Effect of Drying Methods and Processing Conditions on the Quality of Curcuma longa Powder

Abstract

:1. Introduction

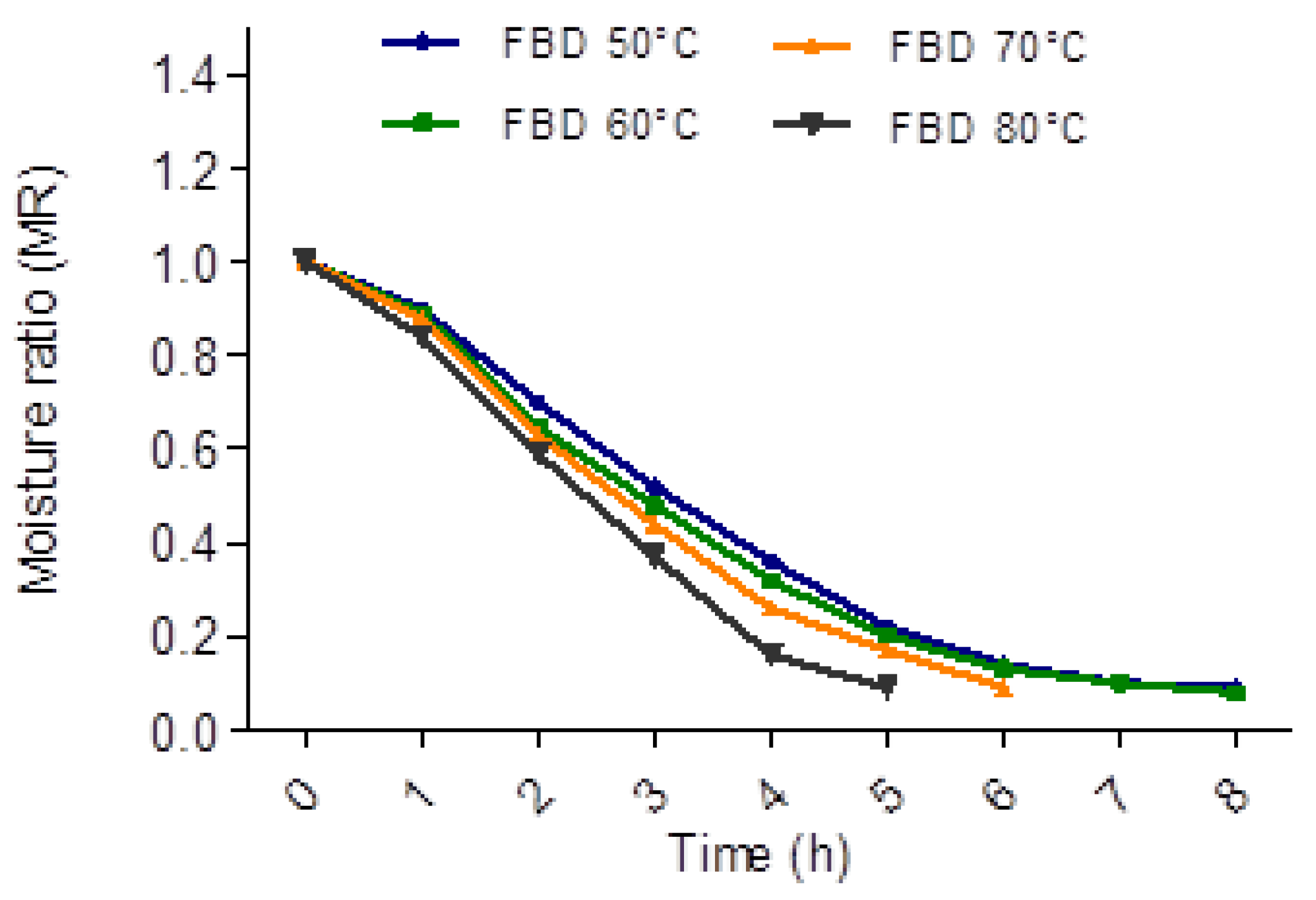

2. Materials and Methods

2.1. Reagents

2.2. Vegetal Material

2.3. Drying Experiments

2.3.1. Traditional Solar Drying (TSD)

2.3.2. Convection Oven Drying (COD)

2.3.3. Fluidized Bed Drying (FBD)

2.4. Turmeric Powder Production

2.5. Turmeric Powder Characterization

2.5.1. Moisture Content and Water Activity

2.5.2. Determination of Curcuminoid Content

2.5.3. Determination of Antioxidant Capacity

2.5.4. Color Measurements

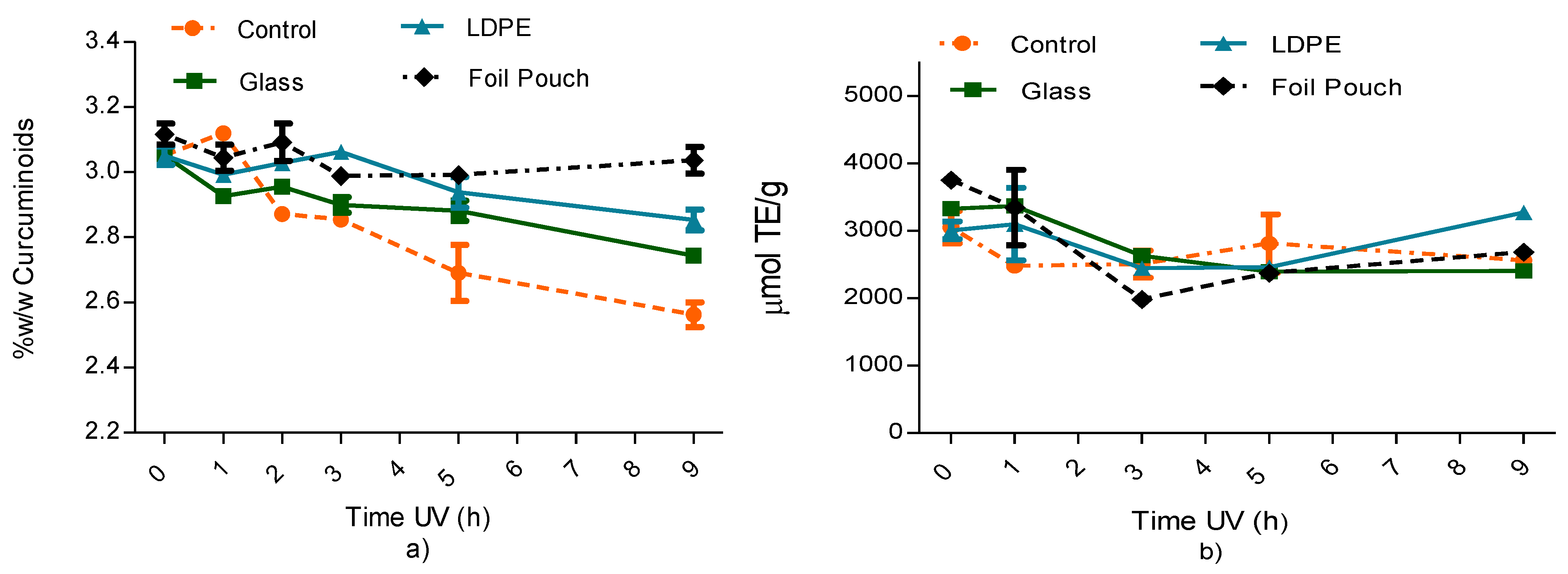

2.6. UV Radiation Effect Using Different Packaging Materials

2.7. Effect of Temperature of Drying

2.8. Statistical Analysis

3. Results

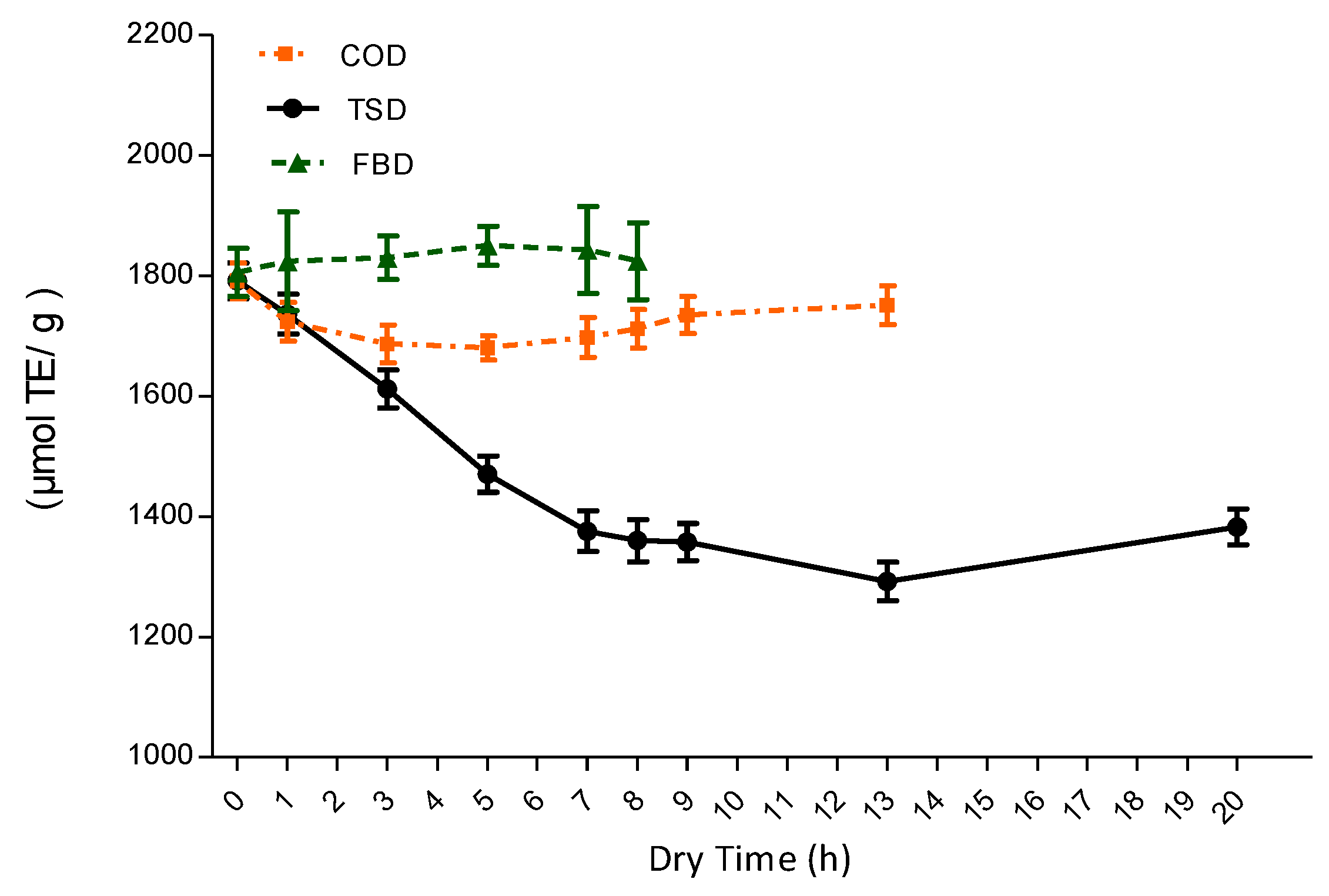

3.1. Drying Experiments Results

3.1.1. Curcuminoid Content

3.1.2. Antioxidant Capacity

3.1.3. Color

3.2. Effect of Drying Temperature on Curcuminoids Content, Antioxidant Capacity and Drying Time

3.3. UV Radiation Effect Using Different Packaging Materials

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Govindarajan, V.S.; Stahl, W.H. Turmeric—Cheamistry, technology, and quality. Crit. Rev. Food Sci. Nutr. 1980, 12, 199–301. [Google Scholar] [CrossRef] [PubMed]

- Martins, R.; Pereira, S.V.; Siqueira, S.; Salomão, W.F.; Freitas, L.A.P. Curcuminoid content and antioxidant activity in spray dried microparticles containing turmeric extract. Food Res. Int. 2011, 50, 657–663. [Google Scholar] [CrossRef] [Green Version]

- Oh, S.H.; Jang, C.S. Development and Validation of a Real-Time PCR Based Assay to Detect Adulteration with Corn in Commercial Turmeric Powder Products. Foods 2020, 9, 882. [Google Scholar] [CrossRef] [PubMed]

- Khodabakhshian, R.; Bayati, M.R.; Emadi, B. An evaluation of IR spectroscopy for authentication of adulterated turmeric powder using pattern recognition. Food Chem. 2021, 364, 130406. [Google Scholar] [CrossRef] [PubMed]

- Chumroenphat, T.; Somboonwatthanakul, I.; Saensouk, S.; Siriamornpun, S. Changes in curcuminoids and chemical components of turmeric (Curcuma longa L.) under freeze-drying and low-temperature drying methods. Food Chem. 2020, 339, 128121. [Google Scholar] [CrossRef]

- Kandiannan, K.; Chandaragiri, K.; Sankaran, N.; Balasubramanian, T.; Kailasam, C. Crop–weather model for turmeric yield forecasting for Coimbatore district, Tamil Nadu, India. Agric. For. Meteorol. 2002, 112, 133–137. [Google Scholar] [CrossRef]

- Komonsing, N.; Khuwijitjaru, P.; Nagle, M.; Müller, J.; Mahayothee, B. Effect of drying temperature together with light on drying characteristics and bioactive compounds in turmeric slice. J. Food Eng. 2021, 317, 110695. [Google Scholar] [CrossRef]

- Kilic, S.; Oz, E.; Oz, F. Effect of turmeric on the reduction of heterocyclic aromatic amines and quality of chicken meatballs. Food Control 2021, 128, 108189. [Google Scholar] [CrossRef]

- MinAgricultura. Reporte: Importaciones del Sector Agropecuario. Valor y Volumen, por Producto, por Cadena, por Partida y País de Origen. Cúrcuma. Agronet, Ministerio de Agricultura de Colombia. 2021. Available online: https://www.agronet.gov.co/estadistica/Paginas/home.aspx?cod=24 (accessed on 26 March 2022).

- Ali, Z.; Saleem, M.; Atta, B.; Khan, S.S.; Hammad, G. Determination of curcuminoid content in turmeric using fluorescence spectroscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2019, 213, 192–198. [Google Scholar] [CrossRef]

- Jayaprakasha, G.K.; Jagan Mohan Rao, L.; Sakariah, K.K. Antioxidant activities of curcumin, demethoxycurcumin and bisdemethoxycurcumin. Food Chem. 2006, 98, 720–724. [Google Scholar] [CrossRef]

- Jurenka, J.S. Anti-inflammatory properties of curcumin, a major constituent of Curcuma longa: A review of preclinical and clinical research. Altern. Med. Rev. A J. Clin. Ther. 2009, 14, 141–153. [Google Scholar]

- López-Lázaro, M. Anticancer and carcinogenic properties of curcumin: Considerations for its clinical development as a cancer chemopreventive and chemotherapeutic agent. Mol. Nutr. Food Res. 2008, 52, S103–S127. [Google Scholar] [CrossRef] [PubMed]

- Moghadamtousi, S.Z.; Kadir, H.A.; Hassandarvish, P.; Tajik, H.; Abubakar, S.; Zandi, K. A Review on Antibacterial, Antiviral, and Antifungal Activity of Curcumin. BioMed Res. Int. 2014, 2014, 186864. [Google Scholar] [CrossRef]

- Mythri, R.B.; Srinivas Bharath, M.M. Curcumin: A potential neuroprotective agent in Parkinson’s disease. Curr. Pharm. Des. 2012, 18, 91–99. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Olszanecki, R.; Jawień, J.; Gajda, M.; Mateuszuk, L.; Gebska, A.; Korabiowska, M.; Chłopicki, S. Effect of curcumin on a therosclerosis in apo e/ldlr–double knockout mice. J. Physiol. Pharm. 2005, 65, 376–380. [Google Scholar]

- Karlsen, J. Studies on curcumin and curcuminoids—5. Alkaline Degradation of Curcumin. Z. Für Lebensm. Unters. Und Forsch. 1985, 180, 132–134. [Google Scholar] [CrossRef]

- Tønnesen, H.H.; Karlsen, J.; van Henegouwen, G.B. Studies on curcumin and curcuminoids VIII. Photochemical stability of curcumin. Z. Lebensm. Unters. Forsch. 1986, 183, 116–122. [Google Scholar] [CrossRef] [PubMed]

- Lee, B.H.; Choi, H.A.; Kim, M.-R.; Hong, J. Changes in chemical stability and bioactivities of curcumin by ultraviolet radiation. Food Sci. Biotechnol. 2013, 22, 279–282. [Google Scholar] [CrossRef]

- Hirun, S.; Utama-Ang, N.; Roach, P.D. Turmeric (Curcuma longa L.) drying: An optimization approach using microwave-vacuum drying. J. Food Sci. Technol. 2012, 51, 2127–2133. [Google Scholar] [CrossRef] [Green Version]

- Madan, M.S. Turmeric. In Turmeric: The Genus Curcuma; Ravindran, K.S.P.N., Nirmal Babu, K., Eds.; CRC Press: Boca Raton, FL, USA, 2007; pp. 369–408. [Google Scholar]

- Jose, K.P.; Joy, C.M. Solar tunnel drying of turmeric (Curcuma longa linn. syn. c. domestica val.) for quality improvement. J. Food Process. Preserv. 2009, 33, 121–135. [Google Scholar] [CrossRef]

- An, K.; Zhao, D.; Wang, Z.; Wu, J.; Xu, Y.; Xiao, G. Comparison of different drying methods on Chinese ginger (Zingiber officinale Roscoe): Changes in volatiles, chemical profile, antioxidant properties, and microstructure. Food Chem. 2016, 197, 1292–1300. [Google Scholar] [CrossRef] [PubMed]

- Nukulwar, M.R.; Tungikar, V.B. Drying kinetics and thermal analysis of turmeric blanching and drying using solar thermal system. Sustain. Energy Technol. Assess. 2021, 45, 101120. [Google Scholar] [CrossRef]

- Borah, A.; Hazarika, K.; Khayer, S. Drying kinetics of whole and sliced turmeric rhizomes (Curcuma longa L.) in a solar conduction dryer. Inf. Process. Agric. 2015, 2, 85–92. [Google Scholar] [CrossRef] [Green Version]

- Prathapan, A.; Lukhman, M.; Arumughan, C.; Sundaresan, A.; Raghu, K.G. Effect of heat treatment on curcuminoid, colour value and total polyphenols of fresh turmeric rhizome. Int. J. Food Sci. Technol. 2009, 44, 1438–1444. [Google Scholar] [CrossRef]

- Cousins, M.; Adelberg, J.; Chen, F.; Rieck, J. Antioxidant capacity of fresh and dried rhizomes from four clones of turmeric (Curcuma longa L.) grown in vitro. Ind. Crop. Prod. 2007, 25, 129–135. [Google Scholar] [CrossRef]

- Pérez-Vicente, A.; Serrano, P.; Abellán, P.; García-Viguera, C. Influence of packaging material on pomegranate juice colour and bioactive compounds, during storage. J. Sci. Food Agric. 2004, 84, 639–644. [Google Scholar] [CrossRef]

- Gunes, G.; Ozturk, A.; Yilmaz, N.; Ozcelik, B. Maintenance of Safety and Quality of Refrigerated Ready-to-Cook Seasoned Ground Beef Product (Meatball) by Combining Gamma Irradiation with Modified Atmosphere Packaging. J. Food Sci. 2011, 76, M413–M420. [Google Scholar] [CrossRef]

- Esmaeili, S.; Barzegar, M.; Sahari, M.A.; Berengi-Ardestani, S. Effect of gamma irradiation under various atmospheres of packaging on the microbial and physicochemical properties of turmeric powder. Radiat. Phys. Chem. 2018, 148, 60–67. [Google Scholar] [CrossRef]

- Tripetch, P.; Borompichaichartkul, C. Effect of packaging materials and storage time on changes of colour, phenolic content, chlorogenic acid and antioxidant activity in arabica green coffee beans (Coffea arabica L. cv. Catimor). J. Stored Prod. Res. 2019, 84, 101510. [Google Scholar] [CrossRef]

- Deng, L.-Z.; Mujumdar, A.S.; Pan, Z.; Vidyarthi, S.K.; Xu, J.; Zielinska, M.; Xiao, H.-W. Emerging chemical and physical disinfection technologies of fruits and vegetables: A comprehensive review. Crit. Rev. Food Sci. Nutr. 2019, 60, 2481–2508. [Google Scholar] [CrossRef]

- Joshi, K.; Mahendran, R.; Alagusundaram, K.; Norton, T.; Tiwari, B. Novel disinfectants for fresh produce. Trends Food Sci. Technol. 2013, 34, 54–61. [Google Scholar] [CrossRef]

- Instituto Colombiano de Normas Técnicas y Certificación, ICONTEC. Norma técnica Colombiana NTC 4423:1998 (reaprobada 2021). Food Industry. Spices and Condiments. Available online: https://tienda.icontec.org/ (accessed on 20 January 2022).

- Cheng, J.; Weijun, K.; Yun, L.; Jiabo, W.; Haitao, W.; Qingmiao, L.; Xiaohe, X. Development and validation of UPLC method for quality control of Curcuma longa Linn.: Fast simultaneous quantitation of three curcuminoids. J. Pharm. Biomed. Anal. 2010, 53, 43–49. [Google Scholar] [CrossRef] [PubMed]

- Cao, G.; Alessio, H.M.; Cutler, R.G. Oxygen-radical absorbance capacity assay for antioxidants. Free Radic. Biol. Med. 1993, 14, 303–311. [Google Scholar] [CrossRef] [Green Version]

- Akter, J.; Hossain, M.A.; Takara, K.; Islam, M.Z.; Hou, D.-X. Antioxidant activity of different species and varieties of turmeric (Curcuma spp.): Isolation of active compounds. Comp. Biochem. Physiol. Part C Toxicol. Pharmacol. 2018, 215, 9–17. [Google Scholar] [CrossRef] [PubMed]

- Duarte, Y.; Chaux, A.; Lopez, N.; Largo, E.; Ramírez, C.; Nuñez, H.; Simpson, R.; Vega, O. Effects of Blanching and Hot Air Drying Conditions on the Physicochemical and Technological Properties of Yellow Passion Fruit (Passiflora edulis Var. Flavicarpa) by-Products. J. Food Process Eng. 2016, 40, e12425. [Google Scholar] [CrossRef]

- Tapia, M.S.; Alzamora, S.M.; Chirife, J. Effects of Water Activity (aw) on Microbial Stability: As a Hurdle in Food Preservation. Water Activity in Foods: Fundamentals and Applications, 2nd ed.; Wiley-Blackwell: Hoboken, NJ, USA, 2020; pp. 239–271. [Google Scholar] [CrossRef]

- Sharma, S.; Dhalsamant, K.; Tripathy, P.P.; Manepally, R.K. Quality analysis and drying characteristics of turmeric (Curcuma longa L.) dried by hot air and direct solar dryers. LWT 2020, 138, 110687. [Google Scholar] [CrossRef]

- Chen, Z.; Xia, Y.; Liao, S.; Huang, Y.; Li, Y.; He, Y.; Tong, Z.; Li, B. Thermal degradation kinetics study of curcumin with nonlinear methods. Food Chem. 2014, 155, 81–86. [Google Scholar] [CrossRef]

- Na Jung, Y.; Hong, J. Changes in chemical properties and bioactivities of turmeric pigments by photo-degradation. AIMS Agric. Food 2021, 6, 754–767. [Google Scholar] [CrossRef]

- Thamkaew, G.; Sjöholm, I.; Galindo, F.G. A review of drying methods for improving the quality of dried herbs. Crit. Rev. Food Sci. Nutr. 2020, 61, 1763–1786. [Google Scholar] [CrossRef]

- Parlak, N. Fluidized bed drying characteristics and modeling of ginger (Zingiber officinale) slices. Heat Mass Transf. 2014, 51, 1085–1095. [Google Scholar] [CrossRef]

- Maheshwari, R.K.; Singh, A.K.; Gaddipati, J.; Srimal, R.C. Multiple biological activities of curcumin: A short review. Life Sci. 2006, 78, 2081–2087. [Google Scholar] [CrossRef] [PubMed]

- Singh, G.; Kapoor, I.; Singh, P.; de Heluani, C.S.; de Lampasona, M.P.; Catalan, C.A. Comparative study of chemical composition and antioxidant activity of fresh and dry rhizomes of turmeric (Curcuma longa Linn.). Food Chem. Toxicol. 2010, 48, 1026–1031. [Google Scholar] [CrossRef] [PubMed]

- Llano, S.; Gómez, S.; Londoño, J.; Restrepo, A. Antioxidant activity of curcuminoids. Phys. Chem. Chem. Phys. 2019, 21, 3752–3760. [Google Scholar] [CrossRef] [PubMed]

- Ray, A.; Mohanty, S.; Jena, S.; Sahoo, A.; Acharya, L.; Panda, P.C.; Sial, P.; Duraisamy, P.; Nayak, S. Drying methods affects physicochemical characteristics, essential oil yield and volatile composition of turmeric (Curcuma longa L.). J. Appl. Res. Med. Aromat. Plants 2021, 26, 100357. [Google Scholar] [CrossRef]

- Osorio-Arias, J.; Delgado-Arias, S.; Cano, L.; Zapata, S.; Quintero, M.; Nuñez, H.; Ramírez, C.; Simpson, R.; Vega-Castro, O. Sustainable Management and Valorization of Spent Coffee Grounds Through the Optimization of Thin Layer Hot Air-Drying Process. Waste Biomass Valorization 2019, 11, 5015–5026. [Google Scholar] [CrossRef]

- Chan, D.-S.; Kuo, M.-I. Wheat Germ Drying with Different Time-Temperature Combinations in a Fluidized Bed Dryer. Processes 2018, 6, 245. [Google Scholar] [CrossRef] [Green Version]

- Dei Cas, M.; Ghidoni, R. Dietary Curcumin: Correlation between Bioavailability and Health Potential. Nutrients 2019, 11, 2147. [Google Scholar] [CrossRef] [Green Version]

- Akoy, E.O.M. Experimental characterization and modeling of thin-layer drying of mango slices. Int. Food Res. J. 2014, 21, 1911–1917. [Google Scholar]

- Royen, M.J.; Noori, A.W.; Haydary, J. Experimental Study and Mathematical Modeling of Convective Thin-Layer Drying of Apple Slices. Processes 2020, 8, 1562. [Google Scholar] [CrossRef]

- Nyangena, D.N.; Mutungi, C.; Imathiu, S.; Kinyuru, J.; Affognon, H.; Ekesi, S.; Nakimbugwe, D.; Fiaboe, K.K.M. Effects of Traditional Processing Techniques on the Nutritional and Microbiological Quality of Four Edible Insect Species Used for Food and Feed in East Africa. Foods 2020, 9, 574. [Google Scholar] [CrossRef]

- Bishop, C.A.; Mount, E.M. Vacuum Metallizing for Flexible Packaging. In Multilayer Flexible Packaging, 2nd ed.; William Andrew: Norwich, NY, USA, 2016; pp. 235–255. [Google Scholar] [CrossRef]

| Drying | Moisture Content (% w/w) | Time (h) | aw |

|---|---|---|---|

| Fresh Turmeric | 83.2 ± 0.5 | ------ | 0.81 ± 0.003 |

| TSD | 7.9 ± 0.2 a | 20 | 0.08 ± 0.003 a |

| COD | 7.6 ± 0.1 a | 13 | 0.07 ± 0.003 a |

| FBD | 7.5 ± 0.2 a | 8 | 0.05 ± 0.003 b |

| Drying | Color Analysis | |||

|---|---|---|---|---|

| L | a | B | ΔE | |

| TSD | 90.4± 0.4 a | −10.7 ± 0.2 a | 123.9 ± 0.1 a | 6,30 ± 0.03 a |

| COD | 91.6 ± 0.1 b | −11.0± 0.1 a | 124.9 ± 0.3 b | 5,1 ± 0.1 b |

| FBD | 92.2 ± 0.3 b | −10.9 ± 0.2 a | 125.9 ± 0.3 c | 4,24 ± 0.02 c |

| Temperature (°C) | Curcumin(% w/w) | Demethoxy-Curcumin (% w/w) | Bisdemethoxy-Curcumin (% w/w) | Total Curcuminoids (% w/w) | ORAC (µmol TE/g) | aw | Moisture Content (% w/w) |

|---|---|---|---|---|---|---|---|

| Fresh | 2.55 ± 0.35 a | 1.09 ± 0.14 a | 0.66 ± 0.09 a | 3.53 ± 0.73 a | 1805.45 ± 39.99 a | 0.85± 0.01 a | 83.2 ± 0.5 a |

| 50 | 2.73 ± 0.38 a | 1.36 ± 0.18 a | 0.87 ± 0.11 a | 3.15 ± 0.64 a | 1854.35 ± 81.88 a | 0.051 ± 0.005 b | 7.5 ± 0.2 b |

| 60 | 2.39 ± 0.33 a | 1.01 ± 0.16 a | 0.83 ±0.11 a | 3.43 ± 0.72 a | 1851.48 ± 71.98 a | 0.050 ± 0.004 b | 7.4 ± 0.2 b |

| 70 | 2.70 ± 0.38 a | 0.92 ± 0.15 a | 0.76 ± 0.099 a | 3.33 ± 0.71 a | 1826.19 ± 63.91 a | 0.042 ± 0.005 b | 7.4 ± 0.3 b |

| 80 | 2.56 ± 0.35 a | 1.15 ± 0.21 a | 0.85 ± 0.119 a | 4.054 ± 0.78 a | 1733.04 ± 35.94 a | 0.041 ± 0.005 b | 6.7 ± 0.2 b |

| Packing Material | Color Analysis | |||

|---|---|---|---|---|

| L | A | B | ΔE | |

| Control | 96.3 ± 1.6 a | −5.0 ± 0.1 a | 119.9 ± 0.3 a | 7.86 ± 0.06 a |

| Glass | 93.5 ± 0.9 b | −3.9 ± 0.2 b | 119.4 ± 1.2 a | 8.9 ± 0.9 a |

| LDPE | 94.0 ± 0.7 a,b | −3.8 ± 0.1 b | 120.0 ± 0.8 a | 8.4 ± 0.6 a |

| Foil Pouch | 93.8 ± 0.7 a,b | −3.9 ± 0.1 b | 118.9 ± 0.4 a | 9.3 ± 0.3 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Llano, S.M.; Gómez, A.M.; Duarte-Correa, Y. Effect of Drying Methods and Processing Conditions on the Quality of Curcuma longa Powder. Processes 2022, 10, 702. https://doi.org/10.3390/pr10040702

Llano SM, Gómez AM, Duarte-Correa Y. Effect of Drying Methods and Processing Conditions on the Quality of Curcuma longa Powder. Processes. 2022; 10(4):702. https://doi.org/10.3390/pr10040702

Chicago/Turabian StyleLlano, Sandra M., Ana María Gómez, and Yudy Duarte-Correa. 2022. "Effect of Drying Methods and Processing Conditions on the Quality of Curcuma longa Powder" Processes 10, no. 4: 702. https://doi.org/10.3390/pr10040702

APA StyleLlano, S. M., Gómez, A. M., & Duarte-Correa, Y. (2022). Effect of Drying Methods and Processing Conditions on the Quality of Curcuma longa Powder. Processes, 10(4), 702. https://doi.org/10.3390/pr10040702