Heterogeneous Biodiesel Catalyst from Steel Slag Resulting from an Electric Arc Furnace

Abstract

:1. Introduction

2. Experimental Methodology

2.1. The Raw Materials Used to Produce Biodiesel

2.2. Catalyst Preparation

2.3. Assessment of EAFS

2.4. Waste Sunflower Cooking Oil Collection and Preparation

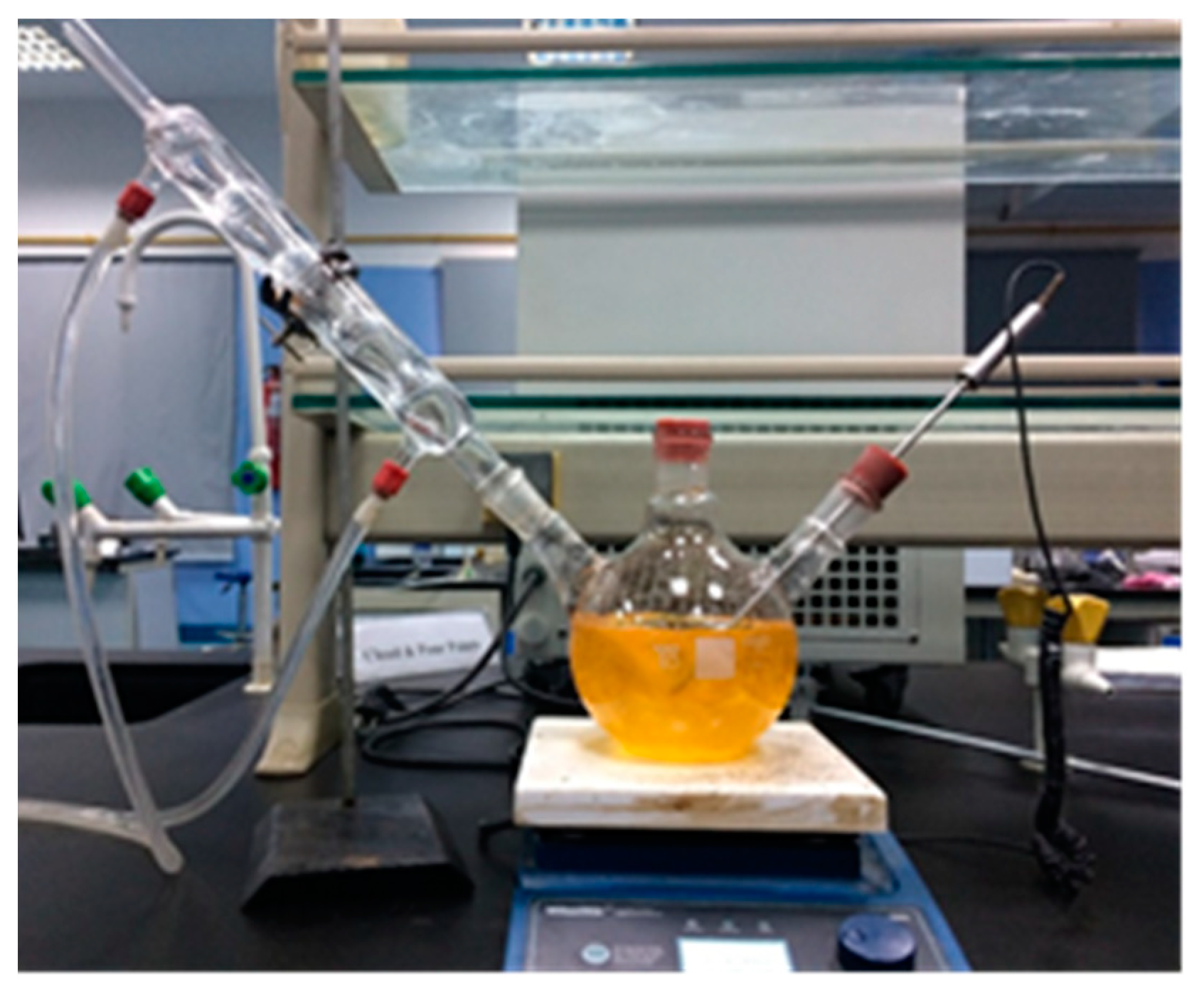

2.5. Production of Biodiesel

2.6. Experimental Design

2.7. Optimal Biodiesel Sample Evaluation

2.8. Reusability of EAFS

3. Experimental Results

3.1. Assessment Results of EAFS

3.1.1. Chemical Composition of EAFS

- The (O-H) bonds of the methanol are broken down rapidly into methoxide anions and hydrogen cations. Surface O2− removes H+ from CH3OH to produce surface CH3O−, which is very basic and catalytic in the transesterification reaction;

- The methyl esters are formed when the methoxide anions combine with triglyceride molecules. The carbonyl carbon atom of the triglyceride molecule attracts a methoxide anion from the metal oxide’s surface to generate a tetrahedral intermediate, which absorbs H+ from the metal oxide’s surface. The tetrahedral intermediate can react with methanol to produce methoxide anions. Finally, the tetrahedral intermediate can be rearranged to produce biodiesel [29,40].

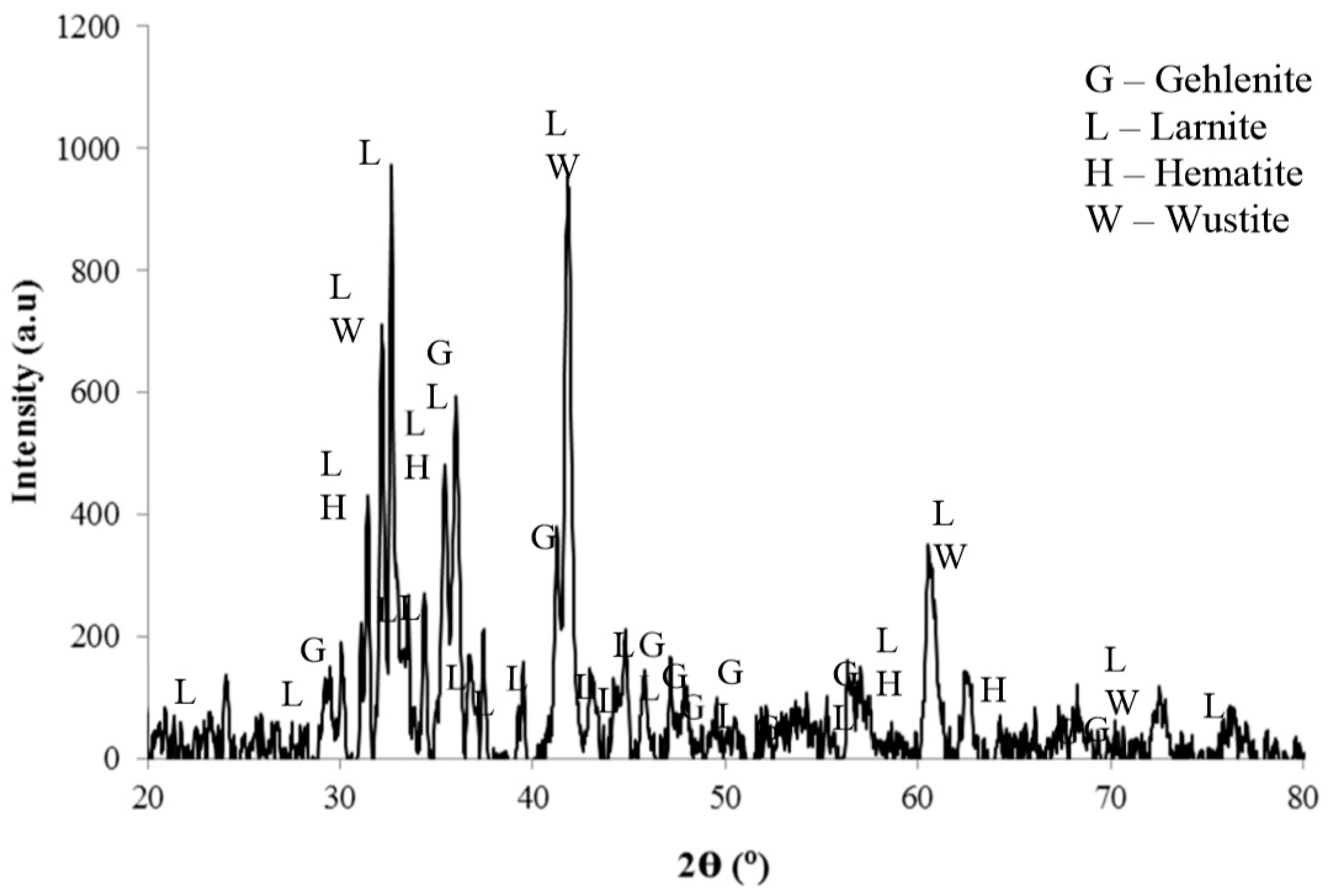

3.1.2. Phases Present in EAFS

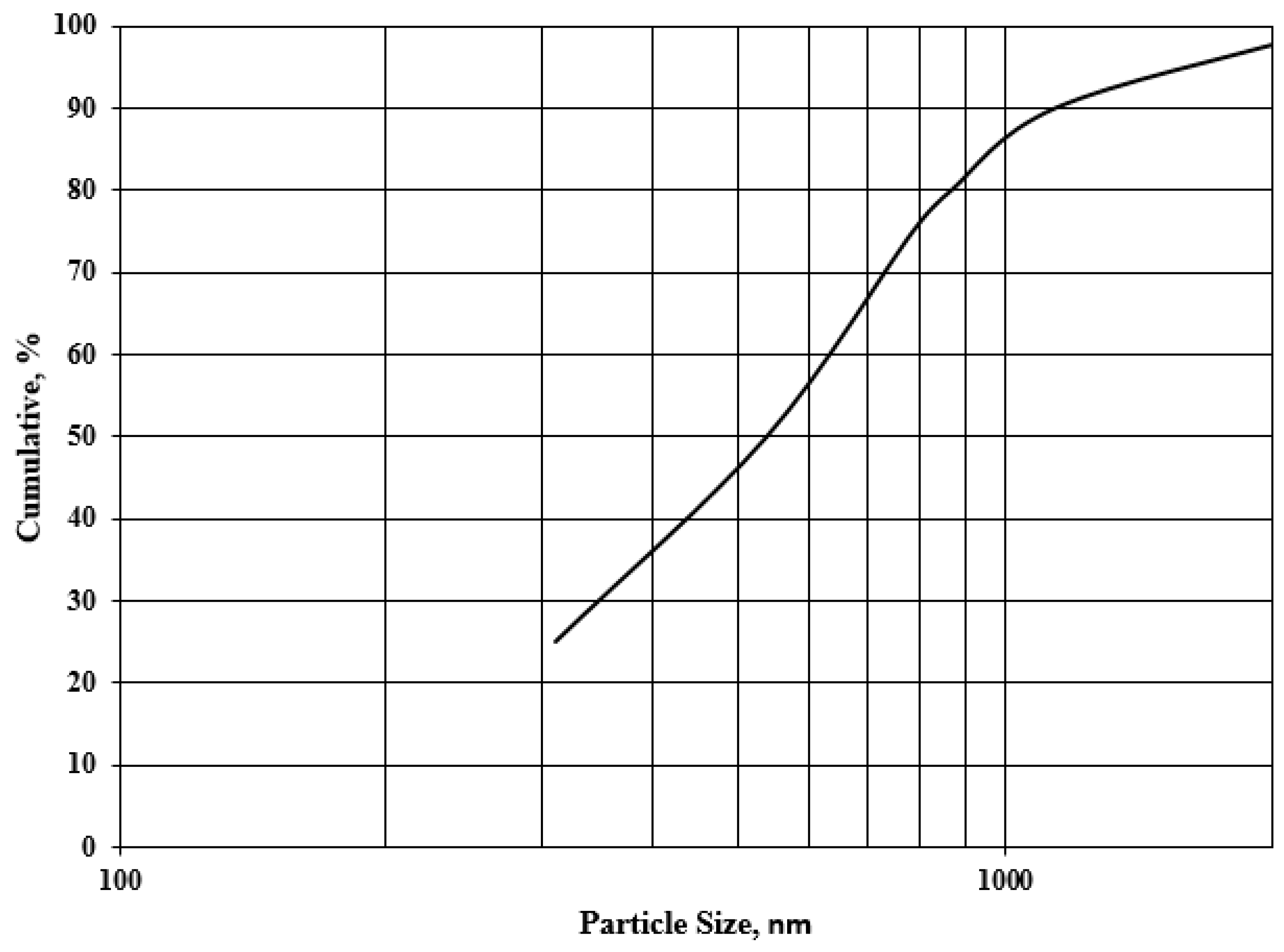

3.1.3. Particle Size Analysis of EAFS

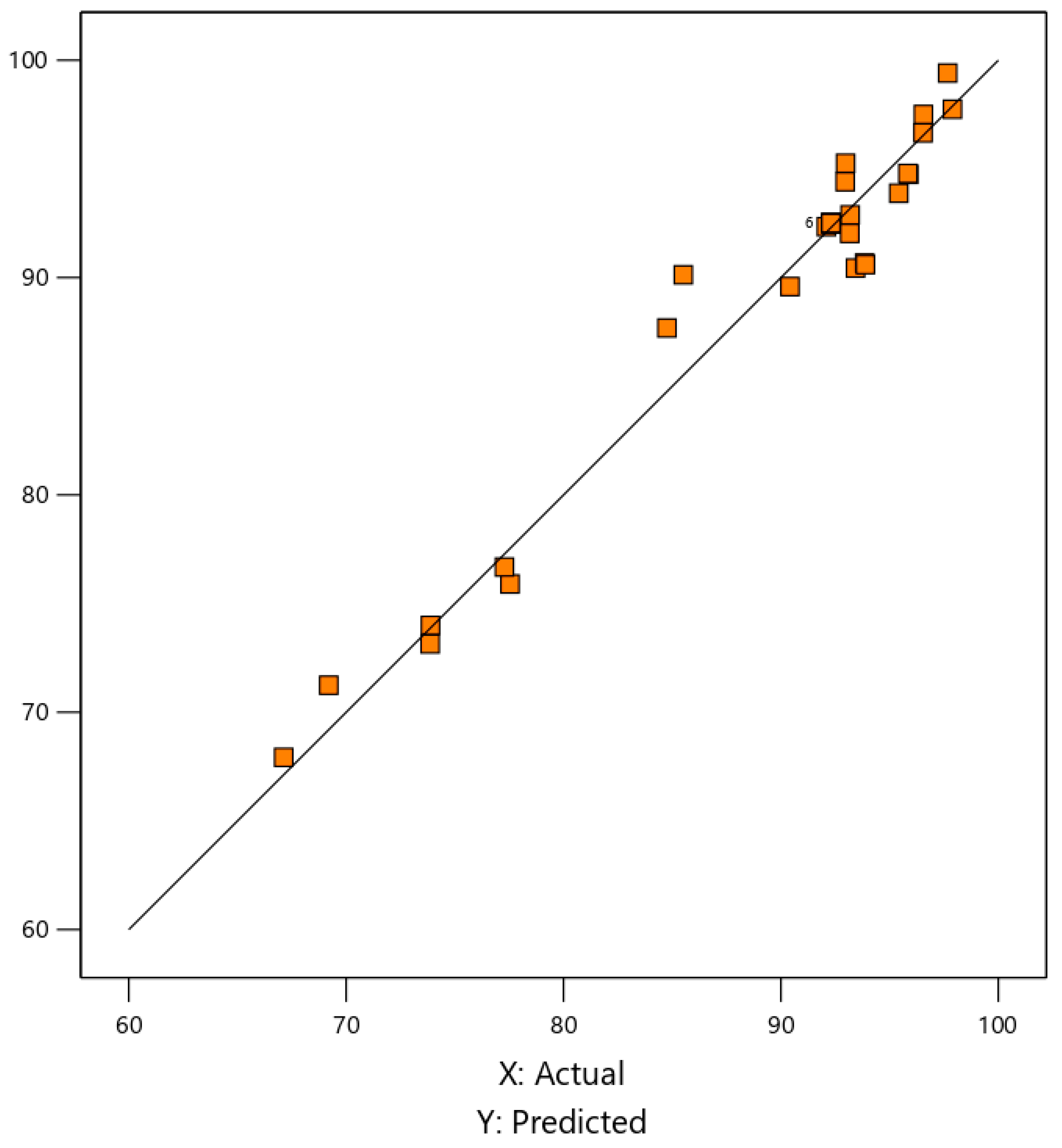

3.2. Analysis of Variance (ANOVA) on the Resulting Biodiesel

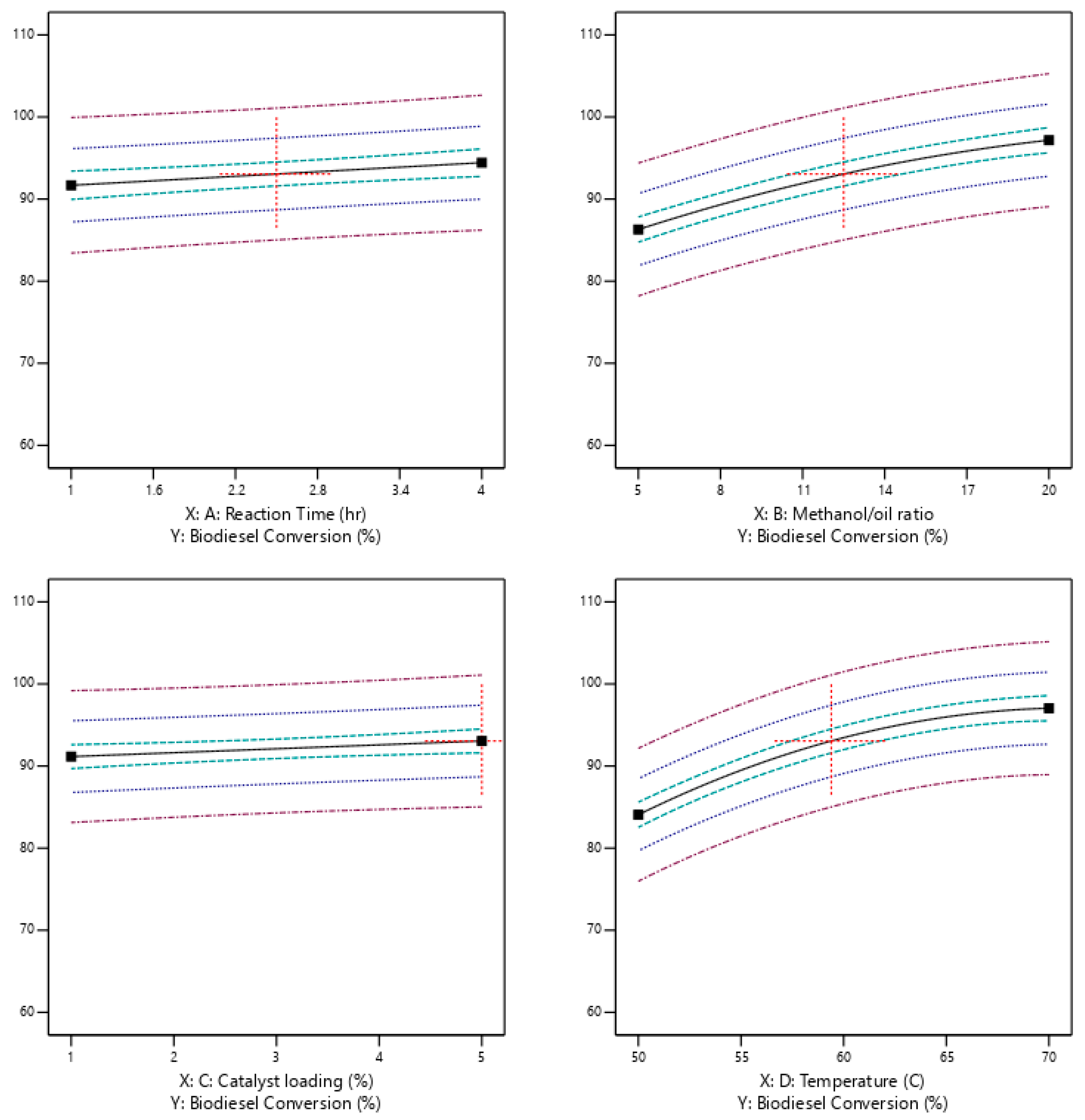

3.3. Reaction Condition’s Impact on the Conversion of Biodiesel

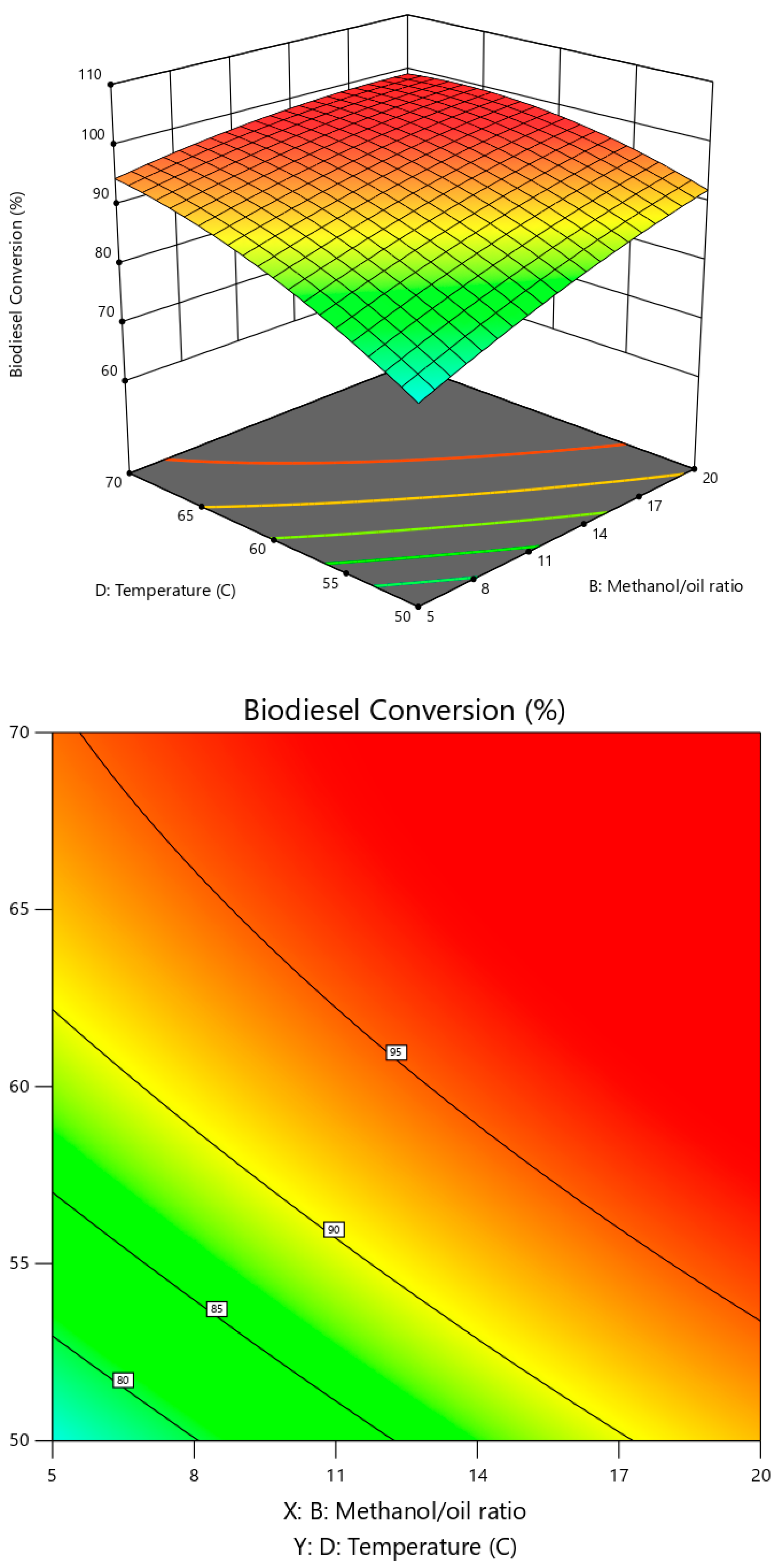

3.4. Impact of Reaction Parameters on the Conversion of Biodiesel

3.5. Optimization of Reaction Variables

3.6. Optimal Biodiesel Sample Analysis

3.7. EAFS Reusability

4. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Sakkari, E.G.; El-Sheltawy, S.T.; Abadir, M.F.; Attia, N.K.; El-Diwani, G. Investigation of cement kiln dust utilization for catalyzing biodiesel production via response surface methodology. Int. J. Energy Res. 2017, 41, 593–603. [Google Scholar] [CrossRef]

- Mukhtar, A.; Saqib, S.; Lin, H.; Hassan Shah, M.U.; Ullah, S.; Younas, M.; Rezakazemi, M.; Ibrahim, M.; Mahmood, A.; Asif, S.; et al. Current status and challenges in the heterogeneous catalysis for biodiesel production. Renew. Sustain. Energy Rev. 2022, 157, 112012. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, L.; Esmaeili, H. A review on biodiesel production using various heterogeneous nanocatalysts: Operation mechanisms and performances. Biomass Bioenergy 2022, 158, 106356. [Google Scholar] [CrossRef]

- Yaashikaa, P.R.; Kumar, P.S.; Karishma, S. Bio-derived catalysts for production of biodiesel: A review on feedstock, oil extraction methodologies, reactors and lifecycle assessment of biodiesel. Fuel 2022, 316, 123379. [Google Scholar] [CrossRef]

- Abdullah, M.O.; Nolasco-hipolito, C. Biodiesel Production using Calcium Oxide as Catalyst: A Review. In Proceedings of the EnCon 2014, 7th Engineering Conference on Advances in Process Engineering & Green Energy, Kuching, Malaysia, 19–22 August 2014. [Google Scholar] [CrossRef]

- Topare, N.S.; Jogdand, R.I.; Shinde, H.P.; More, R.S.; Khan, A.; Asiri, A.M. A short review on approach for biodiesel production: Feedstock’s, properties, process parameters and environmental sustainability. Mater. Today Proc. 2021; in press. [Google Scholar] [CrossRef]

- Dai, Y.-M.; Chen, K.-T.; Wang, Y.-J.; Chen, C.-C. Application of Peanut Husk Ash as a Low-Cost Solid Catalyst for Biodiesel Production. Int. J. Chem. Eng. Appl. 2014, 5, 276–280. [Google Scholar] [CrossRef] [Green Version]

- Ali, M.A.; Al-Hydary, I.A.; Al-Hattab, T.A. Nano-magnetic catalyst CaO-Fe3O4 for biodiesel production from date palm seed oil. Bull. Chem. React. Eng. Catal. 2017, 12, 460–468. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.; Huang, Y.; Liu, Q.; Hu, X.; Liu, Q.; Chen, H.; Dong, Y.; Zhao, Y.; Niu, S. Ferric oxide as a support of carbide slag for effective transesterification of triglycerides in soybean oil. Energy Convers. Manag. 2019, 198. [Google Scholar] [CrossRef]

- Panchal, B. Biodiesel Synthesis with Iron Oxide Nano-Catalyst Catalyzed Pongamia Pinnata Seed Oil and Dimethyl Carbonate. Am. J. Energy Eng. 2018, 6, 21. [Google Scholar] [CrossRef]

- Rengasamy, M.; Mohanraj, S.; Vardhan, S.H.; Balaji, R. Transesterification of castor oil using nano-sized iron catalyst for the production of biodiesel. J. Chem. Pharm. Sci. 2014, 974, 2115. [Google Scholar]

- Widayat; Putra, D.A.; Nursafitri, I. Synthesis and catalytic evaluation of hematite (α-Fe2O3) magnetic nanoparticles from iron sand for waste cooking oil conversion to produce biodiesel through esterification-transesterification method. In Materials Science and Engineering Conference Series; IOP Publishing: Bristol, UK, 2019; p. 509. [Google Scholar] [CrossRef]

- Khodary, K.E.; Naeem, M.M.; Roushdy, M.H. Utilization of electric arc furnace dust as a solid catalyst in biodiesel production. Clean Technol. Environ. Policy 2021, 1–11. [Google Scholar] [CrossRef]

- Cavaliere, P. Clean Ironmaking and Steelmaking Processes; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Arribas, I.; Santamaría, A.; Ruiz, E.; Ortega-López, V.; Manso, J.M. Electric arc furnace slag and its use in hydraulic concrete. Constr. Build. Mater. 2015, 90, 68–79. [Google Scholar] [CrossRef]

- Rastovčan-Mioč, A.; Sofilić, T.; Mioč, B. Application of electric arc furnace slag. In Proceedings of the MATRIB, Korčula, Croatia, 24–26 June 2009; pp. 436–444. [Google Scholar]

- Zhu, H.; Wu, Z.; Chen, Y.; Zhang, P.; Duan, S.; Liu, X.; Mao, Z. Preparation of biodiesel catalyzed by solid super base of calcium oxide and its refining process. Chin. J. Catal. 2006, 27, 391–396. [Google Scholar] [CrossRef]

- Xu, H.; Miao, X.; Wu, Q. High quality biodiesel production from a microalga Chlorella protothecoides by heterotrophic growth in fermenters. J. Biotechnol. 2006, 126, 499–507. [Google Scholar] [CrossRef] [PubMed]

- Rand, S.J. Astm D1298 Density. ASTM Int. 2003, 5, 221. [Google Scholar]

- Astm, D. Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity). In Manual on Hydrocarbon Analysis, 6th ed.; ASTM International: West Conshohocken, PA, USA, 2008; pp. 1–10. [Google Scholar]

- Drews, A.W. Standard Test Method for Acid and Base Number by Color-Indicator Titration. In Manual on Hydrocarbon Analysis, 6th ed.; ASTM International: West Conshohocken, PA, USA, 2008; Volume 91, pp. 543–545. [Google Scholar] [CrossRef]

- Methods, T.; Products, P.; Products, P.; Laboratories, L.T. Standard Test Methods for Saponification Number of Petroleum Products 1; ASTM International: West Conshohocken, PA, USA, 2002; pp. 1–9. [Google Scholar]

- ASTM C114-18; Standard Test Methods for Chemical Analysis of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2018; pp. 1–33. [CrossRef]

- ASTM D422; Particle Size Analysis—ASTM D422 Particle Size Analysis. ASTM International: West Conshohocken, PA, USA, 2017; pp. 70–138.

- ASTM E 11-09; Standard Specification for Woven Wire Test Sieve Cloth and Test Sieves. ASTM International: West Conshohocken, PA, USA, 2010; p. 9.

- Montgomery, D.C. Montgomery Design and Analysis of Experiments, 8th ed.; Arizona State University: Tempe, AZ, USA, 2013; Volume 2009, p. 2001. [Google Scholar]

- El-Sheltawy, S.T.; Al-Sakkari, E.G. Recent Trends in Solid Waste Utilization for Biodiesel Production. J. Solid Waste Technol. Manag. 2016, 42. [Google Scholar] [CrossRef]

- Ling, J.S.J.; Tan, Y.H.; Mubarak, N.M.; Kansedo, J.; Saptoro, A.; Nolasco-Hipolito, C. A review of heterogeneous calcium oxide based catalyst from waste for biodiesel synthesis. SN Appl. Sci. 2019, 1, 810. [Google Scholar] [CrossRef] [Green Version]

- Refaat, A.A. Biodiesel production using solid metal oxide catalysts. Int. J. Environ. Sci. Technol. 2011, 8, 203–221. [Google Scholar] [CrossRef] [Green Version]

- Talha, N.S.; Sulaiman, S. Overview of catalysts in biodiesel production. ARPN J. Eng. Appl. Sci. 2016, 11, 439–442. [Google Scholar]

- ASTM. Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels; ASTM International: West Conshohocken, PA, USA, 2010; Volume i, pp. 1–11. [Google Scholar]

- En, V.A. Liquid Petroleum Products—Fatty Acid Methyl Esters (FAME) for Use in Diesel Engines and Heating Applications—Requirements and Test Methods; European Committee for Standardization: Brussels, Belgium, 2018; p. 14538. [Google Scholar]

- Biodiesel, A.-I.-O. Application note EN 14103 Determination of Total FAME and Linolenic Acid Methyl Ester in FAME with AC Biodiesel All in One Solution; PAC: Houston, TX, USA, 2011; pp. 1–3. [Google Scholar]

- Biodiesel, A.-I.-O.; Glycerol, T. Application Note EN 14105 Determination of Free and Total Glycerol and mono-, di,—triglycerides in Fatty Acid Methyl Esters (FAME); PAC: Houston, TX, USA, 2011; pp. 2–4. [Google Scholar]

- Banerjee, S.; Rout, S.; Banerjee, S.; Atta, A.; Das, D. Fe2O3 nanocatalyst aided transesterification for biodiesel production from lipid-intact wet microalgal biomass: A biorefinery approach. Energy Convers. Manag. 2019, 195, 844–853. [Google Scholar] [CrossRef]

- Correia, L.M.; Saboya, R.M.A.; de Sousa Campelo, N.; Cecilia, J.A.; Rodríguez-Castellón, E.; Cavalcante, C.L.; Vieira, R.S. Characterization of calcium oxide catalysts from natural sources and their application in the transesterification of sunflower oil. Bioresour. Technol. 2014, 151, 207–213. [Google Scholar] [CrossRef]

- El Shimi, H.I.; Attia, N.K.; El Diwani, G.I.; El Sheltawy, S.T. Investigation of silicates as a catalyst in biodiesel production: A review. Int. J. Energy Res. 2016, 40, 1743–1756. [Google Scholar] [CrossRef]

- Puspa, N.; Agustina, D.; Sari, P.; Poedjojono, B. Utilization of Waste Cooking Oil for Biodiesel Production Using Alumina Supported base Catalyst. In Proceedings of the 3rd International Conference on Biological, Chemical and Environmental Sciences, Kuala Lumpur, Malaysia, 21–22 September 2015; pp. 21–25. [Google Scholar] [CrossRef] [Green Version]

- Rasouli, H.; Esmaeili, H. Characterization of MgO nanocatalyst to produce biodiesel from goat fat using transesterification process. 3 Biotech 2019, 9, 1–11. [Google Scholar] [CrossRef]

- Koberg, M.; Gedanken, A. Using Microwave Radiation and SrO as a Catalyst for the Complete Conversion of Oils, Cooked Oils, and Microalgae to Biodiesel; Elsevier: Amsterdam, The Netherlands, 2013; pp. 209–227. [Google Scholar]

- Erchamo, Y.S.; Mamo, T.T.; Workneh, G.A.; Mekonnen, Y.S. Improved biodiesel production from waste cooking oil with mixed methanol–ethanol using enhanced eggshell-derived CaO nano-catalyst. Sci. Rep. 2021, 11, 6708. [Google Scholar] [CrossRef]

- Ajala, E.O.; Ajala, M.A.; Ayinla, I.K.; Sonusi, A.D.; Fanodun, S.E. Nano-synthesis of solid acid catalysts from waste-iron-filling for biodiesel production using high free fatty acid waste cooking oil. Sci. Rep. 2020, 10, 13256. [Google Scholar] [CrossRef]

- de Oliveira, K.G.; de Lima, R.R.S.; de Longe, C.; de Bicudo, T.C.; Sales, R.V.; de Carvalho, L.S. Sodium and potassium silicate-based catalysts prepared using sand silica concerning biodiesel production from waste oil. Arab. J. Chem. 2021, 15, 103603. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Gross Calorific Value of Coal and Coke; ASTM International: West Conshohocken, PA, USA, 2013; pp. 1–19. [Google Scholar]

- ASTM. Standard Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter; ASTM International: West Conshohocken, PA, USA, 2013; pp. 1–8. [Google Scholar] [CrossRef]

- ASTM International. Final Draft Uganda Standard, FDUS 1730. In Standard Test Method for Pour Point of Petroleum Products; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM International. ASTM D93 Flash Point; ASTM International: West Conshohocken, PA, USA, 2004; Volume 5, p. 80112. [Google Scholar]

| Fatty Acid | % |

|---|---|

| Oleic acid | 32.54 |

| Heptadecanoic acid | 34.62 |

| Palmitic acid | 19.03 |

| Linolenic acid | 3.21 |

| n-Pentadecanoic acid | 1.51 |

| Linoleic acid | 1.51 |

| Arachidic acid | 1.71 |

| Myristic acid | 0.75 |

| Eicosadienoic acid | 0.66 |

| Lauric acid | 0.17 |

| Palmitoleic acid | 0.21 |

| Others | 4.08 |

| Property | Value | Reference |

|---|---|---|

| Molecular weight | 820.7806 | [17,18] |

| Density of 25 °C (kg/m3) | 895 | ASTM D 1298-99 [19] |

| Viscosity at 40 °C | 35.8 | ASTM D 445-04 [20] |

| Acid value (mg of KOH/g of oil) | 1.8 | ASTM D 974-02 [21] |

| Saponification value (mg of KOH/g of oil) | 206.85 | ASTM D 94-002 [22] |

| Reaction Parameter | Ranges | Reaction Parameter | Ranges | ||

|---|---|---|---|---|---|

| Minimum | Maximum | Minimum | Maximum | ||

| Methanol-to-oil molar ratio (M:O) | 5 | 20 | Reaction time (h) | 1 | 4 |

| Reaction temperature (°C) | 50 | 70 | EAFS concentration, % | 1 | 5 |

| Stirring rate, RPM | 750 | ||||

| Run No. | Catalyst Loading, % | Methanol/Oil Ratio | Reaction Time, h | Temperature, °C |

|---|---|---|---|---|

| 1 | 1 | 5 | 1 | 50 |

| 2 | 1 | 5 | 4 | 50 |

| 3 | 1 | 20 | 1 | 50 |

| 4 | 1 | 20 | 4 | 50 |

| 5 | 5 | 5 | 1 | 50 |

| 6 | 5 | 5 | 4 | 50 |

| 7 | 5 | 20 | 1 | 50 |

| 8 | 5 | 20 | 4 | 50 |

| 9 | 1 | 5 | 1 | 70 |

| 10 | 1 | 5 | 4 | 70 |

| 11 | 1 | 20 | 1 | 70 |

| 12 | 1 | 20 | 4 | 70 |

| 13 | 5 | 5 | 1 | 70 |

| 14 | 5 | 5 | 4 | 70 |

| 15 | 5 | 20 | 1 | 70 |

| 16 | 5 | 20 | 4 | 70 |

| 17 | 3 | 12.5 | 0.5 | 60 |

| 18 | 3 | 12.5 | 5.5 | 60 |

| 19 | 3 | 3 | 2.5 | 60 |

| 20 | 3 | 27.5 | 2.5 | 60 |

| 21 | 0.5 | 12.5 | 2.5 | 60 |

| 22 | 7 | 12.5 | 2.5 | 60 |

| 23 | 3 | 12.5 | 2.5 | 40 |

| 24 | 3 | 12.5 | 2.5 | 80 |

| 25–30 | 3 | 12.5 | 2.5 | 60 |

| Oxides | % |

|---|---|

| CaO | 26.51 |

| FeO/Fe2O3 | 33.21 |

| SiO2 | 20.73 |

| Al2O3 | 8.77 |

| MgO | 3.55 |

| MnO | 4.13 |

| Cr2O3 | 1.22 |

| Loss on ignition | 0.01 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | Significant |

|---|---|---|---|---|---|---|

| Model | 2153.19 | 7 | 307.60 | 78.12 | <0.0001 | |

| A—Reaction time | 41.25 | 1 | 41.25 | 10.48 | 0.0038 | |

| B—Methanol/oil ratio | 665.39 | 1 | 665.39 | 168.99 | <0.0001 | |

| C—Catalyst loading | 21.78 | 1 | 21.78 | 5.53 | 0.0280 | |

| D—Temperature | 1010.65 | 1 | 1010.65 | 256.68 | <0.0001 | |

| BD | 139.65 | 1 | 139.65 | 35.47 | <0.0001 | |

| B2 | 49.74 | 1 | 49.74 | 12.63 | 0.0018 | |

| D2 | 239.25 | 1 | 239.25 | 60.76 | <0.0001 | |

| Residual | 86.62 | 22 | 3.94 | |||

| Lack of fit | 86.62 | 17 | 5.10 | |||

| Pure error | 0.0000 | 5 | 0.0000 |

| Name | Goal | Lower Limit | Upper Limit | Lower Weight | Upper Weight | Importance |

|---|---|---|---|---|---|---|

| A: Reaction time | Minimize | 1 | 4 | 1 | 1 | 5 |

| B: Methanol/oil ratio | Within range | 5 | 20 | 1 | 1 | 3 |

| C: Catalyst loading | Within range | 1 | 5 | 1 | 1 | 3 |

| D: Temperature | Minimize | 50 | 70 | 1 | 1 | 5 |

| Biodiesel conversion | Maximize | 67.129 | 97.8914 | 3 | 1 | 5 |

| Number | Reaction Time | Methanol/Oil Ratio | Catalyst Loading | Temperature | Biodiesel Conversion | Desirability | Selected |

|---|---|---|---|---|---|---|---|

| 1 | 1.000 | 20.000 | 5.000 | 55.501 | 93.850 | 0.780 | |

| 2 | 1.000 | 20.000 | 5.000 | 55.360 | 93.759 | 0.780 | |

| 3 | 1.000 | 19.999 | 5.000 | 55.242 | 93.685 | 0.780 | |

| 4 | 1.000 | 20.000 | 5.000 | 55.782 | 94.017 | 0.780 | |

| 5 | 1.000 | 20.000 | 4.984 | 55.528 | 93.855 | 0.780 | |

| 6 | 1.000 | 20.000 | 5.000 | 56.070 | 94.187 | 0.780 | |

| 7 | 1.000 | 19.997 | 4.963 | 55.519 | 93.838 | 0.780 | |

| 8 | 1.000 | 20.000 | 4.959 | 55.204 | 93.642 | 0.779 | |

| 9 | 1.000 | 20.000 | 4.951 | 55.734 | 93.965 | 0.779 | |

| 10 | 1.000 | 20.000 | 5.000 | 56.227 | 94.277 | 0.779 |

| Used Catalyst | Catalyst Preparation | Methanol/Oil Ratio | Catalyst Loading | Reaction Temperature | Reaction Time | Biodiesel Conversion | Reference |

|---|---|---|---|---|---|---|---|

| Enhanced eggshell-derived CaO nanocatalyst | Needs preparation steps before usage | 12:1 | 2.5 wt% | 60 °C | 2 h | 94% | [41] |

| α-Fe2O3 | Needs preparation steps before usage | 12:1 | 6 wt% | 80 °C | 3 h | 92% | [42] |

| Beach sand | Needs preparation steps before usage | 9:1 | 2.5 wt% | 70 °C | 2 h | 93.89% | [43] |

| EAF slag | Used as delivered after crushing and grinding steps | 20:1 | 5 wt% | 55 °C | 1 h | 93.850% | (Present work) |

| Physical Properties | Standard Method | Produced Biodiesel | ASTM | Biodiesel |

|---|---|---|---|---|

| Kinematic viscosity at 40 °C (cSt) | ASTM D-445 [20] | 4.1 | 1.9–6.0 | 3.5–5.0 |

| Calorific value (MJ/kg) | ASTM D-5865 [44] | 39.126 | >32.9 | |

| Density at 15 °C (g/cm3) | ASTM D-4052 [45] | 0.862 | 0.86–0.9 | |

| Pour point (°C) | ASTM D-97 [46] | −20 | ||

| Cloud point (°C) | ASTM D-97 [46] | −10 | <−4 | |

| Flash point (°C) | ASTM D-93 [47] | 155 | >130 | >101 |

| Test | Results | Specification | Units | |

|---|---|---|---|---|

| Min | Max | |||

| Total glycerol | 0.022 | 0.25 | % | |

| Free glycerol | 0.016 | 0.02 | % | |

| Triglycerides | 0.0728 | 0.20 | % | |

| Diglycerides | 0.0091 | 0.20 | % | |

| Monoglycerides | 0.0065 | 0.80 | % | |

| Total FAME | 97.2 | 96.5 | % | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roushdy, M.H. Heterogeneous Biodiesel Catalyst from Steel Slag Resulting from an Electric Arc Furnace. Processes 2022, 10, 465. https://doi.org/10.3390/pr10030465

Roushdy MH. Heterogeneous Biodiesel Catalyst from Steel Slag Resulting from an Electric Arc Furnace. Processes. 2022; 10(3):465. https://doi.org/10.3390/pr10030465

Chicago/Turabian StyleRoushdy, Mai Hassan. 2022. "Heterogeneous Biodiesel Catalyst from Steel Slag Resulting from an Electric Arc Furnace" Processes 10, no. 3: 465. https://doi.org/10.3390/pr10030465

APA StyleRoushdy, M. H. (2022). Heterogeneous Biodiesel Catalyst from Steel Slag Resulting from an Electric Arc Furnace. Processes, 10(3), 465. https://doi.org/10.3390/pr10030465