Porous Three-Dimensional Scaffold Generation for 3D Printing

Abstract

1. Introduction

2. Mathematical Model and Numerical Method

3. Numerical Experiments

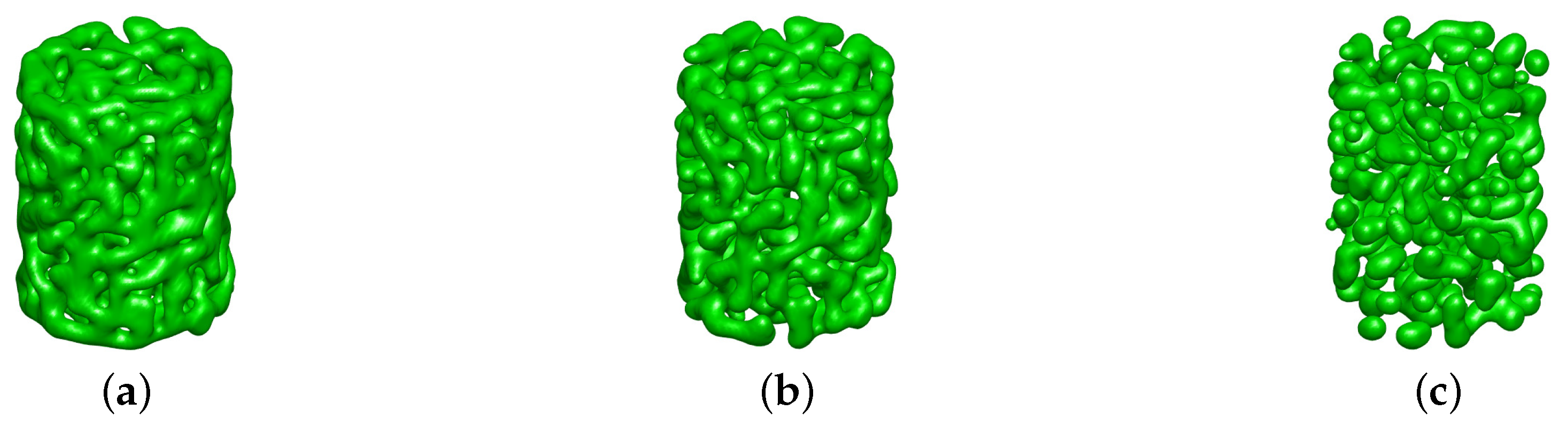

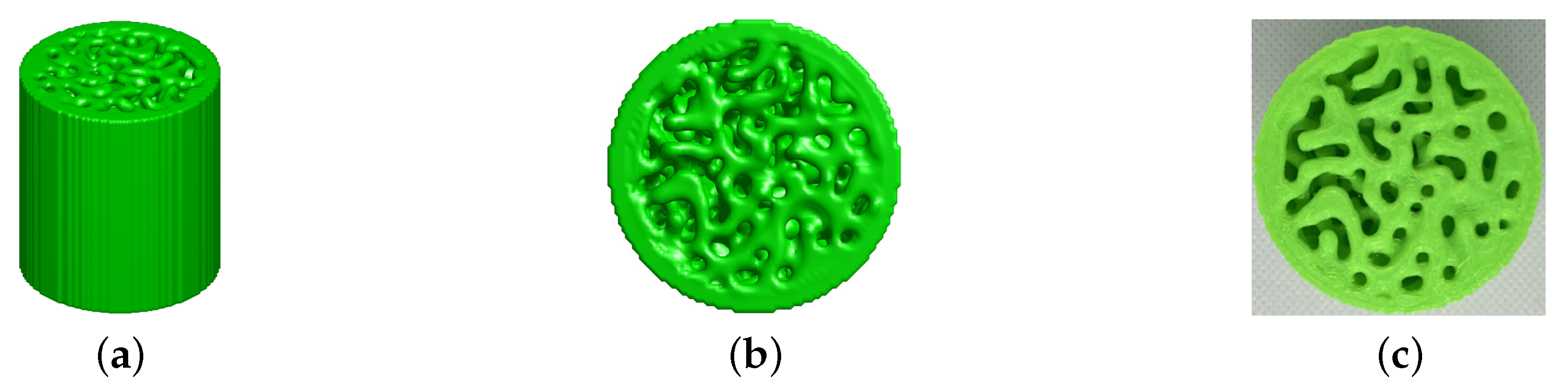

3.1. Simple Structures

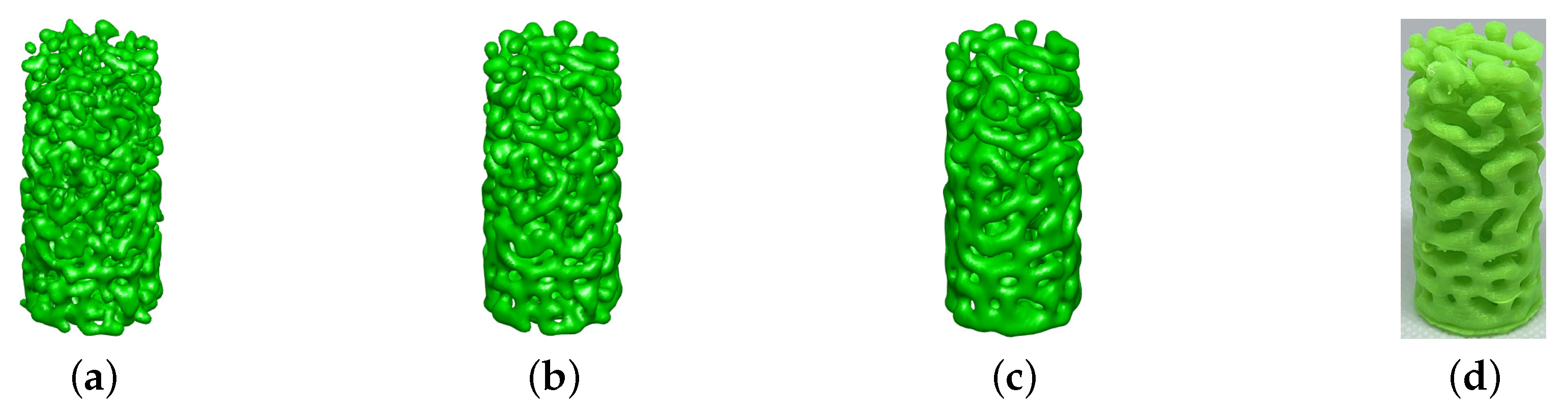

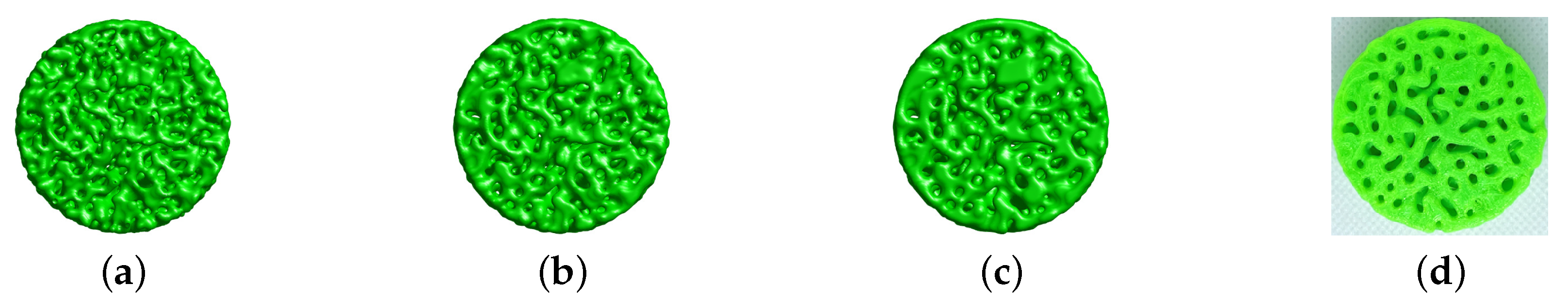

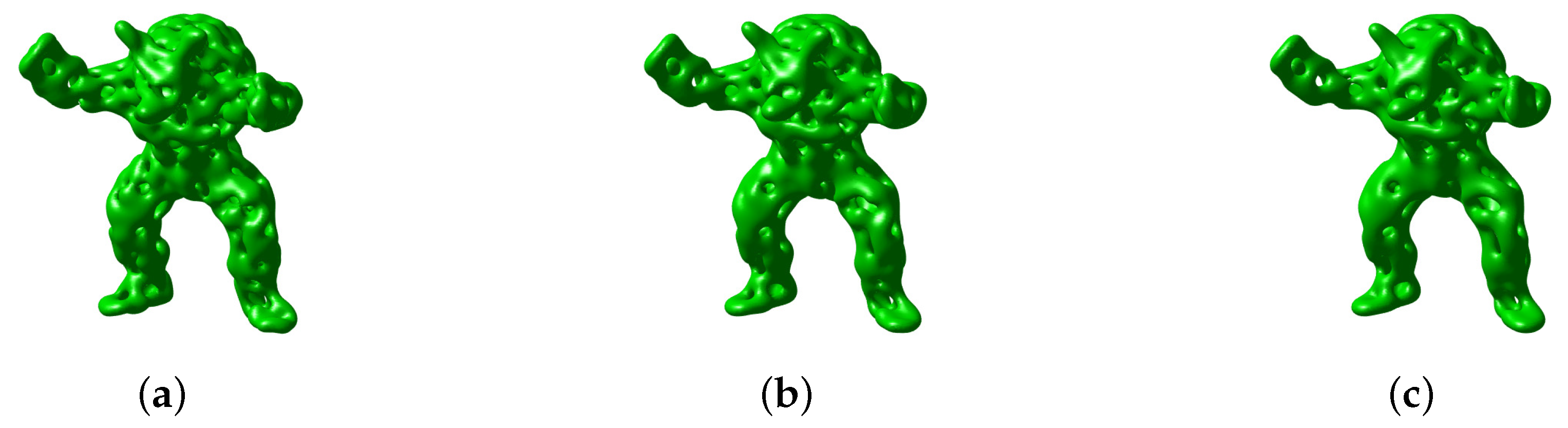

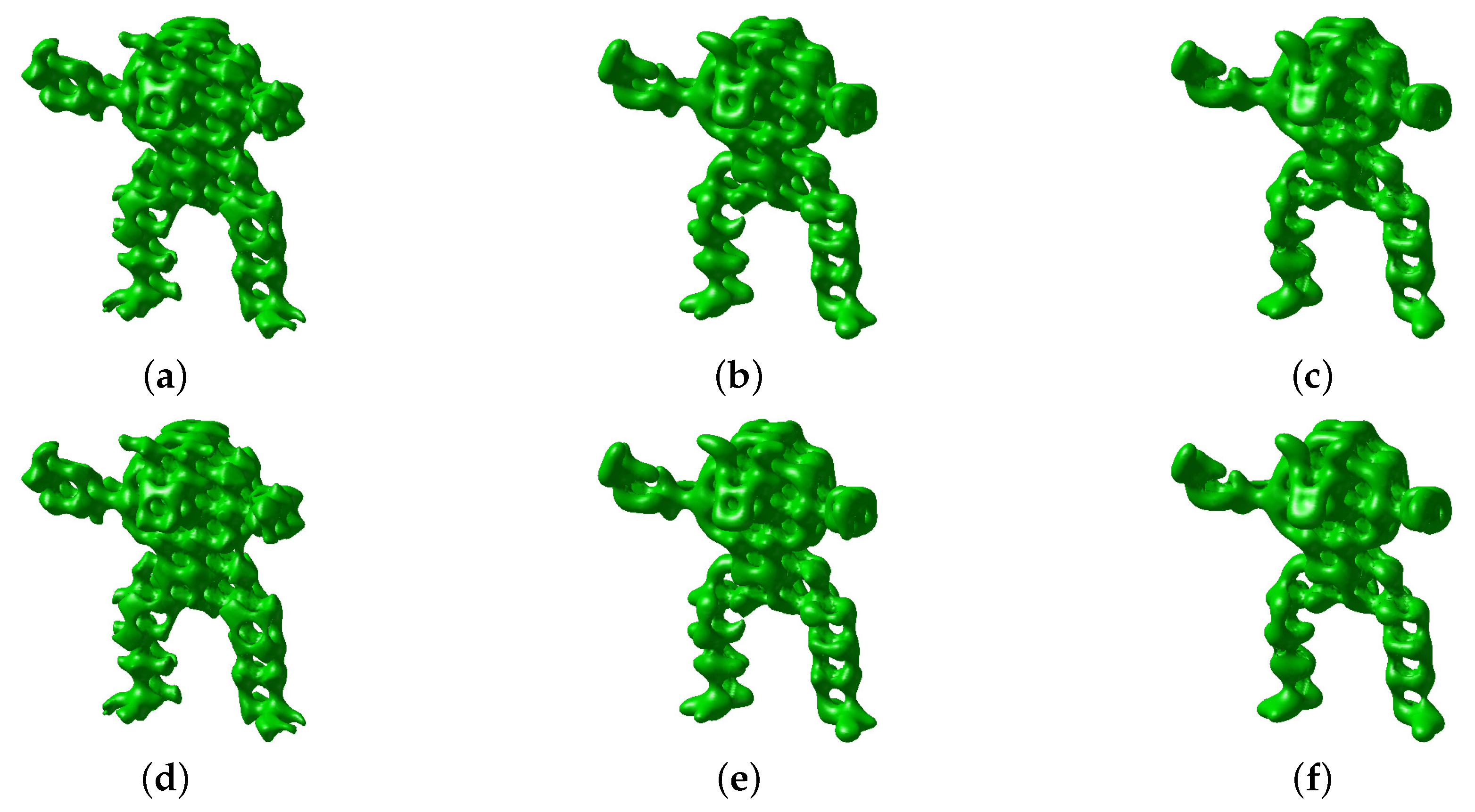

3.2. Complex Structures

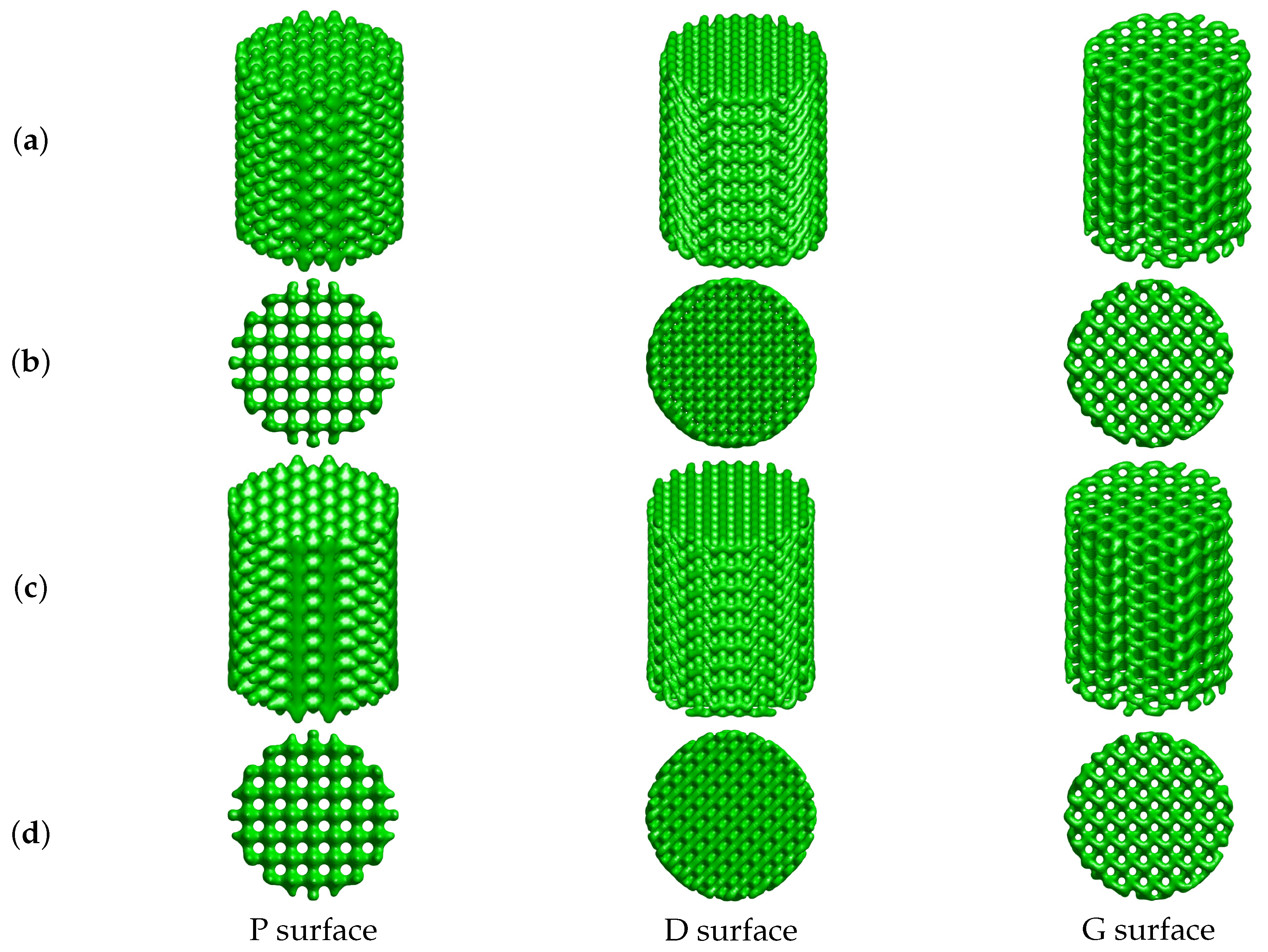

3.3. Porous Structure Generation Using TPMS

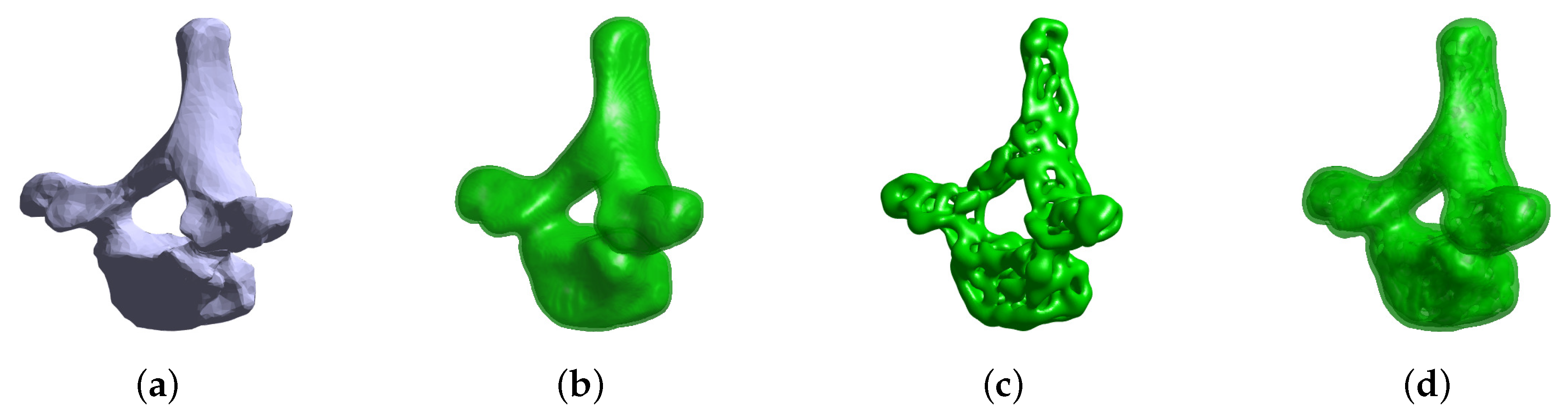

3.4. TPMS Scaffolds Inside Complex Surfaces

4. Conclusions

- •

- The proposed method can generate porous structures from a solid volume using a distance function.

- •

- The porous structure generating algorithm is simple and easy to implement.

- •

- The proposed algorithm can control pore shapes by the space-dependent average concentration function.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Neto, A.; Ferreira, J. Synthetic and marine-derived porous scaffolds for bone tissue engineering. Materials 2018, 11, 1702. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.; Kim, M.; Goh, T.; Lee, J.; Kim, Y.; Yoon, S.; Lee, C. Evaluation of Structural and Mechanical Properties of Porous Artificial Bone Scaffolds Fabricated via Advanced TBA-Based Freeze-Gel Casting Technique. Appl. Sci. 2019, 9, 1965. [Google Scholar] [CrossRef]

- Scheffler, M.; Colombo, P. Cellular Ceramics: Structure, Manufacturing, Properties and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Gajendiran, M.; Choi, J.; Kim, S.J.; Kim, K.; Shin, H.; Koo, H.J.; Kim, K. Conductive biomaterials for tissue engineering applications. J. Ind. Eng. Chem. 2017, 51, 12–26. [Google Scholar] [CrossRef]

- Tang, W.; Lin, D.; Yu, Y.; Niu, H.; Guo, H.; Yuan, Y.; Liu, C. Bioinspired trimodal macro/micro/nano-porous scaffolds loading rhBMP-2 for complete regeneration of critical size bone defect. Acta Biomater. 2016, 32, 309–323. [Google Scholar] [CrossRef] [PubMed]

- Cipitria, A.; Lange, C.; Schell, H.; Wagermaier, W.; Reichert, J.C.; Hutmacher, D.W.; Fratzl, P.; Duda, G.N. Porous scaffold architecture guides tissue formation. J. Bone Miner. Res. 2012, 27, 1275–1288. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Toman, J.; Yu, Y.; Biyikli, E.; Kirca, M.; Chmielus, M.; To, A.C. Efficient design-optimization of variable-density hexagonal cellular structure by additive manufacturing: Theory and validation. J. Manuf. Sci. Eng. 2015, 137, 021004. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Badwal, P.S.; Gibson, I. Design and fabrication considerations for three dimensional scaffold structures. In Proceedings of the International Conference on Design and Technologyy, KEG, Geelong, Australia, 5–8 December 2016; pp. 120–126. [Google Scholar]

- Kou, X.; Tan, S. A simple and effective geometric representation for irregular porous structure modeling. Comput. Aided Des. 2010, 42, 930–941. [Google Scholar] [CrossRef]

- Hollister, S.J. Porous scaffold design for tissue engineering. Nat. Mater. 2005, 4, 518. [Google Scholar] [CrossRef]

- Castro, A.; Pires, T.; Santos, J.; Gouveia, B.; Fernandes, P. Permeability versus Design in TPMS Scaffolds. Materials 2019, 12, 1313. [Google Scholar] [CrossRef]

- Hu, J.; Wang, S.; Wang, Y.; Li, F.; Luo, Z. A lightweight methodology of 3D printed objects utilizing multi-scale porous structures. Vis. Comput. 2019, 35, 949–959. [Google Scholar] [CrossRef]

- Song, Y.; Yang, Z.; Liu, Y.; Deng, J. Function representation based slicer for 3d printing. Comput. Aided Geom. Des. 2018, 62, 276–293. [Google Scholar] [CrossRef]

- Mao, Y.; Wu, L.; Yan, D.M.; Guo, J.; Chen, C.W.; Chen, B. Generating hybrid interior structure for 3D printing. Comput. Aided Geom. Des. 2018, 62, 63–72. [Google Scholar] [CrossRef]

- Wang, X.; Ying, X.; Liu, Y.J.; Xin, S.Q.; Wang, W.; Gu, X.; Mueller-Wittig, W.; He, Y. Intrinsic computation of centroidal Voronoi tessellation (CVT) on meshes. Comput. Aided Des. 2015, 58, 51–61. [Google Scholar] [CrossRef]

- Corsini, M.; Cignoni, P.; Scopigno, R. Efficient and flexible sampling with blue noise properties of triangular meshes. IEEE Trans. Vis. Comput. Graph. 2012, 18, 914–924. [Google Scholar] [CrossRef] [PubMed]

- Schumacher, C.; Thomaszewski, B.; Gross, M. Stenciling: Designing Structurally-Sound Surfaces with Decorative Patterns. Comput. Graph. Forum. 2016, 35, 101–110. [Google Scholar] [CrossRef]

- Turk, G. Generating textures on arbitrary surfaces using reaction-diffusion. In ACM SIGGRAPH Computer Graphics; ACM: New York, NY, USA, 1991; Volume 25, pp. 289–298. [Google Scholar]

- Jeong, D.; Kim, J. Microphase separation patterns in diblock copolymers on curved surfaces using a nonlocal Cahn–Hilliard equation. Eur. Phys. J. E 2015, 38, 117. [Google Scholar] [CrossRef]

- Bertozzi, A.L.; Esedoglu, S.; Gillette, A. Inpainting of binary images using the Cahn–Hilliard equation. IEEE Trans. Image Process. 2006, 16, 285–291. [Google Scholar] [CrossRef]

- Chalupeckỳ, V. Numerical studies of Cahn–Hilliard equation and applications in image processing. In Proceedings of the Czech–Japanese Seminar in Applied Mathematics, Praha, Czech Republic, 4–7 August 2004; pp. 10–22. [Google Scholar]

- Boyer, F.; Lapuerta, C.; Minjeaud, S.; Piar, B.; Quintard, M. Cahn–Hilliard/Navier–Stokes model for the simulation of three-phase flows. Transp. Porous Media 2010, 82, 463–483. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Lu, B.; Jeong, D.; Kim, J. Multicomponent volume reconstruction from slice data using a modified multicomponent Cahn–Hilliard system. Pattern Recognit. 2019, 93, 124–133. [Google Scholar] [CrossRef]

- Eyre, D.J. An unconditionally stable one-step scheme for gradient systems. 1998, 1–15, Unpublished article. [Google Scholar]

- Shen, J.; Tang, T.; Wang, L.L. Spectral Methods: Algorithms, Analysis and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011; Volume 41. [Google Scholar]

- Kim, J. Phase-field models for multi-component fluid flows. Commun. Comput. Phys. 2012, 12, 613–661. [Google Scholar] [CrossRef]

- Shin, J.; Jeong, D.; Kim, J. A conservative numerical method for the Cahn–Hilliard equation in complex domains. J. Comput. Phys. 2011, 230, 7441–7455. [Google Scholar] [CrossRef]

- Yoo, D.J. Computer-aided porous scaffold design for tissue engineering using triply periodic minimal surfaces. Int. J. Precis. Eng. Manuf. 2011, 12, 61–71. [Google Scholar] [CrossRef]

- Lee, H.G.; Park, J.; Yoon, S.; Lee, C.; Kim, J. Mathematical Model and Numerical Simulation for Tissue Growth on Bioscaffolds. Appl. Sci. 2019, 9, 4058. [Google Scholar] [CrossRef]

- Gong, T.; Xie, J.; Liao, J.; Zhang, T.; Lin, S.; Lin, Y. Nanomaterials and bone regeneration. Bone Res. 2015, 3, 15029. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.; Jeong, D.; Yoon, S.; Kim, J. Porous Three-Dimensional Scaffold Generation for 3D Printing. Mathematics 2020, 8, 946. https://doi.org/10.3390/math8060946

Lee C, Jeong D, Yoon S, Kim J. Porous Three-Dimensional Scaffold Generation for 3D Printing. Mathematics. 2020; 8(6):946. https://doi.org/10.3390/math8060946

Chicago/Turabian StyleLee, Chaeyoung, Darae Jeong, Sungha Yoon, and Junseok Kim. 2020. "Porous Three-Dimensional Scaffold Generation for 3D Printing" Mathematics 8, no. 6: 946. https://doi.org/10.3390/math8060946

APA StyleLee, C., Jeong, D., Yoon, S., & Kim, J. (2020). Porous Three-Dimensional Scaffold Generation for 3D Printing. Mathematics, 8(6), 946. https://doi.org/10.3390/math8060946