Prediction of Eddy Current Losses in Cooling Tubes of Direct Cooled Windings in Electric Machines

Abstract

:1. Introduction

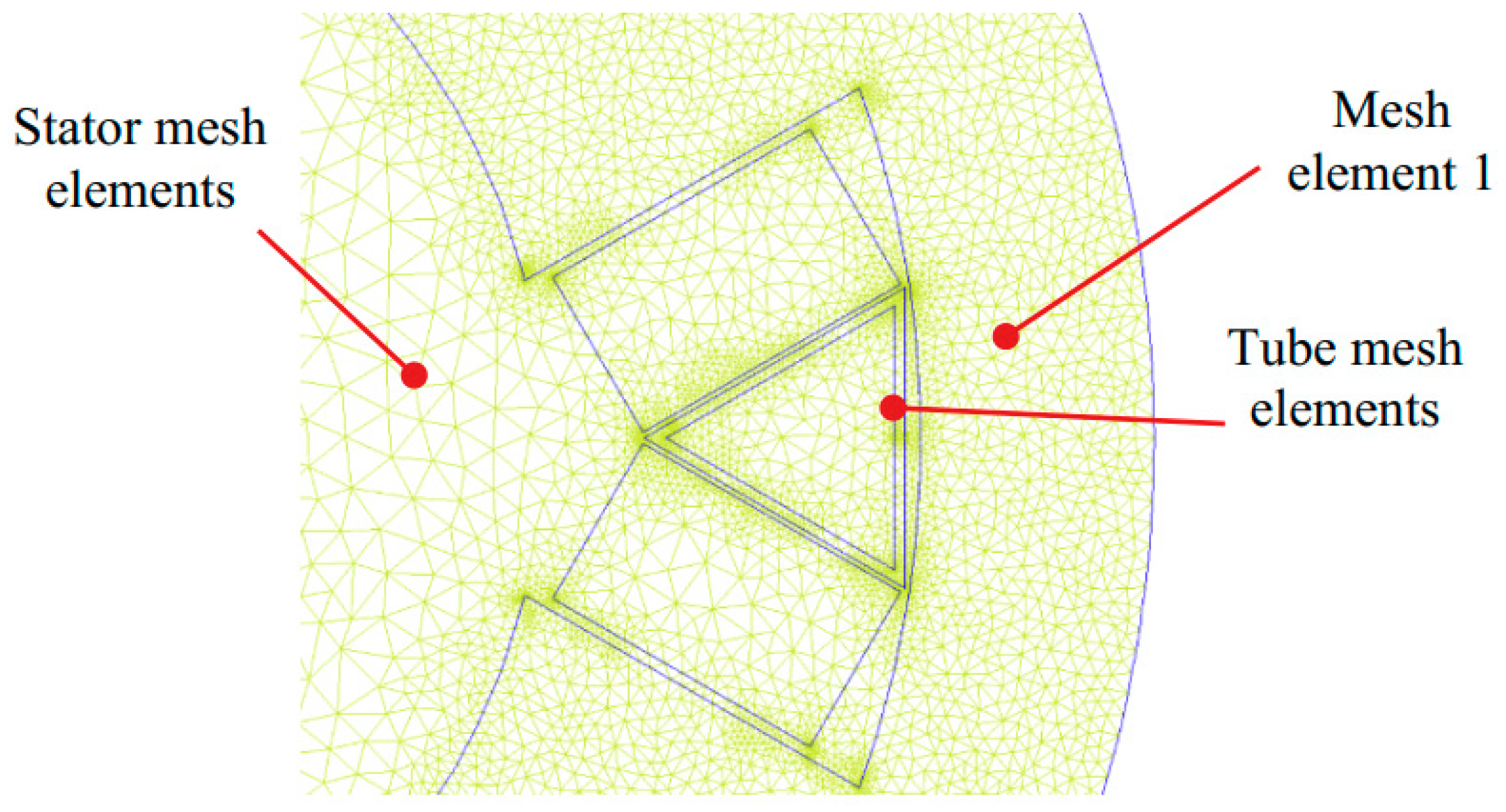

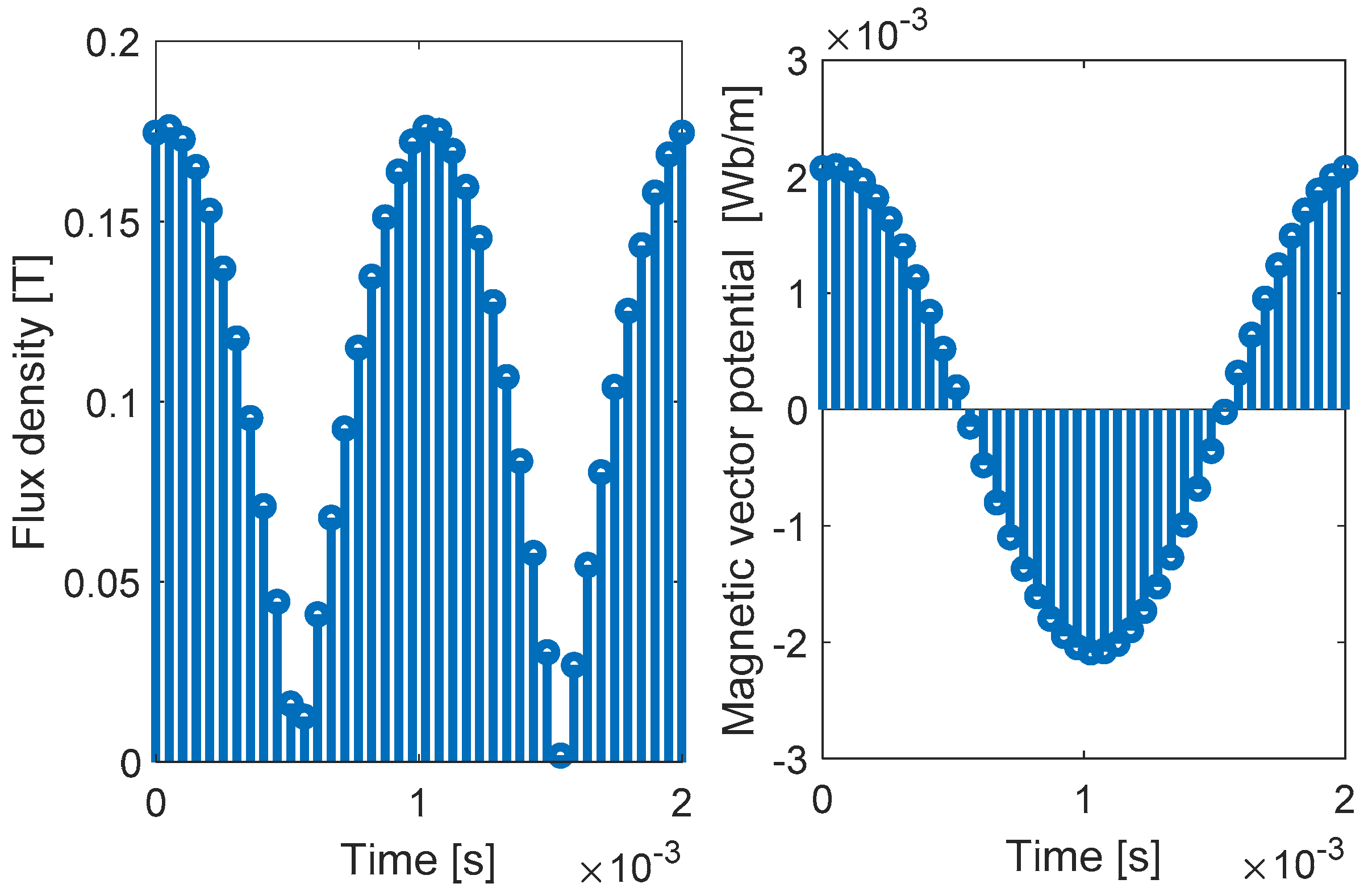

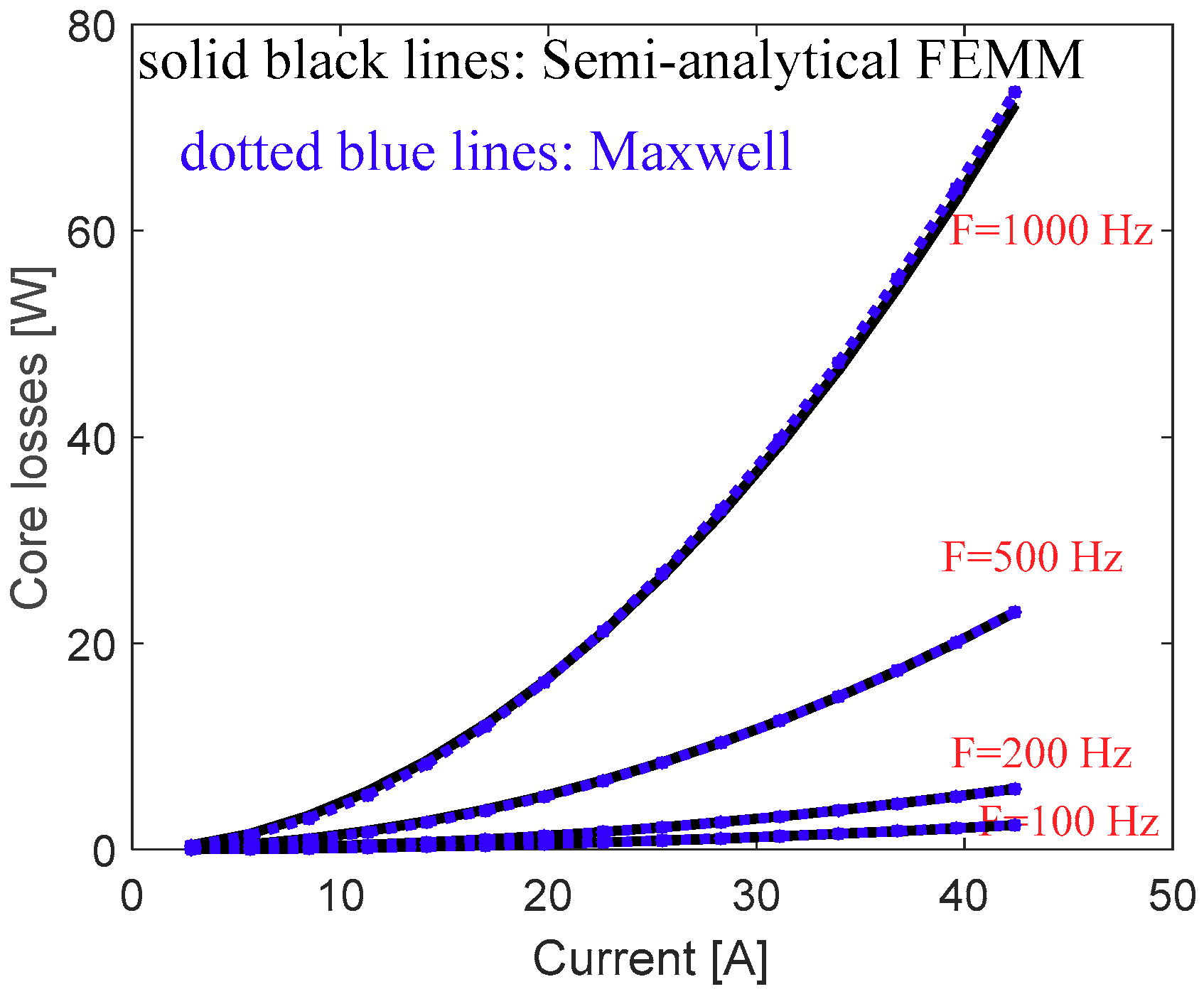

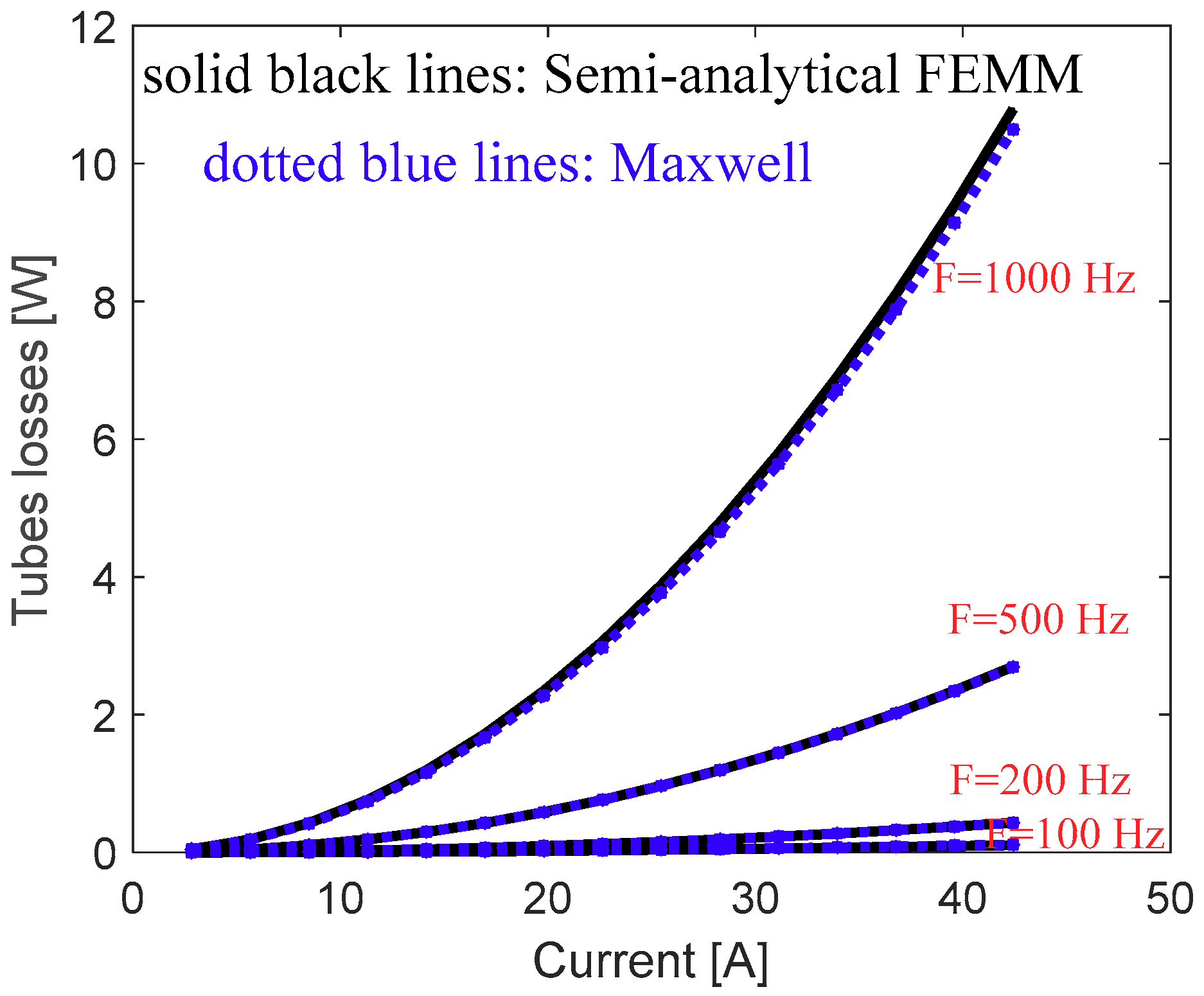

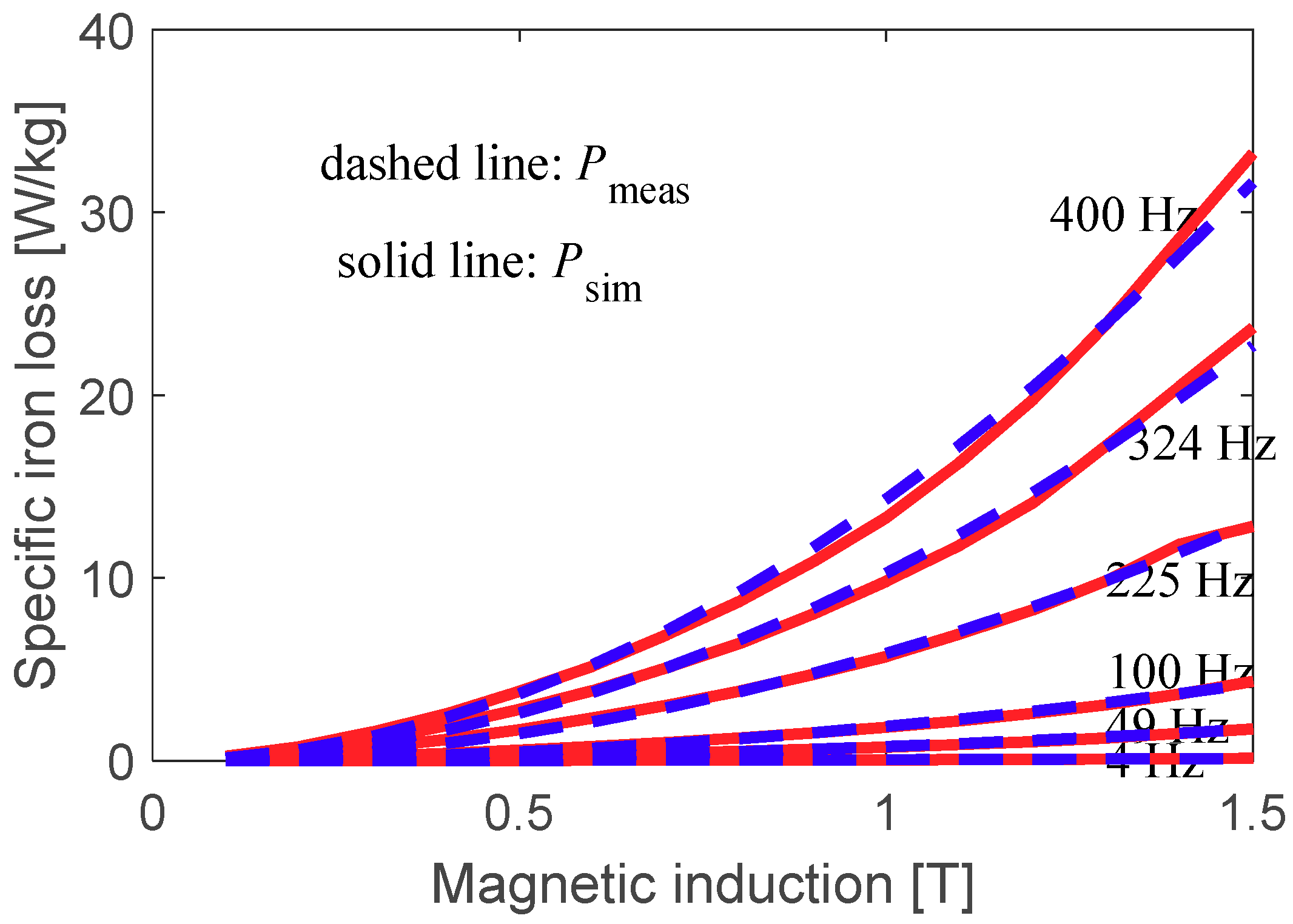

2. Semi-Analytical Based Finite Element Loss Model

3. Case Studies

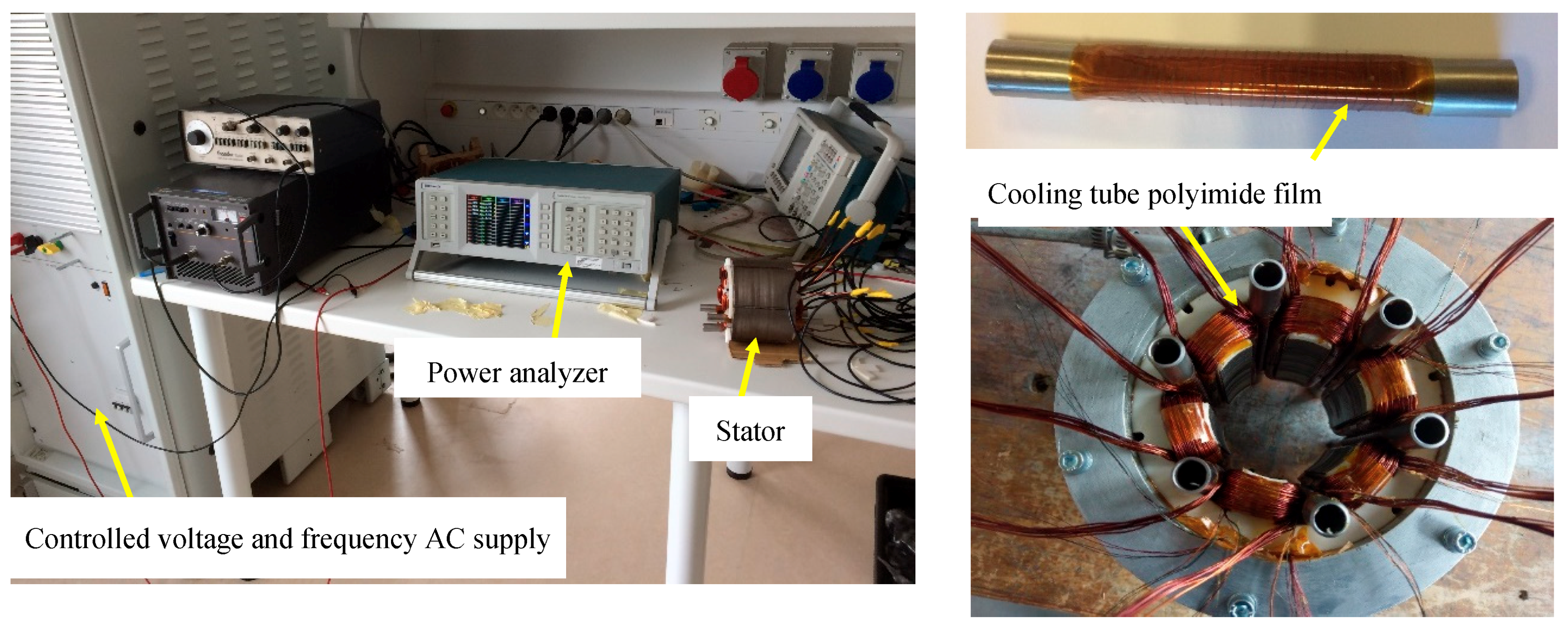

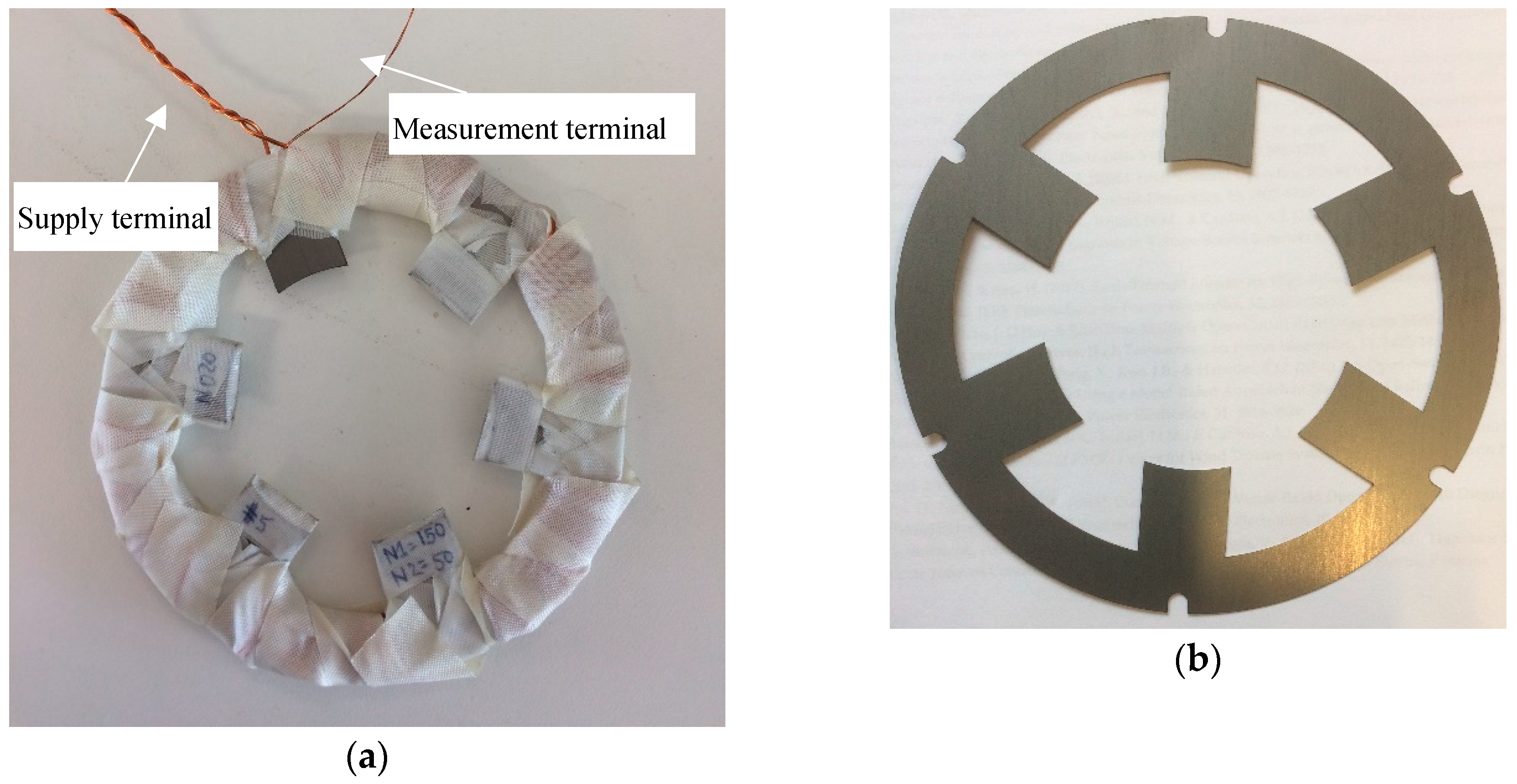

3.1. Stator Setup

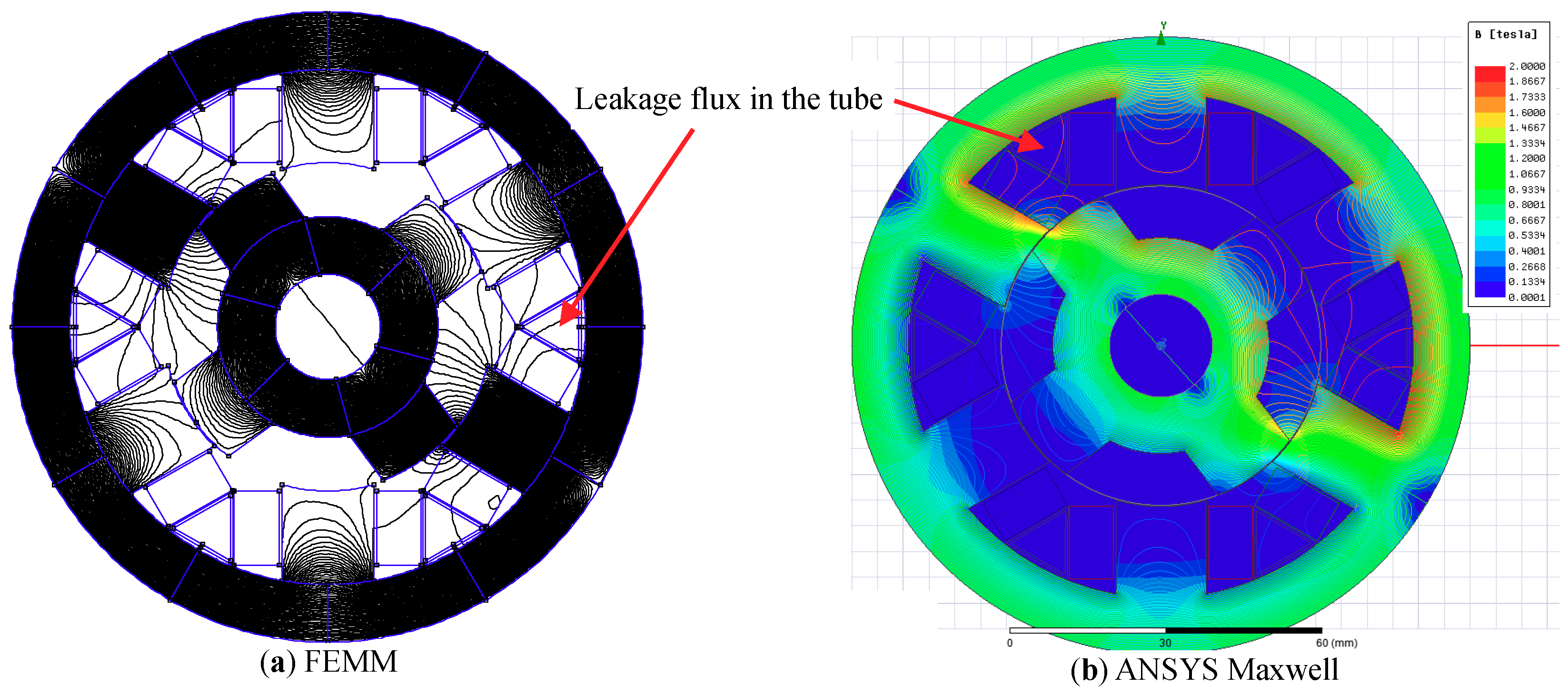

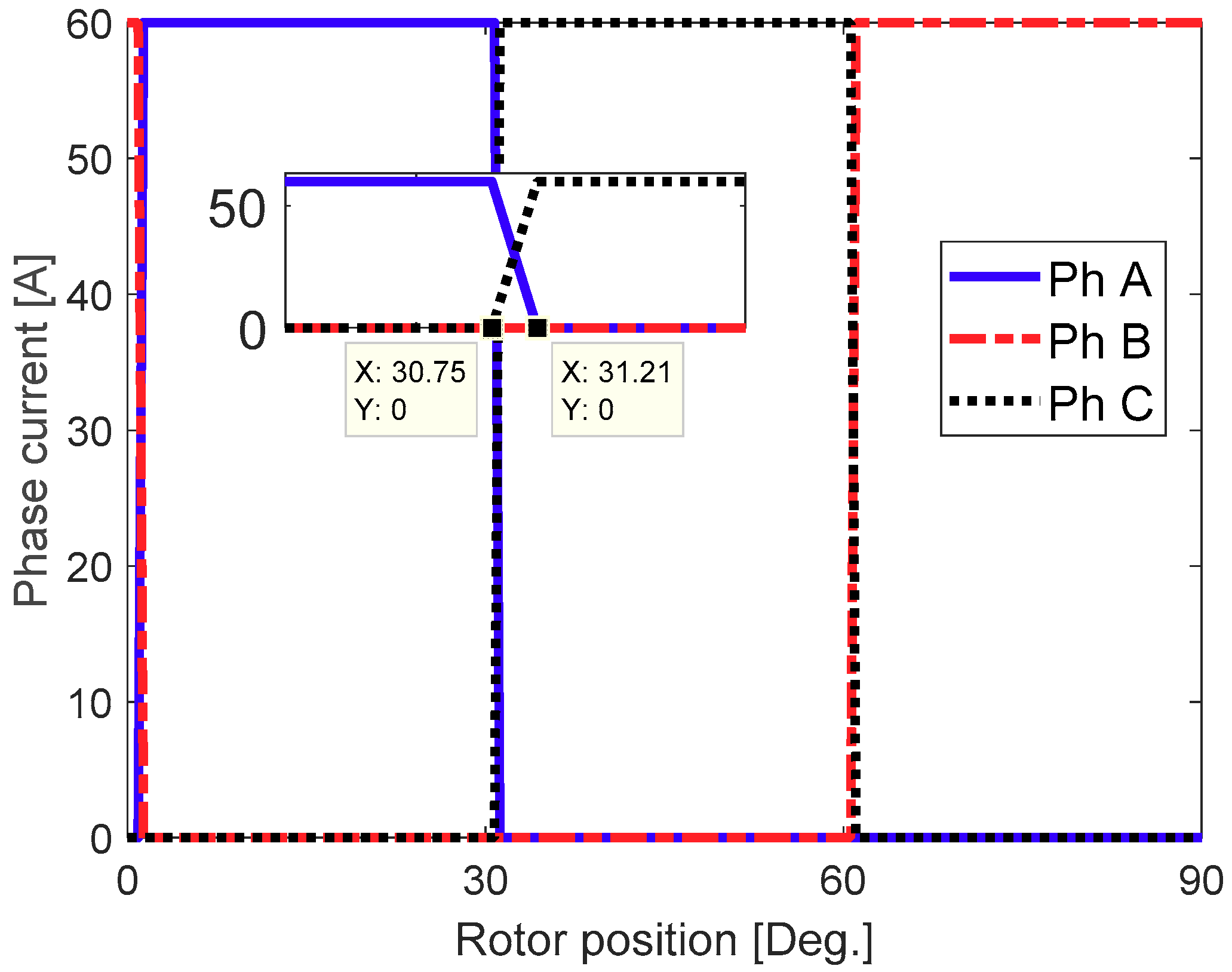

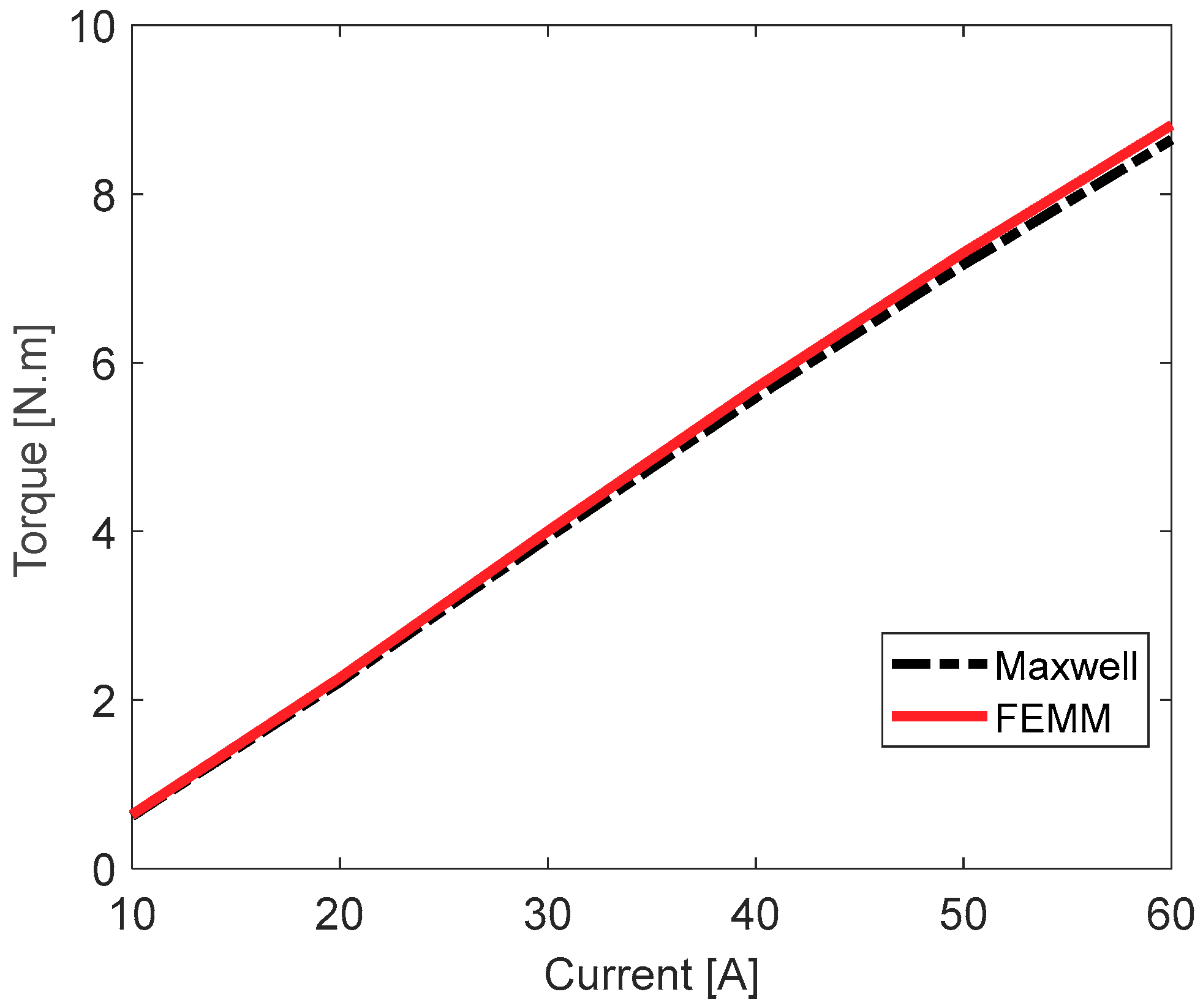

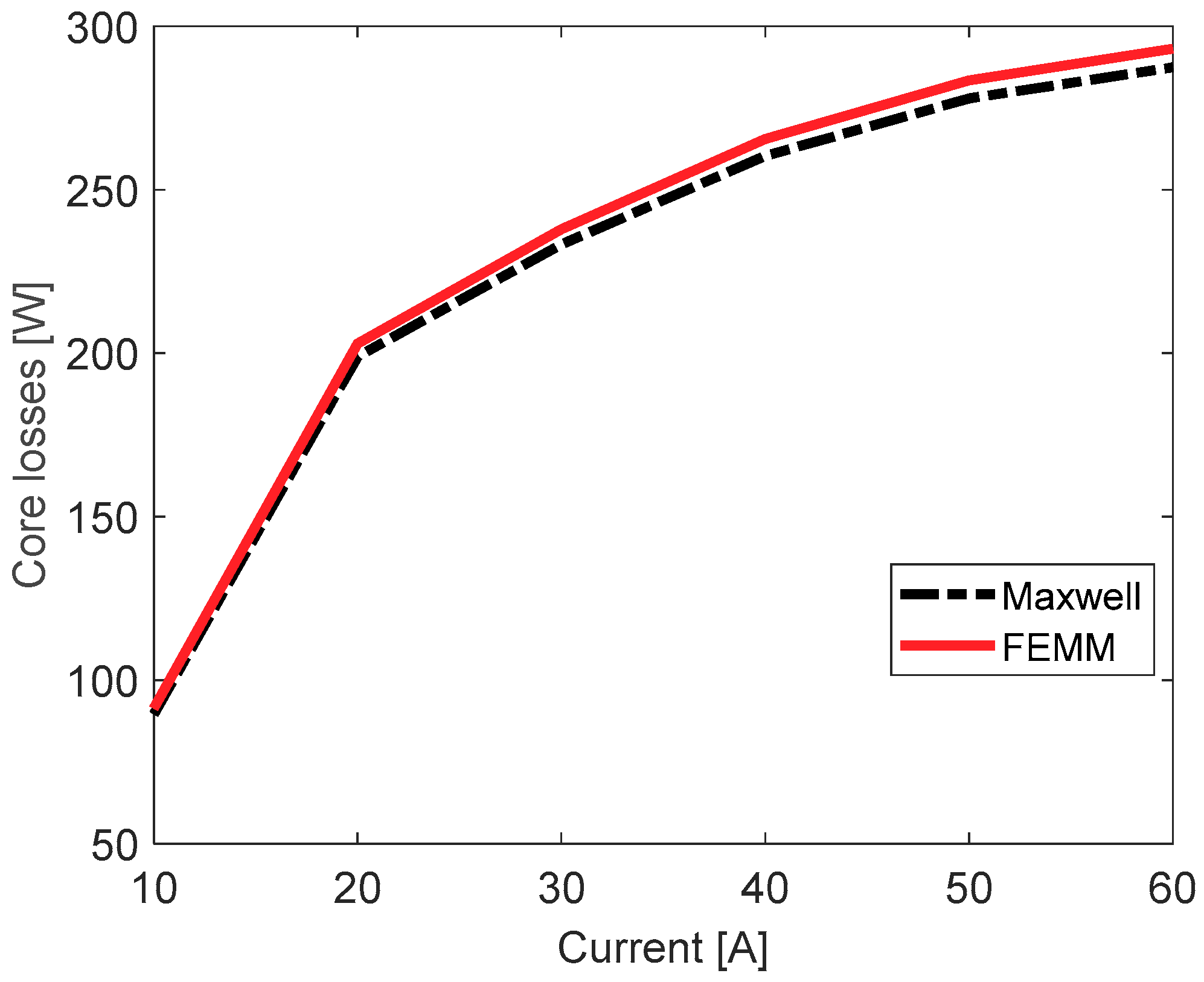

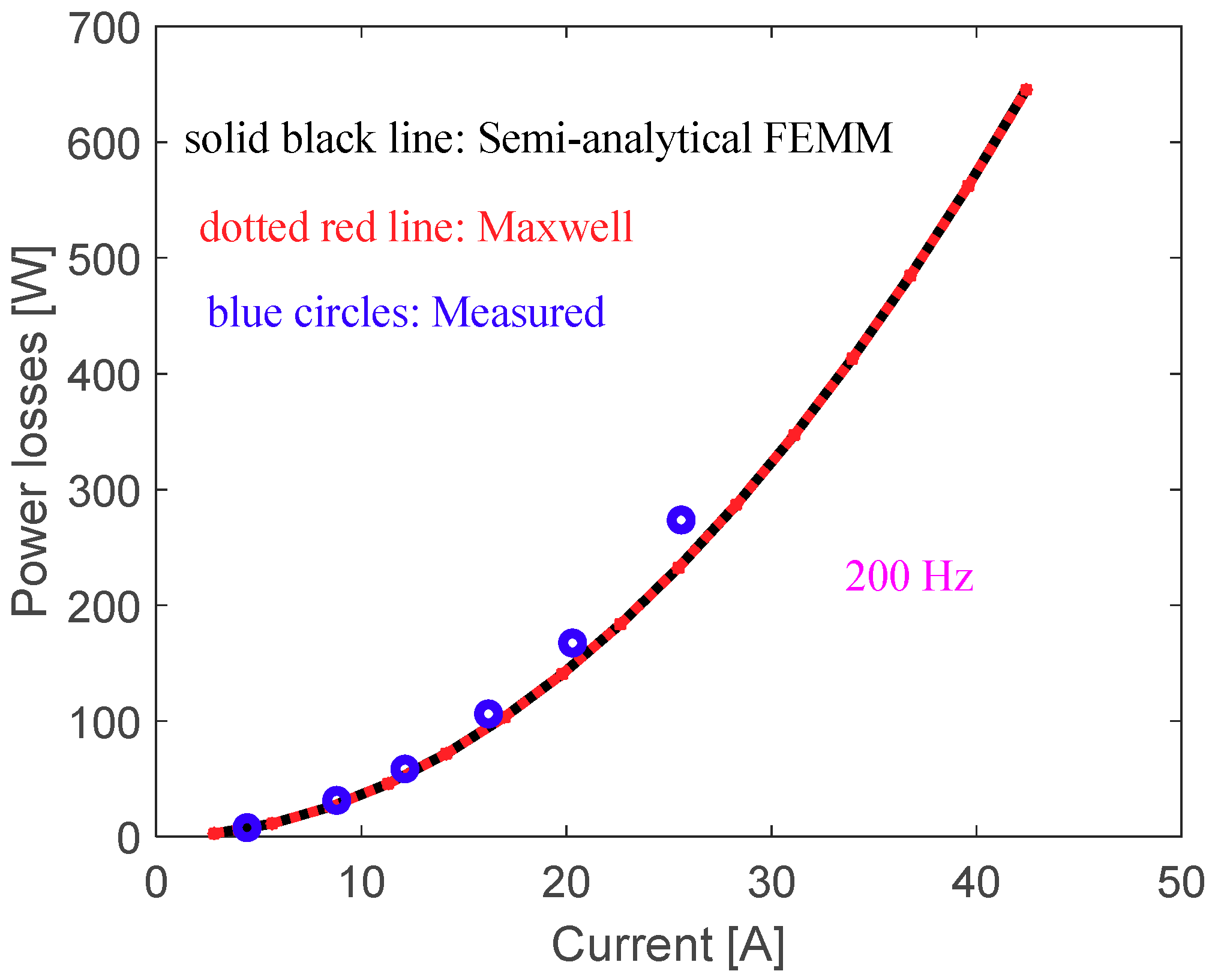

3.2. Switched Reluctance Motor

4. Experimental Validation

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jung, H.; Park, G.; Kim, D.; Jung, S. Optimal design and validation of IPMSM for maximum efficiency distribution compatible to energy consumption areas of HD-EV. IEEE Trans. Magn. 2017, 53, 8201904. [Google Scholar] [CrossRef]

- Fatemi, A.; Ionel, D.M.; Popescu, M.; Chong, Y.C.; Demerdash, N.A.O. Design optimization of a high torque density spoke-type PM motor for a formula E race drive cycle. IEEE Trans. Ind. Appl. 2018, 54, 4343–4354. [Google Scholar] [CrossRef]

- Rodriguez, M.; Sanchez, J.; Perez, A.; Martinez, D. Complete ensemble empirical mode decomposition on FPGA for condition monitoring of broken bars in induction motors. Math. J. 2019, 7, 783. [Google Scholar] [CrossRef]

- Ibrahim, M.N.; Sergeant, P.; Rashad, E.M. Synchronous reluctance motor performance based on different electrical steel grades. IEEE Trans. Magn. 2015, 51, 7403304. [Google Scholar] [CrossRef]

- Ibrahim, M.N.F.; Abdel-Khalik, A.S.; Rashad, E.M.; Sergeant, P. An improved torque density synchronous reluctance machine with a combined star–delta winding layout. IEEE Trans. Energy Convers. 2018, 33, 1015–1024. [Google Scholar] [CrossRef]

- Lindh, P.; Petrov, I.; Immonen, P.; Pyrhönen, J.; Niemelä, M.; Anttila, J.; Paakkinen, M.; Scherman, E. Performance of a direct-liquid-cooled motor in an electric bus under different load cycles. IEEE Access 2019, 7, 86897–86905. [Google Scholar] [CrossRef]

- Huang, J.; Naini, S.S.; Miller, R.; Rizzo, D.; Sebeck, K.; Shurin, S.; Wagner, J. A hybrid electric vehicle motor cooling system—Design, model, and control. IEEE Trans. Veh. Tech. 2019, 68, 4467–4478. [Google Scholar] [CrossRef]

- Dessouky, Y.G.; Williams, B.W.; Fletcher, J.E. Cooling enhancement of electric motors. IEE Proc. Electric Power Appl. 1998, 145, 57–60. [Google Scholar] [CrossRef]

- Ghorbanian, V.; Hussain, S.; Hamidizadeh, S.; Chromik, R.; Lowther, D. The role of temperature-dependent material properties in optimizing the design of permanent magnet motors. IEEE Trans. Magn. 2018, 54, 8101104. [Google Scholar] [CrossRef]

- Lim, S.; Min, S.; Hong, J. Optimal rotor design of IPM motor for improving torque performance considering thermal demagnetization of magnet. IEEE Trans. Magn. 2015, 51, 8202405. [Google Scholar] [CrossRef]

- Prakht, V.; Dmitrievskii, V.; Kazakbaev, V.; Oshurbekov, S.; Ibrahim, M.N. Optimal design of a novel three-phase high-speed flux reversal machine. Appl. Sci. 2019, 9, 3822. [Google Scholar] [CrossRef]

- Gai, Y.; Kimiabeigi, M.; Chong, Y.C.; Widmer, J.; Deng, X.; Popescu, M.; Gross, J.; Staton, D.A.; Steven, A. Cooling of automotive traction motors: schemes, examples, and computation methods. IEEE Trans. Ind. Electron. 2019, 66, 1681–1692. [Google Scholar] [CrossRef]

- Dong, J.; Huang, Y.; Jin, L.; Guo, B.; Lin, H.; Dong, J.Y.; Cheng, M.; Yang, H. Electromagnetic and Thermal analysis of open-circuit air cooled high-speed permanent magnet machines with gramme ring windings. IEEE Trans. Magn. 2014, 50, 8104004. [Google Scholar] [CrossRef]

- Tüysüz, A.; Meyer, F.; Steichen, M.; Zwyssig, C.; Kolar, J.W. Advanced cooling methods for high-speed electrical machines. IEEE Trans. Ind. Appl. 2017, 53, 2077–2087. [Google Scholar] [CrossRef]

- Rahman, N.A.; Bostanci, E.; Fahimi, B. Thermal analysis of switched reluctance motor with direct in-winding cooling system. In Proceedings of the IEEE Conference on Electromagnetic Field Computation (CEFC), Miami, FL, USA, 13–16 November 2016. [Google Scholar]

- Liu, Z.; Winter, Z.; Schier, M. Direct coil cooling of a high performance switched reluctance machine (SRM) for EV/HEV applications. SAE Int. J. Alt. Power 2015, 4, 162–169. [Google Scholar] [CrossRef]

- Kim, H.; Kim, K.; Jo, Y.; Hur, J. Optimization methods of torque density for developing the neodymium free spoke-type BLDC motor. IEEE Trans. Magn. 2013, 49, 2173–2176. [Google Scholar] [CrossRef]

- Schiefer, M.; Doppelbauer, M. Indirect slot cooling for high-power density machines with concentrated winding. In Proceedings of the IEEE International Electric Machines & Drives Conference, Coeur d’Alene, ID, USA, 10–13 May 2015; pp. 1820–1825. [Google Scholar]

- Zhu, S.; Chen, W.; Xie, M.; Liu, C.; Wang, K. Electromagnetic performance comparison of multi-layered interior permanent magnet machines for EV traction applications. IEEE Trans. Magn. 2018, 54, 8104805. [Google Scholar] [CrossRef]

- Yin, H.; Huang, S.; Li, H. Study on the Influence of Internal Water Cooling System on the Loss of Permanent Magnet Synchronous Motor. AIP Conf. Proc. 2018, 1971. [Google Scholar] [CrossRef]

- Liang, Y.; Bian, X.; Yu, H.; Li, C. Finite-element evaluation and eddy-current loss decrease in stator end metallic parts of a large double-canned induction motor. IEEE Trans. Ind. Electron. 2015, 62, 6779–6785. [Google Scholar] [CrossRef]

- Pyrhonen, J.; Jokinen, T.; Hrabovcova, V. Design of Rotating Electrical Machines; Wiley: Hoboken, NJ, USA, 2008. [Google Scholar]

- Simao, C.; Sadowski, N.; Batistela, N.J.; Bastos, J.P.A. Evaluation of hysteresis losses in iron sheets under dc-biased inductions. IEEE Trans. Magn. 2009, 45, 1158–1161. [Google Scholar] [CrossRef]

- Zhu, S.; Cheng, M.; Dong, J.; Du, J. Core loss analysis and calculation of stator permanent-magnet machine considering dc-biased magnetic induction. IEEE Trans. Ind. Electron. 2014, 61, 5203–5212. [Google Scholar] [CrossRef]

- Lin, D.; Zhou, P.; Fu, W.N.; Badics, Z.; Cendes, Z.J. A dynamic core loss model for soft ferromagnetic and power ferrite materials in transient finite element analysis. IEEE Trans. Magn. 2004, 40, 1318–1321. [Google Scholar] [CrossRef]

| Stator/Rotor Poles | 6/4 | Active Axial Length | 80 mm |

|---|---|---|---|

| Stator outer diameter | 120 mm | Turns/pole | 25 |

| Stator inner diameter | 62.5 mm | Rated speed | 3000 rpm |

| Stator and rotor yoke thickness | 11 mm | Rated current | 60 A |

| Stator and rotor pole width | 17.5 mm | DC bus voltage | 300 V |

| Rotor outer diameter | 62 mm | Rated power | 3 kW |

| Shaft diameter | 20 mm | Steel type | NO20 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibrahim, M.N.F.; Sergeant, P. Prediction of Eddy Current Losses in Cooling Tubes of Direct Cooled Windings in Electric Machines. Mathematics 2019, 7, 1096. https://doi.org/10.3390/math7111096

Ibrahim MNF, Sergeant P. Prediction of Eddy Current Losses in Cooling Tubes of Direct Cooled Windings in Electric Machines. Mathematics. 2019; 7(11):1096. https://doi.org/10.3390/math7111096

Chicago/Turabian StyleIbrahim, Mohamed Nabil Fathy, and Peter Sergeant. 2019. "Prediction of Eddy Current Losses in Cooling Tubes of Direct Cooled Windings in Electric Machines" Mathematics 7, no. 11: 1096. https://doi.org/10.3390/math7111096

APA StyleIbrahim, M. N. F., & Sergeant, P. (2019). Prediction of Eddy Current Losses in Cooling Tubes of Direct Cooled Windings in Electric Machines. Mathematics, 7(11), 1096. https://doi.org/10.3390/math7111096