A Sustainable Approach on Spruce Bark Waste Valorization through Hydrothermal Conversion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

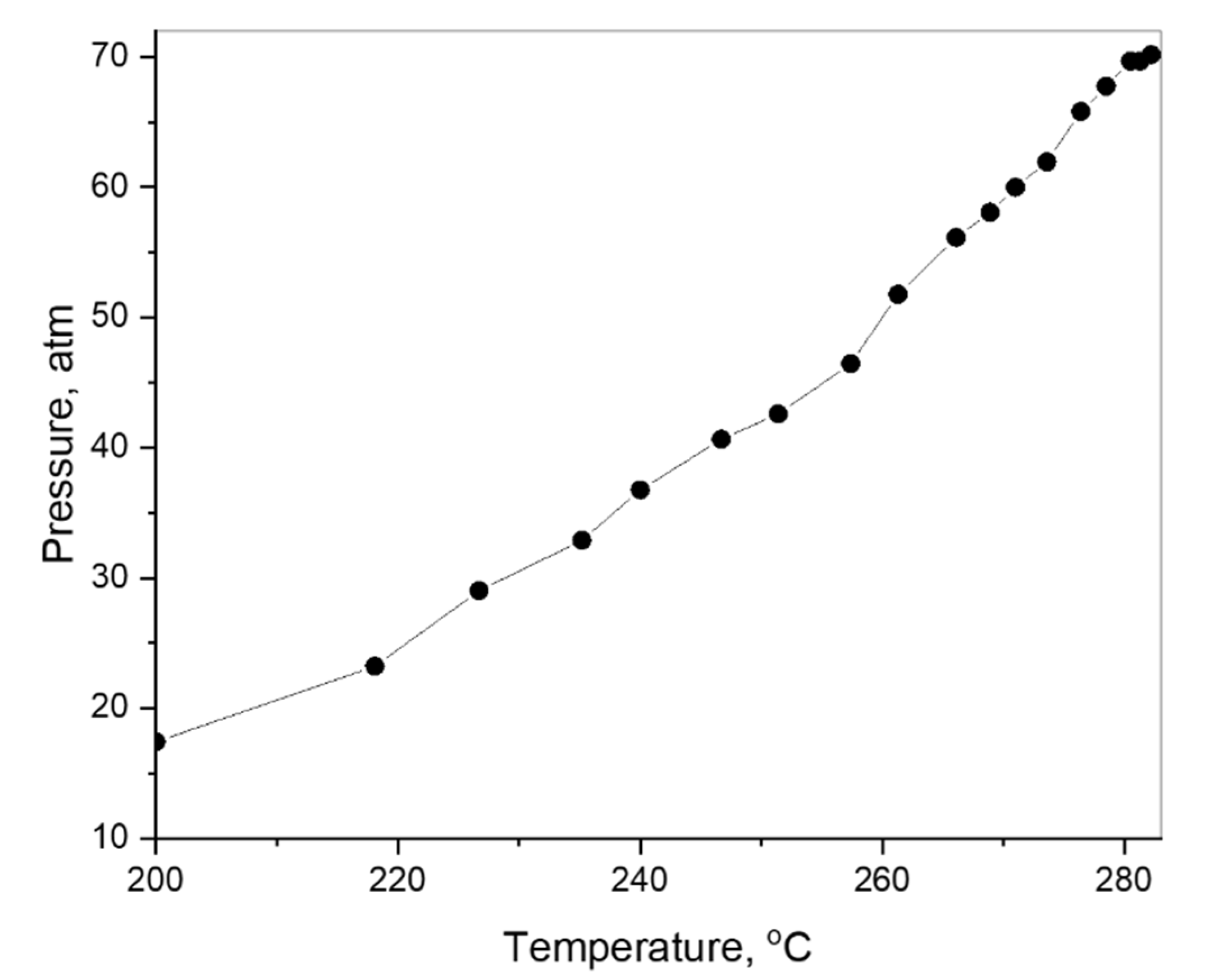

2.2.1. Hydrothermal Process Study

2.2.2. Experimental Design and Statistical Analysis

2.2.3. Characterization Methods

3. Results and Discussion

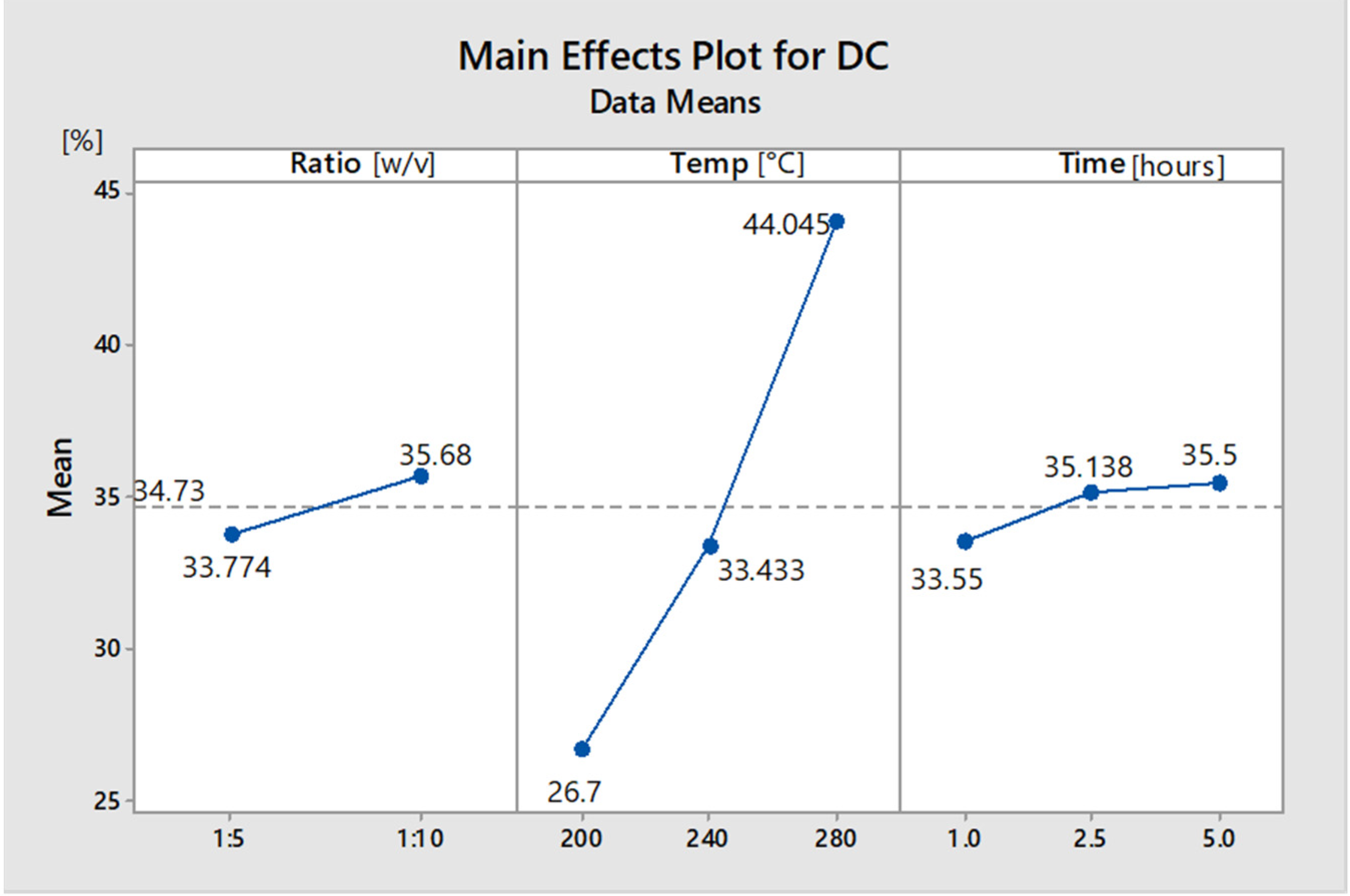

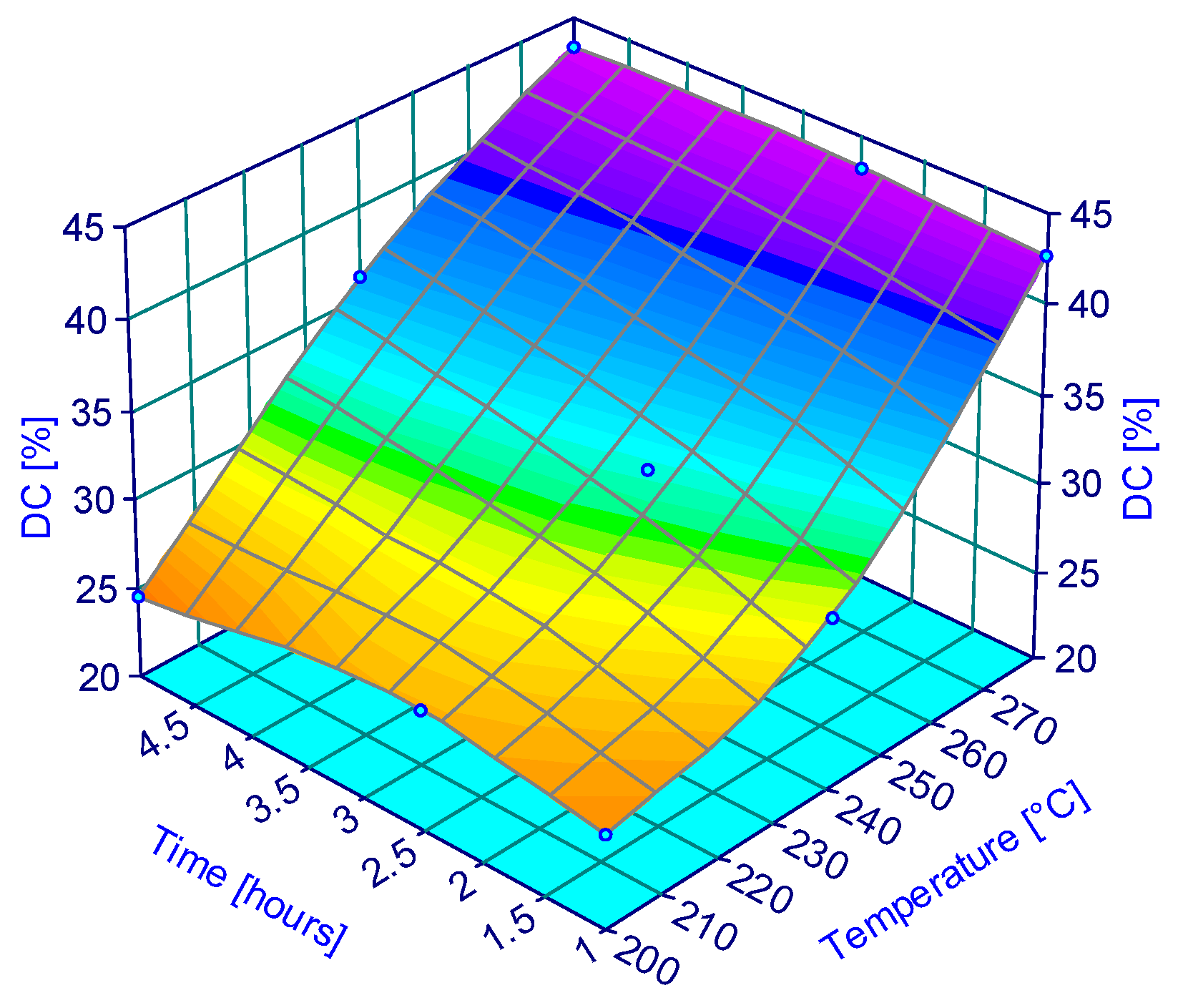

3.1. Experimental Design and Process Study on Spruce Bark HTC

3.2. Proximate and Ultimate Analysis

3.3. The Structural Assessment

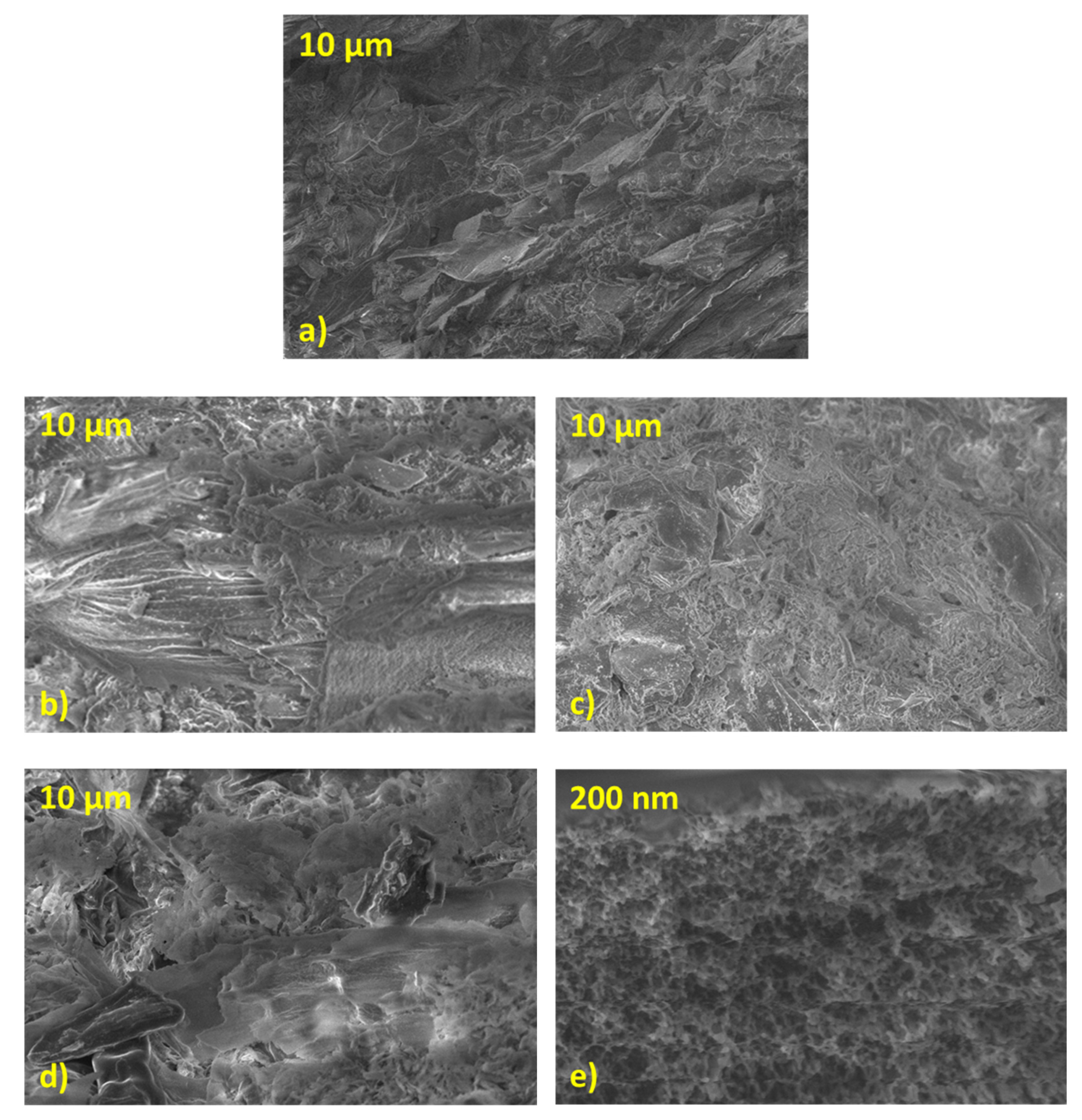

3.4. Fourier Transform Infrared Spectroscopy

3.5. Brunauer-Emmett-Teller (BET) Surface Area Analysis

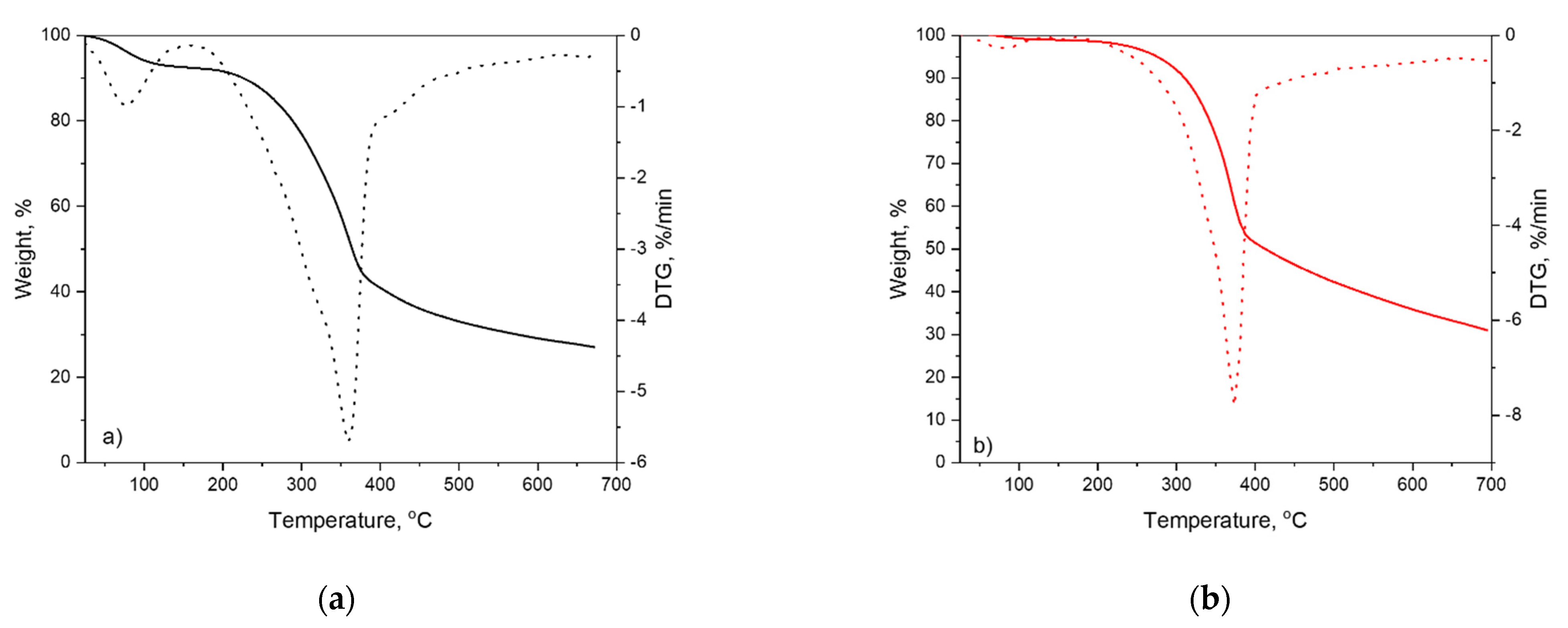

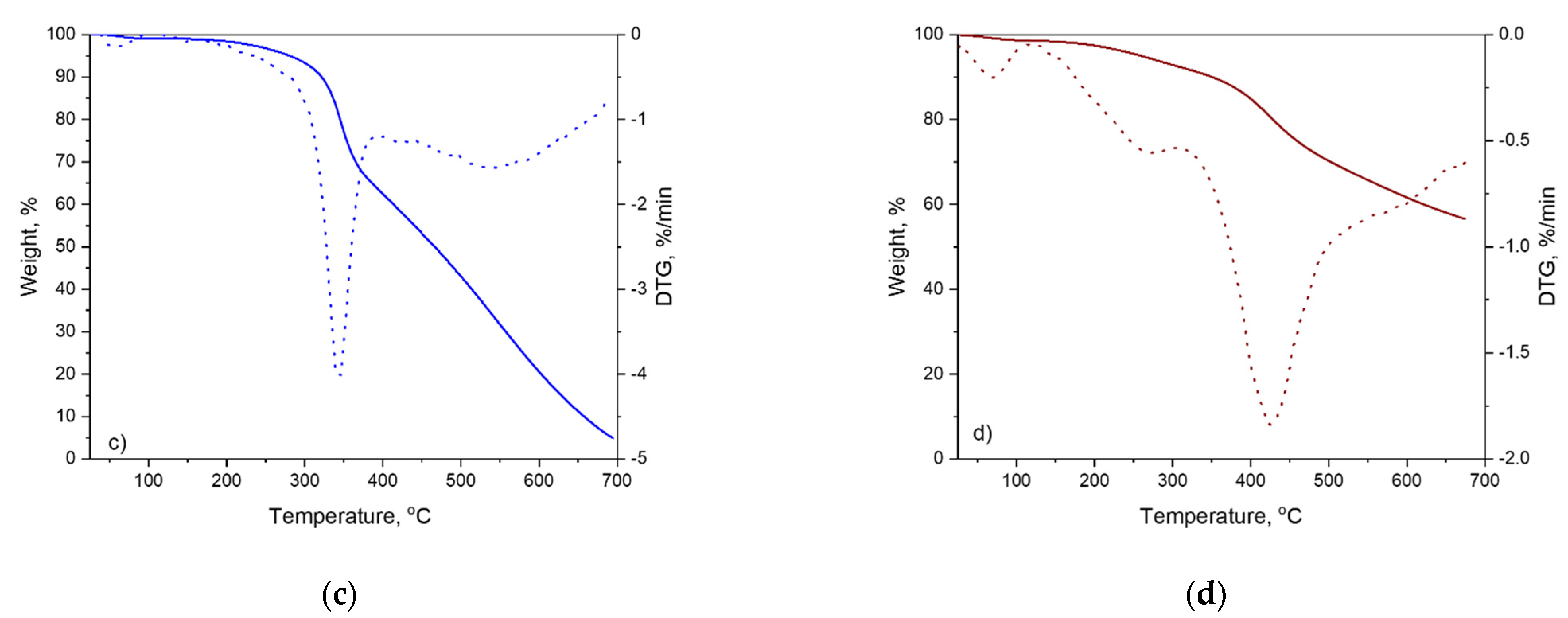

3.6. Thermogravimetric Analysis (TG)

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Volf, I.; Popa, V.I. Integrated Processing of Biomass Resources for Fine Chemical Obtaining: Polyphenols. In Biomass as Renewable Raw Material to Obtain Bioproducts of High-Tech Value; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 9780444637970. [Google Scholar]

- Nuss, P.; Blengini, G.A.; Haas, W.; Mayer, A.; Nita, V.; Pennington, D. Development of a Sankey Diagram of material flows in the EU Economy Based on Eurostat Data: Monitoring of Non-Energy & Non- Food Material Flows in the EU-28 for the EC Raw Materials Information System (RMIS); Publications Office of the European Union: Ispra, Italy, 2017; ISBN 978-92-79-73900-2. [Google Scholar]

- Bujor, O.C.; Le Bourvellec, C.; Volf, I.; Popa, V.I.; Dufour, C. Seasonal variations of the phenolic constituents in bilberry (Vaccinium myrtillus L.) leaves, stems and fruits, and their antioxidant activity. Food Chem. 2016, 213, 58–68. [Google Scholar] [CrossRef] [PubMed]

- Lazar, L.; Talmaciu, A.I.; Volf, I.; Popa, V.I. Kinetic modeling of the ultrasound-assisted extraction of polyphenols from Picea abies bark. Ultrason. Sonochem. 2016, 32, 191–197. [Google Scholar] [CrossRef] [PubMed]

- Ignat, I.; Volf, I.; Popa, V.I. A critical review of methods for characterisation of polyphenolic compounds in fruits and vegetables. Food Chem. 2011, 126, 1821–1835. [Google Scholar] [CrossRef] [PubMed]

- Talmaciu, A.I.; Ravber, M.; Volf, I.; Knez, Ž.; Popa, V.I. Isolation of bioactive compounds from spruce bark waste using sub- and supercritical fluids. J. Supercrit. Fluids 2016, 117, 243–251. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhu, Z.; Shen, B.; Liu, L. Insights into biochar and hydrochar production and applications: A review. Energy 2019, 171, 581–598. [Google Scholar] [CrossRef]

- Şen, A.U.; Pereira, H. State-of-the-art char production with a focus on bark feedstocks: Processes, design, and applications. Processes 2021, 9, 87. [Google Scholar] [CrossRef]

- Lewandowski, W.M.; Ryms, M.; Kosakowski, W. Thermal biomass conversion: A review. Processes 2020, 8, 516. [Google Scholar] [CrossRef]

- Lu, J.S.; Chang, Y.; Poon, C.S.; Lee, D.J. Slow pyrolysis of municipal solid waste (MSW): A review. Bioresour. Technol. 2020, 312, 123615. [Google Scholar] [CrossRef]

- Singh, S.; Chakraborty, J.P.; Mondal, M.K. Pyrolysis of torrefied biomass: Optimization of process parameters using response surface methodology, characterization, and comparison of properties of pyrolysis oil from raw biomass. J. Clean. Prod. 2020, 272, 122517. [Google Scholar] [CrossRef]

- Li, J.; Lin, F.; Li, K.; Zheng, F.; Yan, B.; Che, L.; Tian, W.; Chen, G.; Yoshikawa, K. A critical review on energy recovery and non-hazardous disposal of oily sludge from petroleum industry by pyrolysis. J. Hazard. Mater. 2020, 406, 124706. [Google Scholar] [CrossRef] [PubMed]

- Kambo, H.S.; Dutta, A. Comparative evaluation of torrefaction and hydrothermal carbonization of lignocellulosic biomass for the production of solid biofuel. Energy Convers. Manag. 2015, 105, 746–755. [Google Scholar] [CrossRef]

- Pala, M.; Kantarli, I.C.; Buyukisik, H.B.; Yanik, J. Hydrothermal carbonization and torrefaction of grape pomace: A comparative evaluation. Bioresour. Technol. 2014, 161, 255–262. [Google Scholar] [CrossRef]

- Volf, I.; Bejenari, I.; Popa, V.I. Chapter 6. Valuable biobased products through hydrothermal decomposition: Pulp Production and Processing. In Pulp Production and Processing: High-Tech Applications; Popa, V.I., Ed.; De Gruyter: Berlin, Germany, 2020; pp. 141–162. ISBN 9783110658842. [Google Scholar]

- Yang, W.; Wang, H.; Zhang, M.; Zhu, J.; Zhou, J.; Wu, S. Fuel properties and combustion kinetics of hydrochar prepared by hydrothermal carbonization of bamboo. Bioresour. Technol. 2016, 205, 199–204. [Google Scholar] [CrossRef]

- Wang, T.; Zhai, Y.; Zhu, Y.; Li, C.; Zeng, G. A review of the hydrothermal carbonization of biomass waste for hydrochar formation: Process conditions, fundamentals, and physicochemical properties. Renew. Sustain. Energy Rev. 2018, 90, 223–247. [Google Scholar] [CrossRef]

- Puccini, M.; Ceccarini, L.; Antichi, D.; Seggiani, M.; Tavarini, S.; Latorre, M.H.; Vitolo, S. Hydrothermal carbonization of municipal woody and herbaceous prunings: Hydrochar valorisation as soil amendment and growth medium for horticulture. Sustainability 2018, 10, 846. [Google Scholar] [CrossRef] [Green Version]

- Sharma, R.; Jasrotia, K.; Singh, N.; Ghosh, P.; Srivastava, S.; Sharma, N.R.; Singh, J.; Kanwar, R.; Kumar, A. A Comprehensive Review on Hydrothermal Carbonization of Biomass and its Applications. Chem. Africa 2020, 3, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Stenny Winata, A.; Devianto, H.; Frida Susanti, R. Synthesis of activated carbon from salacca peel with hydrothermal carbonization for supercapacitor application. Mater. Today Proc. 2020, 10–14. [Google Scholar] [CrossRef]

- Sharma, H.B.; Dubey, B.K. Co-hydrothermal carbonization of food waste with yard waste for solid biofuel production: Hydrochar characterization and its pelletization. Waste Manag. 2020, 118, 521–533. [Google Scholar] [CrossRef] [PubMed]

- Su, H.; Zhou, X.; Zheng, R.; Zhou, Z.; Zhang, Y.; Zhu, G.; Yu, C.; Hantoko, D.; Yan, M. Hydrothermal carbonization of food waste after oil extraction pre-treatment: Study on hydrochar fuel characteristics, combustion behavior, and removal behavior of sodium and potassium. Sci. Total Environ. 2021, 754, 142192. [Google Scholar] [CrossRef]

- Gupta, D.; Mahajani, S.M.; Garg, A. Investigation on hydrochar and macromolecules recovery opportunities from food waste after hydrothermal carbonization. Sci. Total Environ. 2020, 749, 142294. [Google Scholar] [CrossRef] [PubMed]

- Saqib, N.U.; Baroutian, S.; Sarmah, A.K. Physicochemical, structural and combustion characterization of food waste hydrochar obtained by hydrothermal carbonization. Bioresour. Technol. 2018, 266, 357–363. [Google Scholar] [CrossRef] [PubMed]

- Marks, E.A.N.; Kinigopoulou, V.; Akrout, H.; Azzaz, A.A.; Doulgeris, C.; Jellali, S.; Rad, C.; Zulueta, P.S.; Tziritis, E.; El-Bassi, L.; et al. Potential for production of biochar-based fertilizers from olive millwaste in mediterranean basin countries: An initial assessment for Spain, Tunisia, and Greece. Sustainability 2020, 12, 6081. [Google Scholar] [CrossRef]

- Xu, S.; Wang, C.; Duan, Y.; Wong, J.W.C. Impact of pyrochar and hydrochar derived from digestate on the co-digestion of sewage sludge and swine manure. Bioresour. Technol. 2020, 314, 123730. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Jiang, Z.; Ying, Z.; Song, J.; Chen, W.; Wang, B. Role of feedstock properties and hydrothermal carbonization conditions on fuel properties of sewage sludge-derived hydrochar using multiple linear regression technique. Fuel 2020, 271, 117609. [Google Scholar] [CrossRef]

- Malhotra, M.; Garg, A. Hydrothermal carbonization of centrifuged sewage sludge: Determination of resource recovery from liquid fraction and thermal behaviour of hydrochar. Waste Manag. 2020, 117, 114–123. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zhai, Y.; Li, S.; Wang, B.; Wang, T.; Liu, Y.; Qiu, Z.; Li, C. Hydrothermal carbonization of sewage sludge: Effect of feed-water pH on hydrochar’s physicochemical properties, organic component and thermal behavior. J. Hazard. Mater. 2020, 388, 122084. [Google Scholar] [CrossRef]

- Tasca, A.L.; Puccini, M.; Gori, R.; Corsi, I.; Galletti, A.M.R.; Vitolo, S. Hydrothermal carbonization of sewage sludge: A critical analysis of process severity, hydrochar properties and environmental implications. Waste Manag. 2019, 93, 1–13. [Google Scholar] [CrossRef]

- Knötig, P.; Etzold, H.; Wirth, B. Model-Based Evaluation of Hydrothermal Treatment for the Energy Efficient Dewatering and Drying of Sewage Sludge. Processes 2021, 9, 1346. [Google Scholar] [CrossRef]

- Lucian, M.; Merzari, F.; Gubert, M.; Messineo, A.; Volpe, M. Industrial-scale hydrothermal carbonization of agro-industrial digested sludge: Filterability enhancement and phosphorus recovery. Sustainability 2021, 13, 9343. [Google Scholar] [CrossRef]

- Garrido, R.A.; Lagos, C.; Luna, C.; Jaime, S.; Georgina, D. Study of the Potential Uses of Hydrochar from Grape Pomace and Walnut Shells Generated from Hydrothermal Carbonization as an Alternative for the Revalorization of Agri-Waste in Chile. Sustainability 2021, 13, 12600. [Google Scholar] [CrossRef]

- Sheng, K.; Zhang, S.; Liu, J.; Shuang, E.; Jin, C.; Xu, Z.; Zhang, X. Hydrothermal carbonization of cellulose and xylan into hydrochars and application on glucose isomerization. J. Clean. Prod. 2019, 237, 117831. [Google Scholar] [CrossRef]

- Saha, N.; Saba, A.; Reza, M.T. Effect of hydrothermal carbonization temperature on pH, dissociation constants, and acidic functional groups on hydrochar from cellulose and wood. J. Anal. Appl. Pyrolysis 2019, 137, 138–145. [Google Scholar] [CrossRef]

- Simsir, H.; Eltugral, N.; Karagoz, S. Hydrothermal carbonization for the preparation of hydrochars from glucose, cellulose, chitin, chitosan and wood chips via low-temperature and their characterization. Bioresour. Technol. 2017, 246, 82–87. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Yu, R.; Ji, X.; Guo, M. Hydrothermal carbonization of holocellulose into hydrochar: Structural, chemical characteristics, and combustion behavior. Bioresour. Technol. 2018, 263, 508–516. [Google Scholar] [CrossRef]

- Castro-Díaz, M.; Uguna, C.N.; Florentino, L.; Díaz-Faes, E.; Stevens, L.A.; Barriocanal, C.; Snape, C.E. Evaluation of hydrochars from lignin hydrous pyrolysis to produce biocokes after carbonization. J. Anal. Appl. Pyrolysis 2017, 124, 742–751. [Google Scholar] [CrossRef]

- Cervera-Mata, A.; Lara, L.; Fernández-Arteaga, A.; Ángel Rufián-Henares, J.; Delgado, G. Washed hydrochar from spent coffee grounds: A second generation of coffee residues. Evaluation as organic amendment. Waste Manag. 2021, 120, 322–329. [Google Scholar] [CrossRef]

- Cai, J.; Li, B.; Chen, C.; Wang, J.; Zhao, M.; Zhang, K. Hydrothermal carbonization of tobacco stalk for fuel application. Bioresour. Technol. 2016, 220, 305–311. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, S.; Dong, X.; Wu, T.; Shi, F.; Zhu, C. Characteristic evolution of hydrochar from hydrothermal carbonization of corn stalk. J. Anal. Appl. Pyrolysis 2015, 116, 1–9. [Google Scholar] [CrossRef]

- Mohammed, I.S.; Na, R.; Kushima, K.; Shimizu, N. Investigating the effect of processing parameters on the products of hydrothermal carbonization of corn stover. Sustainability 2020, 12, 5100. [Google Scholar] [CrossRef]

- Li, J.; Zhao, P.; Li, T.; Lei, M.; Yan, W.; Ge, S. Pyrolysis behavior of hydrochar from hydrothermal carbonization of pinewood sawdust. J. Anal. Appl. Pyrolysis 2020, 146, 104771. [Google Scholar] [CrossRef]

- Gao, P.; Zhou, Y.; Meng, F.; Zhang, Y.; Liu, Z.; Zhang, W.; Xue, G. Preparation and characterization of hydrochar from waste eucalyptus bark by hydrothermal carbonization. Energy 2016, 97, 238–245. [Google Scholar] [CrossRef]

- Başakçılardan Kabakcı, S.; Baran, S.S. Hydrothermal carbonization of various lignocellulosics: Fuel characteristics of hydrochars and surface characteristics of activated hydrochars. Waste Manag. 2019, 100, 259–268. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.; Yang, Z.; Li, H.; Shi, Z.; Kan, H. Preparation and properties of hydrochars from macadamia nut shell via hydrothermal carbonization. R. Soc. Open Sci. 2018, 5, 181126. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sermyagina, E.; Saari, J.; Kaikko, J.; Vakkilainen, E. Hydrothermal carbonization of coniferous biomass: Effect of process parameters on mass and energy yields. J. Anal. Appl. Pyrolysis 2015, 113, 551–556. [Google Scholar] [CrossRef]

- Kang, S.; Li, X.; Fan, J.; Chang, J. Characterization of Hydrochars Produced by Hydrothermal Carbonization of Lignin, Cellulose, d-Xylose, and Wood Meal. Ind. Eng. Chem. Res. 2012, 51, 9023–9031. [Google Scholar] [CrossRef]

- Mendoza Martinez, C.L.; Sermyagina, E.; Saari, J.; Silva de Jesus, M.; Cardoso, M.; Matheus de Almeida, G.; Vakkilainen, E. Hydrothermal carbonization of lignocellulosic agro-forest based biomass residues. Biomass Bioenergy 2021, 147, 106004. [Google Scholar] [CrossRef]

- Lin, H.; Su, J.; Liu, Y.; Yang, L. Application of Hydrothermal Reactions to Biomass Conversion; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 978-3-642-54457-6. [Google Scholar]

- Jain, A.; Balasubramanian, R.; Srinivasan, M.P. Hydrothermal conversion of biomass waste to activated carbon with high porosity: A review. Chem. Eng. J. 2016, 283, 789–805. [Google Scholar] [CrossRef]

- González-Arias, J.; Sánchez, M.E.; Martínez, E.J.; Covalski, C.; Alonso-Simón, A.; González, R.; Cara-Jiménez, J. Hydrothermal carbonization of olive tree pruning as a sustainableway for improving biomass energy potential: Effect of reaction parameters on fuel properties. Processes 2020, 8, 1201. [Google Scholar] [CrossRef]

- Dinu, R.; Bejenari, I.; Volf, I.; Mija, A. Vegetable Oil-Based Resins Reinforced with Spruce Bark Powder and with Its Hydrochar Lignocellulosic Biomass. Appl. Sci. 2021, 11, 649. [Google Scholar] [CrossRef]

- Bejenari, I.; Dinu, R.; Montes, S.; Volf, I.; Mija, A. Hydrothermal carbon as reactive fillers to produce sustainable biocomposites with aromatic bio-based epoxy resins. Polymers 2021, 12, 240. [Google Scholar] [CrossRef]

- Sliuter, A.; Sluiter, J.; Wolfrum, E.J. Chapter 8., Methods for Biomass Compositional Analysis. In Catalysis for the Conversion of Biomass and Its Derivates; Edition Open Access; Behrens, M., Datye, A.K., Eds.; Max Planck Institure for History of Science: Berlin, Germany, 2013; pp. 213–254. ISBN 978384424829. [Google Scholar]

- Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, A.; Sluiter, J.; Templeton, D. Preparation of Samples for Compositional Analysis. Lab. Anal. Proced. 2008, 1617, 65–71. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of structural carbohydrates and lignin in Biomass: TP-510-42618. Lab. Anal. Proced. 2012, 17, 1–16. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Ash in Biomass: TP-510-42622. 2008. Available online: https://www.nrel.gov/docs/gen/fy08/42622.pdf (accessed on 28 December 2021).

- May, C.; Moussa, A. Chemical and structural analysis of lignocellulosic biomass of Ampelodesmos mauritanicus (DISs) and Stipa tenacissima. Wood Res. 2018, 63, 699–712. [Google Scholar]

- Lu, F.; Wang, C.; Chen, M.; Yue, F.; Ralph, J. A facile spectroscopic method for measuring lignin content in lignocellulosic biomass. Green Chem. 2021, 23, 5106–5112. [Google Scholar] [CrossRef]

- Bardhan, M.; Novera, T.M.; Tabassum, M.; Islam, M.A.; Islam, M.A.; Hameed, B.H. Co-hydrothermal carbonization of different feedstocks to hydrochar as potential energy for the future world: A review. J. Clean. Prod. 2021, 298, 126734. [Google Scholar] [CrossRef]

- Fang, J.; Zhan, L.; Ok, Y.S.; Gao, B. Minireview of potential applications of hydrochar derived from hydrothermal carbonization of biomass. J. Ind. Eng. Chem. 2018, 57, 15–21. [Google Scholar] [CrossRef]

- Funke, A.; Ziegler, F. Hydrothermal carbonization of biomass: A summary and discussion of chemical mechanisms for process engineering. Biofuels Bioprod. Biorefining 2010, 4, 160–177. [Google Scholar] [CrossRef]

- Heidari, M.; Dutta, A.; Acharya, B.; Mahmud, S. A review of the current knowledge and challenges of hydrothermal carbonization for biomass conversion. J. Energy Inst. 2019, 92, 1779–1799. [Google Scholar] [CrossRef]

- Zhang, C.; Ma, X.; Huang, T.; Zhou, Y.; Tian, Y. Co-hydrothermal carbonization of water hyacinth and polyvinyl chloride: Optimization of process parameters and characterization of hydrochar. Bioresour. Technol. 2020, 314, 123676. [Google Scholar] [CrossRef] [PubMed]

- Kang, K.; Nanda, S.; Sun, G.; Qiu, L.; Gu, Y.; Zhang, T.; Zhu, M.; Sun, R. Microwave-assisted hydrothermal carbonization of corn stalk for solid biofuel production: Optimization of process parameters and characterization of hydrochar. Energy 2019, 186, 115795. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, J.; Lee, J.Y.; Mao, X.; Ye, L.; Xu, W.; Ning, X.; Zhang, N.; Teng, H.; Wang, C. Hydrothermal carbonization of maize straw for hydrochar production and its injection for blast furnace. Appl. Energy 2020, 266, 114818. [Google Scholar] [CrossRef]

- Díez, D.; Urueña, A.; Piñero, R.; Barrio, A.; Tamminen, T. Determination of hemicellulose, cellulose, and lignin content in different types of biomasses by thermogravimetric analysis and pseudocomponent kinetic model (TGA-PKM Method). Processes 2020, 8, 1048. [Google Scholar] [CrossRef]

- Burhenne, L.; Messmer, J.; Aicher, T.; Laborie, M.P. The effect of the biomass components lignin, cellulose and hemicellulose on TGA and fixed bed pyrolysis. J. Anal. Appl. Pyrolysis 2013, 101, 177–184. [Google Scholar] [CrossRef]

- Raitanen, J.E.; Järvenpää, E.; Korpinen, R.; Mäkinen, S.; Hellström, J.; Kilpeläinen, P.; Liimatainen, J.; Ora, A.; Tupasela, T.; Jyske, T. Tannins of conifer bark as Nordic piquancy—sustainable preservative and aroma? Molecules 2020, 25, 567. [Google Scholar] [CrossRef] [Green Version]

- Krysanova, K.; Krylova, A.; Zaichenko, V. Properties of biochar obtained by hydrothermal carbonization and torrefaction of peat. Fuel 2019, 256, 115929. [Google Scholar] [CrossRef]

- Volpe, M.; Goldfarb, J.L.; Fiori, L. Hydrothermal carbonization of Opuntia ficus-indica cladodes: Role of process parameters on hydrochar properties. Bioresour. Technol. 2018, 247, 310–318. [Google Scholar] [CrossRef] [PubMed]

- Lv, G.; Wu, S.; Lou, R. Hemicellulose pyrolysis. BioResources 2010, 5, 1281–1291. [Google Scholar]

- Dorez, G.; Ferry, L.; Sonnier, R.; Taguet, A.; Lopez-Cuesta, J.M. Effect of cellulose, hemicellulose and lignin contents on pyrolysis and combustion of natural fibers. J. Anal. Appl. Pyrolysis 2014, 107, 323–331. [Google Scholar] [CrossRef]

- Wang, L.; Barta-Rajnai, E.; Skreiberg; Khalil, R.; Czégény, Z.; Jakab, E.; Barta, Z.; Grønli, M. Effect of torrefaction on physiochemical characteristics and grindability of stem wood, stump and bark. Appl. Energy 2018, 227, 137–148. [Google Scholar] [CrossRef]

- Parshetti, G.K.; Kent Hoekman, S.; Balasubramanian, R. Chemical, structural and combustion characteristics of carbonaceous products obtained by hydrothermal carbonization of palm empty fruit bunches. Bioresour. Technol. 2013, 135, 683–689. [Google Scholar] [CrossRef] [PubMed]

- Fuertes, A.B.; Arbestain, M.C.; Sevilla, M.; MacIá-Agulló, J.A.; Fiol, S.; López, R.; Smernik, R.J.; Aitkenhead, W.P.; Arce, F.; MacIas, F. Chemical and structural properties of carbonaceous products obtained by pyrolysis and hydrothermal carbonisation of corn stover. Aust. J. Soil Res. 2010, 48, 618–626. [Google Scholar] [CrossRef]

- Wu, Q.; Yu, S.; Hao, N.; Wells, T.; Meng, X.; Li, M.; Pu, Y.; Liu, S.; Ragauskas, A.J. Characterization of products from hydrothermal carbonization of pine. Bioresour. Technol. 2017, 244, 78–83. [Google Scholar] [CrossRef]

- Guo, S.; Dong, X.; Liu, K.; Yu, H.; Zhu, C. Chemical, energetic, and structural characteristics of hydrothermal carbonization solid products for lawn grass. BioResources 2015, 10, 4613–4625. [Google Scholar] [CrossRef]

- Jaruwat, D.; Udomsap, P.; Chollacoop, N.; Fuji, M.; Eiad-Ua, A. Effects of hydrothermal temperature and time of hydrochar from Cattail leaves. AIP Conf. Proc. 2018, 2010. [Google Scholar] [CrossRef]

- Azaare, L.; Commeh, M.K.; Smith, A.M.; Kemausuor, F. Co-hydrothermal carbonization of pineapple and watermelon peels: Effects of process parameters on hydrochar yield and energy content. Bioresour. Technol. Rep. 2021, 15, 100720. [Google Scholar] [CrossRef]

- Latham, K.G.; Matsakas, L.; Figueira, J.; Rova, U.; Christakopoulos, P.; Jansson, S. Examination of how variations in lignin properties from Kraft and organosolv extraction influence the physicochemical characteristics of hydrothermal carbon. J. Anal. Appl. Pyrolysis 2021, 155, 105095. [Google Scholar] [CrossRef]

- Warowny, W.; Eubank, P.T. Generalized equations of the Burnett P-V-T methods for adsorbing gases. Fluid Phase Equilib. 1995, 103, 77–95. [Google Scholar] [CrossRef]

- Radjy, F.; Sellevold, E.J. A phenomenological theory for the t-method of pore structure analysis: I. Slit-shaped pores. J. Colloid Interface Sci. 1972, 39, 367–378. [Google Scholar] [CrossRef]

- Taskin, E.; de Castro Bueno, C.; Allegretta, I.; Terzano, R.; Rosa, A.H.; Loffredo, E. Multianalytical characterization of biochar and hydrochar produced from waste biomasses for environmental and agricultural applications. Chemosphere 2019, 233, 422–430. [Google Scholar] [CrossRef]

- Reibe, K.; Götz, K.P.; Roß, C.L.; Döring, T.F.; Ellmer, F.; Ruess, L. Impact of quality and quantity of biochar and hydrochar on soil Collembola and growth of spring wheat. Soil Biol. Biochem. 2015, 83, 84–87. [Google Scholar] [CrossRef]

- Gascó, G.; Paz-Ferreiro, J.; Álvarez, M.L.; Saa, A.; Méndez, A. Biochars and hydrochars prepared by pyrolysis and hydrothermal carbonisation of pig manure. Waste Manag. 2018, 79, 395–403. [Google Scholar] [CrossRef] [PubMed]

- Zhao, K.; Li, Y.; Zhou, Y.; Guo, W.; Jiang, H.; Xu, Q. Characterization of hydrothermal carbonization products (hydrochars and spent liquor) and their biomethane production performance. Bioresour. Technol. 2018, 267, 9–16. [Google Scholar] [CrossRef] [PubMed]

- Wilk, M.; Magdziarz, A. Hydrothermal carbonization, torrefaction and slow pyrolysis of Miscanthus giganteus. Energy 2017, 140, 1292–1304. [Google Scholar] [CrossRef]

| No. Exp. | Solid-to-Liquid Ratio (w/v) | Temperature (°C) | Residence Time (h) | Conversion Degree (%) |

|---|---|---|---|---|

| 1 | 1/5 | 200 | 1.0 | 25.24 ± 1.46 |

| 2 | 1/10 | 200 | 1.0 | 26.81 ± 0.72 |

| 3 | 1/5 | 240 | 1.0 | 29.60 ± 0.58 |

| 4 | 1/10 | 240 | 1.0 | 32.01 ± 0.41 |

| 5 | 1/5 | 280 | 1.0 | 42.59 ± 1.48 |

| 6 | 1/10 | 280 | 1.0 | 45.03 ± 0.46 |

| 7 | 1/5 | 200 | 2.5 | 26.71 ± 0.45 |

| 8 | 1/10 | 200 | 2.5 | 29.80 ± 0.53 |

| 9 | 1/5 | 240 | 2.5 | 32.82 ± 0.14 |

| 10 | 1/10 | 240 | 2.5 | 33.19 ± 0.61 |

| 11 | 1/5 | 280 | 2.5 | 43.19 ± 0.74 |

| 12 | 1/10 | 280 | 2.5 | 45.12 ± 0.29 |

| 13 | 1/5 | 200 | 5.0 | 24.48 ± 1.29 |

| 14 | 1/10 | 200 | 5.0 | 27.19 ± 0.67 |

| 15 | 1/5 | 240 | 5.0 | 36.03 ± 0.76 |

| 16 | 1/10 | 240 | 5.0 | 36.96 ± 0.33 |

| 17 | 1/5 | 280 | 5.0 | 43.32 ± 0.70 |

| 18 | 1/10 | 280 | 5.0 | 45.01 ± 0.80 |

| No. crt. | Input Parameters | Unit | Level | Value |

|---|---|---|---|---|

| 1 | Solid-to-liquid ratio | (w/v) | −1 | 1/5 |

| 1 | 1/10 | |||

| 2 | Temperature | °C | −1 | 200 |

| 0 | 240 | |||

| 1 | 280 | |||

| 3 | Residence Time | h | −1 | 1.0 |

| 0 | 2.5 | |||

| 1 | 5.0 |

| Source | DF * | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Solid-to-Liquid Ratio | 1 | 49.05 | 49.05 | 20.78 | <0.001 |

| Temperature | 2 | 2751.83 | 1375.92 | 582.76 | <0.001 |

| Residence Time | 2 | 38.77 | 19.39 | 8.21 | 0.001 |

| Error | 48 | 113.33 | 2.36 | ||

| Lack-of-Fit | 12 | 91.32 | 7.61 | 12.45 | <0.001 |

| Pure Error | 36 | 22.01 | 0.61 | ||

| Total | 53 | 2952.99 |

| Analysis | Spruce Bark (SB) | Hydrochar (HC-200) | Hydrochar (HC-240) | Hydrochar (HC-280) | |

|---|---|---|---|---|---|

| Yield, wt.% | - | 74.76 ± 1.19 | 70.40 ± 0.48 | 57.41 ± 1.21 | |

| Proximate Analysis | Moisture, wt.% | 8.35 ± 0.30 | 3.59 ± 0.29 | 2.46 ± 0.25 | 1.98 ± 0.30 |

| Ash, wt.% | 2.17 ± 0.30 | 1.86 ± 0.24 | 1.03 ± 0.15 | 0.66 ± 0.14 | |

| Hemicellulose, wt.% | 15.42 ± 0.53 | - | - | - | |

| Cellulose, wt.% | 31.27 ± 1.01 | 25.70 ± 0.92 | 13.80 ± 0.45 | 2.50 ± 0.25 | |

| Lignin, wt.% | 40.48 ± 0.73 | 40.10 ± 1.18 | 39.50 ± 1.02 | 38.46 ± 0.63 | |

| Ultimate Analysis | Carbon, wt.% | 58.26 | 60.13 | 62.80 | 71.61 |

| Hydrogen, wt.% | 5.84 | 5.70 | 5.44 | 5.20 | |

| Oxygen, wt.% | 33.15 | 28.14 | 25.12 | 21.11 | |

| Magnesium, wt.% | 0.05 | 0.02 | - | - | |

| Aluminium, wt.% | 0.01 | - | - | - | |

| Silicon, wt.% | 0.01 | - | - | - | |

| Phosphorus, wt.% | 0.04 | - | - | - | |

| Sulphur, wt.% | 0.05 | - | - | - | |

| Chlorine, wt.% | 0.01 | - | - | - | |

| Potassium, wt.% | 0.33 | 0.10 | - | - | |

| Calcium, wt.% | 1.59 | 1.52 | 1.49 | 1.44 | |

| Manganese, wt.% | 0.02 | - | - | - | |

| Copper, wt.% | 0.38 | 0.38 | 0.38 | 0.38 | |

| Zinc, wt.% | 0.27 | 0.27 | 0.26 | 0.26 | |

| Wave Number (cm−1) | Functional Groups | Description | References |

|---|---|---|---|

| 3500–3000 | O–H | Hydroxyl or carboxylic alcohols of cellulose or phenols of lignin | [40,41,44] |

| 2923 | C–H | Stretching vibration of aliphatic C–H | [40,41,44] |

| 2297 | C–O | Stretching vibration of aliphatic C–O | [76] |

| 1696 | C=O | Carbonyl, ester, or carboxyl from cellulose and lignin | [41,79,80] |

| 1611 | C=C | Aromatic skeleton present in lignin | [41,44,78] |

| 1448 | C–H | Deformities in lignin and carbohydrates | [40,80] |

| 1264 | C–O | Esters of hemicellulose | [40,80] |

| 1148 | C–O–C | Vibrations in cellulose and hemicellulose | [41] |

| 1025 | C–O | Vibrations in cellulose and lignin | [40,41,44] |

| 870–750 | C–H | Aromatic C–H out-of-plane bending vibration | [40,77] |

| Sample | Surface Area, m2·g−1 | VS, cm3·g−1 | Vmi, cm3·g−1 | Vme, cm3·g−1 |

|---|---|---|---|---|

| HC-200 | 5 | 0.0195 | 0 | 0.0195 |

| HC-240 | 8 | 0.0379 | 0 | 0.0379 |

| HC-280 | 13 | 0.0899 | 0 | 0.0899 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bejenari, I.; Hristea, G.; Cărăușu, C.; Mija, A.; Volf, I. A Sustainable Approach on Spruce Bark Waste Valorization through Hydrothermal Conversion. Processes 2022, 10, 111. https://doi.org/10.3390/pr10010111

Bejenari I, Hristea G, Cărăușu C, Mija A, Volf I. A Sustainable Approach on Spruce Bark Waste Valorization through Hydrothermal Conversion. Processes. 2022; 10(1):111. https://doi.org/10.3390/pr10010111

Chicago/Turabian StyleBejenari, Iuliana, Gabriela Hristea, Constantin Cărăușu, Alice Mija, and Irina Volf. 2022. "A Sustainable Approach on Spruce Bark Waste Valorization through Hydrothermal Conversion" Processes 10, no. 1: 111. https://doi.org/10.3390/pr10010111

APA StyleBejenari, I., Hristea, G., Cărăușu, C., Mija, A., & Volf, I. (2022). A Sustainable Approach on Spruce Bark Waste Valorization through Hydrothermal Conversion. Processes, 10(1), 111. https://doi.org/10.3390/pr10010111