Abstract

Based on both theoretical and practical experiences, the measures aimed at controlling emergency shutdowns of stopes have been highlighted. These stopes are connected with the emergency rigid settlements of powered complexes. In terms of the Western Donbas mines, there are certain risks of a shutdown of stopping operations within the zone of primary roof caving. Thus, the causes of emergency rigid settlements of the support may include the following: layers of the main roof rocks are hanging and not timely delaminated; sudden changes in lithology; hydraulic overloading of the main roof; structural flaws of support under certain conditions of its use, etc. In this paper, the theoretical method of scientific cognition was applied, which, with its help, makes it possible to switch from single low-efficiency measures to a set of actions aimed at preventing any uncontrolled situation. Obtaining certain generalized knowledge means obtaining a much deeper representation of reality, penetrating into its essence. The study also involves statistical analysis, being the basis for outlining a zone of primary caving where a high degree of risk is observed. Certainly, the generalization of these measures does not solve the problem completely. Consequently, there will be further attempts to search for and achieve principal new solutions in the future.

Keywords:

underground mining; mining depth; support; coal seam; longwall; collapse of a roof; cutting width 1. Introduction

Nowadays, within the framework of the Paris Agreement and the European Green Deal, the Ukrainian government has started preparing a national integrated plan for the transformation of the energy market for 2021–2030 [1,2,3]. The decarbonization plan means a gradual switch to renewable energy sources and the closure of coal mines [4,5,6,7]. Within this period, coal mining is possible only in terms of the prime cost reductions that can make it competitive in the market of energy carriers, including renewable sources [6,8]. One of the ways to reduce the prime cost of coal is the elimination of shutdown periods of coal mining due to the emergency rigid settlement of the powered support units. The indicated problem is caused by the gradual deterioration of mining and geological conditions in the development of very thin coal seams [9,10,11,12].

A series of papers deal with the problem of emergency shutdowns of coal mining processes due to the dynamic caving of the main roof [13,14,15,16]. Thus, this paper analyzes the regularities of the convergence distribution in a longwall during the rigid settlement of the powered support units that occurred due to thick sandstones within the coal seam roofs, based on the stoping practices of the Western Donbas mines. Kang et al. [17] evaluated a breaking mechanism of the main roof with the help of physical and numerical modeling; as a result, an assumption was presented for the considerable increase in horizontal stresses in the center of the potential breaking zone as a geotechnical sign of massive roof failure. Wang et al. [18] studied the characteristics of the energy of main roof breaking and identified the prerequisites of changes in the parameters, e.g., the breaking rate, the values of deformation ruptures, and the interaction of the broken roof with the rock mass. The research shows that these parameters are quite irregular relative to the main roof breaking. Murmu and Budi [19] developed regressive models to evaluate an interval of primary and periodical spacing of the main roof caving, which was based on the stopping practices of Indian mines. The regressive models were used as deterministic mathematical models modeled by means of the Monte Carlo method. Li et al. [20] analyzed the kinetic interaction of the powered support units with the main roof. They also calculated the dynamic loads of powered support due to the breaking of an overhanging beam. The studies were proved by using the data of microseismical monitoring within a site of deep-level stopes. After the breaking of a rock overhanging beam, the dynamic loads were transferred to the roof contact area of the support units. Relying on practical data of stoping operations, Wang et al. [21] studied the main roof breaking with the help of theoretical analysis as well as numerical and physical modeling. The results showed that for the main roof caving; it is possible to predict by controlling the development of the zones of concentration and elasticity, as well as by the smooth movement of the roof rocks. After the roof rock caving, the stresses sharply decrease their concentration; the elasticity zone demonstrates its quick longitudinal propagation, which can cause high dynamic pressure on a powered support. Szurgacz and Brodny [22] have developed a complex methodology for testing and evaluating the possibilities to use powered support for specified mining and geological conditions. This was based on the analysis of safety and control systems that have helped to adapt the support better for the present conditions, as well as to minimize miners’ operations within dangerous mining zones and improve mining efficiency. Guangchao et al. [23] presented a complex approach to field studies, demonstrating their numerical modeling of stability and method of control for the main roof state during the stoping displacement from an installation chamber. Their research results have shown that a process of roof deformation and breaking during the stoping displacement can be divided into three stages of rock disturbance development: the initial stage, the stage of rapid continuous increase, and the stage of accelerated growth of stresses. Changes in the stresses obtained by numerical modeling have proved the described evolution of the disturbance of mining operations. The numerical modeling results have also demonstrated that preliminary roof lamination considerably reduces the peak stress, decreasing the roof breaking at a coal seam. In the work by Zhang et al. [24], a mechanism of dynamic pressure in stopes was analyzed in terms of the Nan Liang mine with the help of numerical experiments for modeling as well as by means of theoretical analysis. This was the basis for analyzing the characteristics of a coefficient of dynamics and instability under different conditions of rock mass structure, which helped to obtain invaluable experience and understanding of the rock pressure behavior under the given geographical conditions. Tymchenko et al. [25] dealt with the prognosis of probable zones of rigid settlement of the powered support units of longwall along the primary caving zone of the main roof, depending on different geological and stressed conditions. Vlasov and Sydelnykov [26] presented the results of a forecast of rock convergence within a stope obtained with the help of step-by-step computer modeling of stope advancement within the layered transversal-isotropic rock mass. Vlasov et al. [25] presented a statistical analysis of the physical properties of sandstones as a separate lithological subsystem, and Begalinov [27] provided a comprehensive approach to evaluate the stress deformed state of rocks around the haulage roadway, which was successfully implemented in further studies [28].

This analysis has made it possible to perform further modeling of step-by-step stope displacement in a spatial, geomechanical model of an extraction site [29], taking into consideration the changeable availability of sandstones in the roof, in order to determine the degree of its influence on the technology of stoping operations for bituminous coal in the Western Donbas mines. Buzylo et al. [30] substantiated the area of applying a noncantilevered powered support under the complicated mining and geological conditions of mining very thin coal seams. Bondarenko et al. [31] presented substantiation of the parameters for preventing rigid settlement of a powered support while coal seam mining, in terms of MSS “ShU Ternivske” of “DTEK Parlohradvuhillia” PJSC. Bondarenko et al. [32] showed the results of mine studies and computational experiments by a finite element method to calculate a stress–strain state of rock mass while mining thin and very thin coal seams under complicated mining and geological conditions in the Western Donbas mines. Scientists of the “Dnipro University of Technology” [33] indicated the zones of stoping effects on the interaction of powered support and roof rocks. Sadovenko and Tymoshchuk [34] developed a methodology for predicting abnormal roof rock caving in the stopes of the Western Donbas mines, along with the substantiation of technology for its prevention. Dychkovskyi et al. [35] proposed to concentrate on mining operations by using paired stopes operating for one transport and ventilation network. Ovchynnikov [36] substantiated the application of the physicochemical method of roof rock weakening. This method allows for reducing the compression and tensile strengths by 2.5 times. It allows effective roof rock weakening along a line of drilled wells, which leads to the avoidance of exploding and weakening (torpedoing) roofs under the conditions of mines with a high methane content. In studies [37,38,39,40,41], the essence of the effect of stoping advance direction, relative to the system of natural fissility of roof rocks, was considered. Vlasov et al. [42] carried out a factorial analysis to determine the degree of influence of factors that can affect the most probable factors of emergency rigid settlement of the support, excluding the accidental ones. Dychkovskiy et al. [43] investigated the stresses existing during dynamic processes in the rock mass. The modern directions of numerical modeling of rock masses during underground mining were also widely discussed in the literature [44,45,46,47,48].

The analyses of the above-mentioned studies show that there has been no consideration to the complex generalization of the operational experience for measures preventing an emergency shutdown of stopes caused by the emergency rigid settlement of powered support while mining very thin coal seams within the primary main roof caving zone under complicated mining-geological conditions. This will make it possible to more efficiently use the powered complexes under conditions of increased loads of the Western Donbas mines (Ukraine).

In the Western Donbas mines, there are risks of stopping mining operations within the primary roof caving zone. It can be caused by rigid settlement layers of the main roof rocks which are hanging and not timely delaminated. The main goal of this paper is to apply the theoretical method, which helps to switch from single low-efficiency measures to a set of actions aimed at preventing any uncontrolled situation.

2. Mining and Geological Conditions in Western Donbas (Ukraine)

Western Donbas (Ukraine) is characterized by rather complicated mining and geological conditions, including the increasing depth of mining; low ultimate compressive strength of aleurites and argillites; high ultimate strength of both sandstones occurring within a roof and bituminous coal; no connection between the rock layers; high structural inhomogeneity; geological disturbances, etc. Coal extraction, as well as the underworking of a coal rock mass, results in the intense manifestation of rock pressure, which is observed in the form of lamination and breaking of the above-occurring rock layers. This results in the failure of the stope supports and the shutdown of a coal mining process. Practically, cases of incomplete compliance with applied powered support within specific conditions are quite frequent, and hence is the reason why supports are overloaded and experience rigid settlement.

The optimization of stoping parameters, based on the prognosis of possible zones of rigid settlement of the powered support units, favors the minimization of shutdowns owing to the aforementioned reasons and reduced prime cost of coal mining correspondingly. The main task here, however, is the search for an engineering solution that would help use the resource of a powered complex to its full extent in terms of complicated mining, geological conditions and increased loads, along with minimizing the costs of measures for its implementation.

3. Materials and Methods

The research method is represented by generalization that helps implement a set of measures to prevent the emergency rigid settlement of the powered support in terms of the Western Donbas mines within the zone of primary caving of the main roof. While applying this generalization, one can single out and then represent and study the parameters of the modeled objects, which are not subjected to the primary cognition. Generalization is widely applied, however, it does not allow for having definite conclusions.

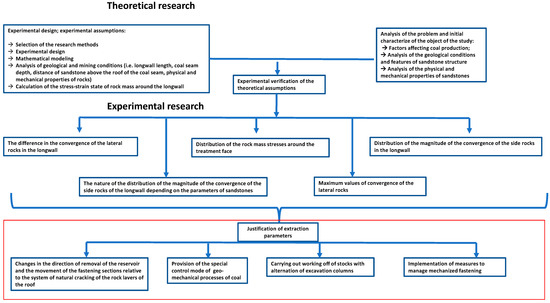

Checking the necessary variants, by means of generalization and the consideration of a set of measures, makes it possible to eliminate certain errors and find effective ways for solving a general problem for emergency stops. The general structural and logical scheme of the study is represented in Figure 1.

Figure 1.

Structural and logical scheme of the study (a red frame outlines a structural-logical scheme of the research).

Figure 1 also shows the following parameters for substantiation: changes in the direction of seam extraction; strengthening of the support resistance reaction; reduction in the mining width; provision of the corresponding mode of control of geomechanical processes; mining of the reserves with alternation of the extracted area; and measures to control powered complexes.

4. Results and Discussion

The following tasks for the research were:

- -

- To outline the boundaries of primary spacing of the main roof caving, for which the parameters of coal mining in terms of very thin coal seams under complicated conditions of the Western Donbas mines were substantiated;

- -

- To perform a comprehensive generalization of the substantiated rational parameters of technology for coal mining within the primary main roof caving zone, based on the variability of mining and geological conditions, which will make it possible to minimize cases of rigid settlement of the powered support units.

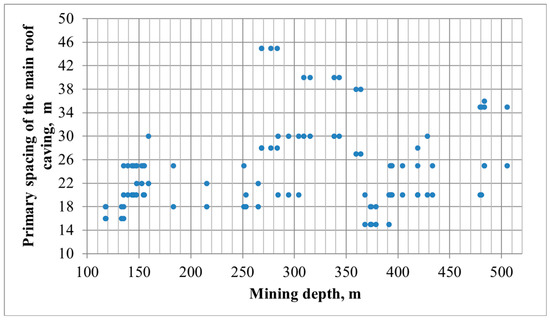

To perform the first task, the boundaries of the primary spacing of the main roof caving were outlined. This was carried out by means of a statistical analysis based on the practices of Western Donbas stopes (Figure 2).

Figure 2.

Dispersion of values of the primary spacing of the main roof caving depending on the depth.

According to Figure 2, a zone of primary main roof caving is within the range of 15.0–45.0 m. At a depth of 120.0–150.0 m as well as at a depth of 370.0–440.0 m, the primary caving spacing has its minimum values of 15.0–20.0 m. At a depth of 220.0–300.0, the caving spacing has a maximum limit of 35.0–45.0 m; at a depth of 470.0–505.0 m, it is 30.0–35.0 m. The 15.0–35.0 value of caving spacing is observed at all depths of the mine working, being 100.0–500.0 m. The scientific contribution of the research, with numerical modeling and an analysis of the stress–strain state around a stope, is presented in this paper [25]. Thus, based on the aforementioned, the zones of the primary main roof caving were outlined, and the sinusoidal nature of the changes in the caving spacing along with the depth was identified. To solve the second problem, a comprehensive generalization of the substantiated rational parameters was performed.

Based on the studies of regularities of changes, such as the convergence value distribution in the longwall, depending on geological and technological parameters as well as changes in its location in space, probable zones of rigid settlement of the powered support units have been forecasted [26]. Thus, emergency shutdowns of a stope were observed only at a depth of 450 m practically throughout the length of the zone of the primary main roof caving, irrespective of the available sandstones within the immediate roof. In this context, the convergence value was 411.0–518.7 mm. Only a value of the length of the settlement zone of the powered support units along the stope, being 5.0–285.0 m, was different, depending on the distance of displacement from an installation chamber as well as its length. Generalizing the parameters of mining very thin coal seams concerns complicated mining and geological conditions at a depth of 450 m, and depends on certain changes in the sandstone’s thickness and distance of its occurrence above the seam roof, which will help in the use of powered complexes under the conditions of increased loads to a greater extent.

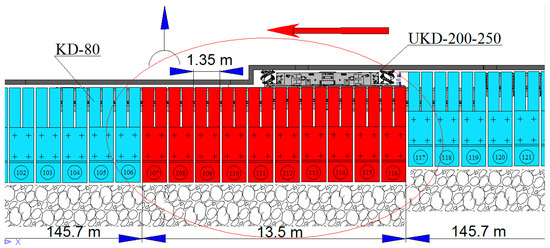

The results of computer modeling show that rock convergence in a stope is described by a curve that has a local extremum within a middle longwall share. In the case of certain positions of a stope along the extraction pillar, a convergence value along the line of the location of hydraulic props of a powered support within its middle share may reach the one being higher than the admissible value of their yielding. In this case, there can be a cutting of the roof rock along the face line, resulting in the emergency longwall shutdown by a rigid settlement of the powered support units, which makes it impossible for both the movement of support units and the shearer to advance (Figure 3 and Figure 4) [26,27,32,34].

Figure 3.

Zone of a convergence value that exceeds the maximum yield of hydraulic props for the conditions of a 450 m mining depth, 10 m distance from the displacement from an installation chamber, and 305 m of longwall length.

Figure 4.

Cutting of the roof rock along the stope line, resulting in rigid settlement of the support units.

When the support yield load is lost or the load formed on the support is exceeded (it often happens due to longwall shutdown or intense lamination of weak roof rocks), there occurs rigid settlement of the hydraulic props (Figure 4) [26,32,34].

This emergency situation is not only connected to considerable operating costs and time for the release of the compressed units but also to their failures (the collapsing of canopies with props, swelling of hydraulic cylinders, and other deformations).

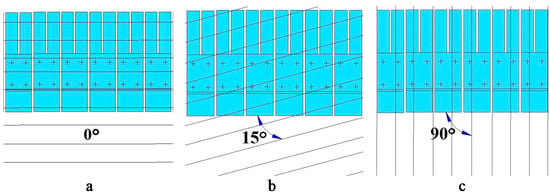

As for the geological factors, it is possible to minimize the effect of structural inhomogeneity (fissility) of rocks. The direction of seam mining and the displacement of the support units, relative to the system of natural fissility of the roof rock, greatly influence the stable operation of a powered support in terms of prevention of the formation of a considerable length of rock hanging over a face. In this context, timely breaking requires that the angle between a face line and crossing of the area of natural roof rock fissility is 0–15.0° (Figure 5a,b) [39,40,41]. If the angle between the face line and crossing of the rock fissility area is about 90°, then their hanging is possible at a length being dangerous for the operation of powered support units (Figure 5c) [39,40,41].

Figure 5.

Direction of seam mining and support unit displacement relative to a system of natural fissility in the roof rock layers: (a) 0°, (b) 15° and (c) 90°.

It should be noted, however, that the parameters described above can be used either with the available sandstones in the roof or at their non-availability, as all the wall enclosing rocks have their own fissility of 0° [29].

To optimize the parameters of the cutting width by a shearer, the rate of its feed, alternation of extraction pillars, mode of longwall operation as well as the operating state of hydraulic props of a powered support were used.

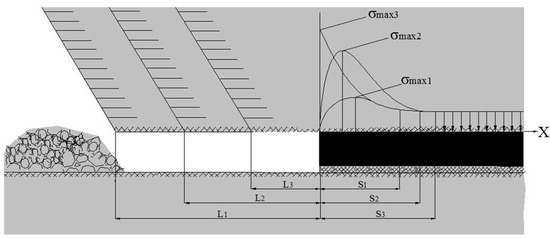

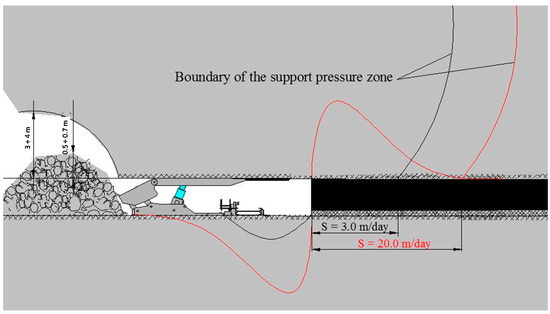

The wider the cutting width of a shearer is, the wider the operating space of a longwall, i.e., the greater the size of the roof rock, hanging in the form of consoles, is (Figure 6).

Figure 6.

Scheme of explanation of the effect of shearer’s cutting width concerning the rock pressure distribution: L1, L2, L3—width of the zone of supported near-face space; S1, S2, S3—width of the zone of support pressure depending on Ln; σmax1, σmax2, σmax3—maximum value of stresses of the zone of support pressure depending on Ln.

In this context, support pressure grows while pressure on the edge share of a seam increases. To reduce a stress–strain state, it is recommended to reduce the cutting width of a shearer as well as the length of the supported span of the roof rock (Figure 6). Switching to coal ploughing makes it possible to reduce the dynamics of the support pressure redistribution. Based on the practices of the stoping operations in the Western Donbas mines, the use of ploughing is stipulated by the inexpediency of shearer operation at deep depths; if shearers demonstrate a rather efficient operation at shallow depths, advantages of ploughing complexes have definitely proved their efficiency at deeper depths.

As a rule, plough-type machines operate within a spalling zone (0.05–0.15 m). Thus, the hanging length of the roof rock consoles does not increase considerably, and support pressure does not experience sharp changes. All the transitional processes in stress changes are smoother compared with the shearer-based extraction method [31,32]. This parameter can be applied in all cases in terms of either available or no available sandstones in the roof.

Currently, shearers extract coal with slow feed velocities, extracting coal in terms of coal spalling zones as well. This results in dynamic processes in the redistribution of pressures within the support zone. When coal is extracted by shearers, a powered support with a cantilevered canopy, reaching two meters, does not stabilize processes of pressure redistribution in time. As a result, roof rock cutting along the longwall face line under certain conditions may be observed that cause an emergency shutdown. When the roof rocks are being cut along the longwall face, loads on the support units increase sharply, taking on the rock weight being distributed equally over the canopy area (Figure 4). Based on the design features of a modern support, in case of equal load distribution, a cantilevered share of a unit creates a moment of forces, thus resulting in its turnover [31].

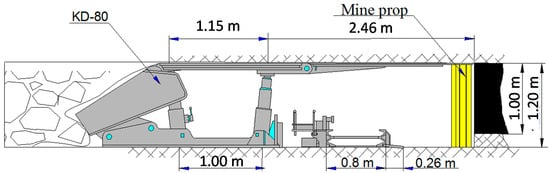

In order to eliminate the design drawbacks of a powered support, increase its bearing capacity, and stabilize anomalous stresses within the rocks neighboring a stope, it is proposed to intensify the support reaction of a powered support by installing (underpropping) additional strength support in the form of mine wooden props in the face under the cantilevered share of a unit canopy. This is because the minimum reaction of support at any crossing of a mine working generates a maximum load from the weight of the breaking zone rocks (Figure 7) [23,24].

Figure 7.

Structural elimination of the drawbacks of a powered support and increase in its bearing capacity.

It has been identified that the more the yielding of that support is, the better the rock state is; and the quicker such support is erected behind a shearer, the more stable the rocks will be [23].

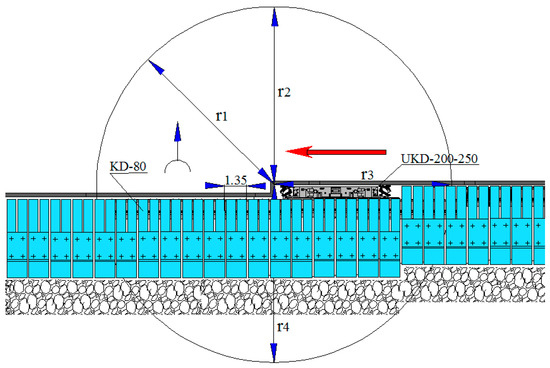

According to the available data, a zone of coal extraction by shearers in the Donbas mines experience its expansion towards a zone of front support pressure before a shearer r1, behind a shearer r3, onto the rock mass r2, and into the mined-out space r4. In this context, r1 ≅ r2 ≅ r3 ≅ 10–12 m. The interruption of a coal extraction process in the longwall results in the relative stabilization of pressure redistribution. Rock deformations during this period continue; however, their velocity decreases (Figure 8) [34].

Figure 8.

Configuration of a zone of shearer influence on the roof rock displacement.

Displacement of the powered support units also influences qualitatively the surrounding rocks, i.e., it considerably deteriorates the state of the immediate roof in a stope. After the displacement of units, consoles of the immediate rock experience their shortening, i.e., the immediate roof breaks within the worked-out space. This reduces the rock stress around a coal seam and within its edge share. Since the indicated main processes in the advancing stope repeat cyclically, the anomalies of stresses within the support zone are also of a continuously cyclical nature.

If the stope advance rate increases, then the width of a zone of support rock pressure increases as well; moreover, the coefficient of concentration of support stress grows, and the maximum of the support rock pressure approaches a face. In all cases, along with the increasing rate of face advance, the state of the immediate roof rock improves, and loads on a face support increase. This is proved by the practices of longwall operation under diverse mining and technical conditions (Figure 9) [32,33,34,35].

Figure 9.

Effect of the face advance rate on the distribution of support rock pressure.

To reduce the load on the development mine workings within the mined-out space, it is recommended to intensify a protective row by switching from the breaker row to the chock-type support [34].

It is also expedient to mine reserves with alternations of extraction pillars by driving new development mine workings for each longwall. Thus, a longwall mines the extraction pillar which neighbors the mined-out space, considerably influencing the processes of above-coal thickness, on both sides [32,34].

Geomechanical displacement processes of the above-coal thickness are controlled as follows. It is required to determine the coordinates according to the length of the extraction pillar of the main roof caving within the already mined-out sites and not to allow any coincidences in the forecasted places of the main roof caving in the longwall, which has experienced caving before. To do this, it is necessary to reduce the stope advance rate down to 3.0–4.0 m/day, during and not less than 2 working days, which will be about 6.0–8.0 m to the previously determined places of the main roof caving in a longwall [32,35].

Subsequently, there should be a following two-stage mode of longwall operation. After the main roof caving, the stope advance rate within the consequent 2 days should be maximally possible (6.0–8.0 m/day) with a 12.0–16.0 m mining of the extraction pillar. During the next two days, the stope advance rate should be no more than 3.0–4.0 m/day with the mining of 6.0–8.0 m of the extraction pillar. After the early main roof caving, a maximum stope advance rate should be provided. If the main roof caving failed to be provoked, then it is required to switch to an intensive mode of mining at the site within not more than three days. Further, the enumerated operations are to be repeated [32,35].

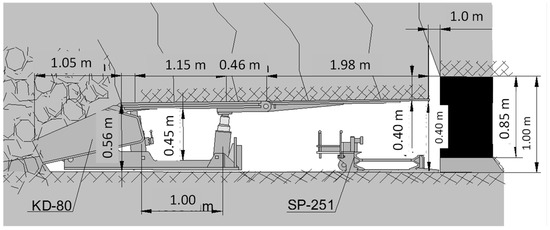

Subsequently, the following measures to control powered support of the 1KD-80 type are to be considered. One should ensure the constant monitoring of pressure in the hydraulic props with an insufficient setting load by regular readings of the pressure indices in the piston cavities. When a unit displaces, it is required to apply an additional setting load to both the front and rare rows of hydraulic props. In the case of the formation of inrushes or false roofs, one should put chocks on the unit canopies or move lower from the roof, leaving a coal bench of 0.1–0.15 m thickness along the roof. In the case of a long-term shutdown of stoping (more than 6 h), the powered support units are to be displaced immediately adjacent to a face. Additional load-bearing supports under the cantilevered part are to be installed in the units with the increased load on the canopy cantilevers (face of the front rows of hydraulic props with the height of 0.01–0.03 m) [32,33,35].

The use of powered support with a much higher bearing capacity in the longwall with a weak floor and a high value of roof layer thickness, as well as their specific physical and mechanical properties, is inexpedient, as it may result in pressing the powered support units into the floor, and is also often accompanied by a rigid settlement of the support.

If there are thick sandstones (m ≥ 5.0 m) in the immediate roof at a depth of H ≥ 450 m [14], it is necessary to apply a preliminary exploding weakening (torpedoing) to a hard-to-cave roof–local weakening of hard rock at the main roof in front of a stoping, by blasting explosive charges in long wells. Advancing torpedoing is a universal method for any mining and geological conditions with the occurrence of seams in hard-to-cave roof rock. This is in terms of any rock thickness and hardness occurring in mines while pillar mining during well drilling and blasting, from the mine workings being ventilated, owing to general shaft depression. Artificial radial fractures, formed as a result of an explosion, and broken contacts within the layering area, can grow into the main fractures along with the approaching of a stope. The latter dissects the rock mass of the main roof into blocks throughout height and layering. As a result of weakening, the hard-to-cave rocks of the main roof are divided into blocks of lesser size. This results in a considerable reduction in the spacing length of primary caving with the main roof, as well as decreased values of load on the stoping support, and minimization of emergency rigid settlement of a powered support.

In terms of mines with high methane content, where explosions are dangerous, a physicochemical method of weakening should be applied [37]. During the physicochemical interaction of effective 6.0% solutions of chemical weakening agents, such as Na2CO3 and NaOH, the volumetric breaking of chemical bonds in a sandstone structure takes place in micro- and macro-fractures in the roof, being f > 7, along a line of drilled wells. In this context, compression and tensile strengths of sandstones decrease by 2.5 times, favoring dilatancy along the line of drilled wells that exclude exploding roof weakening (torpedoing) in terms of very gassy mines [37].

The above-mentioned measures cannot one hundred percent guarantee the elimination of emergency shutdowns of stopping operations. Therefore, this requires further development of more innovative ideas concerning the issue. Therefore, future publications will deal with these considered problems.

5. Conclusions

- The proposed theoretical method allows switching from single low-efficiency measures to a set of actions aimed at preventing any uncontrolled situation in the Western Donbas mines.

- The presented solution allows for minimizing the risk of braking mining activities within the primary roof caving zone.

- The research results have made it possible to substantiate such parameters as follows: changes in the direction of seam extraction relative to a system of intrinsic fractures in the roof rock layers; width of shearer cutting by switching to ploughing; rate of plough assembly supply and the corresponding rate of stope advance; the increasing reaction of powered support resistance; alternation of the extraction pillars; mode of the longwall operation; control of the changes in the operation of powered support hydraulic props; control of advanced explosive and physicochemical weakening of hard-caving rock mass.

- The above-mentioned parameters make it possible to use more efficiently, and to the fullest extent possible, the powered complexes under the conditions of increased loads.

- The identified parameters are useful to develop recommendations to apply to mining very thin coal seams within the primary caving of the main roof zone under complicated mining and geological conditions of the Western Donbas mines, as well as to minimize the cases of emergency rigid settlements of the powered support units that will increase the efficiency of coal mining.

- The identified parameters are expected to be useful in terms of minimizing the risk of cases of emergency rigid settlements of the powered support units, which will increase the efficiency of coal mining.

Author Contributions

Conceptualization, S.V., Y.M., R.D., E.C., N.H., K.W., A.B. and A.S.; methodology, S.V., Y.M., R.D., N.H., A.B. and A.S.; validation, S.V. and Y.M.; formal analysis, S.V., Y.M., R.D., N.H., K.W., A.B. and A.S.; investigation, S.V., Y.M., R.D. and E.C.; writing—original draft preparation, S.V., Y.M. and R.D.; writing—review and editing, S.V., Y.M., R.D. and N.H.; visualization, S.V., Y.M. and R.D.; supervision, A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wierzbowski, M.; Filipiak, I.; Lyzwa, W. Polish energy policy 2050—An instrument to develop a diversified and sustainable electricity generation mix in coal-based energy system. Renew. Sustain. Energy Rev. 2017, 74, 51–70. [Google Scholar] [CrossRef] [Green Version]

- Schmid, D.; Korkmaz, P.; Blesl, M.; Fahl, U.; Friedrich, R. Analyzing transformation pathways to a sustainable European energy system—Internalization of health damage costs caused by air pollution. Energy Strategy Rev. 2019, 26, 100417. [Google Scholar] [CrossRef]

- Tokarski, S.; Magdziarczyk, M.; Smoliński, A. Risk management scenarios for investment program delays in the Polish power industry. Energies 2021, 146, 110. [Google Scholar] [CrossRef]

- Kirkerud, J.G.; Nagel, N.O.; Bolkesj, T.F. The role of demand response in the future renewable northern European energy system. Energy 2021, 235, 121336. [Google Scholar] [CrossRef]

- Howaniec, N.; Smoliński, A. Biowaste utilization in the process of co-gasification with hard coal and lignite. Energy 2017, 118, 18–23. [Google Scholar] [CrossRef]

- Smoliński, A.; Stańczyk, K.; Howaniec, N. Steam gasification of selected energy crops in a fixed bed reactor. Renew. Energy 2010, 35, 397–404. [Google Scholar] [CrossRef]

- Smolinski, A.; Howaniec, N.; Gasior, R.; Polański, J.; Magdziarczyk, M. Hydrogen rich gas production through co-gasification of low rank coal, flotation concentrates and municipal refuse derived fuel. Energy 2021, 235, 121348. [Google Scholar] [CrossRef]

- Potrča, S.; Čučeka, L.; Martin, M.; Kravanja, Z. Sustainable renewable energy supply networks optimization—The gradual transition to a renewable energy system within the European Union by 2050. Renew. Sustain. Energy Rev. 2021, 146, 111186. [Google Scholar] [CrossRef]

- Rabe, M.; Bilan, Y.; Widera, K.; Vasa, L. Application of the Linear Programming Method in the Construction of a Mathematical Model of Optimization Distributed Energy. Energies 2022, 15, 1872. [Google Scholar] [CrossRef]

- Castelli, F.; Grasso, S.; Lentini, V.; Sammito, M.S.V. Effects of Soil-Foundation-Interaction on the Seismic Response of a Cooling Tower by 3D-FEM Analysis. Geosciences 2021, 11, 200. [Google Scholar] [CrossRef]

- Kopacz, M.; Kulpa, J.; Galica, D.; Dyczko, A.; Jarosz, J. Economic valuation of coal deposits—The value of geological information in the resource recognition process. Resour. Policy 2019, 63, 101450. [Google Scholar] [CrossRef]

- Uteshov, Y.; Galiyev, D.; Galiyev, S.; Rysbekov, K.; Nauryzbayeva, D. Potential for increasing the efficiency of design processes for mining the solid mineral deposits based on digitalization and advanced analytics. Min. Miner. Depos. 2021, 15, 102–110. [Google Scholar] [CrossRef]

- Wojtacha-Rychter, K.; Smoliński, A. Multi-component gas mixture transport through porous structure of coal. Fuel 2018, 233, 37–44. [Google Scholar] [CrossRef]

- Vlasov, S.F.; Moldavanov, Y.V. Results of the analysis of the nature of convergence distribution in the longwall during rigid settlement of the powered support units in terms of Western Donbas mines. Messenger Kryvyi Rih Natl. Univ. 2020, 51, 3–8. [Google Scholar] [CrossRef]

- Fedorov, E.; Kassymkanova, K.K.; Jangulova, G.; Miletenko, N. The influence of extensive caving zones on the state and behavior of the surface as a result of underground mining works. E3S Web Conf. 2020, 192, 03009. [Google Scholar] [CrossRef]

- Sotskov, V.; Saleev, I. Investigation of the rock massif stress strain state in conditions of the drainage drift overworking. In Annual Scientific-Technical Collection–Mining of Mineral Deposits; CRC Press: Leiden, The Netherlands, 2013; pp. 197–201. [Google Scholar] [CrossRef]

- Kang, H.; Lou, J.; Gao, F.; Yang, J.; Li, J. A physical and numerical investigation of sudden massive roof collapse during longwall coal retreat mining. Int. J. Coal Geol. 2018, 188, 25–36. [Google Scholar] [CrossRef]

- Wang, J.; Ning, J.; Qiu, P.; Yang, S.; Shang, H. Microseismic monitoring and its precursory parameter of hard roof collapse in longwall faces: A case study. Geomech. Eng. 2019, 17, 375–383. [Google Scholar] [CrossRef]

- Murmu, S.; Budi, G. A probability-based risk assessment of roof strata weighting in longwall panels. Arab. J. Geosci. 2021, 14, 362–378. [Google Scholar] [CrossRef]

- Li, C.; Zuo, J.; Shi, Y.; Wei, C.; Duan, Y.; Zhang, Y.; Yu, H. Deformation and fracture at floor area and the correlation with main roof breakage in deep longwall mining. Nat. Hazards 2021, 107, 1731–1755. [Google Scholar] [CrossRef]

- Wang, P.; Jiang, J.; Xu, B. Breaking and Instability Movement Characteristics of High-Position Double-Layer Hard Thick Strata due to Longwall Mining. Shock. Vib. 2020, 2020, 8887026. [Google Scholar] [CrossRef]

- Szurgacz, D.; Brodny, J. Adapting the Powered Roof Support to Diverse Mining and Geological Conditions. Energies 2020, 13, 405. [Google Scholar] [CrossRef] [Green Version]

- Guangchao, Z.; Chuanwei, Z.; Chen, M.; Guangzhe, T.; You, L.; Weihua, H.; Deshuai, Z. Ground response of entries driven adjacent to a retreating longwall panel. Int. J. Rock Mech. Min. Sci. 2021, 138, 104–115. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, B.; Bai, W.; Yang, S. A Study on the Mechanism of Dynamic Pressure during the Combinatorial Key Strata Rock Column Instability in Shallow Multi-coal Seams. Adv. Civ. Eng. 2021, 2021, 6664487. [Google Scholar] [CrossRef]

- Vlasov, S.; Moldavanov, Y. Effect of geological and technological parameters on the convergence in a stope. Sci. Bull. Natl. Min. Univ. 2021, 6, 16–22. [Google Scholar] [CrossRef]

- Vlasov, S.F.; Sidelnikov, O.A. Spatial Modelling of Geomechanical Processes While Underground Mining; National Mining University: Dnepropetrovsk, Ukraine, 2012; ISBN 978-966-350-348-6. [Google Scholar]

- Begalinov, A.; Almenov, T.; Zhanakova, R.; Bektur, B. Analysis of the stress deformed state of rocks around the haulage roadway of the Beskempir field. Min. Miner. Depos. 2020, 14, 28–36. [Google Scholar] [CrossRef]

- Matayev, A.; Kainazarova, A.; Arystan, I.; Abeuov, Y.; Kainazarov, A.; Baizbayev, M.; Demin, V.; Sultanov, M. Research into rock mass geomechanical situation in the zone of stope operations influence at the 10th Anniversary of Kazakhstan’s Independence mine. Min. Miner. Depos. 2021, 15, 103–111. [Google Scholar] [CrossRef]

- Nikolsky, V.; Dychkovskyi, R.; Cabana, C.E.; Howaniec, N.; Jura, B.; Widera, K.; Smoliński, A. The Hydrodynamics of Translational−Rotational Motion of Incompressible Gas Flow within the Working Space of a Vortex Heat Generator. Energies 2022, 15, 1431. [Google Scholar] [CrossRef]

- Busylo, V.I.; Serdiuk, V.P.; Koshka, A.G.; Yavorska, Y.O.; Koroviaka, Y.A.; Yavorsky, A.V. Substantiating the Parameters and Area of Using Noncantilevered Powered Supports of Coal Face Systems; National Mining University: Dnipropetrovsk, Ukraine, 2014; ISBN 978-966-350-498-8. [Google Scholar]

- Bondarenko, V.I.; Symanovych, G.A.; Tymoshchuk, V.I.; Russkykh, V.V. Recommendations on Preventing Rigid Settlement of Powered Support KD-80 While Mining Longwall 541 of Seam C5, Block #3 of MSS “ShU Ternivske”, “Samarska” ME; National Mining University: Dnipropetrovsk, Ukraine, 2012; pp. 1–3. [Google Scholar]

- Bondarenko, V.I.; Kovalevska, I.A.; Symanovych, G.A.; Chervatiuk, V.G. Geomechanics of Support Loads of Stopings and Development Mine Workings in a Layered Weak-Rock Mass; National Mining University: Dnipropetrovsk, Ukraine, 2012; ISBN 978-966-2575-13-2. [Google Scholar]

- Kharchenko, V.V.; Ovchinnikov, V.I.; Sulaiev, V.I.; Gaidai, A.A.; Russkikh, V.V. Stoping Processes in Terms of Seams of Coal Mines; National Mining University: Dnipropetrovsk, Ukraine, 2014; ISBN 978-966-350-499-5. [Google Scholar]

- Sadovenko, I.A.; Tymoshchuk, V.I. Developing a Method to Forecast Anomalous Subsidence of the Watered Rock Roof in Stopes of Western Donbas Mines and Substantiating Technological Measures for Its Prevention; National Mining University: Dnipropetrovsk, Ukraine, 2014. [Google Scholar]

- Dychkovskyi, R.; Shavarskyi, I.; Saik, P.; Lozynskyi, V.; Falshtynskyi, V.; Cabana, E. Research into stress-strain state of the rock mass condition in the process of the operation of double-unit longwalls. Min. Miner. Depos. 2020, 14, 85–94. [Google Scholar] [CrossRef]

- Ovchinnikov, V.I. Physical and Technical Basis of the Technology to Control Hard-to-Cave Roof While Mining. Habilitation Thesis, National Mining Academy of Ukraine, Dnepropetrovsk, Ukraine, 2001. [Google Scholar]

- Tymchenko, S.E.; Tymchenko, E.M.; Vlasov, S.F.; Vlasov, V.S.; Kovalenko, V.L.; Kotok, V.A. Foundation of a mathematical method for analysis of voice commands. J. Eng. Appl. Sci. 2019, 14, 1908–1918. [Google Scholar]

- Matayev, A.; Abdiev, A.; Kydrashov, A.; Musin, A.; Khvatina, N.; Kaumetova, D. Research into technology of fastening the mine workings in the conditions of unstable masses. Min. Miner. Depos. 2021, 15, 78–86. [Google Scholar] [CrossRef]

- Melnikov, Y.F.; Manko, A.A. Features of the fissured roof control. Coal 1971, 2, 22–25. [Google Scholar]

- Zhingel, I.P. A method to forecast coal of the stope-fissure network contact while longwall mining of coal seams. Coal 1970, 1, 58–59. [Google Scholar]

- Aben, E.; Toktaruly, B.; Khairullayev, N.; Yeluzakh, M. Analyzing changes in a leach solution oxygenation in the process of uranium ore borehole mining. Min. Miner. Depos. 2021, 15, 39–44. [Google Scholar]

- Vlasov, S.; Timchenko, S.; Moldavanov, Y. Factor analysis of components influencing the effectiveness of coal production in the conditions of the mine of PJSC “DTEK Pavlogradvugillia”. J. Donetsk Min. Inst. 2020, 1, 19–27. [Google Scholar] [CrossRef]

- Dychkovskyi, R.; Tabachenko, M.; Zhadiaieva, K.; Dyczko, A.; Cabana, E. Gas hydrates technologies in the joint concept of geoenergy usage. E3S Web Conf. 2021, 230, 01023. [Google Scholar] [CrossRef]

- Azarafza, M.; Bonab, M.H.; Akgun, H. Numerical analysis and stability assessment of complex secondary toppling failures: A case study for the south pars special zone. Geomech. Eng. 2021, 27, 479–493. [Google Scholar]

- Dong, L.; Zou, W.; Li, X.; Shu, W.; Wang, Z. Collaborative localization method using analytical and iterative solutions for microseismic/acoustic emission sources in the rockmass structure for underground mining. Eng. Fract. Mech. 2019, 210, 95–112. [Google Scholar] [CrossRef]

- Ścigała, R.; Szafulera, K. Linear discontinuous deformations created on the surface as an effect of underground mining and local geological conditions-case study. Bull. Eng. Geol. Environ. 2020, 79, 2059–2068. [Google Scholar] [CrossRef]

- Mehrabi, A.; Derakhshani, R.; Nilfouroushan, F.; Rahnamarad, J.; Azarafza, M. Spatiotemporal subsidence over Pabdana coal mine Kerman Province, central Iran using time-series of Sentinel-1 remote sensing imagery. Epis. J. Int. Geosci. 2022, 10, 1–15. [Google Scholar] [CrossRef]

- Ren, Z.; Wang, L.; Bi, L. Robust GICP-based 3D LiDAR SLAM for underground mining environment. Sensors 2019, 19, 2915. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).