3D Computational Fluid Dynamics Analysis of a Convective Drying Chamber

Abstract

1. Introduction

2. Materials and Methods

2.1. Mathematical Model

2.2. CFD Modelling

2.2.1. Geometrical Domain

2.2.2. Grid Generation

2.2.3. Boundary and Initial Condition Selection

2.2.4. Physical Model Selection

3. Results and Discussion

3.1. Mesh Independence Test

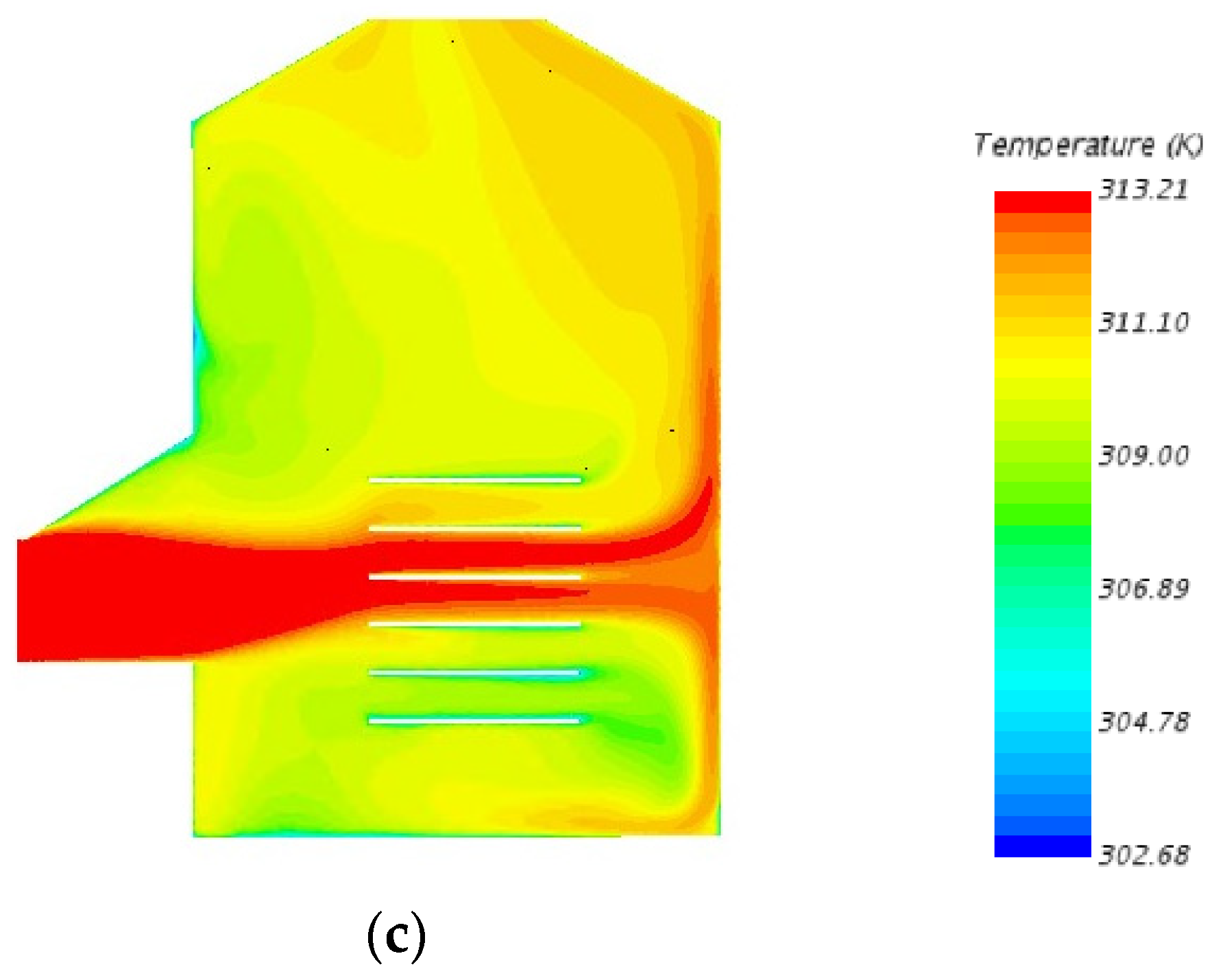

3.2. Model Validation

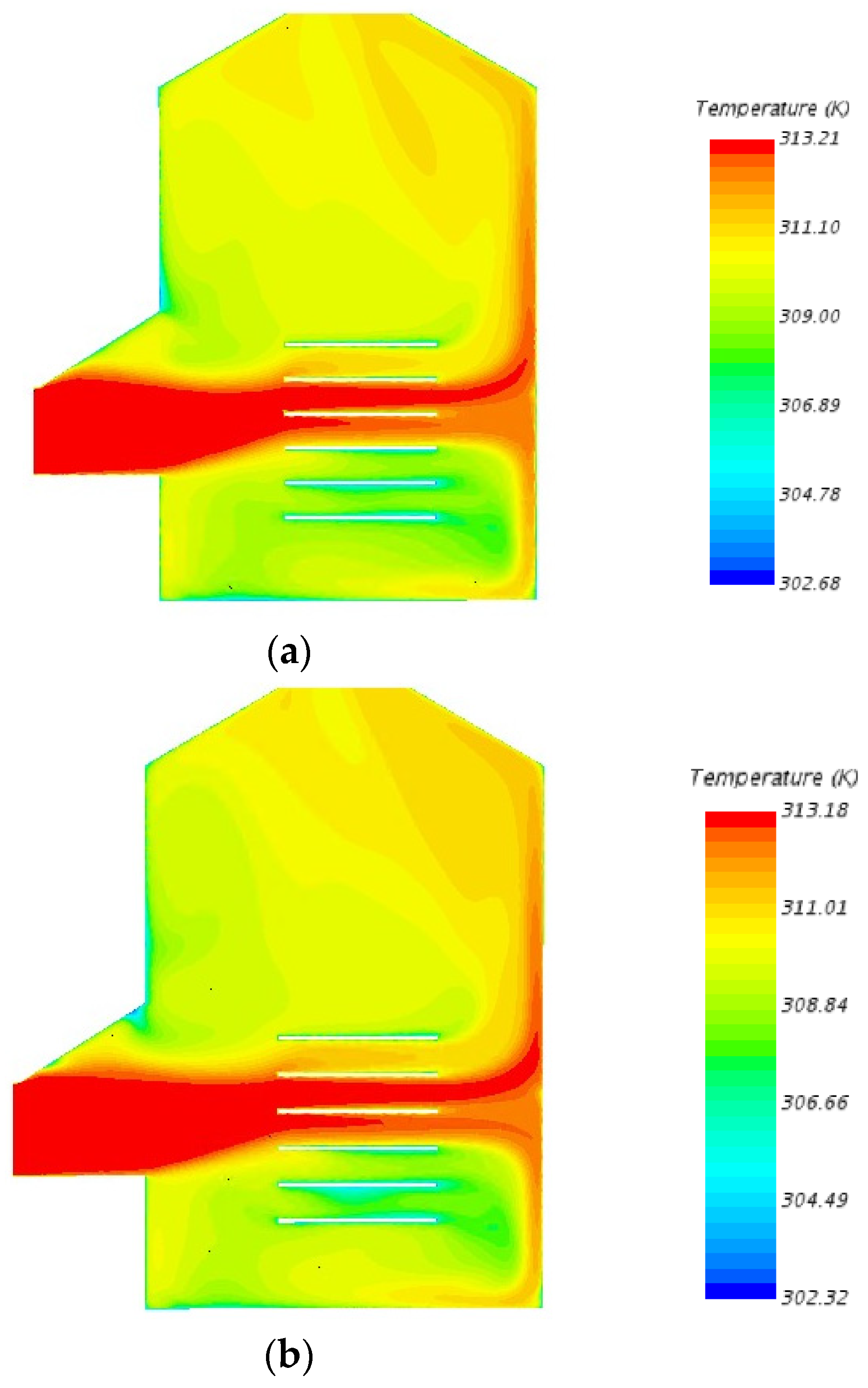

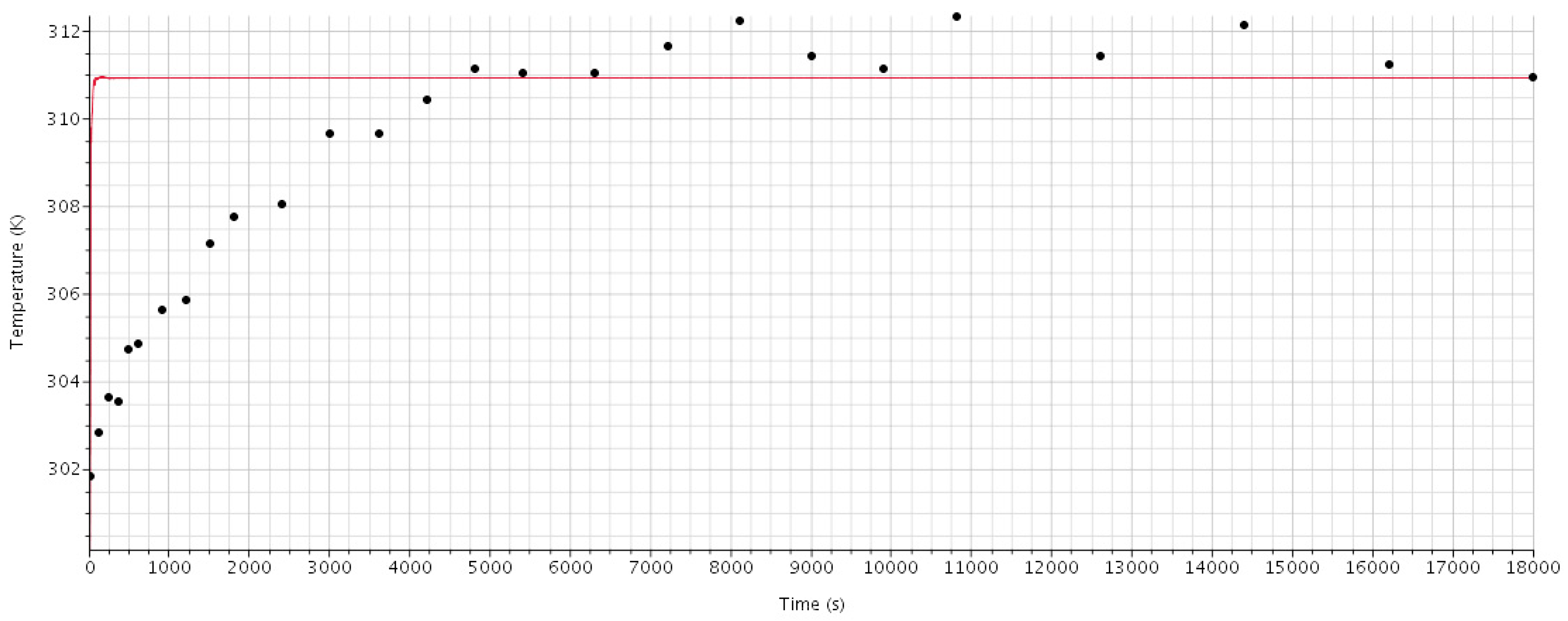

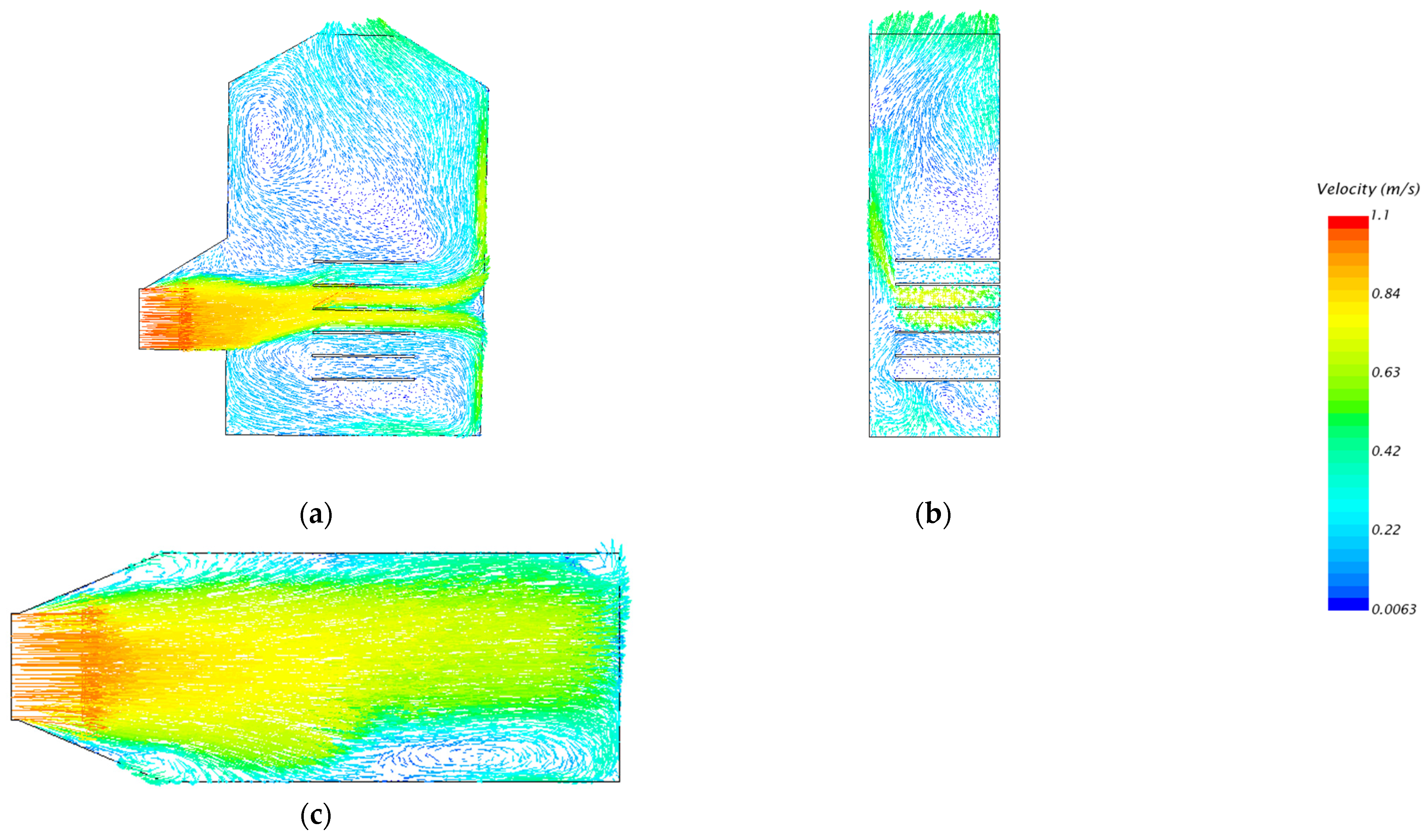

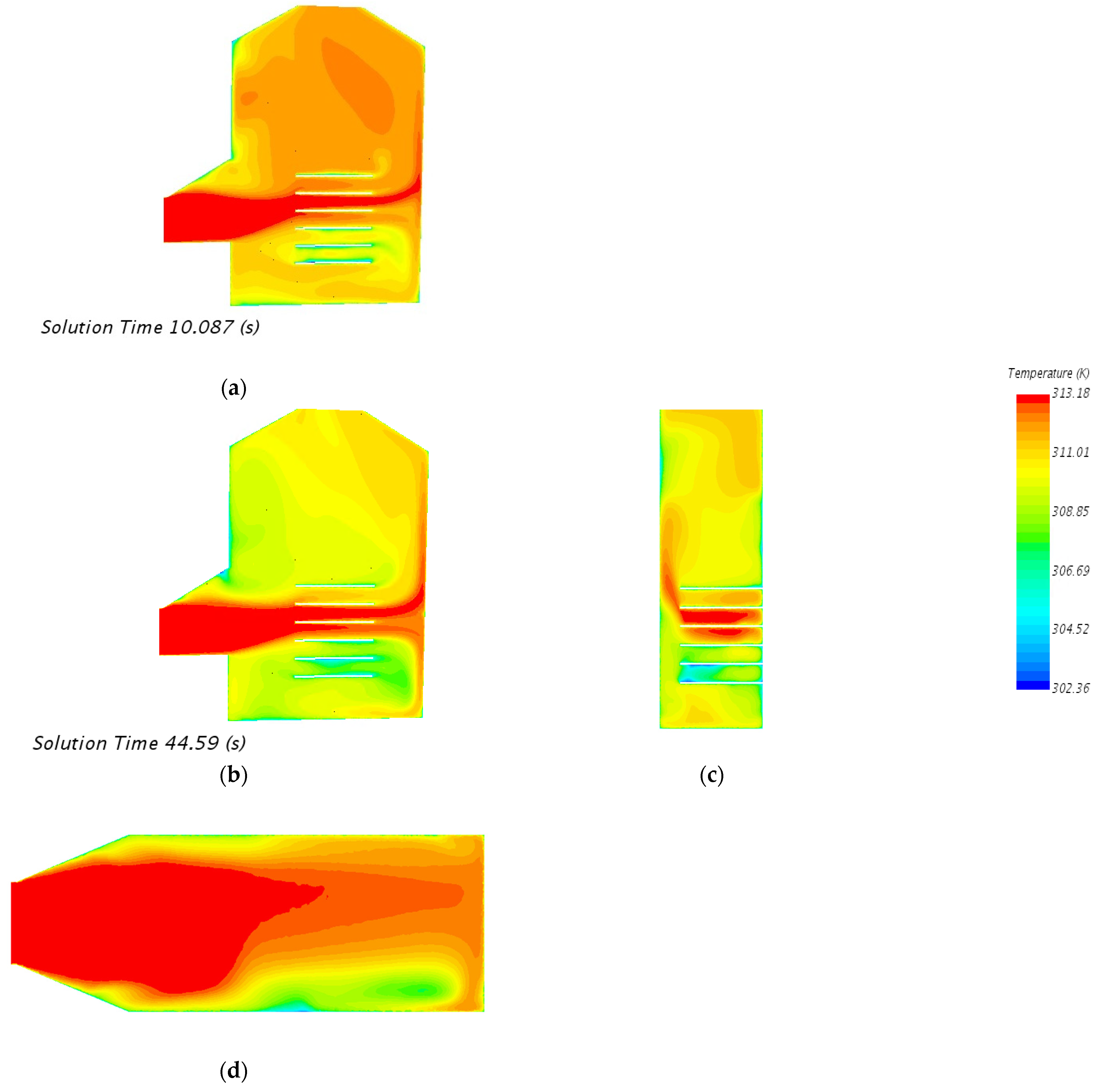

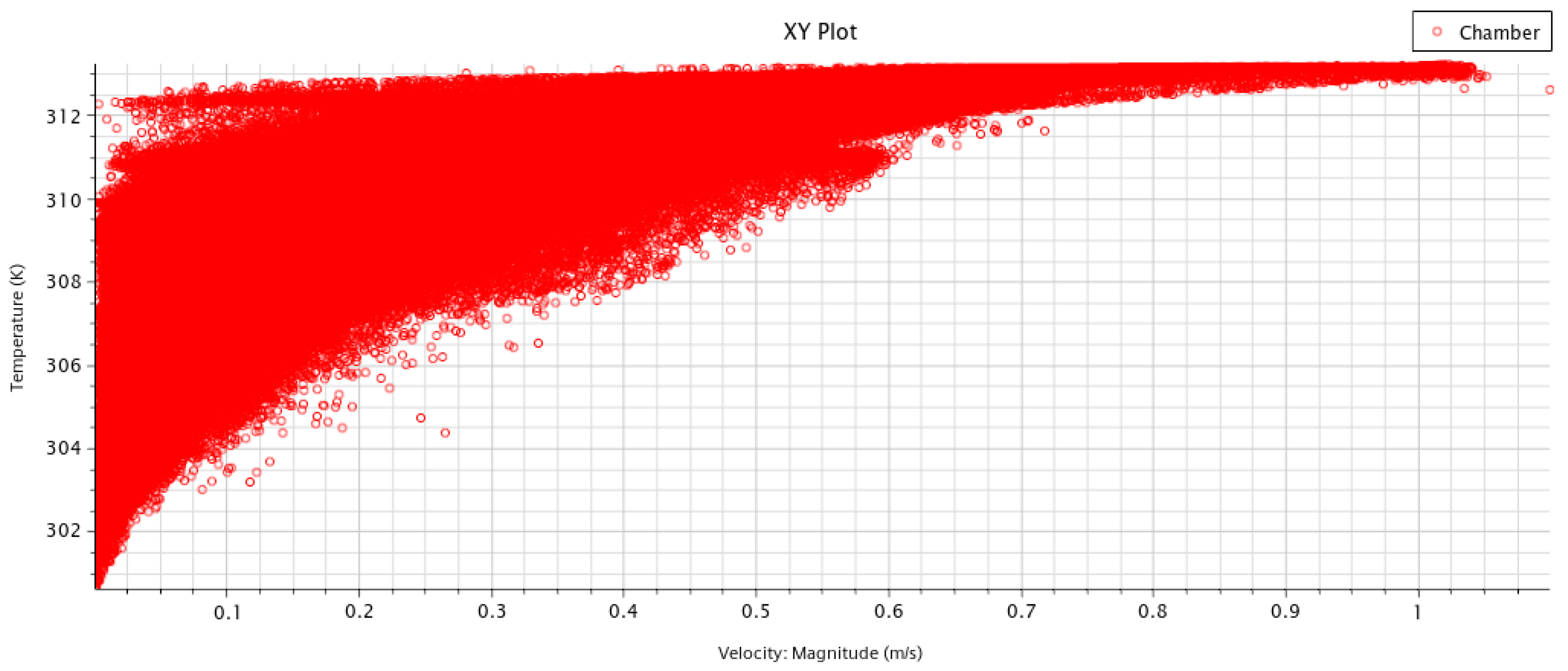

3.3. Velocity Profile and Temperature Distribution

3.4. Velocity and Mass Profile and Temperature Distribution

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mujumdar, A.S. Research and development in drying: Recent trends and future prospects. Dry. Technol. 2004, 22, 1–26. [Google Scholar] [CrossRef]

- Hawlader, M.N.A.; Perera, C.O.; Tian, M. Properties of modified atmosphere heat pump dried foods. J. Food Eng. 2006, 74, 392–401. [Google Scholar] [CrossRef]

- Uengkimbuan, N.; Soponronnarit, S.; Prachayawarakorn, S.; Nathakaranakule, A. Drying kinetics and physical properties of dried por using two-stage techniques. In Proceedings of the 2nd International Conference on Innovations in Food Processing Technology and Engineering, Klong Luang, Thailand, 11–13 January 2005; pp. 320–328. [Google Scholar]

- Hawlader, M.N.A.; Perera, C.O.; Tian, M.; Yeo, K.L. Drying of guava and papaya: Impact of different drying methods. Dry. Technol. 2006, 24, 77–87. [Google Scholar] [CrossRef]

- Alves-Filho, O.; Eikevik, T.; Mulet, A.; Garau, C.; Rossello, C. Kinetics and mass transfer during atmospheric freeze drying of red pepper. Dry. Technol. 2007, 25, 1155–1161. [Google Scholar] [CrossRef]

- Sunthonvit, N.; Srzednicki, G.; Craske, J. Effects of drying treatments on the composition of volatile compounds in dried nectarines. Dry. Technol. 2007, 25, 877–881. [Google Scholar] [CrossRef]

- Nathakaranakule, A.; Kraiwanichkul, W.; Soponronnarit, S. Comparative study of different combined superheated-steam drying techniques for chicken meat. J. Food Eng. 2007, 80, 1023–1030. [Google Scholar] [CrossRef]

- Jangam, S.V.; Joshi, V.S.; Mujumdar, A.S.; Thorat, B.N. Studies on dehydration of sapota (Achras zapota). Dry. Technol. 2008, 26, 369–377. [Google Scholar] [CrossRef]

- Fiala, M.; Guidetti, R. Drying of medicinal plants with a closed-circuit heat pump dryer. Z. Arznei- Gewurzpflanzen 2008, 13, 29–35. [Google Scholar]

- Coogan, R.C.; Wills, R.B.H. Flavor changes in Asian white radish (Raphanus sativus) produced by different methods of drying and salting. Int. J. Food Prop. 2008, 11, 253–257. [Google Scholar] [CrossRef]

- Jamaleddine, T.J.; Ray, M.B. Application of Computational Fluid Dynamics for Simulation of Drying Processes: A Review. Dry. Technol. 2010, 28, 120–154. [Google Scholar] [CrossRef]

- Tong, Y.; Kozai, T.; Nishioka, N.; Ohyama, K. Greenhouse heating using heat pumps with a high coefficient of performance (COP). Biosyst. Eng. 2010, 106, 405–411. [Google Scholar] [CrossRef]

- Erbay, Z.; Hepbasli, A. Advanced exergoeconomic evaluation of a heat pump food dryer. Biosyst. Eng. 2014, 124, 29–39. [Google Scholar] [CrossRef]

- Lemus-Mondaca, R.A.; Vega-Gálvez, A.; Zambra, C.E.; Moraga, N.O. Modeling 3D conjugate heat and mass transfer for turbulent air drying of Chilean papaya in a direct contact dryer. Heat Mass Transf. 2017, 53, 11–24. [Google Scholar] [CrossRef]

- Gómez-Daza, J.C. Secado Asistido por Bomba de Calor: Modelamiento, Simulación y Validación en Zanahoria. Ph.D. Thesis, Universidad del Valle, Cali, Colombia, 2014. [Google Scholar]

- Mohan, V.P.C.; Talukdar, P. Design of an experimental set up for convective drying: Experimental studies at different drying temperature. Heat Mass Transf. 2013, 49, 31–40. [Google Scholar] [CrossRef]

- Xia, B.; Sun, D.W. Applications of computational fluid dynamics (CFD) in the food industry: A review. Comput. Electron. Agric. 2002, 34, 5–24. [Google Scholar] [CrossRef]

- Zare, D.; Minaei, S.; Mohamad Zadeh, M.; Khoshtaghaza, M.H. Computer simulation of rough rice drying in a batch dryer. Energy Convers. Manag. 2006, 47, 3241–3254. [Google Scholar] [CrossRef]

- Moreira, R.; Chenlo, F.; Chaguri, L.; Vazquez, G. Mathematical modeling of the drying kinetics of chestnut: Influence of the natural shells. Food Bioprod. Process 2005, 83, 306–314. [Google Scholar] [CrossRef]

- Rahman, S.M.A.; Islam, M.R.; Mujumdar, A.S. A study of coupled heat and mass transfer in composite food products during convective drying. Dry. Technol. 2007, 25, 1359–1368. [Google Scholar] [CrossRef]

- Lamnatou, C.; Papanicolaou, E.; Belessiotis, V.; Kyriakis, N. Conjugate Heat and Mass Transfer from a Drying Rectangular Cylinder in Confined Air Flow. Numer. Heat Transf. Part A Appl. 2009, 56, 379–405. [Google Scholar] [CrossRef]

- Cârlescu, P.-M.; Arsenoaia, V.; Roşca, R.; Ţenu, I. CFD simulation of heat and mass transfer during apricots drying. LWT—Food Sci. Technol. 2017, 85, 479–486. [Google Scholar] [CrossRef]

- Villegas, J.F.; De La Cruz, H.S.; Altamar, F.B.; Lozano, W.O. CFD numeric simulation to obtain the proper parameters of corozo drying (Bactris guineensis). Contemp. Eng. Sci. 2017, 10, 703–711. [Google Scholar] [CrossRef]

- Pantokratoras, A. Comment on the paper “Modeling 3D conjugate heat and mass transfer for turbulent air drying of Chilean papaya in a direct contact dryer, Roberto A. Lemus-Mondaca, Antonio Vega Galvez, Carlos E. Zambra, Nelson O. Moraga, Heat Mass Transfer, 2017, 53:11–24”. Heat Mass Transf. 2018, 54, 591–592. [Google Scholar] [CrossRef]

- Han, J.; BadÍa-Melis, R.; Yang, X.; Ruiz-Garcia, L.; Qian, J.; Zhao, C. CFD Simulation of Airflow and Heat Transfer During Forced-Air Precooling of Apples. J. Food Process Eng. 2017, 40, e12390. [Google Scholar] [CrossRef]

- Gómez Daza, J.C.; Ochoa Martínez, C.I. Kinetic aspects of a dried thin layer carrot in a heat pump dryer. Dyna 2016, 83, 16–20. [Google Scholar] [CrossRef]

- Ozgen, F. Experimental investigation of drying characteristics of cornelian cherry fruits (Cornus mas L.). Heat Mass Transf. 2015, 51, 343–352. [Google Scholar] [CrossRef]

- Chapchaimoh, K.; Wiset, L.; Poosma-ad, N.; Morris, J. Thermal characteristics of heat pump dryer for ginger drying. Appl. Therm. Eng. 2015, 95, 491–498. [Google Scholar] [CrossRef]

- Coşkun, S.; Doymaz, İ.; Tunçkal, C.; Erdoğan, S. Investigation of drying kinetics of tomato slices dried by using a closed loop heat pump dryer. Heat Mass Transf. 2017, 53, 1863–1871. [Google Scholar] [CrossRef]

- Fayose, F.; Huan, Z. Heat pump drying of fruits and vegetables: Principles and potentials for sub-saharan africa. Int. J. Food Sci. 2016, 2016, 9673029. [Google Scholar] [CrossRef]

- Hii, C.L.; Law, C.L.; Suzannah, S. Drying kinetics of the individual layer of cocoa beans during heat pump drying. J. Food Eng. 2012, 108, 276–282. [Google Scholar] [CrossRef]

- Kuan, M.; Shakir, Y.; Mohanraj, M.; Belyayev, Y.; Jayaraj, S.; Kaltayev, A. Numerical simulation of a heat pump assisted solar dryer for continental climates. Renew. Energy 2019, 143, 214–225. [Google Scholar] [CrossRef]

- Mohammadi, I.; Tabatabaekoloor, R.; Motevali, A. Effect of air recirculation and heat pump on mass transfer and energy parameters in drying of kiwifruit slices. Energy 2019, 170, 149–158. [Google Scholar] [CrossRef]

- Taşeri, L.; Aktaş, M.; Şevik, S.; Gülcü, M.; Uysal Seçkin, G.; Aktekeli, B. Determination of drying kinetics and quality parameters of grape pomace dried with a heat pump dryer. Food Chem. 2018, 260, 152–159. [Google Scholar] [CrossRef] [PubMed]

- Tunckal, C.; Doymaz, İ. Performance analysis and mathematical modelling of banana slices in a heat pump drying system. Renew. Energy 2020, 150, 918–923. [Google Scholar] [CrossRef]

- Zhao, H.; Yang, Z.; Tao, Z. Drying kinetics of continuous and intermittent heat pump drying of green soybean seeds. Int. J. Food Eng. 2017, 13, 1–15. [Google Scholar] [CrossRef]

- Aktaş, M.; Khanlari, A.; Amini, A.; Şevik, S. Performance analysis of heat pump and infrared–heat pump drying of grated carrot using energy-exergy methodology. Energy Convers. Manag. 2017, 132, 327–338. [Google Scholar] [CrossRef]

- Aktas, M.; Khanlari, A.; Akteli, B.; Amini, A. Analysis of a new drying chamber for heat pump mint leaves dryer. Int. J. Hydrogen Energy 2017, 42, 18034–18044. [Google Scholar] [CrossRef]

- Şevik, S. Experimental investigation of a new design solar-heat pump dryer under the different climatic conditions and drying behavior of selected products. Sol. Energy 2014, 105, 190–205. [Google Scholar] [CrossRef]

- Siemens STAR-CCM+ DOCUMENTATION; Siemens: New York, NY, USA, 2015.

- Incropera, F.P.; DeWitt, D.P.; Bergman, T.L.; Lavine, A.S. Fundamentals of Heat and Mass Transfer, 7th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Viviescas Pico, P.D.; Valdés Ujueta, J.P. Experimental and CFD Modelling of the Drift Flux in Two-Phase Air-(non)Newtonian Slug-Flow Pattern Flow along Horizontal and Inclined Pipelines; Universidad de los Andes: Bogotá, Colombia, 2017. [Google Scholar]

- Gómez-Daza, J.C.; Ochoa-Martinez, C.I. Effect of turbulence model for simulating the drying of carrots slices. In Proceedings of the International Conference Science & Technology of Drying 2014, Lyon, France, 24–27 August 2014. [Google Scholar]

- Launder, B.E.; Spalding, D.B. Lectures in Mathematical Models of Turbulence; Academic Press: London, UK, 1972. [Google Scholar]

- Markatos, N.C. The mathematical modelling of turbulent flows. Appl. Math. Model. 1986, 10, 190–220. [Google Scholar] [CrossRef]

- Siemens PLM Software STAR-CCM+® Online Manual; Siemens: Munich, Germany, 2018.

- Mathioulakis, E.; Karathanos, V.T.; Belessiotis, V.G. Simulation of air movement in a dryer by computational fluid dynamics: Application for the drying of fruits. J. Food Eng. 1998, 36, 183–200. [Google Scholar] [CrossRef]

- Amanlou, Y.; Zomorodian, A. Applying CFD for designing a new fruit cabinet dryer. J. Food Eng. 2010, 101, 8–15. [Google Scholar] [CrossRef]

- Mulet, A.; Berna, A.; Borr, M.; Pinaga, F. Effect of Air Flow Rate on Carrot Drying. Dry. Technol. 1987, 5, 245–258. [Google Scholar] [CrossRef]

| Researchers | Material | Year | Ta (°C) | HR (%) | Vel (m/s) | Other variables | Dependent variables | Refrigerant | |

|---|---|---|---|---|---|---|---|---|---|

| Vasquez et al. | Grape | 1997 | 50 | 3 | Pretto | Kinetics | 134a | Cinética | |

| Prasertsan et al. | Banana ABB | 1998 | 50–60 | MER, SMER, COP | R-22 | MER, SMER, COP | |||

| Rahman et al | Green peas | 1998 | 25–60 | 20–60 | 1.5 | Kinetics, isotherms | Cinética, isotermas | ||

| Chua et al. | Guava | 2000 | var. Cyclic | 20–65 | 2.5 | Moisture content, ascorbic acid | Contenido humedad, ácido ascórbico | ||

| Chua et al. | Banana, guava, potato | 2000a | 20–40 | 20–65 | 2.5 | Kinetics, color variation | Cinética, variacion color | ||

| Chua et al. | Banana, guava | 2002b | 25, 30, 40 | 2.5 | t-cycle | Drying time, color | Tiempo secado, color | ||

| Tia et al. | Pineapple, banana, bean, cabbage | 2000 | 45–55 | t, flow | DR, MER, SMER, SEC, COP | R-22 | DR, MER, SMER, SEC, COP | ||

| Achariyaviriya et al. | Papaya | 2000 | fracc-rec | DR, SMER | DR, SMER | ||||

| Alves-Filho | Fruits and vegetables | 2002 | 20–30 | 0.5–1.5 | Kinetics, color, law, size, density | CO2 | Cinética, color, law, tamano, densidad | ||

| Cardona et al. | Lactic acid bacteria | 2002 | 10, 15, 20, 25 | 1.71 | medium | Viability, activity | Viabilidad, actividad | ||

| Teeboonma et al. | Papaya, mango glaze | 2003 | 45–55 | kg/h air | Optimization: Minimum annual cost | R-22 | Optimización: Minimo costo anual | ||

| Hawlader et al. | Food grains | 2003 | COP | R11-R12 | COP | ||||

| Hawlader et al. | Ginger | 2006a | 45 | 10 | 0.7 | atm-mod | Gingerol loss | Pérdida gingerol | |

| Hawlader et al. | Apple, guava, potato | 2006b | 45 | 10 | 0.7 | atm-mod | Color, porosity, rehydration, texture | Color, porosidad, rehidratación, textura | |

| Hawlader et al. | Guava, papaya | 2006c | 45 | 10 | 0.7 | atm-mod | Color, porosity, rehydration, text, Vit C | Color, porosidad, rehidrat, text, Vit C | |

| Ortiz | Banana | 2003 | 10, 60 | 2 | Color, aw, drying time, moisture | R-22 | Color, aw, tiempo secado, humedad | ||

| Sosle et al. | Apple | 2003 | 45–65 | 30–50 | Rehydration time, SEC, SMER | R-22 | Tiempo rehidratación, SEC, SMER | ||

| Kohayakawa et al. | Sliced mango | 2004 | 40, 46, 56 | 1.6–4.4 | thickness | Effective diffusivity, COP | R-22 | Difusividad efectiva, COP | |

| Queiroz et al. | Tomatoes | 2004 | 40, 45, 50 | 1.5–2 | type | Kinetics | R-22 | Cinética | |

| Moreira et al. | Chestnut | 2005 | 45, 55, 65 | 20–40 | 1.8–2.7 | Kinetic Modeling | Modelamiento Cinética | ||

| Sun et al. | Potato | 2005 | 45 | 20 | 1.7 | type of heat | Drying speed, temperature profile | Velocidad secado, perfil temperatura | |

| Fatouh et al | Corcholo, herb, parsley | 2006 | 45, 50, 55 | 1.2, 1.9, 2.7 | size | SEC, drying characteristics | 134a | SEC, caracteristicas secado | |

| Ceylan et al. | Kiwi, avocado, banana | 2007 | 40 | 0.03–0.39 | MR, DR | MR, DR | |||

| Sunthonvit et al. | Nectarines | 2007 | 25 | 10 | 1.6 | Volatile compound composition | Composición compuestos volátiles | ||

| Xanthopoulos et al. | Fig | 2007 | 46–60 | 1, 5 | Single layer drying models | R-22 | Modelos secado capa única | ||

| Ceylan y Aktas | Hazelnut | 2008 | 40, 45, 50 | Time, air speed | Tiempo, velocidad aire | ||||

| Shi et al. | Tuna | 2008 | 10, 40 | 1, 4 | load | Colour, SMER | 134a | Color, SMER | |

| Shi et al. | Tuna | 2008a | 20–30 | 1.5–2.5 | %NaC1 | SMER, DR, color, TVBN | 134a | SMER, DR, color, TVBN | |

| Alves-Filho et al. | Isolated protein | 2008 | −5, 25 | 1, 2.3 | time | MRR, color, density, shrinkage | MRR, color, densidad, encogimiento | ||

| Aktas et al. | Apple | 2009 | t, load | Effective diffusivity, COP, DR | Difusividad efectiva, COP, DR | ||||

| Erbay YIcier | Olive leaves | 2009 | 45–55 | 0.5–1.5 | time | Phenolic content, antioxidant act., hum | R407C | Contenido fenólico, act. antioxid, hum | |

| Lee and Kim | Radish | 2009 | 40 | flow | Time, MER, SMER, energy saving | 134a | Tiempo, MER, SMER, ahorro energia |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Daza-Gómez, M.A.M.; Gómez Velasco, C.A.; Gómez Daza, J.C.; Ratkovich, N. 3D Computational Fluid Dynamics Analysis of a Convective Drying Chamber. Processes 2022, 10, 2721. https://doi.org/10.3390/pr10122721

Daza-Gómez MAM, Gómez Velasco CA, Gómez Daza JC, Ratkovich N. 3D Computational Fluid Dynamics Analysis of a Convective Drying Chamber. Processes. 2022; 10(12):2721. https://doi.org/10.3390/pr10122721

Chicago/Turabian StyleDaza-Gómez, Miguel Andrés Mauricio, Carlos Andrés Gómez Velasco, Juan Carlos Gómez Daza, and Nicolás Ratkovich. 2022. "3D Computational Fluid Dynamics Analysis of a Convective Drying Chamber" Processes 10, no. 12: 2721. https://doi.org/10.3390/pr10122721

APA StyleDaza-Gómez, M. A. M., Gómez Velasco, C. A., Gómez Daza, J. C., & Ratkovich, N. (2022). 3D Computational Fluid Dynamics Analysis of a Convective Drying Chamber. Processes, 10(12), 2721. https://doi.org/10.3390/pr10122721