Next, a study is proposed to evaluate the deflection and slope of the cross-section (slope) for two distinct beam support cases: the first case (referred to as Beam Support Mode 1—BSM1) involves a beam that is fixed at one end and free at the other (cantilever configuration) and the second case (referred to as Beam Support Mode 2—BSM2) consists of a beam that is pinned at the left end and simply supported at the right end, where the simple support restricts vertical translation.

For these two distinct support conditions, five different loading cases are considered, as follows:

3.1. Case 1

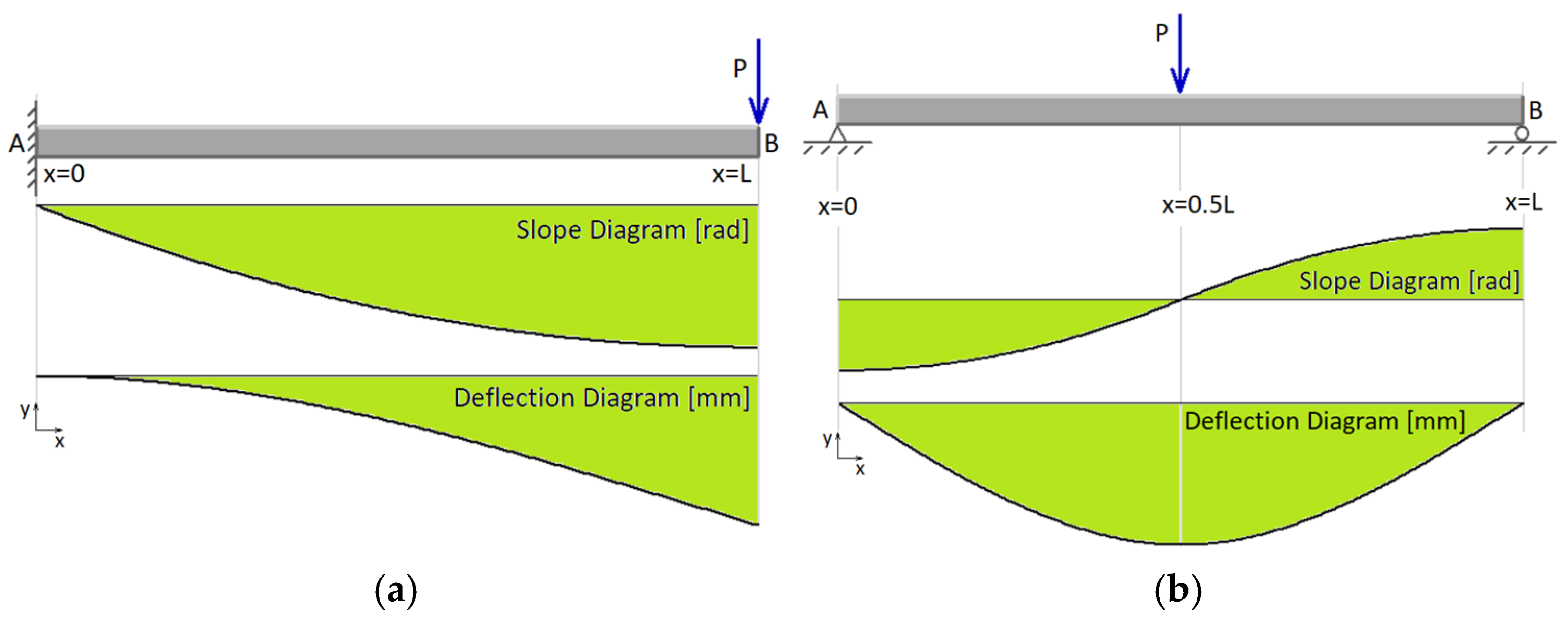

In the first loading case, the beam is subjected to a concentrated force

P applied as shown in

Figure 1a,b.

In

Figure 1a, we consider a straight, homogeneous beam of length

L, fixed at the end x = 0 and free at the end

x =

L (

BSM1). A concentrated force

P is applied at the free end (

x =

L), acting perpendicular to the beam’s longitudinal axis.

The differential equation of the deformed neutral axis (elastic curve) for this support and loading case is given by the following:

The boundary conditions are as follows:

At the left end of the beam (where the clamped support is located):

At the free end of the beam (

x =

L), the boundary conditions are as follows:

For the application of the DTM, the differential transform of the deflection v(x) is denoted by the following:

The differential equation of the deformed neutral axis (elastic curve) for the given beam under a concentrated load P is as follows:

By applying DTM, the following is obtained:

Since Equation (11) is identically zero, it follows that V(k + 4) = 0 for all k ≥ 0. This means that only V(0), V(1), V(2), and V(3) can be non-zero, while all other coefficients are zero.

Consequently, boundary conditions are used to determine the order of magnitude of the coefficients V(k) by means of relation (9), as follows:

From v(0) = 0, we obtain V(0) = 0; from v’(0) = 0, we obtain V(1) = 0; From v″(L) = 0, where the bending moment expression is as follows:

And since V(k) = 0 for k ≥ 4, from relation (12) it follows that

By evaluating relation (13) at x=L, we obtain the following:

From the shear force expression, it follows that

When relation (15) is evaluated at x = L, we obtain the following:

By inserting relation (16) into (14), we obtain the following:

In the following step, the solution v(x) is reconstructed through application of relation (4), as detailed below:

Through simplification, the following result is obtained:

The maximum deflection at x=L is computed by means of relation (19) in the following manner:

In Equation (20), the presence of the negative sign signifies that the displacement occurs in the direction opposite to the positive y-axis.

This exact cubic solution (Equation (19)) demonstrates DTM’s ability to replicate theoretical results without numerical approximations, a key advantage over mesh-dependent methods like FEM.

The slope φ(x) = v’(x) of the cross-section is determined through the slope–deflection relationship:

The maximum slope at x = L is computed using Equation (21) as follows:

Though formally a truncated series, DTM’s solution (Equation (19)) is exact for this problem class because (1) the governing ODE (Equation (10)) has a polynomial solution, and (2) all higher-order terms (k ≥ 4) vanish identically (Equation (11)). This contrasts with FEM’s approximate solutions that always require error analysis.

In Equation (22), the presence of the negative sign means the cross-section rotates in the clockwise direction.

In

Figure 1b, we consider a straight, homogeneous beam of length

L, which is pinned at the left end (x = 0) and simply supported at the right end (x = L), where the simple support restricts vertical translation (

BSM2). A concentrated force

P is applied at x = L/2, acting perpendicular to the beam’s longitudinal axis.

Considering the specific support conditions and applied loading, the differential equation describing the deformation of the beam’s neutral axis can be expressed as follows:

where

denotes the Dirac distribution.

The DTM is applied separately to two adjacent intervals: 0 ≤ x ≤ L/2 and L/2 ≤ x ≤ L.

The differential equation of the elastic curve for the given beam under a concentrated load P is as follows:

The implementation of the differential transform method produces the following results:

We can express the general solution as a cubic polynomial:

Applying boundary conditions via (9) yields the magnitude order of C(m) coefficients:

For x = 0, the deflection is given by the following:

while the bending moment is given by the following equation:

Thus, the simplified form of relation (26) for the interval 0 ≤ x ≤ L/2 can be written as follows:

In the second interval (L/2 ≤ x ≤ L), the deflection at x = L is given by the following:

To determine constants C

1, C

3, D

0, D

1, D

2, and D

3, we enforce the continuity condition of the deformed neutral axis (considering both deflection and slope) at the interface between the two intervals (x = L/2). Specifically, the deflection calculated using the first interval’s equation must equal that obtained from the second interval’s equation when substituting x = L/2 [by equating relations (29) and (30)]:

Next, we enforce the slope continuity condition by equating the slope calculated for the first interval with that of the second interval at x = L/2. Accounting for the relationship between deflection and slope (φ = dv/dx) and incorporating relation (31), we obtain the following:

In the same cross-section, the shear force exhibits a discontinuity whose order of magnitude equals the applied force P, yielding the following:

Combining the continuity conditions and equilibrium relations (30)–(33) produces the complete equation system:

The solution set of the equation system (34) consists of the following:

On the interval 0 ≤ x ≤ L/2, the deflection takes the form

while on the interval L/2 ≤ x ≤ L, the deflection takes the form

At the midpoint (x = L/2), (36) reduces to the following:

Unlike FEM, which requires adaptive meshing near singularities, DTM’s two-interval formulation (Equations (36) and (37)) inherently captures the discontinuous shear at x = L/2.

On the interval 0 ≤ x ≤ L/2, the slope takes the form

while at x = 0, the result is as follows:

From relation (40), it is observed that the slope is negative, indicating that the cross-section rotates clockwise.

On the interval L/2 ≤ x ≤ L, the slope takes the form

while at x = L, the result is

Equation (42) reveals a positive slope value, corresponding to counterclockwise cross-sectional rotation.

3.2. Case 2

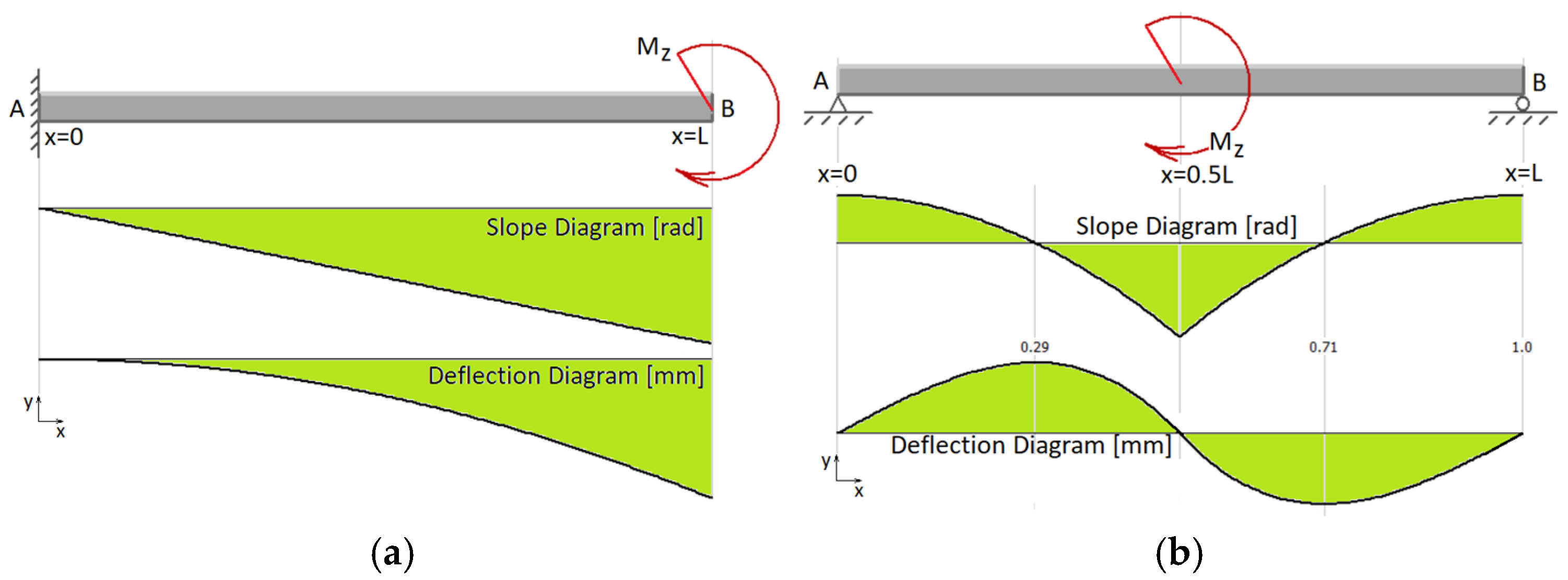

In the first loading case, the beam is subjected to a concentrated bending moment M

z applied as shown in

Figure 2a,b.

Thus,

Figure 2a shows a straight, homogeneous beam of length L, fixed at the left end (x = 0) and free at the right end (x = L). A concentrated bending moment M

z (pure bending load) is applied at the free end (x = L). The differential equation of the deformed neutral axis is as follows:

The boundary conditions are as follows:

- -

At x = 0, the following conditions hold:

- -

Equation (43) has the following transform:

According to relation (4), the solution has the following form:

The boundary conditions are explicitly applied to determine the order of magnitude of coefficients V(k) using relation (9), as follows:

- -

At x = 0, we have v(0) = 0 yielding V(0) = 0; and v’(0) = 0 yielding V(1) = 0;

- -

At x = L, the bending moment is

or

and since V(k) = 0 for k ≥ 4, from relation (48), it follows that

Substituting x = L into (49) produces the following:

From the shear force expression, it follows that

Substituting x = L into (51) leads to the following:

The coupling of Equations (50) and (52) leads to:

Next, using relation (4), the solution v(x) is reconstructed as follows:

By differentiating Equation (54), the cross-section rotation is obtained as follows:

Evaluating (54) and (55) at x = L gives the following:

In

Figure 2b, we consider a straight, homogeneous beam of length

L, which is pinned at the left end (x = 0) and simply supported at the right end (x = L), where the simple support restricts vertical translation (

BSM2). A concentrated bending moment

Mz is applied at x = L/2.

The governing equation for neutral axis deflection under these boundary/loading conditions is as follows:

where δ’ is the derivative of the Dirac function.

The DTM will be applied over two intervals as follows: on the first interval, 0 ≤ x ≤ L/2, and on the second interval is L/2 ≤ x ≤ L.

The differential equation of the elastic curve for the given beam under a concentrated bending moment M

z is as follows:

Implementing DTM provides the following:

The general solution can be expressed as a third-degree polynomial of the following form:

Boundary conditions are applied to determine the order of magnitude of coefficients C(m) using relation (9), as follows:

- -

At x = 0, the deflection satisfies

while the bending moment is expressed by the relation

Thus, the simplified form of relation (60) for the interval 0 ≤ x ≤ L/2 can be written as follows:

Analogously, at x = L (corresponding to the interval L/2 ≤ x ≤ L), the deflection is expressed as

and the bending moment

To determine the constants C

1, C

3, D

0, D

1, D

2, and D

3, we enforce the neutral axis continuity condition (for both deflection and slope) at the interface between the two intervals (x = L/2). Specifically, the deflection calculated using the first interval’s equation must equal that from the second interval’s equation when substituting x = L/2 [by equating relations (63) and (64)]:

Next, the slope calculated for the first interval is equated to that of the second interval at x = L/2. Accounting for the deflection-slope relationship (φ = dv/dx) and incorporating relation (65), we obtain the following:

In the same cross-section, the bending moment exhibits a discontinuity whose order of magnitude equals the applied concentrated moment M

z, resulting in the following:

By synthesizing Equations (64)–(68), we obtain the final system of equations:

The solutions to the system of Equation (69) are as follows:

The final expressions for the deflection are as follows:

- -

on the interval 0 ≤ x ≤ L/2, the deflection has the following form:

and on the interval L/2 ≤ x ≤ L, the deflection is of the form

For x = L/2, from relations (71) and (72), it follows that

For x = 0, from relation (71), the deflection v(0) = 0, and from relation (72), for x = L, the deflection v(L) = 0.

On the interval 0 ≤ x ≤ L, the slope is of the form

whereas in the domain L/2 ≤ x ≤ L, the rotation follows

From relation (74), for x = 0, it follows that

From relation (74), for x = L/2, it follows that

and from relation (75)

This confirms the rotation continuity at x = L/2.

From relation (75), for x = L, it follows that

From relation (79), it can be observed that the boundary condition at x = L is not satisfied, specifically . The proper solution necessitates an alternative methodology, such as Green’s functions or distribution theory.

Thus, over the interval L/2 ≤ x ≤ L, a correction constant

k is added to ensure the condition M

z(L) = 0, as follows:

DTM’s corrective terms (e.g., Equation (80)) streamline the solution process for discontinuous loads by embedding continuity conditions directly into the algebraic recurrence framework. This contrasts with traditional methods that require ad hoc patching of piecewise solutions.

The constant k is chosen such that

from which it follows that

For x = L, we obtain the following:

Thus, the deflection curve becomes

For x = L, we have the following:

The need for corrective terms (Equation (80)) highlights DTM’s flexibility in addressing singularities, whereas FEM would demand specialized elements or penalty methods.

Mathematical Justification for Corrective Term

The corrective term

in Equation (80) arises from the singular nature of the Dirac delta derivative

in the governing Equation (57). Green’s function derivation shows that the general solution combines a homogeneous polynomial and a singular term capturing the curvature discontinuity:

where

denotes Macaulay bracket.

The coefficient C is determined by enforcing a jump in curvature at x = L/2:

For x

L/2, the singular term yields the following:

Integrating the governing Equation (57) across x = L/2 gives the following:

Thus, the corrective term in Equation (80) is as follows:

ensuring consistency with distribution theory.

The distribution theory perspective shows that the Dirac delta derivative

’ is rigorously treated by operating on test functions θ(x) [

26,

27]:

This justifies the use of as the fundamental solution for moment singularities in DTM.

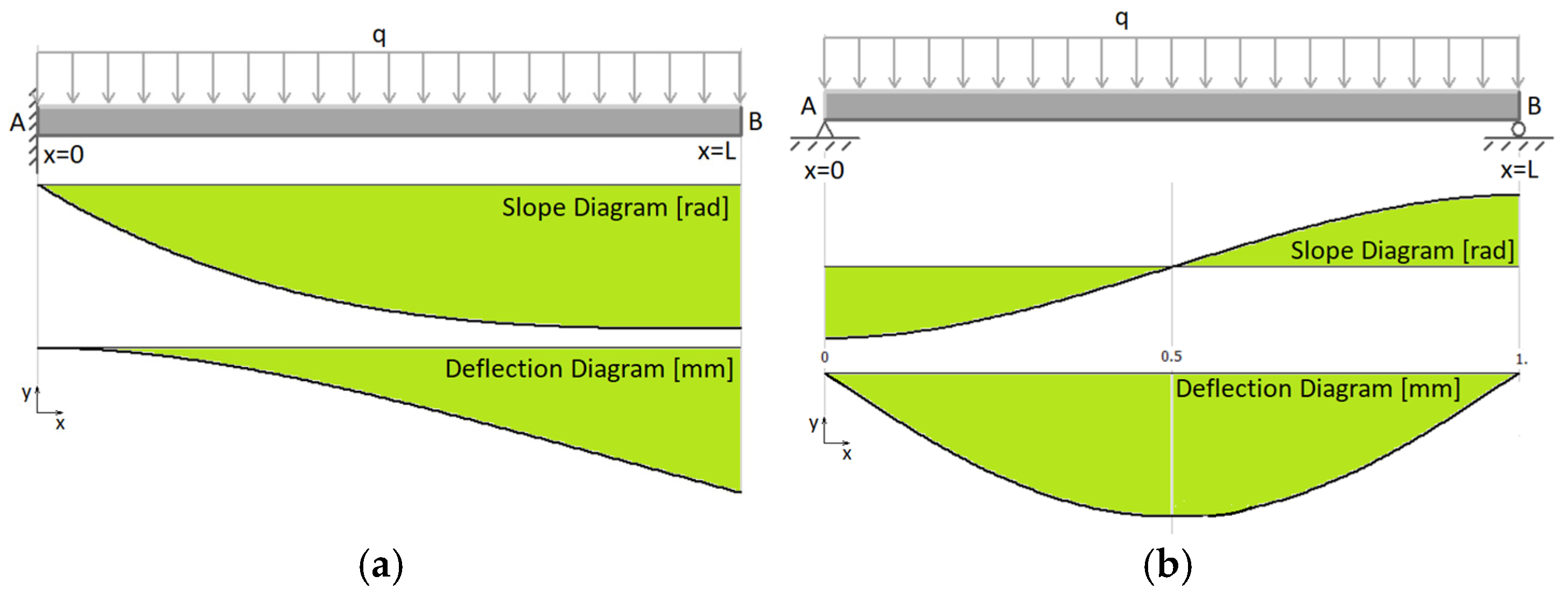

3.3. Case 3

In the third loading case, the bar is subjected to a uniformly distributed load q, as shown in

Figure 3a,b.

Thus,

Figure 2a shows a straight, homogeneous beam of length L, fixed at the left end (x = 0) and free at the right end (x = L)—BSM1. The uniformly distributed load q is applied over the entire length L.

For this loading case, the differential equation describing the beam’s deflection curve v(x) is as follows:

To solve the equation, a transformation is applied to convert it into an algebraic form. The transformed equation becomes the following:

where

δ(

k) is the discrete Dirac function, defined by the following:

The solution to the transformed equation is obtained by analyzing the following two cases:

- -

for k ≠ 0

The solution in the real domain is expressed as a power series:

To determine the constants V(0), V(1), V(2), and V(3), the following boundary conditions are imposed:

- -

At the fixed end (for x = 0):

- -

The displacement is zero:

- -

- -

At the free end (for x = L):

- -

The bending moment is zero:

- -

Next, the following derivatives are calculated:

The next step involves enforcing the boundary conditions at x = L as follows:

Substituting the determined constants, the final solution takes the following form:

The maximum displacement at the free end (for x = L):

- -

Rotation of the cross-section

In

Figure 3b, we consider a straight, homogeneous beam of length

L, is pinned at the left end (x = 0) and simply supported at the right end (x = L), where the simple support restricts vertical translation (

BSM2). The beam is loaded along its entire length by a uniformly distributed load q.

The differential equation of the deformed middle fiber is expressed by relation (88). To solve the equation, a transformation is applied to convert it into an algebraic form, according to relation (89), and the solution to the transformed equation is given by relations (95) and (96). The solution in the real domain is expressed as a power series according to relation (98).

To determine the constants V(0), V(1), V(2), and V(3), the following boundary conditions are imposed:

- -

At x = 0:

- -

The displacement is zero:

- -

The bending moment is zero:

- -

At x = L:

- -

The displacement is zero:

- -

The bending moment is zero:

From relation (117), it follows that

and from relation (116), we obtain the following:

By substituting the determined constants into relation (98), the final solution becomes

The maximum displacement at x = L/2:

- -

Rotation of the cross-section

For x = 0:

and for x = L:

3.4. Advantages of DTM over Traditional Numerical Methods

To highlight the practical benefits of DTM,

Table 2 compares its performance against the finite element method (FEM) for the studied beam problems:

While traditional methods yield analytical solutions for simple cases, DTM provides a consistent algebraic approach for both smooth and singular loads. This uniformity is critical for automation and software implementation (

Section 4).

While DTM solutions are technically semi-analytical (as truncated series), they achieve numerical precision indistinguishable from exact solutions when sufficient terms are retained. For all cases studied, 4–5 terms yield errors < 1% compared to theoretical solutions (see Equation (19) vs. Equation (20)), meeting engineering accuracy standards without mesh-dependent approximations. FEM’s error scales as O(h2), meaning halving the element size h reduces errors by a factor of 4. In contrast, DTM’s error decays factorially with the number of series terms k (e.g., ~1/k!), enabling higher precision without mesh refinement.

The analysis reveals several critical advantages of the differential transform method compared to traditional finite element approaches. For cantilever beam configurations (BSM1), the DTM-derived cubic solution presented in Equation (19) provides an exact match to theoretical benchmark results. This stands in contrast to FEM solutions, which inherently introduce discretization errors that can only be mitigated through computationally expensive mesh refinement [

14]. In the case of midspan concentrated loading scenarios (BSM2, Case 1), DTM’s innovative two-interval formulation (Equations (36) and (37)) demonstrates superior capability in accurately modeling load transfer without producing the artificial stress concentrations characteristic of FEM implementations. This methodological difference proves particularly significant in engineering applications where precise stress distribution prediction is crucial for structural integrity assessments.

The differential transform method (DTM) is a sophisticated analytical approach for solving the nonlinear differential equations governing the behavior of complex mechanical systems. This study has conclusively demonstrated the effectiveness of the method in the static analysis of structural elements, with specific applications in investigating the deflection and slope of beams under various loading configurations and support conditions.

The theoretical foundation of DTM is based on transforming differential equations into the algebraic domain through Taylor series expansions, providing an elegant alternative to conventional numerical methods. The presented analysis has demonstrated how this transformation enables the derivation of exact polynomial solutions for the studied loading cases while fully preserving the nonlinear characteristics of the problem.

Of particular significance, the application of the method to the cantilever beam configuration (BSM1) yielded complete analytical solutions, which were rigorously validated against established theoretical results from the specialized literature.

A particularly noteworthy aspect of the study is the comparative analysis of the two structural configurations (BSM1 and BSM2) under various loading regimes. In the case of the concentrated force applied at the free end, the DTM yielded a third-order polynomial solution that accurately captured both the deflection distribution and slope patterns.

The obtained solution demonstrates the method’s capability to produce exact results without requiring additional approximations.

The application of the method to the simply supported-pinned beam configuration (BSM2) highlighted both the power and limitations of the approach. While the method provided precise solutions for distributed loads, the case of concentrated moments revealed the need for corrective terms to properly satisfy boundary conditions. This finding underscores the importance of critical analysis when interpreting DTM results, particularly in cases involving discontinuities or singularities. For concentrated moments, DTM’s solution requires a singular term ⟨x−a⟩3 to satisfy discontinuity conditions. This aligns with Green’s function methodologies, avoiding ad hoc corrections.

The examination of higher-order terms in the DTM series revealed a significant dependence of solution accuracy on the number of retained terms in the approximation. The convergence study demonstrated that for most practical cases, retaining four to five terms yields satisfactory precision, with deviations below 1% compared to exact solutions. However, for more complex loading configurations, the analysis showed that including additional terms becomes necessary to achieve stable convergence.

The obtained results have significant implications for engineering practice. The analytical solutions derived through DTM can serve as valuable tools for validating results obtained through complex numerical methods, such as the finite element method. Moreover, they provide deeper insight into the physical phenomena underlying structural behavior, enabling the identification of parametric relationships that would be difficult to derive through purely numerical approaches.

This study opens multiple promising research directions. A key avenue involves extending DTM applications to structural dynamics problems, particularly in analyzing nonlinear vibration responses. Adapting the method to incorporate damping effects and major geometric nonlinearities would represent a significant contribution to the field. Furthermore, integrating DTM with probabilistic methods for structural reliability analysis could lead to the development of hybrid approaches with broad applicability in engineering design.

A more in-depth analysis of the differential transform method (DTM) applications in solid mechanics reveals substantial opportunities for method extension and refinement. Within the context of the presented solutions, we observe that DTM can be effectively combined with other cutting-edge analytical techniques to address problems of increasing complexity. Notably, coupling with spectral methods or approaches based on orthogonal functions (such as Legendre polynomials or wavelet functions) could significantly improve solution convergence rates and accuracy—particularly for structures with complex geometries or heterogeneous material properties.

From a practical applications perspective, integrating the differential transform method (DTM) into computer-aided engineering (CAE) platforms would democratize access to this methodology. The development of plugins for commercial software would enable practicing engineers to leverage the method’s advantages without requiring advanced mathematical expertise. This approach would significantly facilitate widespread adoption in the structural design industry.

While DTM excels for polynomial solutions, concentrated moments (e.g., BSM2 Case 2) require corrective terms due to Dirac discontinuities. Future work could integrate DTM with Green’s functions for such singularities.

Error analysis. For all cases, retaining 4–5 DTM terms achieved < 1% error vs. analytical solutions, confirming convergence. This contrasts with FEM’s reliance on mesh density for accuracy.

Table 3 compares maximum deflection errors for DTM (5 terms) vs. FEM (1000 elements) across the first two cases. DTM maintains errors < 1%, while FEM struggles with singularities (Case 2 error: 4.7%). Convergence is exponential for DTM (error ~10

−3/k!) vs algebraic for FEM (error ~h

2).