Algorithm Execution Time and Accuracy of NTC Thermistor-Based Temperature Measurements in Time-Critical Applications

Abstract

:1. Introduction

2. Principle of Temperature Measurement Using NTC Thermistors

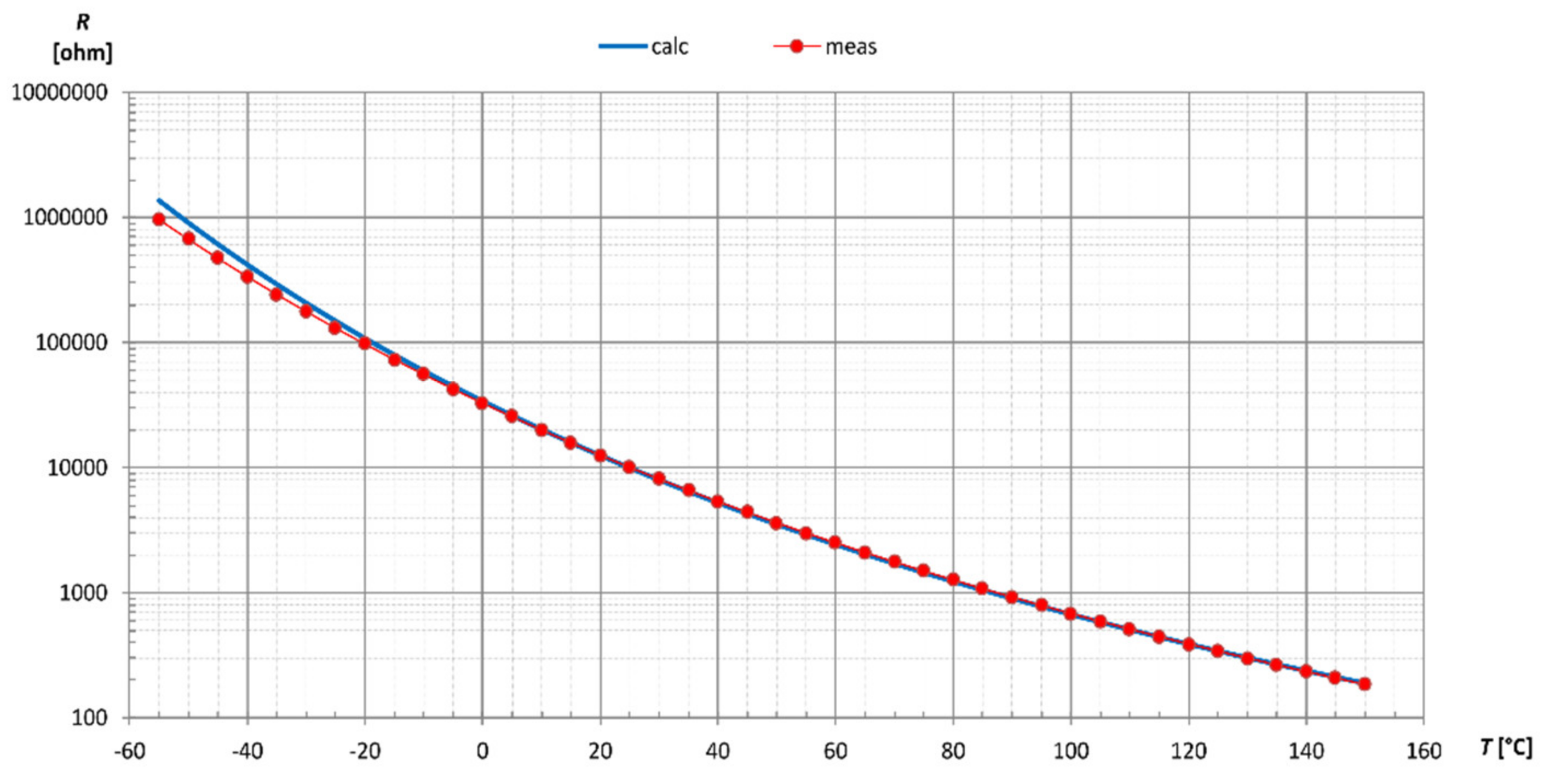

2.1. NTC Thermistor Basics

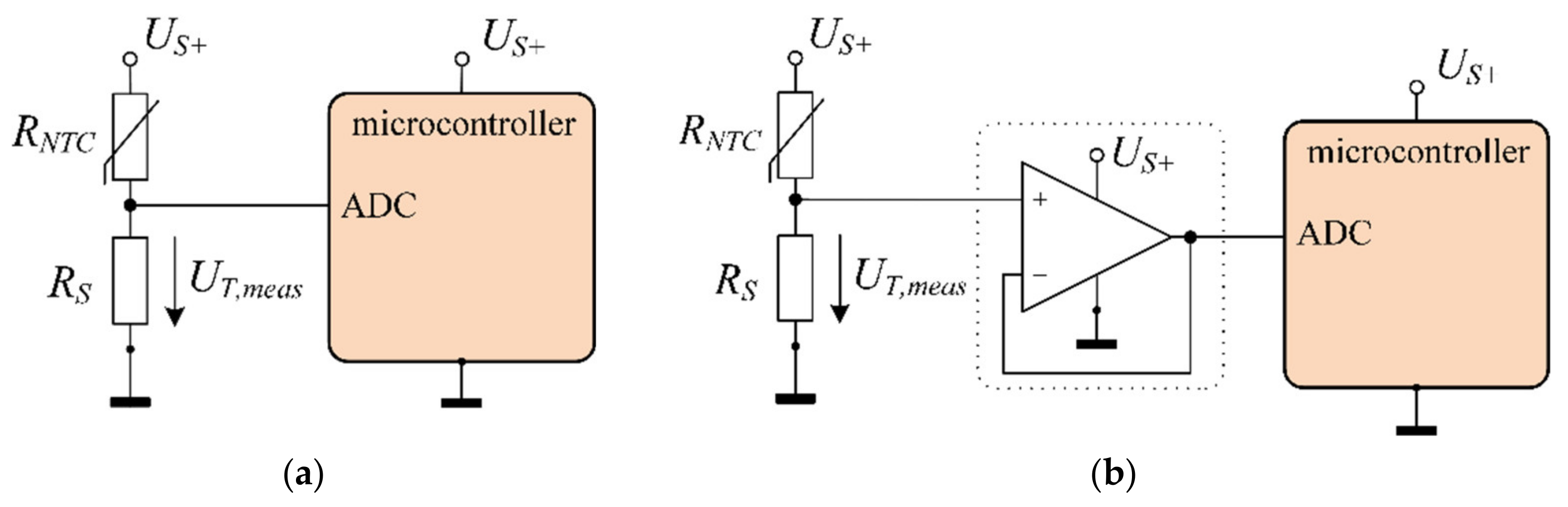

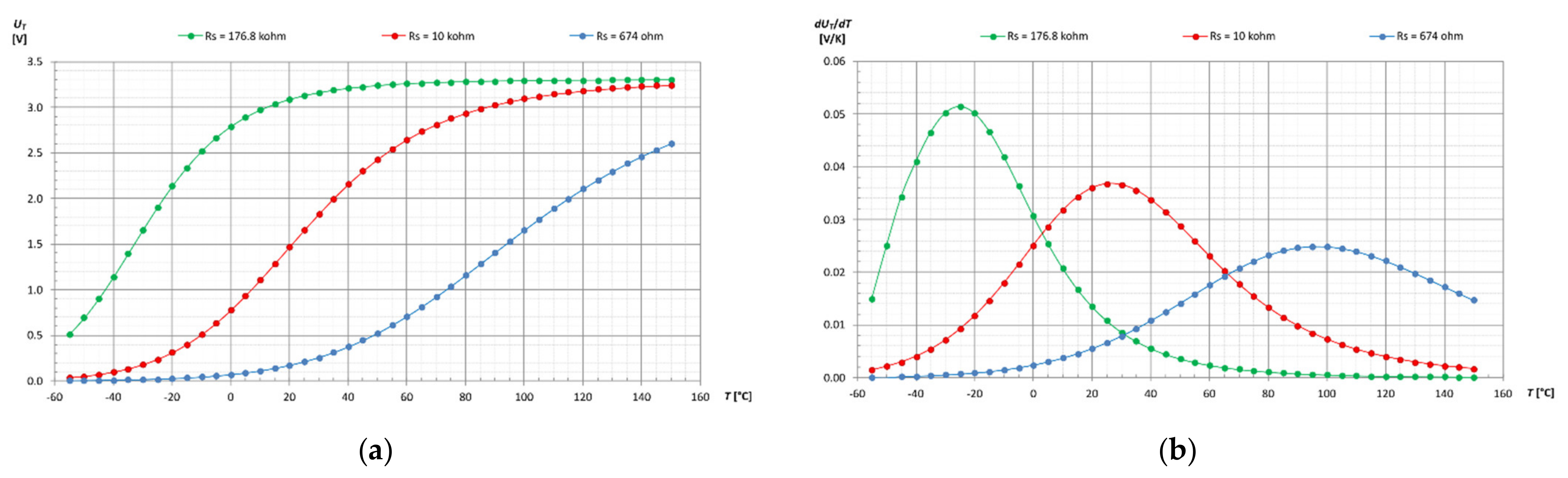

2.2. Signal Conditioning Circuit

3. Simulation-Based Review of Calculation Methods

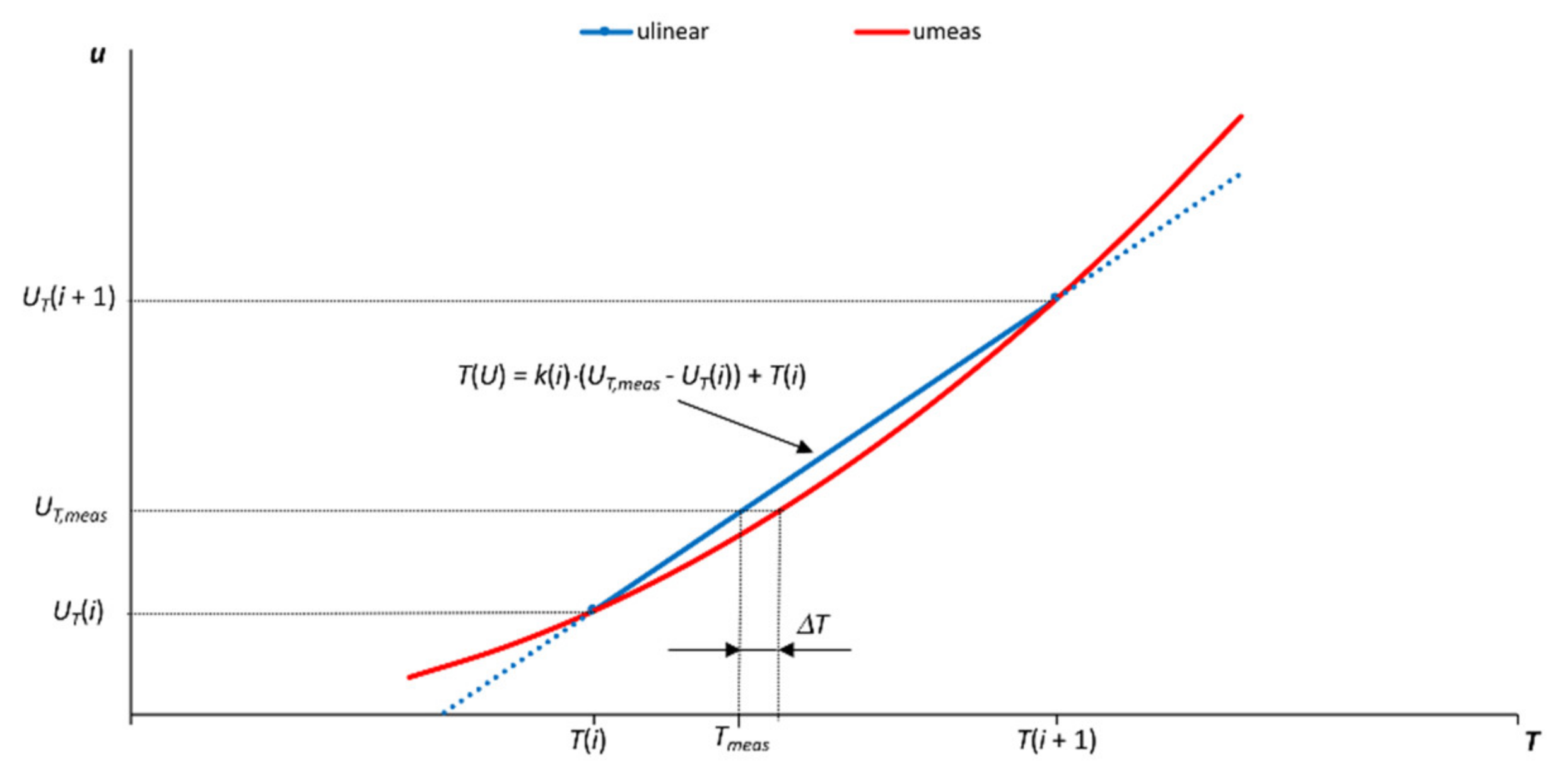

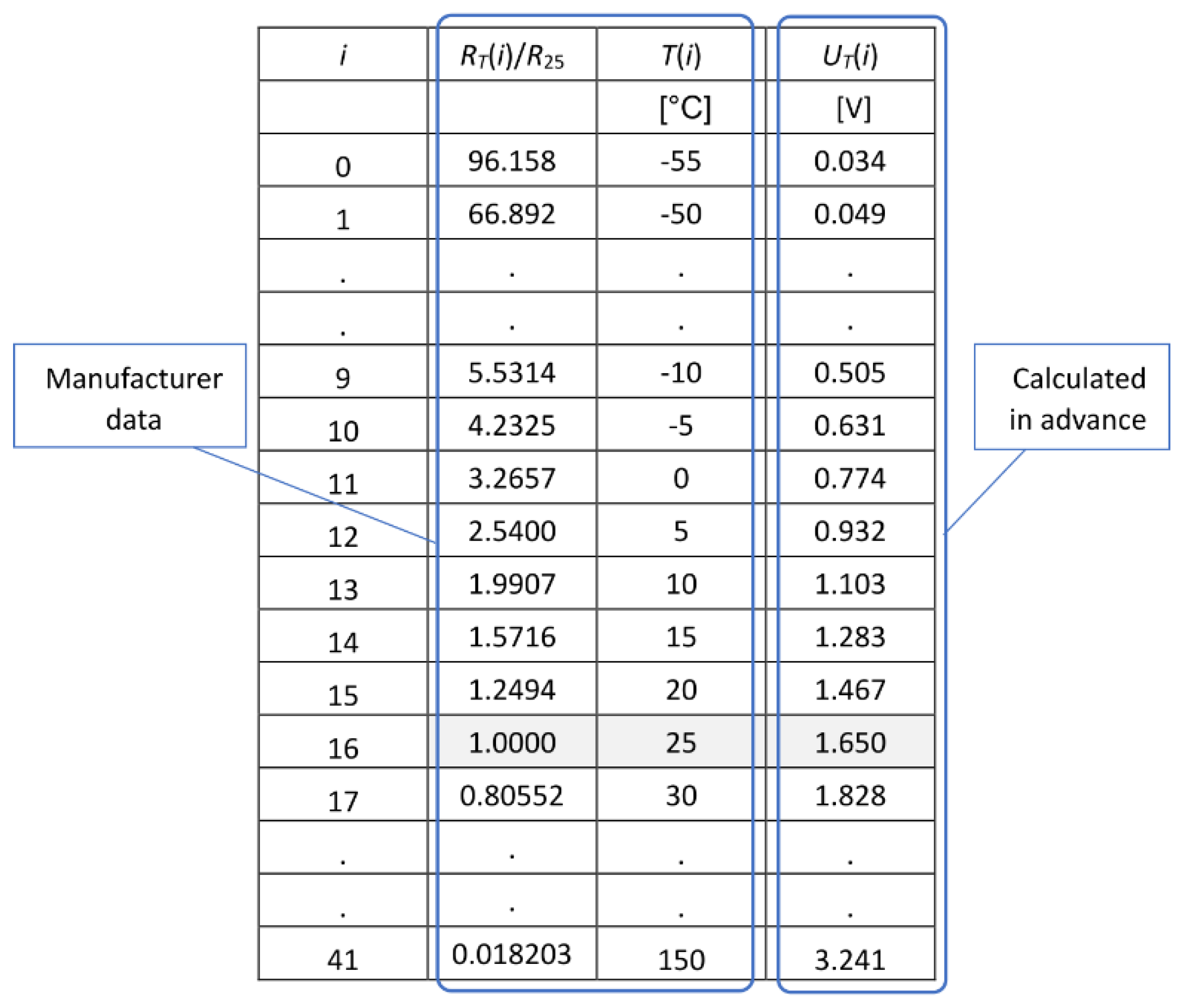

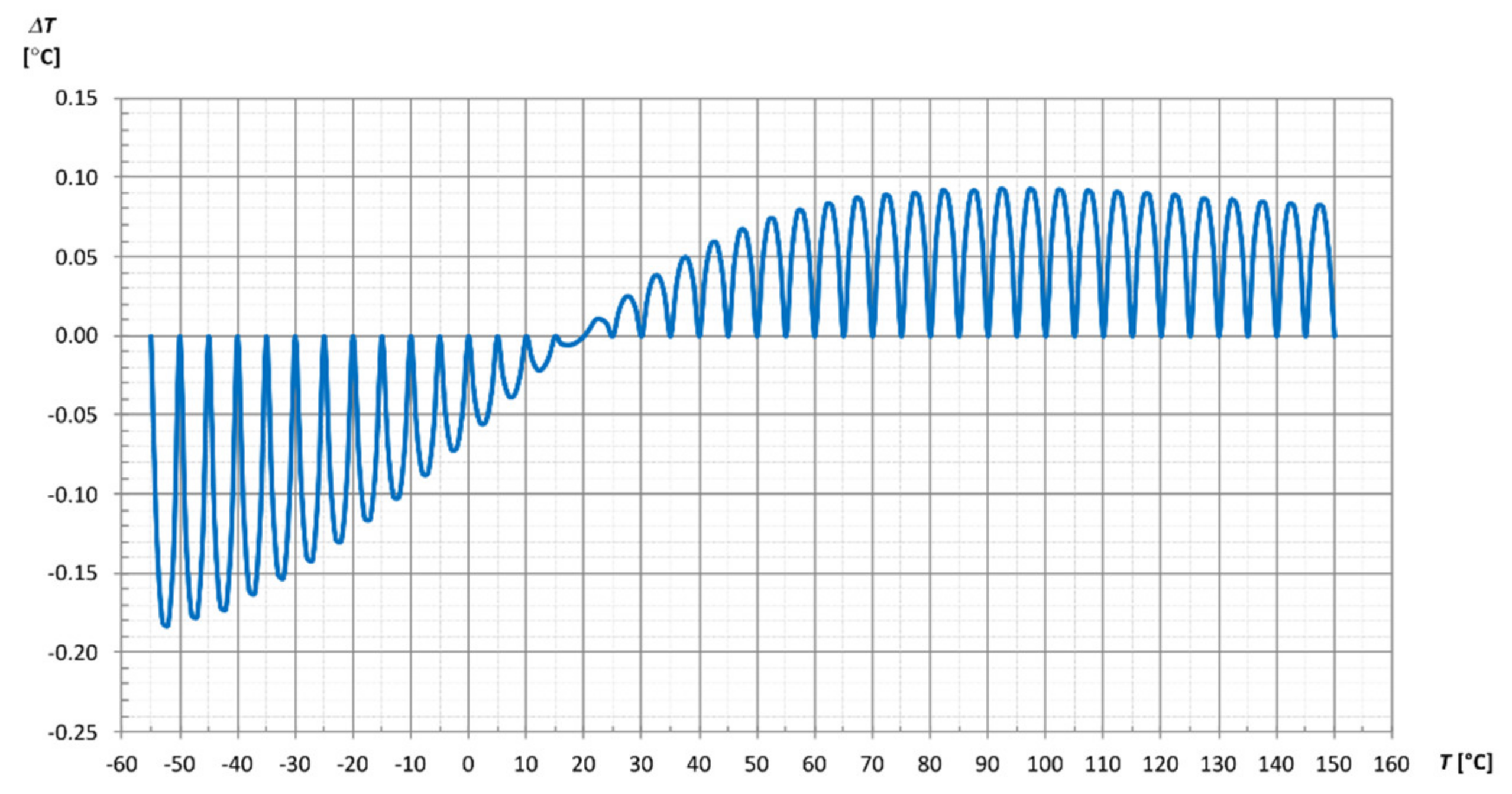

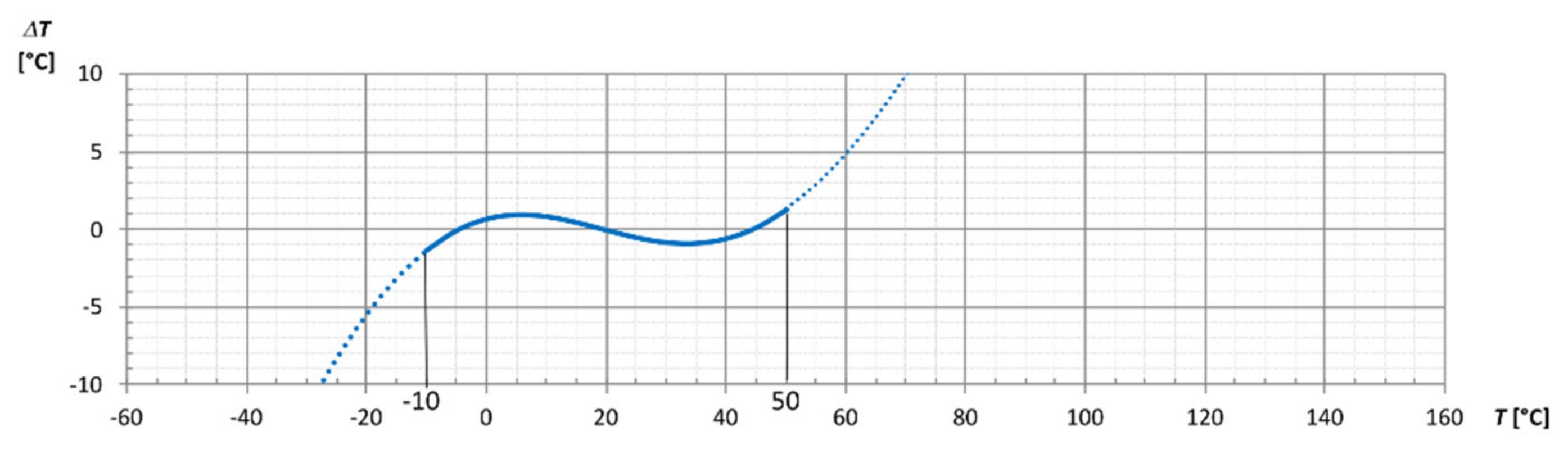

3.1. Look-Up Table with Interpolation

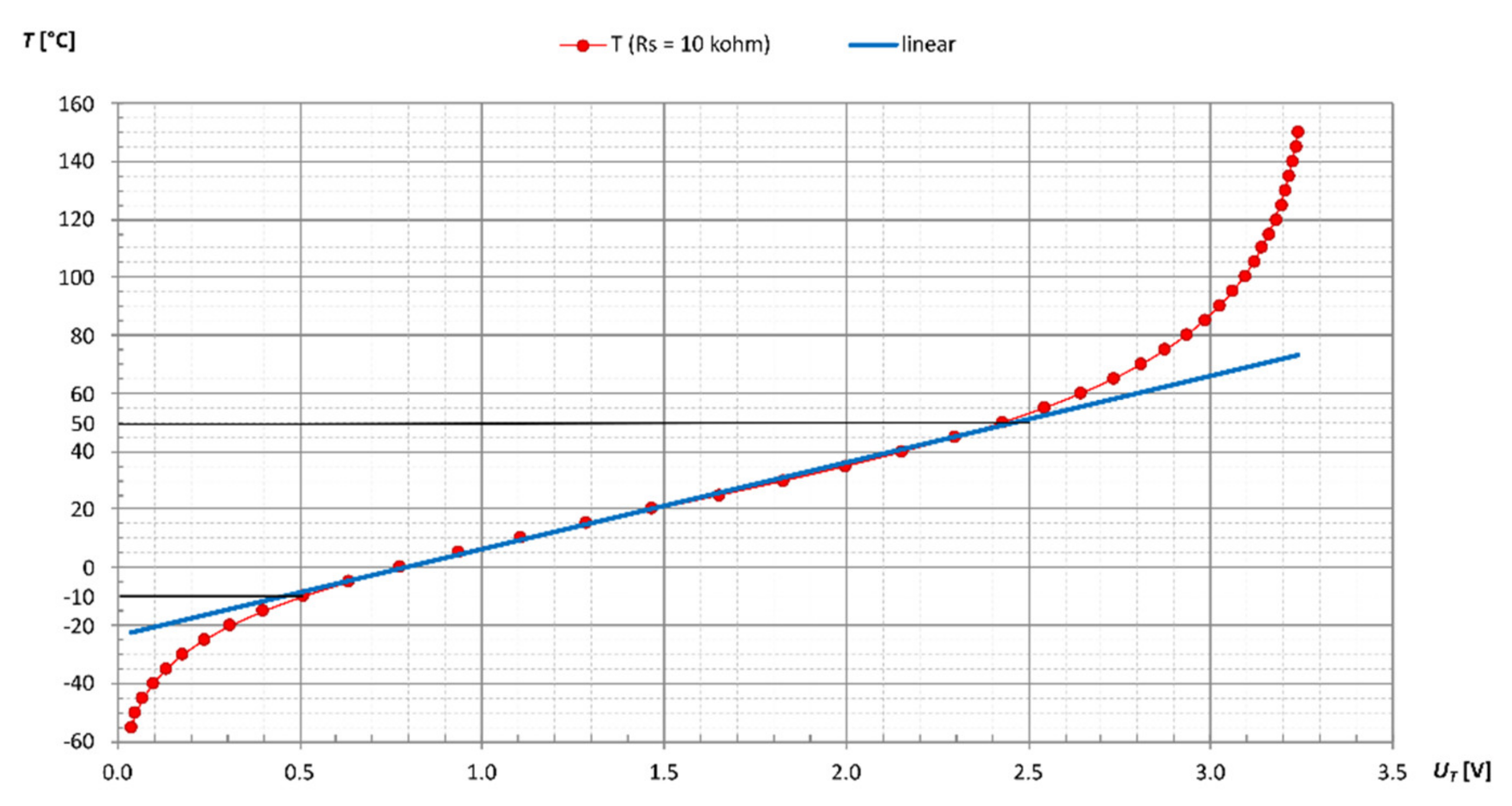

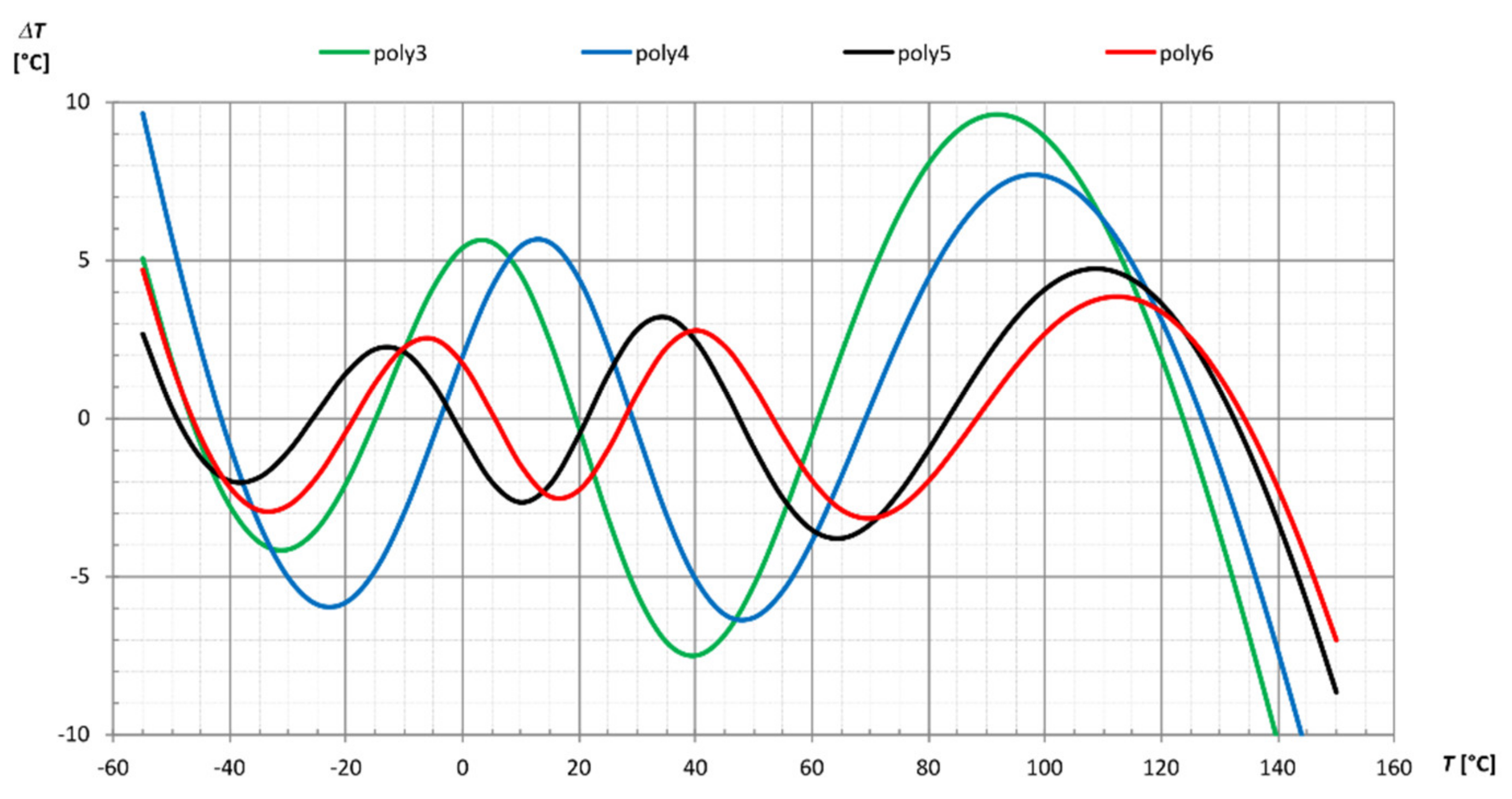

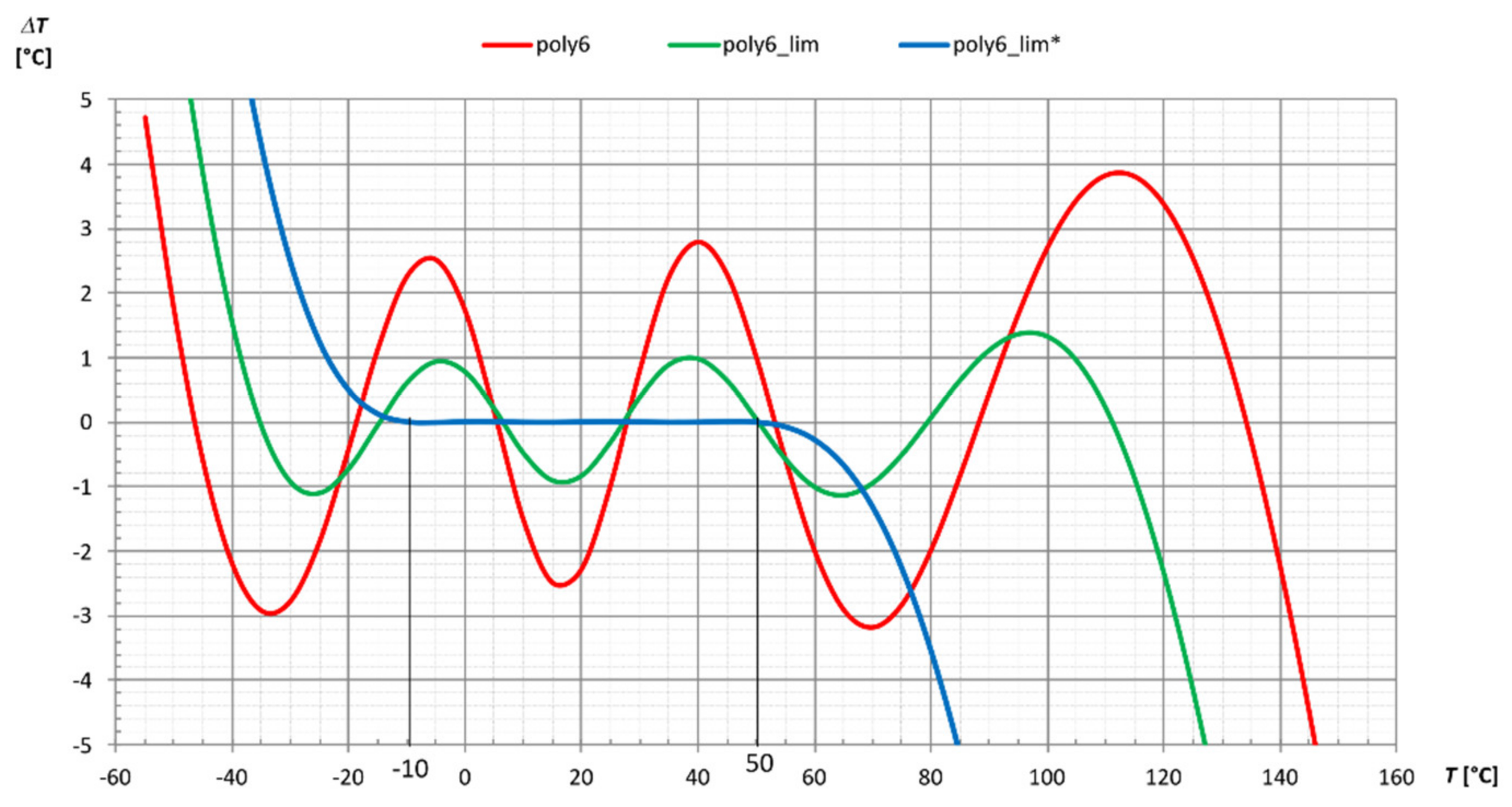

3.2. Approximation of Tabular Data with Polynomials

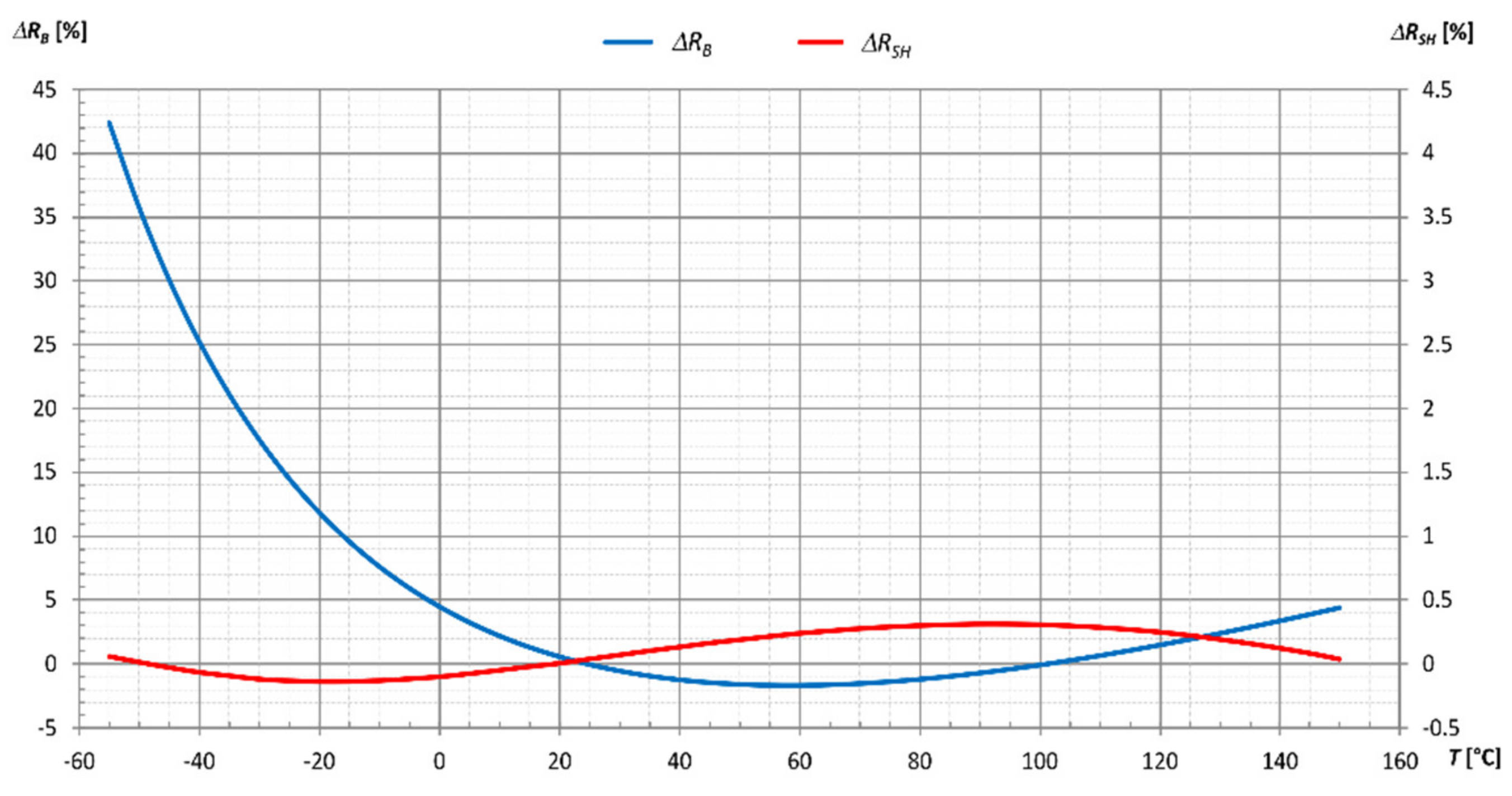

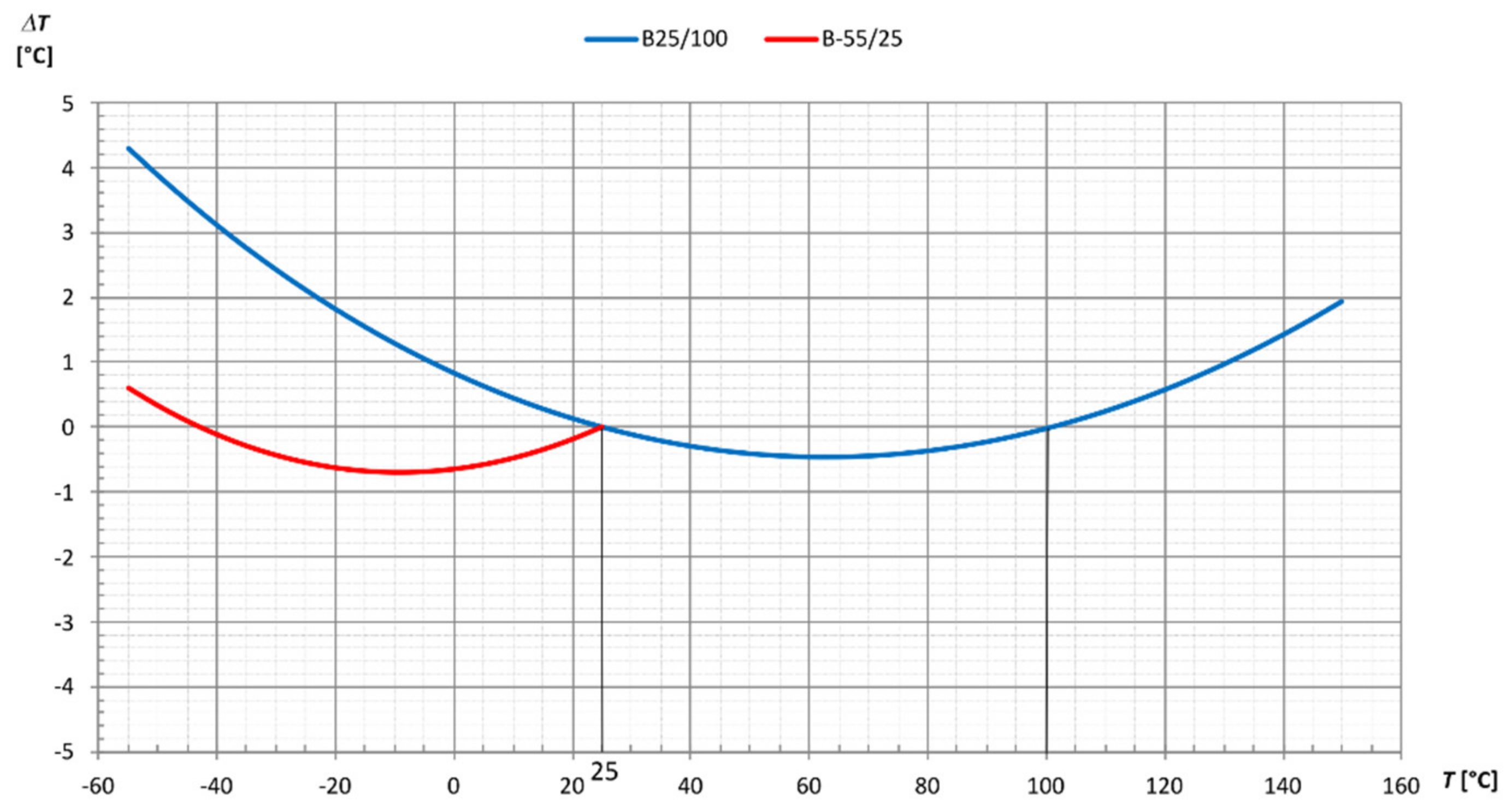

3.3. Analytical Approach Using the B Equation

3.4. Analytical Approach Using the Steinhart–Hart Equation

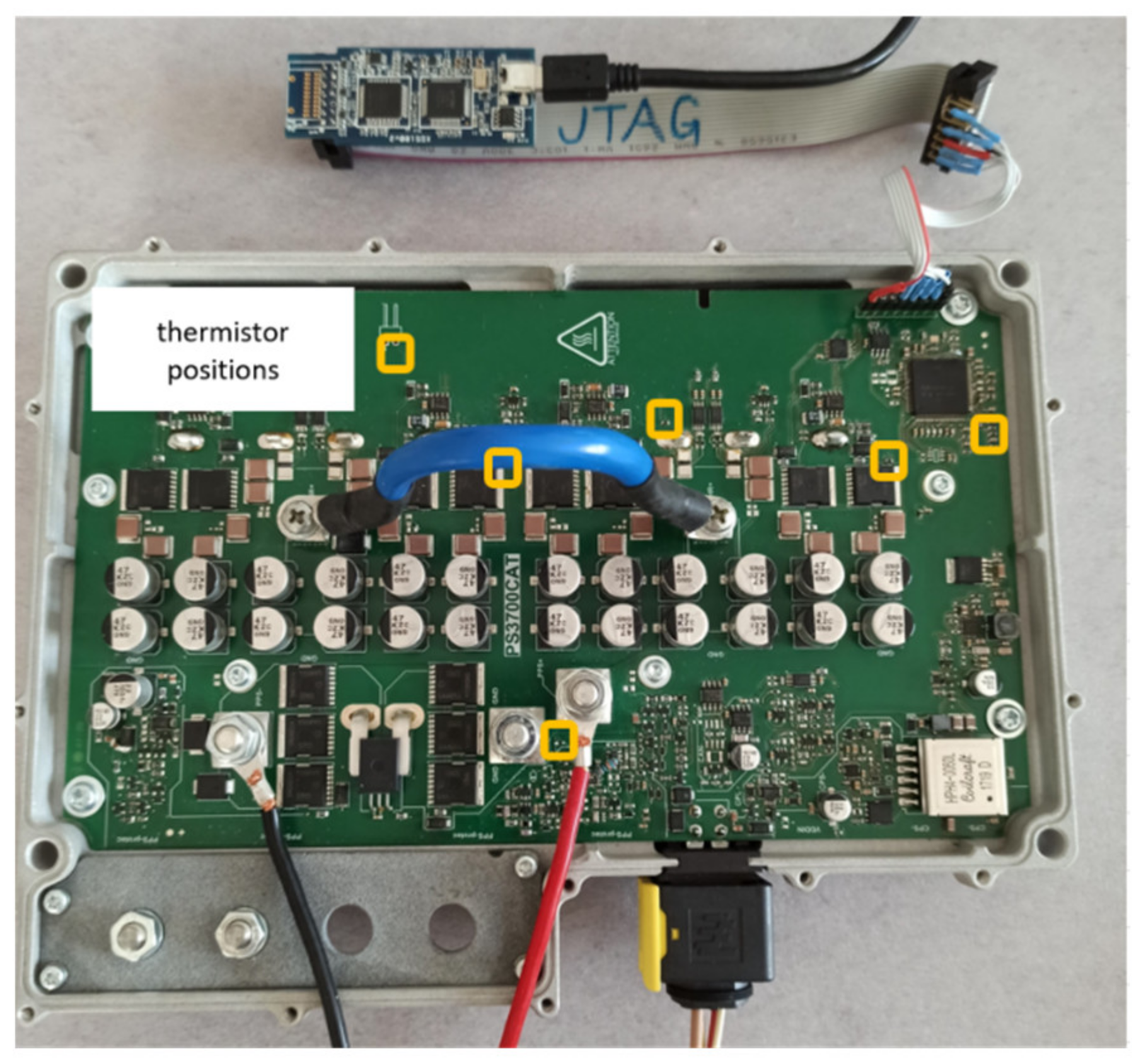

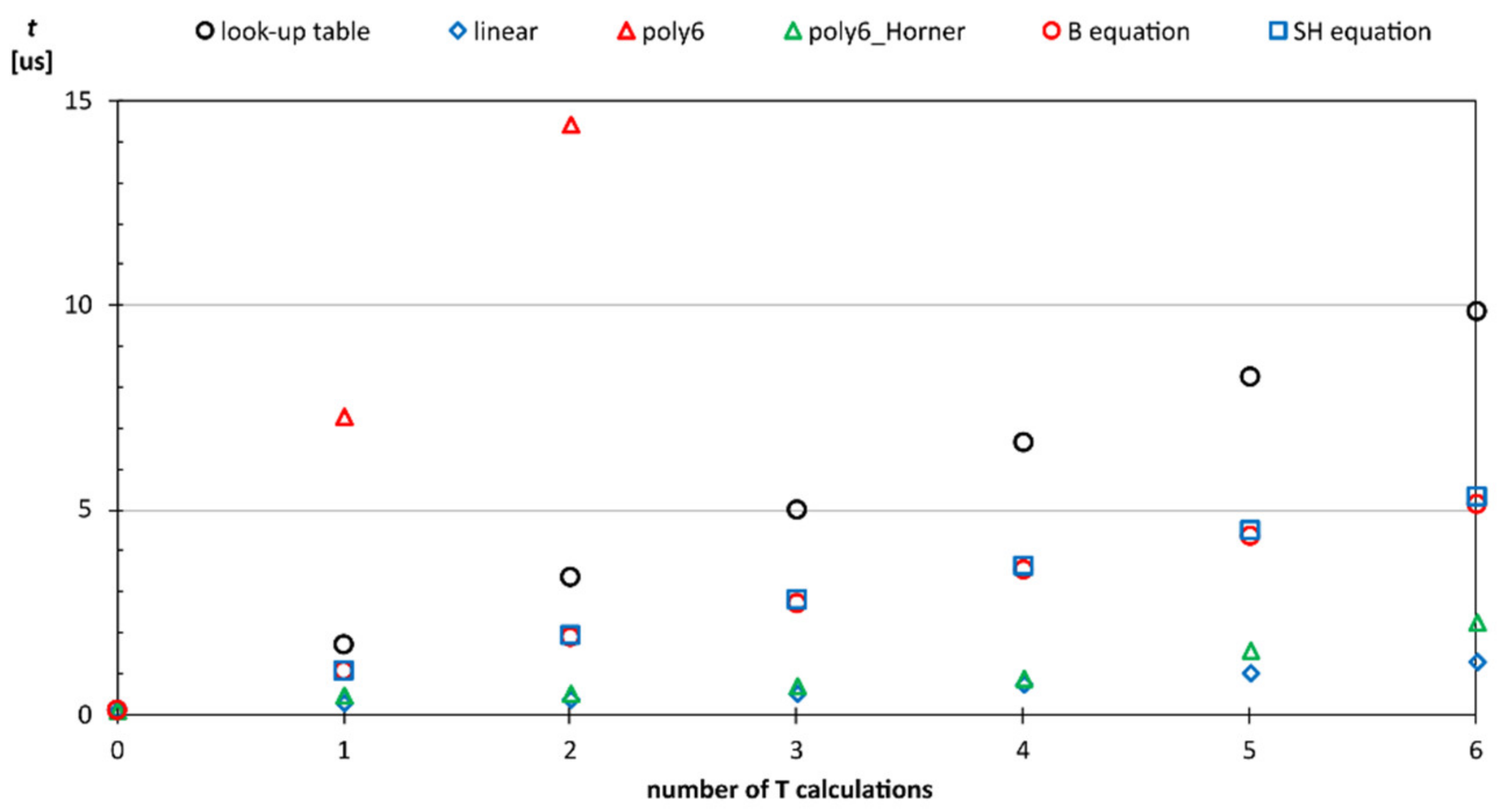

4. Experimental Results—Comparison of Methods

- Look-Up Table

- Approximation of a Tabular Data with Polynomials

- a6 = 3.7883;

- a5 = −27.1741;

- a4 = 59.5590;

- a3 = −10.7668;

- a2 = −109.7692;

- a1 = 145.9399 and

- a0 = −55.1190.

- Analytical Method Using the B Equation

- Analytical Method Using the Steinhart–Hart Equation

5. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Jaraczewski, M.; Mielnik, R.; Gębarowski, T.; Sułowicz, M. Low-Frequency Signal Sampling Method Implemented in a PLC Controller Dedicated to Applications in the Monitoring of Selected Electrical Devices. Electronics 2021, 10, 442. [Google Scholar] [CrossRef]

- Gleissner, M.; Bakran, M.M. Design and Control of Fault-Tolerant Nonisolated Multiphase Multilevel DC–DC Converters for Automotive Power Systems. IEEE Trans. Ind. Appl. 2016, 52, 1785–1795. [Google Scholar] [CrossRef]

- Siouane, S.; Jovanović, S.; Poure, P. Open-Switch Fault-Tolerant Operation of a Two-Stage Buck/Buck–Boost Converter with Redundant Synchronous Switch for PV Systems. IEEE Trans. Ind. Electron. 2019, 66, 3938–3947. [Google Scholar] [CrossRef]

- Xu, L.; Ma, R.; Xie, R.; Xu, J.; Huangfu, Y.; Gao, F. Open-Circuit Switch Fault Diagnosis and Fault-Tolerant Control for Output-Series Interleaved Boost DC-DC Converter. IEEE Trans. Transp. Electrif. 2021. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, J.; Zhang, C.; Wang, W.; Wang, H. High Temperature Dry Tribological Behavior of Nb-Microalloyed Bearing Steel 100Cr6. Materials 2021, 14, 5216. [Google Scholar] [CrossRef]

- Billard, M.W.; Basantani, H.A.; Horn, M.W.; Gluckman, B.J. A Flexible Vanadium Oxide Thermistor Array for Localized Temperature Field Measurements in Brain. IEEE Sens. J. 2016, 16, 2211–2212. [Google Scholar] [CrossRef]

- Haberl-Meglič, S.; Levičnik, E.; Luengo, E.; Raso, J.; Miklavčič, D. The effect of temperature and bacterial growth phase on protein extraction by means of electroporation. Bioelectrochemistry 2016, 112, 77–82. [Google Scholar] [CrossRef]

- Grigorov, E.; Kirov, B.; Marinov, M.B.; Galabov, V. Review of Microfluidic Methods for Cellular Lysis. Micromachines 2021, 12, 498. [Google Scholar] [CrossRef]

- Gagliano, S.; Cairone, F.; Amenta, A.; Bucolo, M. A Real Time Feed Forward Control of Slug Flow in Microchannels. Energies 2019, 12, 2556. [Google Scholar] [CrossRef] [Green Version]

- Shi, B.; Feng, S.; Shi, L.; Shi, D.; Zhang, Y.; Zhu, H. Junction Temperature Measurement Method for Power mosfets Using Turn-On Delay of Impulse Signal. IEEE Trans. Power Electron. 2018, 33, 5274–5282. [Google Scholar] [CrossRef]

- Stella, F.; Pellegrino, G.; Armando, E.; Daprà, D. Online Junction Temperature Estimation of SiC Power MOSFETs through On-State Voltage Mapping. IEEE Trans. Ind. Appl. 2018, 54, 3453–3462. [Google Scholar] [CrossRef]

- Matei, C.; Urbonas, J.; Votsi, H.; Kendig, D.; Aaen, P.H. Dynamic Temperature Measurements of a GaN DC–DC Boost Converter at MHz Frequencies. IEEE Trans. Power Electron. 2020, 35, 8303–8310. [Google Scholar] [CrossRef]

- Bajzek, T.J. Thermocouples: A sensor for measuring temperature. IEEE Instrum. Meas. Mag. 2005, 8, 35–40. [Google Scholar] [CrossRef]

- Burta, A.; Szabo, R.; Gontean, A. Temperature Measurements with Thermocouples Used in a Thermo-electric Hybrid Solar System. In Proceedings of the 2020 Fourth World Conference on Smart Trends in Systems, Security and Sustainability (WorldS4), London, UK, 27–28 July 2020; pp. 614–619. [Google Scholar] [CrossRef]

- Muchenedi, H.K.; Prabu, P.S.; Madhu Mohan, M. Fabrication of Ferroelectric Liquid Crystal Thermistor. IEEE Trans. Electron Devices 2020, 67, 5063–5068. [Google Scholar] [CrossRef]

- Texas Instruments. TMP23x Low-Power, High-Accuracy Analog Output Temperature Sensors. Available online: https://www.ti.com/lit/ds/symlink/tmp235.pdf (accessed on 19 August 2021).

- Aleksic, S.O.; Mitrovic, N.S.; Lukovic, M.D.; Veljovic-Jovanovic, S.D.; Lukovic, S.G.; Nikolic, M.V.; Aleksic, O.S. A Ground Temperature Profile Sensor Based on NTC Thick Film Segmented Thermistors: Main Properties and Applications. IEEE Sens. J. 2018, 18, 4414–4421. [Google Scholar] [CrossRef]

- Deng, X.; Cheng, Y.; Li, L.; Feng, J.; Cui, L.; Du, C.; Zhang, L.; Zhang, L.; Qin, J. Design and Application of High-Precision Temperature Measuring Instrument for Ice Cover Profile of River Based on the Resistance Residual Compensation Method. IEEE Access 2020, 8, 7899–7906. [Google Scholar] [CrossRef]

- Sun, J.; Wu, K.; Fan, M.; Meng, F.; Cai, M.; Zhao, T.; Yang, C.; Xing, H.; Ye, W. Thermistor-Based Nematic Liquid Crystal IM95100-000. IEEE Trans. Electron Devices 2021, 68, 4064–4069. [Google Scholar] [CrossRef]

- Kumar, V.N.; Narayana, K.V.L.; Bhujangarao, A.; Sankar, S. Development of an ANN-Based Linearization Technique for the VCO Thermistor Circuit. IEEE Sens. J. 2015, 15, 886–894. [Google Scholar] [CrossRef]

- Wang, C.; Hou, Z.; You, J. Temperature-to-Frequency Converter With 1.47% Error Using Thermistor Linearity Calibration. IEEE Sens. J. 2019, 19, 4804–4811. [Google Scholar] [CrossRef]

- Rana, K.P.S.; Kumar, V.; Dagar, A.K.; Chandel, A.; Kataria, A. FPGA Implementation of Steinhart–Hart Equation for Accurate Thermistor Linearization. IEEE Sens. J. 2018, 18, 2260–2267. [Google Scholar] [CrossRef]

- Bandyopadhyay, S.; Das, A.; Mukherjee, A.; Dey, D.; Bhattacharyya, B.; Munshi, S. A Linearization Scheme for Thermistor-Based Sensing in Biomedical Studies. IEEE Sens. J. 2016, 16, 603–609. [Google Scholar] [CrossRef]

- Sarkar, A.R.; Dey, D.; Munshi, S. Linearization of NTC Thermistor Characteristic Using Op-Amp Based Inverting Amplifier. IEEE Sens. J. 2013, 13, 4621–4626. [Google Scholar] [CrossRef]

- Nenova, Z.P.; Nenov, T.G. Linearization Circuit of the Thermistor Connection. IEEE Trans. Instrum. Meas. 2009, 58, 441–449. [Google Scholar] [CrossRef]

- Chatterjee, N.; Bhattacharyya, B.; Dey, D.; Munshi, S. A Combination of Astable Multivibrator and Microcontroller for Thermistor-Based Temperature Measurement over Internet. IEEE Sens. J. 2019, 19, 3252–3259. [Google Scholar] [CrossRef]

- Venkata, K.; Narayana, L.; Kumar, V.N. Development of an Intelligent Temperature Transducer. IEEE Sens. J. 2016, 16, 4696–4703. [Google Scholar] [CrossRef]

- TDK. NTC Thermistors for Temperature Measurement. Available online: https://product.tdk.com/system/files/dam/doc/product/sensor/ntc/chip-ntc-thermistor/data_sheet/50/db/ntc/ntc_smd_automotive_series_0603.pdf (accessed on 19 August 2021).

- Steinhart, J.S.; Hart, S.R. Calibration curves for thermistors. Deep Sea Res. Oceanogr. Abstr. 1968, 15, 497–503. [Google Scholar] [CrossRef]

- Stanford Research Systems. Calibrate Steinhart-Hart Coefficients for Thermistors. Application Note. Available online: https://www.thinksrs.com/downloads/PDFs/ApplicationNotes/LDC%20Note%204%20NTC%20Calculator.pdf (accessed on 19 August 2021).

- Stanford Research Systems. Thermistor Calculator. Available online: https://www.thinksrs.com/downloads/programs/therm%20calc/ntccalibrator/ntccalculator.html (accessed on 19 August 2021).

- Liu, Y.; Liu, Y.; Zhang, W.; Zhang, J. The Study of Temperature Calibration Method for NTC Thermistor. In Proceedings of the 4th International Conference on Frontiers of Sensors Technologies (ICFST), Shanghai, China, 6–9 November 2020; pp. 50–53. [Google Scholar] [CrossRef]

- Vaegae, N.K.; Narayana, K.V.L. Development of thermistor signal conditioning circuit using artificial neural networks. IET Sci. Meas. Technol. 2015, 9, 955–961. [Google Scholar] [CrossRef]

- Mahaseth, D.N.; Kumar, L.; Islam, T. An efficient signal conditioning circuit to piecewise linearizing the response characteristic of highly nonlinear sensors. Sens. Actuators A: Phys. 2018, 280, 559–572. [Google Scholar] [CrossRef]

- Jovanović, J.; Denić, D. NTC Thermistor Nonlinearity Compensation Using Wheatstone Bridge and Novel Dual-Stage Single-Flash Piecewise-Linear ADC. Metrol. Meas. Syst. 2021, 28, 523–537. [Google Scholar] [CrossRef]

- TDK. NTC B57351V5103H060 RT Sheet. Available online: https://product.tdk.com/system/files/dam/doc/product/sensor/ntc/chip-ntc-thermistor/rt_sheets/b57351v5103h060.csv (accessed on 19 August 2021).

- Petkovsek, M.; Zajec, P. Evaluating Common-Mode Voltage Based Trade-Offs in Differential-Ended and Single-Supplied Signal Conditioning Amplifiers. Electronics 2021, 10, 1982. [Google Scholar] [CrossRef]

- Texas Instruments. TMS320F280049 Microcontroller. Available online: https://www.ti.com/product/TMS320F280049 (accessed on 19 August 2021).

- Chen, C. Evaluation of resistance–temperature calibration equations for NTC thermistors. Measurement 2009, 42, 1103–1111. [Google Scholar] [CrossRef]

| Look-Up Table with Interpolation | Polynomial Approximation | B Equation | Steinhart–Hart Equation | ||

|---|---|---|---|---|---|

| Parameter Observed | 1st Order | 6th Order | |||

| required prework | −/o | o | −/o | o/+ | o/+ |

| accuracy (limited range) | + | + | + | + | + |

| accuracy (nominal range) | + | − | −/o | o | + |

| MCU load | − | + | + | o | o |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petkovšek, M.; Nemec, M.; Zajec, P. Algorithm Execution Time and Accuracy of NTC Thermistor-Based Temperature Measurements in Time-Critical Applications. Mathematics 2021, 9, 2266. https://doi.org/10.3390/math9182266

Petkovšek M, Nemec M, Zajec P. Algorithm Execution Time and Accuracy of NTC Thermistor-Based Temperature Measurements in Time-Critical Applications. Mathematics. 2021; 9(18):2266. https://doi.org/10.3390/math9182266

Chicago/Turabian StylePetkovšek, Marko, Mitja Nemec, and Peter Zajec. 2021. "Algorithm Execution Time and Accuracy of NTC Thermistor-Based Temperature Measurements in Time-Critical Applications" Mathematics 9, no. 18: 2266. https://doi.org/10.3390/math9182266

APA StylePetkovšek, M., Nemec, M., & Zajec, P. (2021). Algorithm Execution Time and Accuracy of NTC Thermistor-Based Temperature Measurements in Time-Critical Applications. Mathematics, 9(18), 2266. https://doi.org/10.3390/math9182266