From a Single-Stage to a Two-Stage Countercurrent Extraction of Lipids and Proteins from Full-Fat Chickpea Flour: Maximizing Process Extractability and Economic Feasibility

Abstract

1. Introduction

2. Materials and Methods

2.1. Chickpea Flour and Enzyme Use in the EAEP

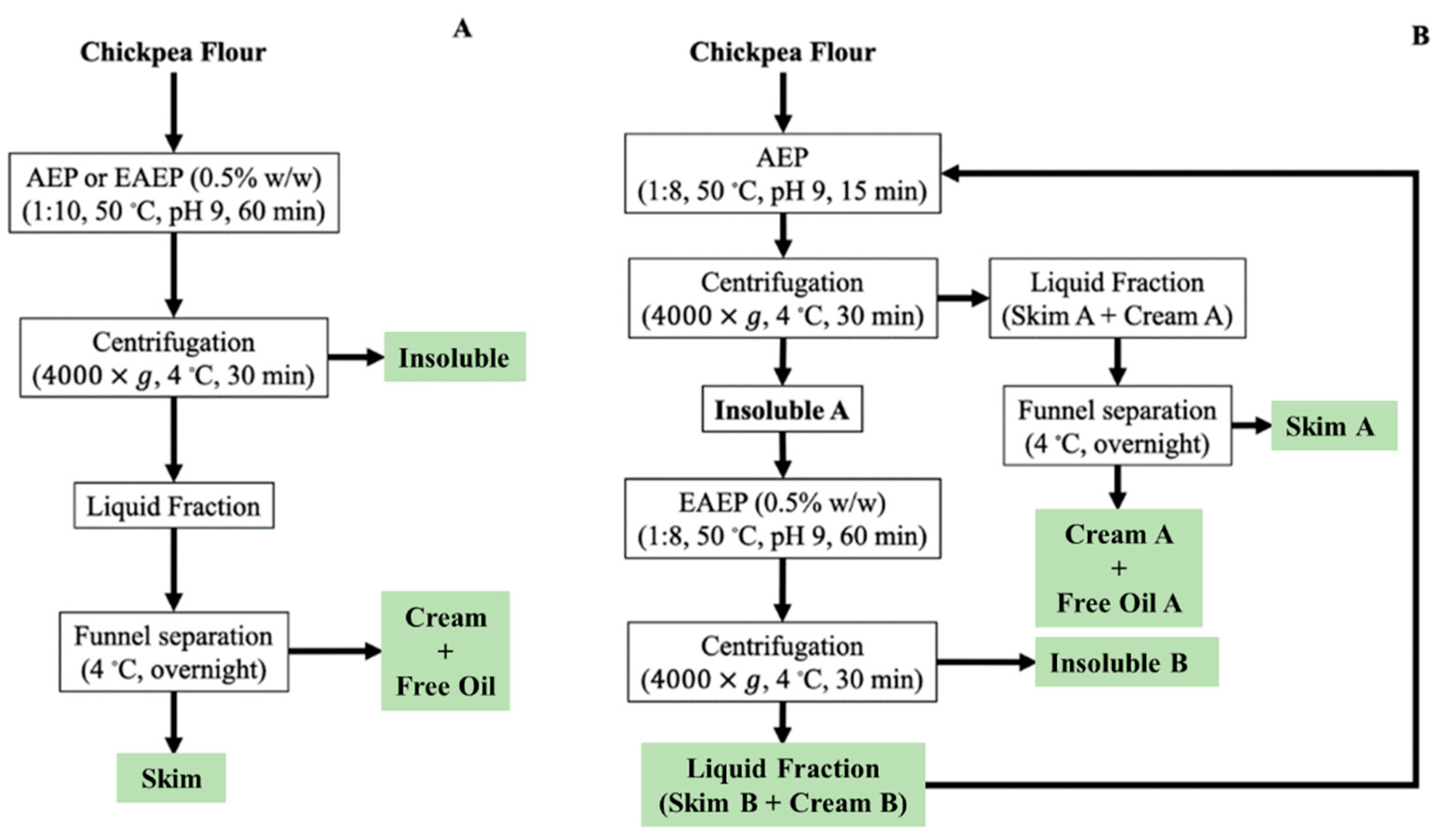

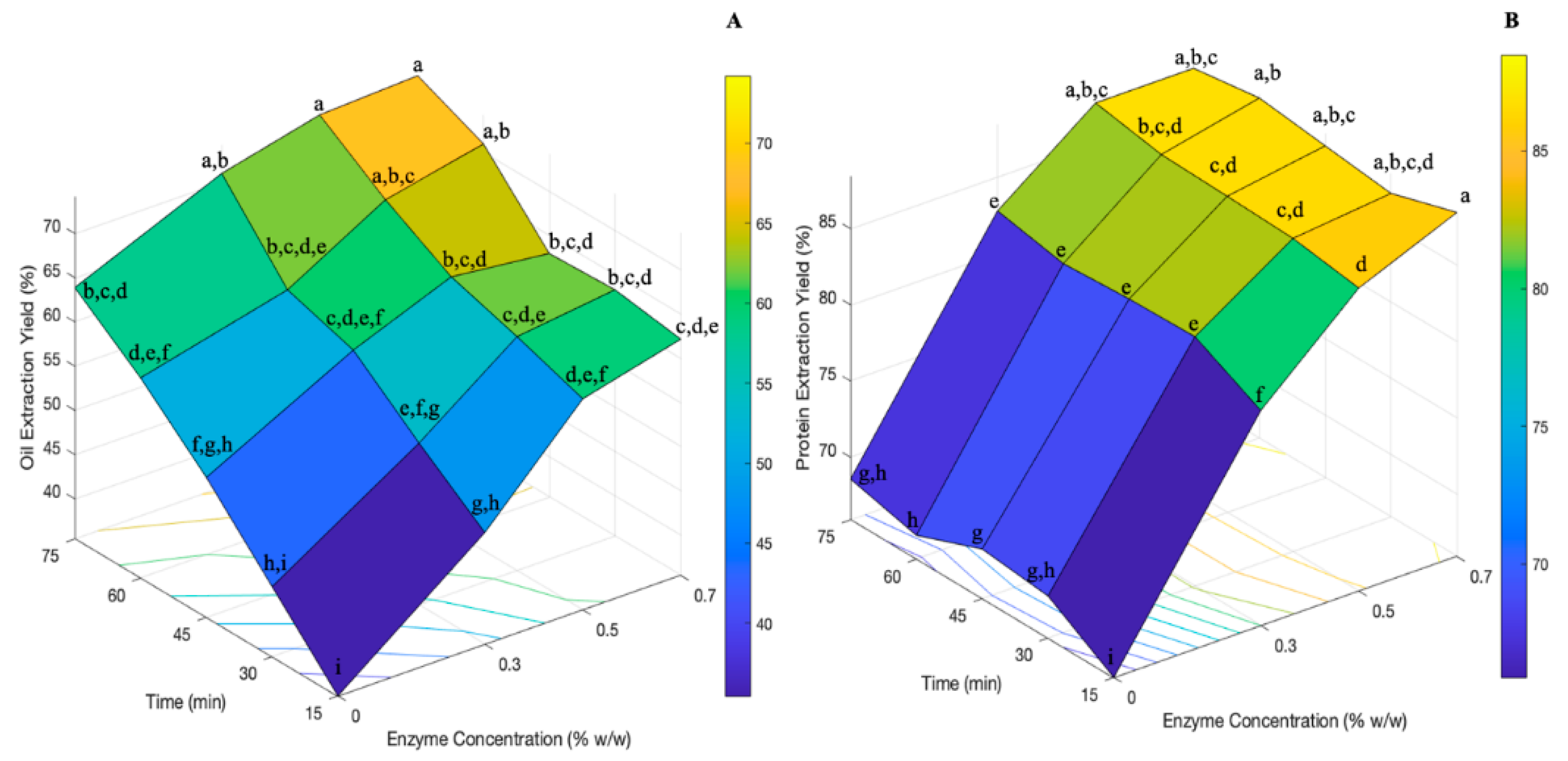

2.2. Effect of Enzyme Concentration and Reaction Time on the Extractability of the Single-Stage Enzyme-Assisted Extraction Process of Chickpea Flour

2.3. Effects of Solids-to-Liquid Ratio (SLR) on the Extractability of the Single-Stage Enzyme-Assisted Aqueous Extraction Process of Chickpea Flour

2.4. Two-Stage Countercurrent Enzyme-Assisted Aqueous Extraction Process of Full-Fat Chickpea Flour

2.5. Proximate Analysis

2.6. Viscosity Analysis

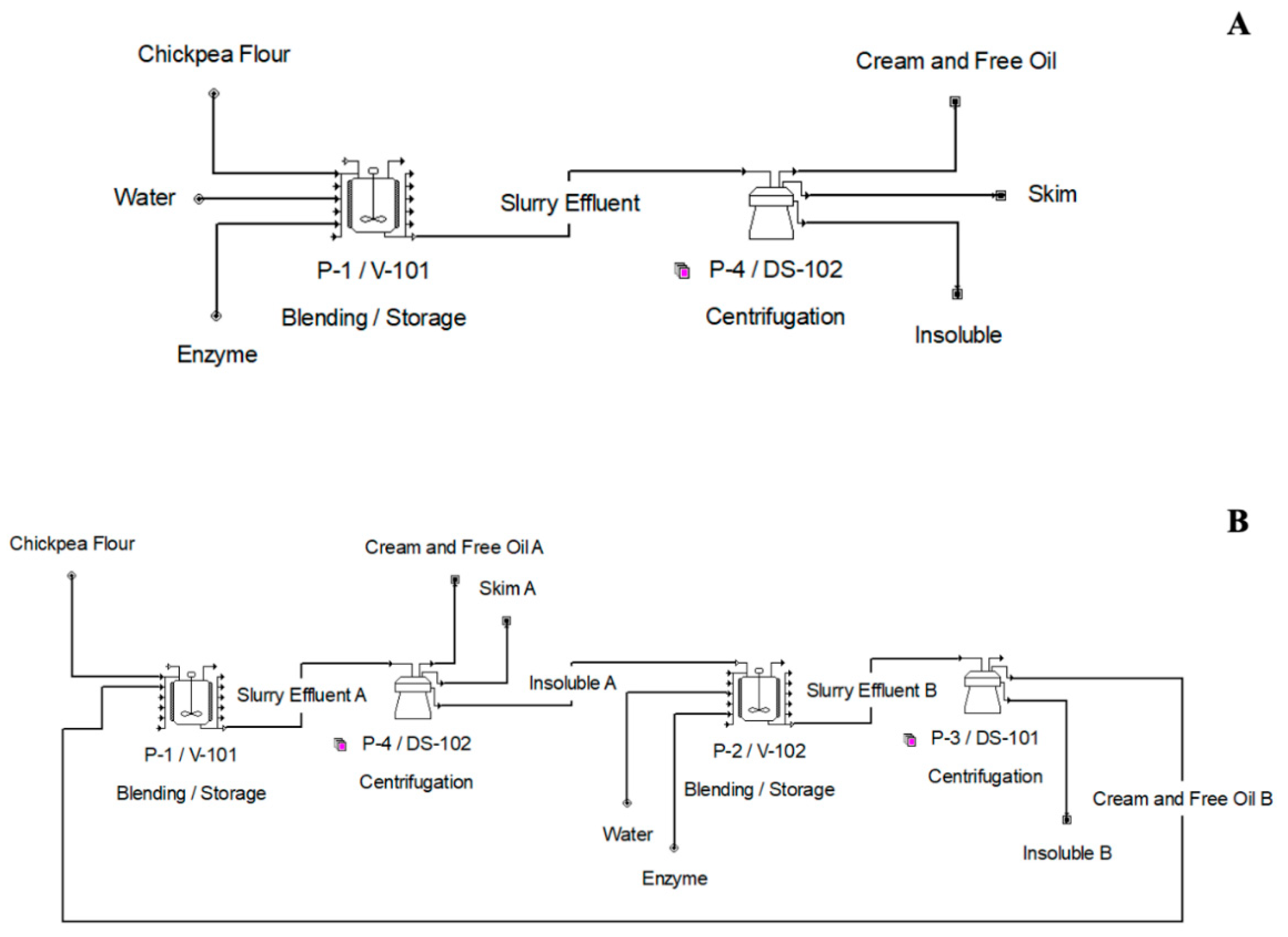

2.7. Techno-Economic Analysis

2.8. Statistical Analysis

3. Results and Discussion

3.1. Effect of Enzyme Concentration and Reaction Time on the Extractability of the Single-Stage Enzyme-Assisted Extraction Process of Chickpea Flour

3.2. Effects of Solids-to-Liquid Ratio (SLR) on the Extractability of the Single-Stage EAEP of Chickpea Flour

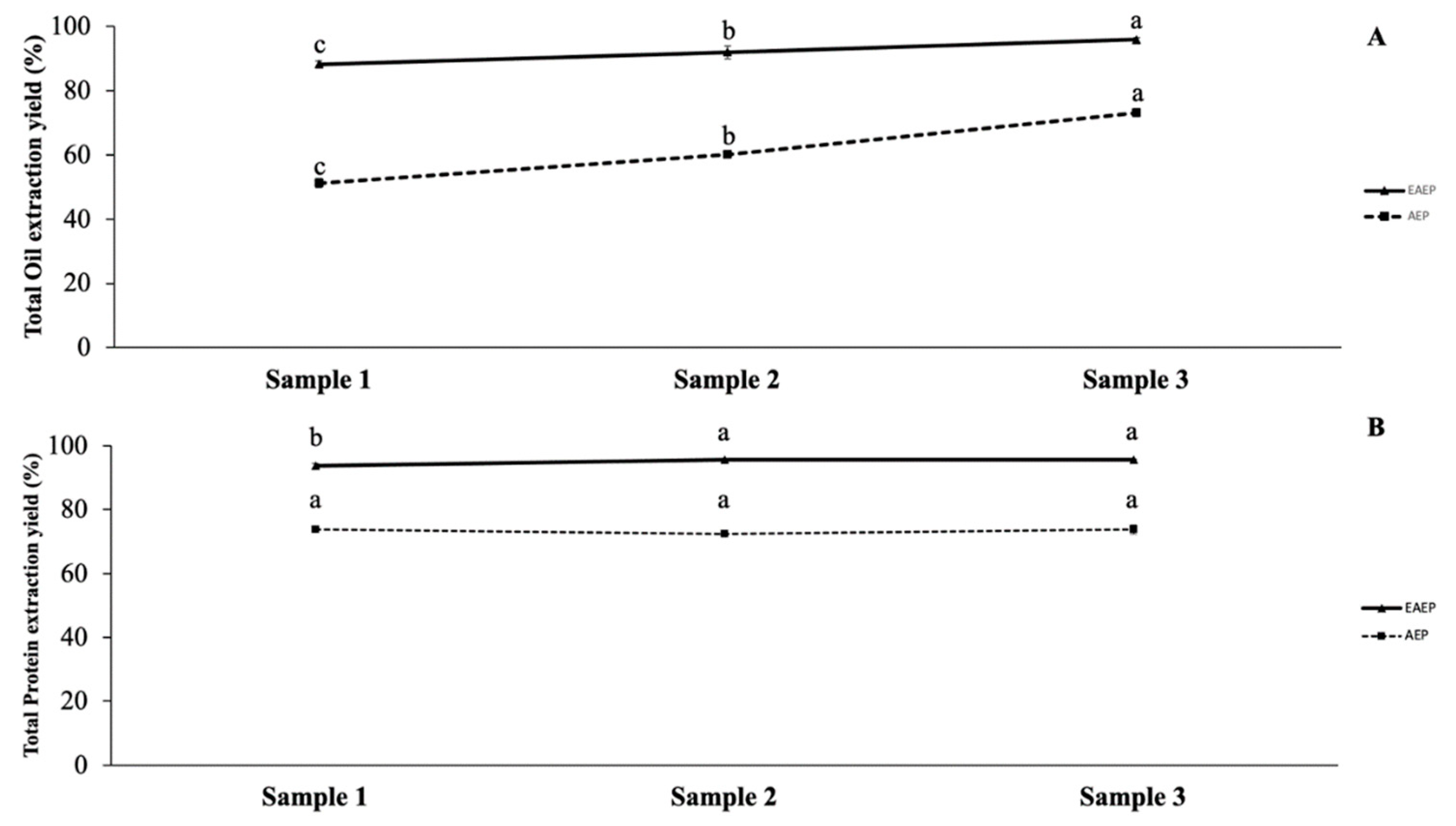

3.3. Two-Stage Countercurrent AEP and EAEP of Chickpea Flour

3.4. Techno-Economic Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- USDA ERS—Pulses Production Expanding as Consumers Cultivate a Taste for U.S. Lentils and Chickpeas. Available online: https://www.ers.usda.gov/amber-waves/2017/januaryfebruary/pulses-production-expanding-as-consumers-cultivate-a-taste-for-us-lentils-and-chickpeas/ (accessed on 16 June 2021).

- Joshi, S. Plant Protein Market Growth Sturdy at 6.2% CAGR to Outstrip. Available online: https://www.globenewswire.com/news-release/2021/05/06/2224574/0/en/Plant-Protein-Market-Growth-Sturdy-at-6-2-CAGR-to-Outstrip-27-965-9-Million-by-2027-COVID-19-Impact-and-Global-Analysis-by-TheInsightPartners-com.html (accessed on 18 June 2021).

- Wild, F.; Czerny, M.; Janssen, A.M.; Kole, A.P.W.; Zunabovic, M.; Domig, K.J. The Evolution of a Plant-Based Alternative to Meat. Agro Food Ind. Hi Tech 2014, 25, 45–49. [Google Scholar]

- Naghshi, S.; Sadeghi, O.; Willett, W.C.; Esmaillzadeh, A. Dietary Intake of Total, Animal, and Plant Proteins and Risk of All Cause, Cardiovascular, and Cancer Mortality: Systematic Review and Dose-Response Meta-Analysis of Prospective Cohort Studies. BMJ 2020, 370, m2412. [Google Scholar] [CrossRef] [PubMed]

- Mekonnen, M.M.; Hoekstra, A.Y. Value of Water Research Report Series No. 48 Value of Water; UNESCO-IHE: Delft, The Netherlands, 2010. [Google Scholar]

- Sheldon, S.; Giles, D.-E.; Lazimy, U.; Capuano, J.D.; Freedgood, A. Sustainability KPI Calculation Methodology; Eat Just, Inc.: San Francisco, CA, USA, 2017. [Google Scholar]

- USDA Commodity Highlights. Available online: https://www.ers.usda.gov/topics/crops/vegetables-pulses/commodity-highlights/ (accessed on 9 September 2021).

- U.S. Department of Agriculture, A.R.Service. FoodData Central. Available online: https://fdc.nal.usda.gov/fdc-app.html#/food-details/173757/nutrients (accessed on 29 May 2020).

- Ghribi, A.M.; Maklouf Gafsi, I.; Sila, A.; Blecker, C.; Danthine, S.; Attia, H.; Bougatef, A.; Besbes, S. Effects of Enzymatic Hydrolysis on Conformational and Functional Properties of Chickpea Protein Isolate. Food Chem. 2015, 187, 322–330. [Google Scholar] [CrossRef] [PubMed]

- Duranti, M.; Gius, C. Legume Seeds: Protein Content and Nutritional Value. Field Crops Res. 1997, 53, 31–45. [Google Scholar] [CrossRef]

- Campbell, K.A.; Glatz, C.E. Mechanisms of Aqueous Extraction of Soybean Oil. J. Agric. Food Chem. 2009, 57, 10904–10912. [Google Scholar] [CrossRef]

- De Queirós, L.D.; Dias, F.F.G.; de Ávila, A.R.A.; Macedo, J.A.; Macedo, G.A.; Leite Nobrega de Moura Bell, J.M. Effects of Enzyme-Assisted Extraction on the Profile and Bioaccessibility of Isoflavones from Soybean Flour. Food Res. Int. 2021, 147, 110474. [Google Scholar] [CrossRef]

- De Moura, J.M.L.N.; Campbell, K.; De Almeida, N.M.; Glatz, C.E.; Johnson, L.A. Protein Recovery in Aqueous Extraction Processing of Soybeans Using Isoelectric Precipitation and Nanofiltration. JAOCS J. Am. Oil Chem. Soc. 2011, 88, 1447–1454. [Google Scholar] [CrossRef]

- Cheng, M.H.; Sekhon, J.J.K.; Rosentrater, K.A.; Wang, T.; Jung, S.; Johnson, L.A. Environmental Impact Assessment of Soybean Oil Production: Extruding-Expelling Process, Hexane Extraction and Aqueous Extraction. Food Bioprod. Process. 2018, 108, 58–68. [Google Scholar] [CrossRef]

- Dias, F.F.G.; de Almeida, N.M.; de Souza, T.S.P.; Taha, A.Y.; de Moura Bell, J.M.L.N. Characterization and Demulsification of the Oil-Rich Emulsion from the Aqueous Extraction Process of Almond Flour. Processes 2020, 8, 1288. [Google Scholar] [CrossRef]

- Nadar, S.S.; Pawar, R.G.; Rathod, V.K. Recent Advances in Enzyme Extraction Strategies: A Comprehensive Review. Int. J. Biol. Macromol. 2017, 101, 931–957. [Google Scholar] [CrossRef]

- Wu, J.; Johnson, L.A.; Jung, S. Demulsification of Oil-Rich Emulsion from Enzyme-Assisted Aqueous Extraction of Extruded Soybean Flakes. Bioresour. Technol. 2009, 100, 527–533. [Google Scholar] [CrossRef] [PubMed]

- Machida, K.; Huang, Y.P.; Furlan Gonçalves Dias, F.; Barile, D.; Leite Nobrega de Moura Bell, J.M. Leveraging Bioprocessing Strategies to Achieve the Simultaneous Extraction of Full-Fat Chickpea Flour Macronutrients and Enhance Protein and Carbohydrate Functionality. Food Bioproc. Tech. 2022, 15, 1760–1777. [Google Scholar] [CrossRef]

- Souza, T.S.P.; Dias, F.F.G.; Koblitz, M.G.B.; de M. Bell, J. Aqueous and Enzymatic Extraction of Oil and Protein from Almond Cake: A Comparative Study. Processes 2019, 7, 472. [Google Scholar] [CrossRef]

- de Almeida, N.M.; Dias, F.F.G.G.; Rodrigues, M.I.; Bell, J.M.L.N.D.M. Effects of Processing Conditions on the Simultaneous Extraction and Distribution of Oil and Protein from Almond Flour. Processes 2019, 7, 844. [Google Scholar] [CrossRef]

- de Moura, J.; Johnson, L.A. Two-Stage Countercurrent Enzyme-Assisted Aqueous Extraction Processing of Oil and Protein from Soybeans. JAOCS J. Am. Oil Chem. Soc. 2009, 86, 283–289. [Google Scholar] [CrossRef]

- Dias, F.F.G.; Taha, A.T.; de Moura Bell, J.M.L. Effects of enzymatic extraction on the simultaneous extraction of oil and protein from full-fat almond flour, insoluble microstructure, emulsion stability, and functionality. Future Foods 2022, 5, 100151. [Google Scholar] [CrossRef]

- Campbell, K.A.; Glatz, C.E.; Johnson, L.A.; Jung, S.; De Moura, J.M.N.; Kapchie, V.; Murphy, P. Advances in Aqueous Extraction Processing of Soybeans. JAOCS J. Am. Oil Chem. Soc. 2011, 88, 449–465. [Google Scholar] [CrossRef]

- De Moura, J.; Campbell, K.; Mahfuz, A.; Jung, S.; Glatz, C.E.; Johnson, L. Enzyme-Assisted Aqueous Extraction of Oil and Protein from Soybeans and Cream de-Emulsification. JAOCS J. Am. Oil Chem. Soc. 2008, 85, 985–995. [Google Scholar] [CrossRef]

- Campbell, K.A.; Vaca-Medina, G.; Glatz, C.E.; Pontalier, P.Y. Parameters Affecting Enzyme-Assisted Aqueous Extraction of Extruded Sunflower Meal. Food Chem. 2016, 208, 245–251. [Google Scholar] [CrossRef]

- Liao, X.Q.E.; Zhao, K.; Mac, J.; Xiangzhao, R. Multi-Stage Countercurrent Process for Extracting Protein from Antarctic Krill (Euphausia Superba). J. Food Sci. Technol. 2018, 55, 4450–4457. [Google Scholar] [CrossRef]

- Dias, F.F.G.; de Moura Bell, J.M.L. Understanding the impact of enzyme-assisted aqueous extraction on the structural, physico chemical, and functional properties of protein extracts from full-fat almond flour. Food Hydrocoll. 2022, 127, 107534. [Google Scholar] [CrossRef]

- AOAC Official Methods Analysis, 15th ed.; AOAC: Rockville, MD, USA, 1990. [CrossRef]

- Cheng, M.; Rosentrater, K.A.; Wang, T. Techno-Economic Analysis of Integrated Enzyme Assisted Aqueous Extraction of Soybean Oil Techno-Economic Analysis of Integrated Enzyme Assisted Aqueous; ASABE: Orlando, FL, USA, 2016. [Google Scholar] [CrossRef][Green Version]

- Rosenthal, A.; Pyle, D.L.; Niranjan, K. Simultaneous Aqueous Extraction of Oil and Protein from Soybean: Mechanisms for Process Design. Food Bioprod. Process. Trans. Inst. Chem. Eng. Part. C 1998, 76, 224–230. [Google Scholar] [CrossRef]

- De Moura, J.; Maurer, D.; Jung, S.; Johnson, L.A. Pilot-Plant Proof-of-Concept for Integrated, Countercurrent, Two-Stage, Enzyme-Assisted Aqueous Extraction of Soybeans. JAOCS J. Am. Oil Chem. Soc. 2011, 88, 1649–1658. [Google Scholar] [CrossRef]

- Cater, C.M.; Rhee, K.C.; Hagenmaier, R.D.; Mattil, K.F. Aqueous Extraction-An Alternative Oilseed Milling Process. J. Am. Oil Chem. Soc. 1974, 51, 137–141. [Google Scholar] [CrossRef]

- Rosenthal, A.; Pyle, D.L.; Niranjan, K. Aqueous and Enzymatic Processes for Edible Oil Extraction. Enzyme Microb. Technol. 1996, 19, 402–420. [Google Scholar] [CrossRef]

- De Almeida, N.M.; De Moura Bell, J.M.L.N.; Johnson, L.A. Properties of Soy Protein Produced by Countercurrent, Two-Stage, Enzyme-Assisted Aqueous Extraction. JAOCS J. Am. Oil Chem. Soc. 2014, 91, 1077–1085. [Google Scholar] [CrossRef]

- de Souza, T.S.P.; Dias, F.F.G.; Oliveira, J.P.S.; de Moura Bell, J.M.L.N.; Koblitz, M.G.B. Biological Properties of Almond Proteins Produced by Aqueous and Enzyme-Assisted Aqueous Extraction Processes from Almond Cake. Sci. Rep. 2020, 10, 10873. [Google Scholar] [CrossRef]

- Tabtabaei, S.; Diosady, L.L. Aqueous and Enzymatic Extraction Processes for the Production of Food-Grade Proteins and Industrial Oil from Dehulled Yellow Mustard Fl Our. FRIN 2013, 52, 547–556. [Google Scholar] [CrossRef]

- Souza Almeida, F.; Furlan Goncalves Dias, F.; Kawazoe Sato, A.C.; Leite Nobrega de Moura Bell, J.M. From Solvent Extraction to the Concurrent Extraction of Lipids and Proteins from Green Coffee: An Eco-Friendly Approach to Improve Process Feasibility. Food Bioprod. Process. 2021, 129, 144–156. [Google Scholar] [CrossRef]

- Chickpea Protein Isolate Cost. Available online: https://www.alibaba.com/product-detail/High-Quality-Chickpea-Protein-Isolate_62290145129.html?spm=a2700.galleryofferlist.normal_offer.d_title.995b47369dwOfu (accessed on 9 September 2021).

- Chickpea Oil 30 mL. Available online: https://www.hemanitrading.us/chickpea-oil-30ml/?gclid=Cj0KCQjwse-DBhC7ARIsAI8YcWLRrWcVOEFelb3dMX4rWU77suUIX-sboEZlW_N_Pxr4SLGuwo9OJ-QaAscdEALw_wcB (accessed on 9 September 2021).

- PROTEX 6L Protease 25 kg. Available online: https://www.fishersci.com/shop/products/NC0603342/NC0603342 (accessed on 9 September 2021).

- Water Rates. Available online: https://www.cityofdavis.org/city-hall/public-works-utilities-and-operations/water/water-rates (accessed on 9 September 2019).

| Viscosity (cP) | ||||

|---|---|---|---|---|

| RPM/SLR | 1:6 | 1:8 | 1:10 | 1:15 |

| 150 | 10.18 ± 0.08 a | 7.69 ± 0.07 b | 6.90 ± 0.17 c | 5.16 ± 0.11 d |

| 200 | 12.20 ± 0.03 a | 9.05 ± 0.04 b | 7.97 ± 0.02 c | 6.12 ± 0.04 d |

| 250 | 13.96 ± 0.04 a | 10.20 ± 0.07 b | 8.88 ± 0.01 c | 6.80 ± 0.07 d |

| Single-Stage EAEP | Two-Stage EAEP | |||||

|---|---|---|---|---|---|---|

| Cost per Unit | Units per Year | Cost per Year | Units per Year | Cost per Year | ||

| Revenue | Protein | USD 20.00 | 902,021 kg | USD 18,040,420.00 | 966,849 kg | USD 19,336,980.00 |

| Oil | USD 15.00 | 70,091 kg | USD 1,051,365.00 | 144,433 kg | USD 2,166,495.00 | |

| Operating Costs | Flour | USD 2.43 | 3,960,000 kg | USD 9,622,800.00 | 3,960,000 kg | USD 9,622,800.00 |

| Enzyme | USD 23.00 | 19,800 kg | USD 455,400.00 | 19,800 kg | USD 455,400.00 | |

| Water | USD 0.0011795 | 59,400,000 L | USD 70,062.89 | 31,680,000 L | USD 37,366.87 | |

| Labor | USD 69.00 | 22,629 h | USD 1,561,401.00 | 45,257 h | USD 3,122,733.00 | |

| Power | USD 0.10 | 1,877,163 kWh | USD 187,716.30 | 2,012,097 kWh | USD 201,209.70 | |

| Steam | USD 12.00 | 2996 MT | USD 35,952.00 | 3934 MT | USD 47,208.00 | |

| Chilled Water | USD 0.40 | 429,382 MT | USD 171,752.80 | 532,663 MT | USD 213,065.20 | |

| Net Gross Profit | USD 6,986,700.01 | USD 7,803,692.23 | ||||

| Single-Stage EAEP | Two-Stage Countercurrent EAEP | ||||

|---|---|---|---|---|---|

| Item | Units | Total Cost | Item | Units | Total Cost |

| Blending Tank | 1 | USD 271,000.00 | Blending Tank | 1 | USD 206,000.00 |

| Disk-stack centrifuge | 4 | USD 2,024,000.00 | Blending Tank | 1 | USD 261,000.00 |

| Disk-stack centrifuge | 3 | USD 1,533,000.00 | |||

| Disk-stack centrifuge | 2 | USD 1,080,000.00 | |||

| Net Equipment Costs | USD 2,295,000.00 | USD 3,080,000.00 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Machida, K.; Furlan Goncalves Dias, F.; Fan, Z.; De Moura Bell, J.M.L.N. From a Single-Stage to a Two-Stage Countercurrent Extraction of Lipids and Proteins from Full-Fat Chickpea Flour: Maximizing Process Extractability and Economic Feasibility. Processes 2022, 10, 2349. https://doi.org/10.3390/pr10112349

Machida K, Furlan Goncalves Dias F, Fan Z, De Moura Bell JMLN. From a Single-Stage to a Two-Stage Countercurrent Extraction of Lipids and Proteins from Full-Fat Chickpea Flour: Maximizing Process Extractability and Economic Feasibility. Processes. 2022; 10(11):2349. https://doi.org/10.3390/pr10112349

Chicago/Turabian StyleMachida, Kazunori, Fernanda Furlan Goncalves Dias, Zhiliang Fan, and Juliana Maria Leite Nobrega De Moura Bell. 2022. "From a Single-Stage to a Two-Stage Countercurrent Extraction of Lipids and Proteins from Full-Fat Chickpea Flour: Maximizing Process Extractability and Economic Feasibility" Processes 10, no. 11: 2349. https://doi.org/10.3390/pr10112349

APA StyleMachida, K., Furlan Goncalves Dias, F., Fan, Z., & De Moura Bell, J. M. L. N. (2022). From a Single-Stage to a Two-Stage Countercurrent Extraction of Lipids and Proteins from Full-Fat Chickpea Flour: Maximizing Process Extractability and Economic Feasibility. Processes, 10(11), 2349. https://doi.org/10.3390/pr10112349