Abstract

Mechanical damage is a threat to both food security and sustainability. Bruising is the most common type of mechanical damage, and it causes a huge economic loss due to rejection of fresh produce and downgrading of the appearance quality by consumers. Therefore, this study aims to examine the effect of bruising during postharvest handling using a pendulum test technique. Pomegranate fruit were bruised once at two impact levels (1.189 ± 0.109 and 2.298 ± 0.239 J) and then stored (at 5 °C ± 1 °C and 22 °C ± 1 °C) for 28 days. The study evaluated the effect of impact bruising, storage temperature, and duration on the bruise magnitude and quality attributes of the bruised and non-bruised pomegranates. The results showed that the investigated factors affect the bruise size of bruised pomegranates. Increasing storage temperature from 5 to 22 °C and impact level from 1.189 to 2.298 J increased the bruise area, bruise volume, and bruise susceptibility over time. Alterations in total soluble solids (TSS) and titratable acidity (TA%) were statistically (p < 0.05) induced by bruising, particularly at a high impact. The total soluble solids (TSS) content was reduced in all tested pomegranate fruit (bruised and non-bruised) and recorded the highest percentage decline in those impacted at a high level and stored at 22 °C, at 16.81%. The combination of both studied factors did not affect the water activity (Aw) of aril or the mesocarp of bruised or non-bruised fruit. Bruising parameters and quality attributes were strongly correlated in this study, excluding water activity (Aw). The regression models showed a good determination coefficient (R2) between the predicted and measured values of bruise susceptibility (BS), total soluble solids (TSS), titratable acidity (TA%), and sugar: acid ratio (TSS:TA). The study demonstrates that bruising at a high impact level and long-term storage both affected the susceptibility of pomegranates to bruise, and altered fruit quality. Thus, these factors need to be considered during the postharvest supply chain.

1. Introduction

The occurrence of postharvest losses in the fresh fruits and vegetables supply chain is a global concern facing food sustainability and security. These losses can occur during supply chain phases such as harvesting, storing, handling, packaging, transporting, etc. Mechanical damage caused by inadequate practices is one of the most common quality challenges to fresh fruits and vegetables during handling and other postharvest stages [1,2]. Mechanical damages to fresh produce can lead to considerable market and economic losses due to declining quality and extreme food safety concerns [3]. Bruising is the most common form of mechanical damage. Bruising, which mostly occurs during postharvest handling, is most commonly attributed to abrasion, compression, cutting, and impact forces [4]. Impact bruising can occur as a result of rough or improper handling, poorly designed equipment, improper packaging, or insufficient supervision during fruit handling [5]. Bruising occurs due to serious external forces on the surface of the fruit, which occur frequently when fruit hit rigid surfaces or other fruit during handling, as described by Stropek and Gołacki [6]. Pathare and Al-Dairi [3] stated that bruising is considered a failure of the subcutaneous tissue of the damaged fruit and vegetables, which does not rapture the external skin and causes an obvious discoloration in the injured spot. Bruising is caused by a loss of cell wall integrity and a subsequent decrease in peel resistance to mechanical damage. Pathare and Al-Dairi [7] stated that bruising is distinguished by unsightly marks (brownish to black) and that the symptoms manifest in the epidermal layer of a banana peel.

Earlier studies have indicated that bruising can influence the external and internal quality attributes of fruit. Opara and Pathare [8] reviewed that bruising has been shown to affect metabolic processes (ethylene production, transpiration, and electrical conductivity) as well as other biological processes (microbial spoilage), reducing shelf life and increasing fruit postharvest losses. Hussein et al. [9] recorded multiple changes in total titratable acidity (TA) and soluble solids (TSS) due to bruising on fruit. Similarly, impact bruising accelerated the lycopene, carotenoids, and color alteration of tomatoes during storage. Bruising can also modify physiological processes and expedite browning, ripening, and other quality characteristics. Additionally, Al-Dairi et al. [10] found that bruising accelerated firmness reduction and increased color changes of bananas over 12 days of storage. Impact damage generated by drop tests of different heights adversely affect the firmness status, weight, respiration rate, and ethylene production rate of pomegranate fruit, as reported by Pathare et al. [11]. Bruise damage reduces fresh produce quality, causing significant postharvest and economic losses. Bruise-induced wounds in fruit trigger higher rates of metabolism and increased moisture loss. Weight loss, total soluble solids, respiration rate, and ethylene production were highly altered by changes in drop height and other factors, such as storage temperature rise [12]. Storage is another important factor that affects the bruise intensity and quality of the fruit. Storage can increase bruising incidence in fresh produce, particularly at higher temperatures [3]. The impact strength of bruising showed higher effects on the bruise area (BA), bruise volume (BV), and total soluble solids (TSS) of banana fruit than storage temperature [7]. In another study, storage temperature and duration had much more effect on the quality of bananas than impact damage [10].

The severity of a bruise can be expressed in terms of bruise diameter, area, and volume. Bruise diameter and depth are considered to be the key measurements used to determine bruise size [7]. For direct measurements of bruise size, bruise diameter and bruise depth can be used [8]. To study the effect of mechanical damage, such as bruising, on several agricultural products at a laboratory scale, the drop test [13,14] and the pendulum test have been employed [15,16].

Like many other fruits, pomegranate is highly susceptible to mechanical damages, including bruising, that result from inappropriate handling, packaging, excessive loading, etc. [17]. Pomegranate fruit is categorized by its hard exocarp; however, the extreme use of mechanical equipment and improper handling practices can make the fruit more susceptible to damage and bruising [18]. Therefore, this study assesses the effect of mechanical damage (impact/bruising), using the pendulum test, on the quality attributes (total soluble solids (TSS), titratable acidity (TA%), sugar:acid ratio (TSS:TA), BrimA, pH, and water activity (Aw)) of pomegranate fruit stored for 28 days at 5 or 22 °C, which has not been attempted before.

2. Materials and Methods

2.1. Pomegranate Material

Pomegranate fruit (cv. Helow) were harvested from Al-Jabal Al-Akhdar, Ad-Dakhliyah Governate, Oman. The fruit were directly transported to Postharvest Technology Laboratory, Sultan Qaboos University, Oman, in two hours. Pomegranate fruit were handily washed and cleaned with normal water. A total of 63 pomegranate fruit weighing 0.456 ± 0.033 kg with no visible injuries or damages were chosen for the impact simulation and storage study.

2.2. Fruit Impact Simulation and Storage

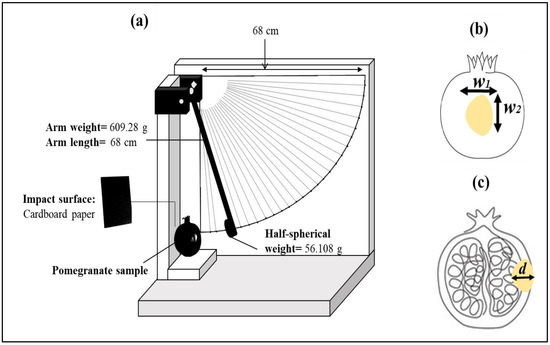

For the impact test, samples consisting of 40 pomegranates were damaged using the pendulum test, (Figure 1a) which allows better control and observation of the falling weight during testing when compared to the drop impact test, as stated by Opara et al. [19]. The pendulum test used in the current study consisted of a pendulum arm with a mass and length of 0.609 kg and 0.68 m, respectively, and a half-spherical weight with 0.056 kg mass connected to the arm of the pendulum that directly damaged the desired pomegranate fruit. The pendulum test was carried out by raising the arm that held the weight to the required angle and then releasing once to hit the pomegranate sample (cheek sides), as shown in Figure 1a. To create two different energy levels, the pomegranate fruit were hit by the half-spherical weight from an angle of 65° and 45°, representing high and low impact levels, respectively. The arm was caught by hand after each initial rebound to avoid multiple impacts, and a marker was used to mark the bruised region for further bruise recognition. The whiteboard with the graduated scale illustrated in Figure 1a was employed to read the initial rebound angle. A camera (Model: EOS FF0D, Canon Inc., Tokyo, Japan) was also used to capture the exact reading of the rebound angle. The absorbed energy was deduced from the difference between energies at both impacts and the rebound, using Equation (1) [5]. The absorbed energy for low (45°) and high (65°) impact levels were 1.189 ± 0.109 J and 2.298 ± 0.239 J, respectively.

where Ea is the absorbed energy, m is the steel ball’s mass, g is the gravitational constant (9.81 ms−2), h1 is the equivalent drop height, and h2 is the equivalent rebound height.

Figure 1.

The pendulum test setup (a), bruised pomegranate fruit with bruise diameter indicated (w1 and w2) (b), and sliced pomegranate fruit showing the bruise depth (d) (c).

The center of the bruised region (marked area) of each damaged pomegranate fruit was sliced for bruise identification. The digital caliper (Model: Mitutoyo, Mitutoyo Corp., Kawasaki, Japan) was used to measure the major (w1) and minor (w2) diameters of the bruised region (Figure 1b), and the bruise depth (d) (Figure 1c). The findings of the bruise measurements were expressed as bruise area (BA-mm2) (Equation (2), bruise volume (BV-mm3) (Equation (3), bruise susceptibility (BS-mm3/J) (Equation (4), and specific bruise susceptibility (SBS-mm3J−1g−1) (Equation (5), as follow [12]:

where mf is the pomegranate fruit’s mass.

A total of 20 pomegranate fruit were assigned as control (non-bruised) samples. After the impact simulation test, the high impact, low impact, and control pomegranate groups, which consisted of 20 samples each, were divided equally and stored at 5 °C ± 1 °C (90% RH) or 22 °C ± 1 °C (69% RH). In this study, the total number of groups (treatments) was 6. A total of 2 pomegranate samples were used per group (treatment) per day. Different quality analysis, including total soluble solids (TSS), titratable acidity (TA%), sugar:acid ratio (TSS:TA), BrimA, pH, and water activity (Aw) of arils and mesocarp, were tested to investigate the effects of bruising and storage temperature on pomegranate fruit after 3, 7, 14, 21, and 28 days of impact. Additionally, 3 of the pomegranate fruit were analyzed before impact and storage (Day 0 analysis).

2.3. Chemical Analysis: Total Soluble Solids (TSS), Titratable Acidity (TA%), Sugar:Acid Ratio (TSS:TA), BrimA, and pH

To obtain the pomegranate juice, the arils of two fruit per treatment were squeezed thoroughly through cheesecloth using a hand press. The total soluble solids (TSS) content was determined by dropping a few drops of the pomegranate juice in the prism of a handheld digital refractometer (Model: PR-32 α, ATAGO Co., Ltd., Tokyo, Japan) [20]. A total of six readings were taken and expressed as Brix° per two replicates per treatment. The titratable acidity (TA%) was measured by titrating 10 mL of the prepared pomegranate juice with 0.1 N NaOH (to a pH of 8.1) [21]. The TA% was expressed as a percentage of citric acid and calculated as follows (Equation (6)) [22]:

where 0.064 is the citric acid milliequivalent factor.

The pH of the pomegranate juice was measured using an electronic pH meter (Model: EUTECH Cyberscan pH 11, Singapore). The balance between the sourness and sweetness of pomegranate juice was determined using the TSS:TA ratio and BrimA, which have been recorded to affect the acceptability of the consumers. BrimA was calculated by following Equation (7) [23].

where k is a constant within a range of 2–10 (based on acid and sugar proportions). The k value of 2 was applied to avoid a negative BrimA value.

BrimA = Brix-k × TA

2.4. Water Activity (Aw)

At 0, 3, 7, 14, 21, and 28 days of storage, the water activity (Aw) of arils and mesocarp fractions of non-bruised and bruised pomegranate fruit stored under both conditions were measured using a water activity meter (Model: 10’972, HygroLab C1, Rotronic, Bassersdorf, Switzerland) calibrated in the water activity (Aw) range of 0.45–0.95. The fruit were cut using a knife in order to separate the arils from the thin white membrane. A sharp blade was used to separate the inner peel fraction (mesocarp) from the outer peel fraction (epicarp) [24].

2.5. Statistical Analysis

Analysis of variance (ANOVA) was performed at a 95% confidence interval using SPSS 20.0 (International Business Machine Crop., Armonk, NY, USA) software to assess the influence of impact level (bruising), storage temperature, and storage duration, as well as their interaction, on the bruise measurements (bruise area (BA), bruise volume (BV), bruise susceptibility (BS), specific bruise susceptibility (SBS)), chemical quality attributes (total soluble solids (TSS), titratable acidity (TA%), sugar:acid ratio (TSS:TA), BrimA, and pH), and water activity (Aw) of the pomegranate fruit. To evaluate the relationship among pomegranate fruit parameters, the Pearson correlation coefficient and scatter plot matrix were employed.

3. Results and Discussions

3.1. Bruise Parameters

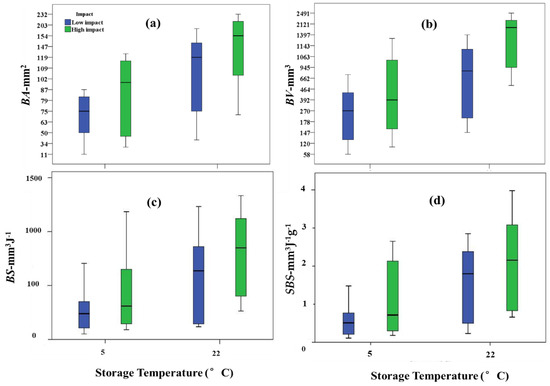

The average bruise size measurements (BA and BV) after 28 days calculated for low- and high-impact bruised pomegranate fruit stored under both storage conditions are shown in Figure 2a,b. The bruise area (BA-mm2) and bruise volume (BV-mm3) of pomegranate fruit increased until the last day of storage, and they were highly affected by impact level, storage temperature, and storage duration, as well as by these factors’ interaction (p < 0.05) (Table 1). On the last day of the experiment, the highest average value of BA and BV was observed in high-impact (2.29 J) bruised pomegranate fruit, followed by low-impact (1.18 J) pomegranate fruit, both stored at ambient temperature (22 °C). The BA and BV values of high-impact bruised pomegranate fruit stored at ambient temperature were 226.61 mm2 and 2447.51 mm3, respectively. The lowest recorded BA (88.10 mm2) and BV (663.90 mm3) values after 28 days of storage at 5 °C were observed on low-impact bruised pomegranate fruit.

Figure 2.

Bruise area (BA) (a), bruise volume (BV) (b), bruise susceptibility (BS) (c), and specific bruise susceptibility (SBS) (d) of pomegranate fruit impacted at different impact angles (45°, 1.18 J; and 65°, 2.29 J) and stored at 5 °C and 22 °C after 28 days of storage. The data are presented in box plots. Error bars represent the SD of the mean values of two readings per group (treatment).

Table 1.

The statistical analysis of bruise area (BA), bruise volume (BV), bruise susceptibility (BS), specific bruise sensitivity (SBS), total soluble solids (TSS), titratable acidity (TA%), sugar:acid ratio (TSS:TA), BrimA, pH, and water activity (Aw) (arils and mesocarp) of non-bruised, low- (45°; 1.18 J), and high-impact (65°; 2.29 J) bruised pomegranate fruit over 28 days stored at 5 °C and 22 °C. Data were subjected to a three-way analysis of variance (ANOVA) (Factor A: impact level, Factor B: storage temperature, Factor C: storage duration). * Significant at p ≤ 0.05; df = degree of freedom.

With increasing impact levels and storage temperatures, bruise susceptibility (BS-mm3 J−1) increased (Figure 2c). A similar scenario was observed with BS, which showed significant correlation with all investigated factors (p < 0.05) (Table 1). Increasing the impact level from 1.18 J to 2.29 J increased the BS of bruised pomegranate fruit for both storage conditions. On Day 28, the pomegranate fruit stored at ambient temperature and bruised using a 65° angle (high impact level) and 45° (low impact level) showed an increment in BS, with values of 1254.93 mm3 J−1 and 1139.34 mm3 J−1, respectively. Storage at 5 °C delayed bruising incidence and severity in low- and high-impact bruised pomegranate fruit.

The specific bruise susceptibility (SBS-mm3 J−1 g−1) of pomegranate fruit followed the trends of BA, BV, and BS for all drop impact levels, as shown by its sharp increase during the experiment, particularly at an ambient temperature (Figure 2d). As shown in Table 1, the impact level, storage temperature, and storage duration statistically affected (p < 0.05) the SBS of the pomegranate fruit. The value of SBS was expectedly higher in bruised pomegranate fruit in the high impact group (2.29 J) than that of fruit in the low impact group (1.18 J) at both storage conditions. This study indicates that temperature and impact level are key, sensitive factors regarding bruising after a long storage period.

Increased bruise size (BA, BV, BS, and SBS) on a bruised pomegranate fruit during a storage period could result in a reduction in turgor pressure [25]. Pomegranate fruit contain a high amount of water which directly affects the turgidity and softness of fruit tissues and leads to reduced strength because of the continuous loss in moisture content during storage, particularly at ambient temperatures [26]. Additionally, Ahmadi [27] stated that storage temperature conditions affected the viscosity and strength of the cell wall of the fruit. He also indicated that storage at higher temperatures can increase the occurrence of bruising in fresh fruit and vegetables, which is attributed to more active enzymes, resulting in cell wall degradation and stiffness. Opara and Pathare [8] confirmed that the BV is strongly correlated with the impact energy level. Shafie et al. [17] found that the BV of damaged pomegranate fruit was preliminarily determined by the impact energy level. Additionally, Tabatabaekoloor [28] found that by dropping fruit from the highest height, more energy can be produced; therefore, accelerating the intensity of the damage resulted in a higher BA. The results of this study are in accordance with the results observed by Hussein et al. [12]. They recorded 18.60% increase in the BA of impacted pomegranate fruit when the level of the impact increased from 40 to 60 cm. Pathare and Al-Dairi [3] experienced a significant interaction between impact level (drop height), storage temperature, and storage duration with BV and BA values of pear fruit within 14 days of storage.

3.2. Chemical Quality Attributes: Total Soluble Solids (TSS), Titratable Acidity (TA%), Sugar:Acid Ratio (TSS:TA), BrimA, and pH

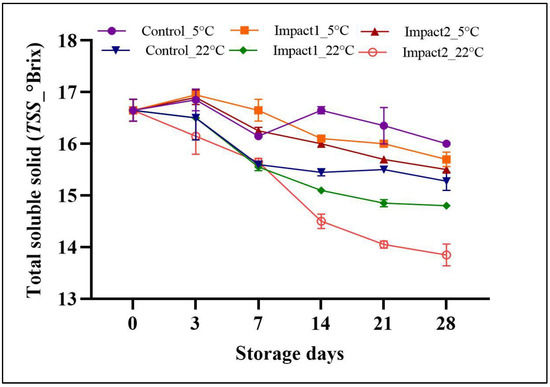

The total soluble solids (TSS) value was affected by impact level/bruising (p = 0.02785), storage temperature (p = 0.00973), and storage duration (p = 0.02248) (Table 1). The overall TSS values ranged from 13.35 to 16.65 Brix° (Figure 3). Over the duration of storage, the TSS values fell in all bruised and non-bruised samples stored at both temperatures. High-impact (65° angle, 2.29 J) bruised pomegranate fruit recorded the lowest TSS value on Day 28, particularly in those stored at ambient temperature. The TSS values fell by 8.25%, 11.11%, and 16.81% in non-bruised (control), low-impact, and high-impact bruised pomegranates stored at 22 °C, respectively. Storage at the cold temperature (5 °C) showed lower percentage reduction in TSS value for non-bruised (control), low-impact, and high-impact bruised pomegranates, with values of 3.90%, 5.70%, and 6.90%, respectively. The overall decline in the TSS values of bruised and non-bruised fruit during storage could be attributed to sugar consumption during the process of respiration, and extreme loss in moisture content. Loss of moisture was also evident in this study, yet a decrease in TSS content was detected. The large reduction in TSS content observed for high-impact bruised pomegranates was due to the depletion of sugar as substrates during the high respiratory activity of mechanically/stressed bruised pomegranate fruit [12]. Additionally, Fawole and Opara [29] stated that the reduction in TSS observed could be due to sugar degradation with prolonged storage duration.

Figure 3.

Total soluble solids (TSS) of non-bruised, low-impact (45°; 1.18 J), and high-impact (65°; 2.29 J) bruised fruit over 28 days of storage at 5 °C and 22 °C. Error bars represent the SD of the mean values of six readings per group (treatment).

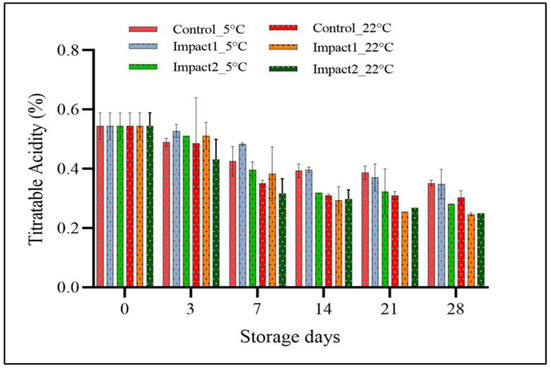

Figure 4 shows the titratable acidity (TA%) of bruised and non-bruised pomegranate fruit stored under both conditions. The TA% was lower in all pomegranate fruit after storage compared to the initial TA% on Day 0 of the experiment. Significant effects on the TA% of pomegranate fruit were recorded due to the drop impact (p = 0.00435), storage temperature (p = 0.00036), and storage duration (p = 0.00048) (Table 1). After 28 days of storage following the pendulum impact test, high- and low-impact bruised pomegranate fruit stored at ambient temperature showed the lowest TA% of 0.24%. The non-bruised pomegranate fruit stored at 5 °C recorded the highest TA% (0.35%) compared to other pomegranate fruit on the last day of storage. The observed reduction in TA% (citric acid) could be attributed to the reparation activity in the pomegranate fruit during the days of storage, where organic acids are consumed more during the process of respiration [12] which was greatly observed in the mechanically damaged fruits. Fawole and Opara [29] reported a significant decline in pomegranates stored at 5, 7, 10, and 22 °C over time, which could be related to ongoing metabolic processes in the pomegranate fruit (non-climacteric fruit) during storage, particularly at 22 °C. Consistent with this study’s findings, previous studies reported a decrease in TSS and TA% in pomegranate fruit compared to the initial value as storage duration increased, which was due to acid and sugar utilization by pomegranate fruit during their respiration process [30,31].

Figure 4.

Titratable acidity (TA%) of non-bruised, low-impact (45°; 1.18 J), and high-impact (65°; 2.29 J) bruised fruit over 28 days of storage at 5 °C and 22 °C. Error bars represent the SD of the mean values of six readings per group (treatment).

Reductions in TSS and TA% during storage in all bruised and non-bruised pomegranate fruit stored at both temperature conditions resulted in a significant increase in TSS:TA ratios (Table 2). The statistical analysis presented in Table 1 shows that impact level (p = 0.04446), storage temperature (p = 0.01227), and storage duration (p = 0.00484) all had significant influence on TSS:TA ratios. The highest TSS:TA ratio was found in low- and high-impact bruised pomegranate stored in ambient conditions, while the lowest value was observed in the non-bruised pomegranate fruit stored at a cold temperature. Furthermore, changes in TSS and TA% resulted in a significant reduction (p < 0.05) in BrimA, mainly due to storage temperature and impact bruising, which particularly impacted the bruised pomegranate samples stored at an ambient temperature (Table 1). The BrimA of control (non-bruised), low-impact, and high-impact bruised pomegranate fruit stored at 5 °C reduced by 1.70, 3.59, and 4.01%, respectively. However, the BrimA declined severely by 5.75, 8.06, and 14.20% for control (non-bruised), low-impact, and high-impact bruised pomegranate fruit stored at an ambient temperature (Table 2). Our results are contrary to Arendse et al. [32] and Lufu et al. [23], who reported increases in BrimA during the storage period. Our results are comparable with the findings of Fawole and Opara [29], who observed an increment in the TSS:TA ratio and a reduction in BrimA, primarily due to storage, in the investigated pomegranate samples. The effects of impact level (p = 0.06333), storage duration (p = 0.00050), and storage temperature (p = 0.52400) on the pH of pomegranate fruit are shown in Table 1. The pH value fell after 7 days of impact in all bruised and non-bruised pomegranate fruit. It then followed a fluctuating trend until the last day of storage, except for pomegranate fruit bruised at the highest impact level and stored at a low temperature (Table 2).

Table 2.

Sugar:acid ratio (TSS:TA), BrimA, and pH of non-bruised, low-impact (45°; 1.18 J), and high-impact (65°; 2.29 J) bruised pomegranate fruit over 28 days of storage at 5 °C and 22 °C. The values are presented as standard deviation (SD) of the mean values of six readings per two replicates of each group (treatment).

3.3. Water Activity (Aw)

The water activity (Aw) of different pomegranate fruit fractions were statistically not affected by impact level or storage duration (p > 0.05). The Aw of the outer part of the fruit (mesocarp) was affected by the storage temperature (p = 0.03930); however, the inner part (arils) was not (p > 0.05), as is shown in Table 1. The average values of the Aw of both the arils and mesocarp of pomegranates are presented in Table 3. The Aw of the pomegranate fruits’ arils and mesocarp in the control, low-impact, and high-impact groups stored at both conditions ranged from 0.920 to 0.958 and 0.909 to 0.952 for the arils and mesocarp, respectively. The results show that the average Aw was usually higher in the arils compared to the mesocarp of the fruit. This implies that the water moves from the inside of the pomegranate fruit to the outside part (or the surrounding) [24]. Additionally, Caleb et al. [33] recorded a higher Aw of 0.984 for pomegranate arils stored at different temperature conditions (5, 10, and 15 °C). On pear fruit, Xanthopoulos et al. [34] found a relatively low value of Aw (0.924) when fruit was stored at 20 °C.

Table 3.

Water activity (Aw) of arils and mesocarp fractions of non-bruised, low-impact (45°; 1.18 J), and high-impact (65°; 2.29 J) bruised pomegranate fruit over 28 days of storage at 5 °C and 22 °C. The values are presented as standard deviation (SD) of the mean values of six readings per two replicates of each group (treatment).

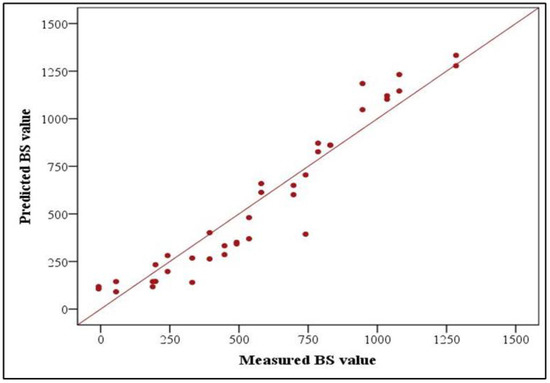

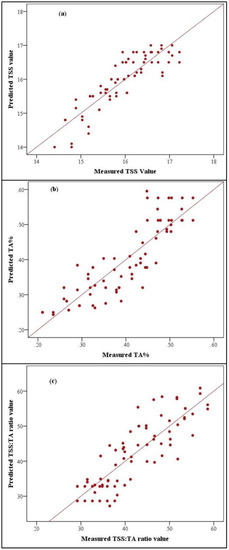

3.4. Multiple Linear Regression Models, with Impact Level, Storage Temperature, and Storage Duration as the Main Independent Variables

In this study, the independent variables had significant effects on some dependent variables. Therefore, multiple regression was employed to predict the dependent variables [35]. Four multiple linear regression models were performed to study the effects of the independent variables (impact level, storage temperature, and storage duration) on the dependent variables (bruise susceptibility (BS), total soluble solids (TSS), titratable acidity (TA%), and sugar:acid ratio (TSS:TA)) at a 5% significance level. Additionally, coefficient determination (R2) was recorded to identify the accuracy of each model. Table 4 shows the equations of the four multiple linear regression models. The first model shown in Table 4 indicated the final BS, which includes all independent variables. Figure 5 presents the plot of predicted BS versus measured BS. A strong fit and correlation (R2 = 0.91) were observed between the measured BS values and the predicted BS values (Table 4). Figure 6a–c present the predicted total soluble solids (TSS), titratable acidity (TA%), and sugar:acid ratio (TSS:TA) plotted against the measured TSS, TA%, and TSS:TA, respectively, in relation to the independent variables. As shown in Table 4, good fits with determination coefficients (R2) of 0.77, 0.75, and 0.84 were observed for Model 2 (predicted TSS versus measured TSS), Model 3 (predicted TA% versus measured TA%), and Model 4 (predicted TSS:TA versus measured TSS:TA), respectively.

Table 4.

Linear regression equations of dependent variables (bruise susceptibility (BS), total soluble solids (TSS), titratable acidity (TA%), and sugar:acid ratio (TSS:TA)) in relation to the independent variables, which include impact level (IL), storage temperature (ST), and storage duration (SD).

Figure 5.

Results for the prediction of bruise susceptibility (BS) values based on the linear regression model. Predicted BS versus measured BS (Model 1).

Figure 6.

Results for the prediction of total soluble solids (TSS) (a), titratable acidity (TA%) (b), and sugar:acid ratio (TSS:TA) (c) values based on a linear regression model. Predicted TSS versus measured TSS (Model 2). Predicted TA versus measured TA (Model 3). Predicted TSS:TA versus measured TSS:TA (Model 4).

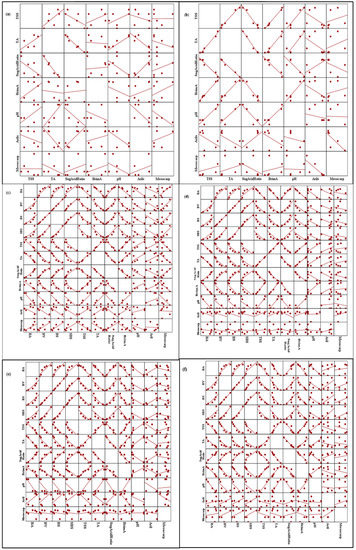

3.5. Pearson Correlation

The Pearson correlation test was applied to determine the correlation between the investigated quality attributes of non-bruised, low-impact (1.18 J), and high-impact (2.29 J) bruised pomegranate fruit over 28 days of storage at 5 °C and 22 °C, which were indicated as *, p < 0.05 and **, p < 0.001 (Table 5). Figure 7 shows a scatter plot matrix that presents the correlation between the quality attributes. In the high- and low-impact bruised pomegranate fruit stored at both temperatures, a significant positive correlation was observed between bruise area (BA) and bruise volume (BV) (r = 0.878), bruise susceptibility (BS) (r = 0.882), specific bruise susceptibility (SBS) (r = 0.785), and sugar: acid ratio (TSS:TA) (r ≥ 0.950). Meanwhile, bruise area (BA) displayed a strong negative correlation with total soluble solids (TSS) (r ≥ −0.875), titratable acidity (TA) (r ≥ −0.969), and pH (r ≥ −0.894). However, bruise area (BA) demonstrated a weak correlation with the water activity (Aw) of both aril (r ≤ 0.641) and mesocarp (r ≤ 0.667). Similar results were obtained between BV, BS, and SBS and other measured variables/parameters.

Table 5.

Pearson correlation coefficients (r) between the BA, bruise volume (BV), bruise susceptibility (BS), specific bruise sensitivity (SBS), total soluble solids (TSS), titratable acidity (TA), sugar:acid ratio (TSS:TA), BrimA, pH, and water activity (Aw) (arils and mesocarp) of non-bruised, low-impact (45°; 1.18 J), and high-impact (65°; 2.29 J) bruised pomegranate fruit over 28 days of storage at 5 °C and 22 °C. Significant correlations of two-tailed tests are indicated: *, p < 0.05; **, p < 0.001. IL; impact level, ST; storage temperature.

Figure 7.

The correlation between resulting parameters of the non-bruised, low-impact (45°; 1.18 J), and high-impact (65°; 2.29 J) bruised pomegranate fruit over 28 days of storage at 5 °C and 22 °C using a scatter plot matrix.

A very strong and significant correlation (r = 1) was observed between the BV and BS of low- and high-impact bruised pomegranate stored at both temperatures. In all pomegranate fruit across all tested conditions, the TSS showed a significant correlation with TA, TSS:TA ratio, pH, and BrimA, except for in the non-bruised (control) samples stored at 5 °C. A significant and negative correlation (r ≥ 0.983) existed between TA and TSS:TA ratio across all tested conditions. TA and BrimA showed a good correlation (r ≥ 0.858); however, this relationship was very weak (r = −0.088) for the control fruit in cold storage. As shown in Table 4, a very weak correlation was observed between TSS:TA ratio and BrimA (r = 0.091) for control pomegranates stored at 5 °C. Furthermore, Figure 7 shows that TSS:TA ratio was strongly correlated with BrimA (r ≥ 0.860). A moderate correlation was noticed between TSS:TA ratio and pH in control pomegranate fruits stored at 5 °C (r = −0.700), and in low-impact pomegranate fruits stored at 5 °C (r = −0.785) and 22 °C (r = −0.790). Other attributes, such as the Aw of aril and mesocarp fractions, did not correlate with any of the investigated quality characteristics. Therefore, it seems that water activity (Aw) was not significantly affected by the external factors used in the current study. Few studies have discussed the correlation between bruising parameters and quality attributes. However, Pathare and Al-Dairi [35] found that the BA of all impacted tomato fruit stored at 10 and 22 °C showed a strong positive correlation (**, p < 0.01, *, p < 0.05) with TSS (r ≥ 0.916).

4. Conclusions

This study examined the effects of storage temperature, storage duration, and impact damage on the magnitude of bruise size (bruise area (BA), bruise volume (BV), bruise susceptibility (BS), and specific bruise susceptibility (SBS)), and other quality attributes, such as total soluble solids (TSS), titratable acidity (TA%), sugar:acid ratio (TSS:TA), BrimA, pH, and water activity (Aw) (arils and mesocarp). This study showed that over the course of impact bruise damage caused by hitting the pomegranate fruit, storage temperature and storage duration had important direct influence on several quality properties, mainly the chemical attributes, of the damaged fruit. The study revealed bigger changes in bruise size measurements for high-impact (2.29 J) bruised pomegranate fruit compared to low-impact (1.18 J) bruised fruit, particularly when stored at 22 °C. The total soluble solids (TSS) reduced over time, and the lowest value was recorded in high-impact bruised fruit stored at an ambient temperature. Similarly, titratable acidity (TA%) was much lower in bruised fruit compared to the non-bruised (control) fruit. Excessive BrimA percentage loss in high-impact bruised pomegranate fruit reached about 14.12% during storage at an ambient temperature. Due to the continued decline in total soluble solids (TSS) and titratable acidity (TA%), the sugar:acid ratio (TSS:TA) fell for all tested conditions, particularly in the bruised fruit stored at an ambient temperature. The water activity did not change significantly for either the arils or mesocarp of bruised nor non-bruised pomegranates as a result of the studied factors. This study can provide industries and pomegranate fruit producers, handlers, and transporters with proof of the importance of mechanical damage and storage management in the postharvest supply chain.

Author Contributions

P.B.P.: Conceptualization, formal analysis, writing—review and editing, funding acquisition, project administration, and supervision. M.A.-D.: Data curation, formal analysis, and writing—original draft. R.A.-Y.: Supervision, and writing—review and editing. A.A.-M.: Formal analysis, and writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Sultan Qaboos University under the project code: IG/AGR/SWAE/19/03.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Al-Dairi, M.; Pathare, P.B.; Al-Yahyai, R.; Opara, U.L. Mechanical damage of fresh produce in postharvest transportation: Current status and future prospects. Trends Food Sci. Technol. 2022, 124, 195–207. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B.; Al-Yahyai, R. Effect of postharvest transport and storage on color and firmness quality of tomato. Horticulturae 2021, 7, 163. [Google Scholar] [CrossRef]

- Pathare, P.B.; Al-Dairi, M. Bruise susceptibility and impact on quality parameters of pears during storage. Front. Sustain. Food Syst. 2021, 5, 658132. [Google Scholar] [CrossRef]

- Opara, U.L.; Fadiji, T. Compression damage susceptibility of apple fruit packed inside ventilated corrugated paperboard package. Sci. Hortic. 2018, 227, 154–161. [Google Scholar] [CrossRef]

- Polat, R.; Aktas, T.; Ikinci, A. Selected mechanical properties and bruise susceptibility of nectarine fruit. Int. J. Food Prop. 2012, 15, 1369–1380. [Google Scholar] [CrossRef]

- Stropek, Z.; Gołacki, K. A New Method for measuring impact related bruises in fruits. Postharvest Biol. Technol. 2015, 110, 131–139. [Google Scholar] [CrossRef]

- Pathare, P.B.; Al-Dairi, M. Effect of mechanical damage on the quality characteristics of banana fruits during short-term storage. Discov. Food 2022, 2, 4. [Google Scholar] [CrossRef]

- Opara, U.L.; Pathare, P.B. Bruise damage measurement and analysis of fresh horticultural produce—A review. Postharvest Biol. Technol. 2014, 91, 9–24. [Google Scholar] [CrossRef]

- Hussein, Z.; Fawole, O.A.; Opara, U.O. Effects of bruising and storage duration on physiological response and quality attributes of pomegranate fruit. Sci. Hortic. 2020, 267, 109306. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B.; Al-Mahdouri, A. The contribution of impact damage to the quality changes of stored banana fruits. Biol. Life Sci. Forum 2022, 16, 31. [Google Scholar]

- Pathare, P.; Al-Dairi, M.; Al-Yahyai, R.; Al-Mahdouri, A. Effect of impact-bruising and storage on quality physiological changes of Omani pomegranate. Acta Hortic. 2022, 1349, 333–340. [Google Scholar] [CrossRef]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Bruise damage susceptibility of pomegranates (Punica granatum, l.) and impact on fruit physiological response during short term storage. Sci. Hortic. 2019, 246, 664–674. [Google Scholar] [CrossRef]

- Htike, T.; Saengrayap, R.; Aunsri, N.; Tontiwattanakul, K.; Chaiwong, S. Investigation and evaluation of impact bruising in guava using image processing and response surface methodology. Horticulturae 2021, 7, 411. [Google Scholar] [CrossRef]

- Pathare, P.B.; Al-Dairi, M.; Al-Mahdouri, A. Bruise damage susceptibility and fruit quality assessment of pear. Open Agric. J. 2021, 15, 82–90. [Google Scholar] [CrossRef]

- Azadbakht, M.; Mahmoodi, M.J.; Vahedi Torshizi, M. Effects of different loading forces and storage periods on the percentage of bruising and its relation with the qualitative properties of pear fruit. Int. J. Hortic. Sci. Technol. 2019, 6, 177–188. [Google Scholar]

- Stropek, Z.; Golacki, K. Viscoelastic response of apple flesh in a wide range of mechanical loading rates. Int. Agrophysics 2018, 32, 335–340. [Google Scholar] [CrossRef]

- Shafie, M.; Rajabipour, A.; Mobli, H. Determination of bruise incidence of pomegranate fruit under drop case. Int. J. Fruit Sci. 2017, 17, 296–309. [Google Scholar] [CrossRef]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Investigating bruise susceptibility of pomegranate cultivars during postharvest handling. J. Rural Dev. 2017, 2, 33–39. [Google Scholar]

- Opara, L.U.; Al-Ghafri, A.; Agzoun, H.; Al-Issai, J.; Al-Jabri, F. Design and Development of a New Device for Measuring Susceptibility to Impact Damage of Fresh Produce. N. Z. J. Crop Hortic. Sci. 2007, 35, 245–251. [Google Scholar] [CrossRef]

- Candir, E.; Ozdemir, A.E.; Aksoy, M.C. Effects of chitosan coating and modified atmosphere packaging on postharvest quality and bioactive compounds of pomegranate fruit cv.‘Hicaznar’. Sci. Hortic. 2018, 235, 235–243. [Google Scholar] [CrossRef]

- Assadi, I.; Elfalleh, W.; Benabderrahim, M.A.; Hannachi, H.; Chaalen, W.; Ferchichi, A. Nutritional quality and antioxidant capacity of a combination of pomegranate and date juices. Int. J. Fruit Sci. 2019, 19, 300–314. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B.; Al-Yahyai, R. Chemical and nutritional quality changes of tomato during postharvest transportation and storage. J. Saudi Soc. Agric. Sci. 2021, 20, 401–408. [Google Scholar] [CrossRef]

- Lufu, R.; Tsige, A.; Opara, U. Characterising water loss in pomegranate fruit cultivars (‘Acco’, ‘Herskawitz’ & ‘Wonderful’) under cold and shelf storage conditions. Res. Sq. 2020. Available online: https://assets.researchsquare.com/files/rs-110814/v1_covered.pdf?c=1631847415 (accessed on 10 October 2022).

- Lufu, R.; Ambaw, A.; Opara, U.L. The contribution of transpiration and respiration processes in the mass loss of pomegranate fruit (cv. Wonderful). Postharvest Biol. Technol. 2019, 157, 110982. [Google Scholar] [CrossRef]

- Hussein, Z.; Fawole, O.A.; Opara, U.O. Bruise damage of pomegranate during long-term cold storage: Susceptibility to bruising and changes in textural properties of fruit. Int. J. Fruit Sci. 2020, 20, S211–S230. [Google Scholar] [CrossRef]

- Singh, F.; Katiyar, V.; Singh, B. Analytical study of turgor pressure in apple and potato tissues. Postharvest Biol. Technol. 2014, 89, 44–48. [Google Scholar] [CrossRef]

- Ahmadi, E. Bruise susceptibilities of kiwifruit as affected by impact and fruit properties. Res. Agric. Eng. 2012, 58, 107–113. [Google Scholar] [CrossRef]

- Tabatabaekoloor, R. Engineering properties and bruise susceptibility of peach fruits (Prunus persica). Agric. Eng. Int. CIGR J. 2013, 15, 244–252. [Google Scholar]

- Fawole, O.A.; Opara, U.L. Effects of storage temperature and duration on physiological responses of pomegranate fruit. Ind. Crops Prod. 2013, 47, 300–309. [Google Scholar] [CrossRef]

- Candir, E.; Özdemir, A.E.; Aksoy, M.C. Effects of modified atmosphere packaging on the storage and shelf life of Hicaznar pomegranate fruits. Turk. J. Agric. For. 2019, 43, 241–253. [Google Scholar] [CrossRef]

- Selcuk, N.; Erkan, M. Impact of passive modified atmosphere packaging on physicochemical properties, bioactive compounds, and quality attributes of sweet pomegranates. Turk. J. Agric. For. 2016, 40, 475–488. [Google Scholar] [CrossRef]

- Arendse, E.; Fawole, O.A.; Opara, U.L. Influence of storage temperature and duration on postharvest physico-chemical and mechanical properties of pomegranate fruit and arils. CYTA-J. Food 2014, 12, 389–398. [Google Scholar] [CrossRef]

- Caleb, O.J.; Mahajan, P.; Al-Said, F.A.; Opara, U.L. Transpiration rate and quality of pomegranate arils as affected by storage conditions. CYTA-J. Food 2013, 11, 199–207. [Google Scholar] [CrossRef]

- Xanthopoulos, G.T.; Templalexis, C.G.; Aleiferis, N.P.; Lentzou, D.I. The contribution of transpiration and respiration in water loss of perishable agricultural products: The case of pears. Biosyst. Eng. 2017, 158, 76–85. [Google Scholar] [CrossRef]

- Pathare, P.B.; Al-Dairi, M. Bruise damage and quality changes in impact-bruised, stored tomatoes. Horticulturae 2021, 7, 113. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).