Techno-Economic Analysis on an Industrial-Scale Production System of Polyhydroxyalkanoates (PHA) from Cheese By-Products by Halophiles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Process Design and Analysis Tool

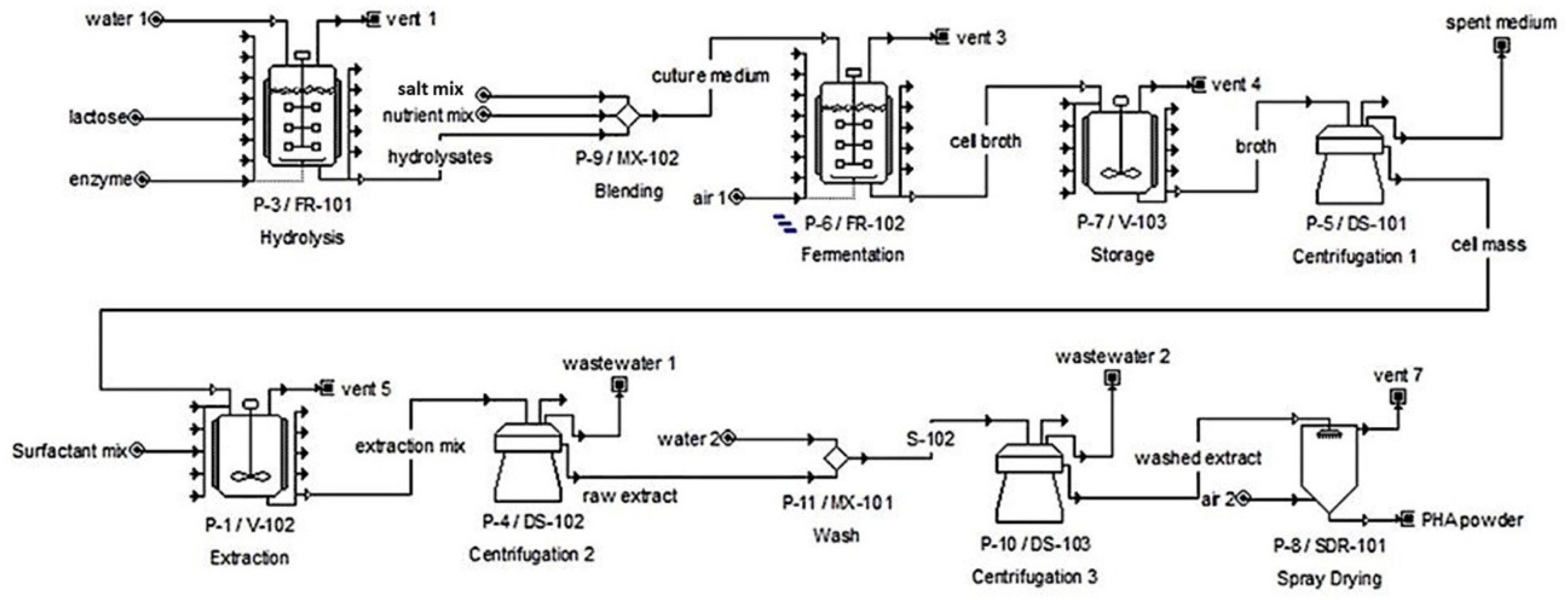

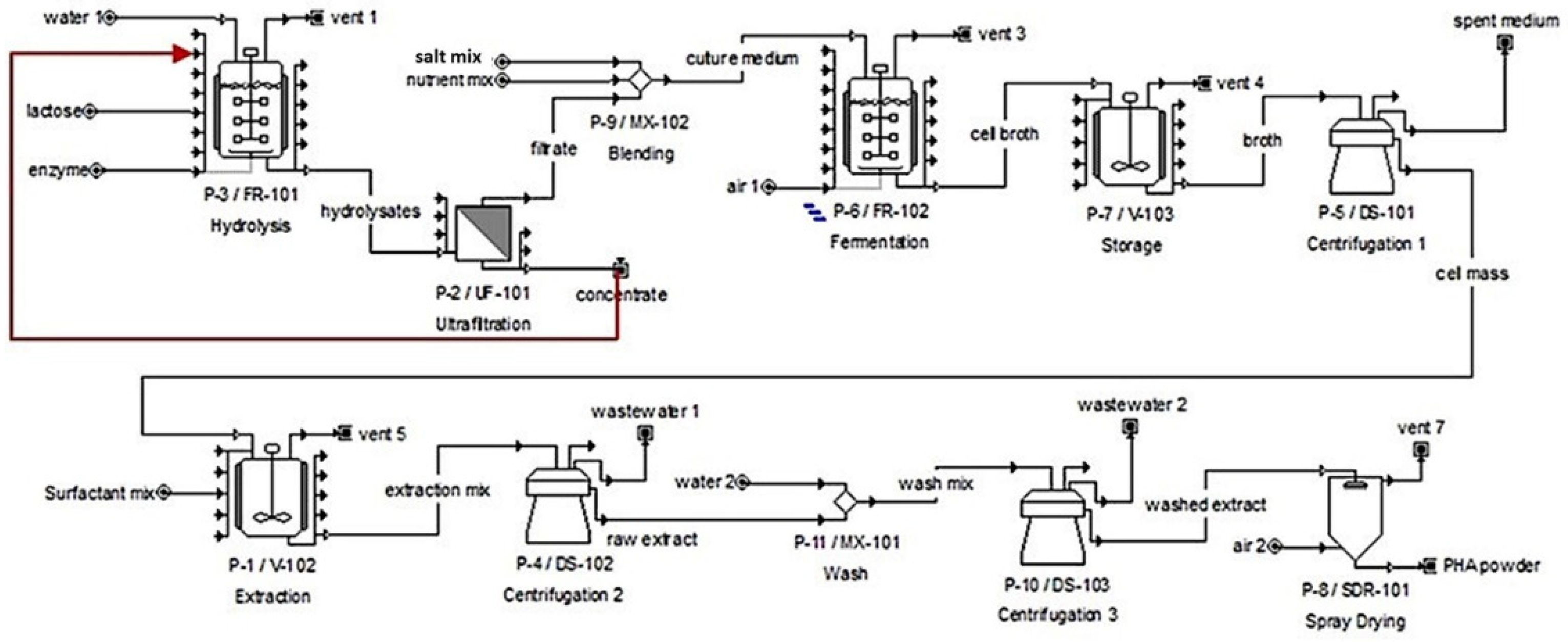

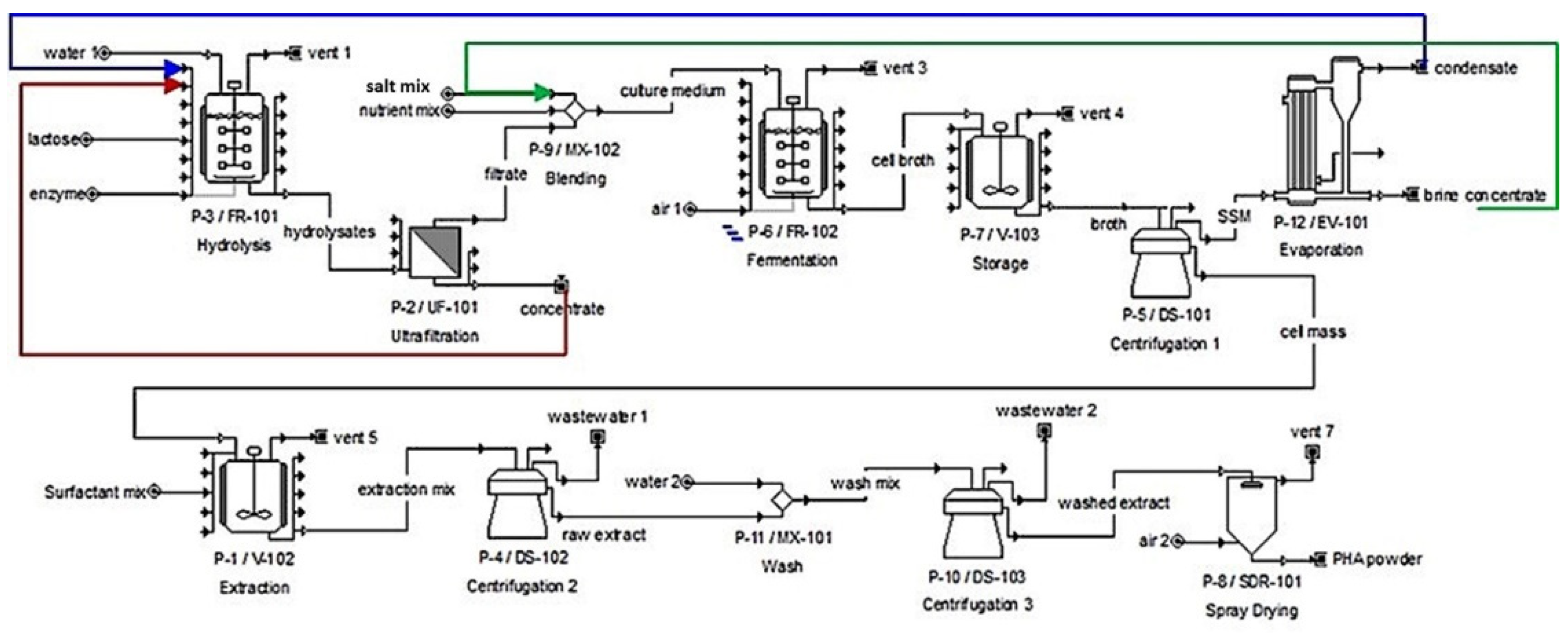

2.2. Specification of Unit Operations in All Scenarios

2.2.1. Hydrolysis

2.2.2. Blending

2.2.3. Fermentation

2.2.4. Cell Mass Separation through Centrifugation

2.2.5. PHA Extraction, Purification, and Drying

2.3. Additional Unit Operations Involved in the Scenario 2 and Scenario 3

2.3.1. Ultrafiltration for Enzyme Reuse

2.3.2. Evaporation for Spent Brine Recycling

2.4. Economic Evaluations

2.5. Sensitivity Analysis

3. Results and Discussion

3.1. Mass and Energy Flows in the Model

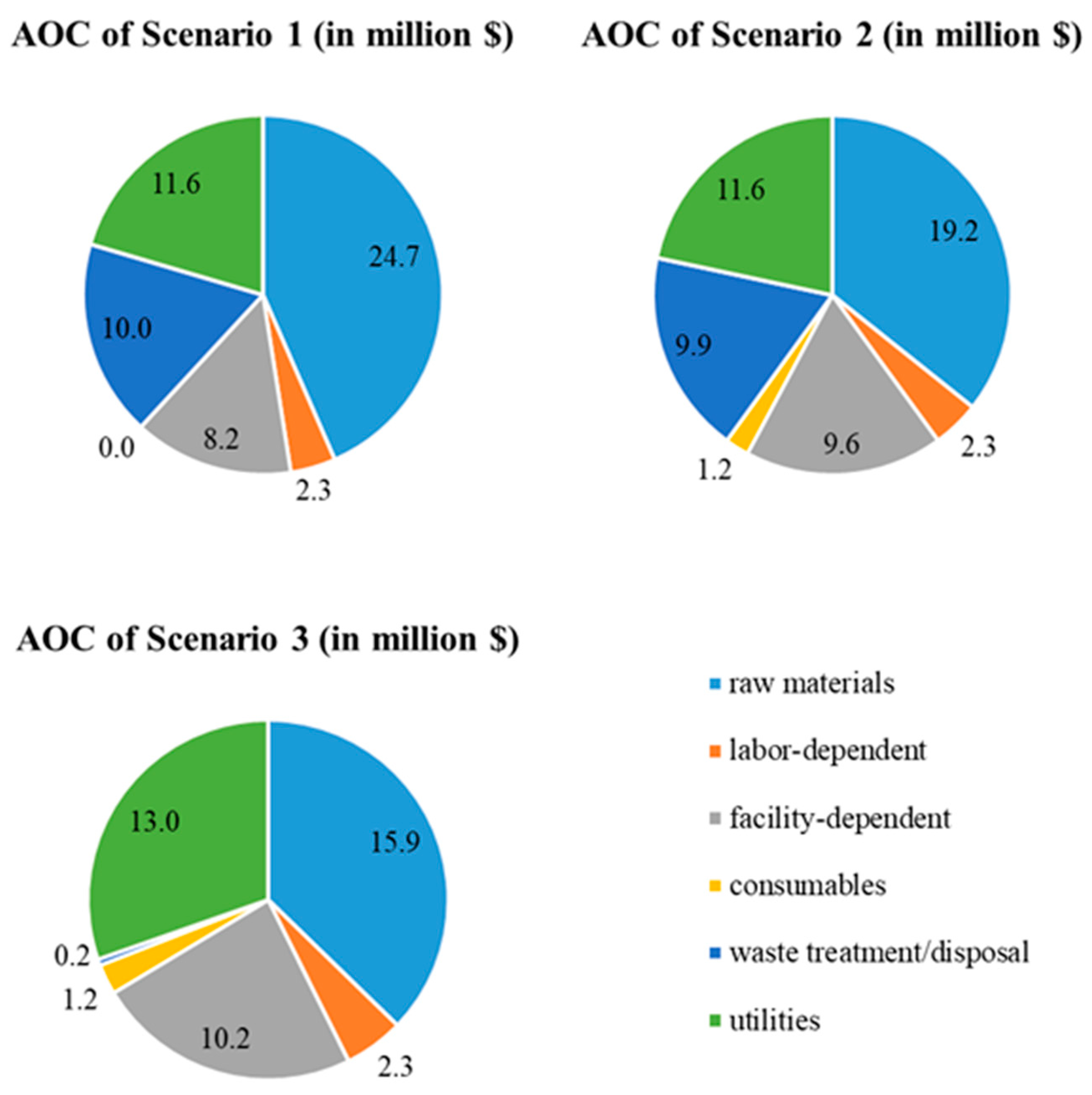

3.2. Economic Analysis: Comparison on Equipment Cost, Direct Capital Cost and Annual Operating Cost

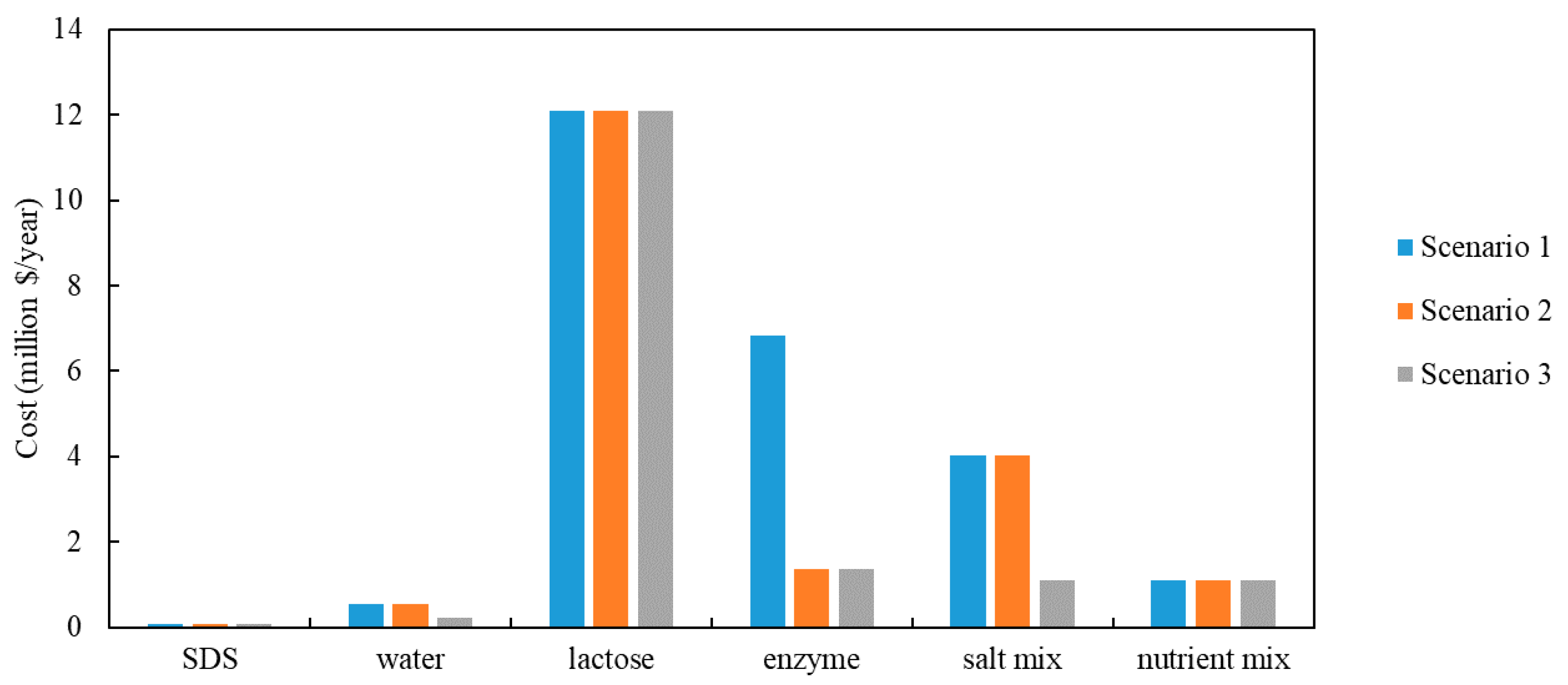

3.3. Economic Analysis: Break-Down of Raw Materials Cost

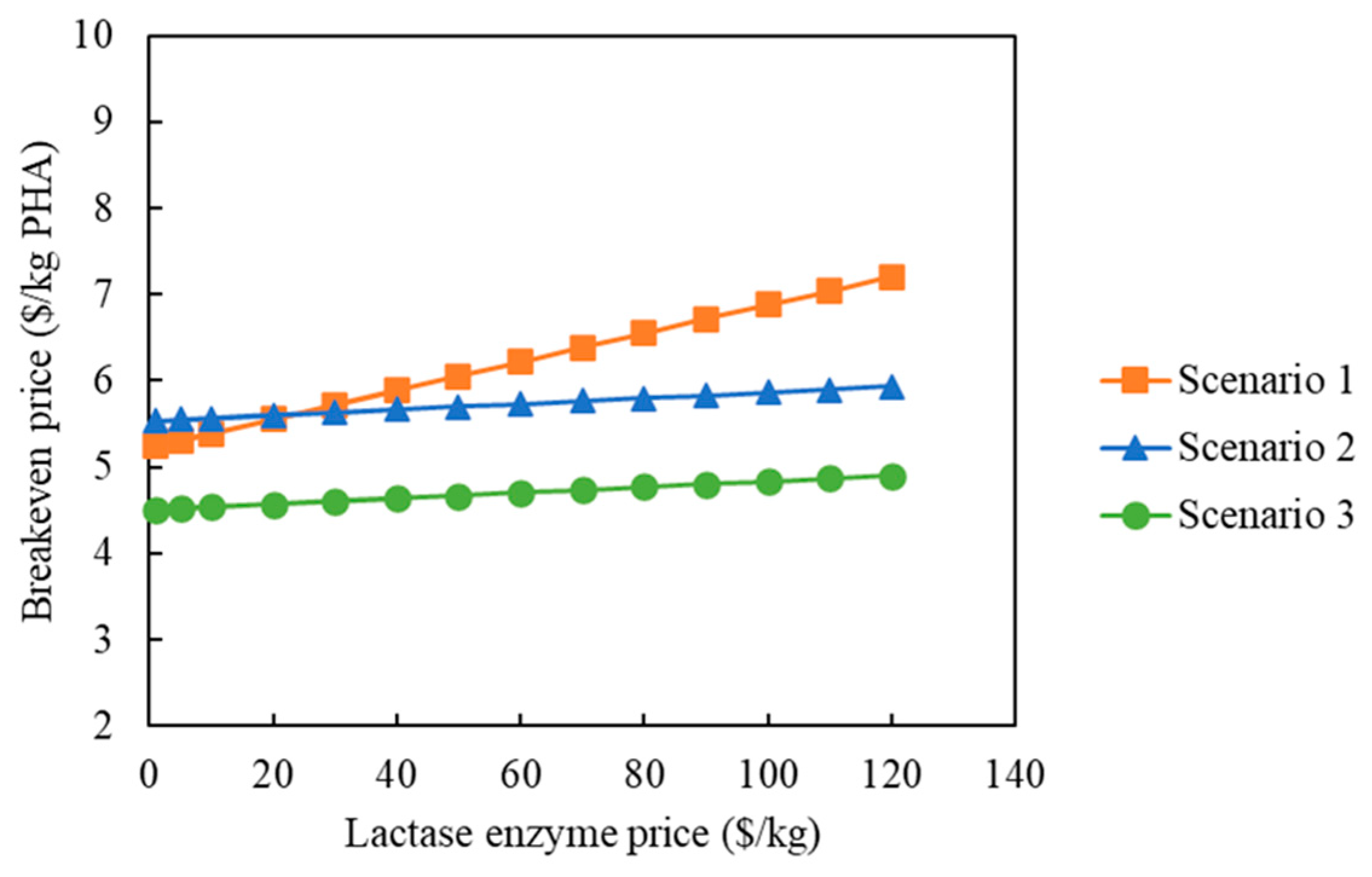

3.4. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Koller, M. A Review on Established and Emerging Fermentation Schemes for Microbial Production of Polyhydroxyalkanoate (PHA) Biopolyesters. Fermentation 2018, 4, 30. [Google Scholar] [CrossRef] [Green Version]

- Sabbagh, F.; Muhamad, I.I. Production of Poly-Hydroxyalkanoate as Secondary Metabolite with Main Focus on Sustainable Energy. Renew. Sustain. Energy Rev. 2017, 72, 95–104. [Google Scholar] [CrossRef]

- Chen, G.Q. A Microbial Polyhydroxyalkanoates (PHA) Based Bio- and Materials Industry. Chem. Soc. Rev. 2009, 38, 2434–2446. [Google Scholar] [CrossRef] [PubMed]

- Aeschelmann, F.; Carus, M. Biobased Building Blocks and Polymers in the World: Capacities, Production, and Applications–Status Quo and Trends Towards 2020. Ind. Biotechnol. 2015, 11, 154–159. [Google Scholar] [CrossRef]

- Kourmentza, C.; Plácido, J.; Venetsaneas, N.; Burniol-Figols, A.; Varrone, C.; Gavala, H.N.; Reis, M.A.M. Recent Advances and Challenges towards Sustainable Polyhydroxyalkanoate (PHA) Production. Bioengineering 2017, 4, 55. [Google Scholar] [CrossRef] [Green Version]

- Leong, Y.K.; Show, P.L.; Lan, J.C.-W.; Loh, H.-S.; Lam, H.L.; Ling, T.C. Economic and Environmental Analysis of PHAs Production Process. Clean Techn Env. Policy 2017, 19, 1941–1953. [Google Scholar] [CrossRef]

- Oliveira, D.; Puri, R.; Fenelon, M.A.; O’Mahony, J.A. Delactosed Permeate as a Dairy Processing Co-Product with Major Potential Value: A Review. Int. J. Food Sci. Technol. 2019, 54, 999–1008. [Google Scholar] [CrossRef]

- Durham, R.J. Modern Approaches to Lactose Production. In Dairy-Derived Ingredients: Food and Nutraceutical Uses; Corredig, M., Ed.; Woodhead Publishing: Sawston, UK, 2009; pp. 103–144. ISBN 978-1-84569-465-4. [Google Scholar]

- Bhattacharyya, A.; Saha, J.; Haldar, S.; Bhowmic, A.; Mukhopadhyay, U.K.; Mukherjee, J. Production of Poly-3-(Hydroxybutyrate-Co-Hydroxyvalerate) by Haloferax Mediterranei Using Rice-Based Ethanol Stillage with Simultaneous Recovery and Re-Use of Medium Salts. Extremophiles 2014, 18, 463–470. [Google Scholar] [CrossRef]

- Cui, Y.-W.; Zhang, H.-Y.; Ji, S.-Y.; Wang, Z.-W. Kinetic Analysis of the Temperature Effect on Polyhydroxyalkanoate Production by Haloferax Mediterranei in Synthetic Molasses Wastewater. J. Polym. Environ. 2017, 25, 277–285. [Google Scholar] [CrossRef]

- Pais, J.; Serafim, L.S.; Freitas, F.; Reis, M.A.M. Conversion of Cheese Whey into Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) by Haloferax Mediterranei. New Biotechnol. 2016, 33, 224–230. [Google Scholar] [CrossRef]

- Alsafadi, D.; Al-Mashaqbeh, O. A One-Stage Cultivation Process for the Production of Poly-3-(Hydroxybutyrate-Co-Hydroxyvalerate) from Olive Mill Wastewater by Haloferax Mediterranei. New Biotechnol. 2017, 34, 47–53. [Google Scholar] [CrossRef]

- Ghosh, S.; Gnaim, R.; Greiserman, S.; Fadeev, L.; Gozin, M.; Golberg, A. Macroalgal Biomass Subcritical Hydrolysates for the Production of Polyhydroxyalkanoate (PHA) by Haloferax Mediterranei. Bioresour. Technol. 2019, 271, 166–173. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, R. Production of Polyhydroxyalkanoates (PHA) by Haloferax Mediterranei from Food Waste Derived Nutrients for Biodegradable Plastic Applications. J. Microbiol. Biotechnol. 2020, 28, 338–347. [Google Scholar] [CrossRef] [PubMed]

- El-Zawawy, W.K.; Ibrahim, M.M.; Abdel-Fattah, Y.R.; Soliman, N.A.; Mahmoud, M.M. Acid and Enzyme Hydrolysis to Convert Pretreated Lignocellulosic Materials into Glucose for Ethanol Production. Carbohydr. Polym. 2011, 84, 865–871. [Google Scholar] [CrossRef]

- Gänzle, M.G.; Haase, G.; Jelen, P. Lactose: Crystallization, Hydrolysis and Value-Added Derivatives. Int. Dairy J. 2008, 18, 685–694. [Google Scholar] [CrossRef]

- Wolf, M.; Gasparin, B.C.; Paulino, A.T. Hydrolysis of Lactose Using β-d-Galactosidase Immobilized in a Modified Arabic Gum-Based Hydrogel for the Production of Lactose-Free/Low-Lactose Milk. Int. J. Biol. Macromol. 2018, 115, 157–164. [Google Scholar] [CrossRef]

- Koller, M. Recycling of Waste Streams of the Biotechnological Poly(Hydroxyalkanoate) Production by Haloferax Mediterranei on Whey. Available online: https://www.hindawi.com/journals/ijps/2015/370164/abs/ (accessed on 3 April 2019).

- McDonald, E.J.; Turcotte, A.L. Density and Refractive Indices of Lactose Solutions. J. Res. Natl. Bur. Stand. 1948, 41, 63–68. [Google Scholar] [CrossRef]

- Escalona, A.M.; Varela, F.R.; Gomis, A.M. Procedure for Extraction of Polyhydroxyalkanoates from Halophilic Bacteria Which Contain Them. U.S. Patent 5536419A, 16 August 1996. [Google Scholar]

- Alibaba Group. CaCl2 Water Purification Calcium Chloride Bulk Agent Calcium Chloride. Available online: https://www.alibaba.com/product-detail/Cacl2-Cacl2-CaCl2-Water-Purification-Calcium_1600206332554.html?spm=a2700.galleryofferlist.normal_offer.d_title.70b5593bA8wM5V&s=p (accessed on 27 July 2021).

- Intelligen, Inc. SuperPro Designer; Intelligen, Inc.: Scotch Plains, NJ, USA, 2021. [Google Scholar]

- Statista Potassium Chloride Price Forecast 2015–2035. Available online: https://www.statista.com/statistics/469705/potassium-chloride-price-forecast/ (accessed on 27 July 2021).

- Alibaba Group. Industrial Grade 6H2O 46% Purity MgCl2 Magnesium Chloride Hexahydrate Flakes. Available online: https://www.alibaba.com/product-detail/Mgcl2-Mgcl2mgcl2-Industrial-Grade-6h2o-46_1600252529812.html?spm=a2700.galleryofferlist.normal_offer.d_title.363d1b71w3FSll&s=p (accessed on 27 July 2021).

- Alibaba Group. High Purity White Powder Anhydrous MgSO4 Magnesium Sulphate Magnesium Sulfate Anhydrou 99% 14168-73-1. Available online: https://www.alibaba.com/product-detail/Mgso4-Mgso4-High-Purity-White-Powder_1600280791324.html?spm=a2700.galleryofferlist.normal_offer.d_title.7c842baaZJs5Xp&s=p (accessed on 27 July 2021).

- Alibaba Group. Industrial Grade High Purity Sodium Bromide (Nabr). Available online: https://www.alibaba.com/product-detail/Industrial-grade-high-purity-sodium-bromide_60377614864.html?spm=a2700.galleryofferlist.normal_offer.d_title.725c4f6eJciUZh (accessed on 27 July 2021).

- Alibaba Group. 94.5% Raw Sea Salt Bulk Sea Salt Price Nacl-Buy Raw Sea Salt, Nacl, Bulk Sea Salt Product on Alibaba.Com. Available online: https://www.alibaba.com/product-detail/Nacl-Nacl-Nacl-94-5-Raw_60286953075.html?spm=a2700.galleryofferlist.normal_offer.d_title.26747c45R7ZfF5&s=p (accessed on 27 July 2021).

- Alibaba Group. High Quality Heavy Alkali Sodium Bicarbonate NaHCO3 3144-55-8 Sodium Bicarbonate. Available online: https://www.alibaba.com/product-detail/Nahco3-Nahco3-High-Quality-Heavy-Alkali_1600257570258.html?spm=a2700.galleryofferlist.normal_offer.d_title.d8d1215fFXiDsD&s=p (accessed on 27 July 2021).

- Alibaba Group. Amonium Chloride/NH4Cl/Ammonium Chloride 99.5%/Feed or Industrial Grade/Good Price. Available online: https://www.alibaba.com/product-detail/Nh4cl-Nh4cl-Ammonium-Chloride-Industrial-Amonium_60586402024.html?spm=a2700.galleryofferlist.normal_offer.d_title.538b7818y6cZX4&s=p (accessed on 27 July 2021).

- Alibaba Group. Sodium Dodecyl Sulfate Sds K12,95%/93%/92% Powder, Cas 151-21-3. Available online: https://www.alibaba.com/product-detail/Sodium-Dodecyl-Sulfate-Sodium-Dodecyl-Sulfate_1600266362204.html?spm=a2700.galleryofferlist.normal_offer.d_title.44495c65X95ddT&s=p (accessed on 27 July 2021).

- California Water Service Home. Available online: https://www.calwater.com/ (accessed on 27 July 2021).

- Gryczko, S.; Alexander, J.; Heinig, A. Wastewater Rate Studies|City of Davis, CA. Available online: https://www.cityofdavis.org/city-hall/public-works-utilities-and-operations/wastewater/wastewater-rate-studies (accessed on 27 July 2021).

- Bhattacharyya, A.; Jana, K.; Haldar, S.; Bhowmic, A.; Mukhopadhyay, U.K.; De, S.; Mukherjee, J. Integration of Poly-3-(Hydroxybutyrate-Co-Hydroxyvalerate) Production by Haloferax Mediterranei through Utilization of Stillage from Rice-Based Ethanol Manufacture in India and Its Techno-Economic Analysis. World J. Microbiol. Biotechnol. 2015, 31, 717–727. [Google Scholar] [CrossRef] [PubMed]

- Choi, D.; Chipman, D.C.; Bents, S.C.; Brown, R.C. A Techno-Economic Analysis of Polyhydroxyalkanoate and Hydrogen Production from Syngas Fermentation of Gasified Biomass. Appl. Biochem. Biotechnol. 2010, 160, 1032–1046. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Lee, S.Y. Process Analysis and Economic Evaluation for Poly(3-Hydroxybutyrate) Production by Fermentation. Bioprocess Eng. 1997, 17, 335–342. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhuang, X.; Ahmad, S.; Sung, S.; Ni, S.-Q. Biotreatment of High-Salinity Wastewater: Current Methods and Future Directions. World J. Microbiol. Biotechnol. 2020, 36, 37. [Google Scholar] [CrossRef] [PubMed]

- Amaro, T.M.M.M.; Rosa, D.; Comi, G.; Iacumin, L. Prospects for the Use of Whey for Polyhydroxyalkanoate (PHA) Production. Front. Microbiol. 2019, 10, 992. [Google Scholar] [CrossRef] [PubMed]

- Shete, B.; Shinkar, N.P. Dairy Industry Wastewater Sources, Characteristics & Its Effects on Environment. Int. J. Curr. Eng. Technol. 2013, 3, 1611–1615. [Google Scholar]

| Raw Materials Price | Utility and Consumable Materials Rate | ||||||

|---|---|---|---|---|---|---|---|

| Item | Price | Unit | Source | Item | Price | Unit | Source |

| CaCl2 | 0.15 | $/kg | [21] | Steam | 12 | $/MT | Default values from SuperPro Designer [22] |

| KCl | 0.3 | $/kg | [23] | Cooling water | 0.05 | $/MT | |

| MgCl2 | 0.1 | $/kg | [24] | Chilled water | 0.4 | $/MT | |

| MgSO4 | 0.35 | $/kg | [25] | Glycol | 0.35 | $/MT | |

| NaBr | 0.4 | $/kg | [26] | Standard electricity | 0.063 | $/MT | |

| NaCl | 0.04 | $/kg | [27] | Filtration membranes | 400 | $/m2 | |

| NaHCO3 | 0.2 | $/kg | [28] | Cleaning powder | 4.91 | $/kg | |

| NH4Cl | 0.2 | $/kg | [29] | lubricant | 1.84 | $/L | |

| SDS | 0.8 | $/kg | [30] | Wastewater Treatment Rate | |||

| water | 0.0017 | $/kg | [31] | Item | Price | Unit | Source |

| PHBV | 10 | $/kg | [6] | Wastewater | 0.002 | $/L | [32] |

| High-saline wastewater | 0.041 | $/L | Communication [a] | ||||

| Cost Item | Estimation Factor | Cost Item | Estimation Factor |

|---|---|---|---|

| Total plant direct cost (TPDC) | Total plant indirect cost (TPIC) | ||

| Equipment cost (EC) | Engineering | 0.25 × TPDC | |

| Unlisted equipment cost | 0.20 × EC | Construction | 0.35 × TPDC |

| Installation | 0.36 × EC | ||

| Process piping | 0.35 × EC | Total plant cost (TPC) | TPDC + TPIC |

| Instrumentation | 0.40 × EC | ||

| Insulation | 0.03 × EC | Other cost (OC) | |

| Electrical facilities | 0.10 × EC | Contractor’s fee | 0.05 × TPC |

| Building | 0.45 × EC | Contingency | 0.10 × TPC |

| Yard improvement | 0.15 × EC | ||

| Auxiliary facilities | 0.40 × EC | Direct fixed capital cost (DCC) | TPC + OC |

| Input (MT/Batch) | Scenario 1 | Scenario 2 | Scenario 3 | Output (MT/Batch) | Scenario 1 | Scenario 2 | Scenario 3 |

|---|---|---|---|---|---|---|---|

| Water | 834.0 | 834.0 | 286.4 | PHBV | 31.8 | 31.8 | 31.8 |

| Lactose | 168.7 | 168.7 | 168.7 | SSM | 743.2 | 743.2 | 44.3 |

| Enzyme | 0.5 | 0.1 | 0.1 | Wastewater | 359.6 | 359.6 | 359.6 |

| Salt mix | 172.4 | 172.4 | 46.7 | Vent | 9631.5 | 9631.5 | 9631.5 |

| Nutrient mix | 16.9 | 16.9 | 16.9 | ||||

| Air | 9499.5 | 9499.5 | 9499.5 | ||||

| Extraction mix | 0.3 | 0.3 | 0.3 |

| Scenario No. | Electricity (Thousand MW-h/Year) | Steam (Thousand MT/Year) | Cooling Water (Million MT/Year) |

|---|---|---|---|

| 1 | 164 | 28 | 19.6 |

| 2 | 164 | 28 | 19.6 |

| 3 | 164 | 140 | 19.3 |

| Equipment | Label | Scenarios [b] | Quantity/Staggered | Description | Unit Cost ($) |

|---|---|---|---|---|---|

| Fermenter | FR-101 | 1,2,3 | 1/0 | Vessel Volume = 1025 m3 | 636,000 |

| Fermenter | FR-102 | 1,2,3 | 1/5 | Vessel Volume = 1129 m3 | 619,000 |

| Blending tank | V-103 | 1,2,3 | 1/0 | Vessel Volume = 939 m3 | 552,000 |

| Disk-Stack centrifuge | DS-101 | 1,2,3 | 1/0 | Throughput = 211 m3/h | 310,000 |

| Blending tank | V-102 | 1,2,3 | 1/0 | Vessel Volume = 376 m3 | 141,000 |

| Disk-Stack centrifuge | DS-102 | 1,2,3 | 1/0 | Throughput = 169 m3/h | 200,000 |

| Disk-Stack centrifuge | DS-103 | 1,2,3 | 1/0 | Throughput = 90 m3/h | 100,000 |

| Spray Dryer | SDR-101 | 1,2,3 | 1/0 | Dryer Volume = 35 m3 | 150,000 |

| Ultrafilter | UF-101 | 2,3 | 1/0 | Membrane Aera = 5575 m2 | 1,000,000 |

| Evaporator | EV-101 | 3 | 1/0 | Evaporation Aera = 111 m2 | 491,000 |

| Scenario No. | BP/Lactose Price | BP/Enzyme Price |

|---|---|---|

| 1 | 5.30 | 0.017 |

| 2 | 5.30 | 0.0033 |

| 3 | 5.30 | 0.0033 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Hobby, A.M.; Chen, Y.; Chio, A.; Jenkins, B.M.; Zhang, R. Techno-Economic Analysis on an Industrial-Scale Production System of Polyhydroxyalkanoates (PHA) from Cheese By-Products by Halophiles. Processes 2022, 10, 17. https://doi.org/10.3390/pr10010017

Wang K, Hobby AM, Chen Y, Chio A, Jenkins BM, Zhang R. Techno-Economic Analysis on an Industrial-Scale Production System of Polyhydroxyalkanoates (PHA) from Cheese By-Products by Halophiles. Processes. 2022; 10(1):17. https://doi.org/10.3390/pr10010017

Chicago/Turabian StyleWang, Ke, Alex Michael Hobby, Yike Chen, Allan Chio, Bryan Martin Jenkins, and Ruihong Zhang. 2022. "Techno-Economic Analysis on an Industrial-Scale Production System of Polyhydroxyalkanoates (PHA) from Cheese By-Products by Halophiles" Processes 10, no. 1: 17. https://doi.org/10.3390/pr10010017

APA StyleWang, K., Hobby, A. M., Chen, Y., Chio, A., Jenkins, B. M., & Zhang, R. (2022). Techno-Economic Analysis on an Industrial-Scale Production System of Polyhydroxyalkanoates (PHA) from Cheese By-Products by Halophiles. Processes, 10(1), 17. https://doi.org/10.3390/pr10010017