Abstract

Despite providing interesting solutions to reduce the number of synthetic steps, to decrease energy consumption or to generate less waste, therefore contributing to a more sustainable way of producing important chemicals, the expansion of the use of homogeneous catalysis in industrial processes is hampered by several drawbacks. One of the most important is the difficulty to recycle the noble metals generating potential high costs and pollution of the synthesized products by metal traces detrimental to their applications. Supporting the metals on abundant and cheap biosourced polymers has recently appeared as an almost ideal solution: They are much easier to recover from the reaction medium and usually maintain high catalytic activity. The present bibliographical review focuses on the development of catalysts based on group 10 transition metals (nickel, palladium, platinum) supported on biopolymers obtained from wood, such as cellulose, hemicellulose, lignin, and their derivatives. The applications of these catalysts in organic synthesis or depollution are also addressed in this review with examples of C-C couplings, oxidation, or hydrogenation reactions.

1. Introduction

Catalysis is one of the pillars of green chemistry. Currently, catalysis, particularly with transition metals, have found numerous applications for the production of fine chemicals. The usefulness of transition metal catalysis is obvious, as it is often a way to reduce the number of synthetic steps and to consume less energy in chemical processes. However, its development in industrial processes still struggles to expand and is hampered by several obstacles. Indeed, frequent use of high catalyst loadings combined to the difficulty to recycle homogeneous catalysts can contribute to an important consumption of noble metals, leading to an elevated cost for the process. Moreover, the toxicity of some metals or the effect of their presence in the final product represent a considerable problem for chemical industry because very low traces of metallic residues can usually be tolerated (particularly if the molecules are intended to pharmaceutical or electronic-organic applications). Therefore, it is necessary to investigate new catalytic systems both efficient and easy to recycle, with low metal leaching, in order to expand the use of catalysis and improve the catalytic processes. Heterogeneous catalysts have many advantages; they can in particular be easily recycled by filtration or centrifugation. With this goal in mind, the use of supported catalysts could represent an interesting solution. Supported catalysis combine some advantages of both types of catalysis: They are easy to recover like heterogeneous catalysts but generally have a higher catalytic activity than them (sometimes close to homogeneous catalysts). The catalytic mechanism of supported catalysts itself could be qualified homogeneous in some cases, in particular that of supported metal complexes [1].

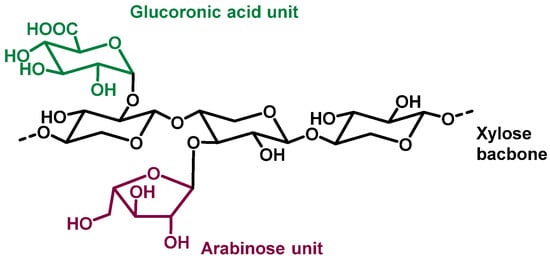

The biopolymers contained in wood seem to be great candidate to act as support for catalysts. They are renewable, biodegradable, abundant so relatively cheap, chemically stable and quite insoluble in most solvents (which enables easy separation from the reaction medium). The chemical composition of wood not only varies from different tree species but it is also different between parts of the same tree [2]. Within a tree species, the composition is also influenced by external factors such as climate, nature of the soil, or geographic location for examples. However, despite these variations, wood generally contains around 50% of carbon, 44% of oxygen, and 6% of hydrogen, with trace amounts of metal cations. From a molecular point of view, wood is constituted of two major components: carbohydrate (65–75% of dry wood weight) and lignin (18–35%), plus other non-polymeric molecules or inorganic residues. Among the carbohydrates, cellulose is the most abundant as it represents 40–50% of the dry mass, with hemicellulose only accounting for 25–35%. Biopolymers extracted from wood, as well as wood itself, can act as support for catalysts [3].

The aim of this review is to offer to readers an overview of the catalysts based on group 10 transition metals (Ni, Pd, Pt) and supported on wood or biopolymers obtained from it. The preparation and characterization of the supported catalysts as well as their catalytic activities are highlighted. Group 10 transition metals have proven themselves to be almost indispensable catalysts for organic synthesis or for depollution purpose [4]. Indeed, they can promote various C-C couplings and although the use of palladium-catalyzed cross couplings in organic synthesis was rewarded with a Nobel prize a little over ten years ago, a lot of new catalysts more efficient, more selective or easier to recycle are still developed every year [5,6,7,8,9,10,11]. Group 10 transition metals are also very efficient redox catalysts with this property being exploited for depollution, in the total oxidation of organic residues for example [12,13] or in synthesis, when they catalyzed hydrogenation of unsaturated compounds [14,15,16]. All this diversity of catalytic reactions is illustrated in the present review.

2. Cellulose

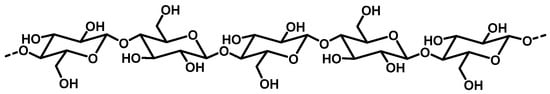

Cellulose is the most common and abundant biopolymer on Earth. It is found in some bacterial biofilms and some algae, but is mostly present as a structural component of green plant cell walls. It accounts for 35 to 55% of the biomass and up to 90% in cotton fibers. Paper is made of almost pure cellulose generally extracted from wood, which contains 40–50% of it. Herbaceous plants, such as hemp, flax, rape, canes, and bamboo are other interesting sources of cellulose, as are plant wastes (e.g., sugarcane bagasse, wheat straw, natural textiles) [17]. Many of the derivatives of cellulose are manufactured on an industrial scale for a very wide range of applications. The annual world production of cellulose in 2017 was 50 billion tons [18]. Cellulose is structured as a linear and fibrous chain of hundreds of D-glucose moieties linked by β-1,4-glycosidic bonds (Figure 1) [2,19]. The numerous hydroxyl groups establish a network of intra- and intermolecular H-bonding. Its formula is (C6H10O5)n with 200 < n < 7000, which makes it insoluble in water. Native cellulose fibers are made of grouped microfibrils exhibiting alternating crystalline and amorphous regions. Various allomorphs can be obtained with different extraction treatments and different plant species [17]. Cellulose is hydrophilic, biocompatible, non-toxic, environmentally-friendly, and easy to chemically modify [18,20].

Figure 1.

Structure of cellulose biopolymer.

The amorphous regions of cellulose are removed by dilute acid hydrolysis to yield microcrystalline cellulose as rod-shaped particles in the microscale [21]. Nanostructured cellulose can be obtained along two processes. Cellulose nanofibrils (CNF) can be isolated by mechanical treatment of cellulose pulp assisted by chemical oxidation or enzymatic treatment; they are semi-flexible, 5–20 nm in diameter and several micrometers long [22]. Cellulose nanocrystal (CNC) are yielded by acid hydrolysis assisted by ultrasonic treatment; it is a highly crystalline material made of smaller rigid fibers (whisker-like, 100–1000 nm long and a few nm in diameter) [23]. Some water-soluble derivatives of cellulose are commonly produced by etherification reactions of the hydroxyl groups: methylcellulose, carboxymethyl cellulose (CMC), hydroxypropyl methylcellulose [18].

2.1. In C-C Coupling

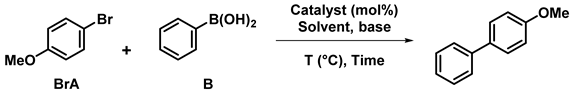

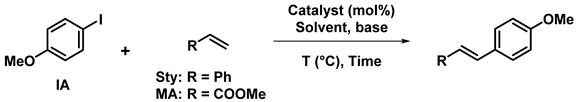

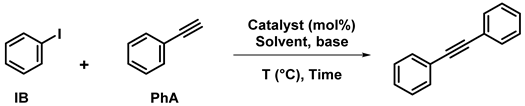

2.1.1. In Suzuki–Miyaura Coupling

Suzuki–Miyaura cross-coupling reaction is amongst the most commonly used ways to create C-C bonds, a key step in organic synthesis with many industrial applications. Suzuki coupling reaction is catalyzed by transition metal species, generally palladium complexes, or nanoparticles (NPs).

Cellulose Derivatized with Functionalized Spacers

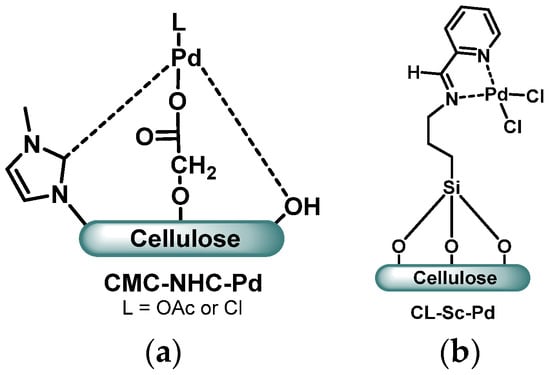

Several cellulose-supported palladium catalysts have been developed for Suzuki coupling reactions. N-heterocyclic carbenes (NHC) have been grafted onto cellulose in order to chelate palladium(II) ions. Wang et al. created sandwiched Pd(II) between N-methylimidazole moieties supported by two different cellulose chains [24]. Other teams have supposed that the modified cellulose acted as a polydentate ligand [25,26], the resulting complex being linked by the NHC, a hydroxyl group and a carboxyl group in the case of carboxymethylcellulose (CMC, Figure 2a). In all three cases, the Pd complex proved to efficiently catalyze Suzuki coupling reactions (up to 93% yield), with very little leaching of Pd in the medium thanks to the multiple capturing sites. However, the recycling of the catalyst was not viable after more than two runs due to an aggregation of palladium leading to a reduced catalytic activity (with less than 75% after 4 cycles).

Figure 2.

(a) Pd(II) complex supported by carboxymethylcellulose derivatized with N-heterocyclic carbenes [25]; (b) cellulose Schiff base-supported Pd(II) catalyst [27].

Cellulose has also been derivatized by a Schiff base supported via a silyl spacer and completed by a pyridyl moiety [27,28]. Such structures create a bidentate site to complex Pd(II) between two nitrogen atoms, with the possible addition of a third chelating atom from a native cellulose hydroxyl group. Both catalysts could be directly reused after filtration or centrifugation and washings, but with a significant loss in the catalytic activity: After 5 runs, the yield dropped to less than 77%, probably due to palladium aggregations. Interestingly, the catalyst CL-Sc-Pd (Figure 2b) developed by Baran et al. [27] proved to be efficient to catalyze Suzuki coupling reactions with both iodo- and bromo-aryl substrates, optimal conditions being under microwave heating in a solvent-free medium.

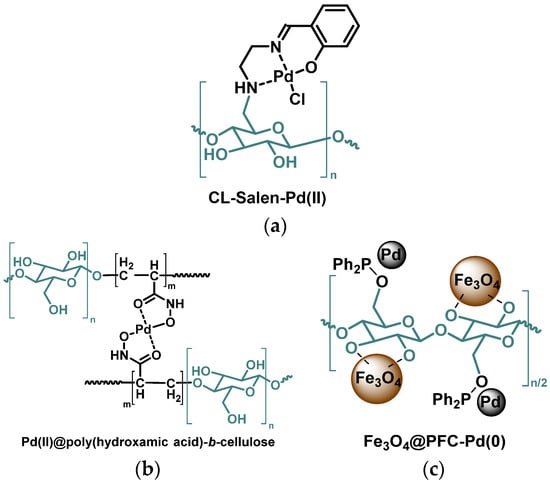

Using the same amino silylated arm, that team [29] has also designed a cellulose Schiff base with a glyoxal moiety bridging two cellulose chains. This functional environment offered a very stable site to complex palladium(II) or platinum(II) ions. Both heterogeneous Pd2+- and Pt2+-complexes showed a coupling of a variety of aryl halides with phenylboronic acid in the presence of K2CO3 under microwave irradiations at 50 °C. After 7 min, 60–98% (resp. 54–96%) yields were reached using aryl iodides and the Pd2+ (resp. Pt2+) catalyst. The yields were slightly lower when the reaction occurred with aryl bromides. The reaction of aryl chlorides was also catalyzed although with a much more reduced catalytic activity. Both catalysts could be recycled for 7 runs but the final yield progressively decreased after each reuse (down to ca. 60%). A similar structure, obtained with an isatine moiety [30] or a 2-hydroxynaphthaldehyde moiety [31] instead of the pyridyl, is also an efficient recyclable catalyst. A palladium complex has been immobilized on cellulose via another Schiff base, more precisely a salen-type tridentate ligand, with no silyl spacer (Figure 3a) [32]. This green supported catalyst was found efficient for Suzuki coupling reaction of various aryl halides with phenylboronic acid in water-ethanol at 50 °C with K2CO3. Furthermore, the catalyst demonstrates high to excellent yields and is easily recycled by simple filtration for up to twelve cycles without any significant loss of catalytic activity.

Sarkar, Rahman, and their team have valorized cellulose extracted from corn cobs. They synthetized poly(hydroxamic acid) (Figure 3b) and poly(amidoxime) derivatives supported on such biomaterial [33,34]. Both nitrogen- and oxygen-containing moieties have been shown to chelate Pd(II), thus forming stable bridging complexes between two polymeric chains. Both cellulose-supported complexes act as catalysts in Suzuki coupling reactions. The poly(hydroxamic acid) Pd(II) complex [34] can be recycled and keeps a good catalytic activity even after 5 runs: from 96% initially, the yield drops to 88%. The poly(amidoxime) Pd(II) complex [33] proves to be much less efficient (with 67% yield). However, after reduction by hydrazine, the resulting cellulose-supported Pd(0) nanoparticles (NPs) exhibit a high catalytic activity using either arylbromide or arylchloride substrates (with up to 99% or 96% yields, respectively) and either phenylboronic acid or 2-naphthylboronic acid. Such a catalyst was successfully used 6 times in a row with filtration, washings, and drying between each run: The yield remained almost constant (from 97% to 93%). Very little Pd leaching is observed due to the multiple complexing bonds, but aggregation occurs in the complex while the NPs remain quite unchanged. Amidoxime-functionalized cellulose has also been used to support both palladium(II) acetate and Fe3O4 NPs. The catalyst obtained, efficient in various Suzuki reactions (up to 95% yield), could be magnetically retrieved and reused at least for 5 successive runs [35].

So as to support Pd(II) complexes, cellulose has been derivatized with other nitrogenated moieties. Cellulose-supported diethylenetriamine [36] and 2-aminopyridine [37] both offer polydentate ligands that stabilize Pd(II) complexes. Their utilization as catalysts in Suzuki reaction was successful. Both could be recycled by centrifugation and rinsing with almost no leaching (thanks to the powerful chelation) but with a progressive aggregation of palladium. The yield of the coupling between 4-bromoanisole and phenylboronic acid goes from 91% initially down to 62% after 4 runs with the diethylenetriamine-Pd complex and from 95% initially down to 42% after 5 runs with 2-aminopyridine-Pd complex.

A nitrogenated spacer, terminated by a trimethylammonium group, was also used to anchor palladium to cellulose. After reduction, Pd NPs were evenly distributed on the cationic nanocellulose and the resulting catalyst was used to perform Suzuki coupling reactions, but good yields were obtained only under non-sustainable conditions (DMF as a solvent, 110 °C). Rapid loss of catalytic activity was observed after only 3 runs [38]. Sun and Mohammadnia have designed an efficient Pd catalyst complexed on [2,2′-bipyridin]-4-amine functionalized nanocellulose. The catalytic activity of the nanocatalyst was investigated through one-pot synthesis of biaryl derivatives from the reaction of aryl halides (mainly bromides) with arylboronic acids in DMSO at 70 °C. This simple and mild procedure exhibited excellent recyclability with good yields (55–99%) and short reaction time inferior to 75 min [39].

Figure 3.

(a) Cellulose-salen-supported Pd(II) complex [32]; (b) Pd(II) complex supported by poly(hydroxamic acid) derivative of cellulose [34]; (c) Pd NPs supported by magnetic Fe3O4 cellulose [40].

Palladium has also been bonded to microcrystalline cellulose (MCC) via phosphines. One team [41] has synthesized a diphenylphospinite-anchored cellulose while other groups have prepared a cellulose-supported triphenylphosphine [42,43]. Those phosphine-containing celluloses bonded with palladium to form stable Pd NPs that proved to be efficient catalysts in Suzuki coupling reactions. The first catalyst (Cell-OPPh3-Pd) can be reused for 4 runs after recovery by centrifugation and washing but the yield drops from 95% down to 56%, due to Pd aggregation. The other ones (Cell-PPh2-Pd) work with aryliodides and arylbromides; they can be recycled by filtration, washings and drying and used 5 times with almost constant catalytic activity (95–90% yield). In all cases, the optimal conditions are 75–80 °C in water-ethanol with K2CO3 as a base. Cellulose derivatized with a diphenylphosphine on the primary alcohol function was shown to offer a more stable environment than non-derivatized cellulose to fix both Fe3O4 NPs and Pd NPs (Figure 3c). The whole set (Fe3O4@PFC-Pd(0)) has been used as magnetically retrievable nanocatalysts, highly efficient (up to 98% yield) in Suzuki coupling reactions in a deep eutectic solvent (DES, K2CO3/glycerol: 1/5) at 70 °C. Yields almost did not drop after four recyclings [40].

Chemically Modified Cellulose

Pd(II)-complexes have been formed with carboxymethylcellulose (CMC) as the ligand. During a Suzuki coupling reaction, palladium ions first undergo in situ reduction to form Pd(0) NPs supported by the CMC, which further catalyze the cross-coupling. The catalyst was used 6 times to couple iodoanisole and phenylboronic acid, with intermediate filtration, washings, and drying, almost without any loss of catalytic activity [44].

The selective oxidation of the primary hydroxyl groups of cellulose yields carboxyl cellulose (CC), which permits the direct coordination of metal ions [45]. CC has been used as a ligand to complex palladium or nickel ions. PdCC was found to catalyze the cross-coupling of various aryl halides with aryl boronic acids in water/DMF at 30 °C with K2CO3 as a base. After 1 h, several reagent combinations led to quantitative couplings. Bromotoluenes were less reactive (60–79% yields), but 100% yield could be reached at higher temperature (80 °C). Chloroanisole was almost not reactive. Sterically hindered arylbromides reacted poorly (1–22% yields). Suzuki reaction was also found possible with NiCC as a catalyst in toluene at 130 °C, although with only 40% yield.

Pd NPs have been incorporated within a cellulose acetate membrane and this works as dip catalyst in aqueous media for Suzuki reaction [46]. However, minor aggregation of NPs, thermal deformation of the membrane and, more importantly, leaching of Pd(0) lead to a non-linear loss of catalytic activity. The first use has a 100% yield, but after 6 runs it drops to 17% only.

Pd NPs on cellulose sulfate, prepared by reduction of palladium(II) ions, have proved to catalyze the coupling reaction of various aryl halides with phenylboronic acid, with yields up to 99%, within 15 min, in DMF under reflux with NaOH. The catalyst could be reused up to 20 times with a yield still over 80%, if the reaction time was increased from 10 min initially to more than 20 min. Very little Pd leaching was observed between each run [47].

Another team has used a cellulose sponge as a carrier for Pd NPs [48]. The nanoparticles were grown on the surface of cross-linked cellulose nanofibers and then used as an efficient catalyst in Suzuki coupling reaction. The yield remained almost constant (from 99% to 93%) when the same sponge-supported catalyst was recovered by pulling, washed and reused in 6 cycles.

Researchers have partially modified cellulose nanocrystals (CNC) in order to make one face much more hydrophobic than the other (Janus particles) so as to use them as a colloidal surfactant (Pickering emulsion). When loaded with Pd NPs, such amphiphilic CNC can act as an efficient catalyst for Suzuki coupling reaction with a reaction mixture being an emulsion. This proves useful to carry out the coupling hydrophobic organic reagents in water as a green solvent [49].

Dialdehyde nanocellulose was obtained by successive oxidation steps in order to reduce palladium ions. This way Pd NPs were homogeneously deposited onto cellulose nanofibrils and the resulting product successfully applied to Suzuki reaction with 90% yield [50].

Non-Chemically Modified Cellulose

An effective palladium-based catalyst has been developed for the Suzuki coupling reaction of aryl halides (including chlorides) with phenylboronic acid in aqueous conditions at room temperature. Pd(II) ions and neat nanocellulose were added to the reaction mixture and Pd NPs grew in situ within the natural polymer to form the actual heterogeneous nanocatalysts. In addition to the absence of volatile organic solvent, the broad substrate scope and the mild reaction conditions, this method proved to be sustainable and efficient with 90% to 99% product isolated yields and a successful reusability up to 11 cycles [51].

Pd(II) species have been reduced, by solvent or NaBH4, in a cellulose solution in ionic liquid solvent. It led to the formation of Pd(0) cores then microencapsulated in a cellulosic film using anhydrous ethanol as a coagulant [52]. The as-prepared hybrid material proved to be a versatile, robust and highly efficient catalyst for various Suzuki coupling reactions performed in 15–20 min in ethanol under reflux with K2CO3. The catalyst could be retrieved by simple filtration and recycled at least 6 times without important loss of its high catalytic activity (91% to 88 % yields).

Non-chemically modified cellulose has also been used as a support for Pd NPs. Stirring commercially available cellulose with Pd(OAc)2 in ethanol at 25 °C followed by reduction with hydrazine hydrate leads to Pd NPs uniformly distributed on the surface of cellulose [53]. This catalytic system was used in Suzuki coupling of various aryl bromides with phenylboronic acid in water at 100 °C using a phase-transfer agent, reaching excellent yields and it was easily recycled (with 96% yield initially to 94% yield at the fifth run). Cotton fibers are mainly made of cellulose (up to more than 90%). Some researchers have imbedded Pd NPs in nonwoven brown cotton fabric, a cheap cellulose substrate still containing tannins. Those naturally occurring polyphenols reduced palladium ions into Pd NPs which were thus deposited on the fibers. The resulting structure was catalytically active at sub-milliequivalent levels in Suzuki coupling reactions (with yields up to 99%), retained catalytic activity for ten experimental cycles and palladium did not leach into isolated products [54].

A distorted honeycomb-like hollow cage-structured bio-nanocellulose (derived from pomegranate peel by simple microwave technique in water with no other reagent) has been loaded with Pd NPs. That nanocomposite material has been utilized as a heterogeneous catalyst for the C-C coupling of various arylbromides with arylboronic acid derivatives. The Suzuki reactions were carried out in a water-ethanol mixture at room temperature for 20–60 min with 80–98% yields; when heteroaromatic compounds were reacted, the reaction was performed at 60 °C for 24 h and 55–98% yields were reached. The catalyst is reusable up to five catalytic cycles without significant loss of its catalytic activity [55].

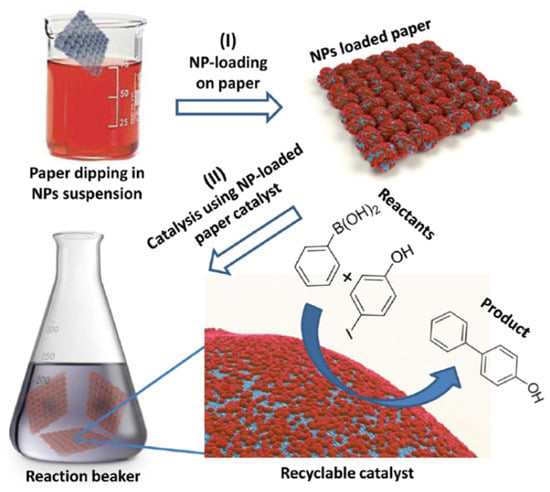

Most interestingly, a very efficient and highly recyclable catalytic system was obtained by immobilization of Pd NPs on filter paper (Figure 4) [56]. The loaded paper was then simply dipped in the reacting mixture and pulled for reuse after washing. Excellent yields (up to 100%) were obtained in coupling iodophenol with phenylboronic acid under microwaves with K2CO3 as a base and the catalyst could be used in 5 successive runs with only a small reduction of the catalytic activity (possibly because of a poisoning by iodide ions).

Figure 4.

Schematic representation of the paper-supported dip catalyst preparation (I) and use (II). (I) Assembly of oleylamine-stabilized Pd NPs on cellulose filter paper by dip coating. (II) Immersion of NP-loaded paper strips in a reaction medium to catalyze a cross-coupling reaction [56].

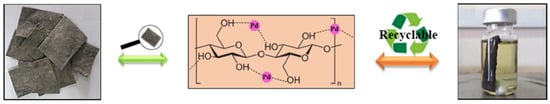

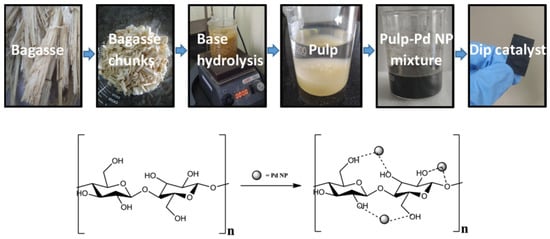

Baruah et al. have synthesized Pd NPs on nanoporous cellulose by reducing palladium(II) ions with a natural wood extract (oxyresveratrol). Those nanoparticles exhibit versatile catalytic activity towards the Suzuki reaction in water under microwave heating with 82–94% yields. The coupling of bromobenzaldehyde with phenylboronic acid was successively catalyzed ten times with almost no leaching of palladium and a yield still over 70% [57]. Similarly, in a green chemistry perspective, Kempasiddaiah et al. have obtained cellulose-supported Pd NPs using waste banana pseudostem both as a source of reducing agent and of cellulose. The dip catalyst obtained (Figure 5) was used in various Suzuki coupling reactions [58]. That of iodobenzene with phenylboronic acid reached a 96% yield under optimized conditions: in water:ethanol (1:1), at room temperature, with Na2CO3 for 30 min. The dip catalyst could be used for 15 cycles with almost no leaching of Pd and a yield still over 88%. A green synthesis of pharmaceutical active principle, Felbinac, has even been successfully performed, by cross-coupling of 4-bromophenylacetic acid with phenylboronic acid, with 94% yield using such dip catalyst.

Figure 5.

Dip catalyst as Pd(0)-loaded cellulose sheets; plausible structure of the Pd NPs-containing cellulose; typical experimental setup using the dip catalyst [58].

Another dip catalyst was prepared as a rectangular sheet by dispersing Pd NPs into the cellulosic pulp of sugarcane bagasse (Figure 6) [59]. Its catalytic activity was demonstrated in the Suzuki cross-coupling reactions of various arylbromides and aryliodides with different arylboronic acids in ethanol–water mixture at room temperature using K2CO3 as a base. Very good yields were reached (up to 98%) and maintained for up to 13 successive runs with the same catalyst sheet simply recovered by pulling with tweezers; at the next cycles, the dip catalyst had been slightly disintegrated on the edges due to abrasion of the stirring bar, which caused a lesser conversion.

Figure 6.

Preparation steps of the dip catalyst from sugarcane bagasse; representation of cellulose-supported Pd NPs proposed by Kandanthil et al. [59].

The one-pot synthesis of cellulosic–carbon-shielded palladium–magnetic nanoparticle hybrid material (Pd-MNP@SCB) has been described by the same team. Calcined natural sugarcane cellulose was used as a green source of carbon for its large surface area and porosity. The prepared hybrid material proved to have an efficient catalytic activity in Suzuki–Miyaura cross-coupling reaction with excellent functional group tolerance and good recyclability [60].

Cellulose Composites

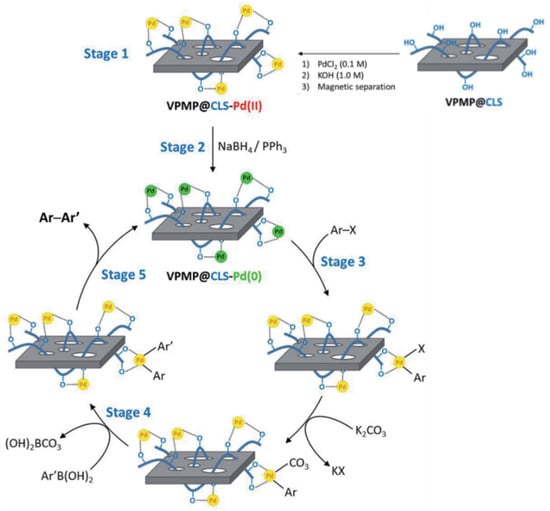

A hybrid device has been developed with the natural magnetic property from a non-modified mineral. Volcanic pumice magnetic particles (VPMP) have been textured by cellulose to further nest Pd NPs and form a biosourced composite suitable for the catalysis of C-C coupling reactions. Heterogeneity, high stability, and inherent magnetic property enable a remarkable recyclability with 10 times successive use. The actual Pd(0) catalyst was found a bit less efficient when used after prior reduction. Therefore the Pd(II) pre-catalyst was reduced in situ (Scheme 1) in order to obtain a biphenyl with high yield (98%) from 4-nitroiodobenzene and phenyl boronic acid in a short time (10 min) in DMSO at room temperature in the presence of the reductive additives (triphenylphosphine and sodium borohydride) and the base (potassium carbonate) under nitrogen. A series of other aryl halides have been tested with 69–97% coupling yields [61].

Scheme 1.

Catalytic cycle suggested for VPMP@CLS-Pd(0) in Suzuki coupling reaction [61].

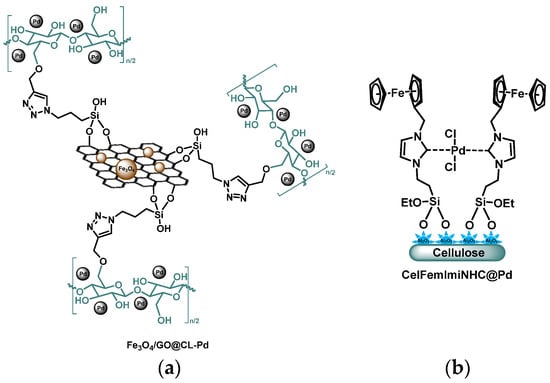

A heterogeneous nanocomposite combining graphene oxide-supported Fe3O4 NPs and cellulose-stabilized Pd NPs (Figure 7a) has been proved an active catalyst in various Suzuki coupling reactions. The optimal reactions were conducted at 70 °C in DES, namely dimethylammonium chloride:glycerol, with K2CO3, and led to 81–99% yields. Aryl iodides reacted much faster (generally 20–30 min) and gave better yields than aryl bromides (40–60 min). Due to the low solubility of catalyst and DES in organic solvents, the separated aqueous phase containing both the catalyst and DES could be readily recovered by evaporating water and reused up to five successive runs with a stable activity. Incidentally, the heterogeneous catalyst could be extracted from the DES by an external magnet [62].

Figure 7.

(a) Palladium supported on cellulose modified Fe3O4-graphene oxide [62]; (b) cellulose–alumina composite supported Fc–NHC Pd(II) complex [63].

Kale et al. have designed a N-heterocyclic carbene-Pd complex anchored on cellulose via Al-O-Si bonds (Figure 7b) [63]. They proved it to be an efficient heterogeneous catalyst in various Suzuki coupling reactions, in ethanol at room temperature using cesium carbonate as a base. Under such conditions, the coupling of phenyl boronic acid with iodobenzene within 3 h led to 78% yield, whereas it grew up to 87% within 30 min when the catalyst was tethered by ferrocene moieties. Indeed, the steric hindrance and the powerful electron donor capacity of the ferrocenyl groups rendered the NHC-Pd complex electron rich. This induced a faster oxidative addition, which is the first and rate-limiting step of the cross-coupling reaction. It is of note that a soluble homogeneous analogue was found more efficient with up to 94% within 30 min, but the heterogeneous catalyst could be recycled for 5 runs with only little loss of catalytic activity. Aminopyridine moieties have been anchored on cellulose-supported alumina with a propylsilyl linker [64]. The nitrogen sites could complex palladium ions thus forming an efficient retrievable hybrid heterogeneous catalyst (Pd(II)-AMP-Cell@Al2O3). The catalyst has been successfully employed in a variety of Suzuki coupling reactions, in DMF at 80 °C for 1 h, using K2CO3 as a base, with up to 94% yield. It could be recycled up to 4 times by filtration, washing, and drying, with almost no Pd leaching and thus minor loss of catalytic activity. Salunkhe and his team have prepared a cellulose–aluminum oxide composite, further silylated with a propyl spacer bearing a primary amine through Al-O-Si bonds [65]. Pd(II) ions were efficiently complexed by the amino groups so that the composite could be used as a highly active heterogeneous catalyst for Suzuki–Miyaura cross-coupling reaction in water and water/DMF mixture at 80 °C (up to 97% yields). Recyclability was limited to 5 successive runs with yield dropping from 97% to 81% and reaction time extending from 20 min to 7 h. Alumina was added in order to supposedly stabilize the hybrid since C-O-Si bonds were said to be easily hydrolyzed. Such instability was however not described by other teams who successfully used C-O-Si bonds in other nanocatalysts [27,28,30,31,66,67].

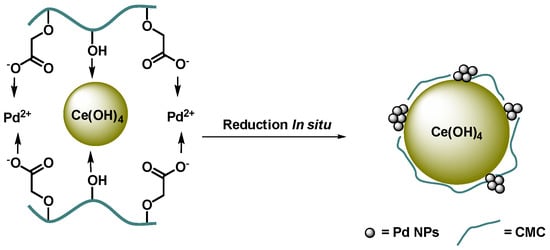

CMC has been loaded with cerium(IV) hydroxide by successive chelation and precipitation within the biopolymer [68]. The organic/inorganic hybrid was then used to design Pd(II)-complexes similar to those in the previous work, which in the very same way proved to be pre-catalysts for Suzuki–Miyaura reactions. The in situ reduction of palladium occurred in the course of the cross-coupling reaction and the activity of the Pd NPs was enhanced synergistically by the redox properties of cerium and coordination with the carboxyl and hydroxyl groups of CMC (Scheme 2). In DMF/water: 1/1, at 80 °C, using K2CO3 as a base, a variety of biaryls were obtained with up to 97% yield for the coupling of iodoanisole with phenylboronic acid. As commonly reported aryl iodides were more reactive than aryl bromides; aryl chloride only reacted poorly. The catalyst could be easily separated by simple filtration and reused at least five times with yield still over 90%. Interestingly, the results exhibit that this Pd-CMC@Ce(OH)4 catalyst has a much higher activity in Suzuki reaction than Pd@CMC, Pd@CeO2, and Pd@Ce(OH)4.

Scheme 2.

Preparation scheme of CMC@Ce(OH)4-supported Pd(II)-complexes and in situ reduction to Pd NPs [68].

Pd NPs have been dispersed onto titanium oxide-cellulose composite by direct reduction [69]. The resulting PdNPs@TiO2-Cell showed an excellent activity as a catalyst in Suzuki–Miyaura reactions, in 95% ethanol at 80 °C with potassium carbonate, with up to 90% yields after 1 h. A wide range of reagents have been used with success, without Pd leaching. The catalyst could be recovered and recycled 4 times with the same yield. A similar catalyst, prepared by the same team with derivatized alumina instead of titanium oxide [65], was more efficient in DMF but less in ethanol. Other Suzuki-type reactions were also performed at room temperature in the presence of K2CO3 using PdNPs@TiO2-Cell as a catalyst to couple aryl boronic acids with: (1) various arenediazonium salts in water with up to 90% yield; (2) a choice of benzoyl chlorides in 95% ethanol with 85–92% yields.

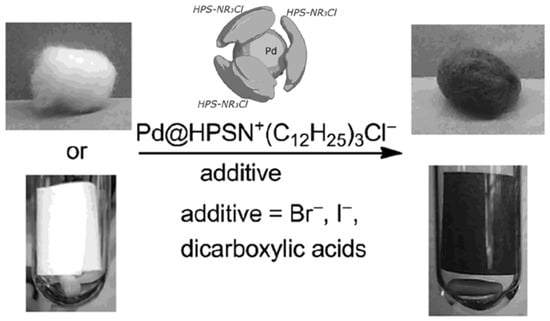

Hyperbranched polystyrene, derivatized so as to exhibit quaternary ammonium groups, have been described by Nishikata et al. as an efficient stabilizer for metallic NPs thanks to the electrostatic and steric properties of its cationic moieties [70]. They further showed that such polystyrene-supported Pd NPs precipitated onto cotton wool or paper cellulose by addition of iodide or bromide ions (Figure 8). The resulting composite proved to catalyze the Suzuki coupling reaction of iodobenzene with phenyl boronic acid in water at 50 °C with K2CO3. After 24 h the reaction was almost quantitative and it remained so after 5 successive runs, with only little Pd leakage over the recycling of the dip catalyst. Interestingly, the same piece of catalyst could be reused four times with different substrate without any cross-contamination or decrease in catalytic activity.

Figure 8.

Preparation of dispersible Pd@HPS-NR3+Cl− and its immobilization on cellulose (cotton wool or filter paper) [70].

Baran et al. have designed a greener nanocomposite of chitosan and cellulose to support either Pd(II) complex [71] or Pd NPs [72]. Both structures exhibited a catalytic activity in the coupling reaction of a wide range of aryl halides with phenyl boronic acid. Under mild conditions (solvent free medium, microwave heating at 50 °C, K2CO3 as a base), various yields were reached within 5 min using aryl iodides or bromides: 22–99% with Pd(II) complex and 60–100% with Pd NPs, according to the substituent on the benzene ring. Yields were only 9–25% with Pd(II) and 55–75% with Pd(0) using aryl chlorides. The chitosan-cellulose-Pd(II) catalyst could be recycled and was still active after 9 cycles (although with a yield dropping from 99% to 43%). Another biosourced composite nanocatalyst, made of Pd NPs dispersed within a cellulose-alginate hydrogel, has been found active to couple three different aryl iodides and three bromo isologues with p-tolylboronic acid at 80 °C in ethanol in the presence of K2CO3 under nitrogen atmosphere [73]. The yields reached 85–99% after 2 h. The recycling of the hydrogel bead catalyst was performed, showing negligible Pd leaching and minimal decrease of the product yield after 5 runs.

An active hydrogel has also been developed by incorporation of Pd NPs stabilized on CNCs into a guar gum-based matrix with a boron-based crosslinking [74]. Over 70 °C, the thermoresponsive hydrogel converted to the sol phase; it then proved to be an efficient catalyst in the Suzuki coupling of aryl bromides with phenyl (or tolyl) boronic acid with K2CO3 at 80 °C in ethanol under N2, with the yield culminating at 86–99% after 2 h. After cooling to 20 °C, the catalyst set to the gel phase; it could then be recovered, rinsed with water and directly reused: the reaction yield was still over 85% after the 5th cycle and the Pd content remained essentially the same.

Pd NPs have been immobilized on a biosourced composite by a one-pot reaction of CMC, agar saccharides, and Pd(II) ions, the latter being spontaneously in situ reduced. The Pd-composite was used as a catalyst to cross-couple various aryl halides with phenyl boronic acid in the presence of K2CO3 at 60 °C under ultrasonic sonication [75]. After 30 min, good to excellent yields were reached (up to 98%). Under conventional heating, the yield was lower (only 75%) even after 5 h reaction. Interestingly three homogeneous Pd(II) catalysts were found less active under the same conditions. Furthermore, the heterogeneous catalyst could be recovered by centrifugation and reactivated by washing with hot ethanol, showing that it could be reused even after 6 runs, although the final yield drastically dropped to less than 50%.

2.1.2. In Mizoroki–Heck coupling

Mizoroki–Heck cross-coupling reaction is useful to create C-C bonds to functionnalize alkenes. It is commonly the reaction between aryl halides and substituted alkenes in the presence of transition metals catalysts.

Cellulose Derivatized with Functionnalized Spacers

Sarkar et al. have synthesized a co-polymer of corn cob cellulose and poly(hydroxamic acid) in order to complex Pd(II) ions between two chains [34,76]. The resulting structure was used as a catalyst for a variety of Heck coupling reactions using different alkenes and whether aryl iodides (89–97% yields), aryl bromides (87–95% yields), heteroaryl halides (72–94% yields), or aryldiazonium tetrafluoroborate salts for a Heck–Matsuda coupling (90–97% yields). All reactions were optimized in non-green conditions: DMF as a solvent, Et3N as a base, at 130 °C (or room temperature for Heck–Matsuda) during 5 h or more. The catalyst was easily recovered by filtration, washed and dried, then reused with very little loss in catalytic activity after up to 7 runs. A pharmaceutical active ingredient, Ozagrel, was successfully prepared under such conditions using such heterogeneous Pd catalyst [76]. In another study, Sarkar’s team has used an analogous Pd(II) complex by replacing poly(hydroxamic acid) with poly(amidoxime) and showed similar catalytic activities: 91–96% (resp. 82–96%) yields for Heck coupling with aryliodides (resp. arylbromides) and 90–97% yields for Heck–Matsuda coupling. That catalyst was also reused with success 7 times with a yield reduced from 95% to 87% [77].

The cellulose-supported Pd(salen)-type catalyst already used in Suzuki reaction has also proved to be efficient to catalyze Heck coupling reactions in the same conditions with 93–99% and good recyclability [32].

A nanomagnetic catalyst has been prepared by chelating palladium(II) ions onto a 5-carboxyoxindole functionalized cellulose already supporting Fe3O4 NPs. Such green composite catalyst was employed for Heck-type arylation of different substituted maleimides with iodoarenes in good to excellent yields, easily magnetically recovered and reused several times with no substantial loss of activity [78].

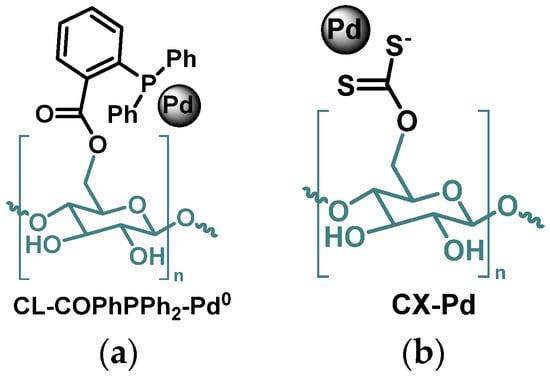

Pd NPs have been dispersed in different phosphine-containing celluloses. It has already been explained that the resulting stable heterogeneous catalyst was used in Suzuki coupling reactions. The same teams have also proved that both structures could catalyze Heck coupling reactions. Both triphenylphosphine cellulose-supported (Figure 9a) [43] and diphenylphosphinite cellulose-supported nanopalladium [79] are catalytically active in DMF with good yields (ca. 90%) and completely recyclable for 5 cycles.

Another bio-supported catalyst was prepared by uniform distribution of Pd NPs onto ethylenediamine-functionalized cellulose (EDAC). It was successfully used in Heck coupling reactions in water as a green solvent and proved to remain stable when recycled, yields ranging from 99% initially to 94% at the fourth run [80].

Figure 9.

(a) Triphenylphosphine containing cellulose-supported Pd NPs [43]; (b) cellulose xanthate-supported Pd NPs [81].

Chemically Modified Cellulose

A stable cellulose xanthate-supported palladium(0) has been synthesized using a simple method (Figure 9b) [81]. It was found to be an efficient catalyst for the Heck reaction of acrylic acid or styrene with aryl iodide. Very high yields (up to almost 100%) were reached at 90 °C after about 8 h. The catalyst could be easily recycled and reused although its catalytic activity rapidly dropped down to 55% after 10 runs.

Besides Suzuki coupling reactions, Pd NPs supported by cross-linked cellulose sponge also catalyze Heck coupling reactions and excellent yields (99%) were obtained to couple iodobenzene with three different aryl ethylene. The catalyst is easily recyclable [23].

Non-Chemically Modified Cellulose

Pd NPs microencapsulated in cellulose proved to catalyze Heck coupling reactions of various arylbromides and aryliodides with styrene and acrylic acid in DMF at 130 °C with tributylamine, reaching 66% to 88% yields within 2 to 12 min [52].

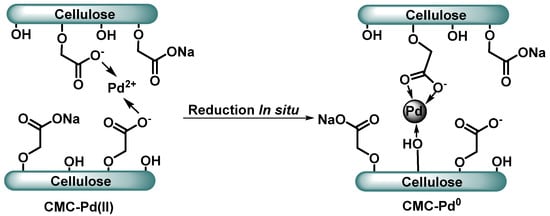

Pd(II)-complex on CMC (Figure 10) has proved to catalyze Heck coupling reactions, in addition to Suzuki coupling reaction, after in situ reduction of Pd as nanoparticles [44]. Acrylic acid and styrene were coupled with various aryliodides with good yields (83–90%).

Figure 10.

Pd(II) complex in carboxymethylcellulose and in situ reduction of Pd NPs in CMC [44].

Pd NPs supported by non-chemically modified microcrystalline cellulose, obtained by reduction with hydrazine, already used in Suzuki reaction, has also been shown to act as a catalyst for Heck coupling reactions [36]. Quantitative conversion was observed with various aryliodides and methylacrylate when the reactions were carried out in acetonitrile or DMF with triethylamine as a base. The catalyst could be recycled by filtration, washing and drying, and lost only little catalytic activity after 4 runs, due to a minimal leaching and some aggregation.

Rezayat et al. reduced Pd NPs in cellulose nanocrystals in subcritical and supercritical carbon dioxide as a solvent. The resulting product showed an interesting catalytic activity in two examples of Heck coupling reactions [82]. Pristine cellulose was used by another team to complex Pd(II) ions and the product obtained has been used to catalyze Heck coupling reactions. Using the Pd(II)-cellulose complex, acrylic acid and styrene were coupled with aryliodides in water as a green solvent, in the presence of tributylamine, with yields up to more than 99%. The catalyst could be reused 5 times with yields still over 76% [83]. Pd NPs on cellulose, developed by Baruah’s team, and already mentioned in Suzuki coupling reactions, have shown an interesting catalytic activity in Heck coupling reactions in water under microwave heating with 87–89% yields [57]. A colloidal catalyst for Heck coupling reaction has been developed by reducing Pd NPs onto cellulose nanocrystallites (Figure 11). Using such a catalyst, iodobenzene reacted with styrene in water–acetonitrile at 100 °C with K2CO3 as a base to yield stilbene with 75% conversion [84].

Figure 11.

Reduction of Pd(II) onto cellulose as Pd NPs [84].

Cellulose Composites

Pd NPs supported by an ammonium-derivatized hyperbranched polystyrene have been glued to filter paper and cotton wool to form dip catalysts [70]. Both were utilized to catalyze the quantitative coupling reaction of phenyl iodide with t-butyl acrylate or styrene, at 80 °C in water with K2CO3 for 24 h. The adhesion of the polystyrene-supported NPs to the cellulose was found very strong so that the dip catalyst could be used five times in a row with almost no Pd leaching detected and a yield still over 99%. Interestingly, the same “black filter paper” could be successively recycled to catalyze the couplings of different substrates for each run.

Masteri–Farahani and his team have devised another magnetic nanocomposite, this one made of graphene oxide (GO) and cellulose [85]. Iron ions were precipitated as Fe3O4 NPs in the sites offered by GO. Cellulose was grafted to GO via click-chemistry after adequate derivatization. The abundant OH groups of cellulose highly stabilized Pd NPs uniformly dispersed over it. The resulting nanocomposite served as a heterogeneous catalyst for C-C coupling of iodobenzene with n-butyl acrylate in various deep eutectic solvents (DES). In optimized conditions (at 100 °C in dimethylammonium chloride:glycerol, with K2CO3), 98% yield was reached after 5 h. The Heck reaction was also conducted with different aryl halides and alkenes, generally with yields over 90–95%. The catalyst could easily be retrieved with an external magnet, but its direct recycling was performed without such recovery. The final reaction mixture was quenched with a water/ethyl acetate mixture so that the product was extracted in the separated organic phase with the DES and the catalyst stayed in the aqueous phase and were recovered by water evaporation for further reaction. Eight actual runs were found possible with only small decrease in the final yield.

GO nanosheets have also been combined with chitosan NPs and dialdehyde cellulose nanowhiskers to form a hydrogel support for Pd NPs [86]. The resulting catalyst was utilized to efficiently cross-couple various olefins with phenyl halides in aqueous ethanol under reflux in the presence of K2CO3. Maximum yields were achieved after 30–40 min with iodobenzene (95–99%), after 40–60 min with bromobenzene (93–97%) and after 120–180 min with chlorobenzene (81–87), a shorter carbon-halogen bond resulting in a more difficult metal penetration and a slower cleavage. The reaction rate decreased when an electron-rich substituent (-NH2) was present on the aryl halide. The hydrogel catalyst could be recycled by filtration, water dialysis, and vacuum drying at 80 °C with no important Pd leaching. After 6 uses, the final yield was still 85%.

Heterogeneous nanocatalyst Pd(II)-AMP-Cell@Al2O3, a Pd-complex supported on derivatized hybrid cellulose-alumina, has been shown efficient in various Heck–Mizoroki cross-coupling reactions [64]. For instance, the coupling of iodoanisole with methyl acrylate in DMF at 100 °C with triethylamine for 2 h yielded 92% reaction product and the catalyst could be used 5 times in a row with almost the same activity, due to a high stability of the palladium complex on the amino-pyridine sites.

Pd NPs supported on TiO2-cellulose composite have been used to catalyze Heck–Mizoroki coupling reactions of aryl bromides with various olefins. In optimized conditions, in DMF at 100 °C with K2CO3, yields reached 80–95%. Heck–Matsuda coupling reactions (using diazonium salts instead of bromides) were also possible with that catalyst in water, at room temperature and without a base, with 75–92% yields [69].

2.1.3. In Sonogashira Coupling

A number of cellulose-supported palladium-based catalysts already used for Heck coupling reactions have also proved to act as catalysts for Sonogashira coupling reactions of arylhalides with phenylacetylene and other alkynes, in similar conditions and with the same ease for recycling. This is the case for EDAC-supported Pd NPs [80] and for cellulose-supported Pd(salen)-type complex [32], using either aryliodides or arylbromides in water in the presence of K2CO3 and CuI, with yields up to 98%. This was also observed with Pd NPs dispersed in phosphine-containing cellulose in DMF with triethylamine and CuI (89–96% yields) [43]. Sonogashira coupling reactions of aryl acetylenes with various aryl halides, performed in deep eutectic solvents at 100 °C, have been catalyzed by Fe3O4@PFC-Pd(0). High yields were obtained (up to 96%) and the catalyst, after magnetic recovery, was reused for five cycles without an appreciable loss of activity [40].

MCC-supported Pd NPs also work as catalysts for Sonogashira reaction, using aryliodides in acetonitrile or DMF with triethylamine as a base but yields were quite contrasted (42–98%), depending on the activation of the aryl group [87]. Honeycomb-structured bio-nanocellulose loaded with Pd NPs has been used to catalyze Sonogashira cross-coupling reactions. The coupling of various alkynes with aryl iodides in water–ethanol at 70 °C or with aryl bromides in DMF at 90 °C were observed with 70–98% yields, using no copper salt but K2CO3 as a base. The reaction was found possible with halo-pyridines and halo-pyrimidines [55].

Another magnetic Pd nanocatalyst has been developed and used for Sonogashira coupling reactions in DES. That nanocomposite of GO-supported Fe3O4 NPs and cellulose-supported Pd NPs has efficiently been used to catalyze the C-C coupling of various aryl halides with phenylacetylene at 120 °C with K2CO3 in a dimethylammonium chloride: glycerol mixture [85]. The products were obtained with 87–96% yields. The nanocatalysts could be recycled by liquid–liquid extraction together with the DES since neither of them were soluble in an organic phase composed of additional ethyl acetate. After 8 runs, the yield decreased from an initial 91% to 80% with negligible leaching. The nanocatalyst could finally be magnetically recovered when necessary.

Jadhav et al. have carried out copper-free Sonogashira coupling reactions of a wide range of arylbromides and aryl alkynes in DMF at 80 °C using K2CO3 as a base and TiO2-cellulose-supported Pd NPs as a catalyst. Yields ranged between 85% and 95% [69].

2.1.4. Other C-C Coupling

Rasouli and Ranjbar claim that they deposited onto microcrystalline cellulose (MCC) Pd(II) ions that spontaneously form stable Pd NPs uniformly distributed within the polymer, without any reducing agent [88]. The product was used as a catalyst for the Ullmann C-C reductive homocoupling of various aryl halides in the presence of zinc, in a water–ethanol mixture, in air. Excellent yields were reached with phenyl bromide (96%) and phenyl iodide (94%) at 25 °C. The reaction was also found possible with various other arenes including aryl chlorides, although with lower yields. The catalyst could be reused but degraded when the reaction temperature was over 75 °C.

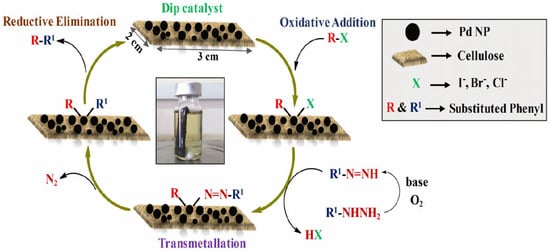

The green dip catalyst developed by Kempasiddaiah et al. for Suzuki reaction [58] has also been utilized by the same team to catalyze denitrogenative cross-coupling reactions. They synthesized a broad array of symmetrical and unsymmetrical biaryls using arylhydrazines and aryl halides as coupling partners through C-N bond cleavage in air as green oxidant (Figure 12) [89]. The dip catalyst could be recycled by simple pulling with tweezers from the reaction medium and rinsing; it remained stable and catalytically active (94% initial yield to 85% yields at the sixth run).

Figure 12.

Mechanism proposed by Kempasiddaiah et al. for denitrogenative cross-coupling reactions [89].

Pastoriza–Santos, Pérez–Juste, and their team have shown that paper-supported Pd nanoparticles efficiently catalyze aqueous aerobic oxidative C-C homocoupling reaction of 4-carboxyphenylboronic acid to form 4,4′-dicarboxybiphenyl in water at 70 °C [56]. The dip catalyst was recovered by simple pulling and washing and could be reused for 10 runs with the same catalytic activity. The cellulose-base Pd(0) dip catalyst prepared by Kandathil et al. has proved to catalyze the 5-arylation reaction of 2-substituted thiophenes. The C-C coupling of various arylbromides and aryliodides with 2-formyl-thiophene and 2-acetyl-thiophene in DMF at 120 °C was found possible by the dip catalyst, in the presence of silver oxide, sodium carbonate and pivalic acid, although with limited yields (52–82%) after 16–18 h [59].

Nishikata et al. have designed “black cotton” and “black filter paper” made of Pd NPs supported by an ammonium-derivative of polystyrene immobilized on cellulose [70]. With those composites, an intramolecular C-C coupling was successfully catalyzed within diaryl iodide compounds to quantitatively yield, after 24 h, the 2H-pyran cycle between the aromatic rings in 9H-10-oxa-phenanthrene-type products. The coupling reaction was carried out at 120 °C in N,N-dimethylacetamide in the presence of potassium acetate. The paper catalyst could be recycled 4 times with the same catalytic activity.

Cotton wool has been treated with chlorosulfuric acid to fabricate a negatively charged derivative of cellulose [90]. Chitosan, a polysaccharide composed of β-(1→4)-linked D-glucosamine-type units, was bound to the cellulose sulfate thanks to its positive charges. This composite served as a support for Pt NPs. The resulting heterogeneous catalyst showed an activity in the reaction of several aromatic aldehydes with 4-hydroxycoumarin to form bis-coumarins. After 5 to 12 min in ethanol under reflux, the reaction was complete with excellent yields (93–98%). Before the crystallization of the product, cellulose sulfate–chitosan-supported platinum was simply recovered by filtration and reused once washed. After 6 successive runs, it retains its catalytic activity, the yield only slightly dropping from 98% to 90%.

2.2. In C-Heteroatom Coupling

A palladium complex has been absorbed under vacuum in porous cellulose. Tsuji Trost coupling reaction of (E)-cinnamyl ethyl carbonate with morpholine was found possible using the resulting compound either as supported aqueous phase catalyst in a mixture of water and benzonitrile or acetonitrile [91] or as heterogeneous catalyst in benzonitrile [92]. However, the reaction rate and yield remained quite poor, except when the amounts of water and surfactant were increased but that then induced an important leaching of palladium, which is polluting and impaired the recyclability of the catalyst. Different C-O couplings (Ullmann condensation or Buchwald–Hartwig etherification) and C-N couplings (Buchwald–Hartwig amination) were shown possible using various examples of cellulose-based Pd catalysts in DMSO at 80 °C with K2CO3 as a base.

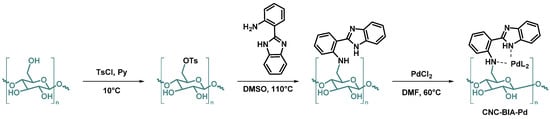

Seyednejhad et al. [93] have developed a Pd(II) complex with crystalline nanocellulose 2-(1H-benzo[d]imidazol-2-yl)aniline as a ligand (CNC-BIA-Pd) (Scheme 3). That strong and novel nanocatalyst proved to catalyze the C-O coupling reaction of aryl halides with phenol derivatives with yields up to 98%. Due to its stability, the catalyst could be reused after filtration, washings and drying, for up to 8 runs with a yield still over 90%.

Scheme 3.

Reaction steps for the synthesis of the Pd(II) complex chelated on 2-(1H-Benzo[d]imidazol-2-yl) aniline-derivatized cellulose nanocrystals (CNC-BIA-Pd) [93].

Sun et al. have performed Buchwald–Hartwig-type reactions using recyclable cellulose-supported Pd(salen)-type catalyst [32]. Their work enables the C-N coupling of aniline (resp. the C-O coupling of phenol) with iodobenzene in mild conditions: in DMSO as a solvent, at 80 °C, with K2CO3 as a base, with 78% yield (resp. 93% yield).

Pd(II) chemically anchored on cellulose nanocrystals via a Schiff base and a silyl spacer was applied for C-O couplings using a series of aryl halide and phenol derivatives [30]. It demonstrated high efficiency with 94% reaction yield and indicated good performance after four times recovery and reuse.

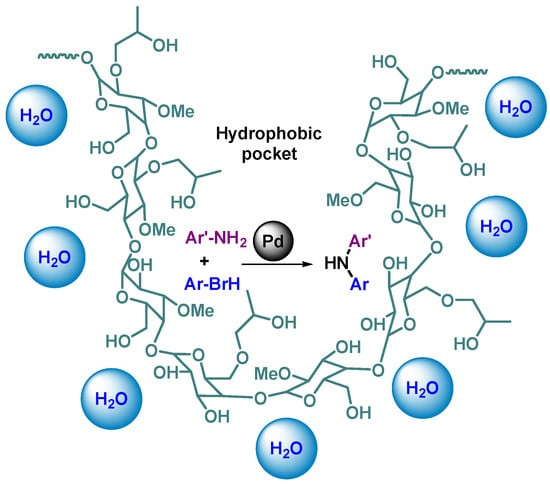

Hydroxypropyl methylcellulose (HPMC) is a food additive used as an emulsifier [94]. Pd NPs have been formed in situ and trapped in hydrophobic pockets appearing in HPMC when the polymer folds in aqueous media (Figure 13). Such cellulose-supported Pd catalyst was tested on a very wide range of C-N coupling reactions using various NH-bearing compounds (anilines, primary and secondary alkylamines, lactams, amides, ureas, and carbamates) with different aryl bromides. In most of the cases, the Buchwald–Hartwig amination was very fast (3 to 15 min) with good to excellent yields (76–97%). It is of note that the catalyst was applied multigram-scale reactions (up to 10 g).

Figure 13.

Pd NP trapped in a hydrophobic pocket of HPMC, catalytic center of C-N coupling [94].

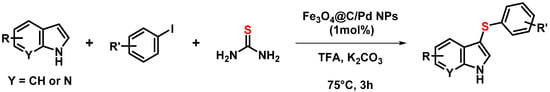

Cellulose deposited over Fe3O4 NPs has been charred at high temperature under inert atmosphere to yield magnetic carbon black suitable to support Pd NPs. The resulting layered composite was found to efficiently catalyze heterogeneously C–H sulfenylation of indoles for the preparation of 3-sulfenylindoles (Scheme 4). The recoverable catalyst was separated from the reaction mixture using an outside magnetic field and could be recycled five times [95].

Scheme 4.

C-H sulfenylation of indoles with thiourea and substituted iodobenzenes [95].

2.3. Redox Reactions

2.3.1. Reduction of Nitro Compounds

An efficient catalyst, obtained via modification of cellulose with N-doped graphene quantum dots and Pd nanoparticles, was introduced for the green reduction of a wide range of nitroaromatics [96]. The reaction was carried out using sodium borohydride at room temperature in water or water–ethanol. Aromatic amines were obtained after 2 h with high yields (up to 95%) and the nanocatalyst was recyclable for six times almost without any decrease in activity.

Perfluorohexyl modified cellulose was utilized as support for Pd NPs. The obtained catalyst showed unexpected high activity and selectivity to the selective reduction of nitrobenzene to N-phenylhydroxylamine (PHA) with NaBH4 at room temperature in water. Modified cellulose with a more hydrophobic surface would favor the adsorption of nitrobenzene over PHA thus prevent full hydrogenation to aniline. The catalyst is recyclable the selectivity remaining excellent while the yield decreases from 98% to 80% after 5 runs [97].

Wu et al. report the one-step synthesis of Pd NPs supported in CNCs with no other reagents. Cellulose played a dual role as a supporting matrix and a reductant [98]. The obtained hybrid material exhibits high catalytic activity in the reduction of methylene blue with hydrazine and of 4-nitrophenol with sodium borohydride; reactions were performed at room temperature with stirring in water. CNC have also been coated with melamine-formaldehyde so as to immobilize in situ-reduced Pd NPs with a controlled size and a uniform distribution over the support [99]. The catalytic activity of the nanocatalyst was observed by the effective reduction of 4-nitrophenol to 4-aminophenol with NaBH4 in water at room temperature. The conversion was complete within 13 min and the catalyst could be filtered and recovered for 10 cycles with almost the same activity. To counter the self-agglomeration of CNC in non-polar media, another research team silylated that cellulose with a propyl spacer bearing a primary amine (CNC-APTES) prior to grafting Pd NPs. The resulting catalyst was efficient for the reduction by sodium borohydride of 4-nitrophenol and derivatives to the respective amino compounds at room temperature, with a good pseudo first order rate constant (kapp = 3.40 × 10−3 s−1) and 98% yield. The catalyst could be recycled up to 4 times [66]. Another example of CNC-supported Pd NPs was used to carry out the hydrogenation reaction of nitrobenzene to aniline in water at room temperature under hydrogen gas. The specially designed amphiphilic particles acted both as colloidal surfactant and catalyst [49]. Full conversion of nitrobenzene could be achieved in 1 h at room temperature, which is much efficient compared with other supported Pd catalysts. The hydrophobic group on CNCs surface played an important role in accelerating the catalytic reaction in the interface between organic phase and water. The recyclability of the catalyst was verified: after 8 repetitive hydrogenation reactions, it maintained high conversion; minor Pd leaching was detected in the reaction solutions after each run and a small aggregation of Pd NPs was observed, which can explain the slight deactivation.

Li et al. fabricated a hydrogel using cellulose derivatized with ionic liquid moiety and reduced Pd(II) ions with NaBH4 within it. The Pd NPs-containing hydrogel composite thus created had high catalytic activity and excellent reusability for the reduction of 4-nitrophenol to 4-aminophenol in water [100]. Yu et al. fabricated 3D polyethylene imine-grafted cellulose nanofibrils (CNF-PEI) aerogels [101]. Those porous materials served as supports for Pt NPs to treat 4-nitrophenol from wastewater. Catalytic reduction of aqueous 4-nitrophenol to 4-aminophenol with NaBH4 was observed in the presence of such a Pt-loaded CNF aerogel. Quantitative conversion could be reached within 30 min with a reaction temperature between 25 and 50 °C. The aerogel catalyst was easily recovered and kept the same activity after 5 recycling loops.

Heterogeneous nickel-based catalysts have also been developed to reduce 4-nitrophenol into 4-aminophenol using NaBH4 in water at room temperature [102]. On this purpose, nickel(II) chloride was reduced onto microcrystalline cellulose (MCC). When hydrazine hydrate was used as a reducing agent for nickel, then the catalytic system was highly crystalline and had strong magnetic properties. Ni NPs obtained by reduction with sodium borohydride were amorphous and much less magnetic. However, both catalysts were able to quantitatively reduce 4-nitrophenol within a few to 30 min. Furthermore, both could be recycled and reused for at least 10 successive reductions without significant loss of catalytic activity; the crystalline MCC-supported Ni NPs were retrieved by an external magnet while the amorphous ones were recovered by centrifugation.

Kamal et al. designed a dip catalyst for pollutants degradation [103]. They coated cellulose filter paper with a thin chitosan layer, then adsorbed nickel(II) ions onto it and reduced them to Ni NPs immobilized all over the biopolymeric support. The nanocomposite was found to catalyze reduction reactions. Reduction of 4- and 2-nitrophenol with NaBH4 occurred in the presence of a strip of cellulose-chitosan-supported Ni NPs. The dip catalyst could be recovered by a simple pulling out of the reaction medium and reused 3 times with more than 90% yield, although the reaction rate decreased after each recycling (70% yield being reached after 10 min initially to 16 min at the third run). A team of researchers have developed paper-supported Pd NPs and showed that such dip catalyst could catalyze the reduction of 4-nitrophenol into 4-aminophenol using NaBH4 in water at room temperature to get excellent yields within 15 min. Catalytic conversion efficiency was almost constant over 90% for 11 consecutive reaction cycles using the same paper [56]. Pt NPs have been deposited by simple contact onto a sheet of wipe paper [104]. The macroporous cellulose fibers offered a very stable support for a steady immobilization of reduced platinum. This was used as a dip catalyst for the reduction of 4-nitrophenol to 4-aminophenol with hydrogen gas. More than 93% yield was reached after 8 min.

A magnetic carbon-supported Pd catalyst has been developed by successive deposition of renewable cellulose and Pd NPs over nanoferrites, followed by calcination. The catalyst could be used for quantitative reduction of various nitroarenes in isopropanol at room temperature under atmospheric hydrogen atmosphere and recycled by magnetic retrieval with almost no activity loss after 3 successive runs [105].

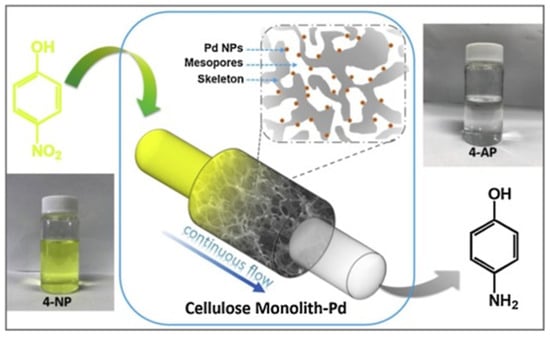

A highly effective, stable, and reusable flow microreactor was developed by filling a tube with environmentally sustainable porous monolithic cellulose. The obtained microreactor could be applied to efficiently and continuously catalyzing the model reduction reaction of 4-nitrophenol with sodium borohydride in water without any post-treatment or regeneration of catalysts (Figure 14). This microreactor exhibited extremely high catalytic efficiency (turnover frequency, TOF = 4660 h−1, almost 4 times higher than that of cellulose nanocrystals supported catalyst) and long-term stability (over 90% reaction efficiency after 16 h of continuous flow at the speed of 1 mL/min) [106].

Figure 14.

Reduction of yellow 4-nitrophenol (4-NP) to colorless 4-aminophenol (4-AP) in a continuous flow reactor filled with cellulose monolith-supported Pd NPs [106].

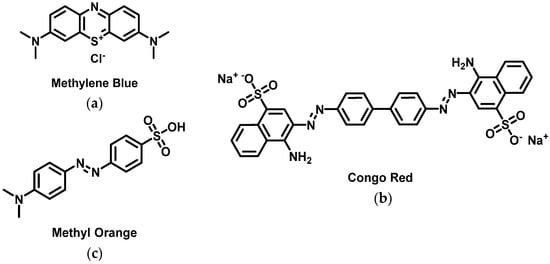

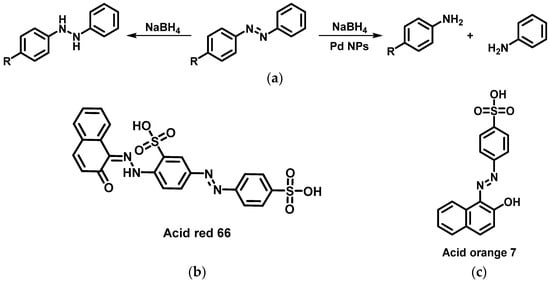

2.3.2. Dyes Depollution

Porous microspheres cellulose-supported Pd NPs have been synthesized according to a simple and environmentally friendly method (direct reduction of palladium(II) with cellulose solution through microwave heating) [107]. Small Pd NPs have been immobilized and reduced on highly porous cellulose nanofibrils that could self-assemble into water-activated aerogels [108]. Both the Pd NPs-containing microspheres and aerogels were found to catalyze the discoloration of methylene blue (Figure 15a) and Congo red (Figure 15b) by sodium borohydride within 5 to 30 min, achieving 99% catalytic efficiency and still higher than 90% after multiple cycles [108].

Figure 15.

Structure of methylene blue (a), Congo red (b) and methyl orange (c).

A hydrogel based on biosourced polymers, cellulose and alginate, has been built as a matrix for Pd NPs [73]. To this end, the cellulose was first made cationic by partial oxidation and grafting of quaternary ammonium groups. The gel set by interactions of calcium ions with cationic cellulose and anionic alginate. The hydrogel-supported Pd NPs proved to catalyze the reduction of a methylene blue with NaBH4 at room temperature. The reductive bleaching was also performed with success in a continuous set-up, the catalytic hydrogel being packed inside a column through which the reaction mixture flowed.

Cellulose fibers have been coated by polypyrrole formed by in situ polymerization [109]. The composite then served as a support for metallic nanocrystals obtained by spontaneous reduction of palladium salts. Polypyrrole-coated cellulose fibers with reduced Pd have been burnt under microwave heating to form PdO/PdO2-embedded carbon. Both Pd@py-cellulose and PdO/PdO2@carbon have been used to reduce model water pollutants. Up to 87% of methylene blue could be reduced to leuco-methylene blue at room temperature in water by the Pd-containing catalyst in a concentration of 6.60 mg·mL−1 over 120 min. The PdO/PdO2 nanocomposite was much more slowly active to reduce the dye but could remove up to 72% of octylphenol, 79% of triclosan, and 17% of atrazine over 100 min from a contaminated water.

Islam et al. have designed a dip catalyst by direct impregnation of Pt NPs on wipe paper [110]. They proved that it enables the reduction of an azo-dye, methyl orange (Figure 15c), in aqueous solutions. With dihydrogen bubbling, it afforded 95% reduction of methyl orange after 6 min and 99% after 10 min. Catalytic oxidation of formic acid followed by reduction of methyl orange was quicker and led to 99% removal after 6 min. The same reductions were slightly slower in fresh drinking water as a solvent, but quantitative bleaching was effective after 10 min in both cases. The paper-supported catalyst was easily recovered after each reaction and could be used 5 times with only little lowering of the catalytic activity. It is of note that the paper-supported Pt NPs were still found active after a 10-days rest.

In the presence of sodium borohydride, the discoloration of azo-dyes is due to a reversible reduction of the N=N bond [111]. CMC-stabilized Pd NPs showed an excellent catalytic activity by non-reversible reducing degradation of such azo-dyes, such as p-aminoazobenzene, acid red 66, or acid orange 7 in the presence of sodium borohydride, due to the actual rupture of the N=N bond (Figure 16).

Figure 16.

(a) Degradation of azo-dyes with and without Pd NPs and structure of acid red 66 (b) and acid orange 7 (c) [111].

Degradation reduction of an azo-dye has also been achieved thanks to the catalytic activity of Ni NPs dispersed in a chitosan layer deposited over cellulose filter paper [103]. In contact with such dip catalyst, a complete reduction of methyl orange was observed within a few minutes in a dilute solution with addition of NaBH4 as a reducing agent.

2.3.3. Hydrogenation

Researchers have grafted fluorinated moieties onto cellulose via a silylated spacer. Pd NPs were then straightforwardly deposited onto the resulting amphiphilic support to yield a catalyst exhibiting excellent catalytic activity and selectivity in hydrodeoxygenation of vanillin (a typical model compound of lignin) to 2-methoxy-4-methylphenol under atmospheric hydrogen pressure in neat water without any other additives at 50 °C. The catalyst was reusable for four cycles with only little loss in its activity [67]. A very similar nanocatalyst was constructed with metallic NPs immobilized on amphiphilic cellulose-based polymers [112]. Hydrophilic CNCs have been grafted with more or less numerous hydrophobic C16 carbon chains to produce such amphiphilic nano-support for Pd-Ni alloy NPs. Under hydrogen, in water, at 70 °C, that catalyst displayed an interesting activity in the selective hydrodeoxygenation of vanillin to 2-methoxy-4-methylphenol, reaction in which vanillin alcohol is a common byproduct. An adequate hydrophilic-lipophilic balance was found in the synthesis of the C16-CNC support so that a 100% conversion could be obtained with a 100% selectivity. The selectivity was induced by the chiral cellulosic support and the catalytic activity by the palladium, since supported NPs made of pure Ni were found inactive. The proportion though could vary from PdNi4 to PdNi8 (at least) with no difference in the results. Supported Pd NPs alone proved to be less efficient. Other common metals (Fe, Co, Cu) could not replace Ni without an important loss in yield and selectivity.

CNC supporting monodispersed Pd NPs has been found an active colloidal catalyst for the hydrogenation reaction of phenol to cyclohexanone in water as a solvent, at room temperature, under 4 bars of dihydrogen [84]. Even-dispersed Pd NPs have been confined within a carboxylic cellulose nanofiber (CNF) matrix, appearing as soft hydrophilic foam. The ultrafine Pd NPs (ca. 6 nm) were in situ grown by reduction on the mesoporous matrix with a dense spatial distribution (9.6 wt%) thus generating nano-confinement catalytic effects on the reactants. An enhanced catalytic activity was indeed observed on the model reaction of 4-nitrophenol hydrogenation with sodium borohydride at room temperature in water, with quantitative yields for 6 consecutive cycles. Interestingly, 100% chemoselective reduction of 3-nitrostyrene with NaBH4 at room temperature was made possible using CNF-Pd, according to the choice of solvent: The reaction yielded 50% of 2-ethyl-nitrobenzene in ethanol after 3 h, 98% of 3-aminostyrene in water/methanol: 1/1 after 1 h, and 100% of 2-ethylaniline in pure water or pure methanol after 3 h [113].

A dip catalyst was developed by reducing palladium salt with formic acid onto jute plant stem getting a uniform distribution Pd NPs on the cellulose matrix. The catalyst was successfully applied to the chemoselective transfer hydrogenation of a series of styrenyl, substituted olefins, quinoline and other N-heteroarenes using tetrahydroxydiboron as reductant. Quantitative hydrogenation of various alkenes and quinolines was shown possible in water at 60–70 °C in 1–2 h. This system is stable in water and displays excellent recyclability; it could be used for 32 consecutive cycles, without losing its original crystallinity or requiring replenishment [114]. A variety of alkenes have successfully been hydrogenated using as a catalyst Pd NPs coated with hyperbranched cationic polystyrene and then immobilized on cellulose (on a piece of paper or of cotton) [70]. Quantitative hydrogenations were observed after 5 h in ethyl acetate at room temperature under hydrogen (2 atm). The catalyst could be recycled for 5 runs with only little Pd leaching and an activity remaining constant. Pd@HPS-NR3+Cl− proved to be a robust recyclable catalyst thanks to a strong adhesion of the resinous ammonium-derivative of polystyrene to cellulose due to multiple electrostatic interactions.

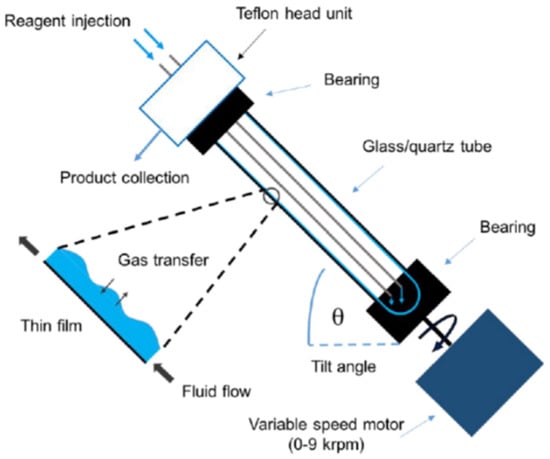

Cellulose-immobilized Pd NPs were prepared by reduction of palladium acetate solution drop-cast over paper sheets under dihydrogen flow for mere 90 s. Most interestingly, that technology was developed for use in a continuous flow reactor by simply lining the walls of the reaction tube of a vortex fluidic device with such sheets of paper-supported Pd NPs (Figure 17). The embedded Pd(0) proved efficient in hydrogenation of alkenes, nitroarenes, ketones, and enamides, with products formed in high yield, under ambient pressure and temperature. The system is also effective for transfer hydrogenation using ammonium methanoate as an alternative hydrogen source. High catalyst stability and re-usability is demonstrated along with the chemoselective and scalable synthesis of industrially important fine chemicals, including the bio-based molecule cyrene [115].

Figure 17.

Scheme of the vortex fluidic device (VFD), a tubular rotating continuous flow reactor, lined with the catalyst-containing paper sheet [115].

The C-supported Pd catalyst developed by Baig and Varma, using cellulose as a source of carbon, was found efficient in the quantitative hydrogenation of various alkenes and of diphenylacetylene in isopropanol at room temperature under atmospheric hydrogen pressure. The catalyst, being magnetically retrievable, could be used at least three times with almost no change in activity and no Pd leaching [105].

Suarez’s team developed metal complexes using carboxyl cellulose (CC) as a ligand. PdCC and NiCC proved to have a catalytic activity in the alkene hydrogenation of the unsaturated fatty chains of a biodiesel [116]. When stirred with a biodiesel obtained from soybean oil, in ethyl acetate at 80 °C under pressured hydrogen, PdCC displayed, after 6 h, a reduction of 60 to 90% of the double bonds when the pressure rose from 10 to 100 bars. Under the same conditions, 55% of the double bonds were reduced in the presence of NiCC catalyst under 100 bars of hydrogen after 24 h. Both catalysts could be recovered and used in 7 consecutive cycles with no change of catalytic activity. Interestingly, in the course of the reaction, the polyunsaturated fatty esters were firstly hydrogenated to monounsaturated compounds, even under low hydrogen pressure.

Moores’ team has devised Pd NPs deposited as patches at the surface of CNCs and used them to catalyze enantioselective hydrogenation of prochiral ketones in water at room temperature under 4 bars of dihydrogen. Cellulose was the sole source of chirality thus induced enantioselectivity with enantiomeric excess as high as 65% with 100% conversions. Recycling test showed that the heterogeneous catalyst could be used up to 5 times with no loss of enantioselectivity while the activity was already reduced from the fourth run onwards [117].

Pd NPs have been formed by reduction with hydrazine and immobilized on cellulose particles (CLP) on the one hand and on a cellulose monolith (CLM) on the other hand. Those composites were applied as hydrogenation catalysts and both were found active (at 1 mol%) to readily reduce a variety of aklynes, alkenes, nitro, and azido compounds in methanol at room temperature under hydrogen at atmospheric pressure with 87–100% yields. Although both catalysts catalyzed the deprotection of benzyloxycarbonyl-protected aromatic amines (Ar-N-Cbz) and aromatic benzyl esters (Ar-CO2Bn), only CLM-supported Pd NPs could accomplish the hydrogenolysis of aliphatic-N-Cbz and aliphatic-CO2Bn protective groups; such protective groups were unchanged when CLP-supported Pd NPs were used. The difference in the physical structure of the cellulose supports induced unique chemoselectivity. Aromatic ketones could be partially hydrogenated in the presence of both catalysts to give the corresponding secondary alcohols as chemoselectively reduced products. On the other hand, both aromatic and aliphatic benzyl ethers were stable under both Pd/CLP and Pd/CLM-catalyzed hydrogenation conditions. Both catalysts could be reused after simple filtration for at least three times [118].

Huang et al. prepared a silica-supported methylcellulose-L-alanine-palladium complex with the interest of it being chiral [119]. Such highly optically active catalyst enabled the asymmetric hydrogenation of ortho-cresol and meta-cresol to give (S)-2-methylcyclohexanone and (R)-3-methylcyclohexanone, respectively, at 25 °C under an atmospheric hydrogen pressure in 64.6% and 61.3% yields and 91.5% ee and 68.5% ee, respectively, after 12 h. Quantitative reaction was possible after a total of 24 h but the enantioselectivity then drastically dropped. Under optimized conditions, the optical yields were kept over 90% and 60%, respectively, when the catalyst was reused up to 4 times.

CMC has been used to stabilize Pd NPs, thus forming a water-soluble system. Liu et al. [120] have used such CMC-capped Pd NPs to efficiently catalyze the hydrodechlorination of trichloroethylene by hydrogen into biodegradable ethane, in order to depollute soiled waters within minutes. The same research group [121,122] have further immobilized CMC-stabilized Pd NPs onto alumina, a hydrophilic support material, in order to obtain a heterogeneous catalyst. The composite catalyst was able to facilitate rapid and complete hydrodechlorination of trichloroethylene in aqueous media. It offered an activity more than 7 times greater than that of the commercial alumina-supported Pd NPs but much lesser than that of unsupported CMC-stabilized Pd NPs. Recyclability was made possible after pre-calcination treatment in order to limit the leaching of palladium, despite a minor drop in activity.

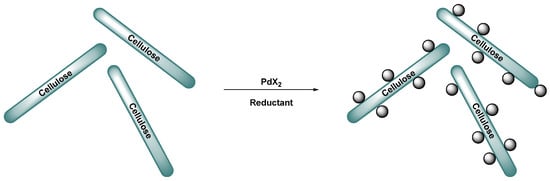

Palladium and platinum have been simultaneously reduced by hydrazine over non-chemically modified cellulose beads [123]. Two bimetallic nanocatalysts (Pd/Pt 7:1 or 1:7) have been produced this way for the removal of polluting chlorates in water. Aqueous potassium chlorate solutions were efficiently treated for hydrogenation to chloride ions using both catalysts with hydrogen bubbling at 80 °C. The reduction of chlorate ions was observed with a slightly higher reaction rate using the Pt-rich NPs. With a pseudo-first-order kinetics, the rate constants were: with Pd-rich catalyst (74% reduction after 3 h); with Pt-rich catalyst (76% reduction after 3 h). When Fe2O3 was deposited onto the cellulose-supported bimetallic NPs, its promoter effect afforded an increase in the rate constants with much lower contents in precious metals: with Pd-rich catalyst (92% reduction after 3 h); with Pt-rich catalyst (85% reduction after 3 h). Pd-rich bimetallic NPs supported by cellulose beads with addition of Fe2O3 could be recycled 4 times with success despite some metal release. When used in a continuous flow hydrogenation set-up, quantitative removal of chlorate occurred within 160 min.

2.3.4. Oxidation

Cellulose-supported on Pd NPs was found to effectively promote the oxidation of glucose by oxygen into gluconic acid under mild conditions. Glucose was fully converted at room temperature after 3 h by the use of a stoichiometric amount of Na2CO3 to neutralize gluconic acid, and gluconic acid was obtained in a high yield of 91.2%. The catalyst was recovered and reused up to five times without significant loss in its catalytic activity [124]. Pd NPs supported on neat cellulose was found to be highly efficient recyclable heterogeneous catalyst for aerobic oxidation of benzyl alcohols using air as the source of molecular oxygen in acetonitrile. This catalytic system provides benzaldehyde derivatives in high yields (ca. 80%) and selectivity but with a rather modest recyclability [53].