Tesla Valve Microfluidics: The Rise of Forgotten Technology

Abstract

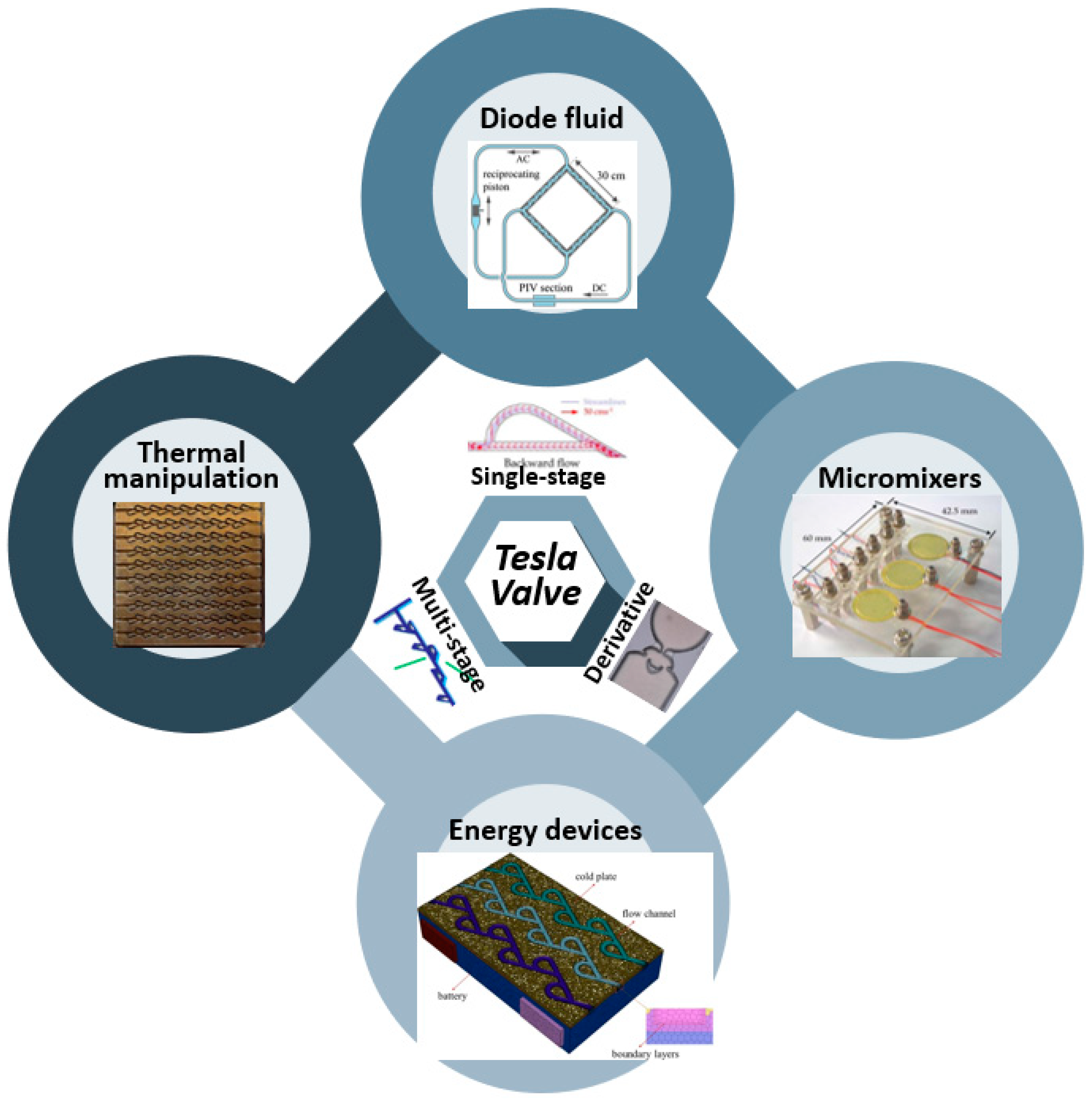

1. Introduction

2. TV Performances

2.1. Flow Rate

2.2. Pressure Drop

2.3. Diodicity

3. TV Design

3.1. Single-Stage TV (STV)

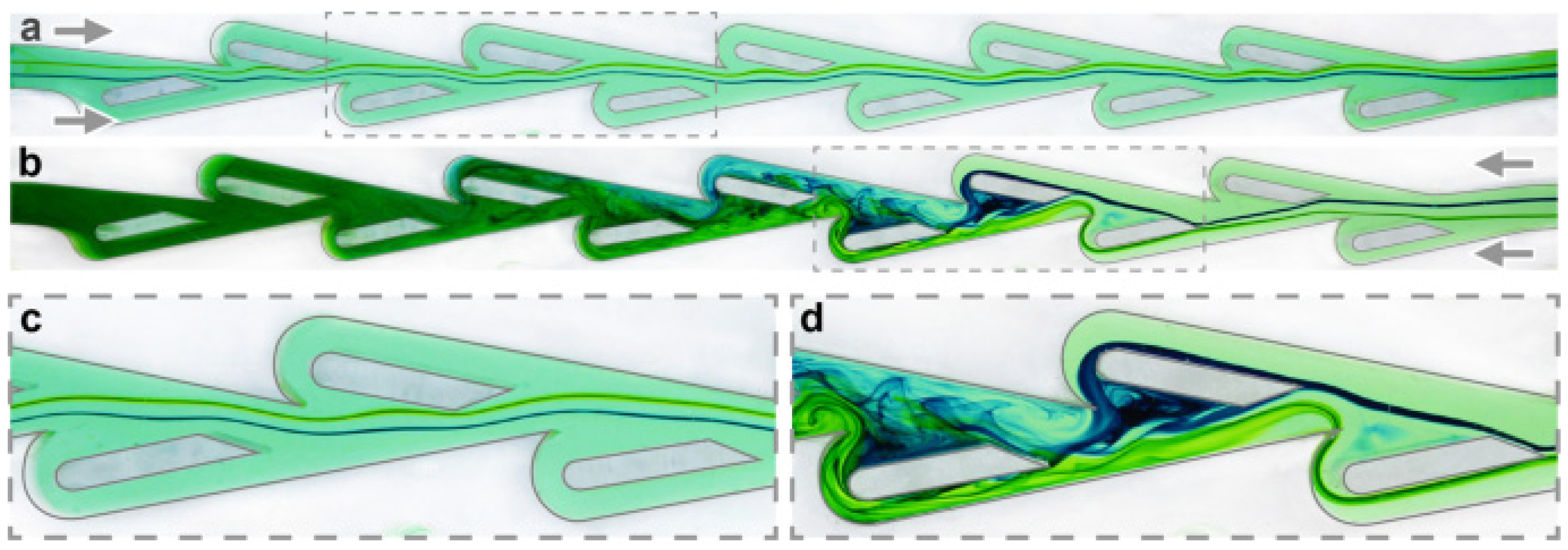

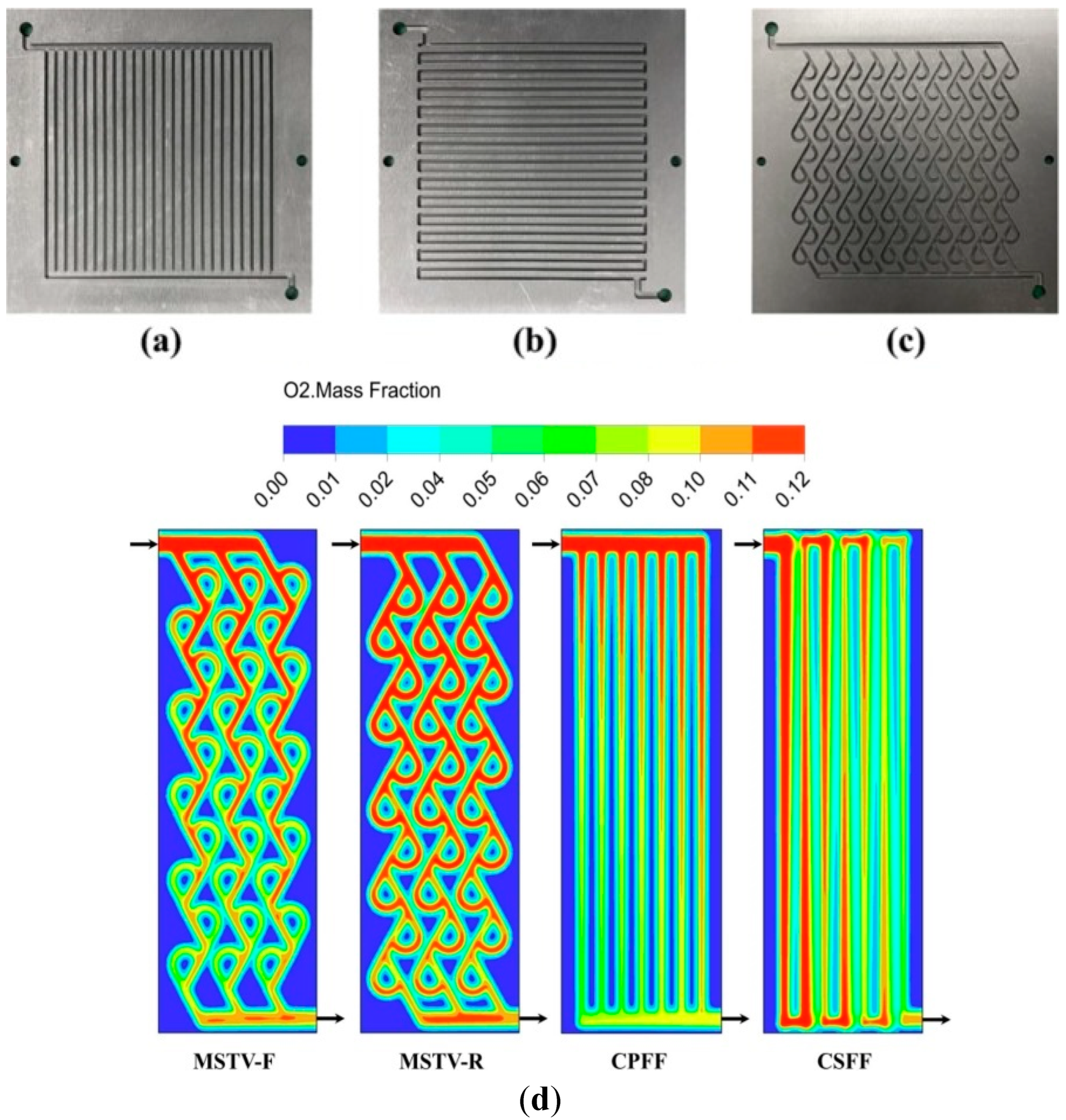

3.2. Multi-Stage TV (MSTV)

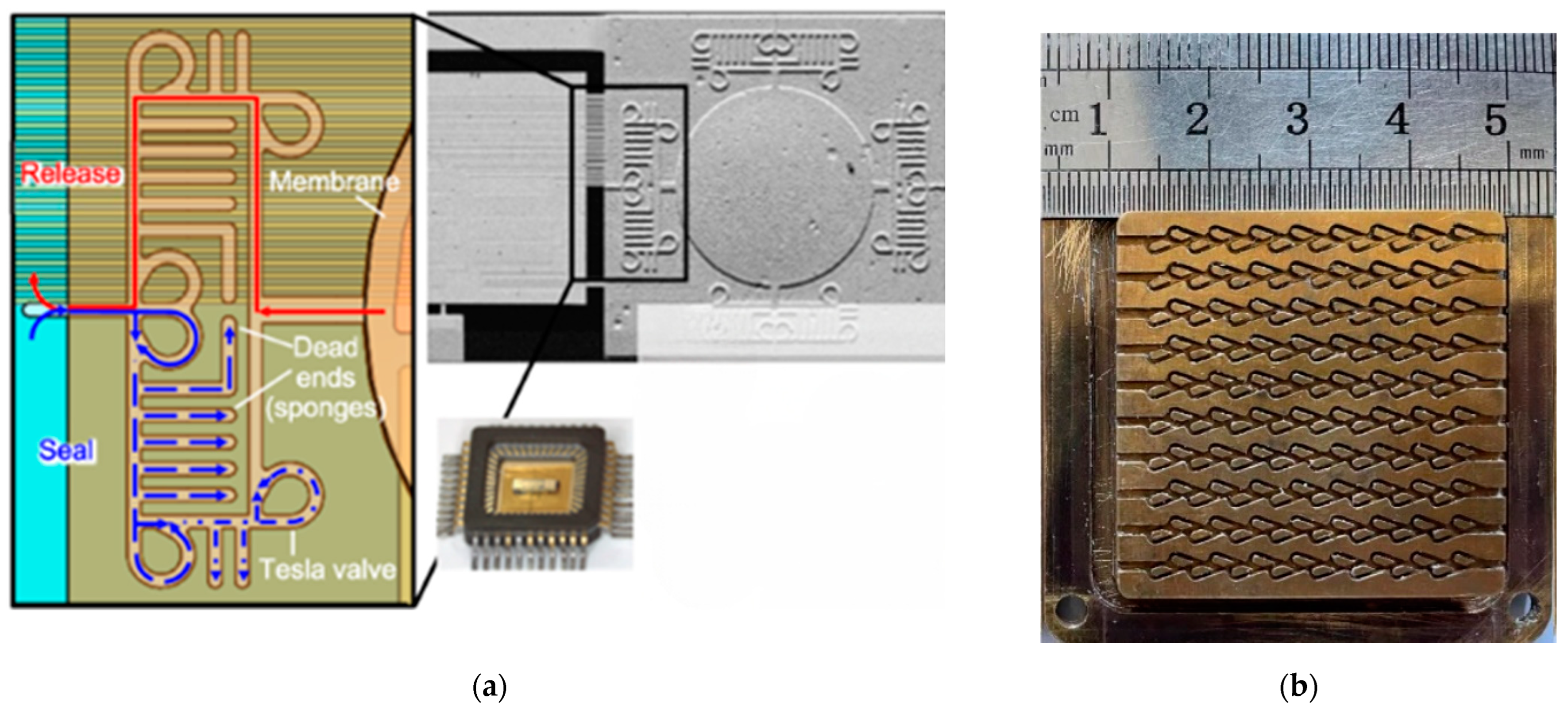

3.3. TV Derivative Design (TVD)

4. Recent Trends and Applications

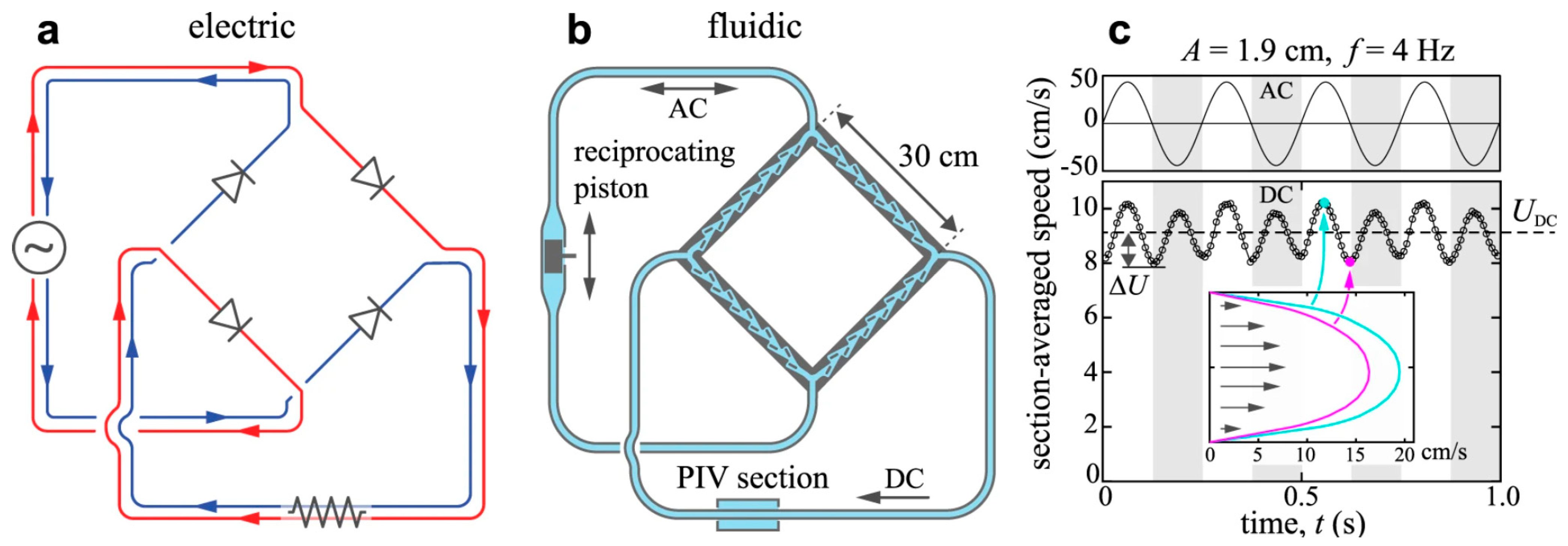

4.1. Unidirectional Flow Components

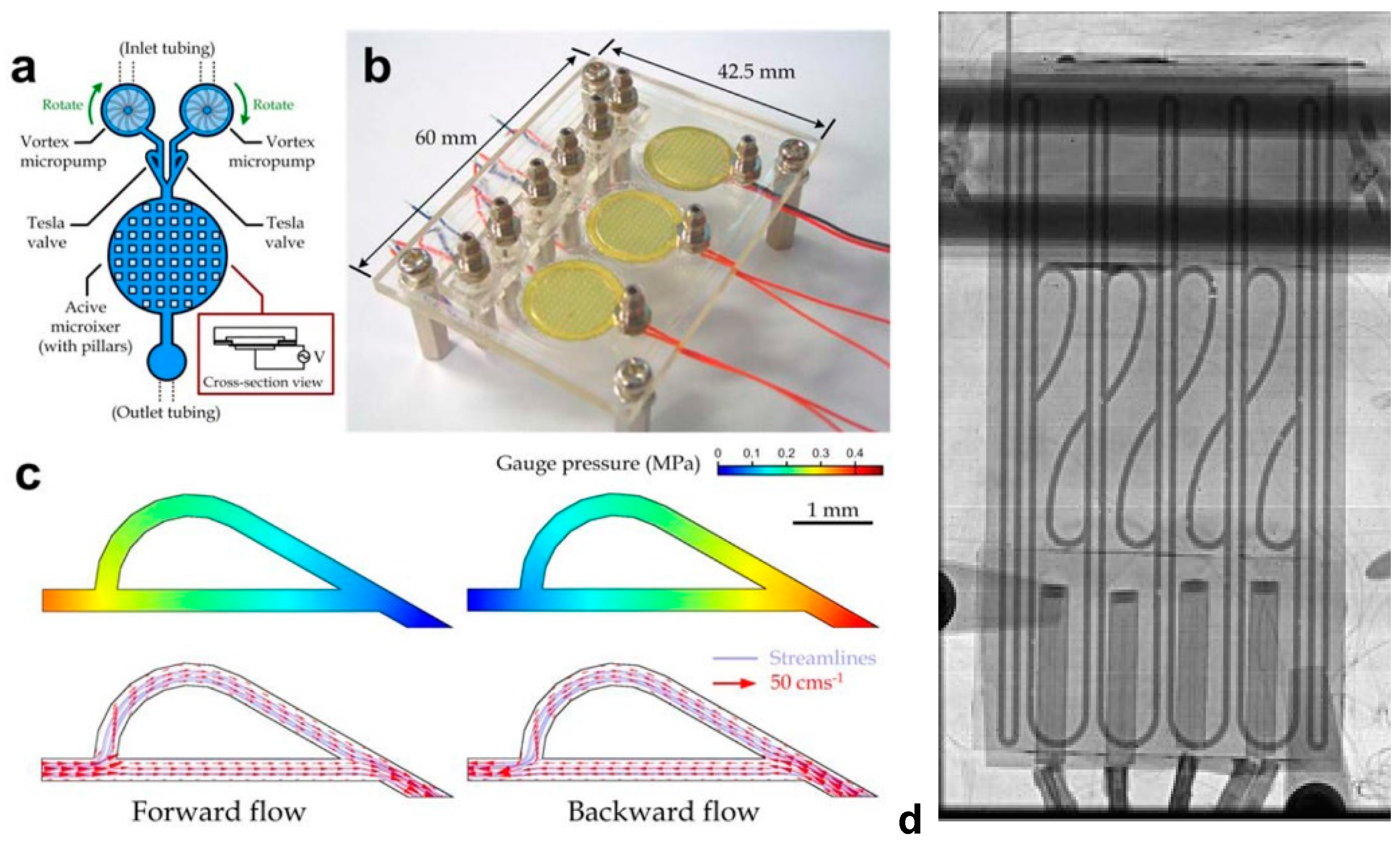

4.2. Micromixer

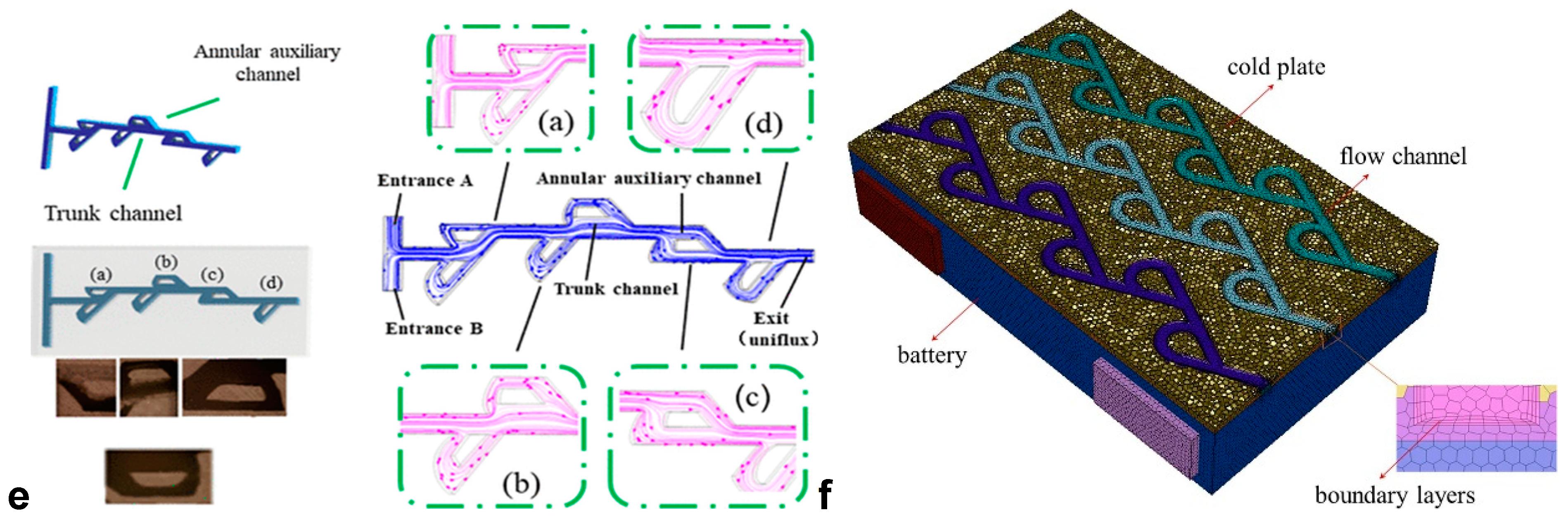

4.3. Thermal Manipulation System

4.4. Energy Devices

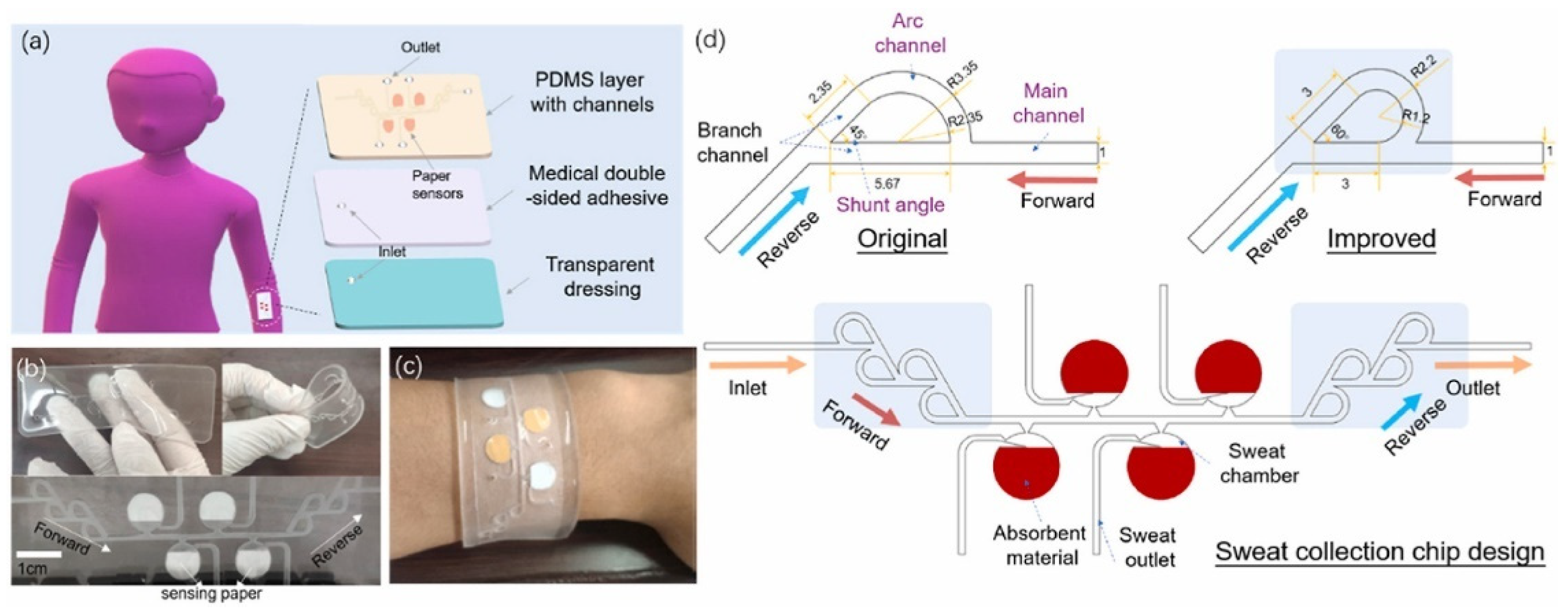

4.5. Lab on a Chip and Chemosensors

5. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tesla, N. Valvular Conduit. U.S. Patent 1329559A, 3 February 1920. [Google Scholar]

- Tesla, N. Method of Obtaining Direct from Alternating Currents. U.S. Patent 413353A, 22 October 1889. [Google Scholar]

- Stith, D. The Tesla Valve—A Fluidic Diode. Phys. Teach. 2019, 57, 201. [Google Scholar] [CrossRef]

- Matthew Sparkes Century—Old Water Valve Invented by Nikola Tesla Could Have Modern Use. Available online: https://www.newscientist.com/article/2277794-century-old-water-valve-invented-by-nikola-tesla-could-have-modern-use/ (accessed on 12 January 2023).

- Leigh, S.C.; Summers, A.P.; Hoffmann, S.L.; German, D.P. Shark Spiral Intestines May Operate as Tesla Valves. Proc. R. Soc. B Biol. Sci. 2021, 288, 20211359. [Google Scholar] [CrossRef] [PubMed]

- Palecek, A. Shark Bellies Flow like Tesla Valves. J. Exp. Biol. 2021, 224, JEB237339. [Google Scholar] [CrossRef]

- Farmer, C.G.; Cieri, R.L.; Pei, S. A Tesla Valve in a Turtle Lung. Integr. Comp. Biol. 2019, 59, E67. [Google Scholar]

- Farmer, C.G.; Cieri, R.L.; Pei, S. A Tesla Valve in a Turtle Lung: Using Virtual Reality to Understand and to Communicate Complex Structure-Function Relationships. J. Morphol. 2019, 280, S70. [Google Scholar]

- Nguyen, Q.M.; Abouezzi, J.; Ristroph, L. Early Turbulence and Pulsatile Flows Enhance Diodicity of Tesla’s Macrofluidic Valve. Nat. Commun. 2021, 12, 2884. [Google Scholar] [CrossRef]

- Wang, C.-T.; Chen, Y.-M.; Hong, P.-A.; Wang, Y.-T. Tesla Valves in Micromixers. Int. J. Chem. React. Eng. 2014, 12, 397–403. [Google Scholar] [CrossRef]

- Buglie, W.L.N.; Tamrin, K.F.; Sheikh, N.A.; Yasin, M.F.M.; Mohamaddan, S. Enhanced Fluid Mixing Using a Reversed Multistage Tesla Micromixer. Chem. Eng. Technol. 2022, 45, 1255–1263. [Google Scholar] [CrossRef]

- Qian, J.Y.; Hou, C.W.; Li, X.J.; Jin, Z.J. Actuation Mechanism of Microvalves: A Review. Micromachines 2020, 11, 172. [Google Scholar] [CrossRef]

- Nguyen, Q.M.; Huang, D.; Zauderer, E.; Romanelli, G.; Meyer, C.L.; Ristroph, L. Tesla’s Fluidic Diode and the Electronic-Hydraulic Analogy. Am. J. Phys. 2021, 89, 393–402. [Google Scholar] [CrossRef]

- Qian, J.-Y.; Wu, J.-Y.; Gao, Z.-X.; Wu, A.; Jin, Z.-J. Hydrogen Decompression Analysis by Multi-Stage Tesla Valves for Hydrogen Fuel Cell. Int. J. Hydrog. Energy 2019, 44, 13666–13674. [Google Scholar] [CrossRef]

- Jin, Z.-J.; Gao, Z.-X.; Chen, M.-R.; Qian, J.-Y. Parametric Study on Tesla Valve with Reverse Flow for Hydrogen Decompression. Int. J. Hydrog. Energy 2018, 43, 8888–8896. [Google Scholar] [CrossRef]

- Nobakht, A.Y.; Shahsavan, M.; Paykani, A. Numerical Study of Diodicity Mechanism in Different Tesla-Type Microvalves. J. Appl. Res. Technol. 2013, 11, 876–885. [Google Scholar] [CrossRef]

- Tesař, V. Time-Delay Circuits for Fluidic Oscillators and Pulse Shapers. Energies 2019, 12, 3071. [Google Scholar] [CrossRef]

- Bohm, S.; Phi, H.B.; Moriyama, A.; Runge, E.; Strehle, S.; König, J.; Cierpka, C.; Dittrich, L. Highly Efficient Passive Tesla Valves for Microfluidic Applications. Microsyst. Nanoeng. 2022, 8, 97. [Google Scholar] [CrossRef]

- Anshori, I.; Lukito, V.; Adhawiyah, R.; Putri, D.; Harimurti, S.; Rajab, T.L.E.; Pradana, A.; Akbar, M.; Syamsunarno, M.R.A.A.; Handayani, M.; et al. Versatile and Low-Cost Fabrication of Modular Lock-and-Key Microfluidics for Integrated Connector Mixer Using a Stereolithography 3D Printing. Micromachines 2022, 13, 1197. [Google Scholar] [CrossRef]

- Prabowo, B.A.; Purwidyantri, A. Environmentally Friendly and Biodegradable Components for Biosensors. IEEE Nanotechnol. Mag. 2022, 16, 13–19. [Google Scholar] [CrossRef]

- Liu, Z.; Shao, W.-Q.; Sun, Y.; Sun, B.-H. Scaling Law of the One-Direction Flow Characteristics of Symmetric Tesla Valve. Eng. Appl. Comput. Fluid Mech. 2022, 16, 441–452. [Google Scholar] [CrossRef]

- Lin, S.; Zhao, L.; Guest, J.K.; Weihs, T.P.; Liu, Z. Topology Optimization of Fixed-Geometry Fluid Diodes. J. Mech. Des. Trans. ASME 2015, 137, 081402. [Google Scholar] [CrossRef]

- Gamboa, A.R.; Morris, C.J.; Forster, F.K. Optimization of the Fixed-Geometry Valve for Increased Micropump Performance. In Proceedings of the ASME 2003 International Mechanical Engineering Congress and Exposition, Washington, DC, USA, 15–21 November 2003; Volume 259, pp. 525–534. [Google Scholar]

- Lam, R.H.W.; Li, W.J. A Digitally Controllable Polymer-Based Microfluidic Mixing Module Array. Micromachines 2012, 3, 279–294. [Google Scholar] [CrossRef]

- Thompson, S.M.; Jamal, T.; Paudel, B.J.; Walters, D.K. Transitional and Turbulent Flow Modeling in a Tesla Valve. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, San Diego, CA, USA, 15–21 November 2013; Volume 7B. [Google Scholar]

- de Vries, S.F.; Florea, D.; Homburg, F.G.A.; Frijns, A.J.H. Design and Operation of a Tesla-Type Valve for Pulsating Heat Pipes. Int. J. Heat Mass Transf. 2017, 105, 1–11. [Google Scholar] [CrossRef]

- Turowski, M.; Chen, Z.; Przekwas, A. Automated Generation of Compact Models for Fluidic Microsystems. Analog. Integr. Circuits Signal. Process. 2001, 29, 27–36. [Google Scholar] [CrossRef]

- Fairley, J.D.; Thompson, S.M.; Anderson, D. Time-Frequency Analysis of Flat-Plate Oscillating Heat Pipes. Int. J. Therm. Sci. 2015, 91, 113–124. [Google Scholar] [CrossRef]

- Qian, J.-Y.; Chen, M.-R.; Liu, X.-L.; Jin, Z.-J. A Numerical Investigation of the Flow of Nanofluids through a Micro Tesla Valve. J. Zhejiang Univ. Sci. A 2019, 20, 50–60. [Google Scholar] [CrossRef]

- Wahidi, T.; Chandavar, R.A.; Yadav, A.K. Stability Enhancement of Supercritical CO2 Based Natural Circulation Loop Using a Modified Tesla Valve. J. Supercrit. Fluids 2020, 166, 105020. [Google Scholar] [CrossRef]

- Yao, Y.; Zhou, Z.; Liu, H.; Li, T.; Gao, X. Valveless Piezoelectric Pump with Reverse Diversion Channel. Electronics 2021, 10, 1712. [Google Scholar] [CrossRef]

- Yang, X.; Song, F.; Wu, Y.; Guo, S.; Xu, S.; Zhou, J.; Liu, H. Suppression of Pressure Feedback of the Rotating Detonation Combustor by a Tesla Inlet Configuration. Appl. Therm. Eng. 2022, 216, 119123. [Google Scholar] [CrossRef]

- Hu, P.; Wang, P.; Liu, L.; Ruan, X.; Zhang, L.; Xu, Z. Numerical Investigation of Tesla Valves with a Variable Angle. Phys. Fluids 2022, 34, 033603. [Google Scholar] [CrossRef]

- Wang, J.; Cui, B.; Liu, H.; Chen, X.; Li, Y.; Wang, R.; Lang, T.; Yang, H.; Li, L.; Pan, H.; et al. Tesla Valve-Based Flexible Microhybrid Chip with Unidirectional Flow Properties. ACS Omega 2022, 7, 31744–31755. [Google Scholar] [CrossRef]

- García-Morales, N.G.; Morales-Cruzado, B.; Camacho-López, S.; Romero-Méndez, R.; Devia-Cruz, L.F.; Pérez-Gutiérrez, F.G. Numerical Modeling of a Micropump without Mobile Parts Actuated by Thermocavitation Bubbles. Microsyst. Technol. 2021, 27, 801–812. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, J.; Liu, F.; Liu, Y.; Wang, F.; Yang, N.; Lu, D.; Jia, Y. Performance Optimisation of Tesla Valve-Type Channel for Cooling Lithium-Ion Batteries. Appl. Therm. Eng. 2022, 212, 118583. [Google Scholar] [CrossRef]

- Thompson, S.M.; Paudel, B.J.; Jamal, T.; Walters, D.K. Numerical Investigation of Multistaged Tesla Valves. J. Fluids Eng. 2014, 136, 081102. [Google Scholar] [CrossRef]

- Thompson, S.M.; Walters, D.K.; Paudel, B.J.; Jamal, T. A Numerical Investigation of Multi-Staged Tesla Valves. In Proceedings of the ASME 2013 Fluids Engineering Division Summer Meeting, Incline Village, NV, USA, 7–11 July 2013; Volume 1A. [Google Scholar]

- Mohammadzadeh, K.; Kolahdouz, E.M.; Shirani, E.; Shafii, M.B. Numerical Study on the Performance of Tesla Type Microvalve in a Valveless Micropump in the Range of Low Frequencies. J. Micro-Bio Robot. 2013, 8, 145–159. [Google Scholar] [CrossRef]

- Habhab, M.-B.; Ismail, T.; Lo, J.F. A Laminar Flow-Based Microfluidic Tesla Pump via Lithography Enabled 3D Printing. Sensors 2016, 16, 1970. [Google Scholar] [CrossRef]

- Gaymann, A.; Montomoli, F.; Pietropaoli, M. Design for Additive Manufacturing: Valves without Moving Parts. In Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, Charlotte, NC, USA, 26–30 June 2017; Volume 2C-2017. [Google Scholar]

- Porwal, P.R.; Thompson, S.M.; Walters, D.K.; Jamal, T. Heat Transfer and Fluid Flow Characteristics in Multistaged Tesla Valves. Numeri Heat Transf. A Appl. 2018, 73, 347–365. [Google Scholar] [CrossRef]

- Juodenas, M.; Tamulevičius, T.; Ulčinas, O.; Tamulevičius, S. Implementation of an Optimized Microfluidic Mixer in Alumina Employing Femtosecond Laser Ablation. J. Micromech. Microeng. 2018, 28, 015013. [Google Scholar] [CrossRef]

- Qian, J.-Y.; Chen, M.-R.; Gao, Z.-X.; Jin, Z.-J. Mach Number and Energy Loss Analysis inside Multi-Stage Tesla Valves for Hydrogen Decompression. Energy 2019, 179, 647–654. [Google Scholar] [CrossRef]

- Abdelwahed, M.; Chorfi, N.; Malek, R. Reconstruction of Tesla Micro-Valve Using Topological Sensitivity Analysis. Adv. Nonlinear Anal. 2019, 9, 567–590. [Google Scholar] [CrossRef]

- Wen, Y.; Chen, R.-F. Study on Seepage Characteristics of Large Scale Tesla Valve and Feasibility of Its Application in Water Pipeline. Shuidonglixue Yanjiu Yu Jinzhan/Chin. J. Hydrodyn Ser. A 2020, 35, 726–735. [Google Scholar] [CrossRef]

- Raffel, J.; Ansari, S.; Nobes, D.S. An Experimental Investigation of Flow Phenomena in a Multistage Micro-Tesla Valve. J. Fluids Eng. Trans. ASME 2021, 143, 111205. [Google Scholar] [CrossRef]

- Shaikh, M.; Liu, X.; Amini, K.; Steinle, T.; Biegert, J. High Density Molecular Jets of Complex Neutral Organic Molecules with Tesla Valves. Rev. Sci. Instrum. 2021, 92, 104103. [Google Scholar] [CrossRef] [PubMed]

- Monika, K.; Chakraborty, C.; Roy, S.; Sujith, R.; Datta, S.P. A Numerical Analysis on Multi-Stage Tesla Valve Based Cold Plate for Cooling of Pouch Type Li-Ion Batteries. Int. J. Heat Mass Transf. 2021, 177, 121560. [Google Scholar] [CrossRef]

- Michalska, M.; Surmiak, M.A.; Maasoumi, F.; Senevirathna, D.C.; Chantler, P.; Li, H.; Li, B.; Zhang, T.; Lin, X.; Deng, H.; et al. Microfluidic Processing of Ligand-Engineered NiO Nanoparticles for Low-Temperature Hole-Transporting Layers in Perovskite Solar Cells. Sol. RRL 2021, 5, 2100342. [Google Scholar] [CrossRef]

- Shi, H.; Cao, Y.; Zeng, Y.; Zhou, Y.; Wen, W.; Zhang, C.; Zhao, Y.; Chen, Z. Wearable Tesla Valve-Based Sweat Collection Device for Sweat Colorimetric Analysis. Talanta 2022, 240, 123208. [Google Scholar] [CrossRef] [PubMed]

- Babaoğlu, N.U.; Parvaz, F.; Foroozesh, J.; Hosseini, S.H.; Ahmadi, G.; Elsayed, K. Analysis and Optimization of Multistage Tesla Valves by Computational Fluid Dynamics and a Multi-Objective Genetic Algorithm. Chem. Eng. Technol. 2022, 45, 2245–2253. [Google Scholar] [CrossRef]

- Du, J.; Liu, Y.; Ren, F.; Guo, J.; Li, M.; Arman, S. Numerical Thermal Analysis of Cold Plate Embedded in Novel Multistage Tesla Valve. In Proceedings of the 2022 International Conference on Smart Manufacturing and Material Processing (SMMP2022), Shanghai, China, 12–13 August 2022; IOS Press: Amsterdam, The Netherlands, 2022; Volume 29, pp. 151–161. [Google Scholar]

- Li, X.; Worrall, K.; Vedanthu, A.; Scott-George, A.; Harkness, P. The Pulse-Elevator: A Pump for Granular Materials. Acta Astronaut. 2022, 200, 33–41. [Google Scholar] [CrossRef]

- Guo, K.; Chen, Y.; Zhou, Z.; Zhu, S.; Ni, Z.; Xiang, N. A Novel 3D Tesla Valve Micromixer for Efficient Mixing and Chitosan Nanoparticle Production. Electrophoresis 2022, 43, 2184–2194. [Google Scholar] [CrossRef]

- Sun, L.; Li, J.; Xu, H.; Ma, J.; Peng, H. Numerical Study on Heat Transfer and Flow Characteristics of Novel Microchannel Heat Sinks. Int. J. Therm. Sci. 2022, 176, 107535. [Google Scholar] [CrossRef]

- Rui, Z.; Zhao, F.; Sun, H.; Sun, L.; Peng, H. Experimental Research on Flow Boiling Thermal-Hydraulic Characteristics in Novel Microchannels. Exp. Therm. Fluid Sci. 2023, 140, 110755. [Google Scholar] [CrossRef]

- Thompson, S.M.; Ma, H.B.; Wilson, C. Investigation of a Flat-Plate Oscillating Heat Pipe with Tesla-Type Check Valves. Exp. Therm. Fluid Sci. 2011, 35, 1265–1273. [Google Scholar] [CrossRef]

- Sato, Y.; Yaji, K.; Izui, K.; Yamada, T.; Nishiwaki, S. Topology Optimization of a No-Moving-Part Valve Incorporating Pareto Frontier Exploration. Struct. Multidiscip. Optim. 2017, 56, 839–851. [Google Scholar] [CrossRef]

- Guo, Y.; Pan, H.; Wadbro, E.; Liu, Z. Design Applicable 3D Microfluidic Functional Units Using 2D Topology Optimization with Length Scale Constraints. Micromachines 2020, 11, 613. [Google Scholar] [CrossRef]

- Kubar, A.A.; Cheng, J.; Kumar, S.; Liu, S.; Chen, S.; Tian, J. Strengthening Mass Transfer with the Tesla-Valve Baffles to Increase the Biomass Yield of Arthrospira Platensis in a Column Photobioreactor. Bioresour. Technol. 2020, 320, 124337. [Google Scholar] [CrossRef]

- Shalabi, N.; Searles, K.; Takahata, K. Switch Mode Capacitive Pressure Sensors. Microsyst. Nanoeng. 2022, 8, 1–14. [Google Scholar] [CrossRef]

- Liosis, C.; Sofiadis, G.; Karvelas, E.; Karakasidis, T.; Sarris, I. A Tesla Valve as a Micromixer for Fe3O4 Nanoparticles. Processes 2022, 10, 1648. [Google Scholar] [CrossRef]

- Wang, H.; Chen, X. Optimization of Micromixer Based on an Improved Tesla Valve-Typed Structure. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 1–11. [Google Scholar] [CrossRef]

- Wang, H.; Chen, X. Optimization of Tesla Valve-Typed Micromixer Based on Simulated Annealing Algorithm. Surf. Rev. Lett. 2022, 29, 2250094. [Google Scholar] [CrossRef]

- Wahidi, T.; Yadav, A.K. Instability Mitigation by Integrating Twin Tesla Type Valves in Supercritical Carbon Dioxide Based Natural Circulation Loop. Appl. Therm. Eng. 2021, 182, 116087. [Google Scholar] [CrossRef]

- Fan, Y.; Wang, Z.; Xiong, X.; Zhu, J.; Gao, Q.; Wang, H.; Wu, H. Novel Concept Design of Low Energy Hybrid Battery Thermal Management System Using PCM and Multistage Tesla Valve Liquid Cooling. Appl. Therm. Eng. 2023, 220, 119680. [Google Scholar] [CrossRef]

- Rajale, M.J.; Prasad, P.I.; Rao, B.N. A Review on the Heat Transfer Performance of Pulsating Heat Pipes. Aust. J. Mech. Eng. 2022, 1–45. [Google Scholar] [CrossRef]

- Prabowo, B.A.; Fernandes, E.; Freitas, P. A Pump-Free Microfluidic Device for Fast Magnetic Labeling of Ischemic Stroke Biomarkers. Anal. Bioanal. Chem. 2022, 414, 2571–2583. [Google Scholar] [CrossRef] [PubMed]

- Gong, F.; Yang, X.; Zhang, X.; Mao, Z.; Gao, W.; Wang, C. The Study of Tesla Valve Flow Field on the Net Power of Proton Exchange Membrane Fuel Cell. Appl. Energy 2023, 329, 120276. [Google Scholar] [CrossRef]

- Prabowo, B.A.; Sousa, C.; Cardoso, S.; Freitas, P.; Fernandes, E. Labeling on a Chip of Cellular Fibronectin and Matrix Metallopeptidase-9 in Human Serum. Micromachines 2022, 13, 1722. [Google Scholar] [CrossRef]

- Leung, C.M.; de Haan, P.; Ronaldson-Bouchard, K.; Kim, G.A.; Ko, J.; Rho, H.S.; Chen, Z.; Habibovic, P.; Jeon, N.L.; Takayama, S.; et al. A Guide to the Organ-on-a-Chip. Nat. Rev. Methods Prim. 2022, 2, 33. [Google Scholar] [CrossRef]

- Rogal, J.; Schlünder, K.; Loskill, P. Developer’s Guide to an Organ-on-Chip Model. ACS Biomater. Sci. Eng. 2022, 8, 4643–4647. [Google Scholar] [CrossRef]

- Moradi, E.; Jalili-Firoozinezhad, S.; Solati-Hashjin, M. Microfluidic Organ-on-a-Chip Models of Human Liver Tissue. Acta Biomater. 2020, 116, 67–83. [Google Scholar] [CrossRef]

- Kanabekova, P.; Kadyrova, A.; Kulsharova, G. Microfluidic Organ-on-a-Chip Devices for Liver Disease Modeling In Vitro. Micromachines 2022, 13, 428. [Google Scholar] [CrossRef]

- Gonçalves, I.M.; Carvalho, V.; Rodrigues, R.O.; Pinho, D.; Teixeira, S.F.C.F.; Moita, A.; Hori, T.; Kaji, H.; Lima, R.; Minas, G. Organ-on-a-Chip Platforms for Drug Screening and Delivery in Tumor Cells: A Systematic Review. Cancers 2022, 14, 935. [Google Scholar] [CrossRef]

- Chen, Q.; Liu, X.; Lei, Y.; Zhu, H. An Electrokinetic Preconcentration Trapping Pattern in Electromembrane Microfluidics. Phys. Fluids 2022, 34, 092009. [Google Scholar] [CrossRef]

- Wang, R.; Wang, X. Sensing of Inorganic Ions in Microfluidic Devices. Sens. Actuators B Chem. 2021, 329, 129171. [Google Scholar] [CrossRef]

- Sabbagh, B.; Stolovicki, E.; Park, S.; Weitz, D.A.; Yossifon, G. Tunable Nanochannels Connected in Series for Dynamic Control of Multiple Concentration-Polarization Layers and Preconcentrated Molecule Plugs. Nano Lett. 2020, 20, 8524–8533. [Google Scholar] [CrossRef]

- Krishnamurthy, A.; Anand, R.K. Recent Advances in Microscale Extraction Driven by Ion Concentration Polarization. Trends Anal. Chem. 2022, 148, 116537. [Google Scholar] [CrossRef]

- Papadimitriou, V.A.; Segerink, L.I.; Eijkel, J.C.T. Free Flow Ion Concentration Polarization Focusing (FF-ICPF). Anal. Chem. 2020, 92, 4866–4874. [Google Scholar] [CrossRef]

- Andriukaitis, D.; Vargalis, R.; Šerpytis, L.; Drevinskas, T.; Kornyšova, O.; Stankevičius, M.; Bimbiraitė-Survilienė, K.; Kaškonienė, V.; Maruškas, A.S.; Jonušauskas, L. Fabrication of Microfluidic Tesla Valve Employing Femtosecond Bursts. Micromachines 2022, 13, 1180. [Google Scholar] [CrossRef]

- Bachman, H.; Chen, C.; Rufo, J.; Zhao, S.; Yang, S.; Tian, Z.; Nama, N.; Huang, P.H.; Huang, T.J. An Acoustofluidic Device for Efficient Mixing over a Wide Range of Flow Rates. Lab Chip 2020, 20, 1238–1248. [Google Scholar] [CrossRef]

- Huang, P.H.; Nama, N.; Mao, Z.; Li, P.; Rufo, J.; Chen, Y.; Xie, Y.; Wei, C.H.; Wang, L.; Huang, T.J. A Reliable and Programmable Acoustofluidic Pump Powered by Oscillating Sharp-Edge Structures. Lab Chip 2014, 14, 4319–4323. [Google Scholar] [CrossRef]

- Lee, S.W.; Kim, D.S.; Lee, S.S.; Kwon, T.H. A Split and Recombination Micromixer Fabricated in a PDMS Three-Dimensional Structure. J. Micromech. Microeng. 2006, 16, 1067–1072. [Google Scholar] [CrossRef]

| No. | TV Structure | Technical Remarks | Finding | Potential Applications | Ref. |

|---|---|---|---|---|---|

| 1 | MSTV | Original design, patented | Detracting from its practical value and significantly adding to its manufacturing and maintenance cost. | Machinery | [1] |

| 2 | STV | 3D simulation, high-fidelity models | Validation of compact model behavior in SPICE and SABER | Microfluidics, micropump, and microsystem | [27] |

| 3 | STV | Fabricated micropump | Optimized structure and its validation | Micropump | [23] |

| 4 | STV | Digitally controlled microfluidics | Real-time fluid mixing and concentration regulation with the mixing module array | Micromixer | [24] |

| 5 | STV | Design and implementation | Novel TV in pulsating heat pipes | PHP | [26] |

| 6 | STV | Numerical study | Hydrogen decompression at the reverse flow | Fuel cell devices | [15] |

| 7 | STV | Topology optimization | Reconstructed TV topology | Optimized TV design | [45] |

| 8 | STV | CFD simulation | TV in the natural circulation loop | Supercritical CO2 circulation | [30,66] |

| 9 | STV | Valveless piezoelectric pump | Suppression enhancement of the backflow | Micropump | [31] |

| 10 | STV | TV inlet of the combustor | Suppression of pressure feedback of the rotating detonation combustor | Combustor | [32] |

| 11 | MSTV | Numerical study | Lower maximum flow rate for all range of operating frequencies | Valveless micropump | [39] |

| 12 | MSTV | An integrated check valve at OHP | Improved thermal circulation at OHP | Thermal flow control | [28,58] |

| 13 | MSTV | CFD simulation | An order-of-magnitude denser gaseous beam of molecules | Gas delivery system | [48] |

| 14 | MSTV | Numerical analysis | Enhancement of heat transfer in the proposed cooling system | Li-ion battery | [49] |

| 15 | MSTV | Micromixer for ligand-engineered NiO nanoparticles | Facile fabrication of low temperature hole-transporting layers in perovskite solar cells | Perovskite solar cell | [50] |

| 16 | MSTV | 3D printed devices | Designed and fabricated turbine fluidic pump using DLP-based 3D printing. | Micropump, Lab-on-a-chip | [40] |

| 17 | MSTV | Numerical modeling | Volumetric efficiencies enhancement than nozzle–diffuser elements. | Micropump | [35] |

| 18 | MSTV | Fluidic rectifier circuit | Comparable electric and fluidic rectifier circuit | Mixing and pumping | [9,13] |

| 19 | MSTV | 3D printed devices | Mixing efficiency improvement up to 87% | Micromixer | [34] |

| 20 | MSTV | TV in flexible microfluidic | Integration of sweat collector and colorimetric sensor | Wearable devices | [51] |

| 21 | MSTV | TV in the cold plate | TV reverse flow causes fluid mixing and vortices effectively | Cold plate system | [53] |

| 22 | MSTV | The vibroconveyor and the Tesla valve | Vertical pulse elevator, independent from frictional interactions, torque less | Pulse elevator of inert materials | [54] |

| 23 | MSTV | Novel 3D TV micromixer | Mixing efficiency: 86.96% at Re = 1.1 | Micromixer for chitosan NP | [55] |

| 24 | MSTV | Fabricated TV microfluidics | Fabrication of TV using femtosecond bursts | Microfluidics device | [82] |

| 25 | MSTV | Numerical optimization | The reverse Tesla valve balances heat exchange performance and energy consumption | Battery cold plate | [36] |

| 26 | MSTV | Reversed TV | Enhanced fluid mixing using a reversed flow | Micromixer | [11] |

| 27 | MSTV | Numerical study | Heat transfer area improves around 94–112% | Heatsink | [26] |

| 28 | MSTV | Proton exchange membrane | Peak net power of MSTV flow field for reverse and forward flow can be increased by 19.89% and 3.90% | Fuel cell | [70] |

| 29 | MSTV | MSTV combination with phase change material | Reduction in the total energy consumption for coolant circulation by 79.9% | Battery | [67] |

| 30 | MSTV | MSTV and MSCB | MCSB has superior thermal-hydraulic performance in the flow boiling process than MCTV | Thermal hydraulic | [57] |

| 31 | TVD | 3D printed TVD | Topology optimization | Novel TV design | [30] |

| 32 | TVD | CFD simulation | 3D design and optimized TVD | Novel TV design | [60] |

| 33 | TVD | TV baffles in bioreactor | Photochemical efficiency enhancement | Photobioreactor | [61] |

| 34 | TVD | Fabrication optimized TVD | Diodicity: 1.8 at Re: 36 | Novel TV design | [18] |

| 35 | TVD | Combination of TV and dead-end channels | Sealed and released control of the main sensor region | Capacitive sensor | [62] |

| 36 | TVD | Topology optimization | Topology optimization incorporating Pareto frontier exploration | Novel TV design | [59] |

| 37 | TVD | Acustofluidic micromixer | Efficient mixing across a broad range of flow rates (20–2000 μL/min) | Micromixer | [83] |

| 38 | TVD | Sharp edge acoustofluidic | Stable flow rates 8 μL/min (~76 Pa) | Acoustofluidic pump | [84] |

| 39 | TVD | 3D PDMS microchannel | Mixing efficiency up to 90% at Re 0.6. | Micromixer | [85] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Purwidyantri, A.; Prabowo, B.A. Tesla Valve Microfluidics: The Rise of Forgotten Technology. Chemosensors 2023, 11, 256. https://doi.org/10.3390/chemosensors11040256

Purwidyantri A, Prabowo BA. Tesla Valve Microfluidics: The Rise of Forgotten Technology. Chemosensors. 2023; 11(4):256. https://doi.org/10.3390/chemosensors11040256

Chicago/Turabian StylePurwidyantri, Agnes, and Briliant Adhi Prabowo. 2023. "Tesla Valve Microfluidics: The Rise of Forgotten Technology" Chemosensors 11, no. 4: 256. https://doi.org/10.3390/chemosensors11040256

APA StylePurwidyantri, A., & Prabowo, B. A. (2023). Tesla Valve Microfluidics: The Rise of Forgotten Technology. Chemosensors, 11(4), 256. https://doi.org/10.3390/chemosensors11040256