1. Introduction

Edible sunflower has a short growth period, strong adaptability, and low requirements for soil conditions, production area environment, ecological climate, etc., so it is widely planted worldwide [

1,

2,

3]. The cleaning process is the core of the mechanical harvesting of sunflowers, and its performance directly affects important technical indicators such as the impurity rate and the seed loss rate of the sunflower harvest [

4,

5,

6]. After threshing, the edible sunflower extracts enter the cleaning device. During the cleaning operation, the components of edible sunflower extracts inevitably have mutual contact and movement. Therefore, based on discrete element numerical simulation, the selection of the contact model and accurate parameter calibration of sunflower extracts can improve the correctness and accuracy of the cleaning process simulation and further optimize the relevant working parameters of the cleaning device [

7,

8,

9,

10].

At present, researchers are calibrating simulation parameters for discrete element models such as grain seeds, grain stems, soil particles, fertilizers, fruits, and vegetables. Zhang Rongfang et al. [

11], Xu Fulong et al. [

12], and Wang Liming et al. [

13] measured the physical angles of repose of rice seeds, blue flax capsules, and pig manure, respectively, and established a regression model between the angle of repose and the significant parameters. Then, the parameters were optimized to obtain the optimal parameter combination. Tian Xinliang et al. [

14] and Wang Weiwei et al. [

15] selected the Hertz–Mindlin with JKR contact parameter model to calibrate the discrete element simulation parameters of a corn kernel–soil mixture and corn stalk powder, respectively, taking the actual physical accumulation angle as the target. The saliency parameters are optimized to obtain the optimal parameter combination. Wang Wanzhang et al. [

16] used a multiscale particle aggregation method to establish a discrete element simulation model of a wheat plant and calibrated the parameters in combination with a bench test and a simulation test. BOAC et al. [

17] took soybeans as the research object and used the physical parameters and contact model parameters of existing soybeans as the basis for the selection of discrete element simulation parameters. They compared the simulation angles of repose of soybeans under the single-sphere particle model and the multisphere particle model. The single-sphere particle model can be better simulated, and the optimal parameter combination can be obtained. In summary, most domestic and foreign research scholars have mainly calibrated discrete element simulation parameters for soil, corn, and wheat stalks, rarely used more comprehensive physical tests to determine the material parameters of sunflower extract, and calibrated the discrete element model simulation parameters of sunflower extract based on the actual parameters.

In this paper, the measured basic physical and mechanical parameters are used as the basis for the selection of discrete element simulation parameters, and the actual measured physical angle of repose is used as the target value. The Plackett–Burman test, the steepest climbing test and the Box–Behnken test are carried out in sequence. The discrete element simulation parameters of the exudate from sunflower are calibrated. Double-sample T detection is performed on the simulated angle of repose and the actual physical angle of repose to prove the authenticity of the simulation test and finally obtain the optimal parameter combination. This research can provide a reliable discrete element simulation parameter basis for the movement law of sunflower in the cleaning process and optimization of the cleaning device.

2. Materials and Methods

The object of the study in this article is edible sunflower extracts from the planting area of Urumqi County, Xinjiang. The sampled variety of edible sunflower is Sanrui No. 39. Sunflower extract is a typical bulk material. The basic physical and mechanical characteristics include the composition, shape and size, moisture content, density, elastic modulus, shear modulus, Poisson’s ratio, and static friction coefficient of the sunflower extract and the collision recovery factor.

2.1. Composition of the Exudate

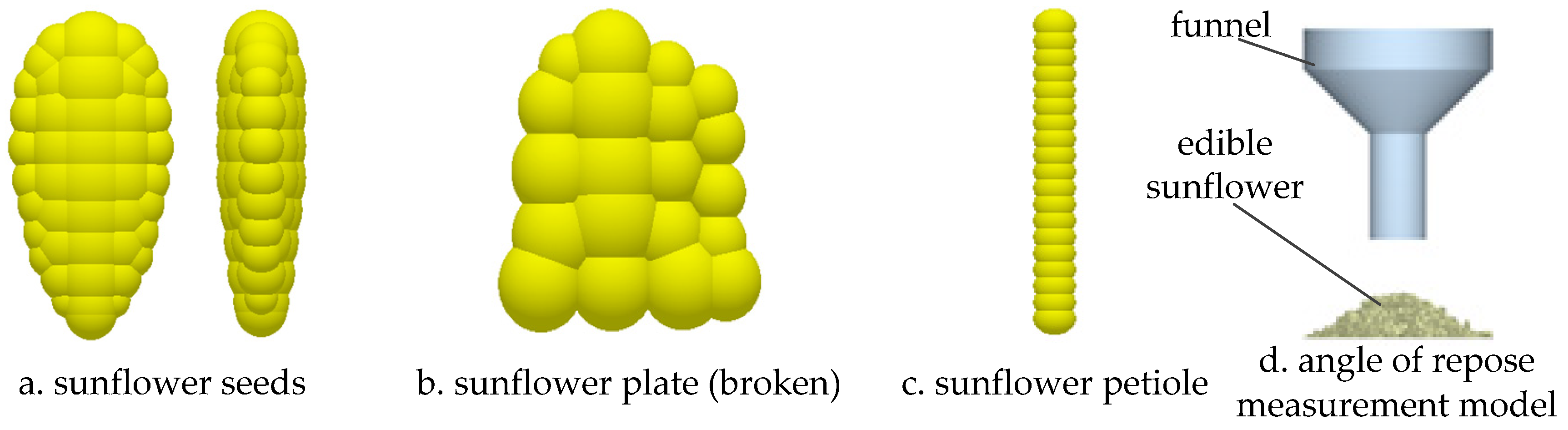

One thousand grams of the material was randomly sampled each time, and then the sample was classified. It can be concluded that the edible sunflower extract contains edible sunflower seeds, edible sunflower plates (broken), edible sunflower petioles, and light impurities. The utilization accuracy was 0.01 g. An electronic scale was used to weigh the four components separately; sampling was repeated 3 times and the average value was taken to obtain the mass percentage of the sunflower seeds, sunflower plates (broken), sunflower petioles, and light impurities in the sunflower extract, as shown in

Figure 1. Since light impurities are directly blown out under the action of wind during the cleaning process, they have almost no effect on the cleaning performance, so only sunflower seeds, sunflower disks (broken), and sunflower petioles were used for the material property analysis.

2.2. Determination of Physical Characteristic Parameters

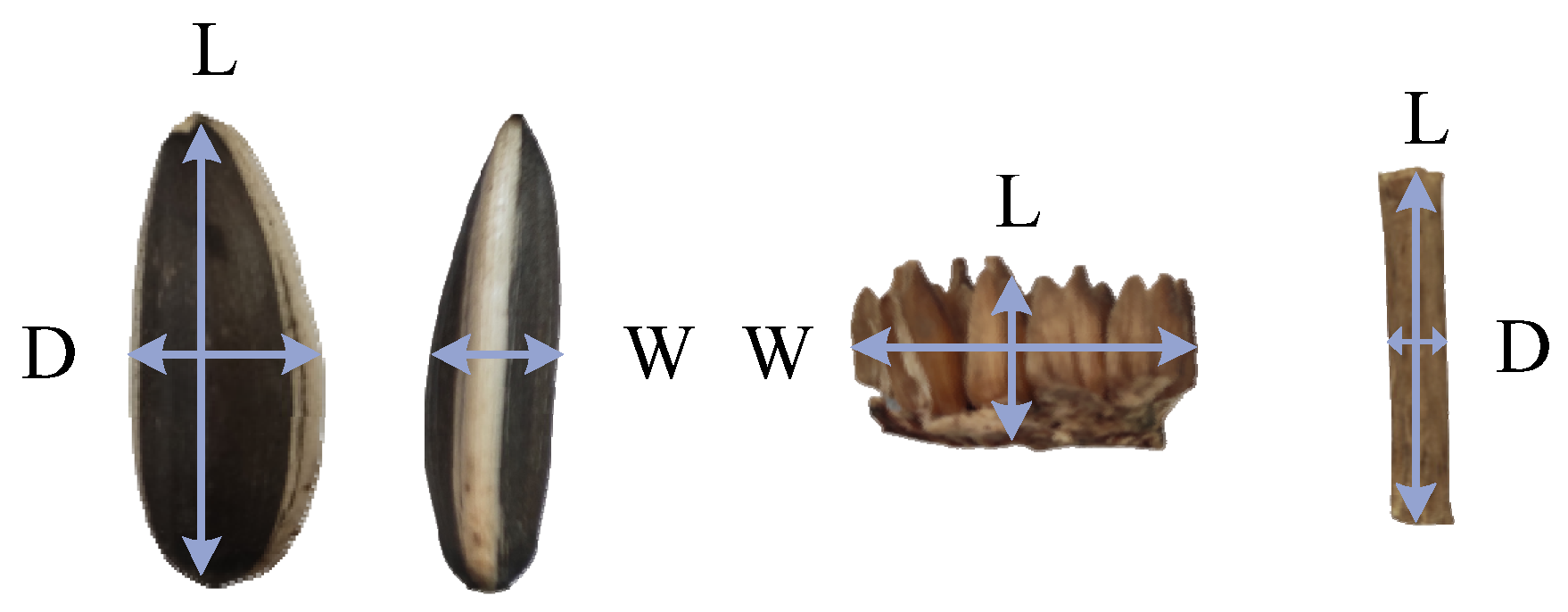

We randomly selected 100 pieces of edible sunflower seeds, edible sunflower disks (broken), and edible sunflower petioles from the extrudates and measured their dimensional characteristics (length, diameter, and width) with an electronic digital caliper with an accuracy of 0.01 mm, as shown in

Figure 2. The drying box method [

18] was used to determine the moisture content of each component of edible sunflower. Thirty grams of edible sunflower seeds was sampled, and 60 g of edible sunflower disks (broken) and 60 g of edible sunflower petioles were sampled. The test was carried out 3 times in total using an electric drum. The sample was dried in an air drying oven and cooled to room temperature. The night soaking method [

19] was used to measure the density of the three kinds of materials: sunflower seeds, sunflower discs (broken), and sunflower petioles.

The geometric size, moisture content and average density of each component of the sunflower extract are shown in

Table 1.

2.3. Determination of Mechanical Characteristic Parameters

2.3.1. Elastic Modulus

The elastic modulus is an important physical quantity to measure the elasticity of materials [

20]. The elastic modulus of edible sunflower exudates was determined by a compression test. Before the test, the original thickness (

T1) of the edible sunflower exudates was measured, and the tested sunflower exudates were naturally placed on the center of the square platform of a TA-XT plus texture analyzer. After positioning, a P/36R compression probe was used. The speed before compression was 1 mm/s, the speed during compression was 0.05 mm/s, and the speed after compression was 5 mm/s, as shown in

Figure 3. The three test samples of edible sunflower seeds, edible sunflower plates (broken), and edible sunflower petioles were tested 10 times, and the average value was taken. The elastic modulus of edible sunflower seeds was calculated by Formula (1) to be 147.6 MPa. The elastic modulus of broken plates was 92.4 MPa, and the elastic modulus of the petioles of edible sunflower was 133.4 MPa.

where

E is the modulus of elasticity, MPa;

F is the applied external force, N;

A is the contact area, mm

2; Δ

L is the deformation distance under the action of external force, mm; and

T1 is the original thickness, mm.

2.3.2. Shear Modulus

The shear modulus is a material constant that refers to the ratio of shear stress to strain [

21]. The shear modulus of edible sunflower extracts was measured by a shear test. During the test, the tested edible sunflower extracts were naturally placed on the center of the square platform of a TA-XT plus texture analyzer, and a P/WB shear probe was used to compress the sample. The speed before compression was 1 mm/s, the speed during compression was 0.05 mm/s, and the speed after compression was 5 mm/s. The three test samples of edible sunflower seeds, edible sunflower plates (broken) and edible sunflower petioles were tested 10 times, and the average value was taken. The shear modulus of edible sunflower seeds was calculated by Formula (2) to be 56.3 MPa. The shear modulus of the discs (broken) was 35.5 MPa, and the shear modulus of the sunflower petioles was 53.1 MPa.

where

G is the shear modulus, MPa;

τ is the shear stress, N; and

γ is the shear strain.

2.3.3. Poisson’s Ratio

When a material is stretched or compressed in one direction, the ratio of the absolute value of the transverse normal strain to the axial normal strain is called Poisson’s ratio, which is an elastic constant that reflects the transverse deformation of the material [

22]. Through the determination of the elastic modulus and shear modulus of edible sunflower, Poisson’s ratio of edible sunflower was calculated using (3), and the calculation results are shown in

Table 2.

In the formula, μ is Poisson’s ratio; E is the modulus of elasticity, MPa; and G is the shear modulus, MPa.

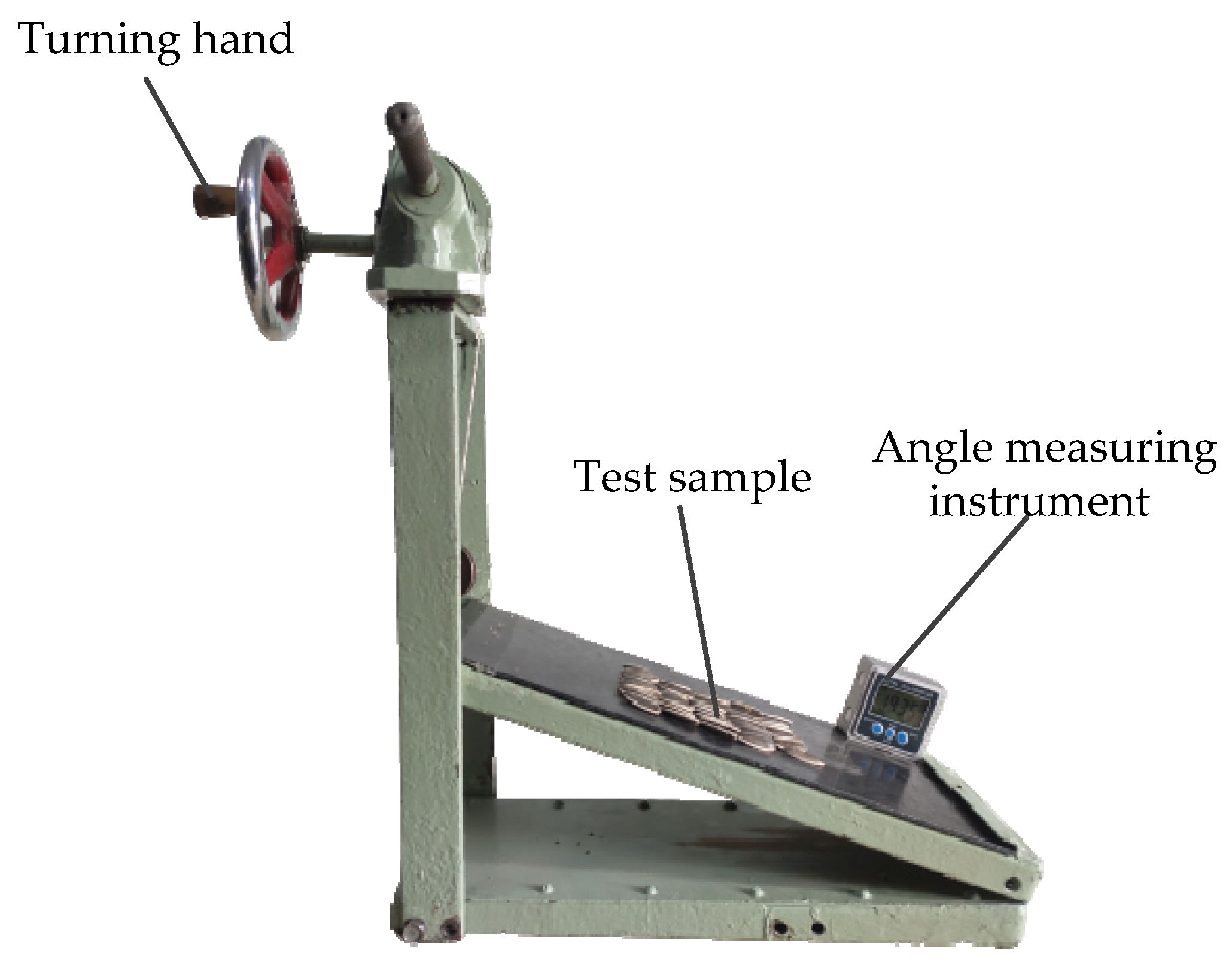

2.4. Static Friction Coefficient

There is a large amount of relative movement in the extraction of sunflower seeds during the cleaning process, and the accurate measurement of the static friction coefficient can directly affect the simulation results of the cleaning process [

23]. The static friction coefficient was measured using the inclined plane method [

24], and a self-designed agricultural material static friction coefficient measuring device was used for the measurement. During the measurement, the sunflower extract was placed on the surface of the material to be tested, and the adjustment handle was slowly turned to increase the inclined plane angle. The movement state of the edible sunflower protruding object was observed. When a downward sliding trend on the material to be tested was observed, the number on the digital display of the angle measuring instrument was read and recorded as σ, and the difference value between the edible sunflower protruding object and the contact material was calculated. The coefficient of static friction f = tanσ, and each test was repeated 10 times, as shown in

Figure 4.

Table 3 shows the measurement results of the static friction coefficient of edible sunflower extracts.

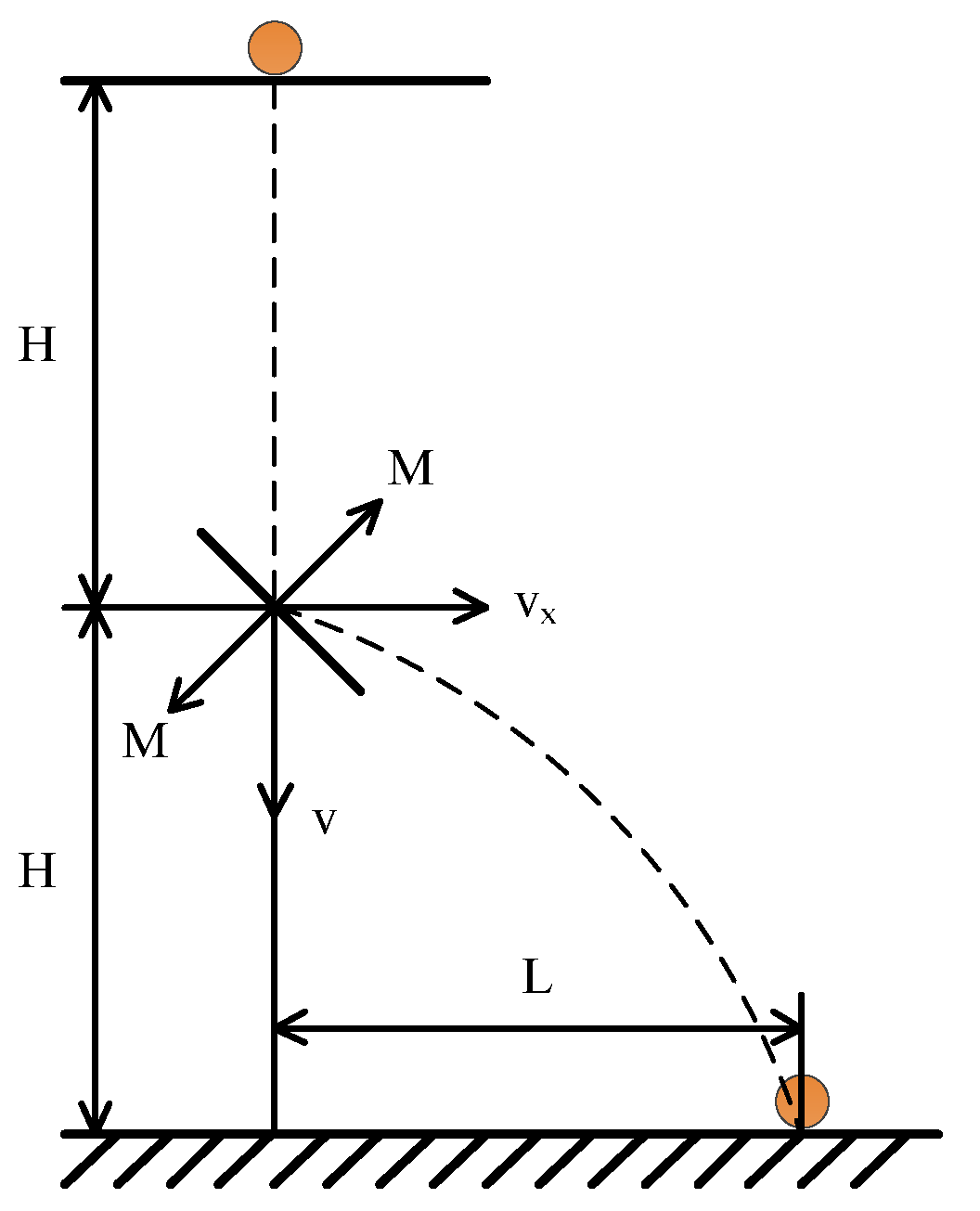

2.5. Collision Recovery Coefficient

The collision recovery coefficient e is a parameter that measures the ability of objects to recover from deformation after collision. It is the ratio of the normal velocity

V1′ of two objects after collision and the normal relative velocity

V1 before collision [

25]. The free-fall test was used to determine the impact recovery coefficient of edible sunflower extracts [

26]. The measurement principle diagram is shown in

Figure 5. The height

H of the measured material falling after colliding with the 45° collision plate was set, and the resulting horizontal distance was

L. The material was measured during free fall from height

H, and the time to reach the collision plate was

t1. After collision with the collision plate, the movement of the material was parabolic. The speed of the free fall before collision was

V2, and the horizontal speed after collision was

Vx. The time to reach the glued board was

t2.

According to the principle of kinematics:

The subvelocity of the edible sunflower protruding object in the normal direction before and after the collision point is

Therefore, the collision recovery coefficient of the edible sunflower protruding object is

A self-designed drop collision device and a high-speed camera (i-SPEED3) were used in the test. During the test, the edible sunflower protruding material fell from a height of 20 cm, bounced after colliding with the measurement sample plate, and finally landed on the bottom plate. The high-speed camera recorded the entire rebound process of the edible sunflower protruding object. The test was repeated 10 times. The test results are shown in the

Table 3.

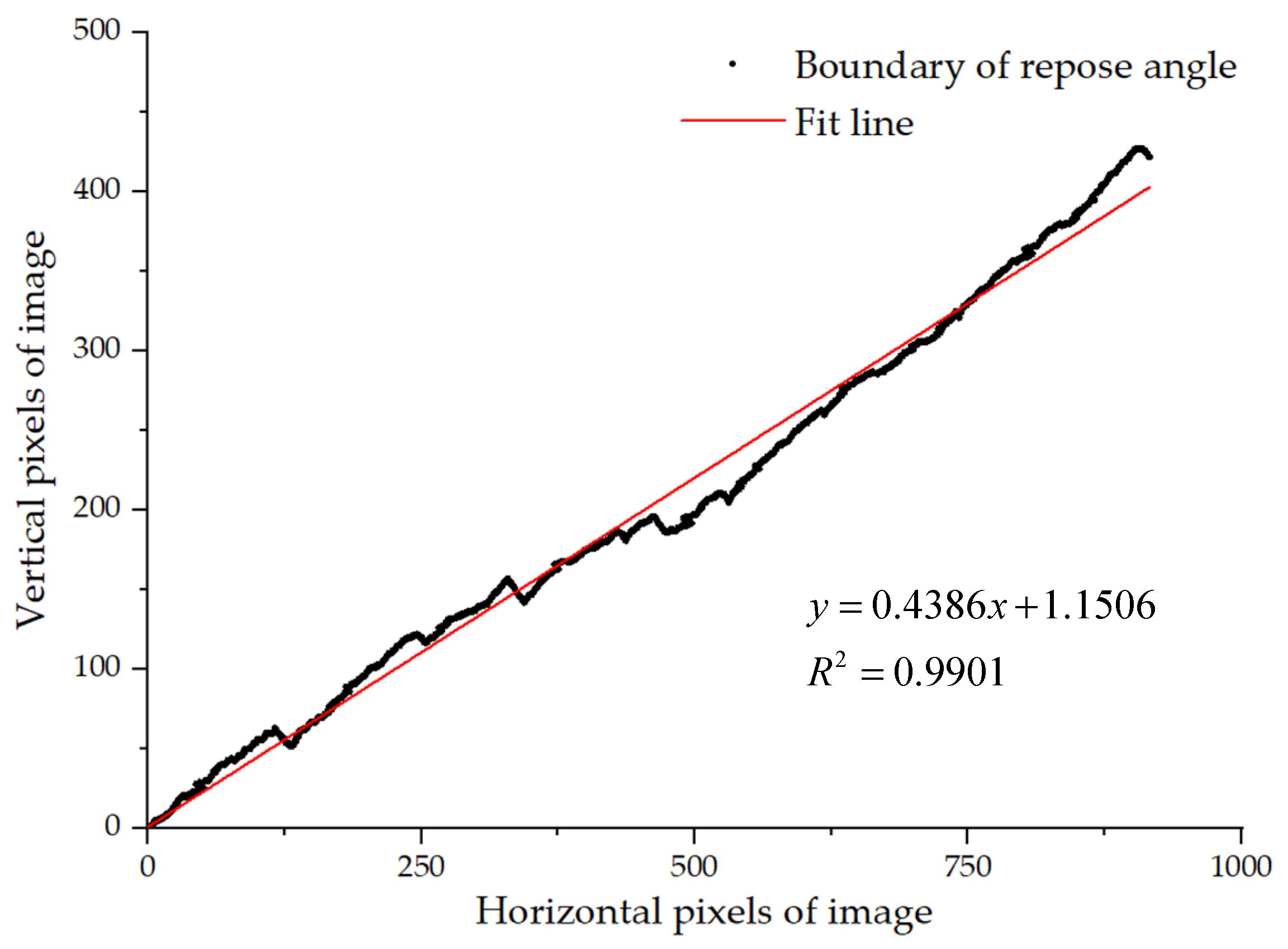

2.6. Angle of Repose

The angle of repose of edible sunflower was measured using a homemade angle of repose tester. As shown in

Figure 6, the funnel length was 130 mm, and the inner diameter of the feed opening and the blanking opening were 114 mm and 30 mm, respectively. Thirty grams of edible sunflower was tested and poured from the funnel inlet in a free fall manner. When all the leached objects were completely still on the bottom steel plate, the camera was used to take the image of the leached objects, and MATLAB was used to ash the image of the edible sunflower leached objects. Binarization processing and boundary pixel extraction were conducted. The pixel coordinates were input into Origin software to fit the boundary line. The experiment was repeated 10 times, the average value of the accumulation angle of the edible sunflower protuberance was 24.68°, and the angle of repose boundary was fitted as shown in

Figure 6.

3. Establishment of a Discrete Element Model of Edible Sunflower Extraction and Calibration of Simulation Parameters

3.1. Establishment of a Discrete Element Simulation Model

Through the early determination of the physical characteristics of edible sunflower extracts, the three-dimensional modeling software SolidWorks was used to model the actual size of the edible sunflower extracts, and then the extracted object model was converted into an IGES model and imported into the discrete element simulation software EDEM. The single spherical particles in the EDEM software filled the edible sunflower exudate model to establish a simulation model of the edible sunflower exudate [

27,

28], as shown in

Figure 7. In the EDEM simulation test, the measurement model of the simulation test of the angle of repose of the edible sunflower exudates was modeled according to the actual size of the homemade angle of the repose tester, as shown in

Figure 7. At the beginning of the simulation, edible sunflower exudates were dynamically generated from the feed opening above the funnel in a free-falling motion. After 4 s of simulation time, all edible sunflower exudates fell on the bottom plate and remained stationary, forming an angle of repose for the accumulation of edible sunflower exudates.

3.2. Calibration of Discrete Element Simulation Parameters

Determination of Significant Influence Parameters

The Plackett–Burman mode of Design-Expert 11 software was used to design the experiment. The test parameters were selected according to the results of the material test, and the angle of repose after accumulation of edible sunflower was used as the response value to screen out the parameters that have a significant impact on the response value [

29]. The Plackett–Burman test program has a total of 24 test parameters, which are represented by X1-X24, and three virtual parameters are set, which are represented by X25-X27. The high (+1) and low (−1) levels of each parameter are the measured maximum and minimum values, respectively, as shown in

Table 4. After each set of simulation experiments, the method of obtaining the angle of repose of the simulation model of the sunflower exudate is the same as the method of physically measuring the angle of repose. The Plackett–Burman test scheme and results are shown in

Table 5.

Design-Expert 11 software was used to analyze the variance of the test results and obtain the significance results of each simulation parameter, as shown in

Table 6. From

Table 6, it can be seen that

p < 0.01 for the shear modulus of sunflower grain-sunflower grain, the static friction coefficient of sunflower grain-sunflower grain, and the coefficient of recovery of sunflower grain-sunflower grain, which have extremely significant influence on the angle of repose in the simulation experiment. For other simulation test parameters,

p > 0.05, which indicates minimal influence on the angle of repose of the simulation test.

3.3. The Steepest Climbing Test Design

The steepest climbing test is carried out on the three significant parameters of sunflower kernel-sunflower kernel shear modulus, static friction coefficient and collision recovery coefficient obtained from the Plackett–Burman test, which can quickly determine the optimal selection of the significant factors. For the value range, the relative error between the simulated angle of repose and the actual angle of repose is used as the evaluation index. The results are shown in

Table 7. With the increase in the value of each saliency parameter, the relative error first decreases and then increases. For No. 3, the relative error is the smallest, so it can be determined that the level range of the optimal parameter is approximately No. 3 [

30].

In the simulation test, the other nonsignificant parameters are the average values determined by the physical test. The Poisson ratio of edible sunflower seeds is 0.31, the Poisson ratio of edible sunflower disks (broken) is 0.3, the Poisson ratio of edible sunflower petioles is 0.26, the shear modulus of sunflower plates (broken) is 35.5, the shear modulus of sunflower petioles is 53.1, the static friction coefficient of sunflower grain-sunflower plates (broken) is 0.55, and the collision recovery coefficient is 0.67. The static friction coefficient of sunflower petioles is 0.54, the collision recovery coefficient is 0.53, the static friction coefficient of sunflower plates (broken)-sunflower plates (broken) is 0.81, the collision recovery coefficient is 0.56, the static friction coefficient of sunflower plates (broken)-sunflower plates (broken) is 0.82, the collision recovery coefficient is 0.4, the static friction coefficient of sunflower petioles-sunflower petioles is 0.83, the collision recovery coefficient is 0.48, the static friction coefficient of sunflower grain-rigid sieve plate is 0.73, and the collision recovery coefficient is 0.58. The static friction coefficient of discs (broken)-rigid sieve plate is 0.61, the collision recovery coefficient is 0.5, the static friction coefficient of sunflower petioles-rigid sieve plate is 0.78, and the collision recovery coefficient is 0.5.

3.3.1. Box–Behnken Experimental Design

Using the Box–Behnken mode of Design-Expert 11 software for testing, the test factors are 3, of which No. 2 and No. 4 are low (−1) and high (+1) levels, and No. 3 is the center point (0). The designed scheme and results are shown in

Table 8. In the simulation test, other nonsignificant parameters are the average values determined by the physical test.

Design-Expert 11 software was used to perform multiple regression analysis on the significant parameters of the Box–Behnken test and obtain the second-order regression model of the angle of repose and the significant parameters:

Table 9 shows that X1, X2, X3, X1X2, and X1

2 have extremely significant effects on the angle of repose; X2

2 has significant effects on the angle of repose; X1X3, X2X3, and X3

2 have no significant effects on the angle of repose.

p < 0.0001 is observed for the fitting model of the angle of repose,

p = 0.2805 > 0.05 is observed for the lack-of-fit term, and the coefficient of variation CV = 1.59%, indicating that the equation is well fitted. The regression determination coefficient R

2 = 0.983 and the adjustment determination coefficient Adjust R

2 = 0.9612 are all close to 1, indicating that the angle of repose model is extremely significant and can truly reflect the situation, thereby predicting the target angle of repose.

3.3.2. Simulation Parameter Calibration and Test Verification

Taking the actual physical angle of repose as the target value, module optimization is used in Design-Expert 11 software to optimize the second-order regression equation so that the simulated angle of repose value is closest to the physical test angle of repose value, and a set of data similar to the physical test data is obtained. The optimal parameter combination of sunflower kernel-sunflower kernel shear modulus, static friction coefficient and collision recovery coefficient is 58.34 MPa, 0.62 and 0.608, respectively, and the values of other nonsignificant parameters are the same as those of the steepest climbing test.

To verify the authenticity of the optimal parameter combination after calibration of the sunflower exudates, the parameters obtained above were input into EDEM 2020 software for simulation, and the angles of repose of the sunflower exudates were 25.96°, 25.31°, and 23.47°, respectively, on average. The value is 24.91°. The actual physical test and simulated angles of repose of the sample were tested by two-sample

T test, and

p = 0.827 > 0.05, indicating that there was no significant difference between the simulated angle of repose and the actual physical test angle of repose. The actual physical angle of repose is compared with the optimal parameters. The relative error of the average value of the simulated angle of repose under the combination is 0.923%, and the experimental comparison result is shown in

Figure 8 and

Table 10.

4. Conclusions

The composition and basic physical properties of the extract from sunflower were obtained through physical tests using a homemade static friction coefficient measuring instrument. A collision device and a high-speed camera were used to obtain the static friction coefficient and the collision recovery coefficient between components of sunflower extract.

Taking the basic physical characteristics and mechanical characteristic parameters determined by the physical test as the basis of the simulation test, the Plackett–Burman test was carried out, and the parameters that have a significant effect on the simulation angle of repose were obtained: sunflower kernel-sunflower kernel shear modulus, static friction coefficient and collision recovery coefficient, to determine the value range of the significant parameters through the steepest climbing test.

On the basis of the steepest climbing test, the Box–Behnken test was carried out to obtain the second-order regression equation of the simulated angle of repose and the significant parameters, and the actual physical angle of repose (24.68°) was used as the target value to optimize the solution and obtain the best parameter combination.

Through the two-sample T test, we obtained p = 0.827 > 0.05, indicating that there was no significant difference between the simulated angle of repose and the actual physical test angle of repose, and the relative error was 0.923%, which verifies the reliability of the optimal simulation parameter combination after calibration. The above verification test results show that the calibration results of simulation parameters of discrete element model of sunflower extract are true and reliable, which can provide important reference value for the simulation of mechanized operation of sunflower harvesting, cleaning, and other processes.

Author Contributions

Conceptualization, X.S. and B.L.; methodology, B.L.; software, X.S.; validation, X.S.; formal analysis, Y.L. and X.S.; data curation, X.S. and X.G.; writing—original draft preparation, X.S. and B.L.; writing—review and editing, B.L. and Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institution Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Liu, H.M. Development Trend of Edible Sunflower. Mod. Agric. 2018, 2, 56. [Google Scholar]

- Yu, Y.F. Characteristics Research on Sunflower Disc and Seed of Mechanical and Threshing; Henan University of Science and Technology: Luoyang, China, 2018. [Google Scholar]

- Du, Y.F.; Mao, E.R.; Zhu, Z.X. Design and Experiment of Two-row Corn Harvester Header. Trans. Chin. Soc. Agric. Mach. 2013, 44, 21–22. [Google Scholar]

- Zou, L.; Zhuo, J.Q.; Yang, R.Q. Analysis of Development Foreground of Maize Harvester in China. J. Agric. Mech. Res. 2008, 4, 205–208. [Google Scholar]

- Zong, W.Y.; Liu, Y.; Huang, X.M. Present Situation and Developmental Strategies for Sunflower Mechanized Harvest in China. Acta Agric. Univ. Jiangxiensis 2017, 39, 600–606. [Google Scholar]

- Chen, L. Design and Experiment Study on Cleaning Unit of Rape Combine Harvester; Huazhong Agricultural University: Wuhan, China, 2013. [Google Scholar]

- Zheng, Z.H. Screening Process; Northeast Agricultural University: Harbin, China, 2020. [Google Scholar]

- Zeng, Z.W.; Ma, X.; Cao, X.L.; Li, Z.H. Critical Review of Applications of Discrete Element Method in Agricultural Engineering. Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–20. [Google Scholar]

- Chen, L.T.; Mou, X.W.; Peng, Z.J. Application of Discrete Element Method in Agricultural Engineering. Agric. Eng. 2021, 11, 29–34. [Google Scholar]

- Yu, J.Q.; Fu, H.; Li, H.; Shen, Y.F. Application of discrete element method to research and design of working parts of agricultural machines. Trans. Chin. Soc. Agric. Eng. 2005, 5, 1–6. [Google Scholar]

- Zhang, R.F.; Jiao, W.; Zhou, J.L. Parameter Calibration and Experiment of Rice Seeds Discrete Element Model with Different Filling Particle Radius. Trans. Chin. Soc. Agric. Mach. 2020, 51, 227–235. [Google Scholar]

- Xu, F.L.; He, J.L.; Wang, Y.H. Simulation parameters calibration about capsule discrete element model of blue flax. J. Gansu Agric. Univ. 2021, 56, 144–153. [Google Scholar]

- Wang, L.M.; Fan, S.Y.; Cheng, H.S. Calibration of contact parameters for pig manure based on EDEM. Trans. Chin. Soc. Agric. Eng. 2020, 36, 95–102. [Google Scholar]

- Tian, X.L.; Cong, X.; Qi, J.T. Parameter Calibration of Discrete Element Model for Corn Straw-Soil Mixture in Black Soil Areas. Trans. Chin. Soc. Agric. Mach. 2021, 52, 100–108, 242. [Google Scholar]

- Wang, W.W.; Cai, D.Y.; Xie, J.J. Parameters Calibration of Discrete Element Model for Corn Stalk Powder Compression Simulation. Trans. Chin. Soc. Agric. Mach. 2021, 52, 127–134. [Google Scholar]

- Wang, W.Z.; Liu, W.R.; Yuan, L.H. Calibration of discrete element parameters of wheat plants at harvest period based on EDEM. J. Henan Agric. Univ. 2021, 55, 64–72. [Google Scholar]

- Boac, J.M.; Casada, M.E.; Maghirang, R.G.; Harner, J.P., III. Material and Interaction Properties of Selected Grains and Oilseeds for Modeling Discrete Particles; American Society of Agricultural and Biological Engineers: Reno, NV, USA, 2009. [Google Scholar]

- Zhao, J.; Huang, C.J.; Li, B.Z. Overview of grain moisture content detection methods. Agric. Sci.-Technol. Inf. 2018, 16, 46–49. [Google Scholar]

- Ma, Y.H. Agricultural Materials Science; Chemical Industry Press Co., Ltd.: Beijing, China, 2015. [Google Scholar]

- Zhou, Z. Agricultural Materials Science; China Agricultural Press: Beijing, China, 1994. [Google Scholar]

- Liu, H.W. Mechanics of materials; Higher Education: Beijing, China, 2011. [Google Scholar]

- Mu, P.L. Research on High Net and Low Loss Cleaning Screen of Corn Grain Harvester; Jilin University: Changchun, China, 2020. [Google Scholar]

- Lijun, W.; Rui, L. Determination of the coefficient of rolling friction of an irregularly shaped maize particle group using physical experiment and simulations. Particuology 2018, 38, 185–195. [Google Scholar]

- Wu, M.C.; Cong, J.L.; Yan, Q. Calibration and experiments for discrete element simulation parameters of peanut seed particles. Trans. Chin. Soc. Agric. Eng. 2020, 36, 30–38. [Google Scholar]

- Liu, W.Z.; He, J.; Li, H.W. Calibration of Simulation Parameters for Potato Minituber Based on EDEM. Trans. Chin. Soc. Agric. Mach. 2018, 49, 125–135, 142. [Google Scholar]

- Shi, L.R.; Ma ZTZhao, W.Y. Calibration of simulation parameters of flaxed seeds using discrete element method and verification of seed-metering test. Trans. Chin. Soc. Agric. Eng. 2019, 35, 25–33. [Google Scholar]

- Masson, S.; Martinez, J. Effect of particle mechanical properties on silo flow and stresses from distinct element simulations. Powder Technol. 2000, 109, 164–178. [Google Scholar] [CrossRef]

- Shi, L.; Wu, J.M.; Sun, W. Simulation test for metering process of horizontal disc precision metering device based on discrete element method. Trans. Chin. Soc. Agric. Eng. 2014, 30, 40–48. [Google Scholar]

- Liu, F.Y.; Zhang, J.; Li, B. Calibration of parameters of wheat required in discrete element method simulation based on repose angle of particle heap. Trans. Chin. Soc. Agric. Eng. 2016, 32, 247–253. [Google Scholar]

- Ma, Y.H.; Song, C.D.; Xuan, C.Z. Parameters calibration of discrete element model for alfalfa straw compression simulation. Trans. Chin. Soc. Agric. Eng. 2020, 36, 22–30. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).