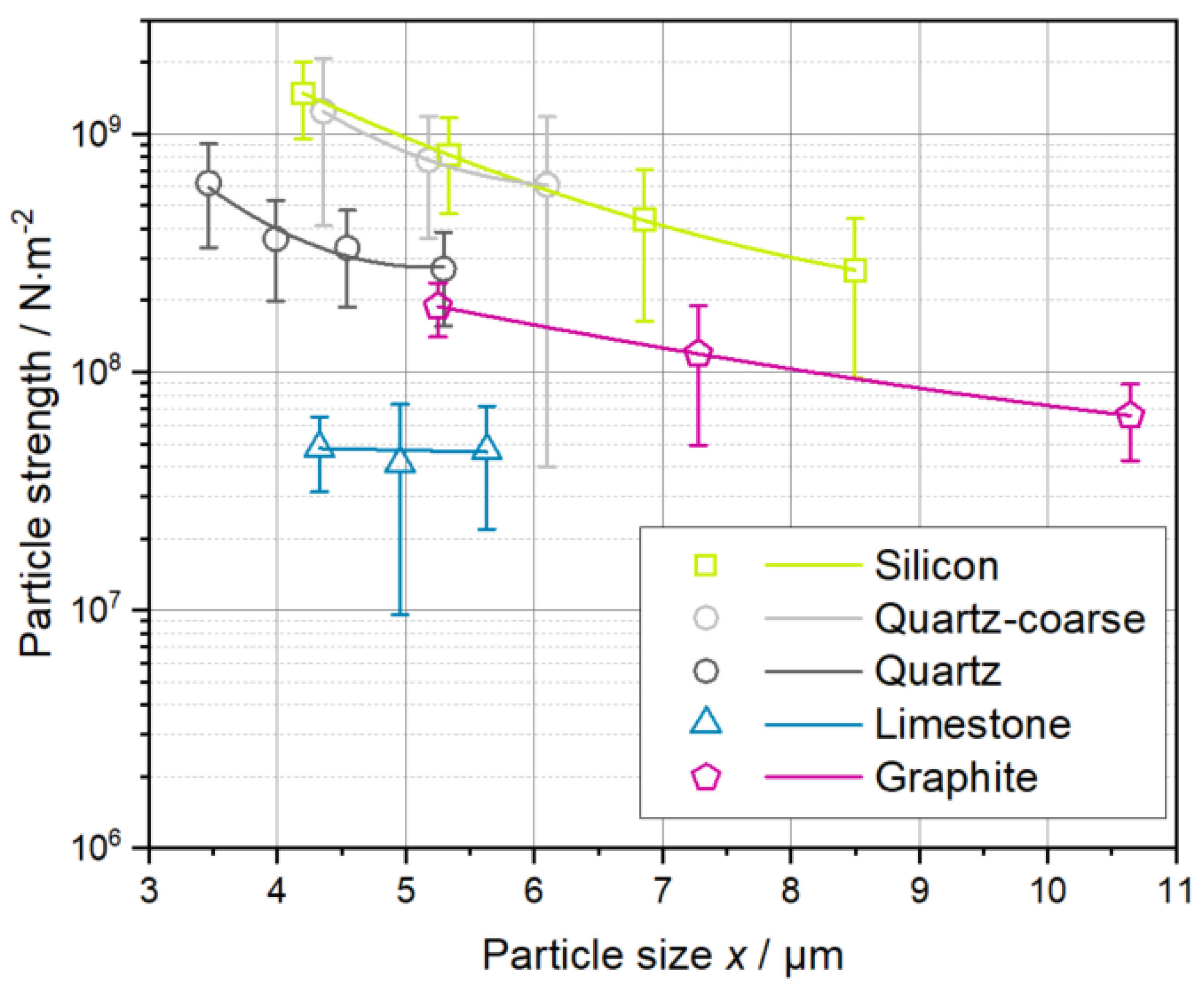

3.1. Investigation of the Feed Particle Strength

At the beginning of the investigations, the fracture-mechanical characterization of the particulate feed materials was carried out with the help of indentation tests. In each case, 40 particles of material were stressed in compression between a base plate and a movable, flattened indenter tip.

Figure 7 shows the results of the five materials for which true fracture behavior was completely or, in the case of graphite, at least partially detectable.

For all materials, an increase in the particle fracture strength with decreasing particle size can be observed. This characteristic behavior is independent of the material type and can be explained by the reduced number of defects in smaller particles [

19].

When comparing the materials with each other, it is evident that silicon and the coarser quartz material (quartz-coarse) have almost identical particle fracture strengths for equivalent particle sizes. At a particle size of 5 µm, therefore, both materials exhibit a particle fracture strength of approx. 800 MN·m−2, which represents the highest value of all investigated materials.

In contrast, the particles of the finer quartz grade (quartz) show only a reduced particle fracture strength of approx. 300 MN·m−2. This result clearly shows that, in addition to the pure material property, the “history” of the material or, in other words, its intrinsic material structure, which may contain dislocations and initial cracks from more intensified previous milling processes, also plays a decisive role in the fracture behavior of the particles. Furthermore, it must be noted that the optical resolution reached its limit for the detection and size measurement of the single particles in the range of 3 to 5 µm. Thus, due to its high fineness, the incorrect detection of quartz agglomerates as individual particles could have contributed incorrectly to the determination of lower strength values.

With regard to the fracture strength values of the graphite particles, which can be as high as 200 MN·m−2 for 5 µm particles, a true fracture was only detectable in approx. 50% of the stressed particles. In the other cases, the material seemed to “slide away” under the indenter tip when the pressure load was increased so that no measured value for the breaking strength could be identified. This finding can be explained by the intrinsic material structure of the layered graphite particles and the accompanying transverse shearing of individual graphite layers during particle loading.

The limestone particles exhibit the lowest detectable fracture strength. At a particle size of 5 µm, they have an average particle fracture strength of only approx. 41 MN·m−2.

In the case of the carbon black aggregates, no breakage signal was detectable during the measurement. Thus, although dislocation and local breakage of primary particle bridges occur by the indenter method, no significant interruption of the force-displacement curve could be detected, which would characterize particle breakage of hard materials. Therefore, the microscale carbon black aggregates appear to have a local strength that is below the detection limit of the method used. Hence, no curve could be plotted in

Figure 7 for this material. However, we assume that the carbon black aggregates have the lowest strength of all the materials investigated in this study.

3.2. Basic Grinding Behavior of Stirred Media Mills during Grinding of Particulate Mixtures with Different Feed Particle Sizes

In order to analyze the influence of the component-specific feed particle size on the result of grinding material mixtures within a stirred media mill, basic experiments were carried out following our previous study [

14]. Therefore, the two easily analyzable model materials, quartz (hard component) and limestone (soft component), were used. For the investigations, operating conditions of the stirred media mill were selected, which ensure an almost identical grinding of both components with identical feed particle size [

14].

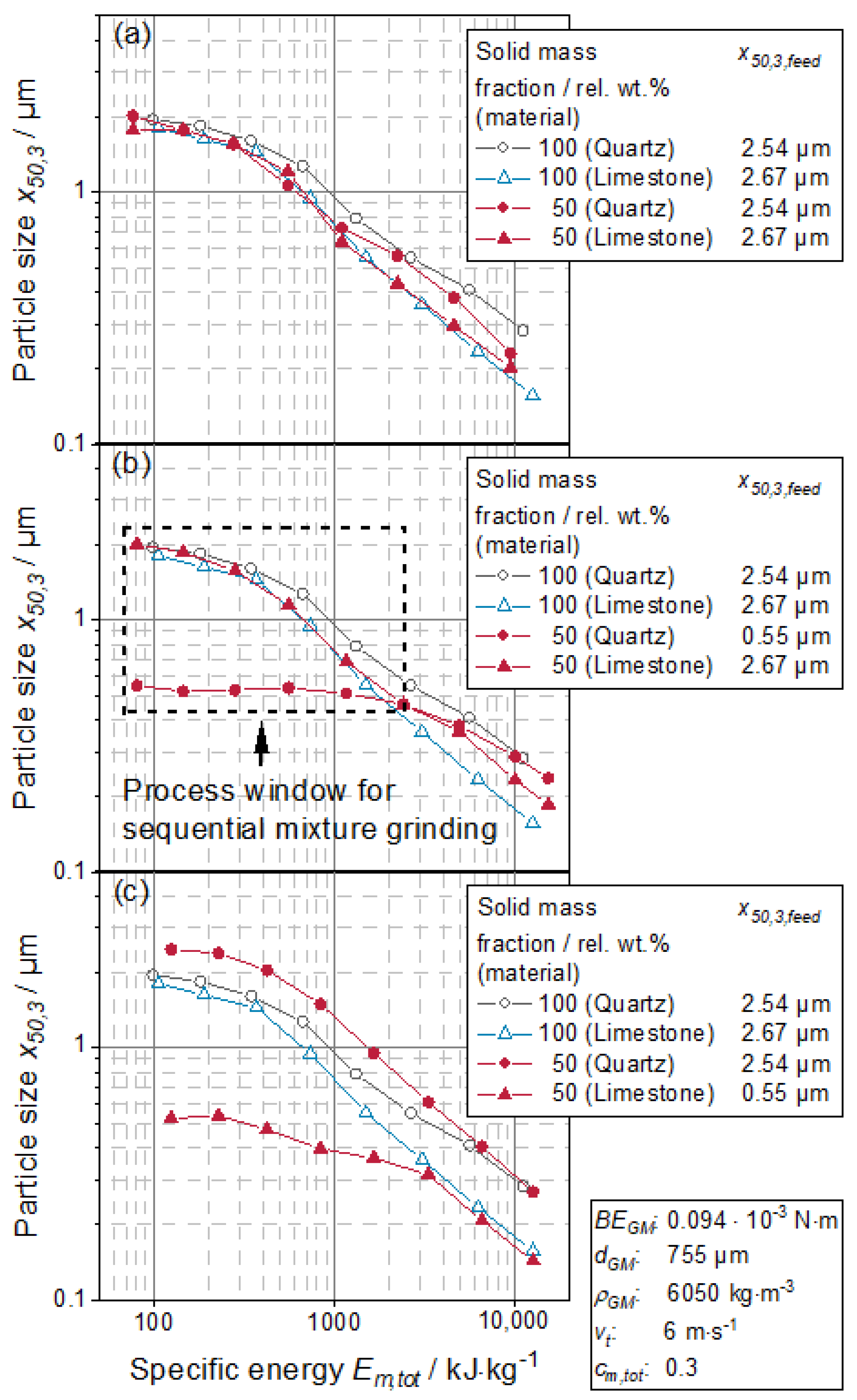

In

Figure 8 the resulting component-specific particle sizes (red lines: grinding of material mixtures) are shown in dependency of the total specific energy input for the grinding of three different quartz-limestone mixtures and in comparison, to the single component grinding result (gray lines: quartz; blue lines: limestone).

Compared to the multicomponent grinding with very similar starting feed sizes (see

Figure 8a), a considerable influence of the starting particle size ratio on the grindability of the quartz particles can be seen in the mixtures with pre-ground quartz (cf.

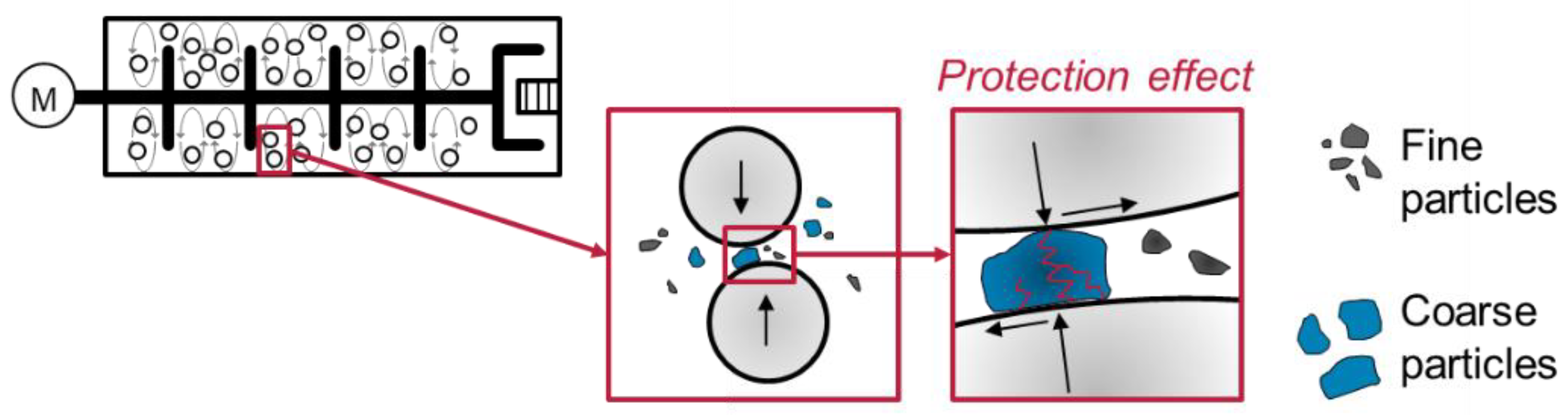

Figure 8b). Thus, the finer quartz particles provided are not significantly ground at the beginning of the process. Only after the limestone particle size has been equalized with the quartz particle size the latter is also ground during further processing. Thus, the coarser limestone particles present in the mixture at the beginning of the process seem to apply a protective effect on the quartz particles. This protective effect is shown schematically in

Figure 9.

Thus, during stirred media milling of mixtures in which hard but finer particles have been added, it can be assumed that no grinding progress is made with respect to this component until the other component also exhibits a similar particle size. This process window is shown in

Figure 8 as a stable process window for the sequential grinding of several mixture components with fine hard particles.

In order to investigate this hypothesis in more detail, further investigations were undertaken with the particle size ratio of the components reversed. Here, the limestone particles were pre-ground to a median particle size

x50,3 of 0.55 µm and further ground after mixing with coarse quartz feed material. The results are shown in

Figure 8c. When comparing the grinding progress with pre-ground limestone and with pre-ground quartz (cf.

Figure 8b), no grinding progress can be observed for the limestone particles, even in the case of a finer limestone fraction presented at the beginning of the process. However, this already starts after a shorter process time of 10 min or a specific energy input

Em,tot of approx. 420 kJ·kg

−1 compared to the case of the mixture with pre-ground quartz (160 min, 4867 kJ·kg

−1). Thus, although the quartz particles are still much coarser in the mixture at this stage (

x50,3 ≈ 2 µm), an initially reduced number of low-intensity stress events is consequently sufficient to further grind the softer limestone particles. In the further course of grinding, in contrast to the previous results with pre-ground quartz, there is no equalization of the particle sizes of the pre-ground limestone and the coarser quartz noticeable. From a quartz particle size

x50,3 of 0.6 µm, a constant particle size ratio of two is generated. According to Kwade [

19], the capturing of multiple particles is very likely in this particle size range. At the same time, the particle-specific stress energy demand also decreases because the ratio of the provided stress energy of the grinding media related to the average captured particle mass and the stress intensity required for a particle breakage increases. Hence, it can be assumed that in the case of fine limestone particles, the transferable stress energy is sufficient on average to cause a fracture. Therefore, the fracture behavior of the particles is set according to their fracture-relevant material properties so that the material-specific grinding course of both components in the mixture follows the respective course of their individual material grinding course.

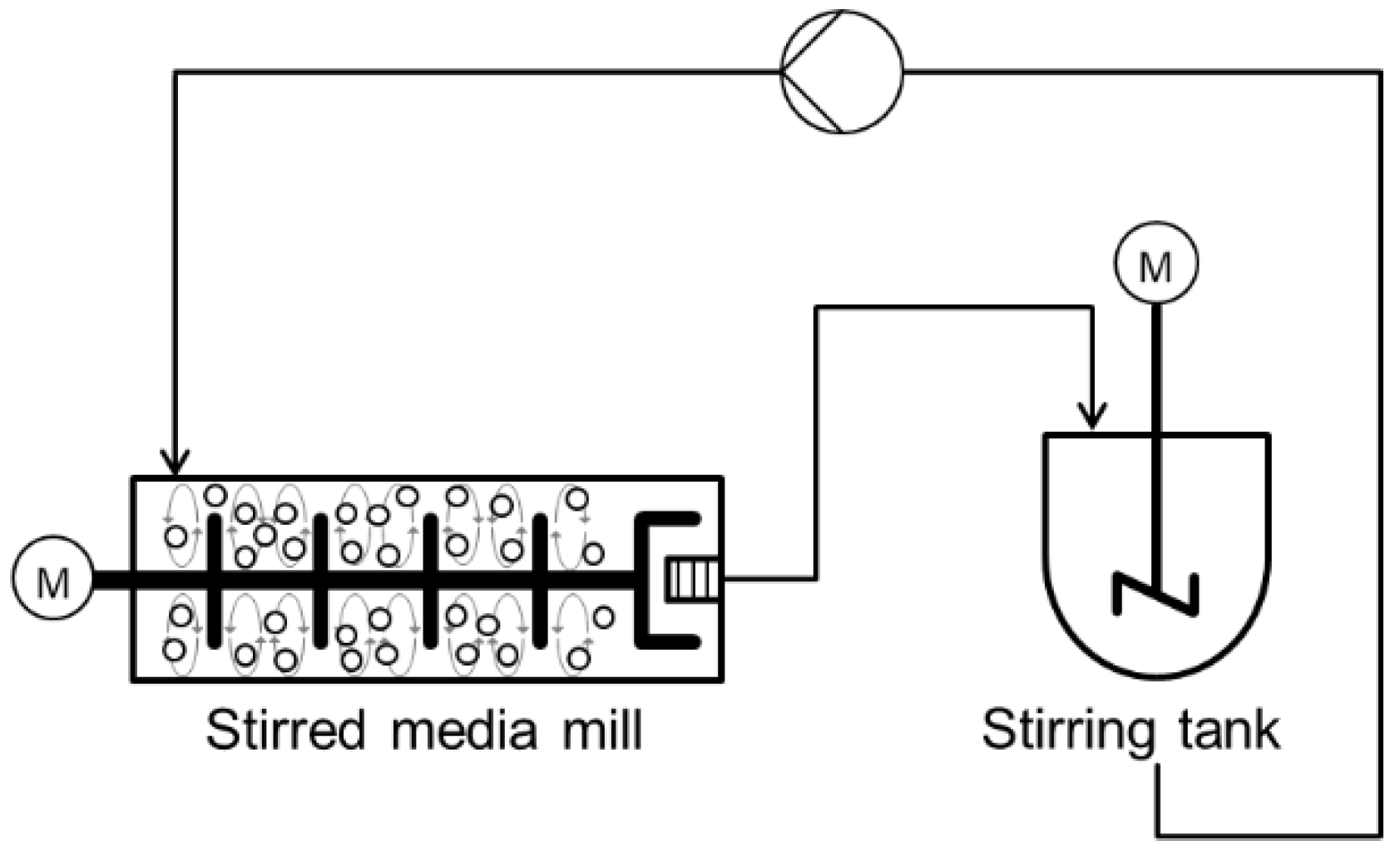

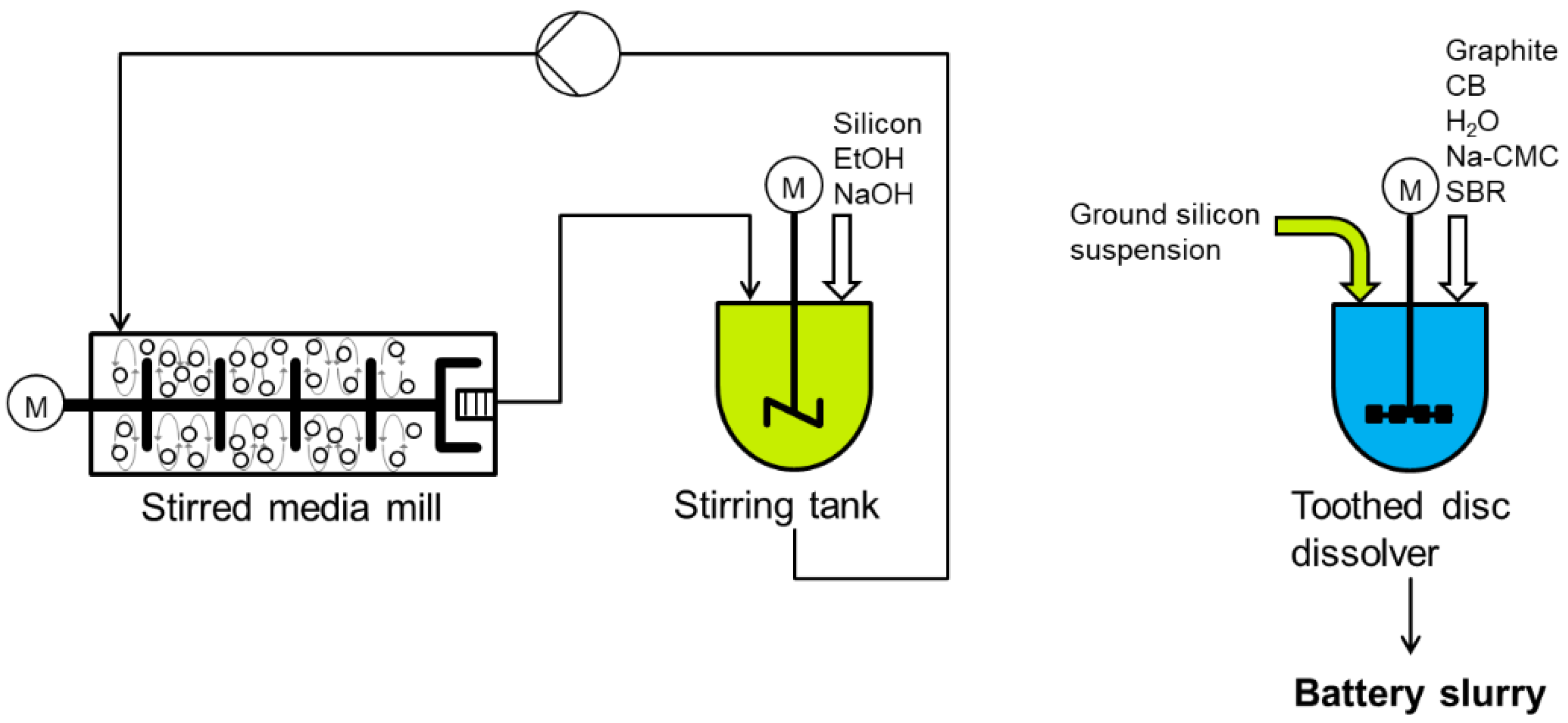

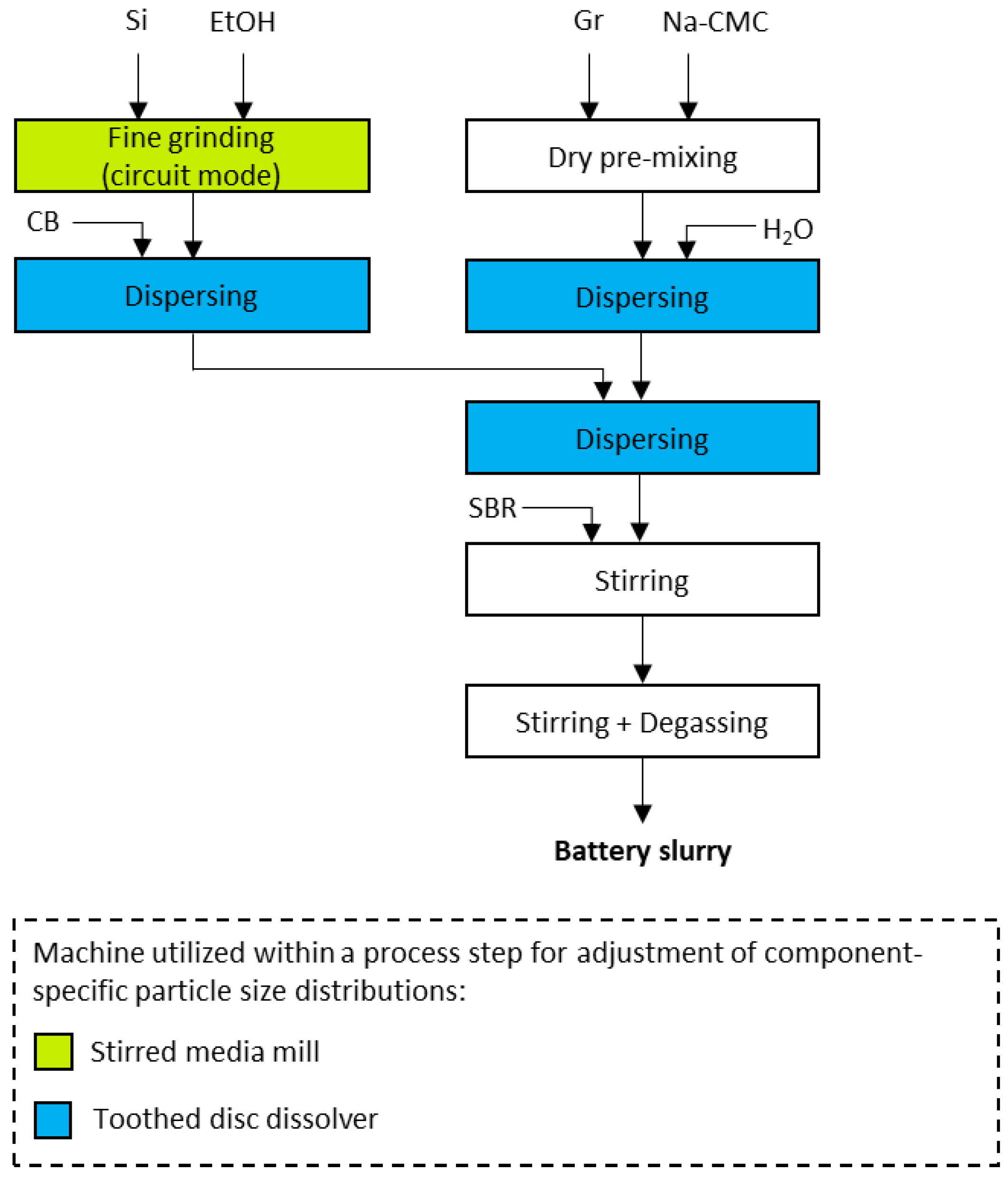

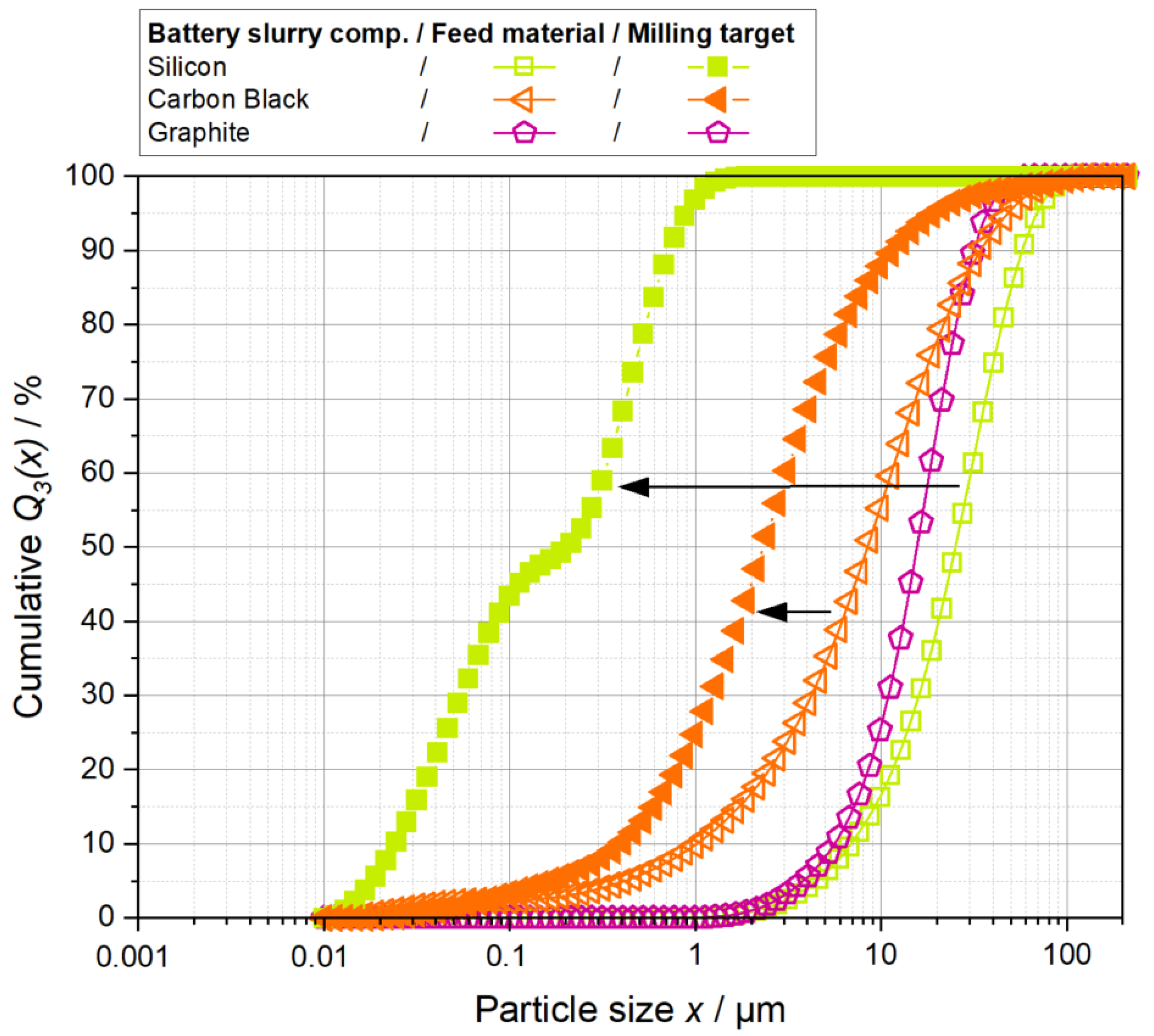

3.3. Targeted Preparation of Battery Slurries within a Stirred Media Mill

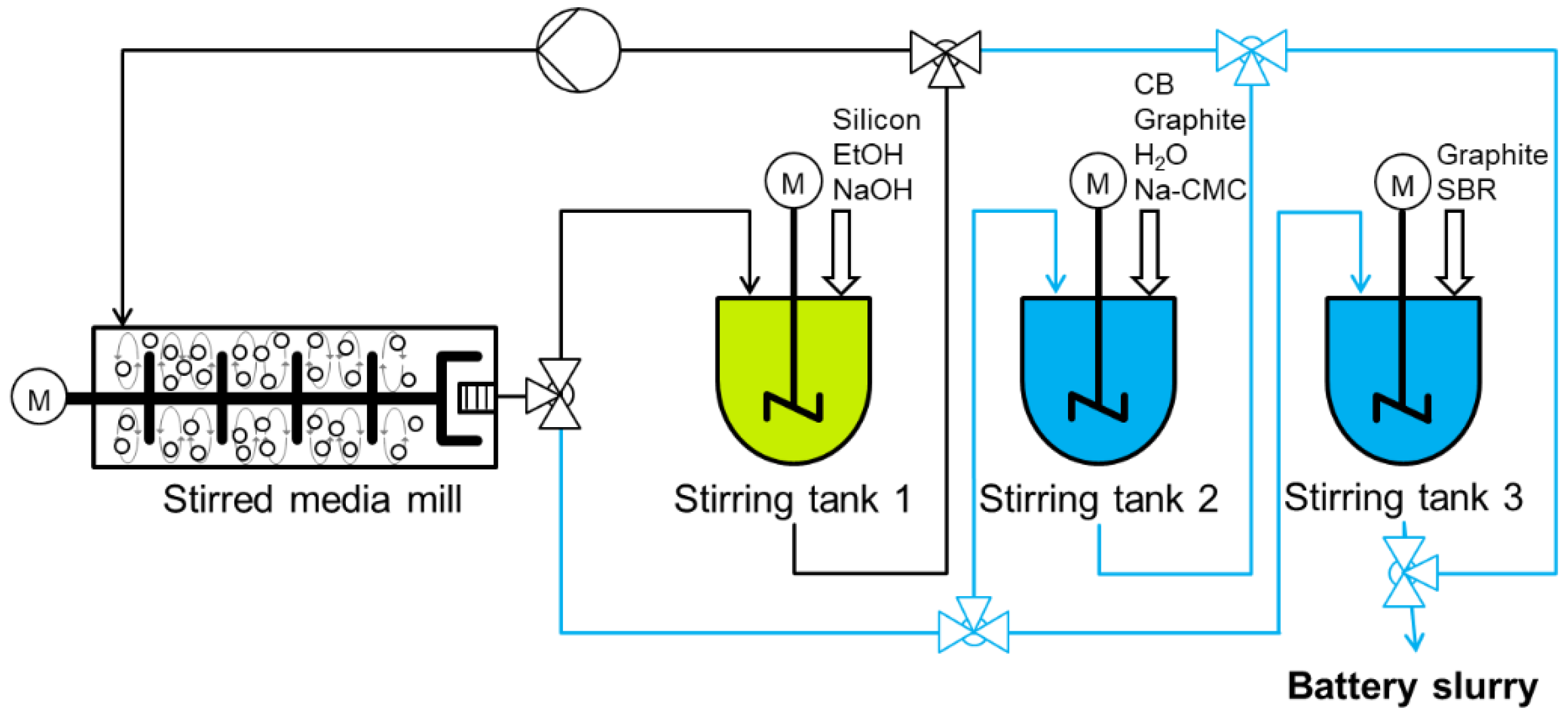

The resulting component-specific particle size distributions after silicon grinding and further processing of all components to a battery slurry within the reference process (cf.

Figure 3) are shown in

Figure 10, together with the particle size distributions of the respective feed materials. It can be seen that the hardest mixture component, silicon (cf.

Figure 7), which starts with a median feed particle size

x50,3 around 20 µm, is present with the highest fineness in the system (

x50,3 = 200 nm). The most fragile material, carbon black, on the other hand, was not completely deagglomerated and, therefore, is widely distributed in the particle size range of 0.02–20 µm (

x50,3 = 2.5 µm) after the dispersing process, which is advantageous from an application point of view [

20]. In addition, the medium hard battery grade graphite (

x50,3 = 17 µm) was not broken but only distributed homogeneously in the suspension so that it has an identical particle size distribution to its feed material. Based on the investigated particle strength values (see

Figure 7), the determined stable process window for stirred media milling of mixtures (see

Figure 8) and the component-specific grinding target (see

Figure 10), a clear option for the sequential multicomponent comminution of these three battery components can be identified with the following sequence of component addition: 1. silicon, 2. carbon black, 3. graphite.

As it was already known that one to a few mill passages would be sufficient for the size reduction in the carbon black, the strategy was chosen to process all battery slurry components together within a passage-based operation of the mill. An exception was made regarding the silicon particles, which needed to be ground to such fine values that the circuit operation of the mill was chosen upstream. Thus, this process step was identical to the silicon grinding step of the reference process.

In order to investigate the general comminution behavior of the three particulate components of the battery slurry, all three components were processed at their respective concentrations in the final coating suspension and within the final Na-CMC binder solution (without SBR). Since the single component grinding of silicon was planned upstream to this passage-based processing, the silicon particles were used as already ground particles in these experiments. In addition to the single component tests, carbon black—silicon and carbon black—graphite mixtures were also processed. The results of these experiments are summarized in

Figure 11. For these results, a stirrer tip speed

vt of 4 m·s

−1 (

SEGM = 0.006·10

−3 N·m) and a constant volume flow

through the mill of 11.4 L·h

−1 was selected.

In the case of a graphite—silicon mixture, no significant grinding can be detected within the considered process window of five passages. However, for silicon, a comparison of the results with laser diffraction and acoustic spectroscopy shows that a significant agglomeration of the particles has already occurred after one passage. In the further course of the process, the median value of the agglomerate size x50.3 (LD) of 1.35 µm also remains constant. However, it must be noted that the particle size analysis was based on a purely ethanolic silicon suspension before the first passage (0 passages) and that the silicon suspension was subsequently mixed with an aqueous binder solution using the binder Na-CMC.

It is also known that the partially deprotonated carboxyl group of the binder and the oxidized silicon surface react chemically [

21], causing agglomeration of the silicon particles due to their high molecular weight, similar to flocculants. In contrast, Na-CMC increases the colloidal stability of carbon black particles in water and also ensures the formation of a homogeneous network between silicon and carbon black particles within coating suspensions for electrode production [

21]. In the case of carbon black, in addition to single-material grinding, two-component processing with ground silicon particles or with graphite feed material was also investigated. The results show that in all three cases, a significant size reduction in the carbon black takes place within five passages. Here, the individual material size reduction and the two-component processing with silicon particles (

x50.3 (AS) = 120 nm) proceed at almost identical levels, resulting in a reduction in the median value from 10 µm to about 2 µm at the end of the process. This result can be explained by the existing size ratios of the particulate components since the silicon particles are smaller than the carbon black agglomerates, and therefore the latter is exposed to the grinding media with the same frequency and intensity compared to the individual milling of the carbon black. However, it is interesting to note that multicomponent comminution with a carbon black—graphite mixture results in a more efficient comminution of the carbon black. In this case, the graphite particles increase the intensity and/or frequency of stresses acting on the carbon black agglomerates. Stadler et al. [

22] described that for pigment deagglomeration with stirred media mills, the dispersing result for different applied stress energies of the grinding media could be represented by a predominantly stress-number-dependent correlation. Therefore, it is assumed in this context, with regard to the more efficient carbon black deagglomeration, that the graphite particles present in the two-component system provide additional shear forces acting on the carbon black. As described by Stadler et al. [

22] and Kwade [

19], for dispersing particles such as carbon black, the shear forces between the grinding media are relevant so that an increasing viscosity improves the shear stress acting on the carbon black agglomerates and, by that, improves the maximum possible fineness according to the model of Schilde et al. [

23].

With regard to the median values determined for the individual components, these investigations show that the basic principle of passage-based processing in a stirred media mill is suitable for the production of a property-optimized battery slurry. However, it is also known from earlier work [

20,

24] that the carbon black particle size distribution, in particular, has significant influences on the coating suspension and final electrode properties. Therefore, in addition to considering the median value, the adjustment of the carbon black particle size distribution was also investigated in further experiments.

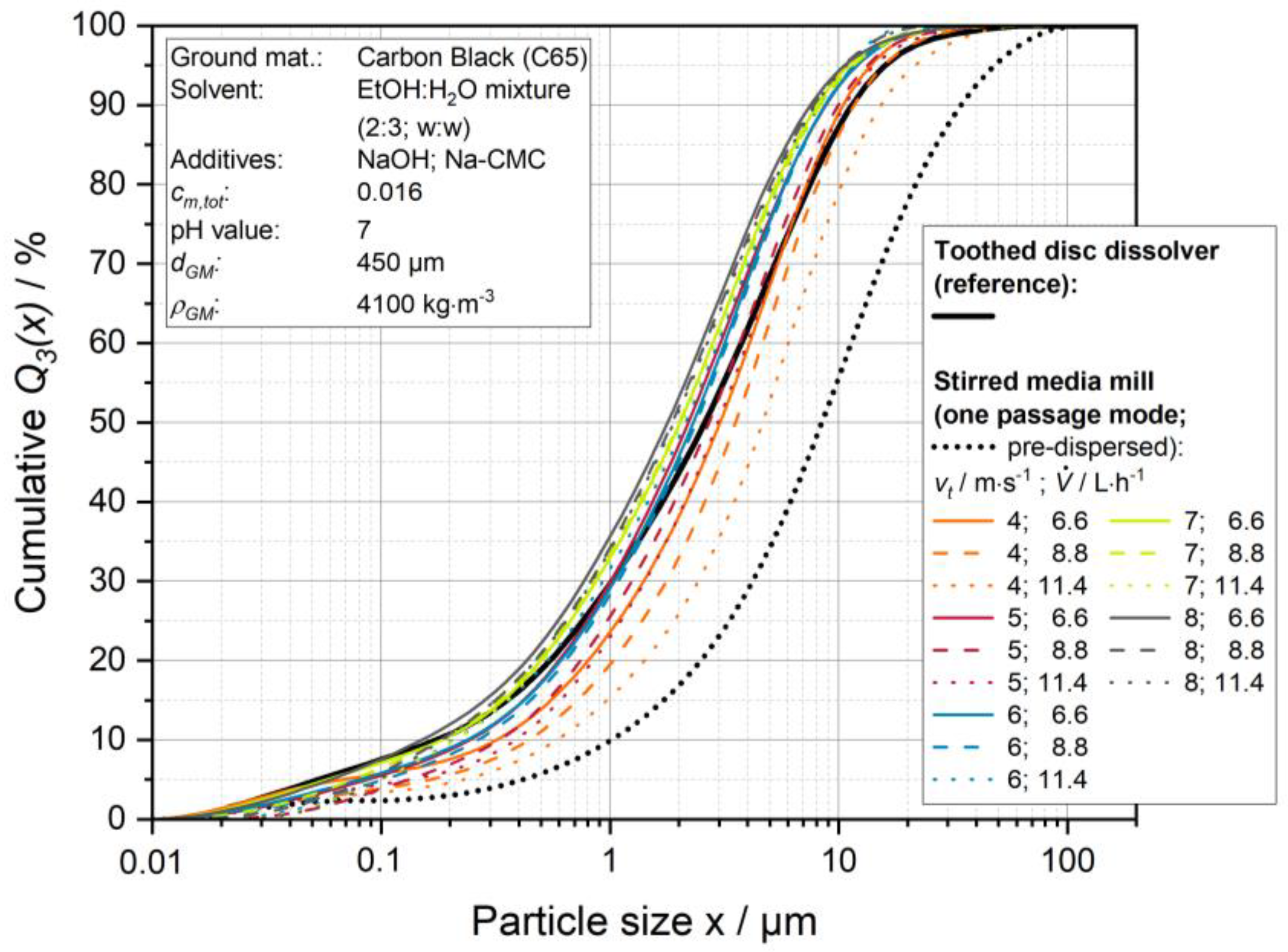

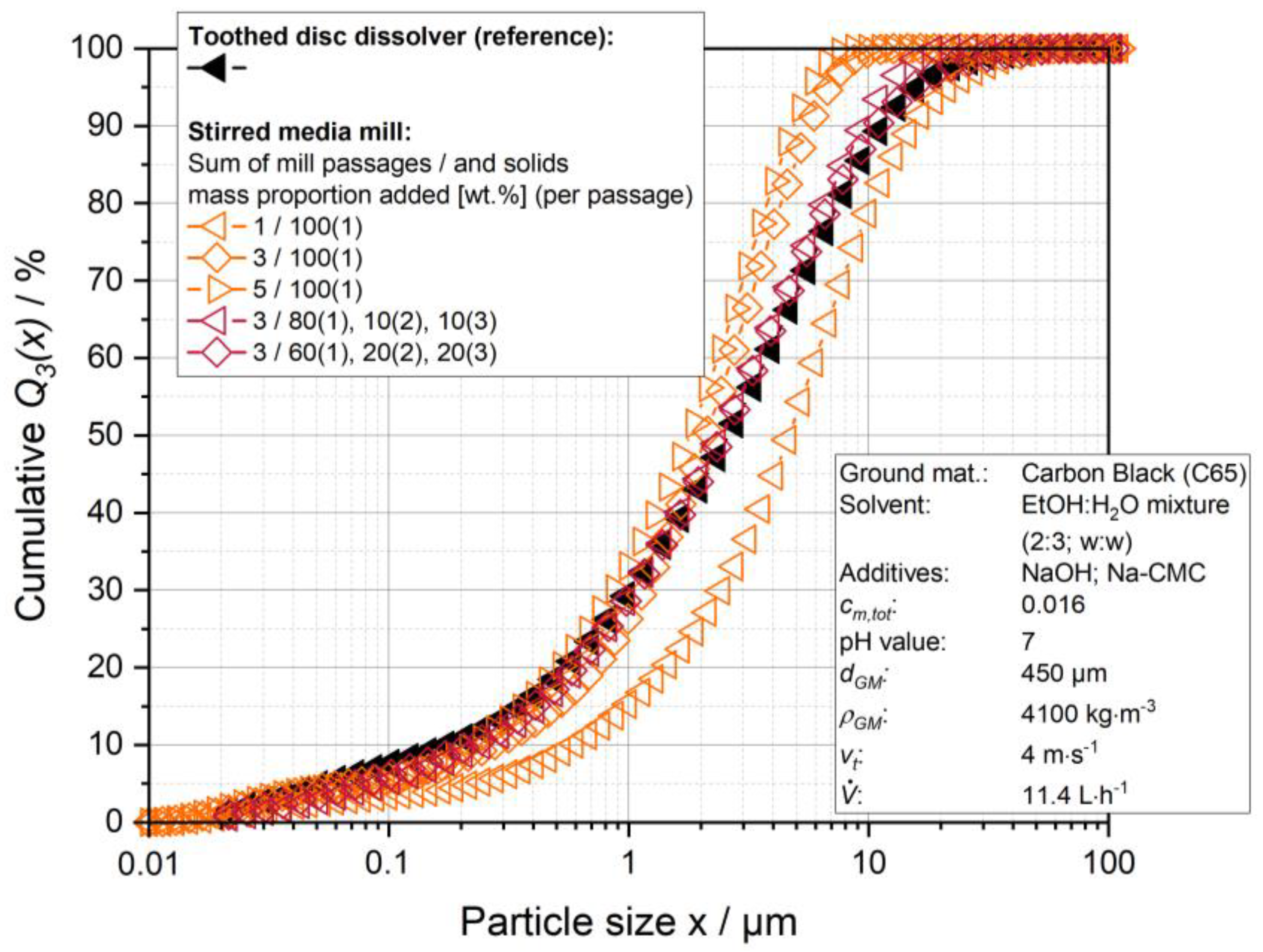

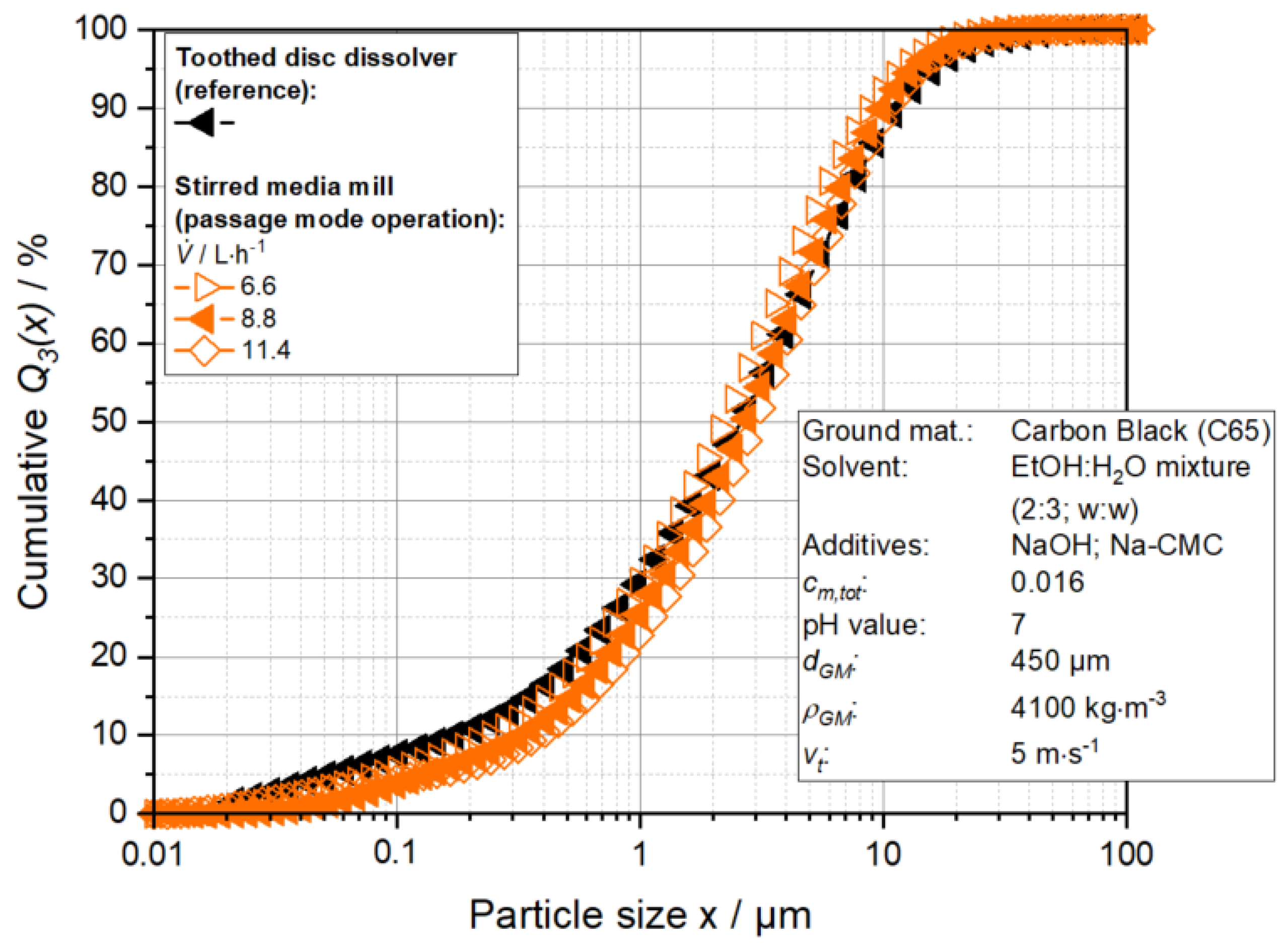

Figure 12 presents the comparison between the reference process and the results for the passage-based single component comminution of the carbon black with the constant operation of the mill at a stirrer tip speed

vt of 4 m·s

−1 (

SEGM = 0.006·10

−3 N·m) and a volume flow

through the mill of 11.4 L·h

−1.

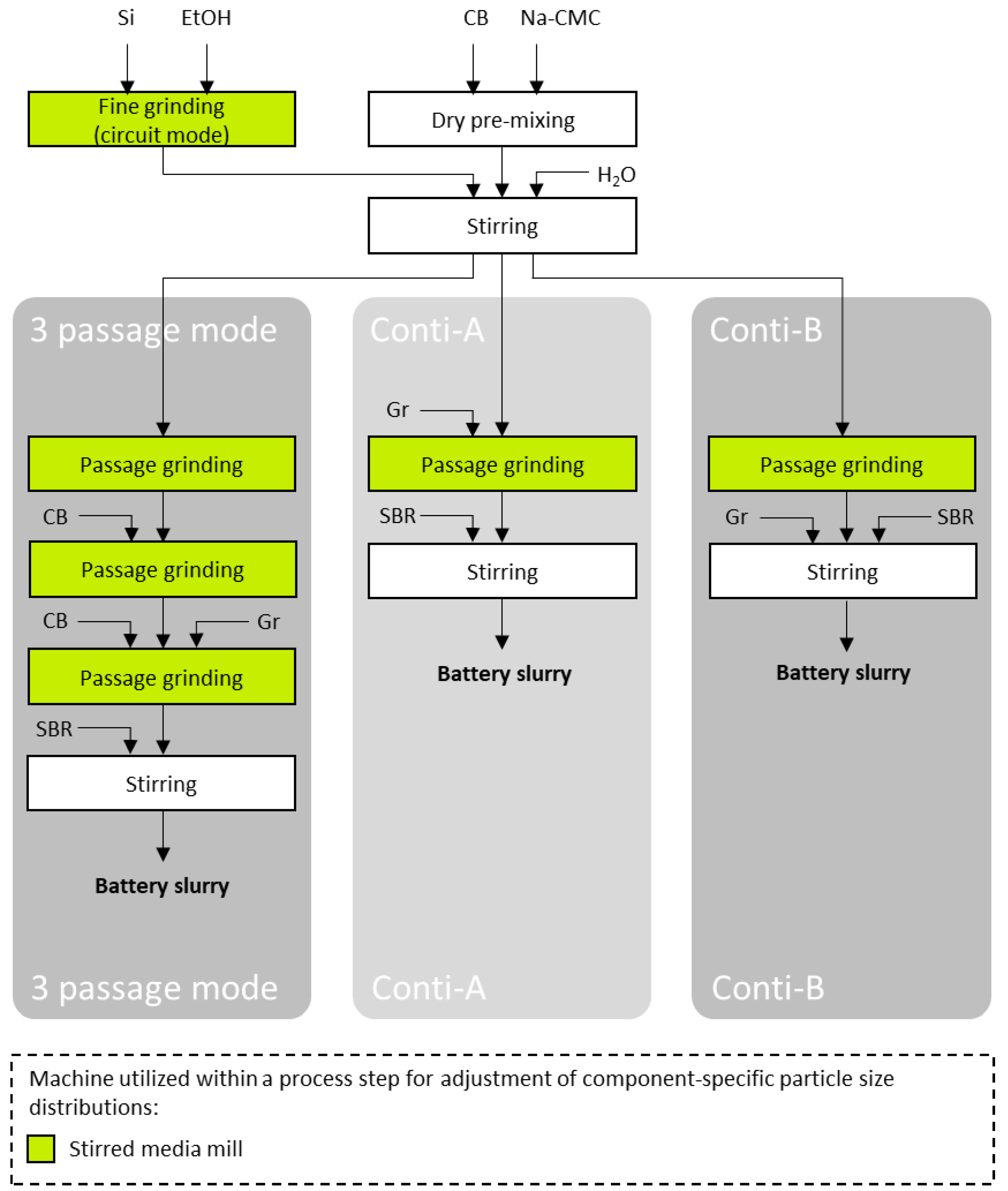

Firstly, the milling result was investigated with a single addition of the entire carbon black mass at the start of the process with respect to the one, three, or five passages, as well as the sequential addition of the carbon black within three passages. The latter dosing method provided a sequential addition of carbon black of 80/10/10 wt.% and 60/20/20 wt.% before the first, second, and third passages. The corresponding result of this sequential carbon black addition was then analyzed after the third passage. The results show that for the selected operating parameters, a single addition of the entire carbon black mass at the beginning of the process results in narrower particle size distributions compared to the reference process. However, for one passage, the maximum carbon black size is still higher than in the reference process and gets significantly smaller than in the reference process for three and five passages. For five passages, almost no further dispersing effect is detectable as the stress intensity is too small to further disperse the fine carbon black agglomerates. In contrast, with the constant operation of the stirred media mill and sequential addition of the carbon black mass, an almost identical particle size distribution is obtained after three passages compared to the reference. Here, the best agreement is achieved with a particle size distribution of the carbon black addition of 60/20/20 wt.%. For the subsequent investigations regarding the feasibility of the coating suspension production with a stirred media mill, this sequence was selected as a possible process variant, with the graphite also being added in the third passage (3 passage mode).

In order to reduce the number of passages required for the targeted size reduction in the carbon black agglomerates from three to one passage, a parameter study was also undertaken on the influence of the stirrer tip speed

vt and the product volume flow. For this purpose, the stirrer tip speed

vt was set to 4/5/6/7, and 8 m·s

−1 and three volume flows

of 6.6/8.8 and 11.4, L·h

−1 were investigated. The previously used grinding media were kept constant. All resulting particle size distributions are shown in

Figure A1 in the

Appendix A.

Figure 13 illustrates the experimental results with the highest agreement compared to the reference process. Thus, with a slightly increased stirrer, tip speed

vt of 5 m·s

−1 and corresponding increased stress energy of the grinding media

SEGM of 0.009·10

−3 N·m and simultaneously reduced product volume flow

of 8.8 L·h

−1, an almost identical carbon black particle size distribution can be obtained in continuous single-passage operation. By reducing the product volume flow

, the residence time distribution within the mill becomes broader, also resulting in a broader particle size distribution [

19]. Moreover, by increasing

SEGM, a finer product is also obtained at the product outlet of the mill, so that, in contrast to the one-passage result in

Figure 12, one continuous passage already leads to a sufficient fineness of the carbon black.

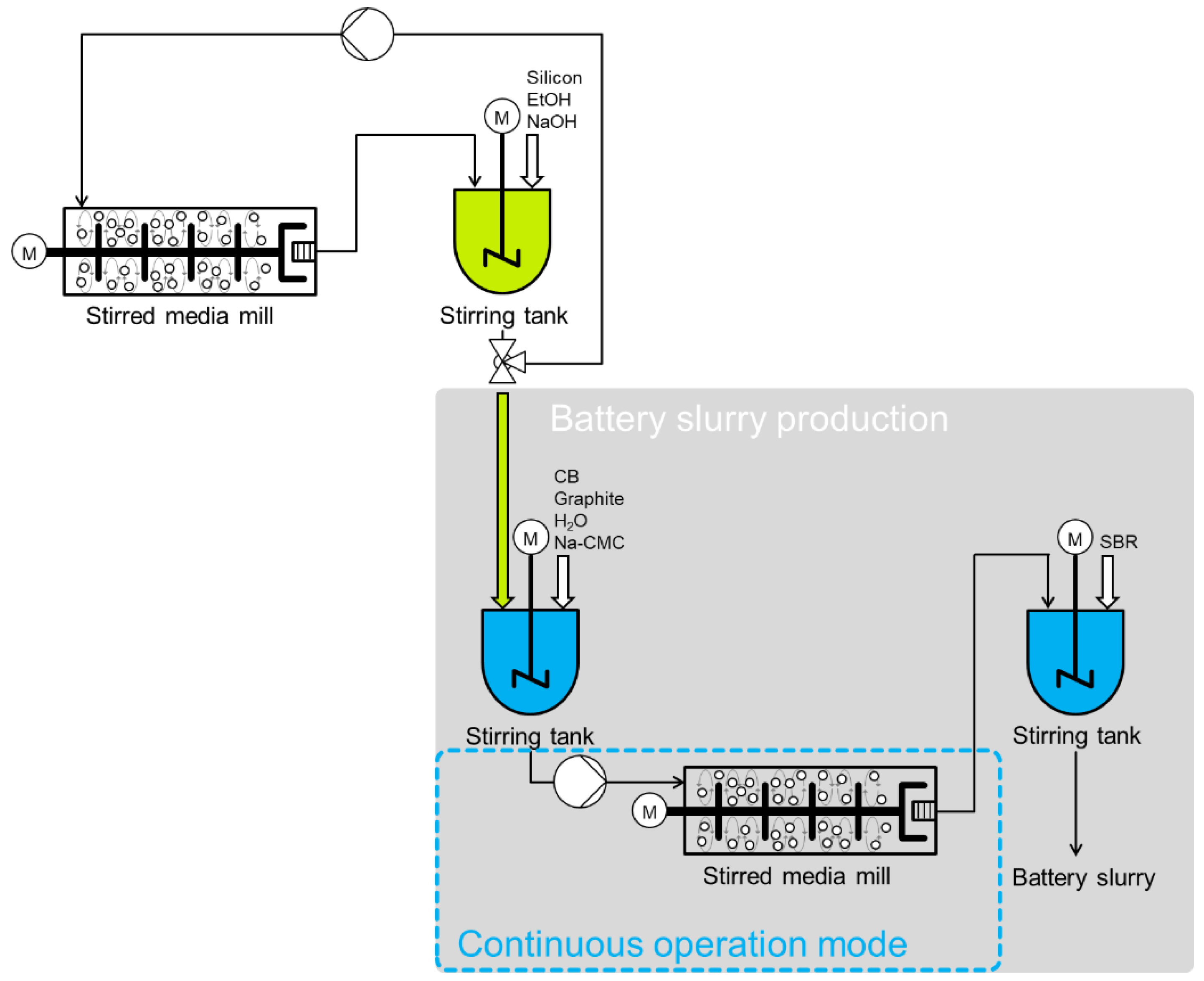

For the following investigations on coating suspension production with a continuously operated stirred media mill, these parameters were used, and two process variants were investigated, in which the graphite was added before (Conti-A) and after the continuous passage (Conti-B) through the stirred media mill. In order to obtain an overview of the investigated processes used for the production of the battery slurry in a stirred media mill, the schematic summary of the process strategies in

Figure 5 should be looked at.

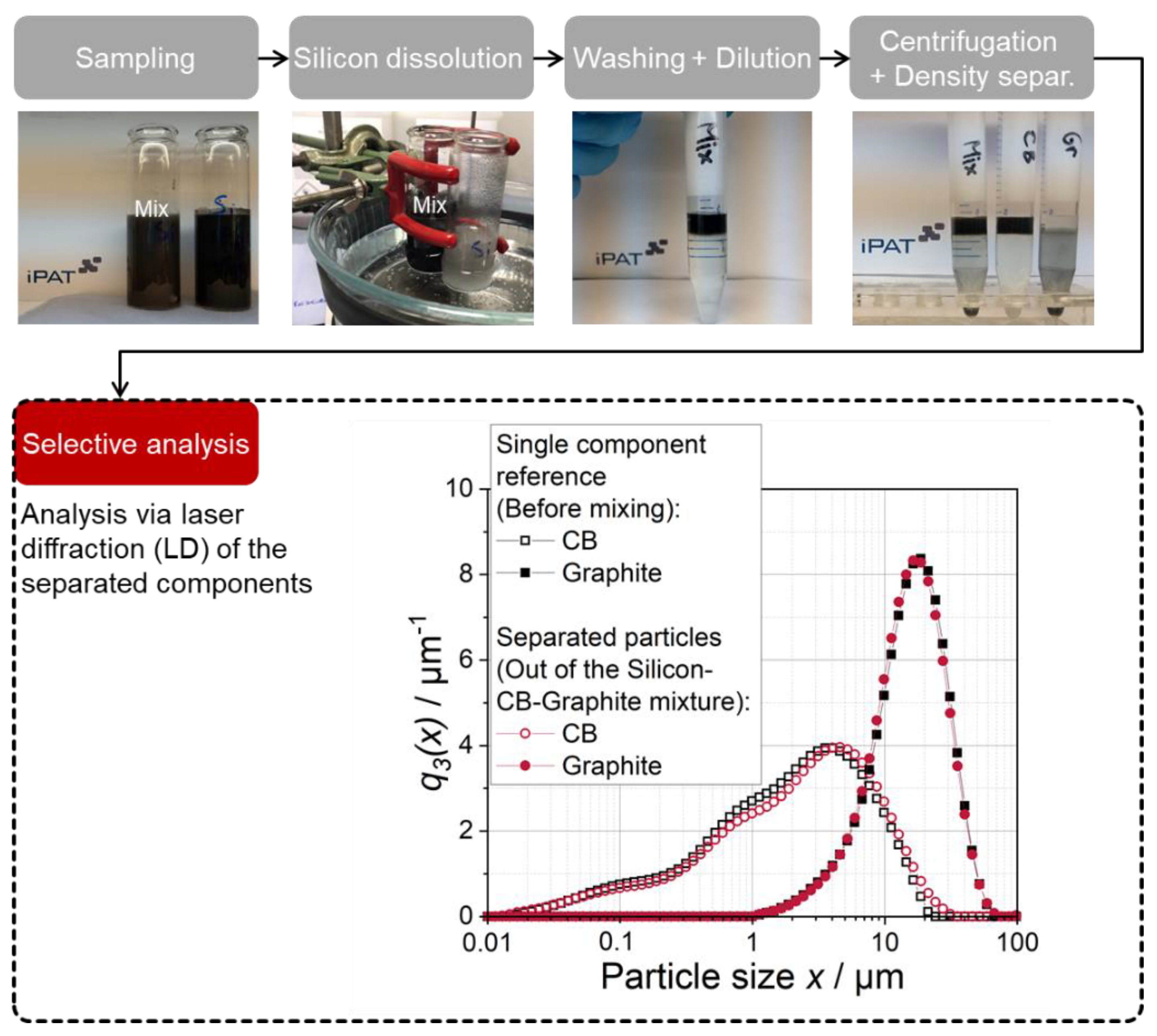

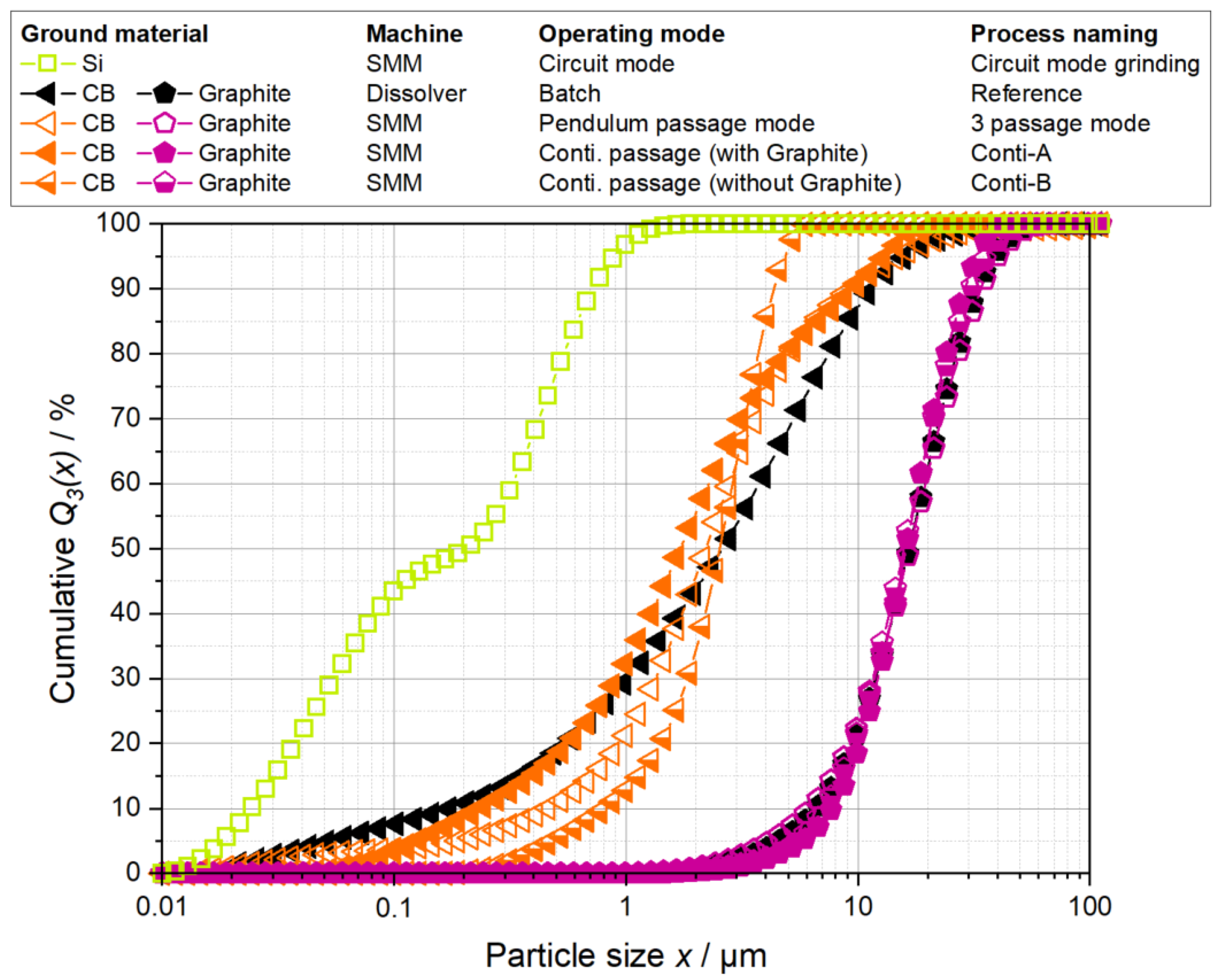

The different process variants for the targeted carbon black dispersion in a stirred media mill: three passage mode, Conti-A, and Conti-B, were investigated with regard to their suitability for battery slurry production. In contrast to the results of the single component grinding of the carbon black, mixtures were always processed in these investigations. Here, silicon, as well as carbon black, were always part of the mixture, and graphite was added at a process-dependent stage. In the three passage mode, graphite was added before the third passage, and in the continuous single-passage processes before (Conti-A) or after (Conti-B) the passage. The component-specific particle size distributions of the produced battery slurries are compared with the reference process in

Figure 14. Due to the constant processing of silicon in the circuit grinding process upstream, only an exemplary sum distribution of this material was shown for a better overview.

For the graphite, the results show that its particle size distributions were almost identical for the four suspension types. This result shows that with sufficiently reduced stress energy of the grinding media

SEGM (3 passage mode:

SEGM = 0.006·10

−3 N·m; Conti-A:

SEGM = 0.009·10

−3 N·m), significant damage to the graphitic material structure can be avoided and the graphite is only suspended homogeneously. Comparing the obtained carbon black particle size distributions, similar median values in the range of 1.8–2.5 µm are obtained with all processes. Comparable particle size distributions with respect to the reference process are obtained with the Conti-A process and the three passage mode of the stirred media mill. Here, the presence of coarse graphite particles seems to have a positive effect on the formation of a broader carbon black particle size distribution. As already discussed, shear forces between the graphite particles cause a more efficient dispersing of the carbon black fines (see

Figure 11). However, the results also suggest that there appears to be an additional protective effect of the coarse graphite particles on the capturing and stressing of the carbon black agglomerates between the grinding media (see

Figure 9, described protection effect). Thus, coarser carbon black agglomerates remain in the mixture compared to the Conti-B processing without the presence of the graphite particles. Thus, both effects support the formation of a broader particle size distribution. The very narrow particle size distribution resulting from the Conti-B process might be caused by the addition of the agglomerated silicon nanoparticles and, thus, by an increased viscosity which improved the shear forces acting on the carbon black particles.

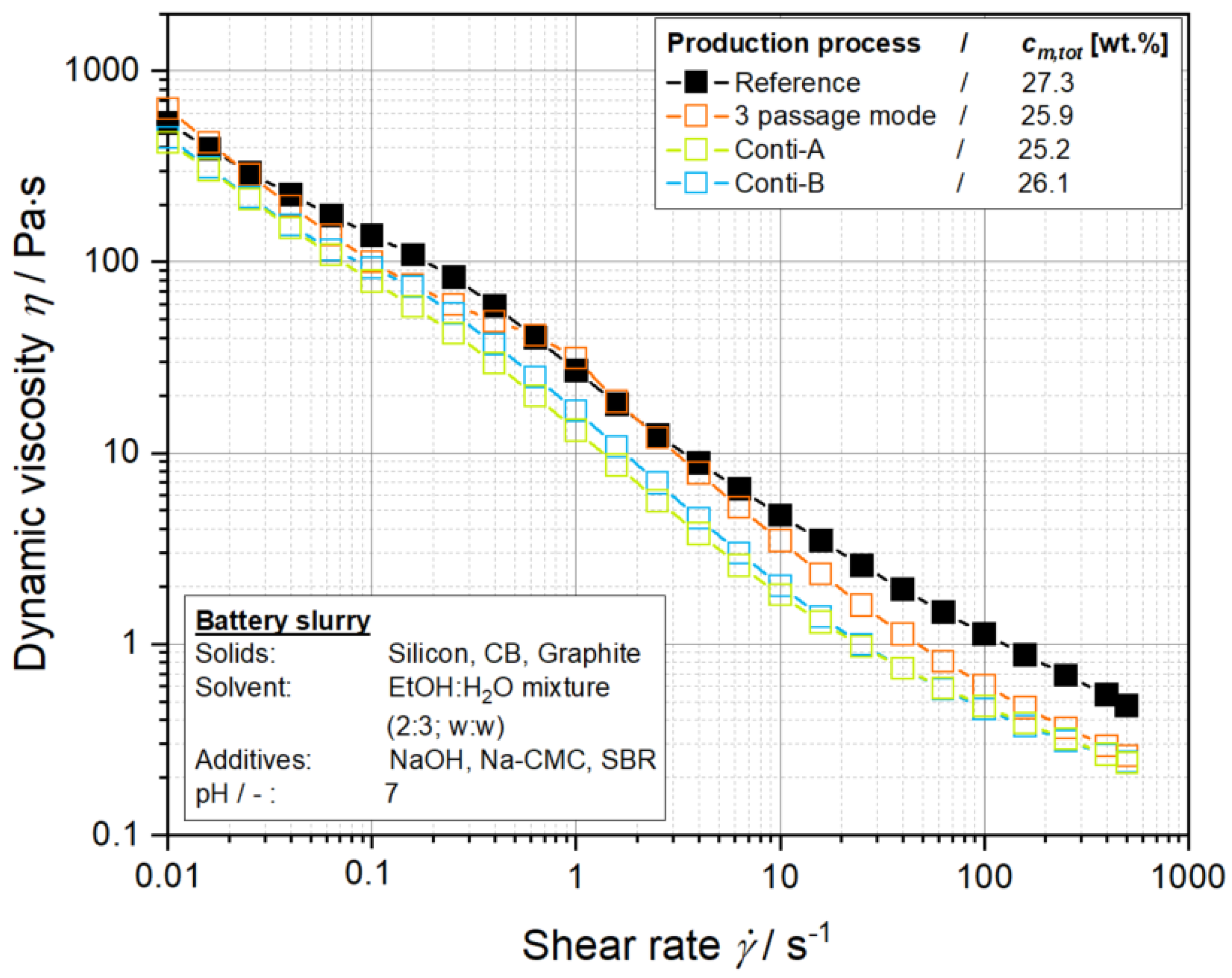

The rheological behaviors of the suspensions were also of interest for the further processing of the produced battery slurries to electrode layers within the context of standardized processing downstream. Thus, the viscosity behavior influences the formation of the particulate electrode structure during the drying of coated wet films [

25,

26]. All prepared suspensions were characterized with respect to their rheological properties directly before the coating process (see

Figure 15).

Figure 15 shows the dynamic viscosity of the coating suspensions as a function of the shear rate. All suspensions exhibit comparable shear-thinning flow behavior, which is required for a successful coating process. Especially in the low shear rate range, it is known for battery suspensions that the fractal dimensions of the carbon black aggregates play a major role in the formation of a certain viscosity level [

27]. Thus, in combination with the findings shown in

Figure 14, a similar structuring of carbon black for all produced battery slurries can be proven. In contrast to this, the suspensions produced with the process variants based on the stirred media mill exhibit a slightly lower viscosity in the higher shear rate range compared to the reference process. Within this shear rate range, the viscosity is mainly influenced by the total solids concentration

cm,tot [

27]. Therefore, small deviations regarding the

cm,tot values of the single processes investigated may account for this effect (see

Figure 15).

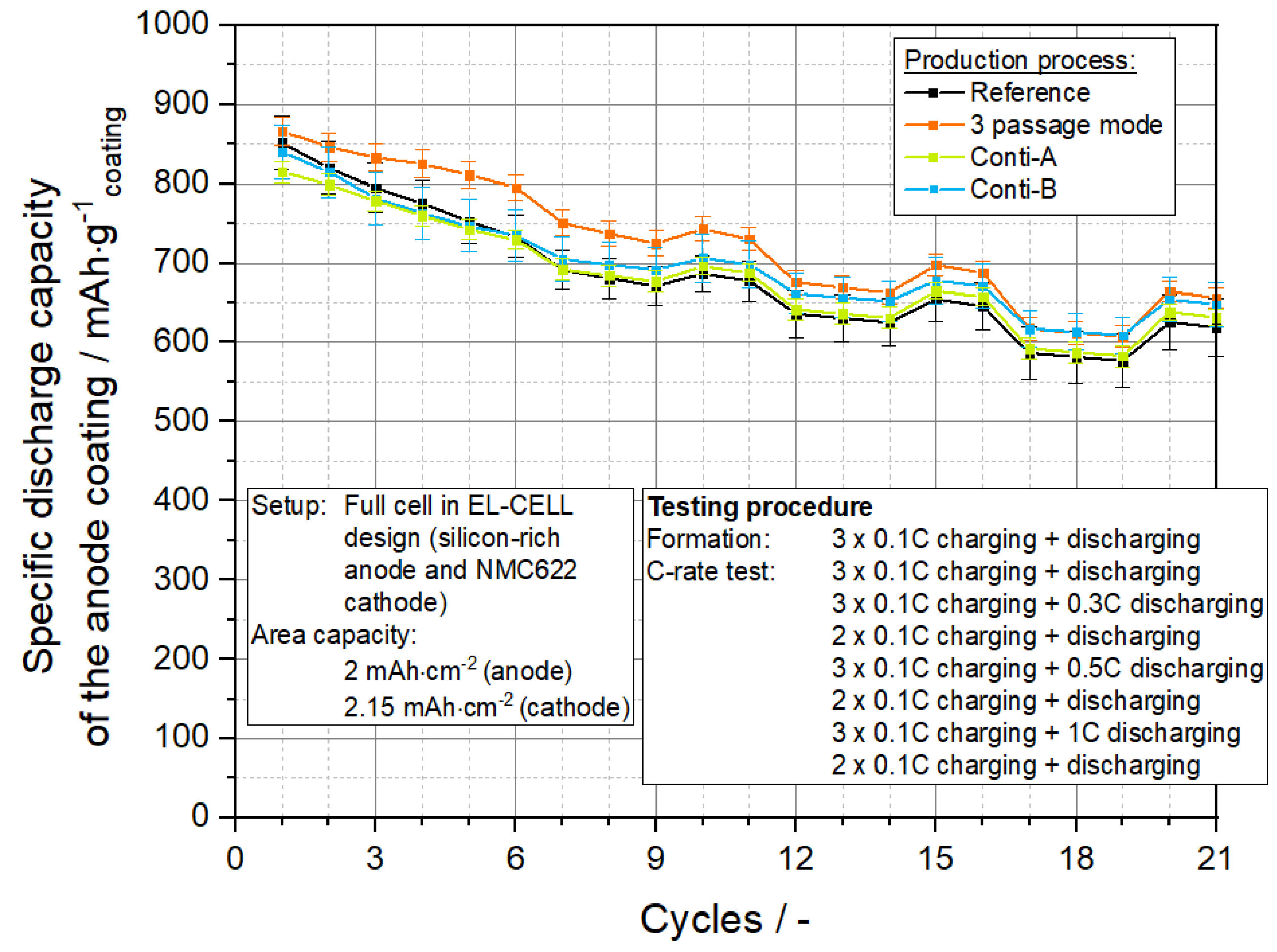

The obtained results of the selective particle size analysis and the viscosity investigations show that the process feasibility exists and that a property-optimized coating suspension can be obtained for all investigated multicomponent comminution processes.