PHEV Routing with Hybrid Energy and Partial Charging: Solved via Dantzig–Wolfe Decomposition

Abstract

1. Introduction

- Model Innovation: We formulate a novel hybrid-mode PHEVRP model that integrates customer time windows with partial charging decisions. The proposed model adopts a mixed-integer linear programming (MILP) formulation that accurately reflects hybrid energy usage and partial charging behavior and is solvable using standard commercial optimization solvers. (e.g., Gurobi).

- Algorithmic Innovation: We design a tailored Dantzig–Wolfe decomposition algorithm that enables efficient solution of large-scale PHEVRP instances. Compared to direct optimization, this method significantly accelerates computation while preserving high solution quality.

2. Literature Review

3. Problem Description and Formulation

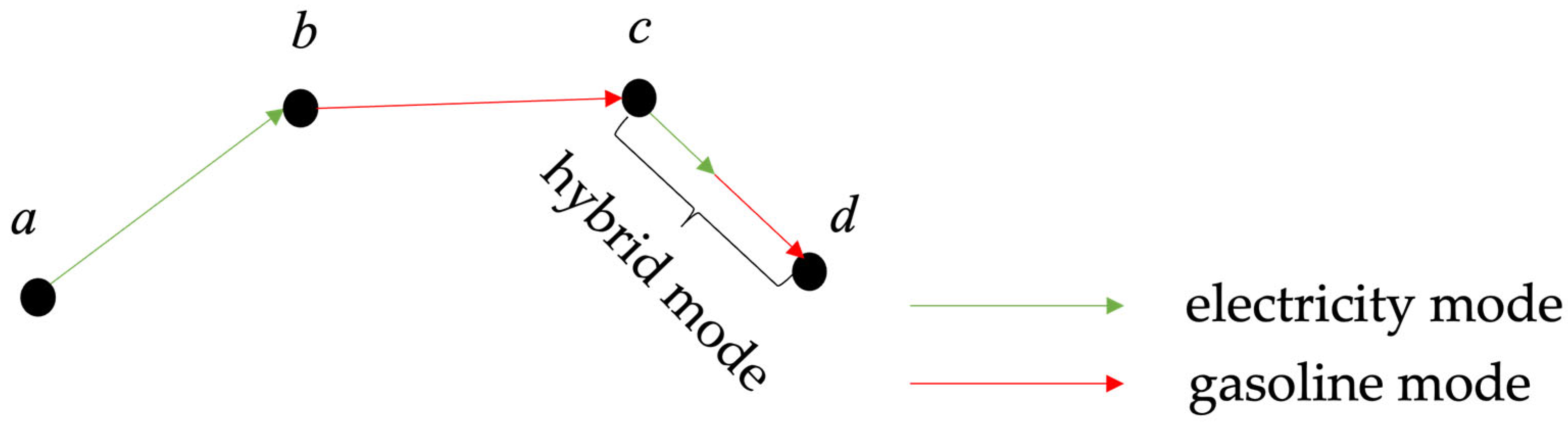

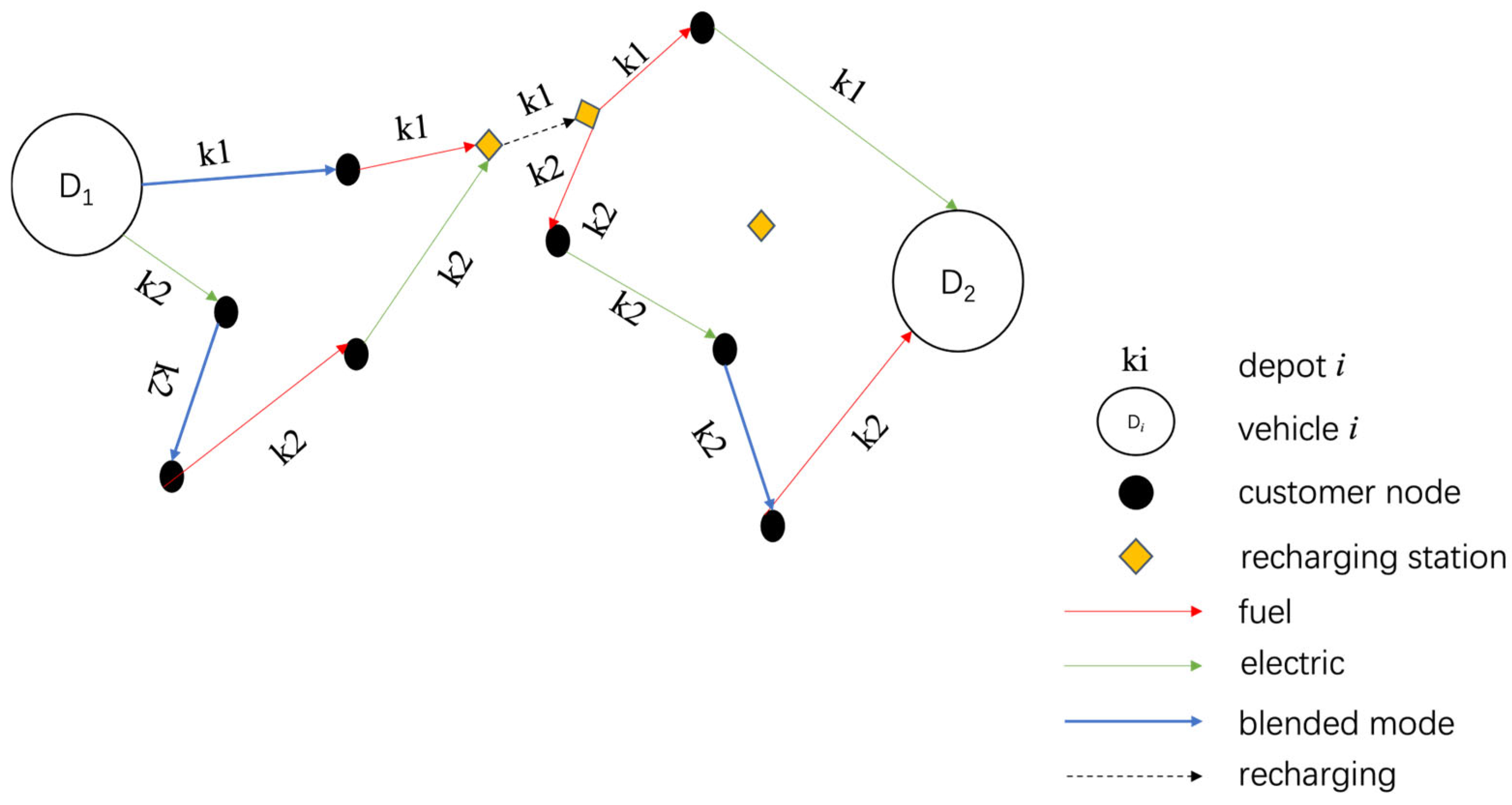

3.1. Problem Description

- Fleet Consistency: Only one type of PHEV is used in the distribution.

- Linear Charging Behavior: The charging process is assumed to be linear, meaning that the amount of energy replenished is directly proportional to the charging time.

3.2. Formulation

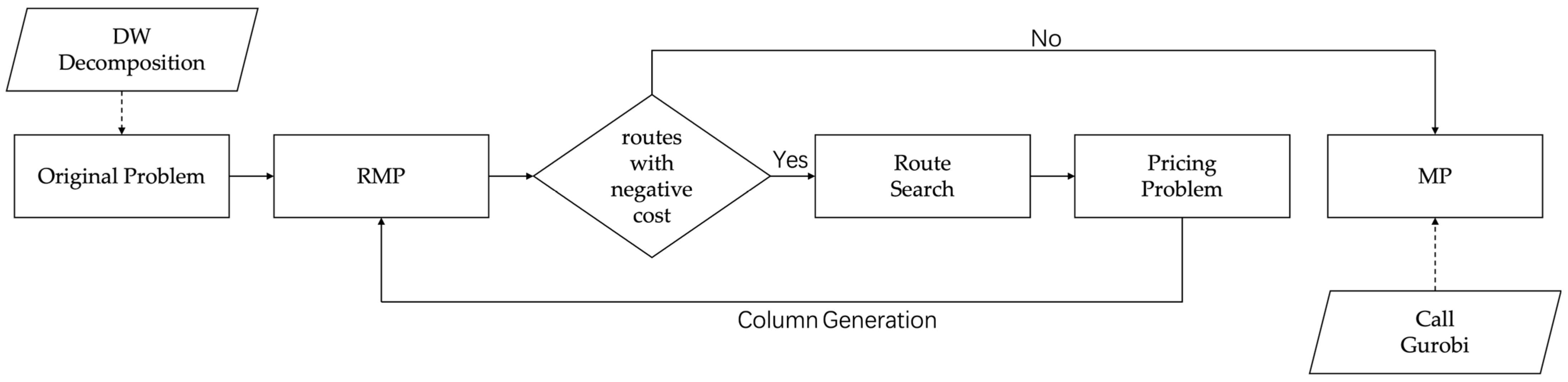

4. Decomposition-Based Algorithm for the PHEVRP

- Algorithm Overview

- Step 1: Apply Dantzig–Wolfe decomposition to divide the original problem into an RMP and a pricing subproblem.

- Step 2: Construct an initial feasible solution and add it to the RMP.

- Step 3: Solve the RMP to obtain dual variables and use them to guide the pricing subproblem. Add routes (columns) with negative reduced cost to the RMP.

- Step 4: If no more columns with negative reduced cost are found, proceed to Step 5; otherwise, return to Step 3.

- Step 5: Convert the continuous RMP into an Integer Master Problem (MP) by enforcing binary constraints.

- Step 6: Solve the MP to obtain the final optimal route combination.

4.1. Path-Based Reformulation of the Restricted Master Problem (RMP)

- Transformation and Constraints

- Cost Calculation

4.2. Heuristic Initialization via IMPACT-Based Node Insertion

- Insertion Slack (IS):

- Urgency Index (IU):

4.3. Pricing Subproblem: Resource-Constrained Shortest Path Model

4.3.1. Reduced-Cost Model

4.3.2. Reduced-Cost Calculation

4.3.3. Label-Correcting Algorithm for Path Generation

| Algorithm 1: Label Extension Procedure | |||

| Input: (i, Lp, j) | |||

| Output: Lp* | |||

| 1: if () or > ) or () then | |||

| 2: | Lp* = Lp | ||

| 3: else | |||

| 4: | Update , , and | ||

| 5: | if | ||

| 6: | |||

| 7: | |||

| 8: | if (j ) then | ||

| 9: | = +1 | ||

| 10: | = 1 | ||

| 11: | for all t ∈ successors of j: | ||

| 12: | if adding t violates load, fuel, or time window: | ||

| 13: | = +1 | ||

| 14: | = 1 | ||

4.4. Master Problem and Algorithm Pseudo-Code

| Algorithm 2: Dantzig–Wolfe Decomposition | |

| Input: Original PHEVRP instance data | |

| Output: Optimal route combination and energy mode strategy | |

| 1: Generate initial feasible paths Ω0 using heuristic (see Section 4.2); | |

| 2: Initialize the Restricted Master Problem (RMP) with the initial path set (see Section 4.3.1) | |

| 3: Repeat (Column Generation Loop) | |

| 4: | Solve RMP (Relaxed version) to obtain dual variables πi and φj (see Section 4.3.2) |

| 5: | Solve Pricing Subproblem using Label-Correcting Algorithm (see Section 4.3.3) |

| 6: | If a path p negative reduced cost c̅p < 0 is found, add it to Ω |

| 7: Until no more columns with negative reduced cost are identified; | |

| 8: Convert the relaxed RMP into the final Integer Master Problem (MP); | |

| 9: | Fix λp ∈ {0,1} in RMP |

| 10: | Solve the MP as a mixed-integer program to determine the optimal route set. |

5. Numerical Experiments

5.1. Experimental Setup and Parameter Configuration

- C-type: clustered customer locations;

- R-type: randomly distributed customers;

- RC-type: a combination of R-type and C-type distributions.

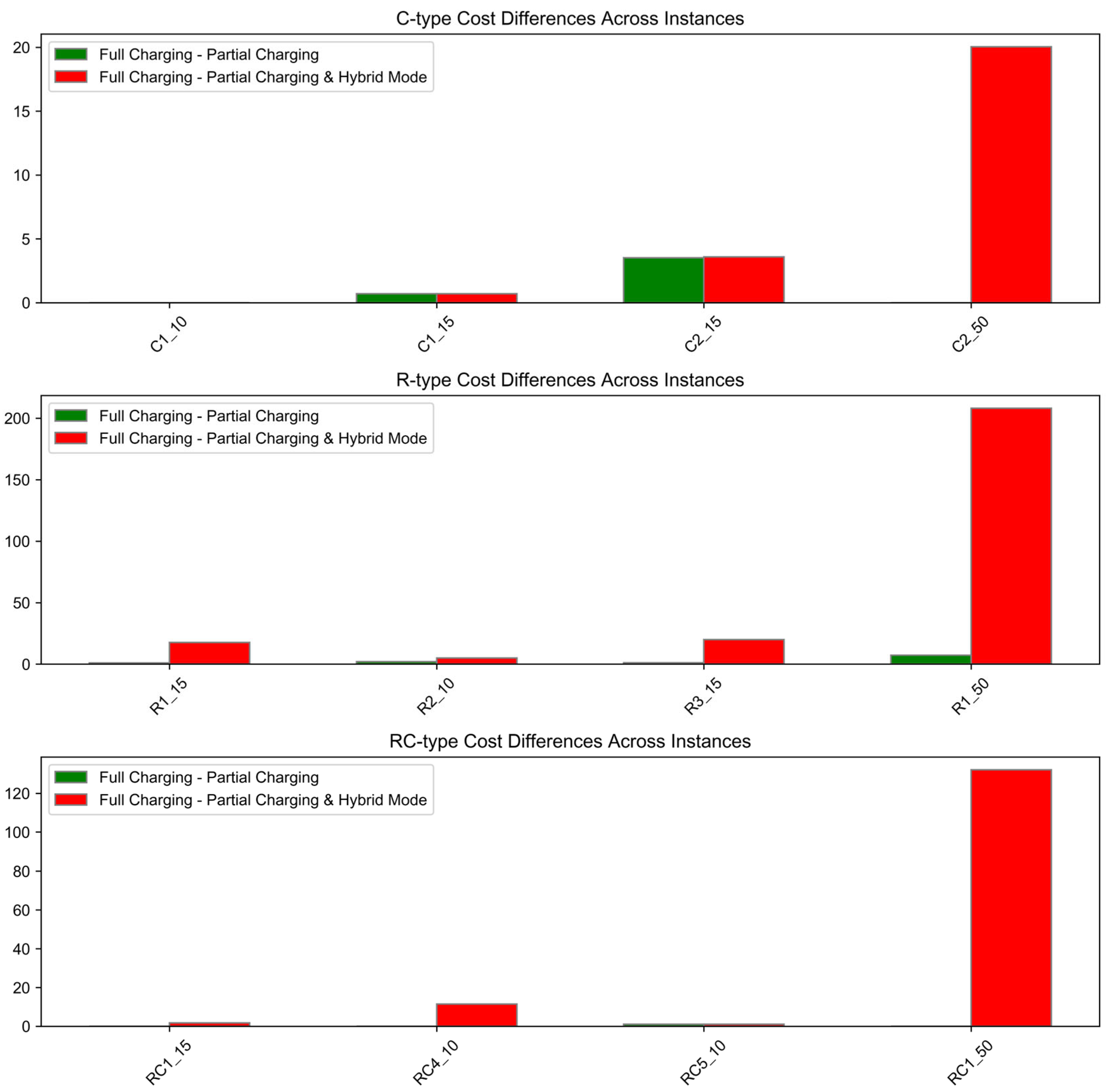

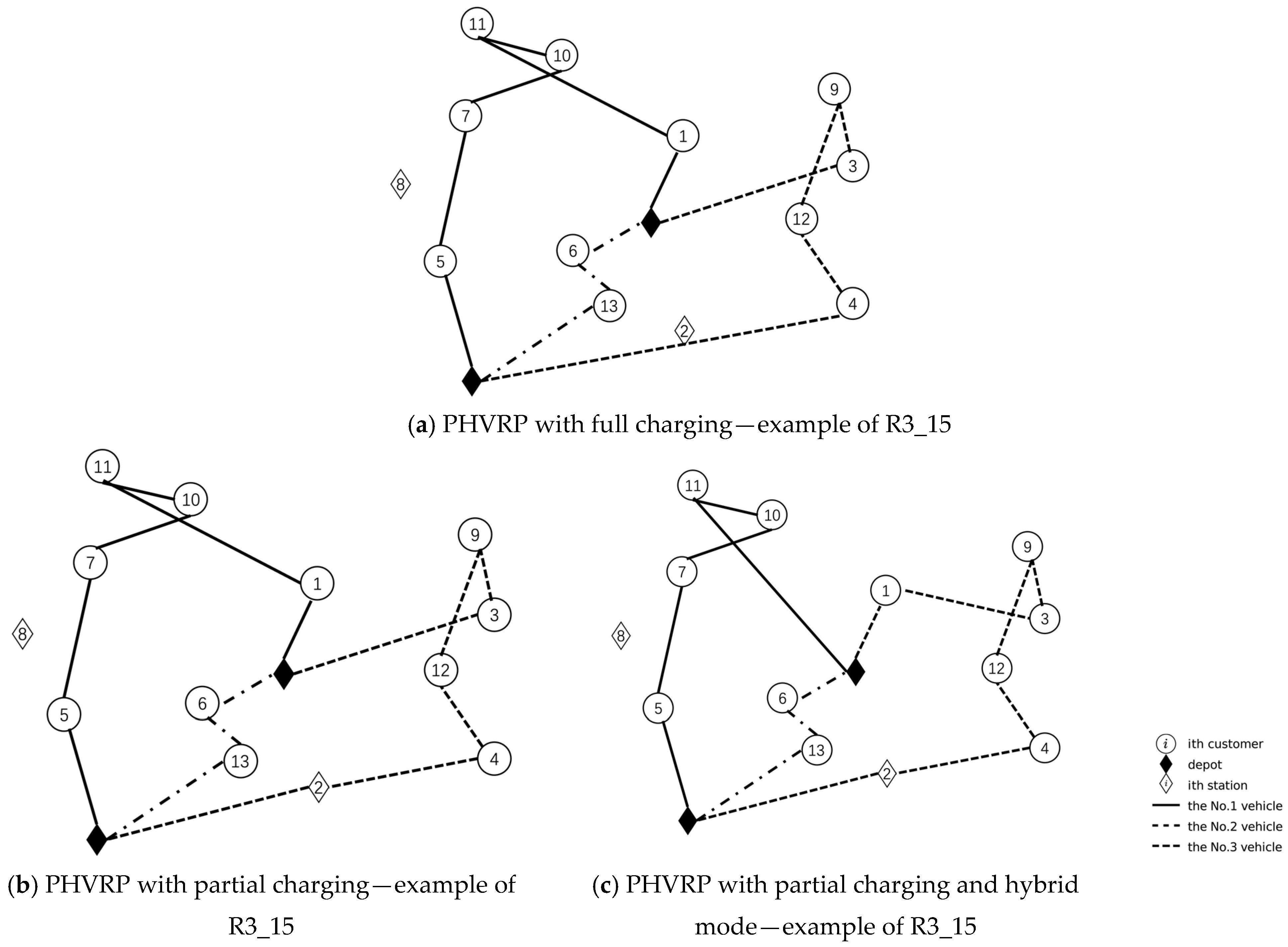

5.2. Cost Advantages of Partial Charging and Hybrid Mode

- For most C-type instances (e.g., C1_10, C1_15), the costs across all three strategies—full charging, partial charging, and hybrid mode—are nearly identical. This suggests that when customers are geographically clustered and the instance size is small, the choice of energy strategy has a minimal impact on cost.

- An exception is C2_50, where the hybrid mode reduces the cost by approximately 20 units, indicating that in larger clustered instances, energy-mode flexibility can yield meaningful cost improvements.

- Significant cost reductions are observed under the hybrid mode. In particular, R1_50 and R3_15 achieve savings of 208 and 19.9 units, respectively.

- These findings suggest that when customer locations are dispersed, and routing becomes more complex, allowing partial charging or enabling hybrid mode significantly enhances route feasibility and cost efficiency.

- Even in smaller instances such as R2_10, moderate savings are observed, indicating that random distributions benefit from flexible energy strategies regardless of scale.

- In most small-scale RC-type instances (e.g., RC1_15, RC5_10), the cost differences across strategies are relatively small.

- However, for larger instances like RC1_50, the hybrid mode achieves a cost saving of 132 units, demonstrating that energy flexibility becomes increasingly valuable in mixed-distribution scenarios as instance size increases.

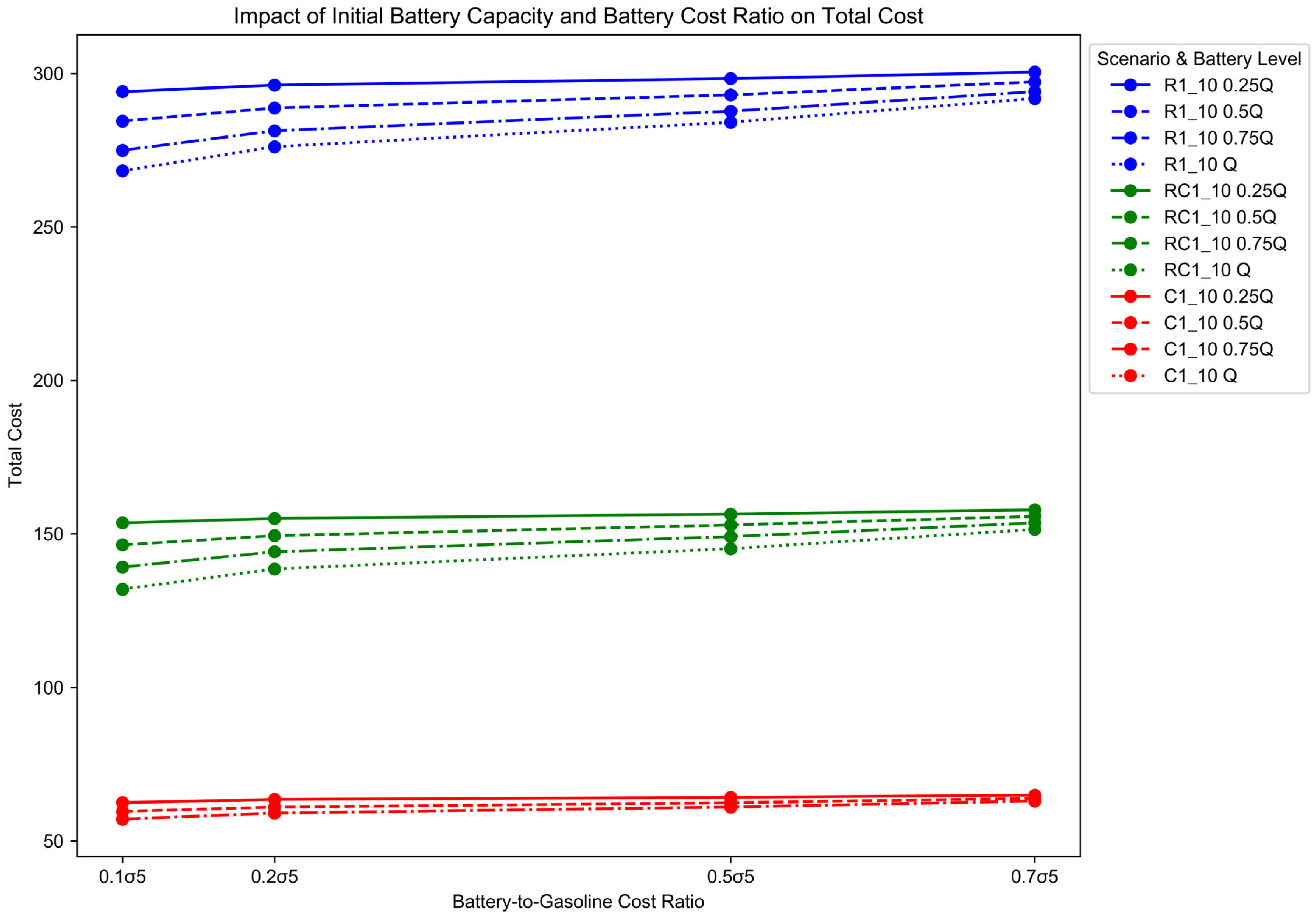

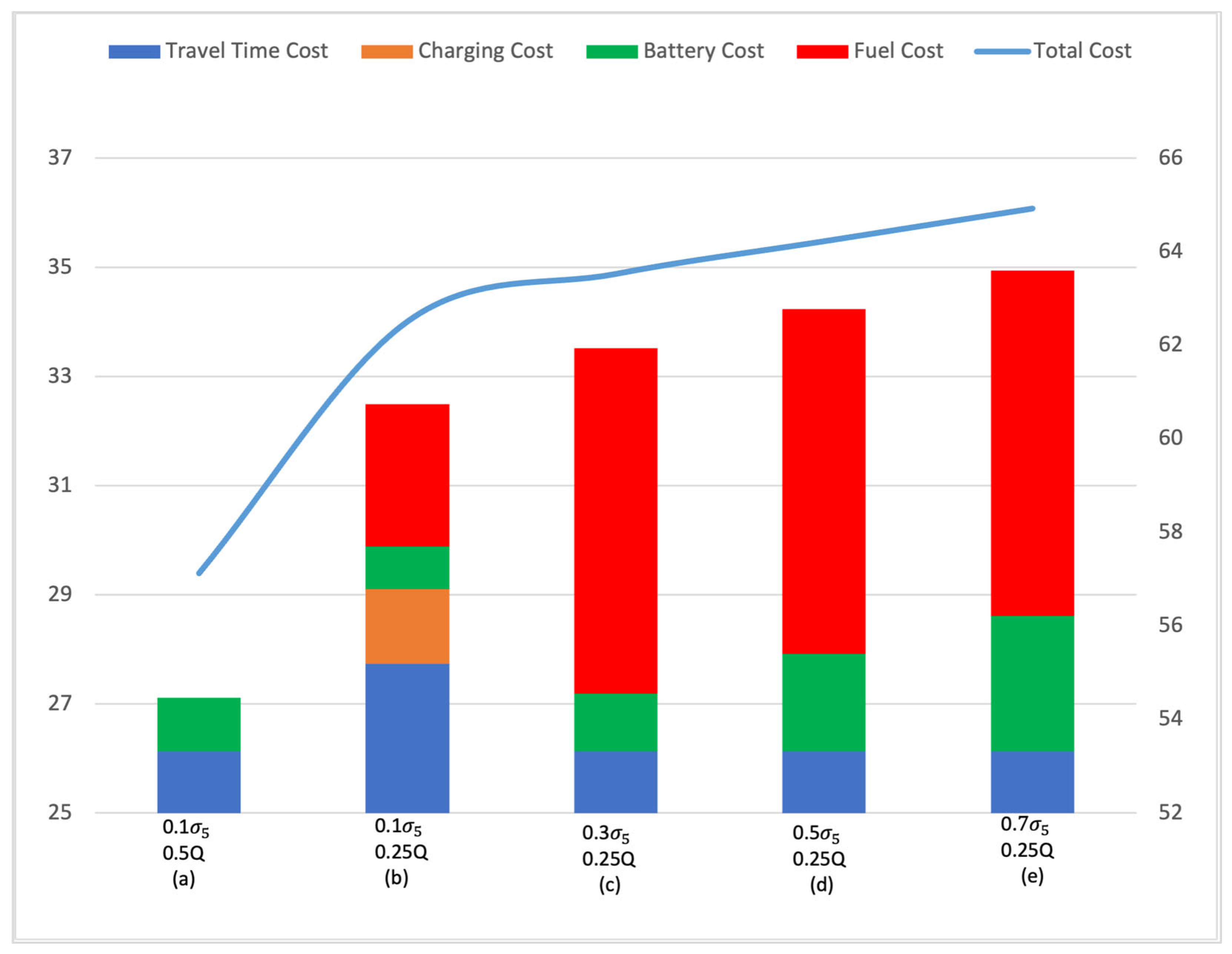

5.3. Cost Sensitivity Analysis

5.3.1. Influence of Initial Battery Capacity and Battery-to-Gasoline Cost Ratio on Total Cost

- Impact of IBC:

- Impact of BGR:

- Sensitivity Differences by Scenario Type:

- Travel Time vs. Charging Cost:

- Charging Cost with Low IBC:

- Battery vs. Fuel Trade-Off:

5.3.2. Sensitivity Analysis of Charging Price at Charging Stations

5.4. Performance Evaluation of Dantzig–Wolfe Decomposition

- Gap1 = (DW Objective − Model Objective)/Model Objective;

- Gap2 = (ACO Objective − Model Objective)/Model Objective;

- Gap3 = (ACO Objective − DW Objective)/DW Objective.

- Solution Quality Comparison

- 2.

- Computational Efficiency and Time Stability

- 3.

- Instance Type and Size Effects

- Clustered Instances (C-type): These are generally easier for both methods due to geographical compactness. Nevertheless, ACO still yields large errors in bigger instances, e.g., C1_30 (23%) and C2_25 (21%).

- Random Instances (R-type): These present the most difficulty due to spatial dispersion and complex routing paths. DW retains reasonable accuracy, but its runtime becomes significantly longer (e.g., R2_15: 42,463 s; R2_100: 37,000 s). In contrast, ACO remains fast but shows sharp declines in solution quality—e.g., R1_50 (37%), R1_100 (52%), R1_200 (95%).

- Mixed Instances (RC-type): These have intermediate difficulty. ACO produces moderate gaps (e.g., RC1_50: 24%), while DW maintains accuracy as long as runtime remains within practical limits.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix A.1. ACO-Based Routing Procedure

| Algorithm A1: ACO-Based Routing | ||||

| Input: Original PHEVRP instance data | ||||

| Output: Optimal route combination and energy mode strategy | ||||

| 1: Set initial pheromone ; number of ants A, max iterations M | ||||

| 2: for all m : | ||||

| 3: | for all a : | |||

| 4: | Initialize unvisited customers | |||

| 5: | Start a new route from depot | |||

| 6: | while : | |||

| 7: | Identify feasible customers satisfying: | |||

| 8: | Remaining vehicle capacity | |||

| 9: | Arrival time at j within its time window | |||

| 10: | - Select next node using: | |||

| 11: | Append selected customer to current route | |||

| 12: | If no feasible node, return to depot and start new route | |||

| 13: | For each constructed path, apply the exact pricing subproblem model (Model 38–43) (see Section 4.3.1) | |||

| 14: | Compute the reduced cost (RC) using Equation (44) | |||

| 15: | Apply evaporation: | |||

| 16: | For arcs in best-performing ants: (i.e., those with lowest reduced cost): | |||

| 17: |

←

+ Δ where Δ = ξ/(1 + RC) if RC ≥ 0 = ξ × (1 − RC) if RC < 0 | |||

Appendix A.2. Parameter Settings

| Parameter | Value |

|---|---|

| max iterations M | 50 |

| number of ants A | 50 |

| Pheromone weight | 1 |

| Heuristic weight | 3 |

| evaporation rate | 0.85 |

| pheromone reward ξ | 5 |

References

- International Energy Agency. Tracking Clean Energy Progress 2023. Available online: https://www.iea.org/reports/tracking-clean-energy-progress-2023 (accessed on 13 February 2025).

- UPS. Doing Good Is Good for Business. Available online: https://about.ups.com/us/en/our-impact/sustainability/sustainable-services/2022-ups-sustainability-report-.html (accessed on 13 February 2025).

- Dantzig, G.B.; Ramser, J.H. The Truck Dispatching Problem. Manag. Sci. 1959, 6, 80–91. [Google Scholar] [CrossRef]

- Nejad, M.M.; Mashayekhy, L.; Grosu, D.; Chinnam, R.B. Optimal Routing for Plug-In Hybrid Electric Vehicles. Transp. Sci. 2017, 51, 1031–1386. [Google Scholar] [CrossRef]

- Bahrami, S.; Nourinejad, M.; Amirjamshidi, G.; Roorda, M.J. The Plugin Hybrid Electric Vehicle Routing Problem: A Power-Management Strategy Model. Transp. Res. Part C Emerg. Technol. 2020, 111, 318–333. [Google Scholar] [CrossRef]

- Chabrier, A. Vehicle Routing Problem with Elementary Shortest Path Based Column Generation. Comput. Oper. Res. 2006, 33, 2972–2990. [Google Scholar] [CrossRef]

- Lee, G.; Lee, J.S.; Park, K.S. Battery Swapping, Vehicle Rebalancing, and Staff Routing for Electric Scooter Sharing Systems. Transp. Res. Part E Logist. Transp. Rev. 2024, 186, 103540. [Google Scholar] [CrossRef]

- Trotta, A.; Andreagiovanni, F.D.; Di Felice, M.; Natalizio, E.; Chowdhury, K.R. When UAVs Ride a Bus: Towards Energy-Efficient City-Scale Video Surveillance. In Proceedings of the IEEE INFOCOM 2018—IEEE Conference on Computer Communications, Honolulu, HI, USA, 15–19 April 2018. [Google Scholar] [CrossRef]

- Kim, G. Electric Vehicle Routing Problem with States of Charging Stations. Sustainability 2024, 16, 3439. [Google Scholar] [CrossRef]

- Longo, H.; Poggi de Aragão, M.; Uchoa, E. Solving Capacitated Arc Routing Problems Using a Transformation to the CVRP. Comput. Oper. Res. 2006, 33, 1823–1837. [Google Scholar] [CrossRef]

- Fang, C.; Cai, Y.; Wu, Y. A Discrete Wild Horse Optimizer for Capacitated Vehicle Routing Problem. Sci. Rep. 2024, 14, 21277. [Google Scholar] [CrossRef]

- Desrochers, M.; Desrosiers, J.; Solomon, M.M. A New Optimization Algorithm for the Vehicle Routing Problem with Time Windows. Oper. Res. 1992, 40, 342–354. [Google Scholar] [CrossRef]

- Saksuriya, P.; Likasiri, C. Vehicle Routing Problem with Time Windows to Minimize Total Completion Time in Home Healthcare Systems. Mathematics 2023, 11, 4846. [Google Scholar] [CrossRef]

- Balakrishnan, N. Simple Heuristics for the Vehicle Routeing Problem with Soft Time Windows. J. Oper. Res. Soc. 1993, 44, 279–287. [Google Scholar] [CrossRef]

- Demir, E.; Bektaş, T.; Laporte, G. An Adaptive Large Neighborhood Search Heuristic for the Pollution-Routing Problem. Eur. J. Oper. Res. 2012, 223, 346–359. [Google Scholar] [CrossRef]

- Lysgaard, J.; Letchford, A.N.; Eglese, R.W. A New Branch-and-Cut Algorithm for the Capacitated Vehicle Routing Problem. Math. Program. 2004, 100, 423–445. [Google Scholar] [CrossRef]

- Baldacci, R.; Christofides, N.; Mingozzi, A. An Exact Algorithm for the Vehicle Routing Problem Based on the Set Partitioning Formulation with Additional Cuts. Math. Program. 2008, 115, 351–385. [Google Scholar] [CrossRef]

- Xia, Y.; Zeng, W.; Zhang, C.; Yang, H. A Branch-and-Price-and-Cut Algorithm for the Vehicle Routing Problem with Load-Dependent Drones. Transp. Res. Part B Methodol. 2023, 171, 80–110. [Google Scholar] [CrossRef]

- Baker, B.M.; Ayechew, M.A. A Genetic Algorithm for the Vehicle Routing Problem. Comput. Oper. Res. 2003, 30, 787–800. [Google Scholar] [CrossRef]

- Cordeau, J.F.; Laporte, G.; Mercier, A. A Unified Tabu Search Heuristic for Vehicle Routing Problems with Time Windows. J. Oper. Res. Soc. 2001, 52, 928–936. [Google Scholar] [CrossRef]

- Homberger, J.; Gehring, H. A Two-Phase Hybrid Metaheuristic for the Vehicle Routing Problem with Time Windows. Eur. J. Oper. Res. 2005, 162, 220–238. [Google Scholar] [CrossRef]

- Altabeeb, A.M.; Mohsen, A.M.; Ghallab, A. An Improved Hybrid Firefly Algorithm for Capacitated Vehicle Routing Problem. Appl. Soft Comput. 2019, 84, 105728. [Google Scholar] [CrossRef]

- Passias, A.; Sirakoulis, G.C. Comparative Study of Metaheuristic Algorithms for the Vehicle Routing Problem with Application to Recycling Waste Management. Parallel Process. Lett. 2025, 35, 2250001. [Google Scholar] [CrossRef]

- Erdoğan, S.; Miller-Hooks, E. A Green Vehicle Routing Problem. Transp. Res. Part E Logist. Transp. Rev. 2012, 48, 100–114. [Google Scholar] [CrossRef]

- Schneider, M.; Stenger, A.; Goeke, D. The Electric Vehicle-Routing Problem with Time Windows and Recharging Stations. Transp. Sci. 2014, 48, 500–520. [Google Scholar] [CrossRef]

- Felipe, Á.; Ortuño, M.T.; Righini, G.; Tirado, G. A Heuristic Approach for the Green Vehicle Routing Problem with Multiple Technologies and Partial Recharges. Transp. Res. Part E Logist. Transp. Rev. 2014, 71, 111–128. [Google Scholar] [CrossRef]

- Schiffer, M.; Walther, G. The Electric Location Routing Problem with Time Windows and Partial Recharging. Eur. J. Oper. Res. 2017, 260, 995–1013. [Google Scholar] [CrossRef]

- Goeke, D.; Schneider, M. Routing a Mixed Fleet of Electric and Conventional Vehicles. Eur. J. Oper. Res. 2015, 245, 81–99. [Google Scholar] [CrossRef]

- Macrina, G.; Di Puglia Pugliese, L.; Guerriero, F.; Laporte, G. The Green Mixed Fleet Vehicle Routing Problem with Partial Battery Recharging and Time Windows. Comput. Oper. Res. 2019, 101, 183–199. [Google Scholar] [CrossRef]

- Du, S.; Li, S.; Han, H.; Qiao, J. Diversity-Based Niche Genetic Algorithm for Bi-Objective Mixed Fleet Vehicle Routing Problem with Time Window. Neural Comput. Appl. 2025, 37, 11479–11499. [Google Scholar] [CrossRef]

- Rahmanifar, G.; Mohammadi, M.; Hajiaghaei-Keshteli, M.; Colombaroni, C.; Fusco, G.; Gholian-Jouybari, F. Two-Echelon Electric Vehicle Routing Problem with Battery Swap Stations on Real Network. IFAC-Pap. Online 2024, 58, 46–51. [Google Scholar] [CrossRef]

- Desaulniers, G.; Errico, F.; Irnich, S.; Schneider, M. Exact Algorithms for Electric Vehicle-Routing Problems with Time Windows. Oper. Res. 2016, 64, 1388–1405. [Google Scholar] [CrossRef]

- Keskin, M.; Çatay, B. Partial Recharge Strategies for the Electric Vehicle Routing Problem with Time Windows. Transp. Res. Part C Emerg. Technol. 2016, 65, 111–127. [Google Scholar] [CrossRef]

- Gil-Gala, F.J.; Đurasević, M.; Jakobović, D. Evolving Routing Policies for Electric Vehicles by Means of Genetic Programming. Appl. Intell. 2024, 54, 12391–12419. [Google Scholar] [CrossRef]

- Wei, X.; Niu, C.; Zhao, L.; Wang, Y. Combination of Ant Colony and Student Psychology-Based Optimization for the Multi-Depot Electric Vehicle Routing Problem with Time Windows. Clust. Comput. 2025, 28, 99. [Google Scholar] [CrossRef]

- Raykin, L.; Roorda, M.J.; MacLean, H.L. Impacts of Driving Patterns on Tank-to-Wheel Energy Use of Plug-In Hybrid Electric Vehicles. Transp. Res. D Transp. Environ. 2012, 17, 243–250. [Google Scholar] [CrossRef]

- Arslan, O.; Yıldız, B.; Kara¸san, O.E. Minimum Cost Path Problem for Plug-in Hybrid Electric Vehicles. Transp. Res. Part E Logist. Transp. Rev. 2015, 80, 123–141. [Google Scholar] [CrossRef]

- Murakami, K. Formulation and Algorithms for Route Planning Problem of Plug-In Hybrid Electric Vehicles. Oper. Res. Int. J. 2018, 18, 497–519. [Google Scholar] [CrossRef]

- Murakami, K. A New Model and Approach to Electric and Diesel-Powered Vehicle Routing. Transp. Res. Part E Logist. Transp. Rev. 2017, 107, 23–37. [Google Scholar] [CrossRef]

- Wu, F.; Adulyasak, Y.; Cordeau, J. Modeling and Solving the Traveling Salesman Problem with Speed Optimization for a Plug-In Hybrid Electric Vehicle. Transp. Sci. 2024, 58, 562–577. [Google Scholar] [CrossRef]

- Yu, V.F.; Redi, A.A.N.P.; Hidayat, Y.A.; Wibowo, O.J. A Simulated Annealing Heuristic for the Hybrid Vehicle Routing Problem. Appl. Soft Comput. 2017, 53, 119–132. [Google Scholar] [CrossRef]

- Li, X.; Shi, X.; Zhao, Y.; Liang, H.; Dong, Y. SVND Enhanced Metaheuristic for Plug-In Hybrid Electric Vehicle Routing Problem. Appl. Sci. 2020, 10, 441. [Google Scholar] [CrossRef]

- Ioannou, G.; Kritikos, M.; Prastacos, G. A Greedy Look-Ahead Heuristic for the Vehicle Routing Problem with Time Windows. J. Oper. Res. Soc. 2001, 52, 523–537. [Google Scholar] [CrossRef]

- Solomon, M.M. Algorithms for the Vehicle Routing and Scheduling Problems with Time Window Constraints. Oper. Res. 1987, 35, 254–265. [Google Scholar] [CrossRef]

- Liu, Z.; Zhou, Y.; Feng, D.; Xu, S.; Yi, Y.; Li, H.; Wang, H. Dynamic Pricing of Electric Vehicle Charging Station Alliances under Information Asymmetry. CSEE J. Power Energy Syst. 2025, 1–12, in press. [Google Scholar] [CrossRef]

- Fan, L. A Two-Stage Hybrid Ant Colony Algorithm for the Multi-Depot Half-Open Time-Dependent Electric Vehicle Routing Problem. Complex Intell. Syst. 2024, 10, 2107–2128. [Google Scholar] [CrossRef]

| Papers | Problem | Charging Stations | Hybrid Mode | Method |

|---|---|---|---|---|

| [37] | SPP | Full only | Considered (nonlinear model) | Labeling + Dynamic Programming |

| [38] | SPP | Full only | Not considered | MILP + Heuristic |

| [39] | SPP | Full only | Considered (original graph) | MILP |

| [4] | SPP | Full only | Not considered | Exact + Approximation |

| [5] | VRP | Full only | Discretized energy levels | MINLP + Heuristic |

| [42] | VRP | Full only | Not considered | Hybrid metaheuristic |

| [40] | TSP | Full only | Considered (optimized per segment) | MINLP reformulated + Branch-and-Cut |

| This paper | VRP | Partial | Considered (continuous and switchable per arc) | Linear Model Dantzig–Wolfe Decomposition |

| Parameters: | |

|---|---|

| The set of origin node (depot) | |

| The set of customer nodes, , totally n customers | |

| The set of destination node (the depot) | |

| The set of charging station node, , totally s available charging stations | |

| Total number of available vehicles | |

| The set of vehicles, | |

| Distances between node i and j | |

| Travel time between node i and j | |

| Maximum travel time for the route | |

| Service time at customer node i | |

| Demand at customer node i | |

| [ , li] | Time window limit for serving the customer i (i I) |

| The remaining battery level for vehicle k that arrival at node i | |

| The remaining battery level for vehicle k that departs node i | |

| The remaining gasoline level for vehicle k that arrival at node i | |

| The consumption rate of battery per distance | |

| The consumption rate of gasoline per distance | |

| Recharging rate | |

| Battery capacity for the vehicle | |

| Gasoline tank capacity for the vehicle | |

| Maximum load of commodity for the vehicle | |

| The cost for vehicles travel time (i.e., salary for drivers) | |

| The cost for charging at charging station | |

| The cost for using a vehicle per day | |

| The cost for using battery per distance | |

| The cost for using gasoline per distance | |

| Decision variable | |

| Binary variable equal to 1 if a vehicle travels from node i to j and 0 otherwise | |

| Departure time for vehicle k at node i | |

| The portion of distance for vehicle k passing through arc (i, j) with the electric mode activated | |

| The proportion of distance for vehicle k passing through arc (i, j) with the fuel mode activated |

| Sets: | |

|---|---|

| Set of all feasible routes for vehicle k; | |

| Set of all feasible routes across all vehicles | |

| Variable | |

| 1 if edge (i,j) is included in route p, 0 otherwise | |

| Total cost of route p | |

| Proportion of electric energy used on edge (i,j) in route p | |

| Proportion of fuel energy used on edge (i,j) in route p | |

| Selection weight (decision variable) for route p | |

| Integer variable indicating whether node i is visited in route p |

| Customer | IMPACT Score | |||||

|---|---|---|---|---|---|---|

| 20 | 5 | 5 | 33 | 3 | 35 | |

| 22 | 7 | 5 | 28 | 2 | 31 | |

| 18 | 6 | 2 | 30 | 4 | 28 |

| Sets: | |

|---|---|

| Reduced cost of path p | |

| Load consumed along path p | |

| Fuel consumed along path p | |

| Arrival time at the current node | |

| Number of nodes unreachable from the current partial path | |

| Binary: 1 if node is unreachable Via path p; 0 otherwise |

| Parameter | Value |

|---|---|

| Battery capacity (Q) | 10.5 kWh |

| Electricity consumption rate ( ) | 0.5 kWh/mile |

| Electricity cost ( ) | USD 0.12/kWh |

| Fuel tank capacity ( ) | 25 gallons |

| Fuel consumption rate ( ) | 17.7 m/g |

| Fuel cost ( ) | USD 4.18/gal |

| Instance | Model | Dantzig–Wolfe Decomposition | Ant Colony Optimization | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Objective | CPU (s) | Objective | CPU (s) | Gap1 (%) | Objective | CPU (s) | Gap2 (%) | Gap3 (%) | |

| C1_15 | 155.30 | 1305.40 | 155.30 | 418.60 | 0 | 155.30 | 1591.30 | 0 | |

| C1_25 | 227.54 | 9162.10 | 234.30 | 1147.30 | 3 | 268.40 | 4383.10 | 18 | 15 |

| R1_15 | 406.12 | 1121.60 | 406.12 | 84.44 | 0 | 415.91 | 2910.80 | 2 | 2 |

| R1_25 | 844.14 | 33,031.75 | 850.10 | 160.20 | 1 | 866.80 | 5715.20 | 3 | 2 |

| R2_15 | 341.80 | 42,463.53 | 344.56 | 258.40 | 1 | 378.13 | 1679.50 | 11 | 10 |

| RC1_25 | 763.75 | 5535.12 | 763.75 | 104.60 | 0 | 834.39 | 4267.10 | 9 | 9 |

| C1_30 | / | / | 335.30 | 3826.80 | / | 413.16 | 5421.16 | / | 23 |

| C2_25 | / | / | 285.48 | 8515.80 | / | 344.87 | 4837.84 | / | 21 |

| C2_30 | / | / | 595.30 | 7568.10 | / | 682.64 | 5849.80 | / | 15 |

| C3_25 | / | / | 500.59 | 15,087.10 | / | 523.79 | 5349.67 | / | 5 |

| C3_30 | / | / | 672.70 | 28,031.75 | / | 758.76 | 6637.16 | / | 13 |

| R1_30 | / | / | 960.17 | 121.10 | / | 1110.58 | 7846.10 | / | 16 |

| R1_50 | / | / | 1617.40 | 303.30 | / | 2223.52 | 12,924.40 | / | 37 |

| R1_100 | / | / | 2177.51 | 2647.80 | / | 3301.90 | 28,678.60 | / | 52 |

| R2_25 | / | / | 761.03 | 457.70 | / | 880.53 | 6555.20 | / | 16 |

| R2_30 | / | / | 819.76 | 1721.06 | / | 901.10 | 8618.30 | / | 10 |

| R2_50 | / | / | 1558.60 | 5082.52 | / | 1876.20 | 13,540.60 | / | 20 |

| RC1_50 | / | / | 1574.27 | 506.96 | / | 1949.10 | 9685.10 | / | 24 |

| R2_100 | / | / | 2298.20 | 37,031.80 | / | 3034.10 | 27,051.32 | / | 32 |

| R1_200 | / | / | 7656.44 | 110,013.16 | / | 15,004.23 | 52,689.7 | / | 95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Chen, Q.; Xue, C.; Chao, Y. PHEV Routing with Hybrid Energy and Partial Charging: Solved via Dantzig–Wolfe Decomposition. Mathematics 2025, 13, 2239. https://doi.org/10.3390/math13142239

Chen Z, Chen Q, Xue C, Chao Y. PHEV Routing with Hybrid Energy and Partial Charging: Solved via Dantzig–Wolfe Decomposition. Mathematics. 2025; 13(14):2239. https://doi.org/10.3390/math13142239

Chicago/Turabian StyleChen, Zhenhua, Qiong Chen, Cheng Xue, and Yiying Chao. 2025. "PHEV Routing with Hybrid Energy and Partial Charging: Solved via Dantzig–Wolfe Decomposition" Mathematics 13, no. 14: 2239. https://doi.org/10.3390/math13142239

APA StyleChen, Z., Chen, Q., Xue, C., & Chao, Y. (2025). PHEV Routing with Hybrid Energy and Partial Charging: Solved via Dantzig–Wolfe Decomposition. Mathematics, 13(14), 2239. https://doi.org/10.3390/math13142239