A Flexible Capacitive Paper-Based Pressure Sensor Fabricated Using 3D Printing

Abstract

:1. Introduction

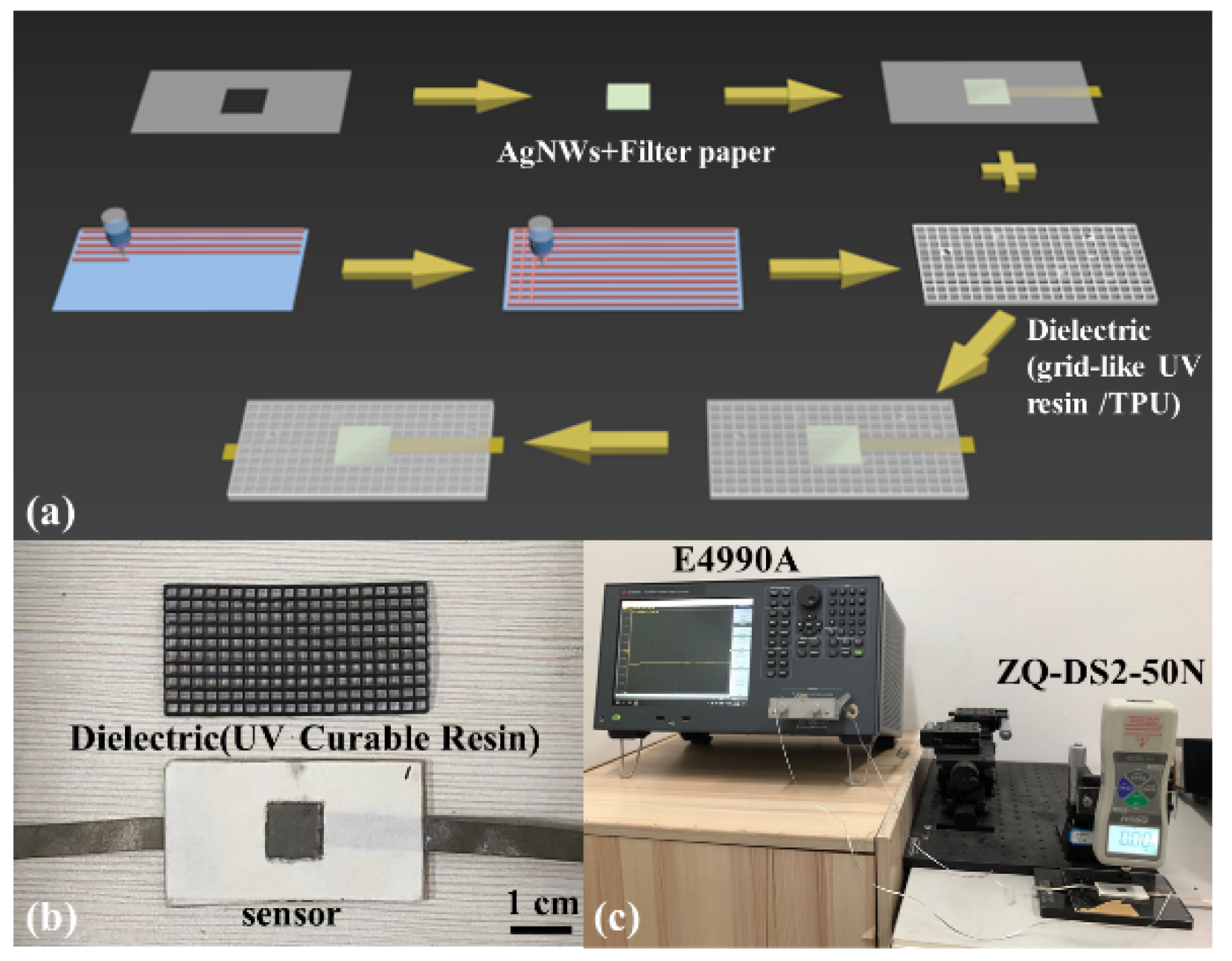

2. Experimental Section

2.1. Materials

2.2. Methods

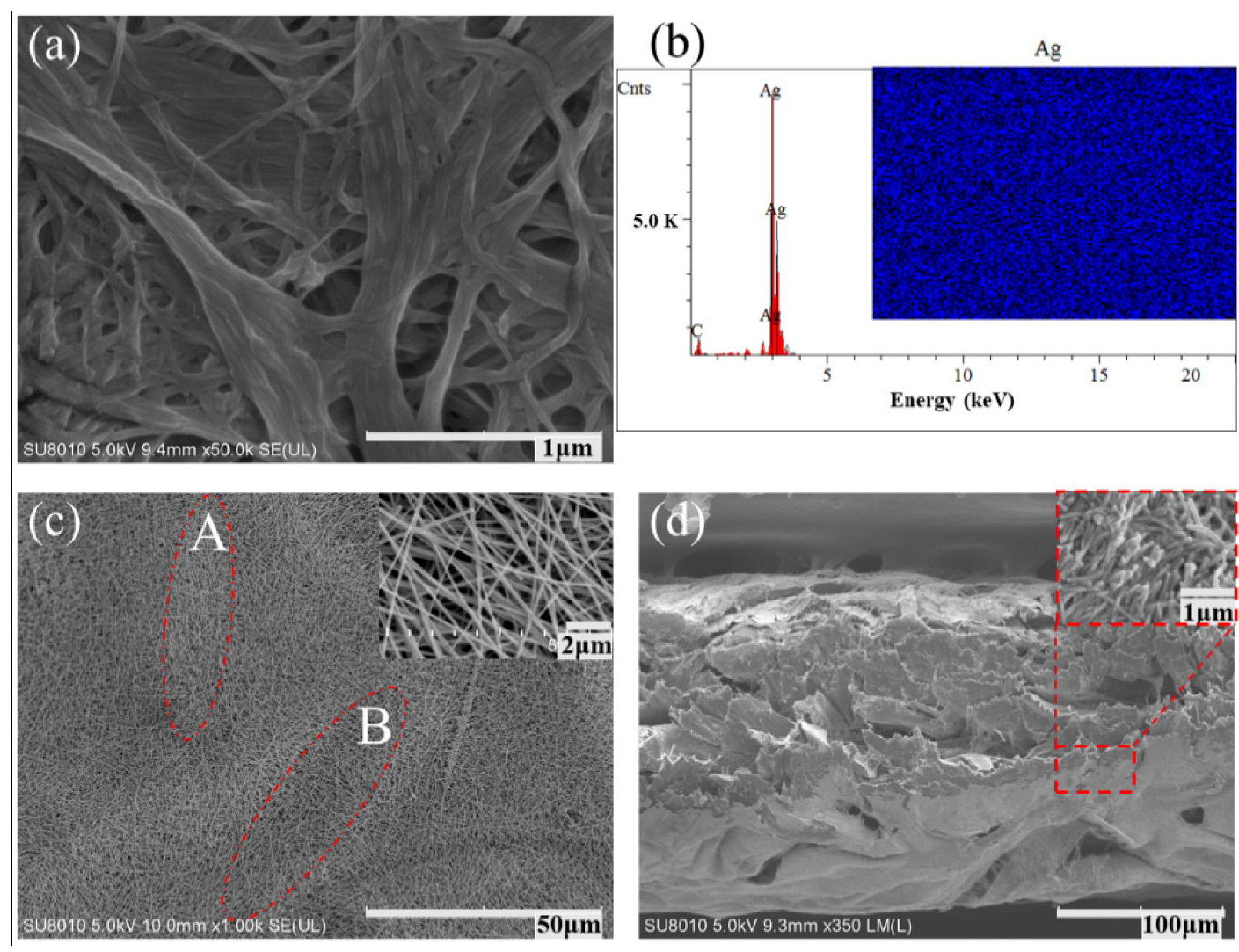

2.3. Characterization and Measurement

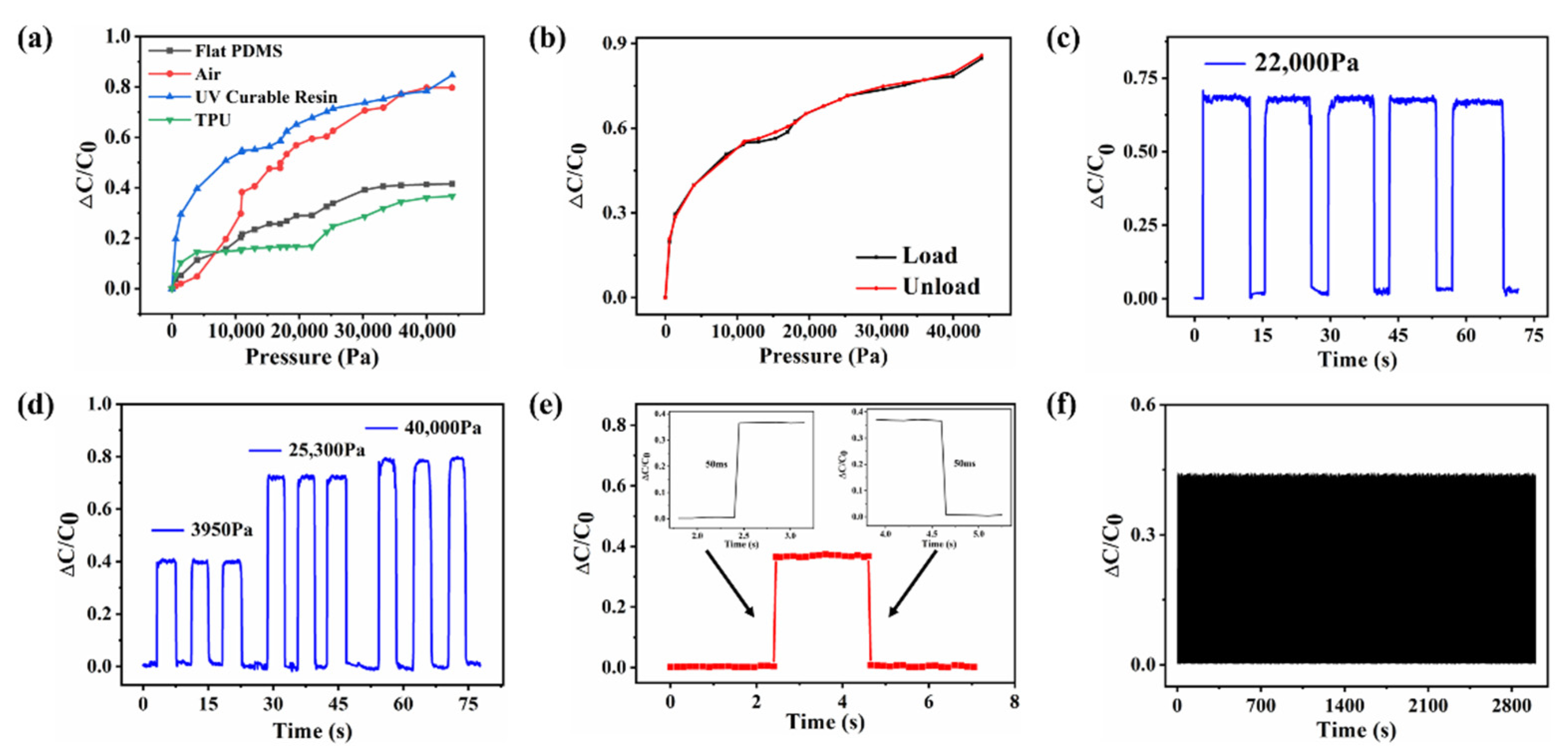

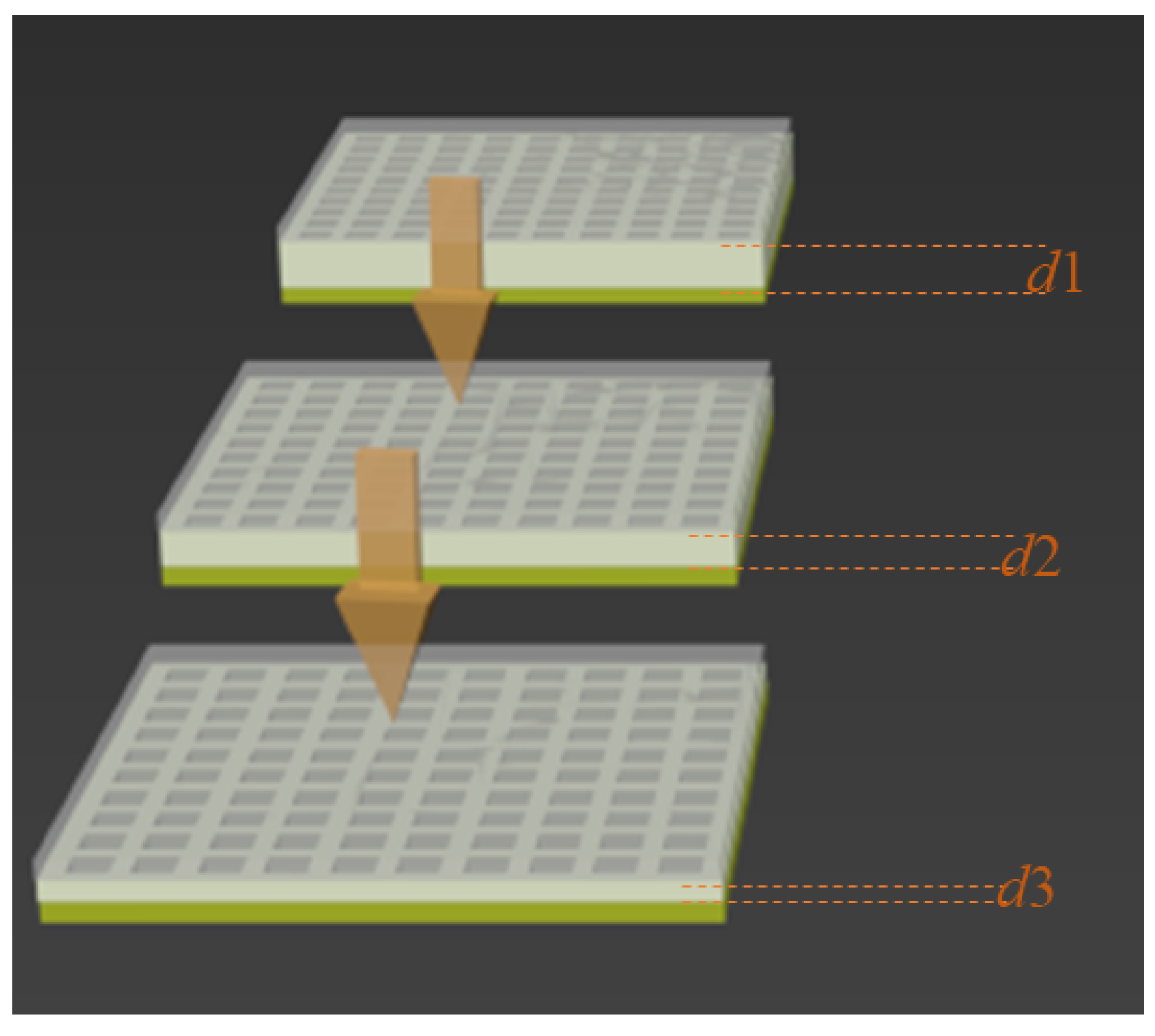

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, Y.; Ji, Z.; Zhang, Y.; Wang, X.; Zhou, F. Solvent-free and photocurable polyimide inks for 3D printing. J. Mater. Chem. A 2017, 5, 16307–16314. [Google Scholar] [CrossRef]

- Fan, Z.; Feng, H. Study on selective laser melting and heat treatment of Ti-6Al-4V alloy. Results Phys. 2018, 10, 660–664. [Google Scholar] [CrossRef]

- Rastogi, P.; Kandasubramanian, B. Breakthrough in the printing tactics for stimuli-responsive materials: 4D printing. Chem. Eng. J. 2019, 366, 264–304. [Google Scholar] [CrossRef]

- Zeng, X.; Chen, H.; Chen, L.; Zheng, B. Insights into the relationship between structure and rheological properties of starch gels in hot-extrusion 3D printing. Food Chem. 2021, 342, 128362. [Google Scholar] [CrossRef]

- Yang, Y.; Song, X.; Li, X.; Chen, Z.; Zhou, C.; Zhou, Q.; Chen, Y. Recent Progress in Biomimetic Additive Manufacturing Technology: From Materials to Functional Structures. Adv. Mater. 2018, 30, 1706539. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X.; Zheng, X.; Chen, Z.; Zhou, Q.; Chen, Y. 3D-Printed Biomimetic Super-Hydrophobic Structure for Microdroplet Manipulation and Oil/Water Separation. Adv. Mater. 2018, 30, 1704912. [Google Scholar] [CrossRef]

- Jian, Z.; Zhuang, T.; Qinyu, T.; Liqing, P.; Kun, L.; Xujiang, L.; Diaodiao, W.; Zhen, Y.; Shuangpeng, J.; Xiang, S. 3D bioprinting of a biomimetic meniscal scaffold for application in tissue engineering. Bioact. Mater. 2021, 6, 1711–1726. [Google Scholar] [CrossRef]

- Li, Y.; Zhong, J.; Wu, L.; Weng, Z.; Zheng, L.; Peng, S.; Zhang, X. High performance POSS filled nanocomposites prepared via UV-curing based on 3D stereolithography printing. Compos. Part A Appl. Sci. Manuf. 2019, 117, 276–286. [Google Scholar] [CrossRef]

- Ji, X.F.; Zhu, H.; Zhao, L.M.; Xiao, J. Recent advances in 3D bioprinting for the regeneration of functional cartilage. Regen. Med. 2018, 13, 73–87. [Google Scholar]

- Chin, S.Y.; Dikshit, V.; Meera Priyadarshini, B.; Zhang, Y. Powder-based 3D printing for the fabrication of device with micro and mesoscale features. Micromachines 2020, 11, 658. [Google Scholar] [CrossRef]

- Karakurt, I.; Lin, L. 3D printing technologies: Techniques, materials, and post-processing. Curr. Opin. Chem. Eng. 2020, 28, 134–143. [Google Scholar] [CrossRef]

- Lu, B.; Lan, H.; Liu, H. Additive manufacturing frontier: 3D printing electronics. Opto-Electron. Adv. 2018, 1, 170004. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, W.; Zhang, Q.; Zheng, K.; Xu, J.; Xu, W.; Shang, E.; Jiang, J.; Zhang, J.; Liu, Y. 3D-printed graphene/polydimethylsiloxane composites for stretchable and strain-insensitive temperature sensors. ACS Appl. Mater. Interfaces 2018, 11, 1344–1352. [Google Scholar] [CrossRef] [PubMed]

- Joung, K.Y.; Kim, S.Y.; Kang, I.; Cho, S.H. 3D-Printed load cell using nanocarbon composite strain sensor. Sensors 2021, 21, 3675. [Google Scholar] [CrossRef]

- Seo, M.; Hwang, S.; Hwang, T.; Yeo, J. Fabrication of soft sensor using laser processing techniques: For the alternative 3D printing process. Materials 2019, 12, 2955. [Google Scholar] [CrossRef] [Green Version]

- Eijking, B.; Sanders, R.; Krijnen, G. Development of whisker inspired 3D multi-material printed flexible tactile sensors. In Proceedings of the 2017 IEEE Sensors, Glasgow, UK, 29 October–1 November 2017; pp. 1–3. [Google Scholar]

- Li, B.; Zhang, S.; Zhang, L.; Gao, Y.; Xuan, F. Strain sensing behavior of FDM 3D printed carbon black filled TPU with periodic configurations and flexible substrates. J. Manuf. Process. 2022, 74, 283–295. [Google Scholar] [CrossRef]

- Xiang, D.; Zhang, Z.; Han, Z.; Zhang, X.; Zhou, Z.; Zhang, J.; Luo, X.; Wang, P.; Zhao, C.; Li, Y. Effects of non-covalent interactions on the properties of 3D printed flexible piezoresistive strain sensors of conductive polymer composites. Compos. Interfaces 2021, 28, 577–591. [Google Scholar] [CrossRef]

- Wan, Y.; Wang, Y.; Guo, C.F. Recent progresses on flexible tactile sensors. Mater. Today Phys. 2017, 1, 61–73. [Google Scholar] [CrossRef]

- Huang, Y.; Fan, X.; Chen, S.C.; Zhao, N. Emerging technologies of flexible pressure sensors: Materials, modeling, devices, and manufacturing. Adv. Funct. Mater. 2019, 29, 1808509. [Google Scholar] [CrossRef]

- Luo, Y.; Shao, J.; Chen, S.; Chen, X.; Tian, H.; Li, X.; Wang, L.; Wang, D.; Lu, B. Flexible capacitive pressure sensor enhanced by tilted micropillar arrays. ACS Appl. Mater. Interfaces 2019, 11, 17796–17803. [Google Scholar] [CrossRef]

- Li, T.; Luo, H.; Qin, L.; Wang, X.; Xiong, Z.; Ding, H.; Gu, Y.; Liu, Z.; Zhang, T. Flexible capacitive tactile sensor based on micropatterned dielectric layer. Small 2016, 12, 5042–5048. [Google Scholar] [CrossRef] [PubMed]

- Gross, B.C.; Erkal, J.L.; Lockwood, S.Y.; Chen, C.; Spence, D.M. Evaluation of 3D printing and its potential impact on biotechnology and the chemical sciences. Anal. Chem. 2014, 86, 3240–3253. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Song, Y.; Ding, D.; Ling, Z.; Xu, F. Flexible and anisotropic strain sensor based on carbonized crepe paper with aligned cellulose fibers. Adv. Funct. Mater. 2018, 28, 1802547. [Google Scholar] [CrossRef]

- Hua, D.; Zhang, X.; Ji, Z.; Yan, C.; Yu, B.; Li, Y.; Wang, X.; Zhou, F. 3D printing of shape changing composites for constructing flexible paper-based photothermal bilayer actuators. J. Mater. Chem. C 2018, 6, 2123–2131. [Google Scholar] [CrossRef]

- Li, Y.; Samad, Y.A.; Taha, T.; Cai, G.; Fu, S.Y.; Liao, K. Highly flexible strain sensor from tissue paper for wearable electronics. ACS Sustain. Chem. Eng. 2016, 4, 4288–4295. [Google Scholar] [CrossRef]

- Long, Y.; He, P.; Xu, R.; Hayasaka, T.; Shao, Z.; Zhong, J.; Lin, L. Molybdenum-carbide-graphene composites for paper-based strain and acoustic pressure sensors. Carbon 2020, 157, 594–601. [Google Scholar] [CrossRef]

- Liao, X.; Zhang, Z.; Liang, Q.; Liao, Q.; Zhang, Y. Flexible, cuttable, and self-waterproof bending strain sensors using microcracked gold nanofilms@ paper substrate. ACS Appl. Mater. Interfaces 2017, 9, 4151–4158. [Google Scholar] [CrossRef]

- Guo, H.; Yin, Z.; Namkoong, M.; Li, Y.; Nguyen, T.; Salcedo, E.; Arizpe, I.; Tian, L. Printed Ultrastable Bioplasmonic Microarrays for Point-of-Need Biosensing. ACS Appl. Mater. Interfaces 2022, 14, 10729–10737. [Google Scholar] [CrossRef]

- Santhiago, M.; Corrêa, C.C.; Bernardes, J.S.; Pereira, M.P.; Oliveira, L.J.; Strauss, M.; Bufon, C.C. Flexible and foldable fully-printed carbon black conductive nanostructures on paper for high-performance electronic, electrochemical, and wearable devices. ACS Appl. Mater. Interfaces 2017, 9, 24365–24372. [Google Scholar] [CrossRef]

- Li, Y.Q.; Liang, F. Progress in paper-based colorimetric sensor array. Chin. J. Anal. Chem. 2020, 48, 1448–1457. [Google Scholar] [CrossRef]

- Zhang, Q.; Jia, W.; Ji, C.; Pei, Z.; Jing, Z.; Cheng, Y.; Zhang, W.; Zhuo, K.; Ji, J.; Yuan, Z. Flexible wide-range capacitive pressure sensor using micropore PE tape as template. Smart Mater. Struct. 2019, 28, 115040. [Google Scholar] [CrossRef]

- He, Z.; Chen, W.; Liang, B.; Liu, C.; Yang, L.; Lu, D.; Mo, Z.; Zhu, H.; Tang, Z.; Gui, X. Capacitive pressure sensor with high sensitivity and fast response to dynamic interaction based on graphene and porous nylon networks. ACS Appl. Mater. Interfaces 2018, 10, 12816–12823. [Google Scholar] [CrossRef] [PubMed]

- Ke, K.; McMaster, M.; Christopherson, W.; Singer, K.D.; Manas-Zloczower, I. Highly sensitive capacitive pressure sensors based on elastomer composites with carbon filler hybrids. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105614. [Google Scholar] [CrossRef]

- Metzger, C.; Fleisch, E.; Meyer, J.; Dansachmüller, M.; Graz, I.; Kaltenbrunner, M.; Keplinger, C.; Schwödiauer, R.; Bauer, S. Flexible-foam-based capacitive sensor arrays for object detection at low cost. Appl. Phys. Lett. 2008, 92, 013506. [Google Scholar] [CrossRef]

- Lei, K.F.; Lee, K.F.; Lee, M.Y. Development of a flexible PDMS capacitive pressure sensor for plantar pressure measurement. Microelectron. Eng. 2012, 99, 1–5. [Google Scholar] [CrossRef]

- Wang, X.; Li, T.; Adams, J.; Yang, J. Transparent, stretchable, carbon-nanotube-inlaid conductors enabled by standard replication technology for capacitive pressure, strain and touch sensors. J. Mater. Chem. A 2013, 1, 3580–3586. [Google Scholar] [CrossRef]

- Dobrzynska, J.A.; Gijs, M. Polymer-based flexible capacitive sensor for three-axial force measurements. J. Micromech. Microeng. 2012, 23, 015009. [Google Scholar] [CrossRef]

- Lei, K.F.; Lee, K.F.; Lee, M.Y. A flexible PDMS capacitive tactile sensor with adjustable measurement range for plantar pressure measurement. Microsyst. Technol. 2014, 20, 1351–1358. [Google Scholar] [CrossRef]

- Yao, S.; Zhu, Y. Wearable multifunctional sensors using printed stretchable conductors made of silver nanowires. Nanoscale 2014, 6, 2345–2352. [Google Scholar] [CrossRef]

- Atalay, O.; Atalay, A.; Gafford, J.; Walsh, C. A highly sensitive capacitive-based soft pressure sensor based on a conductive fabric and a microporous dielectric layer. Adv. Mater. Technol. 2018, 3, 1700237. [Google Scholar] [CrossRef]

- Zhang, B.; Xiang, Z.; Zhu, S.; Hu, Q.; Cao, Y.; Zhong, J.; Zhong, Q.; Wang, B.; Fang, Y.; Hu, B. Dual functional transparent film for proximity and pressure sensing. Nano Res. 2014, 7, 1488–1496. [Google Scholar] [CrossRef]

- Subramaniam, S.; Majumder, S.; Faisal, A.I.; Deen, M.J. Insole-based systems for health monitoring: Current solutions and research challenges. Sensors 2022, 22, 438. [Google Scholar] [CrossRef] [PubMed]

- Baek, S.; Jang, H.; Kim, S.Y.; Jeong, H.; Han, S.; Jang, Y.; Kim, D.H.; Lee, H.S. Flexible piezocapacitive sensors based on wrinkled microstructures: Toward low-cost fabrication of pressure sensors over large areas. RSC Adv. 2017, 7, 39420–39426. [Google Scholar] [CrossRef]

- Maddipatla, D.; Narakathu, B.B.; Ali, M.M.; Chlaihawi, A.A.; Atashbar, M.Z. Development of a novel carbon nanotube based printed and flexible pressure sensor. In Proceedings of the 2017 IEEE Sensors Applications Symposium (SAS), Glassboro, NJ, USA, 13–15 March 2017; pp. 1–4. [Google Scholar]

| Dielectric Material | Pressure Range (kPa) | Sensitivity (kPa−1) | Ref. |

|---|---|---|---|

| Graphene and porous nylon n/w | 0–1 1–5 | 0.33 0.007 | [33] |

| Branched-CNTs and GNPs (3:1) | 0–1200 | 0.00205 | [34] |

| Polyolefin foam | 0–1.029 | 8.25 fF | [35] |

| PDMS | 0–945 | 0.0019 | [36] |

| Ecoflex | 10–150 | 0.00059 | [37] |

| PDMS/Parylene-C | 0–10 10–140 | 0.024 0.00066 | [38] |

| PDMS | 240–1000 | 0.000022 | [39] |

| Ecoflex | 0–500 500–1400 | 0.0016 0.00057 | [40] |

| Silicone | 0–100 | 0.0121 | [41] |

| PDMS | 0–50 | 0.0004 | [42] |

| PDMS | 0–15.601 15.601–45 | 0.0486 0.0025 | [32] |

| Ecoflex silicone elastomer | 0–200 | 0.012 | [43] |

| Wrinkled μ-structures Ecoflex | <1 >8 | 0.0012 0.0000042 | [44] |

| PDMS | 1.52–337 | 0.021 | [45] |

| Grid-like UV resin | 0.3–3.95 3.95–44 | 0.101 0.01123 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, W.; Zhang, Q.; Cheng, Y.; Wang, J.; Zhang, H.; Sang, S.; Ji, J. A Flexible Capacitive Paper-Based Pressure Sensor Fabricated Using 3D Printing. Chemosensors 2022, 10, 432. https://doi.org/10.3390/chemosensors10100432

Jia W, Zhang Q, Cheng Y, Wang J, Zhang H, Sang S, Ji J. A Flexible Capacitive Paper-Based Pressure Sensor Fabricated Using 3D Printing. Chemosensors. 2022; 10(10):432. https://doi.org/10.3390/chemosensors10100432

Chicago/Turabian StyleJia, Wendan, Qiang Zhang, Yongqiang Cheng, Jie Wang, Hulin Zhang, Shengbo Sang, and Jianlong Ji. 2022. "A Flexible Capacitive Paper-Based Pressure Sensor Fabricated Using 3D Printing" Chemosensors 10, no. 10: 432. https://doi.org/10.3390/chemosensors10100432

APA StyleJia, W., Zhang, Q., Cheng, Y., Wang, J., Zhang, H., Sang, S., & Ji, J. (2022). A Flexible Capacitive Paper-Based Pressure Sensor Fabricated Using 3D Printing. Chemosensors, 10(10), 432. https://doi.org/10.3390/chemosensors10100432