An Enhanced Extremum Seeking-Based Energy Management Strategy with Equivalent State for Hybridized-Electric Tramway-Powered by Fuel Cell–Battery–Supercapacitors

Abstract

:1. Introduction

1.1. Literature Review

1.2. State-of-the-Art

1.3. Motivations and Contributions

- (1)

- Different from existing works that utilize the ES approach, this work applies a new methodology to facilitate the ES-based control framework to deal with multiple supplements for power distribution by expressing an equivalent component.

- (2)

- A new penalty function is introduced with the PEMFC power and its change rate is included besides the standard former [32,33]. With this objective function, the PEMFC power can be more effectively regulated to operate in the high-efficiency region with smooth response whereas the SOCs of the ESDs are maintained to vary in the suitable intervals.

- (3)

- The comprehensive controlled system with high- and low-level control units is presented with more details of the control structure and compensation regarding each device’s characteristics. The effectiveness of the proposed strategy is then verified through comparative simulations with another real-time optimization and baseline fuzzy-based EMS.

2. System Descriptions

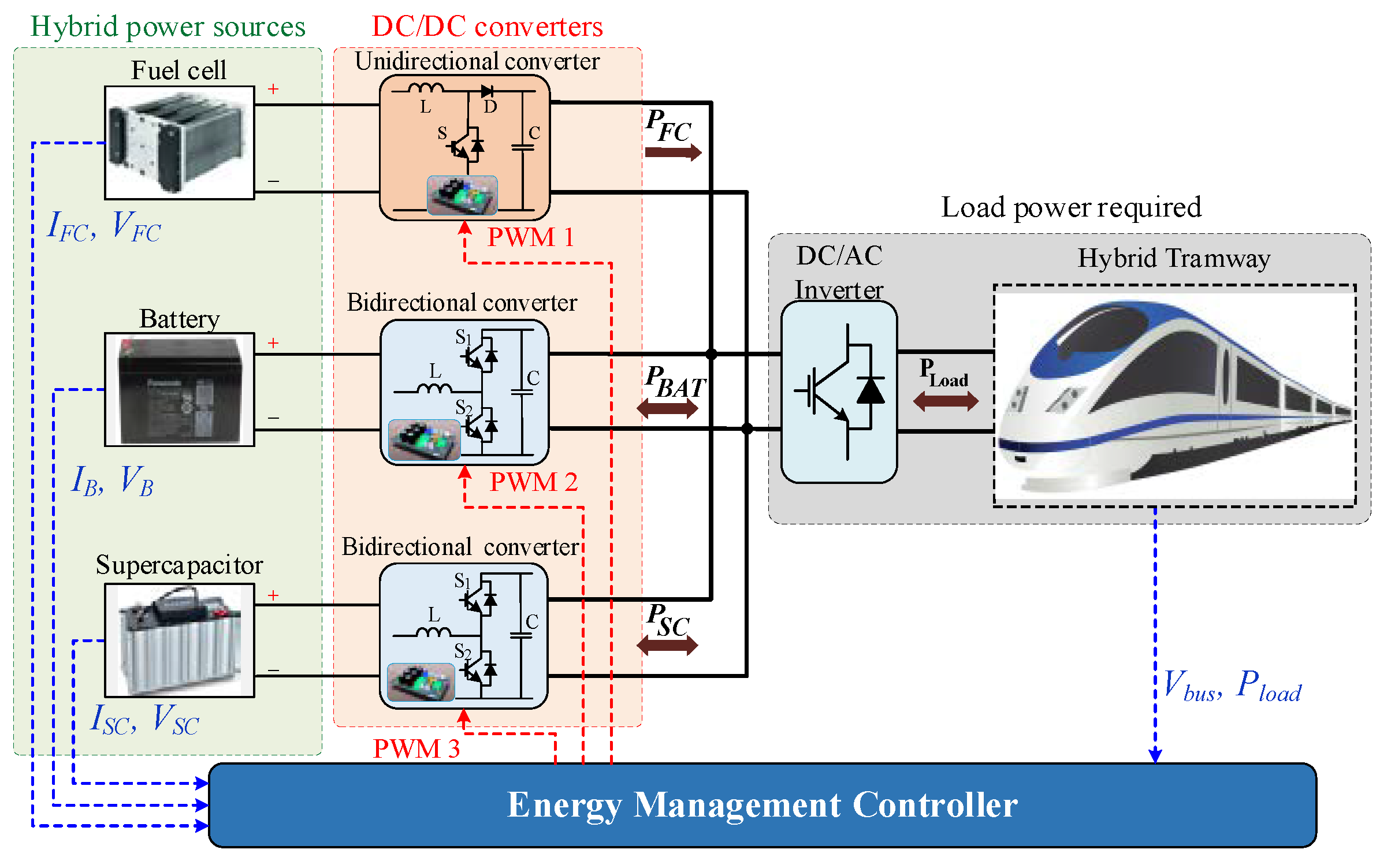

2.1. Power-Train Architecture

2.2. PEMFC Model

2.3. Battery Model

2.4. Supercapacitor Model

2.5. Modeling of DC-DC Converters

3. Proposed ES-Based EMS for the Hybrid Tramway System

3.1. PEMFC Reference Power

3.2. Battery and Supercapacitor Reference Power Split

3.3. Low-Level Control

4. Simulations

4.1. Reasons for Adopting Compared Approaches

4.2. Comparative Control Strategies Implementation

4.2.1. Fuzzy-Based EMS (Method 2)

4.2.2. Equivalent Consumption Minimum Strategy (Method 3)

4.3. Main Results

4.3.1. Case Study 1

4.3.2. Case Study 2

4.4. Discussions and Perspectives

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Peng, F.; Chen, W.; Liu, Z.; Li, Q.; Dai, C. System integration of China’s first proton exchange membrane fuel cell locomotive. Int. J. Hydrogen Energy 2014, 39, 13886–13893. [Google Scholar] [CrossRef]

- Zhang, G.; Li, Q.; Chen, W.; Meng, X. Synthetic Strategy Combining Speed Self-Adjusting Operation Control and Adaptive Power Allocation for Fuel Cell Hybrid Tramway. IEEE Trans. Ind. Electron. 2021, 68, 1454–1465. [Google Scholar] [CrossRef]

- Yan, Y.; Li, Q.; Chen, W.; Huang, W.; Liu, J. Online Control and Power Coordination Method for Multistack Fuel Cells System Based on Optimal Power Allocation. IEEE Trans. Ind. Electron. 2021, 68, 8158–8168. [Google Scholar] [CrossRef]

- Fernandez, L.M.; Garcia, P.; Garcia, C.A.; Torreglosa, J.P.; Jurado, F. Comparison of control schemes for a fuel cell hybrid tramway integrating two dc/dc converters. Int. J. Hydrogen Energy 2010, 35, 5731–5744. [Google Scholar] [CrossRef]

- Fernandez, L.M.; Garcia, P.; Garcia, C.A.; Jurado, F. Hybrid electric system based on fuel cell and battery and integrating a single dc/dc converter for a tramway. Energy Convers. Manag. 2011, 52, 2183–2192. [Google Scholar] [CrossRef]

- Garcia, P.; Fernandez, L.M.; Garcia, C.A.; Jurado, F. Energy Management System of Fuel-Cell-Battery Hybrid Tramway. IEEE Trans. Ind. Electron. 2010, 57, 4013–4023. [Google Scholar] [CrossRef]

- Trovão, J.P.; Pereirinha, P.G.; Jorge, H.M.; Antunes, C.H. A multi-level energy management system for multisource electric vehicles—An integrated rule-based meta-heuristic approach. Appl. Energy 2013, 105, 304–318. [Google Scholar] [CrossRef]

- Caux, S.; Gaoua, Y.; Lopez, P. A combinatorial optimisation approach to energy management strategy for a hybrid fuel cell vehicle. Energy 2017, 133, 219–230. [Google Scholar] [CrossRef]

- Wu, X.; Hu, X.; Yin, X.; Li, L.; Zheng, Z.; Pickert, V. Convex programming energy management and components sizing of a plug-in fuel cell urban logistics vehicle. J. Power Sources 2019, 423, 358–366. [Google Scholar] [CrossRef]

- Wu, Y.; Ravey, A.; Chrenko, D.; Miraoui, A. Demand side energy management of EV charging stations by approximate dynamic programming. Energy Convers. Manag. 2019, 196, 878–890. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Y.; Zhan, J.; Shang, F. Heuristic Dynamic Programming Based Online Energy Management Strategy for Plug-In Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2019, 68, 4479–4493. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Y.; Wang, L.; Chen, Z. Load-adaptive real-time energy management strategy for battery/ultracapacitor hybrid energy storage system using dynamic programming optimization. J. Power Sources 2019, 438, 227024. [Google Scholar] [CrossRef]

- Yi, H.S.; Jeong, J.B.; Cha, S.W.; Zheng, C.H. Optimal component sizing of fuel cell-battery excavator based on workload. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 103–110. [Google Scholar] [CrossRef]

- Yi, H.S.; Cha, S. Optimal Energy Management of the Electric Excavator Using Super Capacitor. Int. J. Precis. Eng. Manuf. Green Technol. 2021, 8, 151–164. [Google Scholar] [CrossRef]

- Yan, Y.; Li, Q.; Chen, W.; Su, B.; Liu, J.; Ma, L. Optimal Energy Management and Control in Multimode Equivalent Energy Consumption of Fuel Cell/Supercapacitor of Hybrid Electric Tram. IEEE Trans. Ind. Electron. 2019, 66, 6065–6076. [Google Scholar] [CrossRef]

- Yan, Y.; Li, Q.; Huang, W.; Chen, W. Operation Optimization and Control Method Based on Optimal Energy and Hydrogen Consumption for the Fuel Cell/Supercapacitor Hybrid Tram. IEEE Trans. Ind. Electron. 2021, 68, 1342–1352. [Google Scholar] [CrossRef]

- Li, Q.; Wang, T.; Li, S.; Chen, W.; Li, H.; Breaz, E.; Gao, F. Online extremum seeking-based optimized energy management strategy for hybrid electric tram considering fuel cell degradation. Appl. Energy 2021, 285, 116505. [Google Scholar] [CrossRef]

- Peng, H.; Li, J.; Thul, A.; Deng, K.; Ünlübayir, C.; Löwenstein, L.; Hameyer, K. A Scalable, Causal, Adaptive Rule-Based Energy Management for Fuel Cell Hybrid Railway Vehicles Learned from Results of Dynamic Programming. eTransportation 2020, 4, 100057. [Google Scholar] [CrossRef]

- Deng, K.; Peng, H.; Dirkes, S.; Gottschalk, J.; Ünlübayir, C.; Thul, A.; Löwenstein, L.; Pischinger, S.; Hameyer, K. An adaptive PMP-based model predictive energy management strategy for fuel cell hybrid railway vehicles. eTransportation 2021, 7, 100094. [Google Scholar] [CrossRef]

- Zhang, G.; Li, H.; Xiao, C.; Jermsittiparsert, K. Optimal size selection for fuel cell and battery in a hybrid power system of the intercity locomotives. J. Clean. Prod. 2021, 317, 128498. [Google Scholar] [CrossRef]

- Dang, T.D.; Do, T.C.; Truong, H.V.A.; Ho, C.M.; Dao, H.V.; Xiao, Y.Y.; Jeong, E.; Ahn, K.K. Design, Modeling and Analysis of a PEM Fuel Cell Excavator with Supercapacitor-Battery Hybrid Power Source. J. Drive Control 2019, 16, 45–53. [Google Scholar] [CrossRef]

- Do, T.C.; Truong, H.V.A.; Dao, H.V.; Ho, C.M.; To, X.D.; Dang, T.D.; Ahn, K.K. Energy Management Strategy of a PEM Fuel Cell Excavator with a Supercapacitor/Battery Hybrid. Energies 2019, 12, 4362. [Google Scholar] [CrossRef]

- Truong, H.V.A.; Dao, H.V.; Do, T.C.; Ho, C.M.; To, X.D.; Dang, T.D.; Ahn, K.K. Mapping Fuzzy Energy Management Strategy for PEM Fuel Cell–Battery–Supercapacitor Hybrid Excavator. Energies 2020, 13, 3387. [Google Scholar] [CrossRef]

- Dao, H.V.; To, X.D.; Truong, H.V.A.; Do, T.C.; Ho, C.M.; Dang, T.D.; Ahn, K.K. Optimization-Based Fuzzy Energy Management Strategy for PEM Fuel Cell/Battery/Supercapacitor Hybrid Construction Excavator. Int. J. Precis. Eng. Manuf. Green Technol. 2021, 8, 1267–1285. [Google Scholar] [CrossRef]

- Li, H.; Ravey, A.; N’Diaye, A.; Djerdir, A. Online adaptive equivalent consumption minimization strategy for fuel cell hybrid electric vehicle considering power sources degradation. Energy Convers. Manag. 2019, 192, 133–149. [Google Scholar] [CrossRef]

- Garcia, P.; Torreglosa, J.P.; Fernández, L.M.; Jurado, F. Viability study of a FC-battery-SC tramway controlled by equivalent consumption minimization strategy. Int. J. Hydrogen Energy 2012, 37, 9368–9382. [Google Scholar] [CrossRef]

- Li, Q.; Chen, W.; Liu, Z.; Li, M.; Ma, L. Development of energy management system based on a power sharing strategy for a fuel cell-battery-supercapacitor hybrid tramway. J. Power Sources 2015, 279, 267–280. [Google Scholar] [CrossRef]

- Peng, F.; Zhao, Y.; Li, Z.; Liu, Z.; Chen, W.; Liu, Y.; Zhou, D. Development of master-slave energy management strategy based on fuzzy logic hysteresis state machine and differential power processing compensation for a PEMFC-LIB-SC hybrid tramway. Appl. Energy 2017, 206, 346–363. [Google Scholar] [CrossRef]

- Trinh, H.A.; Truong, H.V.A.; Ahn, K.K. Development of Fuzzy-Adaptive Control Based Energy Management Strategy for PEM Fuel Cell Hybrid Tramway System. Appl. Sci. 2022, 12, 3880. [Google Scholar] [CrossRef]

- Zhang, W.; Li, J.; Zu, L.; Ouyang, M. Optimization for a fuel cell/battery/capacity tram with equivalent consumption minimization strategy. Energy Convers. Manag. 2017, 134, 59–69. [Google Scholar] [CrossRef]

- Wang, T.; Li, Q.; Yin, L.; Chen, W.; Breaz, E.; Gao, F. Hierarchical Power Allocation Method Based on Online Extremum Seeking Algorithm for Dual-PEMFC/Battery Hybrid Locomotive. IEEE Trans. Veh. Technol. 2021, 70, 5679–5692. [Google Scholar] [CrossRef]

- Zhou, D.; Ravey, A.; Al-Durra, A.; Gao, F. A comparative study of extremum seeking methods applied to online energy management strategy of fuel cell hybrid electric vehicles. Energy Convers. Manag. 2017, 151, 778–790. [Google Scholar] [CrossRef]

- Zhou, D.; Al-Durra, A.; Matraji, I.; Ravey, A.; Gao, F. Online Energy Management Strategy of Fuel Cell Hybrid Electric Vehicles: A Fractional-Order Extremum Seeking Method. IEEE Trans. Ind. Electron. 2018, 65, 6787–6799. [Google Scholar] [CrossRef]

- Khan, M.J.; Iqbal, M.T. Modeling and Analysis of Electro-chemical, Thermal, and Reactant low Dynamics for a PEM Fuel Cell System. Fuel Cells 2005, 5, 463–475. [Google Scholar] [CrossRef]

- Truong, H.V.A.; Trinh, H.A.; Ahn, K.K. Optimization-based Energy Management Strategy for Hybrid Electric Tramways. In Proceedings of the 22nd International Conference on Control, Automation and Systems (ICCAS), Jeju, Republic of Korea, 27 November–1 December 2022; pp. 574–579. [Google Scholar] [CrossRef]

- Xu, L.; Li, J.; Hua, J.; Li, X.; Ouyang, M. Optimal vehicle control strategy of a fuel cell/battery hybrid city bus. Int. J. Hydrogen Energy 2009, 34, 7323–7333. [Google Scholar] [CrossRef]

- Torreglosa, J.P.; Jurado, F.; García, P.; Fernández, L.M. Hybrid fuel cell and battery tramway control based on an equivalent consumption minimization strategy. Control Eng. Pract. 2011, 19, 1182–1194. [Google Scholar] [CrossRef]

- Hong, Z.; Li, Q.; Han, Y.; Shang, W.; Zhu, Y.; Chen, W. An energy management strategy based on dynamic power factor for fuel cell/battery hybrid locomotive. Int. J. Hydrogen Energy 2018, 43, 3261–3272. [Google Scholar] [CrossRef]

- Iris, C.; Jasmine, S.L.L. Optimal energy management and operations planning in seaports with smart grid while harnessing renewable energy under uncertainty. Omega 2021, 103, 102245. [Google Scholar] [CrossRef]

| Rule-Based EMS | Optimization-Based EMS | ||

|---|---|---|---|

| Global | Real-Time | ||

| Category | Online calculation | Offline calculation | Online calculation |

| Merits | Real-time applications | Can achieve a globally optimal solution | Real-time applications |

| Demerits | Cannot exhibit an optimal solution | Require information driving cycles and system dynamics (burden calculation) Not real-time applications | Become trapped in local optima Limited only in two sources |

| gB | gr-load | |||||

|---|---|---|---|---|---|---|

| NB | NM | Z | PM | PB | ||

| VL | NB | NB | NM | NS | Z | |

| L | NB | NM | NS | Z | PS | |

| SOCB | M | NM | NS | Z | PS | PM |

| H | NS | Z | PS | PM | PB | |

| VH | Z | PS | PM | PB | PB | |

| Condition 1 | Condition 2 | Output |

|---|---|---|

| If Pscaled ≤ 0 | – | αFC,ref is min |

| If Pscaled is PL | SOCB is VL, SOCB is L or M, SOCB is H or VH, | αFC,ref is Opt. αFC,ref is Opt.L αFC,ref is min |

| If Pscaled is PM | SOCB is VL, SOCB is L or M, SOCB is H or VH, | αFC,ref is Opt.H αFC,ref is Opt. αFC,ref is Opt.L |

| If Pscaled is PH | SOCB is VL, SOCB is L or M, SOCB is H or VH, | αFC,ref is Max αFC,ref is Opt.H αFC,ref is Opt. |

| Parameters | Value | Unit |

|---|---|---|

| Cells number | 762 | |

| Rated power | 200 | kW |

| Maximum voltage | 550 | V |

| Maximum current | 300 | A |

| Nominal air flowrate | 3653 | lpm |

| Nominal hydrogen supply pressure | 2.25 | bar |

| Nominal air supply pressure | 2.06 | bar |

| Maximum operating temperature | 57 | °C |

| Parameters | Value | Unit |

|---|---|---|

| Nominal voltage | 450 | V |

| Rated capacity | 68 | Ah |

| Initial SOC | 50 | % |

| Battery response time | 0.1 | s |

| Maximum discharge current | 180 | A |

| Internal resistance | 0.066 | Ohm |

| Parameters | Value | Unit |

|---|---|---|

| Rated voltage | 625 | V |

| Rated capacitance | 12.6 | F |

| Initial SOC | 50 | % |

| Equivalent DC series resistance | 0.003 | Ohm |

| Operating temperature | 25 | °C |

| Number of series capacitors | 5 | - |

| Number of parallel capacitors | 1 | - |

| Parameters | FEMS | ECMS | Proposed |

|---|---|---|---|

| Average efficiency (%) | 45.94 | 46.72 | 46.7 |

| Maximum PFC (kW) | 130.1558 | 51.45 | 54.25 |

| Maximum PFC change rate (kW) | 0.2155 | 0.0125 | 0.0205 |

| SOCini-final (battery) | −0.0034 | 1.3 × 10−4 | 5 × 10−5 |

| SOCini-final (SC) | −0.03 | 0.0002 | 3.5 × 10−5 |

| Hydrogen consumption (kg) | 0.267 | 0.235 | 0.236 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Truong, H.V.A.; Trinh, H.A.; Do, T.C.; Nguyen, M.H.; Phan, V.D.; Ahn, K.K. An Enhanced Extremum Seeking-Based Energy Management Strategy with Equivalent State for Hybridized-Electric Tramway-Powered by Fuel Cell–Battery–Supercapacitors. Mathematics 2024, 12, 1849. https://doi.org/10.3390/math12121849

Truong HVA, Trinh HA, Do TC, Nguyen MH, Phan VD, Ahn KK. An Enhanced Extremum Seeking-Based Energy Management Strategy with Equivalent State for Hybridized-Electric Tramway-Powered by Fuel Cell–Battery–Supercapacitors. Mathematics. 2024; 12(12):1849. https://doi.org/10.3390/math12121849

Chicago/Turabian StyleTruong, Hoai Vu Anh, Hoai An Trinh, Tri Cuong Do, Manh Hung Nguyen, Van Du Phan, and Kyoung Kwan Ahn. 2024. "An Enhanced Extremum Seeking-Based Energy Management Strategy with Equivalent State for Hybridized-Electric Tramway-Powered by Fuel Cell–Battery–Supercapacitors" Mathematics 12, no. 12: 1849. https://doi.org/10.3390/math12121849

APA StyleTruong, H. V. A., Trinh, H. A., Do, T. C., Nguyen, M. H., Phan, V. D., & Ahn, K. K. (2024). An Enhanced Extremum Seeking-Based Energy Management Strategy with Equivalent State for Hybridized-Electric Tramway-Powered by Fuel Cell–Battery–Supercapacitors. Mathematics, 12(12), 1849. https://doi.org/10.3390/math12121849