test verification of dust extraction port. Appl. Sci. 2022, 12, 5188. [Google Scholar] [CrossRef]

- Sher, M.; Kamal, S.; Zareen, A.K.; Hasib, K.; Aziz, K. Computational and theoretical modeling of the transmission dynamics of novel COVID-19 under Mittag-Leffler power law. Alex. Eng. J. 2020, 59, 3133–3147. [Google Scholar] [CrossRef]

- Zeng, G.Y.; Li, X.F.; Xiao, T.Y.; Xu, Y. Simulation for the design of dust suction system of highway sweeper. Syst. Simul. 2004, 16, 2770–2773. [Google Scholar]

- Xin, Y.H.; Li, H.; Wu, J.J. Applications of CFD technique in the flow field analysis of road sweeper. In Applied Mechanics and Materials; Trans Tech Publ: Zurich, Switzerland, 2015. [Google Scholar] [CrossRef]

- Tan, G.; Chen, M.; Xu, H.; Luo, B. Vacuum cleaning vehicle dust subsidence system design. In Proceedings of the SAE 2014 World Congress & Exhibition, Detroit, MI, USA, 8–10 April 2014. [Google Scholar] [CrossRef]

- Haider, A.; Levenspiel, O. Drag coefficient and terminal velocity of spherical and nonspherical particles. Powder Technol. 1989, 58, 63–67. [Google Scholar] [CrossRef]

- Saffman, P.J. The lift on a small sphere in a slow shear flow. J. Fluid Mech. 1965, 22, 385–400. [Google Scholar] [CrossRef] [Green Version]

- Koshkarev, S.A.; Evtushenko, A.I.; Roschin, P.A. Modeling of cleaning of dust emission in fluidized bed building aspiratioz collector. MATEC Web Conf. 2017, 106, 07020. [Google Scholar] [CrossRef] [Green Version]

- Shen, H. Influence of gas flow speed on laser plume attenuation and powder bed particle pickup in laser powder bed fusion. JOM 2020, 72, 1039–1051. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.-J.; Wang, X.-F.; Liu, K.-K. Simulation and optimization of fan system for road sweeper. J. Highw. Transp. Res. Dev. 2018, 12, 92–97. [Google Scholar] [CrossRef]

- Zhou, J.; Xu, L.; Du, C. Prediction of lump coal particle pickup velocity in pneumatic conveying. Powder Technol. 2019, 343, 599–606. [Google Scholar] [CrossRef]

- Li, C.; Deng, Y.; Xin, Y. Flow Field Analysis and Structure Optimization of the Suction Nozzle for Road Sweeper; SAE Technical Paper, 2016-01-1356; SAE International: Warrendale, PA, USA, 2016. [Google Scholar] [CrossRef]

- Stefanenko, I.; Azarov, V.; Borovkov, D. Experimental optimization of dust collecting equipment parameters of counter swirling flow with coaxial leadthrough for air ventilation system and dust elimination. IOP Conf. Ser. Mater. Sci. Eng. 2019, 224, 012037. [Google Scholar] [CrossRef]

- Yang, D.; Liang, X.; Chen, Z.; Sun, Y.; Yin, F. Experimental study and fuzzy prediction of surface bulk negative pressure collection. IOP Conf. Ser. Mater. Sci. Eng. 2019, 612, 042037. [Google Scholar] [CrossRef]

- Zhan, H.; Tan, G.; Gao, Y.; Xia, J.; Xue, W.; Huang, S. Electric sweeping vehicle vacuum dust control system research. In Proceedings of the 2015 IEEE International Transportation Electrification Conference (ITEC), Dearborn, MI, USA, 14–17 June 2015; IEEE: Wuhan. China, 2015. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Length, L (mm) | 1000 |

| Width, B (mm) | 390 |

| Height, h (mm) | 120 |

| Thickness, H (mm) | 20 |

| Outlet duct, D1 (mm) | 110 |

| Inlet duct, D2 (mm) | 65 |

| Inlet duct, D3 (mm) | 65 |

| Feature | Gas Phase | Feature | Solid Phase |

|---|---|---|---|

| Fluid | Air | Particle diameter distribution | Rosin–Rammler |

| Compressibility | Incompressible | Mass velocity (kg/s) | 0.5 |

| Dimensions | 3D | ) | 1.225 |

| Time dependence | Steady state | Spread parameter (n) | 5.95 |

| Turbulence model | (2eqn) | ) | 50 |

| Inlet condition | Velocity inlet | ) | 250 |

| Outlet condition | Pressure outlet | ) | 125 |

| Material | |

|---|---|

| Wood | 600 |

| Sand | 1650 |

| Clay | 2080 |

| Asphalt | 2400 |

| Glass | 2500 |

| PVC | 1230 |

| Polypropylene | 900 |

| Gypsum | 1650 |

| Bricks | 1900 |

| Granite | 2600 |

| Steel | 7850 |

| Material | Shape | Particle Density, | Particle Diameter, | Suction Duct Diameter, D (mm) | |

|---|---|---|---|---|---|

| Asphalt concrete | Non-spherical | 2400 | 3.45 | 100 | 12.33 |

| Granite | Non-Spherical | 2600 | 3.3 | 100 | 13.15 |

| Clay (wet) | Non-spherical | 2080 | 4.1 | 100 | 10.24 |

| Sand | Spherical | 1650 | 3.2 | 100 | 11.32 |

| Gypsum | Non-spherical | 1200 | 3.78 | 100 | 8.83 |

| Glass | Spherical | 2480 | 2.9 | 100 | 14.25 |

| Bricks | Non-spherical | 1900 | 2.75 | 100 | 13.41 |

| PVC | Spherical | 1230 | 3.7 | 100 | 9.06 |

| Polypropylene PP | Spherical | 900 | 3.2 | 100 | 8.98 |

| Gravel | Non spherical | 1800 | 4.8 | 100 | 8.59 |

| Steel | Spherical | 7850 | 2.95 | 100 | 21.82 |

| Airflow Velocity (m/s) | Light Particles Velocity (m/s) | Sandy Particles Velocity (m/s) |

|---|---|---|

| 15 | 13.2 | 11.77 |

| 20 | 17.86 | 15.8 |

| 25 | 22.37 | 19.9 |

| 30 | 27.3 | 24.15 |

| 35 | 31.8 | 28.35 |

| Suction Mouth Distance with Conveyor Belt Surface, L (mm) | Particle’s Size Range, d (mm) | Particle Material | (%) |

|---|---|---|---|

| 120 | 10–25 | Leaf | 0.97 |

| 3 | PVC | 0.93 | |

| 8–20 | Wood | 0.91 | |

| 15 | Paper | 0.98 | |

| 3–5 | Glasses | 0.86 | |

| <5 | Stone–Sand | 0.80 | |

| 130 | 10–25 | Leaf | 0.92 |

| 3 | PVC | 0.87 | |

| 8–20 | Wood | 0.85 | |

| 15 | Paper | 0.93 | |

| 3–5 | Glasses | 0.79 | |

| <5 | Stone–Sand | 0.73 | |

| 140 | 10–25 | Leaf | 0.86 |

| 3 | PVC | 0.81 | |

| 8–20 | Wood | 0.80 | |

| 15 | Paper | 0.89 | |

| 3–5 | Glasses | 0.73 | |

| <5 | Stone–Sand | 0.66 | |

| 150 | 10–25 | Leaf | 0.80 |

| 3 | PVC | 0.74 | |

| 8–20 | Wood | 0.71 | |

| 15 | Paper | 0.82 | |

| 3–5 | Glasses | 0.67 | |

| <5 | Stone–Sand | 0.58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fayzullayevich, J.V.; Tan, G.; Alex, F.J.; Wu, Y.; Agyeman, P.K. Numerical Study of Factors Affecting Particle Suction Efficiency of Pick-Up Head of a Regenerative Air Vacuum Sweeper. Processes 2022, 10, 1252. https://doi.org/10.3390/pr10071252

Fayzullayevich JV, Tan G, Alex FJ, Wu Y, Agyeman PK. Numerical Study of Factors Affecting Particle Suction Efficiency of Pick-Up Head of a Regenerative Air Vacuum Sweeper. Processes. 2022; 10(7):1252. https://doi.org/10.3390/pr10071252

Chicago/Turabian StyleFayzullayevich, Jamshid Valiev, Gangfeng Tan, Frimpong J. Alex, Yongjia Wu, and Philip K. Agyeman. 2022. "Numerical Study of Factors Affecting Particle Suction Efficiency of Pick-Up Head of a Regenerative Air Vacuum Sweeper" Processes 10, no. 7: 1252. https://doi.org/10.3390/pr10071252

APA StyleFayzullayevich, J. V., Tan, G., Alex, F. J., Wu, Y., & Agyeman, P. K. (2022). Numerical Study of Factors Affecting Particle Suction Efficiency of Pick-Up Head of a Regenerative Air Vacuum Sweeper. Processes, 10(7), 1252. https://doi.org/10.3390/pr10071252