Abstract

China is a large consumer of meat and meat products. People’s daily diets include a variety of meat, but meat food adulteration problems are common. This paper discusses the research progress of the electronic nose and near-infrared spectroscopy in the field of meat adulteration detection. Through the study of dozens of related papers in recent years, it has been found that the use of the electronic nose and near-infrared spectroscopy for meat detection has the advantages of speed, a nondestructive nature, high sensitivity, strong quantitative analysis, high automation, a wide applicability, an improved product quality, and cost reduction over the traditional detection, but it may be limited in detecting the adulteration of a specific meat, and there are issues with the life and stability of the sensors of the electronic nose in the process of detection, along with the problems of the high requirements for the modeling of the data of near-infrared spectroscopy. This paper takes adulterated meat as the research object and briefly summarizes the detection principles of the electronic nose and near-infrared spectroscopy, as well as the types of sensors applied in the electronic nose. The research progress of the electronic nose and near-infrared detection technology in meat adulteration assessment is reviewed, the advantages and disadvantages of the two in practical application are analyzed, the classification of pattern recognition methods and their applications in meat identification are described, and the feasibility and practical significance of the joint application of the two in meat adulteration detection are envisioned. Meanwhile, the challenges faced by the two in meat detection are pointed out.

1. Introduction

With the rapid growth in meat consumption, the problem of adulteration occurs from time to time. The study of techniques for identifying the adulteration of meat and meat products has been a hot research topic in the field of food safety [1]. However, due to the variety and complexity of meat products, the appearance, composition, and nature of most meats are relatively close to each other, and the meat in the food loses its original morphological characteristics and texture after processing and cooking, such as chopping, mixing, steaming, etc., which increases the difficulty in identifying the species of meat contained in the food [2]. The adulteration of meat and its processed products not only harms the interests of consumers and disrupts the market order but also may jeopardize the health of consumers; therefore, it is of great significance to adopt accurate, efficient, and sensitive identification techniques to identify adulterated meat products.

Traditional meat adulteration detection methods include sensory, chemical, and molecular biology tests. Sensory testing is used to determine whether meat is adulterated by observing its color, odor, texture, and other indicators; chemical testing is used to determine whether meat is adulterated by analyzing the chemical components in the meat; and molecular biology testing is used to determine whether meat is adulterated by analyzing molecular markers, such as DNA or RNA, in the meat. However, sensory testing is susceptible to personal preferences, experience, judgment, and other factors. The results have a certain degree of subjectivity and cannot be qualitatively and quantitatively analyzed. The chemical testing and molecular biology testing detection time is long, and the testing methods require professional personnel to operate them, need expensive equipment, and have a complex operation. Therefore, choosing the electronic nose and near-infrared spectroscopy to detect meat adulteration can help people better understand the quality, nutrient content, and safety of meat, as well as improve the accuracy and reliability of detection.

Nowadays, sensor technology is constantly developing and maturing, and in the field of food safety inspection it has gradually popularized and deepened the intelligent sensory instrument that imitates the human sense of smell—the electronic nose [3]. Because of its fast detection speed, simple operation, good repeatability, and other advantages, it has become a well-established meat inspection tool. It has been widely used in the fields of meat freshness detection [4,5,6,7], quality judgment [8,9,10], and adulteration detection [11,12,13]. It can identify the authenticity and freshness of meat by analyzing the odor released from the meat. In the field of meat inspection, the electronic nose is widely used to detect the freshness, authenticity, and adulteration of meat. For example, an electronic nose can determine whether meat is fresh, spoiled, or adulterated by analyzing the odor released from the meat.

Near-infrared spectroscopy (NIRS) can be used to achieve the rapid and nondestructive detection of adulterated meat by obtaining the NIR spectral information of the meat being tested and using chemometrics to establish the qualitative and quantitative relationship between adulteration and the spectral information of the meat samples being tested [14]. In the field of meat testing, substances such as additives and leptin in meat can be detected by analyzing the chemical composition and structure of the substance, as well as determining the variety and origin of the meat. Near-infrared (NIR) technology has been applied to grain inspection [15,16,17,18], fruit and vegetable processing [19,20,21], and meat processing [22,23,24] and achieved good results.

In recent years, in the adulteration of meat and meat products and quality testing and other aspects of the application of a single instrument for detection, in order to improve the accuracy of single-instrument detection, two or more pieces of testing equipment have been jointly used in food quality assessment as part of a new development trend. For example, electronic noses and electronic tongues, electronic noses and mass spectrometers, and the combined use of near-infrared and hyperspectral spectroscopy have been fully developed and widely used [25]. The combined use of the electronic nose and infrared spectroscopy can give full play to the advantages of both and improve the accuracy and reliability of the identification of the authenticity and adulteration of meat. For example, in the meat industry, an electronic nose can analyze the odors released from meat, while infrared spectroscopy can analyze the chemical composition of the meat to make a more accurate determination of its authenticity and place of origin. In addition, the combined use of the electronic nose and infrared spectroscopy in meat testing can improve the efficiency of detecting meat freshness and adulteration, providing consumers with more reliable product information. Many of the articles related to meat adulteration detection are summaries of single-instrument tests, and such summaries of single-instrument tests can provide information about the relevance of a particular instrument in meat adulteration detection and help to assess its applicability, strengths, and weaknesses in different situations. However, meat adulteration detection is a complex field, and relying on a single instrument for detection may not meet all the needs in practical applications. In actual meat adulteration detection, it is often necessary to combine multiple methods and instruments for more comprehensive and accurate detection. For example, spectroscopic techniques (e.g., near-infrared spectroscopy), image analysis techniques (e.g., machine vision), and sensor techniques can be combined to comprehensively analyze and process multiple aspects of meat products. This can make up for the shortcomings of single-instrument detection and improve the accuracy and reliability of meat adulteration detection. In addition, data fusion technology can also play an important role in meat adulteration detection. By fusing data from different sensors or data sources, more comprehensive and accurate information can be obtained for better discrimination in adulteration detection. For example, data from multiple sensors can be fused together, or results obtained from different pattern recognition methods can be fused to obtain a more comprehensive and accurate analysis.

This paper describes in detail the application of the electronic nose and near-infrared (NIR) technology in the determination of meat adulteration and the application of the combination of the two in the detection of meat and also discusses the problems and challenges in their application. The pattern recognition algorithm applied in the re-detection and recognition is expounded.

2. Method

To compile this paper, our primary search engine was CNKI.com; however, we also used Web of Science. Only papers with full access were included. Because the nature of this paper is to discuss the role of the electronic nose and near-infrared spectroscopy in analyzing adulteration detection in meat and meat products, we did not set an exclusion date range so that we could provide a broad overview of adulteration detection.

The search terms begin with electronic nose or NIR with the AND Boolean operator followed by one or more of the following: meat, meat products, beef, chicken, lamb, adulteration, pattern recognition, sensors, and hybrid.

3. Electronic Nose and Near-Infrared Detection Technology

3.1. Composition and Working Principle of Electronic Nose System

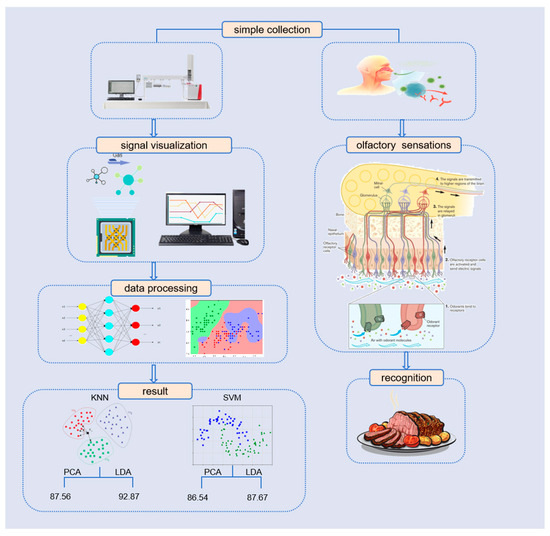

The electronic nose, also known as the odor scanner, is an instrument that analyzes the odor of a sample by using sensors to mimic the human/animal olfactory organ’s perception of odor [26]. It is based on a combination of different gas sensors with different sensitivities and/or specialties to provide a characteristic fingerprint of odors or aromas in concentrations of parts per million (ppm) [27]. In the electronic nose system, the gas sensor array is equivalent to a large number of olfactory receptor cells in the biological olfactory system, the computer is equivalent to the brain, and the pattern recognition system is equivalent to the neural signal transmission system [28]. When the biological olfactory system has been in a certain odor environment for a long time, fatigue will occur, which will affect the accuracy of odor analysis, but the electronic nose as a biomimetic olfactory system can be used for a long time to detect the sample odor, which greatly makes up for this defect. Figure 1 shows a comparison between the electronic nose system and the human olfactory system.

Figure 1.

Comparison of electronic nose system and human olfactory system.

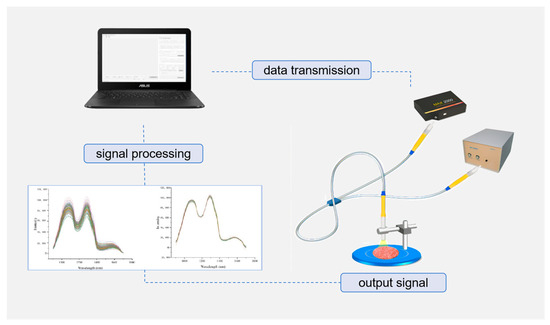

The electronic nose system uses specific sensors and pattern recognition systems to quickly provide holistic information about the sample under test, indicating hidden characteristics of the sample [29]. It consists of gas sensors, signal processing, and pattern recognition components [30]. A workflow diagram of the electronic nose system is shown in Figure 2. The system includes two parts, hardware and software, which can realize the detection of unknown samples and the output of detection results [31]. The working principle of an electronic nose system can be summarized as follows: sensor array—signal prepossessing—neural networks and various algorithms—computer recognition (qualitative and quantitative gas analysis).

Figure 2.

Flow diagram of the electronic nose system.

3.2. Gas Sensors Used in Electronic Noses

Electronic nose systems typically use various types of gas sensors, which vary in operating principle, sensitivity, selectivity, response time, energy consumption, reversibility, and manufacturing costs [32]. For example, a volatile substance has a high response in some sensors and a low response in others [33]. The gas sensor in the electronic nose is divided into a metal oxide sensor, electrochemical sensors, a conductive polymer sensor, a mass sensor, and other types according to the principle [34]. The metal oxide sensor has the advantages of a low cost and wide application range, and it is the most widely used in the electronic nose system. Different materials of the conductive polymer sensor have specific responses to different gases. The work does not require heating, and the application has its own advantages. The quality of the FET sensor is stable, but there is reference value drift. The fiber optic sensor has a strong anti-noise ability and extremely high sensitivity, but it has a high cost and short life. As shown in Table 1, which lists the advantages and disadvantages of different sensor arrays in electronic noses.

Table 1.

Advantages and disadvantages of sensor arrays applied in electronic noses.

3.2.1. Metal Oxide-Type Sensor

The metal oxide gas sensor cause changes in conductivity, mainly through the chemical or biological effects of gas molecular adsorption or physical adsorption changes [35]. After the gas adsorption, due to the charge transfer between the gas and the metal oxide semiconductor, the metal oxide semiconductor will bend, and its resistance value will change. When the sensor is in contact with the relevant gas molecules, the affinity energy of the gas molecules is greater than the work function of the semiconductor material, so that its resistance value increases to produce a high response, which can judge the type of gas. The German PEN2 portable electronic nose and the Fox 3000 and Fox 4000 electronic noses use this type of sensor.

With the in-depth study of this type of sensor, its application in meat freshness and quality detection is more mature, and it can accurately identify the gas produced in the storage and transportation of meat. Bonah et al. [36] used an electronic nose composed of ten metal oxide sensors to detect Salmonella contamination levels in fresh pork samples with 99.99% identification accuracy via principal component analysis. Liu et al. [37] used an electronic nose based on a metal oxide semiconductor (MOS) sensor to monitor the freshness of fish, beef, and chicken, and the results showed that the electronic nose combined with the HMM algorithm could well identify the freshness of meat. The sensitivity and specificity values for fish, beef, and chicken samples were 96.32% ± 2.83% and 99.07% ± 0.69%; 99.09% ± 2.40% and 99.82% ± 0.48%; and 99.35% ± 0.27% and 98.31% ± 0.71%, respectively. It also has a good application for flavor detection for meat products. For example, the PEN3 electronic nose was used to conduct grade analysis and detection of three batches of pork breast samples from 12 brands, with an accuracy rate of 89.81%. The identification of pork breast quality based on electronic nose technology is feasible to a certain extent [38].

3.2.2. Electrochemical Sensor

Electrochemical sensors detect the concentration of specific gases by means of electrochemical principles. The detected ambient gas diffuses into the electrolyte of the sensor through the film at the lower end of the sensor. There is a measuring electrode, a reverse electrode, and a reference electrode in the electrolyte. By selecting the appropriate voltage, electrolyte, and electrode material, the detected gas will undergo a chemical reaction on the measuring electrode and generate a small current. This current is proportional to the concentration of the detected gas [39]. The output current of the sensor can be amplified, temperature compensation and parameter correction can be used to obtain the concentration of the specific gas, and the detection of the measured object can be realized. Wojnowski et al. [40] used the electronic nose of an electrochemical sensor array to predict the biogenic amine in fresh chicken samples during refrigeration based on headspace analysis technology. The verification results showed that the coefficient of determination was 0.954 (p < 0.01), and the root mean square error (RMSE) was 1.65. Also, the shelf life of different meat products is different. The detection of fish, chicken breast, and pork stored at room temperature for 0 days, 1 day, and 2 days is carried out using electrochemical sensors, and classification with 100% accuracy can be achieved using the SVM algorithm [41]. It is proved to be fast and reliable in evaluating the freshness of meat.

3.2.3. Conductive Polymer Gas Sensor

In conductive polymer sensors, the active materials in contact with the VOC are generally conductive polymers composed of thiophene, indole, furan, and other components. When the gas molecules are in contact with the above-mentioned polymer materials, ionization or co-valence will occur. This interaction affects the transmission of electrons along the polymer chain; that is, it changes the conductivity. The gas molecules adsorbed on the surface of the conductive polymer can change the resistance of the conductive polymer through a variety of mechanisms to achieve the sensing function [42]. Simanjuntak et al. [43] applied the electronic nose based on a conductive polymer gas sensor to distinguish fresh, unqualified, and rotten beef and mutton, and the success rate of using an artificial neural network and Kohonen algorithm to identify beef and mutton was 90%. To demonstrate whether conductive polymer gas sensors can be used to detect meat contamination, TVC measurements were performed on fresh and frozen beef and sausages inoculated with Escherichia coli, Salmonella, Staphylococcus aureus, and Pseudomonas aeruginosa. The results showed that the system was able to detect microorganisms in beef and sausage samples. Moreover, the gas concentrations before and after the contamination of beef and sausage with pathogenic bacteria were significantly correlated (p < 0.005) [44], indicating that it has a relatively good application in meat freshness detection.

3.2.4. Mass-Sensitive Gas Sensor

Mass-sensitive sensors generate acoustic signals by acting on piezoelectric materials with alternating electric fields and obtain the information of detected objects by measuring changes in acoustic parameters (amplitude, frequency, wave speed, etc.) [45]. Mass-sensitive gas sensors are divided into the surface acoustic wave gas sensor (SAW) [46] and quartz crystal microbalance gas sensor (QCM) [47]. The QCM sensor is a disk coated with a polymer material with a diameter of a few millimeters. When the gas molecules are absorbed into the polymer coating surface, the mass of the disk changes and the resonance frequency changes. The resonance frequency is inversely proportional to the absorbed gas molecular mass [48]. A surface acoustic wave (SAW) sensor means that after the crystal adsorbs gas molecules, the frequency, amplitude, and phase velocity of the surface acoustic wave will change [49]. Fulgione et al. [50] detected Salmonella typhoid in chicken based on the QCM, and the experimental results showed that the detected frequency (115 Hz) when only Salmonella infected chicken samples was comparable to the results reported on the dose–response curve. Kim et al. [51] used a surface acoustic wave sensor to evaluate the freshness of chicken, and the results showed that the phase of the response signal linearly decreased with increases in the reference gas concentration and the storage time of chicken samples. The coefficient of determination of the reference gas and storage time is above 0.9. Also, to prove the application of the electronic nose in meat variety differentiation, Zhang et al. [52] used an electronic nose to identify four varieties of raw and cooked chicken samples. The results showed that the prediction set recognition rate of raw meat was 93.94%, that of Beijing oil chicken was 96.97%, and that of cooked meat was 95.45%. The recognition rate of Beijing oil chicken was 98.48%, which provided some technical support for meat adulteration.

3.2.5. Field Effect Tube-Type Gas Sensor

The field effect tube-type gas sensor is composed of a semiconductor layer, an insulating layer, and three electrodes [53]. It is based on the mechanism that the drain-source current changes when the sensitive film interacts with the gas. When the drain-source current changes, the performance of the sensor changes with it, and a sensitive film is coated on the gate during preparation, covering different sensitive films to form a gas sensor with different selectivities. For example, the odor fingerprint analysis of chicken shows that the freshness of chicken at different storage times at 0 °C and 10 °C can be distinguished via electronic nose PCA and DFA [54]. In order to prove the accuracy of meat flavor detection, the electronic nose was used to detect the volatile odors of frozen and chilled chicken at different storage periods, all of which could achieve obvious differentiation, and the flavor detection of chilled chicken at the early storage stage was the best [55], providing technical support for the meat storage process.

3.2.6. Fiber Optic Sensor

Different from the principle of traditional gas sensors to measure electrical signals such as voltage, resistance, potential, or frequency, fiber optic gas sensors are realized by using the interaction between the gas to be measured and the transmitted light in the fiber. Their sensing mechanism depends on the detection of absorbance changes in a specific frequency range, with strong specificity, such as strong sensitivity and selectivity for CO2 gas, but they are almost insensitive to other low-concentration gases. In addition, the detection method of the optical gas sensor can also use color as an indicator, such as metal porphyrins, and when interacting with the target gas, the absorbance of the target gas is detected with LED. Antonio et al. [56] tested mutton fed with a pomegranate by-product diet through the electronic nose, and the results showed that the accuracy of PCA in recognizing the flavor of mutton reached 97.7%, providing a basis for the detection of meat flavors. In order to distinguish different types of meat, Li Xiu et al. [57] used a vapor phase electronic nose to conduct qualitative and quantitative detection of volatile flavor substances in the leg meat of four livestock species, namely donkeys, pigs, cows and sheep, and obtained a contribution accuracy of 99.8795% through DFA, indicating that it has a high application prospect in meat type analysis.

In the practical application of the electronic nose, the selection and configuration of the gas sensor is crucial, and the application of different types of gas sensors in the detection of meat can realize the quality distinction of meat. Different gas sensors have different sensitivities and selectivities for different gases, so we need to select a suitable sensor array according to the practical application requirements. At the same time, the service life and stability of the gas sensors also need to be considered to ensure the reliability and accuracy of the electronic nose.

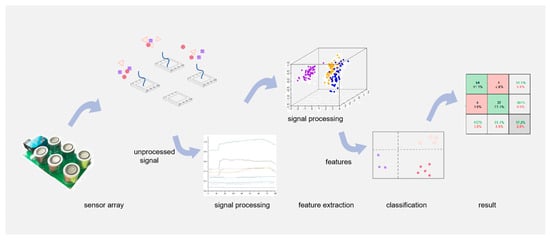

3.3. The Working Principle of Near-Infrared Spectroscopy

In recent years, spectroscopy has been one of the fastest growing analytical tools. In particular, near-infrared (NIR) spectroscopy has attracted a lot of attention as a fast and versatile detection method. The NIR spectrometer consists of a light source, a beam splitter system (wavelength selector), a sample detector, an optical detector, and a data processing/analysis system. The principle of near-infrared spectroscopy detection is shown in Figure 3.

Figure 3.

Schematic diagram of visible near-infrared spectroscopy detection system.

Near-infrared light is an electromagnetic wave between visible light and mid-infrared light (wavelength in the range of 780~2500 nm). Near-infrared spectroscopy can determine almost all of the organic matter and part of the inorganic matter in material molecules, and the chemical bonding of the various groups of expansion, vibration, and bending have their fixed frequency; when these molecules are irradiated by infrared light, part of the energy of the light is absorbed. You can obtain a very complex picture, as each component in the near-infrared region has specific absorption characteristics, and because to this feature, the original material can be analyzed [58]. The NIR region (780 to 2500 nm) contains information related to the relative proportions of C-H, O-H, N-H, and S-H bonds (the major structural components of organic molecules), mainly due to overtone vibrations and rotational leaps in these molecular bonds. According to the location and absorption intensity of the near-infrared spectrum of these chemical bonds, combined with chemometrics, qualitative or quantitative analysis of one or more components of the detected object can be achieved [59,60]. In addition, near-infrared light has a greater penetration ability than infrared light, so that information deep in the sample can be detected [61]. Near-infrared spectroscopy (NIRS) is a widely used, convenient, rapid, and nondestructive technique that requires minimal sample processing prior to analysis [62].

In meat quality testing, NIR spectroscopy has been shown to be capable of simultaneously determining multiple quality parameters, such as the protein, fat, moisture, and carbohydrate content for a wide range of meat types [63]. Near-infrared spectroscopy has the advantages of no sample pretreatment, a high efficiency, a low cost, good test reproducibility, environmental protection, no pollution, etc. According to the absorption of different compounds at specific infrared wavelengths, it can be used directly on the sample for qualitative analysis. It has been widely used in the agriculture [64,65,66,67], food [68,69,70,71], petrochemical [72,73,74,75], and medical [76,77,78,79,80] fields, among others.

4. Application and Problems of Electronic Nose and Near-Infrared Spectroscopy in Meat Adulteration Detection

4.1. Application of Electronic Nose in Meat Adulteration Detection

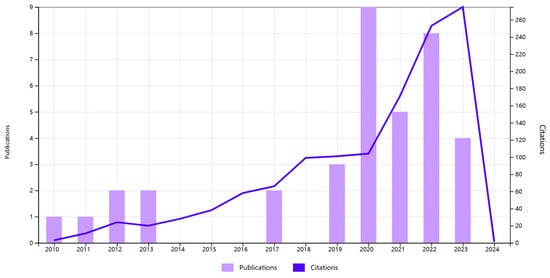

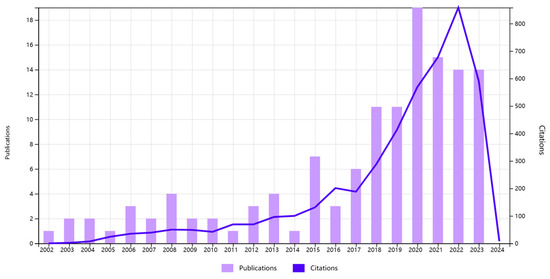

Nowadays, there are many varieties of meat, and the phenomenon of low-priced meat being used as high-priced meat is becoming more and more common. Typical cases of intentional adulteration are inter-species meat mixes, designed to deceive consumers by substituting cheaper meat for more expensive meat, such as beef adulterated with pork [81], with pork, duck, and other low-priced meat pretending to be beef, lamb, donkey meat, and other high-priced meat, with some spices added, so that consumers cannot identify the real attributes of the meat. This is the main means of adulteration in the market. At present, the adulteration of meat products is mainly manifested in the (1) adulteration of raw meat; (2) substitution of other animal tissues (fat, etc.) for muscle tissue components; and (3) addition of nonmeat components, such as water or vegetable proteins [82]. Some examples are the incident of adding ‘lean meat extract’ to mutton in Qingxian County in 2021 [83] and the incident of passing off lard and sheep tail oil as mutton in 2019 [84]. The electronic nose provides effective and accurate identification of meat at different storage times/temperatures. And the electronic nose detection technology has been widely used in meat product inspection. The electronic nose is capable of detecting and recognizing characteristics such as the different types of meat and the freshness of the meat through its unique array of sensors. However, specific use cases, including the type and amount of meat tested, may vary depending on the study, application scenario, and region. The following Figure 4 shows the statistics of the number of articles published in recent years on the detection of meat adulteration using electronic noses.

Figure 4.

Statistics on the number of articles published about electronic nose and meat adulteration detection.

Beef adulteration is the main part of fresh meat adulteration in the market. For beef adulterated with different kinds of meat or different ratios of meat, the electronic nose can detect and analyze the odor emitted by the beef so as to make effective distinctions. Han et al. [85] used a low-cost electronic nose with a colorimetric sensor to detect beef adulterated with duck meat, and the root mean square error (RMSE) and the correlation coefficient (r) of predicting the degree of adulteration were 1.28% and 0.841, respectively, which could effectively achieve the detection of beef adulterated with duck meat. Similarly, the electronic nose was able to differentiate between different proportions of pork forequarter, chicken breast, and chicken skin in beef brisket, with accuracies of 87.82%, 99.04%, and 98.57%, respectively [86]. The recognition accuracy of fake beef rolls adulterated with different proportions of pork and duck can reach more than 95% [87], and that of beef samples adulterated with different proportions of pork can be as accurate as 97.4% to 99.99% [88,89,90]. It can be seen that, although beef adulteration means are complex and diverse, the electronic nose can still be used on the beef according to the unique volatile substances emitted by the different meats to distinguish them effectively to detect the adulteration of different types and different quantities of other meats to provide technical support. In order to explore the feasibility of the electronic nose for the identification of adulteration in different parts of meat, Jia et al. [91] analyzed beef and pork samples using an electronic nose. They accurately identified yak meat and common beef in different parts of the meat and also identified the beef stuffing when it was adulterated with pork stuffing in different proportions.

Similarly, mutton is one of the most adulterated meat varieties on the market. Wang et al. [92] used an electronic nose to differentiate roasted lamb adulterated with roasted duck meat samples of different proportions (0%, 25%, 50%, 75%, and 100%). The principal component analysis (PCA) model R2X was 0.986, and the Q2 was 0.849, indicating that the model accurately identified the adulterated duck meat samples. Wang et al. [93] used an electronic nose to detect the adulteration of Ningxia small-tailed cold sheep meat with different ratios of cooked duck meat, and the accuracy of identification reached 98.2%. Wang et al. [94] used an electronic nose to identify the adulterated duck meat in fresh lamb meat, and the accuracy reached more than 96%.

The common market after the smoking, curing, hot and cold processing, canning, and other processing of sausage, bacon, and canned meat products such as ham is the most easily adulterated. For example, the raw materials of Jinhua ham and the mixed Jinhua ham flavor are differentiated. It was observed from the PCA results that the aroma profile of the blended Jinhua ham flavor could be clearly distinguished from the raw Jinhua ham [95]. Zhang et al. [96] used an electronic nose to examine the changes in odor of four different manufacturers’ corn flavors used in ham sausages and ham sausages with added flavors during storage, and the results showed that even though there was little difference in the sensory evaluation, there were significant differences between the same flavors produced by different manufacturers. Table 2 provides a more intuitive look at the types of meat used in meat adulteration detection, the types of sensors, and the accuracy of model predictions.

Table 2.

Detection accuracy of meat adulteration using electronic nose (detection method: electronic nose).

The above results show that in the detection of adulteration of beef, mutton, and other meat products, the electronic nose, based on the information of odor fingerprints of different meats, can detect the differences in the odor of adulterated meats and thus identify the adulteration behavior. The data were processed and analyzed by combining chemometrics methods to improve the accuracy and reliability of the detection. The data obtained from electronic nose detection were processed and analyzed using principal component analysis (PCA) and linear discriminant analysis (LDA), and the model prediction accuracy was good, showing that it can realize fast, accurate, and nondestructive meat adulteration detection. It is a kind of analytical method with good development prospects, which provides a fast and cheap evaluation method for the determination of odor composition difference.

4.2. Problems of Electronic Nose in Meat Adulteration Detection

In recent years, the electronic nose technology in software and hardware has made breakthroughs, and it has become widely applied in meat testing. The adulteration of different meat ingredients can be more accurately differentiated, but due to the rise of artificial science and technology of adulteration in a variety of ways, the addition of flavors and so on may affect the accuracy of the test. The electronic nose can still be used on volatile substances, but it cannot be used for qualitative and quantitative detection, as the long time use of the sensor is prone to baseline drift problems, it is easily affected by the environment during the detection process, etc. At present, the electronic nose equipment is a large-scale, experimental type of equipment that exists in colleges, universities, and research institutes, and it is not suitable to move, which has a certain impact on the immediate detection of meat. Therefore, it is necessary to find a relatively stable instrument to be used in combination and to find a new breakthrough in information fusion. Near-infrared (NIR) detection technology is simple and stable, and it is suitable to be applied to food quality assessment in combination with electronic nose technology.

4.3. Application of Near-Infrared Spectroscopy in the Detection of Meat Adulteration

In the context of meat adulteration, NIR technology can be used to rapidly detect and identify other meat or nonmeat components adulterated in meat samples. Since the chemical composition of meat is related to the composition of organic matter, such as moisture, fat, and protein, NIR technology can be used to identify different types of meat by detecting the spectral characteristics of these organic matter [102]. Bai et al. [103] used near-infrared spectroscopy to determine the proportion of adulteration in lamb meat rolls with different pork fat percentages, with a correlation coefficient between the predicted value and the true value of 0.9138, to more accurately identify different proportions of adulterated lamb. Effective identification can also be achieved for mutton adulterated with different fractions of duck meat. Zheng et al. added duck meat to mutton in 5% increments with a coefficient of determination (R2P) of 0.98 [104]. They also provided an efficient detection technique for the qualitative and quantitative detection of lamb adulteration. Kamruzzaman et al. [105] admixed chopped lamb samples with chopped pork in the range of 2–40% (w/w) in increments of about 2%. Similarly, for beef adulterated with different portions of horse and chicken meat, rapid screening was achieved with coefficients of determination, R2P, of 0.98 and 0.97, respectively [106,107]. Weng et al. [108] tested beef adulterated with different proportions of pork, beef heart, and tallow adulterants with 99% accuracy. And the feasibility of homologous adulterants in beef was verified. Zhao et al. [109] achieved rapid nondestructive quantitative detection of the adulteration of spoiled beef using near-infrared spectroscopy in fresh beef adulterated with spoiled beef, with calibrated and predicted root mean square error (RMSE) values of 7.23% and 6.54%, respectively. In addition to identifying adulterated meat, NIR spectroscopy can also detect nonmeat components added to meat and meat products, such as water, soy protein, and meat additives, such as carrageenin and nitrite [110]. Yang et al. [111] used near-infrared spectroscopy combined with principal component analysis and the Fisher’s two-class discrimination method to establish a discrimination model for raw meat and adulterated meat, and the model was 100% correct in the discrimination of adulterated meat, but there were five misjudgments of raw meat, making the correct rate 86.1%. The addition of carrageenin to meat will make the meat taste good, but the excessive addition of carrageenin will affect the rights of consumers. He et al. [112] used PLS combined with the SPA modeling method for the rapid nondestructive testing of injected meat. The root mean square error (RMSEP) was 3.51%, and the prediction deviation was 2.66, which showed they were able to distinguish the injected meat effectively. Similarly, for fake pork adulterated with carrageenin and sodium chloride, a more accurate distinction could still be realized, with an identification accuracy of 94.2% [113]. In Table 3, it can also be observed that the accuracy prediction when choosing different pattern recognition methods varies for different meats and meat products. The following Figure 5 shows the statistics of the number of articles published on the detection of meat adulteration using near-infrared spectroscopy.

Table 3.

Detection accuracy of meat adulteration using electronic nose (detection method: NIR sepctroscopy).

Figure 5.

Statistics on the number of articles published on the detection of meat adulteration using near-infrared spectroscopy.

The above results show that, in the detection of meat and meat product adulteration, NIR spectroscopy can detect the chemical composition and structural characteristics of meat, and based on the spectral fingerprint information of different meats, it can identify whether the meat is authentic or not and can also detect whether the meat is adulterated with other meats or not. Near-infrared spectroscopy can not only qualitatively determine whether meat is doped but also quantitatively determine the amount of meat doping. The accurate prediction and calculation of the doping amount can be performed by establishing the corresponding mathematical model. At the same time, the technique also needs to be combined with other detection methods and chemometrics methods for data processing and analysis in order to improve the accuracy and reliability of detection.

4.4. Problems of Near-Infrared Spectroscopy in the Detection of Meat Adulteration

Near-infrared spectroscopy technology has been gradually applied to the detection of agricultural products because it can realize the simultaneous detection of multiple items with a fast speed and no pollution. It is mostly used in meat testing for quality and freshness testing, and its application in the detection of meat adulteration is still relatively small. Although infrared testing can simultaneously predict different items, such as the fat, moisture, and protein in meat, modeling of each item is required, which is time-consuming, and different modeling methods can lead to over-adaptation or under-adaptation of the model. Due to its limited detection range, the number of samples to be tested cannot be small, and the accuracy of the test is not as good as that of chemical methods; therefore, there is also a need to find a complementary technique that can be used in conjunction with NIR detection in the detection of meat adulteration.

5. Combined Application of Electronic Nose and Near-Infrared Spectroscopy in Detection of Meat Adulteration

Electronic noses and near-infrared spectroscopy are both sensor technologies used to detect and identify different odors or chemical components. These technologies have a wide range of applications in the food industry, medical industry, and environmental monitoring. The fusion of electronic nose and near-infrared spectroscopy data can further improve the accuracy of odor and ingredient identification. The quality and safety of food products are detected using the electronic nose and near-infrared spectroscopy. An electronic nose can detect volatile organic compounds in food, while near-infrared spectroscopy can detect ingredients in food. At present, there are few research results on the joint application of electronic nose and near-infrared (NIR) detection technology in food, and its application value and prospects need to be explored. Evaluation results derived from a technical method have a high probability of error, relatively low reliability, and often do not accurately reflect the real situation of the product. The electronic nose can realize the effective differentiation of meat adulteration, but in the process of detecting meat adulteration, the electronic nose can only obtain the odor description of the volatile components by consulting the literature and choose an appropriate sensor model for the detection of the volatile gases emitted, while near-infrared spectroscopy can differentiate according to the different characteristics of the meat itself. Studies have shown that for synthetic and reactive beef flavors, the electronic nose is not only able to detect adulterated beef and real beef but also able to detect different adulteration ratios more effectively, but for blended beef flavors, the electronic nose can only detect adulterated beef and real beef, not different adulteration ratios [118]. In order to better realize meat detection, data fusion can be carried out using the electronic nose combined with near-infrared spectroscopy equipment and other instruments to improve the accuracy of detection.

The fusion of data from these two technologies can improve the quality and safety of food by more accurately detecting harmful substances in food or categorizing and identifying food products. The three different levels of fusion methods in data fusion are data layer fusion, feature layer fusion, and decision layer fusion. Among them, data layer fusion is performed at the raw data level, and it extracts the complementary and redundant information from raw data from multiple sensors through comprehensive analysis and processing and then optimally combines them to obtain a more comprehensive and accurate characterization or estimation. Feature layer fusion extracts representative features from the raw observation data provided by each sensor, which are fused to form a single feature vector and then processed using pattern recognition methods as a basis for further decision making. Decision layer fusion is the highest level of fusion, where first each sensor performs a recognition decision on the target and then the recognition results from each sensor are fused to make an optimal decision according to certain criteria. Each of these three levels of convergence methods has its own characteristics, and the appropriate convergence method can be selected according to specific application scenarios and requirements. Data fusion in meat inspection can be applied to food safety and quality control, etc. In meat inspection, data fusion technology can combine data from multiple sensors, such as freshness, nutrient content, and other indicators. Li et al. [119] used an electronic nose combined with an electronic tongue to qualitatively and quantitatively analyze minced chicken meat doped with different proportions of soy protein or starch, and the results of the assay showed that the combined assay of the two has a good differentiation ability for minced chicken meat. Liu et al. [120] combined surface-enhanced Raman spectroscopy with electronic nose technology to compare three different data fusion strategies with multiple machine learning methods to achieve the detection of the peanut oil oxidation degree. The results show that the data fusion strategy effectively improves the prediction performance of the model. Li et al. [121] proposed a novel efficient back-propagation adaptive enhancement (BP-AdaBoost) algorithm for data fusion and modeling for the nondestructive detection of the total volatile saline nitrogen (TVSN) content in pork using a combination of hyperspectral imaging and colorimetric sensors, which confirmed that the model of data fusion was superior to that of a single-sensor technique. Data fusion technology applied to meat adulteration detection can improve the accuracy and reliability of meat adulteration detection by comprehensively analyzing and processing data from multiple sources. For example, the color, texture, shape, and other characteristics of meat products can be comprehensively analyzed using spectral technology, image analysis technology, etc., and data fusion can be carried out by combining information from a variety of data sources, so as to more accurately determine whether meat products are adulterated. In addition, near-infrared spectroscopy can be utilized to quickly and accurately detect fat, protein, and other components of meat products, and data fusion can be performed in conjunction with information from other data sources, thereby improving the accuracy and reliability of meat adulteration detection. Zhang et al. [122] used an electronic nose combined with near-infrared spectroscopy technology to qualitatively and quantitatively detect pork, chicken, and duck samples mixed with different proportions (0%, 20%, 40%, 60%, 80%, 100%) in mutton, and the overall discrimination accuracy was over 96%. Han et al. [85] used an electronic nose and near-infrared spectroscopy to identify independent samples of raw beef, a beef and duck mixture, and raw duck meat. Both the near-infrared spectroscopy and electronic nose could distinguish samples well when used alone, but the correlation coefficient of detection with the combination of the two was increased from 0.913 to 0.972, and the combination more accurately distinguished adulterated duck meat in beef.

The above studies have shown that the electronic nose can sensitively detect changes in volatiles in meat due to changes in tissue composition and that near-infrared (NIR) spectroscopy can be used to validate the changes detected by the electronic nose by reflecting the internal changes in the meat at a deeper level. The use of the electronic nose combined with visible/near-infrared spectroscopy can be applied to food authenticity identification. This combined detection method can improve the accuracy and reliability of detection, make up for the deficiency of single-instrument detection, and provide a more reliable decision-making basis for the food industry. However, the amount of research on the joint detection of the electronic nose combined with near-infrared (NIR) spectroscopy in meat adulteration and other aspects of this study is relatively small, and further in-depth research is needed.

6. Pattern Recognition Algorithm

The detection data of the electronic nose and near-infrared spectroscopy are generally processed using multivariate statistics and the stoichiometric method. At present, the K-nearest neighbor method, support vector machine (SVM), and artificial neural network are common pattern recognition algorithms in electronic nose signal classification and near-infrared spectroscopy. Pattern recognition refers to the processing and analysis of various forms of information that represent things or phenomena using computers and mathematical methods [123]. The process of pattern recognition includes several steps, such as signal preprocessing, pattern segmentation, feature extraction, pattern classification, and context post-processing [124].

When analyzing the electronic nose and NIR spectral data, the required pattern identification method can be flexibly selected according to the model and the actual situation. All of the pattern recognition methods have their own advantages and disadvantages, as shown in Table 4.

Table 4.

Commonly used pattern recognition algorithms and their advantages and disadvantages.

Most of the traditional algorithms, such as principal component analysis, linear discriminant analysis, and functional discriminant analysis, are still used in electronic nose systems [141]. Some other machine learning algorithms have also been used in e-nose systems, such as artificial neural networks (ANNs), support vector machines (SVMs), and decision trees. These algorithms can be used in conjunction with PCA or LDA to further improve the performance of the electronic nose system. Commonly used algorithms in NIR spectral analysis include principal component analysis (PCA), partial least squares (PLSs), support vector machines (SVMs), and neural network algorithms. While principal component analysis (PCA) is one of the most used algorithms for the fusion of data from instruments such as the electronic nose and near-infrared spectroscopy, it can fuse data from different instruments and environments with uniform coordinate transformations and weighted averages and at the same time extract the eigenvectors of the data, in addition to being combined with other machine learning algorithms in order to further improve the accuracy and reliability of the data. Different types of data contain different information and exist in different dimensions; spectral data usually contain continuous spectral information, while electronic nose data usually contain discrete chemical sensor responses. Therefore, for both types of data characteristics, algorithms need to be selected that can effectively handle the corresponding data types. Different classification algorithms have different characteristics, such as sensitivity to noise, the need for a number of training samples, and control of model complexity. When selecting an algorithm, the extent to which these properties match the characteristics of the data needs to be considered. An initial selection of potentially suitable algorithms is then made based on the degree of match between the data and the algorithm. The performance of the initially selected algorithms is also evaluated using cross-validation methods, while for each algorithm, its parameters are adjusted to optimize the performance. Based on the results of cross-validation and tuning parameters, the best-performing algorithm is selected as the final model, and the final selected model is evaluated with an independent test set and compared with other algorithms to ensure that the selected model has the best performance. Wiedemair et al. [142] used different techniques to preprocess the raw data and find out the difference between pure and adulterated meat using the principal component analysis technique and then analyzed the preprocessed sample data using partial least squares discriminant analysis and found that effective identification can be achieved when the degree of adulteration is higher than 2% in pure beef or mutton. Leng et al. [143] used 1H NMR spectroscopy combined with chemometrics to identify adulterated pork and duck meat in beef, where PCA was used to visualize the difference between beef and binary adulterated beef but could not identify the unknown samples, and the PLS model accurately predicted the level of beef adulteration, with an R2 value of greater than 0.90 and RMSEE and RMSEP values close to zero. And using the OPLS-DA model, both binary and ternary adulterated beef can be effectively distinguished. In addition to traditional machine learning algorithms, some novel pattern recognition algorithms are also being developed. Huang et al. [144] proposed a novel framework, 1DCNN-RFR, consisting of a 1DCNN skeleton and RFR in the quantitative detection of beef doped with pork via an MOS sensor-based electronic nose system. This framework obtained the best results on the test set compared to four models, SVR, RFR, BPNN, and 1DCNN, with an R2 of 0.9977, RMSE of 0.9491%, and MSE of 0.4619%. Similarly, the optimization of the algorithm can improve the accuracy and reliability of the model for better food safety. Ren et al. [145] investigated the use of miniature near-infrared spectroscopy and electronic tongues based on gray wolf optimization, ant colony optimization, particle swarm optimization, nondominant classification, and genetic algorithm II data optimization, which were used as modeling features, combining support vector machines, extreme learning machines, and K-nearest neighbor algorithms in order to construct a classification model for prediction. They found that the ant colony optimization–support vector machines model had the highest classification accuracies of 3.42 mg/100 g; 0.74 and 3.21 mg/100 g; 0.73 and 3.32 mg/100 g; 0.79 and 3.17 mg/100 g; and 0.73 and 3.28 mg/100 g, respectively, whereas the model prediction sets’ RP2 and RMSEP values from the fusion of the two sets of data were 0.75 and 2.62 mg/100 g; 0.85 and 2.39 mg/100 g; and 0.83 and 2.42 mg/100 g, which were better than the models constructed with their corresponding data [146].

7. Conclusions

Electronic nose technology is now more widely used. It has been used in food, pharmaceutical, tobacco, chemical, environmental, and medical diagnosis fields, among others. In the food industry, the electronic nose is used to detect and analyze the smell and flavor of food to ensure the quality and safety of products. Through the electronic nose detection technology, food enterprises can detect and analyze the quality and safety of food more quickly and accurately, thus improving the quality and reliability of products. Near-infrared spectroscopy technology currently has a wide range of applications and potential in many fields. It can be used for the quality and safety testing of food, such as fruits, vegetables, meat, dairy products, etc.; for the identification and quality control of drugs, such as the authenticity identification of Chinese medicinal materials and validity period testing of drugs; and in biomedical fields, such as human tissue composition analysis and medical diagnosis.

The indicators reflecting meat are multifaceted, including color, texture, flavor, nutrition, and so on. The evaluation results obtained by a single technical method often have the problems of error and a relatively low reliability, which cannot accurately reflect the real situation of the product. In order to more comprehensively and accurately assess the quality and safety of meat, various technical methods are needed for comprehensive analysis. When its quality changes, one of the most visible indicators is the changes in sexual substances, and the electronic nose is the ideal tool for sensing such changes. In order to improve the accuracy and reliability of the evaluation results, the meat characteristics can be deeply verified, and the data verification and analysis can be conducted. In addition, new technical methods and indicators need to be constantly explored to better reflect the real situation of meat. The research and application of electronic nose–near-infrared spectroscopy combined technology in the adulteration detection of meat products has great economic potential value and social benefits.

8. Challenge and Future Trend

Scholars at home and abroad have accumulated a large number of methods and practical experience in gas sensor technology and near-infrared spectroscopy detection, which fully reflects the implementation of modern nondestructive testing technology for meat adulteration detection. Nondestructive testing, such as the electronic nose and near-infrared spectroscopy, have been increasingly used in the detection of adulterated meat and meat products in recent years, but the future development still faces certain challenges. The electronic nose has the advantages of safety, rapidity, convenience, and accuracy in the application of meat and meat product testing, which makes up for the subjectivity, ambiguity, and repeatability of human testing. However, there are limitations in the detection accuracy and use of the sensor: the commercial electronic nose is larger, more expensive, and has other issues. Although the electronic nose detection system has had breakthroughs in recent years in the software and hardware parts of the technology, the single use of electronic nose detection is affected by environmental factors (temperature, humidity) and other gases in the air, as well as interference before and after the collection of gas. The sampling device and the chamber face cleaning difficulties, and the response signal of the gas-sensitive sensor array is susceptible to influencing the problem. Therefore, in order to improve the accuracy of electronic nose detection, it can be used in the selection of characterization feature vectors, and the establishment of the data model should be fully considered through data preprocessing, pattern recognition algorithms, and other data processing means to eliminate these interference in the hardware to ensure the accuracy of detection and enhance the sensitivity and service life of the sensor, gas phase, and MS instruments to find new breakthroughs in information fusion; expand the amount of data of the electronic nose; and seek algorithmic innovations to the problem of baseline drift. Near-infrared spectroscopy detection has problems such as cumbersome data processing, difficult modeling, and insufficient supporting facilities. Particularly, the selection of data processing and modeling methods is a large amount of work, and the current near-infrared spectroscopy analysis technology is still limited to laboratory research. Therefore, improving the performance of the spectrometer to increase the spectral resolution, optimizing the spectral preprocessing method to improve the accuracy of the subsequent analysis, and developing the multimodal fusion technique award the combination the advantages of different techniques. Thus, the development of a near-infrared spectrometer with a low production cost, good versatility, and consistent supporting facilities is needed to realize the near-infrared rapid detection technology. Therefore, how to effectively give full play to the characteristics of different detection technologies and improve the integrity and reliability of nondestructive testing to achieve high-precision, rapid, and comprehensive detection is still worth further study.

With the development of modern instrumental analytical techniques and the mutual integration of chemometrics and various disciplinary fields, the study of near-infrared spectroscopy and electronic nose detection of meat adulteration has led to their popular application, and the safety of meat has been improved, but these two techniques still have certain limitations, and the combinations of the two are still relatively few, so exploring more accurate, rapid, economical, and comprehensive detection technology for meat adulteration is one of the directions of our efforts in the future.

Author Contributions

Conceptualization, W.J. and X.S.; writing—original draft preparation, X.S.; writing—review and editing: X.S., W.J. and S.W.; supervision, W.J. and S.W.; project administration, W.J.; funding acquisition, W.J. and S.W. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the Key Research and Development Projects of Hebei Province (21375501D), Innovative Entrepreneurial Team Project of Anhui Institute of Innovation for Industrial Technology (LAY-2022-CXGB006), Capacity Building Project of Beijing Academy of Agriculture and Forestry Sciences (KJCX20230438), National Natural Science Foundation of China (31801634), and the Surface Project of Liaoning Provincial Department of Education (LJKZ0606).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Chen, Y.; Yu, L.; Guo, S.Y. Advances in identification techniques for Adulteration of Livestock and Poultry Products. Port Health Control 2019, 24, 35–37. [Google Scholar]

- Wu, J.; Huang, X.Y.; Wang, H.H.; Chen, X.C. Detection of porcine-derived components in meat products by real-time fluorescence PCR. J. Food Saf. Qual. 2021, 12, 3715–3720. [Google Scholar]

- Qu, A.L.; Ma, C.L. Application and Development Trend of Electronic Nose in Food Safety. Food Ind. 2022, 43, 320–325. [Google Scholar]

- Wojciech, W.; Tomasz, M.; Tomasz, D.; Gębicki, J.; Namieśnik, J. Poultry meat freshness evaluation using electronic nose technology and ultra-fast gas chromatography. Monatshefte Chem. 2017, 148, 1631–1637. [Google Scholar]

- Lu, W.; Wu, Y.; Guo, Q.; Ren, L.C.; Zhu, P.F.; Xu, L.; Chang, G.B.; Chen, G.H. Establishment of a Freshness-Evaluating Standard for Chilled Yellow Chicken Meat. Food Anal. Methods 2017, 10, 2629–2635. [Google Scholar] [CrossRef]

- Li, H.; Chen, Q.; Zhao, J. Non-destructive evaluation of pork freshness using a portable electronic nose (E-nose) based on a colorimetric sensor array. Anal. Methods 2014, 6, 6271–6277. [Google Scholar] [CrossRef]

- Tian, X.; Cai, Q.; Zhang, Y. Rapid Classification of Hairtail Fish and Pork Freshness Using an Electronic Nose Based on the PCA Method. Sensors 2011, 12, 260–277. [Google Scholar] [CrossRef]

- Varidi, J.M.; Varidi, M.; Vajdi, M.; Azam, S.; Mohammad-R, A.T. Best Precision–Recall Confidence Threshold and F-Measure to Determine Quality of Camel Meat by Support Vector Regression Based Electronic Nose. Int. J. Food Eng. 2019, 15, 20180235. [Google Scholar] [CrossRef]

- Wijaya, R.D.; Sarno, R.; Zulaika, E. Electronic nose dataset for beef quality monitoring in uncontrolled ambient conditions. Data Brief 2018, 21, 2414–2420. [Google Scholar] [CrossRef]

- Wijaya, R.D.; Sarno, R.; Zulaika, E.; Sabila, S.I. Development of mobile electronic nose for beef quality monitoring. Procedia Comput. Sci. 2017, 124, 728–735. [Google Scholar] [CrossRef]

- Tian, X.; Wang, J.; Cui, S. Analysis of pork adulteration in minced mutton using electronic nose of metal oxide sensors. J. Food Eng. 2013, 119, 744–749. [Google Scholar] [CrossRef]

- Tian, H.X.; Chen, B.; Lou, X.M.; Yu, H.Y.; Yuan, H.B.; Huang, J.; Chen, C. Rapid detection of acid neutralizers adulteration in raw milk using FGC E-nose and chemometrics. J. Food Meas. Charact. 2022, 16, 2978–2988. [Google Scholar] [CrossRef]

- Han, L.; Chen, M.; Li, Y.T.; Wu, S.S.; Zhang, L. Discrimination of different oil types and adulterated safflower seed oil based on electronic nose combined with gas chromatography-ion mobility spectrometry. J. Food Compos. Anal. 2022, 114, 104804. [Google Scholar] [CrossRef]

- He, H.J.; Wang, W.; Ma, H.J.; Liu, S.H.; Chen, F.S.; Kang, Z.L.; Pan, R.S.; Zhu, M.M.; Zhao, S.M.; Wang, Z.R. Research Progress on Near-infrared Spectroscopy for Meat Adulteration. Sci. Technol. Food Ind. 2020, 41, 345–350+356. [Google Scholar]

- Fortini, S.S.; Maria, S.S.D.B.; Evandro, B. Genotypic classification of wheat using near-infrared spectroscopy and PLS-DA. Appl. Food Res. 2021, 1, 100019. [Google Scholar]

- Guo, T.; Dai, L.M.; Yan, B.P.; Lan, G.S.; Li, F.D.; Li, F.; Pan, F.M.; Wang, F.B. Measurements of Chemical Compositions in Corn Stover and Wheat Straw by Near-Infrared Reflectance Spectroscopy. Animals 2021, 11, 3328. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Jiang, H.; Lin, J.; Chen, Q.S. Rice Freshness Identification Based on Visible Near-Infrared Spectroscopy and Colorimetric Sensor Array. Food Anal. Methods 2021, 14, 1305–1314. [Google Scholar] [CrossRef]

- Jamshidi, B. Ability of near-infrared spectroscopy for non-destructive detection of internal insect infestation in fruits: Meta-analysis of spectral ranges and optical measurement modes. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2020, 225, 117479. [Google Scholar] [CrossRef] [PubMed]

- Huang, D.; Fan, F.F.; Liu, Y.Y.; Zhang, B.; Liu, Y. Rapid Determination of Fatty Acid Value of Indica Rice in Guangxi by near infrared spectroscopy. Cereal Feed. Ind. 2022, 6, 60–63. [Google Scholar]

- Katarzyna, W.; Julia, S.; Igor, K.; Ewa, S. Non-destructive determination of strawberry fruit and juice quality parameters using ultraviolet, visible, and near-infrared spectroscopy. J. Sci. Food Agric. 2019, 99, 5953–5961. [Google Scholar]

- Alhamdan, M.A.; Fickak, A.; Atia, R.A. Evaluation of sensory and texture profile analysis properties of stored Khalal Barhi dates nondestructively using Vis/NIR spectroscopy. J. Food Process Eng. 2019, 42, e13215. [Google Scholar] [CrossRef]

- De Marchi, M.; Manuelian, C.L.; Ton, S.; Cassandro, M.; Penasa, M. Feasibility of near infrared transmittance spectroscopy to predict fatty acid composition of commercial processed meat. J. Sci. Food Agric. 2018, 98, 64–73. [Google Scholar] [CrossRef]

- Povše, P.M.; Karolyi, D.; Tomažin, U.; Škrlep, M.; Pugliese, C.; Lebret, B.; Marjeta, C.P. Accuracy of Near Infrared Spectroscopy to Predict Quality of Pork and Pork Products Including Samples of Krškopolje and Turopolje Pigs. Agric. Conspec. Sci. 2017, 82, 205–209. [Google Scholar]

- De Marchi, M.; Manuelian, C.L.; Ton, S.; Manfrin, D.; Meneghesso, M.; Cassandro, M.; Penasa, M. Prediction of sodium content in commercial processed meat products using near infrared spectroscopy. Meat Sci. 2017, 125, 61–65. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, W.; Li, Y. Detection Combined Application of Aquatic Products Fresh Degree Evaluation Based on Feasibility og Electronic Nose and Near Infrared. Food Res. Dev. 2014, 35, 134–136. [Google Scholar]

- Wang, W.J.; Zhang, S.S.; Xie, P.; Zhang, Z.S.; Sun, B.Z. Quick Detection of the Quality Stewed Beef UsingE-nose and E-tongue. Food Res. Dev. 2017, 38, 124–128. [Google Scholar]

- Jordi, P.; Eduard, C.; Elena, R. Assessing over Time Performance of an eNose Composed of 16 Single-Type MOX Gas Sensors Applied to Classify Two Volatiles. Chemosensors 2022, 10, 118. [Google Scholar]

- Sanaeifar, A.; Zaki, D.H.; Jafari, A.; Migue, D.L.G. Early detection of contamination and defect in foodstuffs by electronic nose: A review. Trends Anal. Chem. 2017, 97, 257–271. [Google Scholar] [CrossRef]

- Liu, Y.T.; Liu, Q.C.; Li, H.J.; Kong, W.F.; Yan, L.J. Analysis of the Difference in Flavoring Components of Dry Red Wine Produced by Different Grape Varieties in Yantai. Liquor-Mak. Sci. Technol. 2019, 8, 40–47. [Google Scholar]

- Licen, S.; Barbieri, G.; Fabbris, A.; Briguglio, S.C.; Pillon, A.; Stel, F.; Barbieri, P. Odor control map: Self organizing map built from electronic nose signals and integrated by different instrumental and sensorial data to obtain an assessment tool for real environmental scenarios. Sens. Actuators B-Chem. 2018, 263, 476–485. [Google Scholar] [CrossRef]

- Zhou, Y.; Du, J. Work Principle of Electronic Nose and Its Application in Meat Products Detection. Meat Ind. 2016, 4, 42–45. [Google Scholar]

- Robbiani, S.; Lotesoriere, B.J.; Dellacà, R.; Capelli, L. Physical Confounding Factors Affecting Gas Sensors Response: A Review on Effects and Compensation Strategies for Electronic Nose Applications. Chemosensors 2023, 11, 514. [Google Scholar] [CrossRef]

- Wang, Z.C. Research on Electronic Nose Device and Algorithm for Pneumonia Detection; Guizhou University: Guizhou, China, 2018. [Google Scholar]

- Zhang, S.Z.; Jia, W.S.; Ma, J.; Liang, G.; Wang, J.H. An efficient tool for detecting freshness of chilled meat-electronic nose. Chin. J. Anal. Lab. 2019, 38, 878–884. [Google Scholar]

- Yamazoe, N.; Sakai, G.; Shimanoe, K. Oxide semiconductor gas sensors. Catal. Surv. Asia 2003, 7, 63–75. [Google Scholar] [CrossRef]

- Ernest, B.; Huang, X.Y.; Yang, H.Y.; Aheto, J.H.; Yi, R.; Yu, S.S.; Tu, H.Y. Detection of Salmonella Typhimurium contamination levels in fresh pork samples using electronic nose smellprints in tandem with support vector machine regression and metaheuristic optimization algorithms. J. Food Sci. Technol. 2020, 58, 3861–3870. [Google Scholar]

- Liu, T.P.; Zhang, W.T.; Mitchell, Y.; Zhang, M.; Ueland, M.; Forbes, L.S.; Su, W.S. A data-driven meat freshness monitoring and evaluation method using rapid centroid estimation and hidden Markov models. Sens. Actuators B Chem. 2020, 311, 127868. [Google Scholar] [CrossRef]

- Chen, T.; Qi, X.P.; Chen, B.; Cheng, Q.W.; Liu, P. Quality Discrimination of Dried Pork Slices Using Electronic Nose Technology. Meat Res. 2021, 35, 31–34. [Google Scholar]

- Liu, T.; Li, D.X. Basic concept of gas detection system and application of ammonia detection. J. Refrig. Technol. 2014, 3, 34–41. [Google Scholar]

- Wojciech, W.; Kaja, K.; Tomasz, M.; Justyna, P.W.; Jacek, N. Prediction of the Biogenic Amines Index of Poultry Meat Using an Electronic Nose. Sensors 2019, 19, 1580. [Google Scholar]

- Wojciech, W.; Tomasz, M.; Tomasz, D.; Jacek, G.; Jacek, N. Portable Electronic Nose Based on Electrochemical Sensors for Food Quality Assessment. Sensors 2017, 17, 2715. [Google Scholar]

- Wang, Z.P.; Guo, M.Z.; Xing, J.F. Research progress of conductive polymer gas sensors. Chem. Ind. Eng. 2023, 40, 75–84. [Google Scholar]

- Edwin, B.S.; Marhaposan, S.; Syahrul, H.; Marzuki, S. Classification of Beef and Lamb Patterns Using Conducting Polymer Sensor Series and Kohonen Algorithm Method. Adv. Sci. Technol. 2023, 126, 97–109. [Google Scholar]

- Abdallah, S.A.; Al-Shatti, L.A.; Ali, F.A.; Noura, A.H.; Bashayer, A.A. The detection of foodborne bacteria on beef: The application of the electronic nose. SpringerPlus 2013, 2, 687. [Google Scholar] [CrossRef]

- Wang, J.; Cui, S.Q.; Chen, X.W.; Hong, X.Z.; Qiu, S.S. Advanced Technology and New Application in Electronic Nose. Trans. Chin. Soc. Agric. Mach. 2013, 44, 160–167+179. [Google Scholar]

- Ajay, K.; Rahul, P. The Potential of Acoustic Wave Devices for Gas Sensing Applications. Sens. Actuators A Phys. 2022, 339, 113498. [Google Scholar]

- Liu, X.; Wang, J.J.; Hou, J.C. Repeatability and sensitivity of quartz crystal microbalance (QCM) sensor array modified with four sensitive materials. Mater. Sci. Semicond. Process. 2022, 147, 106764. [Google Scholar] [CrossRef]

- Kuchmenko, A.T.; Lvova, B.L. A Perspective on Recent Advances in Piezoelectric Chemical Sensors for Environmental Monitoring and Foodstuffs Analysis. Chemosensors 2019, 7, 39. [Google Scholar] [CrossRef]

- Xu, X.M.; Wang, J.D.; Li, H.Y. Principles and Applications of QCM and SAW in Real-Time Detection. Prog. Chem. 2005, 5, 876–880. [Google Scholar]

- Fulgione, A.; Cimafonte, M.; Ventura, D.B.; Iannaccone, M.; Ambrosino, C.; Capuano, F.; Proroga, Y.T.R.; Velotta, R.; Capparelli, R. QCMbased immunosensor for rapid detection of Salmonella Typhimurium in food. Sci. Rep. 2018, 8, 16137. [Google Scholar] [CrossRef]

- Geonwoo, K.; Kwan, B.C.; Hyub, S.O.; Kim, K.B. Feasibility Study for the Evaluation of Chicken Meat Storage Time Using Surface Acoustic Wave Sensor. J. Biosyst. Eng. 2020, 45, 261–271. [Google Scholar]

- Zhang, H.B.; Gao, S.; Jia, F.; Zheng, L.M.; Liu, Y. Identification of Beijing-You Chicken Based on Electronic Nose Technology Combined with Chemometrics. Meat Res. 2020, 34, 53–59. [Google Scholar]

- Cao, B.Q.; Mu, N. Development for the detection of harmful gases by organic field effect transistor sensor. Chem. Anal. Meterage 2019, 28, 112–119. [Google Scholar]

- Wu, S.G.; Zhang, Y.H.; Meng, Y.; Chen, D.J.; Zhang, Y.M.; Zhang, Y.L. Analysis of chicken quality deterioration by electronic nose. Sci. Technol. Food Ind. 2015, 36, 53–56. [Google Scholar]

- Li, S.Y.; Deng, L.; Wang, X.; Cui, J.; He, C.Y. Comparative Analysis of the Effect of Different Storage Methods on the Flavor of Small Fragrant Chicken Broth by Electronic Nose and Electronic Tongue. Meat Res. 2017, 31, 50–55. [Google Scholar]

- Natalello, A.; Menci, R.; Luciano, G.; Monahan, F.; Gravador, R.S.; Valenti, B.; Pauselli, M.; Belvedere, G.; Scerra, M.; Priolo, A. Effect of dietary pomegranate by-product on lamb flavour. Meat Sci. 2023, 198, 109118. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Sang, P.T.; Dauda, S.A.; Zhou, G.Y.; Fan, Y.M.; Cheng, X.R.; Wang, D.L. Comparative study on volatile flavor among the leg meat from donkey and other livestock animals. Food Mach. 2019, 35, 50–54+162. [Google Scholar]

- Bao, S.Y.; Jiang, H.Y.; Wu, X.L. Application of Near Infrared Spectra Technique for Non-destructive Measurement on Fields of Agriculture and Food. J. Agric. Mech. Res. 2006, 10, 167–168+172. [Google Scholar]

- Shao, X.Y.; Jiang, L.F.; Zhang, M.; Zhang, C.; Wan, C.B.; Liu, Y.; Geng, X. Application of Near-Infrared Spectroscopy in The Detection of Oil-Tea Camellia Seed Meal. Infrared 2023, 44, 38–45. [Google Scholar]

- SooIn, S.; Subramani, P.; Young, J.O.; Zinia, Z.J.; Kang, H.J.; Ryu, T.H.; Cho, W.S.; Cho, Y.S.; Shin, E.K.; Cho, B.K. An Overview of Near Infrared Spectroscopy and Its Applications in the Detection of Genetically Modified Organisms. Int. J. Mol. Sci. 2021, 22, 9940. [Google Scholar]

- Jiang, H.Z.; Zhang, Y.; Zhang, C.; Yuan, W.D.; Zhou, H.P. Evaluation of Dual-Band Near-Infrared Spectroscopy and Chemometric Analysis for Rapid Quantification of Multi-Quality Parameters of Soy Sauce Stewed Meat. Foods 2023, 12, 2882. [Google Scholar] [CrossRef]

- Nicolai, B.M.; Beullens, K.; Bobelyn, E.; Els, H.; Hertog, L.A.T.M.M.; Saeys, W.; Torricelli, A.; Thomas, V.; Pieter, V. Nondestructive Measurement of Fruit and Vegetable Quality. Annu. Rev. Food Sci. Technol. 2014, 5, 285–312. [Google Scholar] [CrossRef] [PubMed]

- Samuel, M.; Paulo, C.C.; Vanessa, M.; Letícia, O.C.; Paulo, E.T.; Dágila, M.R.; Kellen, F.A.; Larissa, P.R.T.; Érico, M.M.F. Drying and intermittence processes on the polished and brown rice physicochemical and morphological quality by near-infrared spectroscopy, X-ray diffraction, and scanning electron microscopy. Food Chem. X 2023, 19, 100753. [Google Scholar]

- Guo, X.D.; Sun, Y.; Zhang, Y.M. Design and Experiments of Nondestructive Moisture Content Testing System Based on Near-infrared Spectroscopy. Chin. Agric. Sci. Bull. 2023, 39, 153–158. [Google Scholar]

- Li, J.R.; Zhong, Y.; Li, Y.; Yang, J.; He, L. Real-time on-line-determination for main components of biogas slurry by near infrared spectroscopy based on PLSR. Chem. Res. Appl. 2023, 35, 1089–1094. [Google Scholar]

- Pérez-Marín, D.; Torres, I.; Entrenas, J.A.; Vega, M.; Sánchez, M.T. Pre-harvest screening on-vine of spinach quality and safety using NIRS technology. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2019, 207, 242–250. [Google Scholar] [CrossRef]

- León, L.; Ortiz, A.; Ezquerro, S.; Tejerina, D. NIRS (Near Infrared Spectroscopy) classification of sliced Duroc dry-cured ham under various packaging systems and storage temperature and time. Meat Sci. 2023, 206, 109348. [Google Scholar] [CrossRef] [PubMed]

- Cao, M.Y.; Huang, H.Q.; Zhang, P.P.; Shi, B.M.; Lan, Z.H. Determination of crude protein content in fish meal by near infrared reflectance spectroscopy. Mod. Anim. Husb. 2022, 6, 57–60. [Google Scholar]

- Yang, Y.; Yang, Q.S.; Lu, Y.; Shang, H.Y.; Ji, G.Z. Rapid determination of pigment content in capsaicin by near infrared spectroscopy. China Food Addit. 2023, 34, 310–314. [Google Scholar]

- Šubrtová, M.; Danková, V.; Suran, P.; Zeleny, L. Determination of soluble solid content in apples using near infrared spectroscopy. Acta Hortic. 2021, 1311, 169–177. [Google Scholar] [CrossRef]

- He, L.; Ran, Y.; Li, B.F. Separation of Butyric Acid and lso butyric Acid in Biogas Slurry by NIRS. China Biogas 2020, 38, 9–12. [Google Scholar]

- Hao, M. Application of Near-infrared Spectroscopy in Rapid Crude Assay. Technol. Dev. Chem. Ind. 2021, 50, 75–78. [Google Scholar]

- Cheng, H.Y. Study on Oil Analysis by Near Infrared Spectroscopy. Chem. Eng. Manag. 2021, 12, 82–83+86. [Google Scholar]

- Shen, C.L.; Lou, Q.; Zang, J.H.; Liu, K.K.; Qu, S.N.; Dong, L.; Shan, C.X. Near-Infrared Chemiluminescent Carbon Nanodots and Their Application in Reactive Oxygen Species Bioimaging. Adv. Sci. 2020, 7, 1903525. [Google Scholar] [CrossRef]

- Zou, H.L.; Zhang, A.; Zheng, J.F. Application of near infrared spectroscopy in the analysis and detection of gasoline and diesel oil. China Stand. 2019, 22, 199–200. [Google Scholar]

- Che, W.K.; Xie, S.X.; Li, Z.S.; Chen, X.; Wang, P.L.; Ling, W.B. Application of Near infrared Spectroscopy in Early Assessment of Cerebral Hypoxia in Newborns. J. Med. Theory Pract. 2019, 32, 2698–2703. [Google Scholar]

- Yi, Z.Z.; Fan, Z.; Ye, Y.; Cao, C.G.; Li, C.J.; Deng, S.H.; Sun, Y.H.; Huang, T.L.; Guan, Y.H.; Li, N.; et al. Near-infrared targeted probe designed for intraoperative imaging of prostatic neurovascular bundles. Beijing Da Xue Xue Bao Yi Xue Ban 2023, 55, 843–850. [Google Scholar]

- Wei, X.; Huang, J.S.; Zhang, H.C.; Xu, C.; Pu, K.Y.; Zhang, Y. Highly Bright Near-Infrared Chemiluminescent Probes for Cancer Imaging and Laparotomy. Angew. Chem. 2023, 62, e202213791. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Wan, L.C.; Wu, Y.H. Rapid Identification of Rukuaixiao Tablet Using Near Infrared Spectral Consistency Test Model. Drug Eval. 2020, 17, 11–13. [Google Scholar]

- Li, H.; Song, F.L.; Song, L. Establishment of correction model for non-invasive detection of blood glucose concentration based on near infrared spectroscopy. China Sci. Technol. Inf. 2021, 16, 105–106. [Google Scholar]

- Pu, K.; Qiu, J.; Tong, Y.Q.; Liu, B.L.; Cheng, Z.B.; Chen, S.Y.; Ni, W.X.; Lin, Y.; Ng, K.M. Integration of non-targeted proteomics mass spectrometry with machine learning for screening cooked beef adulterated samples. J. Agric. Food Chem. 2023, 71, 2173–2182. [Google Scholar] [CrossRef]

- Xu, Y.Z.; Wang, X.Q. Reflections on the phenomenon of water injection of pig viscera in designated slaughterhouse. Fujian J. Anim. Husb. Vet. Med. 2022, 44, 75–76. [Google Scholar]

- Fan, X. Cause analysis and countermeasure of false positive of clenbuterol rapid test. New Agric. 2023, 3, 66. [Google Scholar]

- Tian, H.N.; Guo, G.L.; Wei, N. According to the Case: An Analysis of a Case of Selling Fake Mutton. China Food Saf. Mag. 2020, 10, 22–23. [Google Scholar]

- Han, F.K.; Huang, X.Y.; Aheto, J.H.; Zhang, X.R.; Rashed, M.M.A. Fusion of a low-cost electronic nose and fourier transform near-infrared spectroscopy for qualitative and quantitative detection of beef adulterated with duck. Anal. Methods 2022, 14, 417–426. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.L.; Liu, Q.; Zha, E.H. Application of electronic nose in identification of adulterated beef mince. Sci. Technol. Food Ind. 2018, 38, 73–76+80. [Google Scholar]

- Dong, F.K.; Zhou, X.L.; Zha, E.H. Application of electronic nose in identification of adulterated beef rolls. Sci. Technol. Food Ind. 2018, 39, 219–221+227. [Google Scholar]

- Pulluri, K.K.; Kumar, V.N. Qualitative and quantitative detection of food adulteration using a smart E-nose. Sensors 2022, 22, 7789. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhang, S.; Zhang, L.; Wang, J.; Ding, W. Identification of pork adulteration in beef by electronic nose combined with statistical analysis. Food Sci. 2018, 39, 296–300. [Google Scholar]

- Xu, W.J.; Han, F.; Zhao, H.; Ding, K.Y.; Liu, W.P.; Tian, G.N. Rapid identification of adulterated beef by electronic nose combined with principal component analysis. Meat Ind. 2021, 10, 33–35. [Google Scholar]