Evaluating Industry 4.0 Technology Application in SMEs: Using a Hybrid MCDM Approach

Abstract

1. Introduction

2. Literature Review

2.1. Related Literature on the Elements Influencing Industry 4.0 Technology Application in SMEs

2.2. Elements for Assessing the Industry 4.0 Technology Application Procedure

3. Methods

3.1. DEMATEL Technique

3.2. DANP Method

3.3. Modified VIKOR

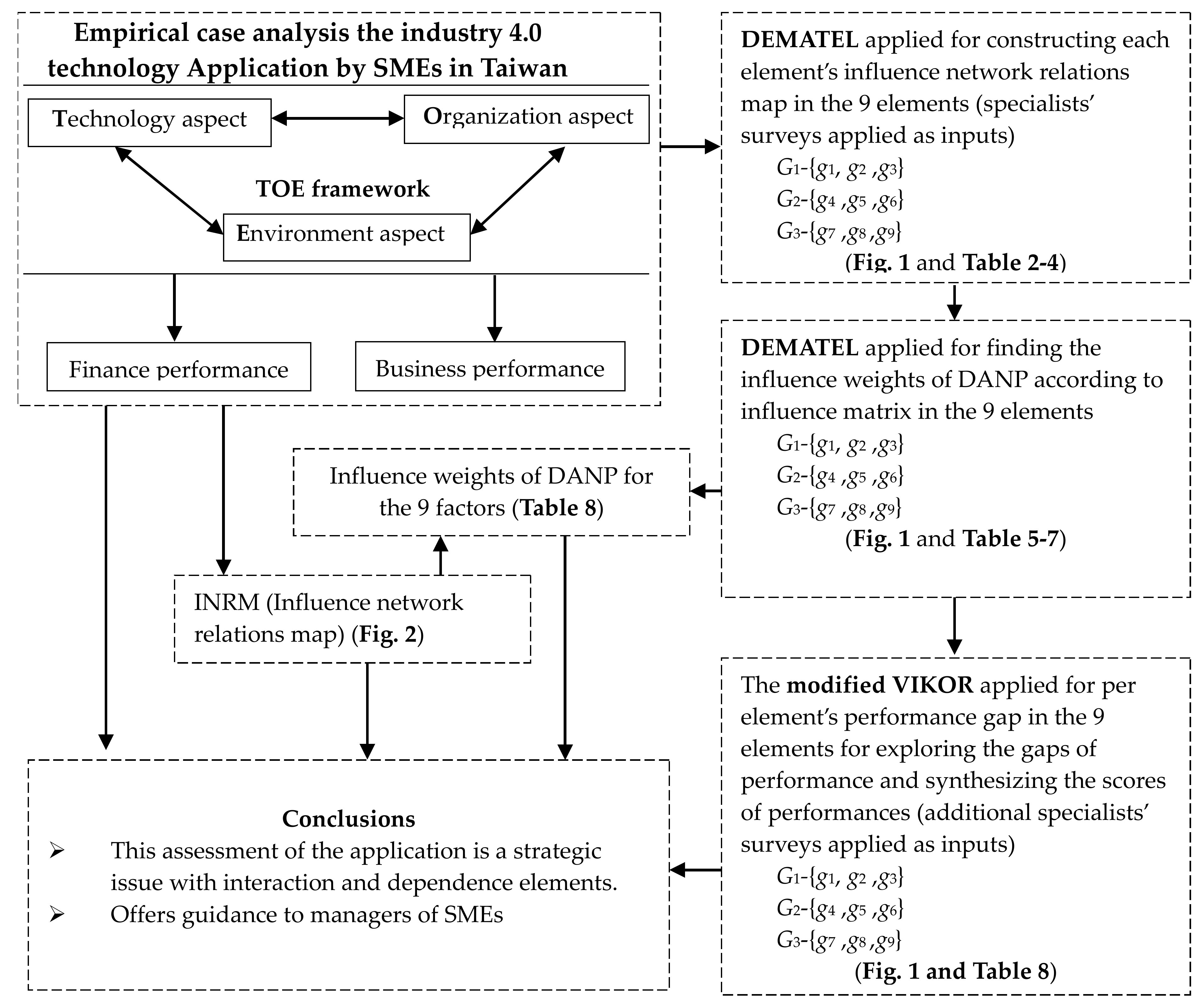

4. Case Analysis

4.1. Data Collection

4.2. Results Analysis

4.3. Implications and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Raj, A.; Dwivedi, G.; Sharma, A.; Jabbour, A.B.L.D.S.; Rajak, S. Barriers to the adoption of industry 4.0 technologies in the manufacturing sector: An inter-country comparative perspective. Int. J. Prod. Econ. 2020, 224, 107546. [Google Scholar] [CrossRef]

- Li, L. China’s manufacturing locus in 2025: With a comparison of “Made-in-China 2025” and “Industry 4.0”. Technol. Forecast. Soc. Chang. 2018, 135, 66–74. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integrat. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Lu, Y.; Papagiannidis, S.; Alamanos, E. Internet of Things: A systematic review of the business literature from the user and organizational perspectives. Technol. Forecast. Soc. Chang. 2018, 136, 285–297. [Google Scholar] [CrossRef]

- Gardan, J. Additive manufacturing technologies: State of the art and trends. Int. J. Prod. Res. 2016, 10, 3118–3132. [Google Scholar] [CrossRef]

- Urbinati, A.; Borges, M.; Chiesa, V.; Frattini, F. Creating and capturing value from Big Data: A multiple-case study analysis of provider companies. Technovation 2019, 84, 21–36. [Google Scholar] [CrossRef]

- Nuccio, M.; Guerzoni, M. Big Data: Hell or Heaven? Digital platforms and market power in the data-driven economy. Compet. Chang. 2019, 23, 312–328. [Google Scholar] [CrossRef]

- Nosalska, K.; Piatek, Z.M.; Mazurek, G.; Rzadca, R. Industry 4.0: Coherent definition framework with technological and organizational interdependencies. J. Manuf. Technol. Manag. 2020, 31, 837–862. [Google Scholar] [CrossRef]

- Fatorachian, H.; Kazemi, H. A critical investigation of Industry 4.0 in manufacturing: Theoretical operationalisation framework. Prod. Plann. Control. 2018, 29, 633–644. [Google Scholar] [CrossRef]

- Xu, D.X.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Pournader, M.; Shi, Y.; Seuring, S.; Koh, S.C.L. Blockchain applications in supply chains, transport and logistics: A systematic review of the literature. Int. J. Prod. Res. 2020, 58, 2063–2081. [Google Scholar] [CrossRef]

- Osterrieder, P.; Budde, L.; Friedli, T. The smart factory as a key construct of Industry 4.0: A systematic literature review. Int. J. Prod. Econ. 2020, 221, 107476. [Google Scholar] [CrossRef]

- Liao, Y.; Deschamps, F.; Loures, E.D.F.R.; Ramos, L.F.P. Past, present and future of Industry 4.0-a systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Chiarini, A.; Belvedere, V.; Grando, A. Industry 4.0 strategies and technological developments. An exploratory research from Italian manufacturing companies. Prod. Plann. Control. 2020, 31, 1385–1398. [Google Scholar] [CrossRef]

- Schniederjans, D.G.; Curado, C.; Khalajhedayati, M. Supply chain digitalization trends: An integration of knowledge management. Int. J. Prod. Econ. 2020, 220, 107439. [Google Scholar] [CrossRef]

- Garay-Rondero, C.L.; Martinez-Flores, J.L.; Smith, N.R.; Caballero Morales, S.O.; Aldrette-Malacara, A. Digital supply chain model in Industry 4.0. J. Manuf. Technol. Manag. 2020, 31, 887–933. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Zhang, D.; Li, D.; Zhang, C. Towards smart factory for industry 4.0: A self-organized multi-agent system with big data based feedback and coordination. Comput. Netw. 2016, 101, 158–168. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Foropon, C.; Godinho Filho, M. When titans meet–Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol. Forecast. Soc. Chang. 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Masood, T.; Egger, J. Augmented reality in support of Industry 4.0—Implementation challenges and success factors. Robot. Comput. Integr. Manuf. 2019, 58, 181–195. [Google Scholar] [CrossRef]

- Masood, T.; Egger, J. Adopting augmented reality in the age of industrial digitalisation. Comput. Ind. 2020, 115, 103112. [Google Scholar] [CrossRef]

- Lin, D.; Lee, C.K.M.; Lau, H.; Yang, Y. Strategic response to Industry 4.0: An empirical investigation on the Chinese automotive industry. Ind. Manag. Data Syst. 2018, 118, 589–605. [Google Scholar] [CrossRef]

- Ardito, L.; Petruzzelli, A.M.; Panniello, U.; Garavelli, A.C. Towards Industry 4.0: Mapping digital technologies for supply chain management-marketing integration. Bus. Process Manag. J. 2019, 25, 323–346. [Google Scholar] [CrossRef]

- Mariani, M.; Borghi, M. Industry 4.0: A bibliometric review of its managerial intellectual structure and potential evolution in the service industries. Technol. Forecast. Soc. Chang. 2019, 149, 119752. [Google Scholar] [CrossRef]

- Lu, M.T.; Hu, S.K.; Huang, L.H.; Tzeng, G.H. Evaluating the implementation of business-to-business m-commerce by SMEs based on a new hybrid MADM model. Manag. Decis. 2015, 53, 290–317. [Google Scholar] [CrossRef]

- Liou, J.J.H.; Lu, M.T.; Hu, S.K.; Cheng, C.H.; Chuang, Y.C. A hybrid MCDM model for Improving the Electronic Health Record to Better Serve Client Needs. Sustainability 2017, 9, 1819. [Google Scholar] [CrossRef]

- Lu, M.T.; Tzeng, G.H.; Tang, L.L. Environmental strategic orientations for improving green innovation performance in fuzzy environment-Using new fuzzy Hybrid MCDM model. Int. J. Fuzzy Syst. 2013, 15, 297–316. [Google Scholar]

- Lu, M.T.; Tsai, J.F.; Shen, S.P.; Lin, M.H. Hu, Y.C. Estimating sustainable development performance in the electrical wire and cable industry: Applying the integrated fuzzy MADM approach. J. Clean Prod. 2020, 277, 122440. [Google Scholar] [CrossRef]

- Sevinç, A.; Gür, Ş.; Eren, T. Analysis of the Difficulties of SMEs in Industry 4.0 Applications by Analytical Hierarchy Process and Analytical Network Process. Processes 2018, 6, 264. [Google Scholar]

- Çalık, A. A novel Pythagorean fuzzy AHP and fuzzy TOPSIS methodology for green supplier selection in the Industry 4.0 era. Soft Comput. 2020, 23, 1–13. [Google Scholar] [CrossRef]

- Braziotis, C.; Rogers, H.; Jimo, A. 3D printing strategic deployment: The supply chain perspective. Supply Chain Manag. 2019, 24, 397–404. [Google Scholar] [CrossRef]

- Gress, D.R.; Kalafsky, R.V. Geographies of production in 3D: Theoretical and research implications stemming from additive manufacturing. Geoforum 2015, 60, 43–52. [Google Scholar] [CrossRef]

- Ancarani, A.; Di Mauro, C.; Legenvre, H.; Cardella, M.S. Internet of Things adoption: A typology of projects. Int. J. Oper. Prod. Manag. 2020, 40, 849–872. [Google Scholar] [CrossRef]

- Castelo-Branco, I.; Cruz-Jesus, F.; Oliveira, T. Assessing Industry 4.0 readiness in manufacturing: Evidence for the European Union. Comput. Ind. 2019, 197, 22–32. [Google Scholar] [CrossRef]

- Doh, S.; Kim, B. Government support for SME innovations in the regional industries: The case of government financial support program in South Korea. Res. Policy. 2014, 43, 1557–1569. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Strozzi, F.; Colicchia, C.; Creazza, A.; Noè, C. Literature review on the ‘smart factory’ concept using bibliometric tools. Int. J. Prod. Res. 2017, 55, 6572–6591. [Google Scholar] [CrossRef]

- Galati, F.; Bigliardi, B. Industry 4.0: Emerging themes and future research avenues using a text mining approach. Comput. Ind. 2019, 109, 100–113. [Google Scholar] [CrossRef]

- Frank, G.A.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Sharp, R.; Lopik, K.V.; Neal, A.; Goodall, P.; Conway, P.P.; West, A.A. An industrial evaluation of an Industry 4.0 reference architecture demonstrating the need for the inclusion of security and human components. Comput. Ind. 2019, 108, 37–44. [Google Scholar] [CrossRef]

- Yin, Y.; Stecke, K.E.; Li, D. The evolution of production systems from Industry2.0 through Industry 4.0. Int. J. Prod. Res. 2018, 56, 848–861. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.; Muztoba, A.; Romero, D.; Wuest, T. A critical review of smart manufacturing & Industry 4.0 maturity models: Implications for small and medium-sized enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar]

- Etemad, H. Internationalization of small and medium sized enterprises: A grounded theoretical framework and an overview. Can. J. Adm. Sci. Rev. Can. Des Sci. L Adm. 2009, 21, 1–21. [Google Scholar] [CrossRef]

- European Commission. User Guide to the SME Definition; Publications Office-of-the European Union: Luxembourg, 2016; pp. 3–44. [Google Scholar]

- Knight, G. Entrepreneurship and marketing strategy: The SME under globalization. J. Int. Mark. 2000, 8, 12–32. [Google Scholar] [CrossRef]

- Wallsten, S.J. The effects of government industry R&D programs on private R&D: The case of the Small Business Innovation Research program. Rand J. Econ. 2000, 31, 82–100. [Google Scholar]

- Brunswicker, S.; Vanhaverbeke, W. Open Innovation in Small and Medium Sized Enterprises (SMEs): External Knowledge Sourcing Strategies and Internal Organizational Facilitators. J. Small Bus. Manag. 2015, 53, 1241–1263. [Google Scholar] [CrossRef]

- Kaartinen, H.; Pieska, S.; Vahasoyrinki, J. Digital manufacturing toolbox for supporting the manufacturing SMEs. In Proceedings of the 7th IEEE International Conference on Cognitive Infocommunications, Wroclaw, Poland, 16–18 October 2016; pp. 71–76. [Google Scholar]

- Müller, J.; Voigt, K.I. Industry 4.0 for small and medium sized enterprises. Product. Manag. 2016, 21, 28–30. [Google Scholar]

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The industrial management of SMEs in the era of Industry 4.0. Int. J. Prod. Res. 2018, 56, 1118–1136. [Google Scholar] [CrossRef]

- Vrchota, J.; Volek, T.; Novotná, M. Factors introducing industry 4.0 to SMES. Soc. Sci. 2019, 8, 130. [Google Scholar] [CrossRef]

- Rauch, E.; Linder, C.; Dallasega, P. Anthropocentric perspective of production before and within Industry 4.0. Comput. Ind. Eng. 2020, 139, 105644. [Google Scholar] [CrossRef]

- Modrak, V.; Soltysova, Z.; Poklemba, R. Mapping requirements and roadmapdefinition for introducing I 4.0 in SME environment. In Advances in Manufacturing Engineering and Materials, Proceedings of the International Conference on Manufacturing Engineering and Materials (ICMEM 2018), Nový Smokovec, Slovakia, 18–22 June 2018; Hloch, S., Klichová, D., Krolczyk, G., Chattopadhyaya, S., Ruppenthalová, L., Eds.; Springer Nature Switzerland AG: Cham, Switzerland, 2019. [Google Scholar]

- Fettermann, D.C.; Cavalcante, C.G.S.; Almeida, T.D.D.; Tortorella, G.L. How does Industry 4.0 contribute to operations management? J. Ind. Prod. Eng. 2018, 35, 255–268. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 implications in logistics: An overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Ben-Daya, M.; Hassini, E.; Bahroun, Z. Internet of things and supply chain management: A literature review. Int. J. Prod. Res. 2017, 57, 4719–4742. [Google Scholar] [CrossRef]

- Haddud, A.; DeSouza, A.; Khare, A.; Lee, H. Examining potential benefits and challenges associated with the Internet of Things integration in supply chains. J. Manuf. Technol. Manag. 2017, 28, 1055–1085. [Google Scholar] [CrossRef]

- Mellor, S.; Hao, L.; Zhang, D. Additive manufacturing: A framework for implementation. Int. J. Prod. Econ. 2014, 149, 194–201. [Google Scholar] [CrossRef]

- Svan, F.; Lars, M.; Rikard, L. Embracing digital innovation in incumbent firms: How Volvo cars managed competing concerns. MIS Q. 2017, 41, 239–254. [Google Scholar] [CrossRef]

- Zangiacomi, A.; Pessot, E.; Fornasiero, R.; Beretti, M.; Sacco, M. Moving towards digitalization: A multiple case study in manufacturing. Prod. Plann. Control. 2020, 31, 143–157. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Cawley Vergara, A.M.; Garza-Reyes, J.A.; Sawhney, R. Organizational learning paths based upon Industry 4.0 adoption: An empirical study with Brazilian manufacturers. Int. J. Prod. Econ. 2020, 219, 284–294. [Google Scholar] [CrossRef]

- Veile, J.W.; Kiel, D.; Müller, J.M.; Voigt, K.I. Lessons learned from Industry 4.0 implementation in the German manufacturing industry. J. Manuf. Technol. Manag. 2020, 31, 977–997. [Google Scholar] [CrossRef]

- Reynolds, E.B.; Yilmaz, U. Strengthening advanced manufacturing innovation ecosystem: The case of Massachusetts. Technol. Forecast. Soc. Chang. 2018, 136, 178–191. [Google Scholar] [CrossRef]

- Sung, T. Industry 4.0: A Korea perspective. Technol. Forecast. Soc. Chang. 2018, 132, 40–45. [Google Scholar] [CrossRef]

- Kummitha, R.K.R.; Crutzen, N. Smart cities and the citizen-driven Internet of Things: A qualitative inquiry into an emerging smart city. Technol. Forecast. Soc. Chang. 2019, 140, 44–53. [Google Scholar] [CrossRef]

- Fukuda, K. Science, technology and innovation ecosystem transformation toward Society 5.0. Int. J. Prod. Econ. 2020, 220, 107460. [Google Scholar] [CrossRef]

- Horváth, D.; Szabó, R.Z. Driving forces and barriers of Industry 4.0: Do multinational and small and medium-sized companies have equal opportunities? Technol. Forecast. Soc. Chang. 2019, 146, 119–132. [Google Scholar] [CrossRef]

- Moeuf, A.; Lamouri, S.; Pellerin, R.; Tamayo-Giraldo, S.; Tobon-Valencia, S.; Eburdy, R. Identification of critical success factors, risks and opportunities of Industry 4.0 in SMEs. Int. J. Prod. Res. 2020, 58, 1384–1400. [Google Scholar] [CrossRef]

- Arcidiacono, F.; Ancarani, A.; Di Mauro, C.; Schupp, F. Where the rubber meets the road. Industry 4.0 among SMEs in the automotive sector. IEEE Eng. Manag. Rev. 2019, 47, 86–93. [Google Scholar]

- Tornatzky, L.G.; Fleischer, M. The Processes of Technological Innovation; Lexington Books: Lanham, MD, USA, 1990. [Google Scholar]

- Yeh, C.C.; Chen, Y.F. Critical success factors for adoption of 3D printing. Technol. Forecast. Soc. Chang. 2018, 132, 209–216. [Google Scholar] [CrossRef]

- Lu, M.T.; Lin, S.W.; Tzeng, G.H. Improving RFID adoption in Taiwan’s healthcare industry based on a DEMATEL technique with a hybrid MCDM model. Decis. Support Syst. 2013, 56, 259–269. [Google Scholar] [CrossRef]

- Lu, M.T.; Hsu, C.C.; Liou, J.J.; Lo, H.W. A hybrid MCDM and sustainability balanced scorecard model to establish sustainable performance evaluation for international airports. J. Air Transp. Manag. 2018, 71, 9–19. [Google Scholar] [CrossRef]

- Lu, M.T.; Tzeng, G.H.; Cheng, H.; Hsu, C.C. Exploring mobile banking services for user behavior in intention adoption: Using new hybrid MADM model. Serv. Bus. 2015, 9, 541–565. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision Making with Dependence and Feedback: The Analytic Network Process; RWS Publications: Pittsburgh, PA, USA, 1996. [Google Scholar]

- Opricovic, S.; Tzeng, G.H. Compromise solution by MCDM methods: A comparative analysis of VIKOR and TOPSIS. Eur. J. Oper. Res. 2004, 156, 445–455. [Google Scholar] [CrossRef]

- Opricovic, S.; Tzeng, G.H. Extended VIKOR method in comparison with outranking methods. Eur. J. Oper. Res. 2007, 178, 514–529. [Google Scholar] [CrossRef]

| Aspects/Element | Descriptions |

|---|---|

| Technology aspect (G1) | |

| Technology readiness (g1) | Technology needs to be organized to make procedure changes, and latent sites must make changes for Industry 4.0 technology if benefits are to accrue. |

| Technology security (g2) | This refers to internet platforms being considered secure for conducting online transactions and exchanging data, including isolated data security and protection in using Industry 4.0 technology. |

| Technology integration (g3) | This refers to improving the responsiveness of information systems and decreasing incompatibility between legacy systems. |

| Organization aspect (G2) | |

| Financial commitment (g4) | This refers to the company that can offer the financial resources for FinTech, and is especially committed to investing in employee training, software, hardware, system development, and system integration. |

| Organizational readiness (g5) | This refers to potential sites having to make decisions and businesses needing to be prepared to make business procedure changes for Industry 4.0 technology if benefits are to accrue. |

| Top management support (g6) | This refers to the top managers offering the support, and a promise to ensure a positive influence on this Industry 4.0 technology application procedure. |

| Environment aspect (G3) | |

| Competitive pressure (g7) | This refers to the adoption of Industry 4.0 technology, so that companies can benefit from more accurate data collection and a greater operational efficiency. |

| Regulatory support (g8) | This refers to elements of conception such as the policies of the government, which impact the diffusion of IT. |

| Environmental uncertainty (g9) | This refers to the environmental uncertainty, and how managers and entrepreneurs tend to act proactively according to well-informed conjectures about the strategic path ahead. |

| Elements | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Technology readiness | 0.443 | 0.565 | 0.560 | 0.529 | 0.538 | 0.582 | 0.475 | 0.560 | 0.484 | |

| Technology security | 0.496 | 0.409 | 0.502 | 0.470 | 0.488 | 0.526 | 0.419 | 0.496 | 0.455 | |

| Technology integration | 0.458 | 0.458 | 0.357 | 0.385 | 0.441 | 0.449 | 0.376 | 0.432 | 0.388 | |

| Financial commitment | 0.488 | 0.510 | 0.495 | 0.386 | 0.500 | 0.533 | 0.461 | 0.483 | 0.432 | |

| Organizational readiness | 0.565 | 0.607 | 0.601 | 0.575 | 0.465 | 0.621 | 0.528 | 0.588 | 0.518 | |

| Top management support | 0.320 | 0.317 | 0.335 | 0.309 | 0.315 | 0.268 | 0.270 | 0.301 | 0.270 | |

| Competitive pressure | 0.548 | 0.570 | 0.554 | 0.537 | 0.526 | 0.570 | 0.395 | 0.578 | 0.501 | |

| Regulatory support | 0.475 | 0.466 | 0.461 | 0.451 | 0.451 | 0.470 | 0.425 | 0.375 | 0.385 | |

| Environmental uncertainty | 0.504 | 0.515 | 0.497 | 0.489 | 0.486 | 0.527 | 0.444 | 0.527 | 0.358 | |

| Aspects | G1 | G2 | G3 | ||||

|---|---|---|---|---|---|---|---|

| Technology aspect | 0.472 | 0.490 | 0.454 | 1.415 | 1.453 | 2.868 | −0.037 |

| Organization aspect | 0.471 | 0.441 | 0.428 | 1.340 | 1.432 | 2.772 | −0.092 |

| Environment aspect | 0.510 | 0.501 | 0.443 | 1.454 | 1.325 | 2.779 | 0.129 |

| Aspects/Elements | |||||

|---|---|---|---|---|---|

| G1 | Technology aspect | ||||

| g1 | Technology readiness | 4.736 | 4.298 | 9.033 | 0.438 |

| g2 | Technology security | 4.260 | 4.417 | 8.676 | −0.157 |

| g3 | Technology integration | 3.744 | 4.360 | 8.104 | −0.617 |

| G2 | Organization aspect | ||||

| g4 | Financial commitment | 4.289 | 4.131 | 8.420 | 0.158 |

| g5 | Organizational readiness | 5.067 | 4.209 | 9.277 | 0.858 |

| g6 | Top management support | 2.706 | 4.546 | 7.252 | −1.841 |

| G3 | Environment aspect | ||||

| g7 | Competitive pressure | 4.780 | 3.794 | 8.573 | 0.986 |

| g8 | Regulatory support | 3.959 | 4.340 | 8.299 | −0.382 |

| g9 | Environmental uncertainty | 4.347 | 3.791 | 8.138 | 0.556 |

| Elements | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Technology readiness | 0.283 | 0.360 | 0.357 | 0.321 | 0.326 | 0.353 | 0.313 | 0.369 | 0.319 | |

| Technology security | 0.352 | 0.291 | 0.357 | 0.317 | 0.329 | 0.354 | 0.306 | 0.362 | 0.332 | |

| Technology integration | 0.360 | 0.360 | 0.280 | 0.302 | 0.346 | 0.352 | 0.314 | 0.362 | 0.324 | |

| Financial commitment | 0.327 | 0.341 | 0.332 | 0.272 | 0.352 | 0.375 | 0.335 | 0.351 | 0.314 | |

| Organizational readiness | 0.319 | 0.342 | 0.339 | 0.346 | 0.280 | 0.374 | 0.323 | 0.360 | 0.317 | |

| Top management support | 0.329 | 0.326 | 0.344 | 0.346 | 0.353 | 0.300 | 0.321 | 0.358 | 0.321 | |

| Competitive pressure | 0.328 | 0.341 | 0.331 | 0.329 | 0.322 | 0.349 | 0.268 | 0.392 | 0.340 | |

| Regulatory support | 0.339 | 0.332 | 0.329 | 0.329 | 0.329 | 0.343 | 0.359 | 0.316 | 0.325 | |

| Environmental uncertainty | 0.333 | 0.340 | 0.328 | 0.325 | 0.324 | 0.351 | 0.334 | 0.397 | 0.269 | |

| Elements | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Technology readiness | 0.094 | 0.118 | 0.120 | 0.115 | 0.112 | 0.116 | 0.115 | 0.119 | 0.117 | |

| Technology security | 0.120 | 0.097 | 0.120 | 0.120 | 0.120 | 0.115 | 0.119 | 0.117 | 0.119 | |

| Technology integration | 0.119 | 0.119 | 0.094 | 0.117 | 0.119 | 0.121 | 0.116 | 0.115 | 0.115 | |

| Financial commitment | 0.111 | 0.110 | 0.104 | 0.090 | 0.114 | 0.114 | 0.113 | 0.113 | 0.112 | |

| Organizational readiness | 0.113 | 0.114 | 0.120 | 0.116 | 0.092 | 0.116 | 0.111 | 0.113 | 0.111 | |

| Top management support | 0.122 | 0.123 | 0.122 | 0.124 | 0.123 | 0.099 | 0.120 | 0.118 | 0.121 | |

| Competitive pressure | 0.100 | 0.098 | 0.101 | 0.107 | 0.103 | 0.102 | 0.082 | 0.109 | 0.102 | |

| Regulatory support | 0.118 | 0.116 | 0.116 | 0.112 | 0.115 | 0.114 | 0.120 | 0.096 | 0.121 | |

| Environmental uncertainty | 0.102 | 0.106 | 0.104 | 0.100 | 0.101 | 0.102 | 0.104 | 0.099 | 0.082 | |

| Elements | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Technology readiness | 0.114 | 0.114 | 0.114 | 0.114 | 0.114 | 0.114 | 0.114 | 0.114 | 0.114 | |

| Technology security | 0.116 | 0.116 | 0.116 | 0.116 | 0.116 | 0.116 | 0.116 | 0.116 | 0.116 | |

| Technology integration | 0.115 | 0.115 | 0.115 | 0.115 | 0.115 | 0.115 | 0.115 | 0.115 | 0.115 | |

| Financial commitment | 0.109 | 0.109 | 0.109 | 0.109 | 0.109 | 0.109 | 0.109 | 0.109 | 0.109 | |

| Organizational readiness | 0.112 | 0.112 | 0.112 | 0.112 | 0.112 | 0.112 | 0.112 | 0.112 | 0.112 | |

| Top management support | 0.119 | 0.119 | 0.119 | 0.119 | 0.119 | 0.119 | 0.119 | 0.119 | 0.119 | |

| Competitive pressure | 0.101 | 0.101 | 0.101 | 0.101 | 0.101 | 0.101 | 0.101 | 0.101 | 0.101 | |

| Regulatory support | 0.114 | 0.114 | 0.114 | 0.114 | 0.114 | 0.114 | 0.114 | 0.114 | 0.114 | |

| Environmental uncertainty | 0.100 | 0.100 | 0.100 | 0.100 | 0.100 | 0.100 | 0.100 | 0.100 | 0.100 | |

| Aspects/Elements | Local Weights | Global Weights | Industry 4.0 Technology Gap | ||

|---|---|---|---|---|---|

| FP | BP | ||||

| G1 | Technology aspect | 0.345 | 0.428 | 0.254 | |

| g1 | Technology readiness | 0.330 | 0.114 | 0.280 | 0.140 |

| g2 | Technology security | 0.337 | 0.116 (2) | 0.560 | 0.360 |

| g3 | Technology integration | 0.333 | 0.115 (3) | 0.440 | 0.260 |

| G2 | Organization aspect | 0.340 | 0.317 | 0.392 | |

| g4 | Financial commitment | 0.321 | 0.109 | 0.427 | 0.240 |

| g5 | Organizational readiness | 0.329 | 0.112 | 0.420 | 0.320 |

| g6 | Top management support | 0.350 | 0.119 (1) | 0.120 | 0.600 |

| G3 | Environment aspect | 0.315 | 0.360 | 0.295 | |

| g7 | Competitive pressure | 0.320 | 0.101 | 0.387 | 0.300 |

| g8 | Regulatory support | 0.362 | 0.114 | 0.320 | 0.320 |

| g9 | Environmental uncertainty | 0.318 | 0.100 | 0.380 | 0.260 |

| SA1 | Total gaps | 0.258 | 0.228 | ||

| Scheme | Array of Enhancement Precedence |

|---|---|

| F1: Influence network of aspects | ,, |

| F2: Influence network of elements within individual aspects | :,, |

| :,, | |

| : ,, | |

| F3: Array of aspects required to rise to aspired value (through high to low, via the value of the gap) | Financial performance ,, |

|

Business performance ,, | |

| F4: Array of elements required to rise to aspired value by individual aspects (through high to low, via the value of gap) | Financial performance : ,, : ,, : ,, |

| Business performance : ,, : ,, : ,, |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, S.-C.; Chang, H.-H.; Lu, M.-T. Evaluating Industry 4.0 Technology Application in SMEs: Using a Hybrid MCDM Approach. Mathematics 2021, 9, 414. https://doi.org/10.3390/math9040414

Chang S-C, Chang H-H, Lu M-T. Evaluating Industry 4.0 Technology Application in SMEs: Using a Hybrid MCDM Approach. Mathematics. 2021; 9(4):414. https://doi.org/10.3390/math9040414

Chicago/Turabian StyleChang, Shih-Chia, Hsu-Hwa Chang, and Ming-Tsang Lu. 2021. "Evaluating Industry 4.0 Technology Application in SMEs: Using a Hybrid MCDM Approach" Mathematics 9, no. 4: 414. https://doi.org/10.3390/math9040414

APA StyleChang, S.-C., Chang, H.-H., & Lu, M.-T. (2021). Evaluating Industry 4.0 Technology Application in SMEs: Using a Hybrid MCDM Approach. Mathematics, 9(4), 414. https://doi.org/10.3390/math9040414