Effect of Fouling Layer (Acid–Ash Reaction) on Low-Temperature Corrosion Covering Heating Surface in Coal-Fired Flue Gas

Abstract

:1. Introduction

2. Experimental Set Ups

2.1. Design Consideration

2.2. Experimental Methodologies

2.3. Samples and Analysis Methods

3. Results and Discussion

3.1. Reaction Mechanism between acid Solution and Particles

3.1.1. Acid–Ash Reaction Degree Tested for Reaction Products

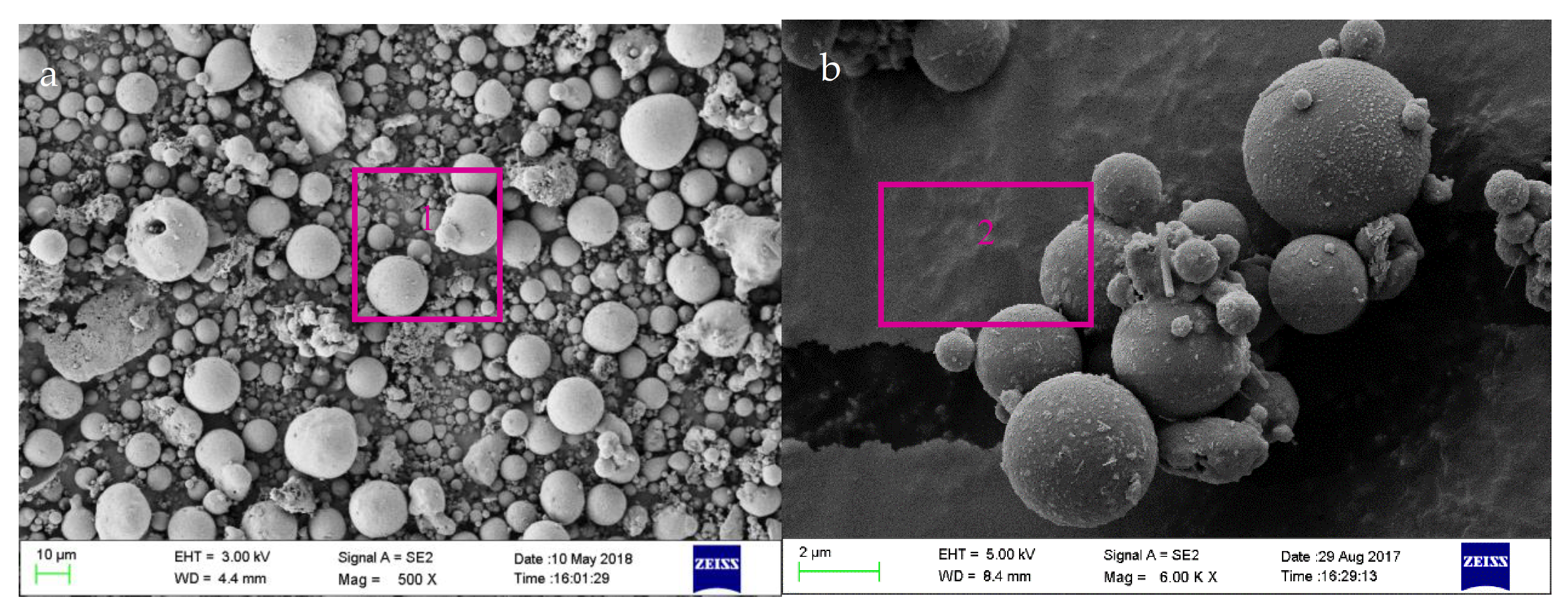

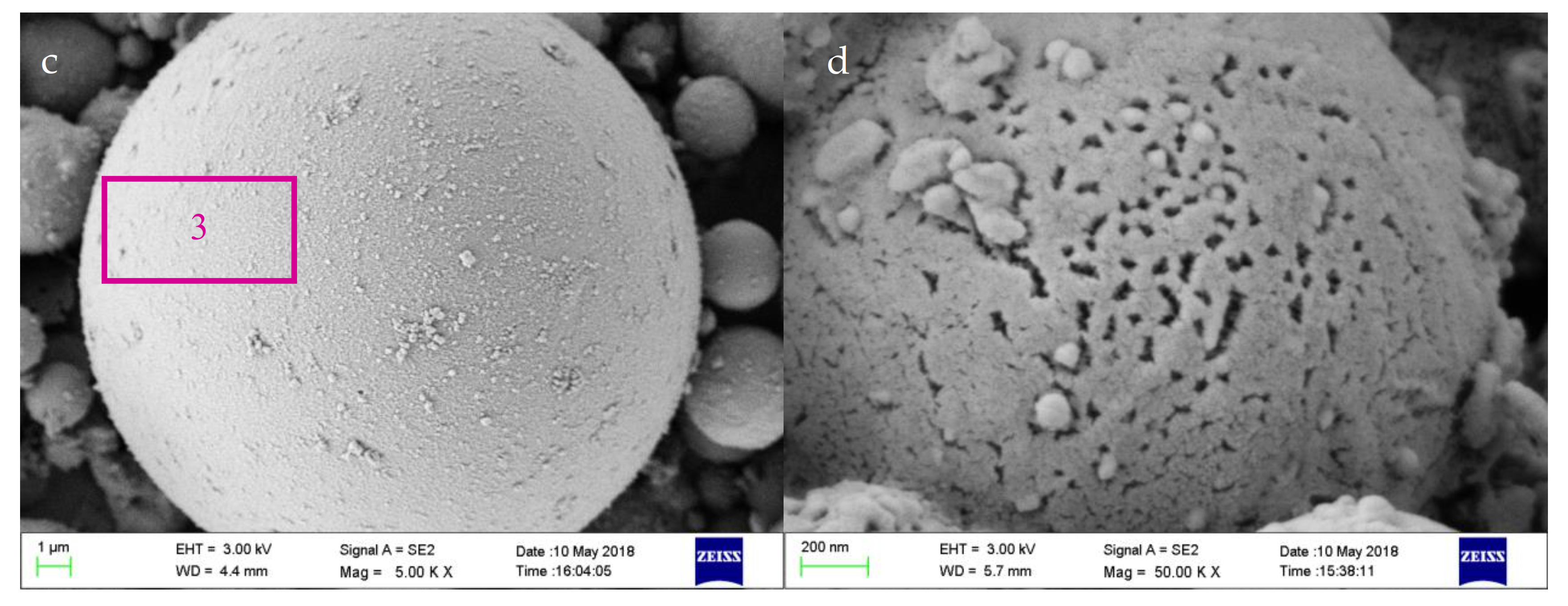

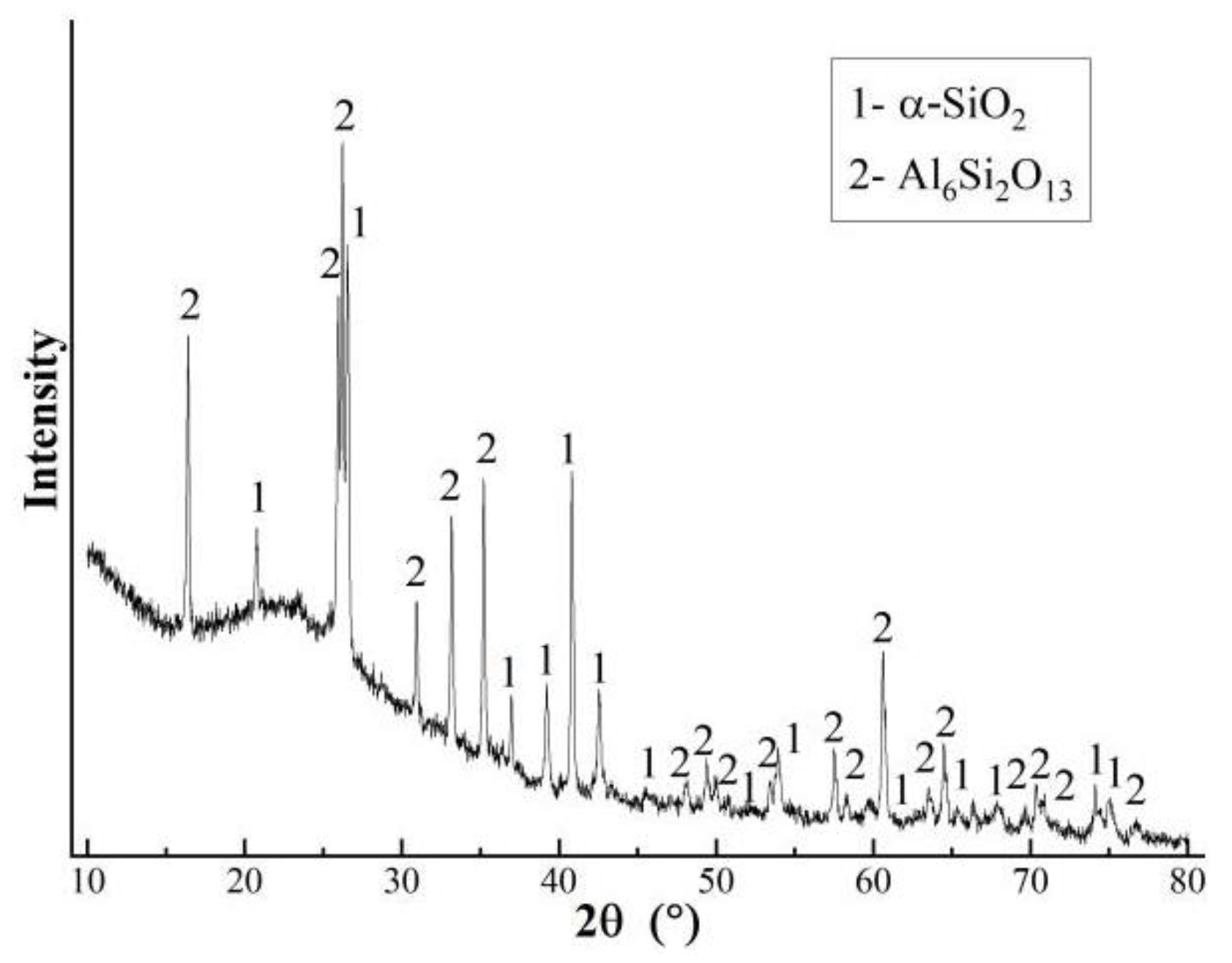

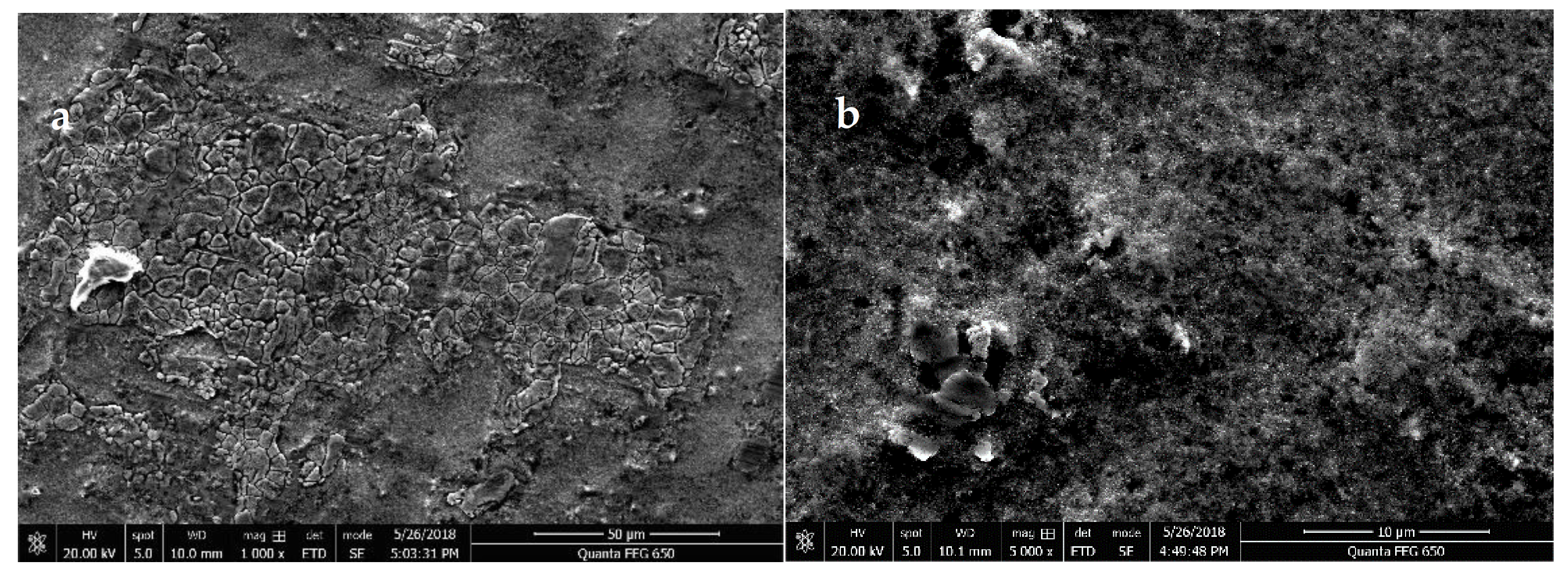

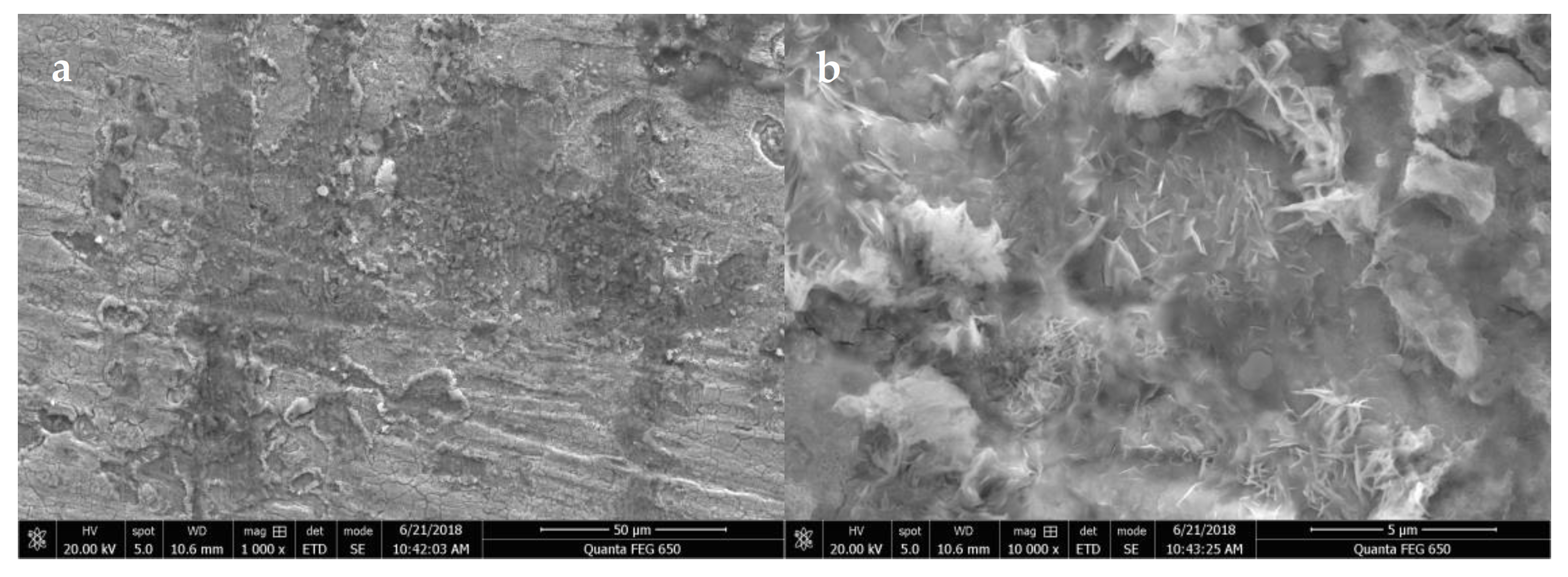

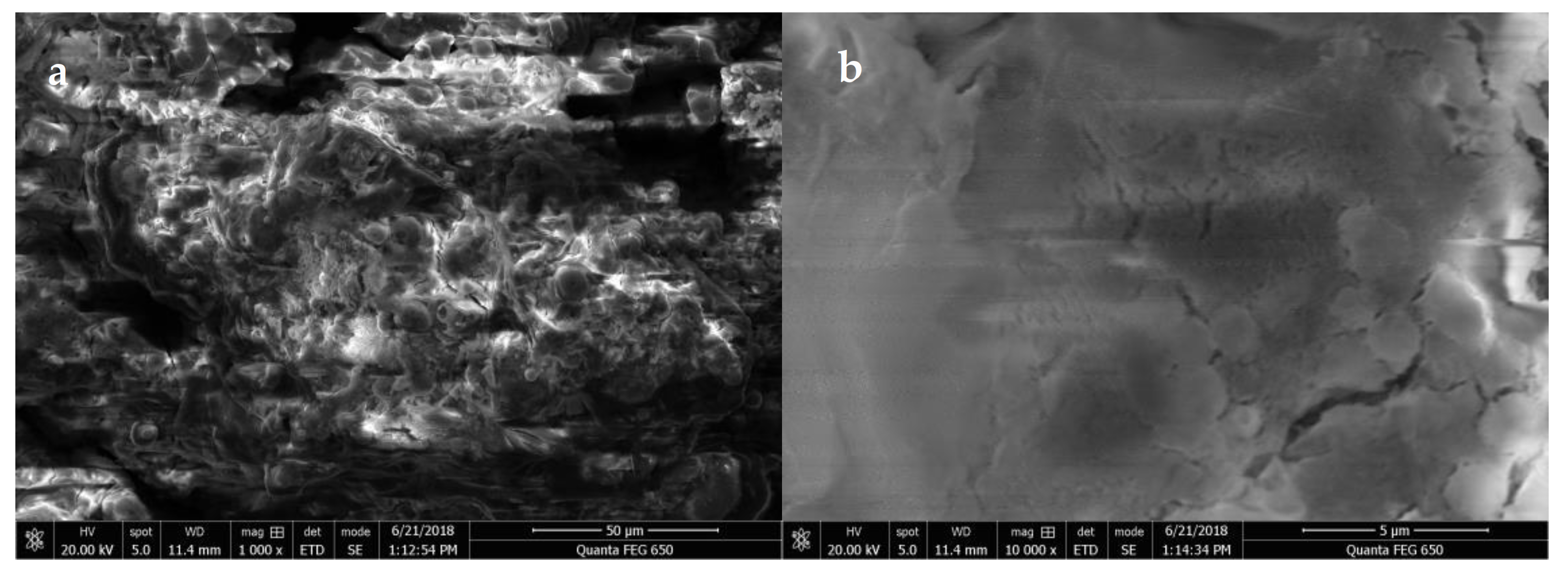

3.1.2. Micro-Topography

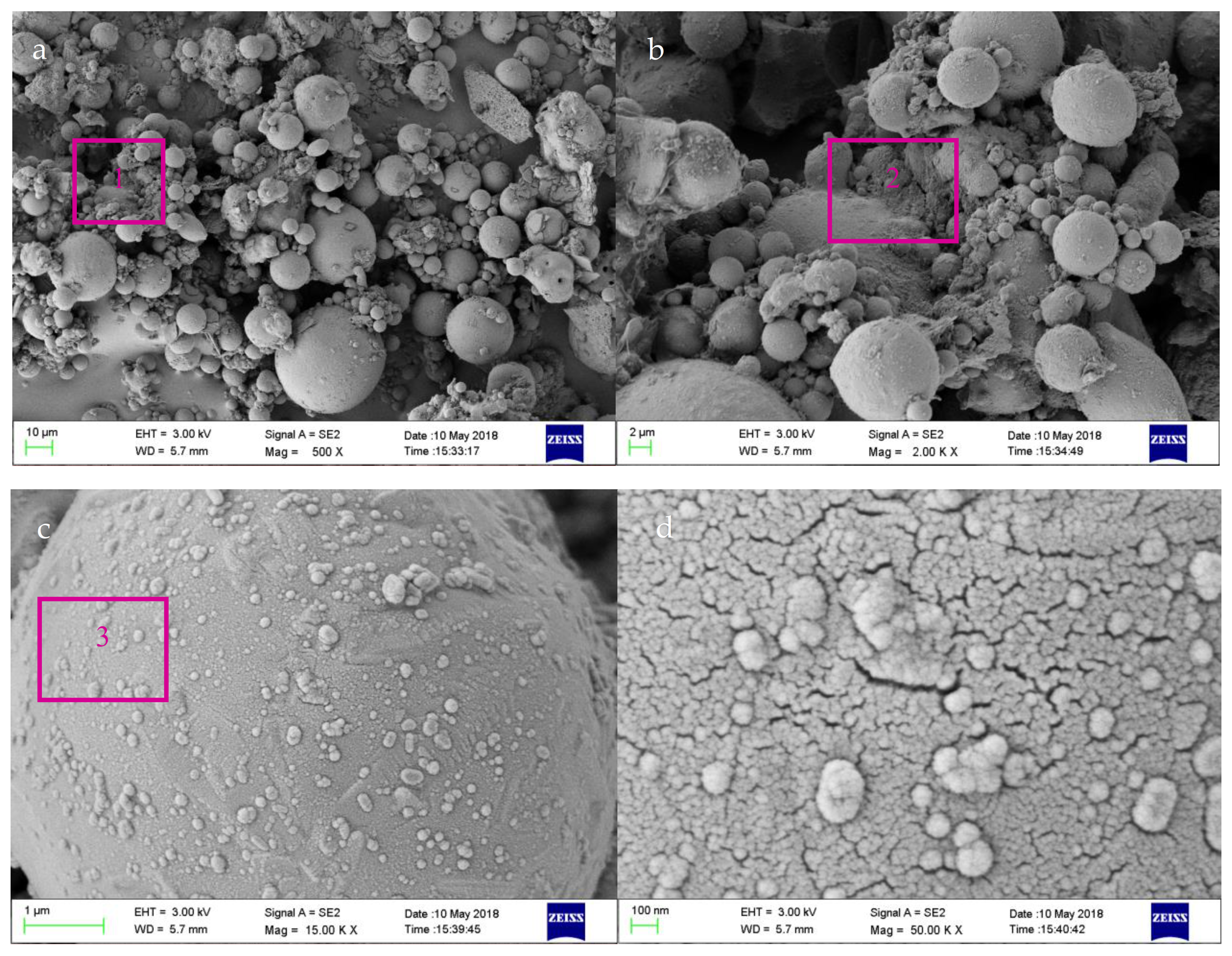

3.1.3. Mineralogy

3.1.4. Elemental Analysis

3.2. Effect of Typical Fouling Layer on the Low-Temperature Corrosion of Metal Surface

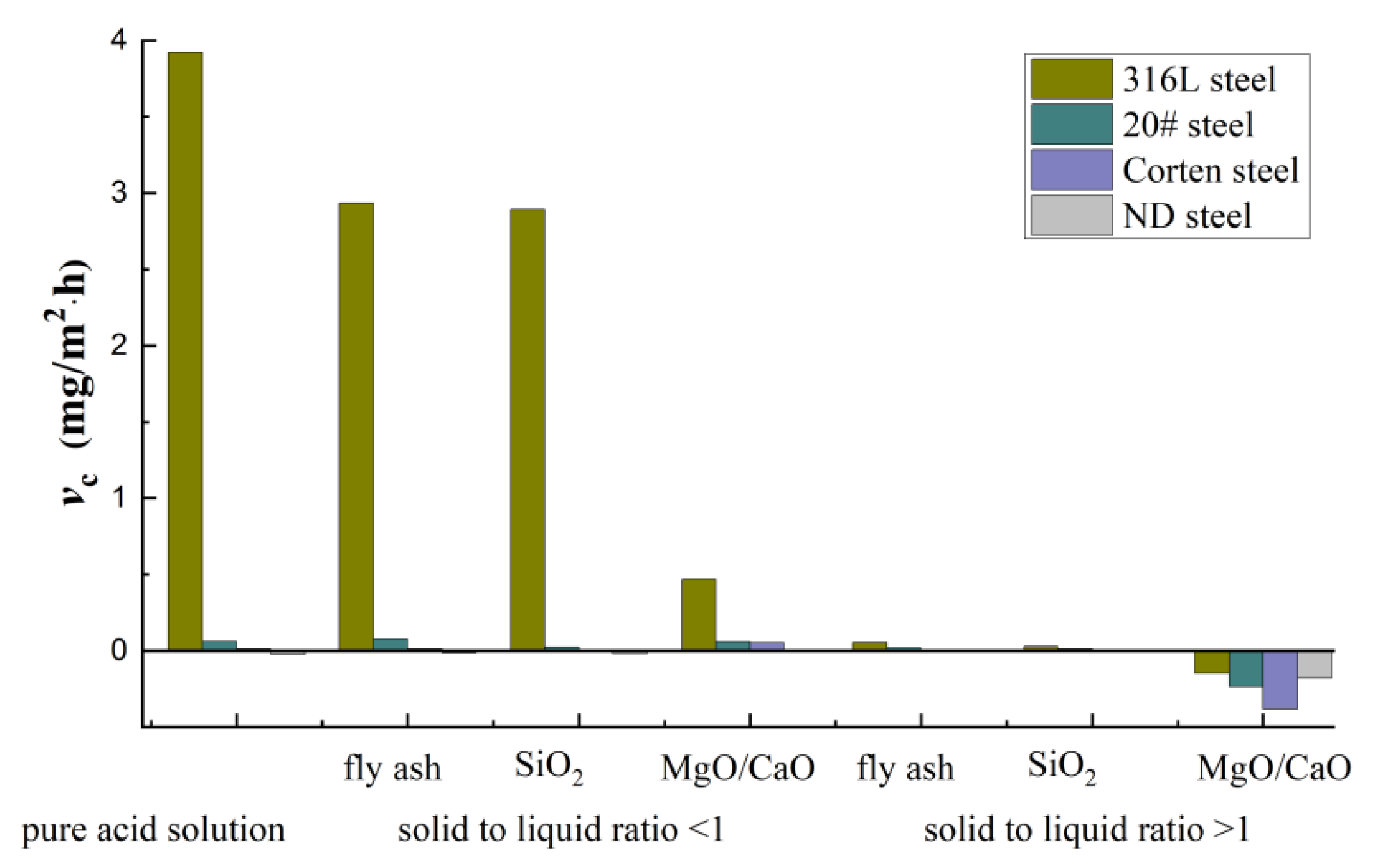

3.2.1. Corrosion Rates of Different Materials Considering Different Reaction Products

3.2.2. Effects of Acid–Ash Reaction Products on Metal Corrosion

3.3. Theory of Screening Laboratory Tests

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Smith, J.S.; Safferman, S.I.; Saffron, C.M. Development and application of a decision support tool for biomass co-firing in existing coal-fired power plants. J. Clean. Prod. 2019, 236, 117375. [Google Scholar] [CrossRef]

- Babcock, W.C. Steam: Its Generation and Use; Kessinger Publishing: Whitefish, MT, USA, 2005. [Google Scholar]

- Guo, H.; Fan, W.; Liu, Y.; Zhang, X.; Liu, S.; Wu, X.; Chen, J.; Liu, Z.; Wang, X.; Ma, R. Dynamic simulation on high-temperature corrosion behaviour of tube surface with fouling in utility boiler fired by high-chlorine coal. J. Energy Inst. 2021, 95, 120–131. [Google Scholar] [CrossRef]

- Song, G.; Qi, X.; Yang, S.; Yang, Z. Investigation of ash deposition and corrosion during circulating fluidized bed combustion of high-sodium, high-chlorine Xinjiang lignite. Fuel 2018, 214, 207–214. [Google Scholar] [CrossRef]

- Xiong, X.; Liu, X.; Tan, H.; Deng, S. Investigation on high temperature corrosion of water-cooled wall tubes at a 300 MW boiler. J. Energy Inst. 2020, 93, 377–386. [Google Scholar] [CrossRef]

- Skrifvars, B.J.; Westén-Karlsson, M.; Hupa, M.; Salmenoja, K. Corrosion of super-heater steel materials under alkali salt deposits. Part 2: SEM analyses of different steel materials. Corros. Sci. 2010, 52, 1011–1019. [Google Scholar] [CrossRef]

- Kinnunen, H.; Hedman, M.; Engblom, M.; Lindberg, D.; Uusitalo, M.; Enestam, S.; Yrjas, P. The influence of flue gas temperature on lead chloride induced high temperature corrosion. Fuel 2017, 196, 241–251. [Google Scholar] [CrossRef]

- Sadeghi, E.; Joshi, S. Chlorine-induced high-temperature corrosion and erosion-corrosion of HVAF and HVOF-sprayed amorphous Fe-based coatings. Surf. Coat. Technol. 2019, 371, 20–35. [Google Scholar] [CrossRef]

- Mahajan, S.; Chhibber, R. Hot corrosion studies of boiler steels exposed to different molten salt mixtures at 950 °C. Eng. Fail. Anal. 2019, 99, 210–224. [Google Scholar] [CrossRef]

- Abu-Warda, N.; López, A.; Pedraza, F.; Utrilla, M. Fireside corrosion on T24 steel pipes and HVOF NiCr coatings exposed to different salt mixtures. Corros. Sci. 2020, 173, 108747. [Google Scholar] [CrossRef]

- Fu, C.; Li, Y.; Wang, Y. Microstructure and corrosion resistance of ERNiCrMo-13 and NiCrBSi coatings in simulated coal-fired boiler conditions: The effect of fly-ash composition. Surf. Coat. Technol. 2020, 399, 126134. [Google Scholar] [CrossRef]

- Li, M.-J.; Tang, S.-Z.; Wang, F.-L.; Zhao, Q.-X.; Tao, W.-Q. Gas-side fouling, erosion and corrosion of heat exchangers for middle/low temperature waste heat utilization: A review on simulation and experiment. Appl. Therm. Eng. 2017, 126, 737–761. [Google Scholar] [CrossRef]

- Wang, F.; Tang, S.; Tao, W.; He, Y.; Zhao, Q. Gas-side fouling, erosion and corrosion of heat exchanger for middle and low temperature flue gas waste heat recovery. Chin. Sci. Bull. 2016, 61, 1858–1876. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.-G.; Zhao, Q.-X.; Zhang, Z.-X.; Tao, W.-Q. Mechanism research on coupling effect between dew point corrosion and ash deposition. Appl. Therm. Eng. 2013, 54, 102–110. [Google Scholar] [CrossRef]

- Chen, H.; Pan, P.; Jiao, J.; Wang, Y.; Zhao, Q. Low-temperature ash deposition and dewpoint corrosion of a coal-fired travelling grate boiler. Appl. Therm. Eng. 2017, 117, 752–761. [Google Scholar] [CrossRef]

- Chen, H.; Pan, P.; Wang, Y.; Zhao, Q. Field study on the corrosion and ash deposition of low-temperature heating surface in a large-scale coal-fired power plant. Fuel 2017, 208, 149–159. [Google Scholar] [CrossRef]

- Chen, H.; Pan, P.; Shao, H.; Wang, Y.; Zhao, Q. Corrosion and viscous ash deposition of a rotary air preheater in a coal-fired power plant. Appl. Therm. Eng. 2017, 113, 373–385. [Google Scholar] [CrossRef]

- Pan, P.; Chen, H.; Liang, Z.; Zhao, Q. Desulfurized flue gas corrosion coupled with deposits in a heating boiler. Corros. Sci. 2018, 131, 126–136. [Google Scholar] [CrossRef]

- Pan, P.; Chen, H.; Liang, Z.; Zhao, Q. Deposition and corrosion characteristics of liquid-solid droplets on tubular corrosion probes in desulfurized flue gas. Eng. Fail. Anal. 2018, 90, 129–140. [Google Scholar] [CrossRef]

- Pan, P.; Chen, H.; Liang, Z.; Zhao, Q. Experimental study on corrosion of steels for flue gas reheaters in a coal-fired power plant. Appl. Therm. Eng. 2017, 115, 267–279. [Google Scholar] [CrossRef]

- Wei, W.; Cheng, S.; Sun, F. Research on formation mechanism of typical low-temperature fouling layers in coal-fired boilers. Fuel 2019, 261, 116215. [Google Scholar] [CrossRef]

- Wei, W.; Sun, F.; Ma, L. Effect of fine ash particles on formation mechanism of fouling covering heat exchangers in coal-fired power plants. Appl. Therm. Eng. 2018, 142, 269–277. [Google Scholar] [CrossRef]

- Wei, W.; Sun, F.; Shi, Y.; Ma, L. Experimental research of fouling layer and prediction of acid condensation outside heat exchanger used in coal-fired boiler. Appl. Therm. Eng. 2018, 131, 486–496. [Google Scholar] [CrossRef]

- Shimogori, M.; Mine, T.; Ohyatsu, N.; Takarayama, N.; Matsumura, Y. Effects of fine ash particles and alkali metals on ash deposition characteristics at the initial stage of ash deposition determined in 1.5MWth pilot plant tests. Fuel 2012, 97, 233–240. [Google Scholar] [CrossRef]

- Henry, C.; Minier, J.-P.; Lefèvre, G. Towards a description of particulate fouling: From single particle deposition to clogging. Adv. Colloid Interface Sci. 2012, 185–186, 34–76. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, C.; Hui, S.; Zhao, Q.; Zhou, Q. Deposition of Cement Kiln Ash on the Tubes of Waste Heat Recovery Boiler. In Proceedings of the 2011 Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 25–28 March 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 1–4. [Google Scholar]

- Wang, F.-L.; He, Y.-L.; Tong, Z.-X.; Tang, S.-Z. Real-time fouling characteristics of a typical heat exchanger used in the waste heat recovery systems. Int. J. Heat Mass Transf. 2017, 104, 774–786. [Google Scholar] [CrossRef]

- Han, H.; He, Y.-L.; Tao, W.-Q.; Li, Y. A parameter study of tube bundle heat exchangers for fouling rate reduction. Int. J. Heat Mass Transf. 2014, 72, 210–221. [Google Scholar] [CrossRef]

- Wei, W.; Sun, F.; Shi, Y.; Ma, L. Theoretical prediction of acid dew point and safe operating temperature of heat exchangers for coal-fired power plants. Appl. Therm. Eng. 2017, 123, 782–790. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, G. Numerical investigation on the coupling of ash deposition and acid vapor condensation on the H-type fin tube bank. Appl. Therm. Eng. 2018, 139, 524–534. [Google Scholar] [CrossRef]

- Qin, K.; Fan, J.; Chi, Z.; Shen, L. Boiler and Heat Exchanger Fouling, Slagging, Abrasion and Corrosion Prevention Principles and Calculation; Science Press: Beijing, China, 1994. (In Chinese) [Google Scholar]

- Wang, Y.; Tan, H.; Dong, K.; Liu, H.; Xiao, J.; Zhang, J. Study of ash fouling on the blade of induced fan in a 330 MW coal-fired power plant with ultra-low pollutant emission. Appl. Therm. Eng. 2017, 118, 283–291. [Google Scholar] [CrossRef]

- Vuthaluru, H.B.; French, D.H. Investigations into the air heater ash deposit formation in large scale pulverised coal fired boiler. Fuel 2015, 140, 27–33. [Google Scholar] [CrossRef] [Green Version]

- Zhou, A. Experimental Study on the Coupling Mechanism between Dew Pint Corrosion and Ash Deposition of the Low-Temperature Heat Exchagner System; Zhejiang University: Zhejiang, China, 2015. [Google Scholar]

- Chen, X.; Zhao, Q.; Liang, Z. Investigations on the Ash Deposit Formation of Tubular Air Preheater in a Coal-Fired Traveling Grate Boiler. Energy Fuels 2017, 31, 13215–13220. [Google Scholar] [CrossRef]

- Liang, Z.Y.; Zhao, Q.X.; Wang, Y.G.; Li, Y.X.; Zhang, Z.C. Coupling mechanism of dew point corrosion and viscous ash deposits. Mater. Corros. 2013, 65, 797–802. [Google Scholar] [CrossRef]

- Feng, J.; Shen, Y.; Yang, R. Principle and Calculation of Boiler[M]; Science Press: Beijing, China, 2003. (In Chinese) [Google Scholar]

| Reaction Products | SiO2 Particles | Fly Ash Particles | Mgo/Cao Particles | |

|---|---|---|---|---|

| H2SO4 Concentration | ||||

| 80% | 2.34 | 2.69 | 7.26 | |

| 70% | 2.38 | 2.95 | 9.15 | |

| 60% | 2.48 | 3.09 | 9.39 | |

| 56% | 2.58 | 3.2 | 9.63 | |

| 45% | 2.71 | 3.57 | 9.91 | |

| Reaction Products | SiO2 Particles | Fly Ash Particles | Mgo/Cao Particles | |

|---|---|---|---|---|

| H2SO4 Concentration | ||||

| 80% | 2120 | 1015 | 731 | |

| 70% | 1811 | 979 | 652 | |

| 60% | 1568 | 811 | 504 | |

| 56% | 1153 | 497 | 399 | |

| 45% | 931 | 357 | 341 | |

| Ash Samples | Area | C | O | Na | Mg | Al | Si | S | K | Ca | Ti | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Original ash particles | 1 | - | 40.76 | 0.75 | 0.5 | 12.68 | 38.59 | - | 2.36 | - | 0.67 | 3.71 |

| 2 | 0.75 | 43.98 | - | - | 14.99 | 28.23 | - | - | 5.27 | 5.06 | 1.71 | |

| 3 | - | 56.25 | 1.1 | - | 8.21 | 30.57 | - | 1.54 | 0.87 | - | 1.46 | |

| Reacted ash particles | 1 | - | 46.28 | - | 0.51 | 14.98 | 19.03 | 9.63 | 0.97 | 3.13 | 0.84 | 4.63 |

| 2 | - | 49.74 | 0.41 | 0.46 | 11.19 | 18.14 | 8.64 | 0.86 | 4.51 | 2.67 | 3.38 | |

| 3 | - | 48.62 | 0.46 | 0.39 | 12.97 | 20.44 | 8.59 | 0.91 | 2.83 | 0.92 | 3.87 |

| Original Ash Particles | Reacted Ash Particles | ||

|---|---|---|---|

| Compound | m/m% | Compound | m/m% |

| SiO2 | 44.04 | SiO2 | 37.02 |

| Al2O3 | 41.66 | Al2O3 | 33.48 |

| Fe2O3 | 3.85 | SO3 | 19.23 |

| CaO | 3.78 | Fe2O3 | 3.83 |

| MgO | 1.98 | CaO | 1.75 |

| Na2O | 1.29 | MgO | 1.51 |

| TiO2 | 1.11 | TiO2 | 1.13 |

| SO3 | 0.94 | P2O5 | 0.95 |

| K2O | 0.77 | K2O | 0.69 |

| P2O5 | 0.26 | SrO | 0.11 |

| SrO | 0.08 | ZrO2 | 0.07 |

| V2O5 | 0.05 | Co3O4 | 0.05 |

| Co3O4 | 0.05 | V2O5 | 0.05 |

| ZrO2 | 0.05 | MnO | 0.03 |

| MnO | 0.02 | Cr2O3 | 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, W.; Yu, H.; Guo, C.; Zhang, X.; Liu, G.; Cheng, S.; Zhao, B. Effect of Fouling Layer (Acid–Ash Reaction) on Low-Temperature Corrosion Covering Heating Surface in Coal-Fired Flue Gas. Processes 2022, 10, 241. https://doi.org/10.3390/pr10020241

Wei W, Yu H, Guo C, Zhang X, Liu G, Cheng S, Zhao B. Effect of Fouling Layer (Acid–Ash Reaction) on Low-Temperature Corrosion Covering Heating Surface in Coal-Fired Flue Gas. Processes. 2022; 10(2):241. https://doi.org/10.3390/pr10020241

Chicago/Turabian StyleWei, Wei, Hewei Yu, Chang Guo, Xingyu Zhang, Guofu Liu, Shen Cheng, and Baofeng Zhao. 2022. "Effect of Fouling Layer (Acid–Ash Reaction) on Low-Temperature Corrosion Covering Heating Surface in Coal-Fired Flue Gas" Processes 10, no. 2: 241. https://doi.org/10.3390/pr10020241

APA StyleWei, W., Yu, H., Guo, C., Zhang, X., Liu, G., Cheng, S., & Zhao, B. (2022). Effect of Fouling Layer (Acid–Ash Reaction) on Low-Temperature Corrosion Covering Heating Surface in Coal-Fired Flue Gas. Processes, 10(2), 241. https://doi.org/10.3390/pr10020241