1. Introduction

Partial differential equations (PDEs) are essential in engineering applications, as most natural and complex systems are governed by physical phenomena that can be described by PDEs [

1,

2,

3]. However, finding solutions to most PDEs poses a significant challenge and often requires complex numerical techniques. Currently, the finite element method (FEM) [

1,

4], the finite difference method (FDM) [

5], and the material point method (MPM) [

6] are the primary numerical methods used for solving PDEs. Discretization is often necessary when solving complex PDEs by using numerical methods, such as FEM, FDM, and MPM. The computational efficiency and accuracy of a model are closely linked to the mesh density and computational step size.

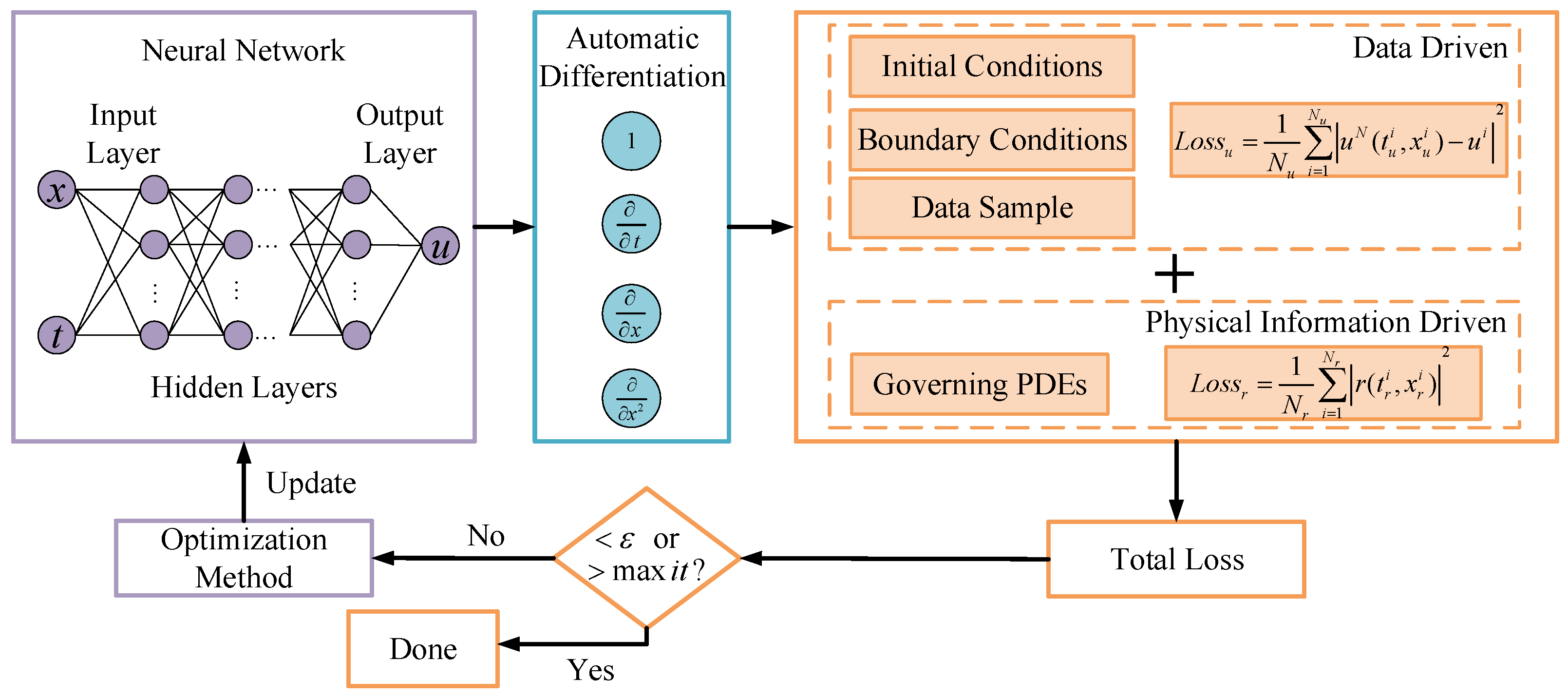

Physics-informed deep learning, which has emerged in recent years, is based on novel ideas for solving PDE problems [

7]. An example of this is physics-informed neural networks (PINNs), which are typical representatives that utilize automatic differentiation to incorporate PDEs into the loss function of the neural network. This approach can solve various types of PDEs accurately, and the computational accuracy remains unaffected by variations in computational step size [

8,

9,

10]. As a result, compared to traditional numerical methods, the solving process and results for high-dimensional PDE problems are no longer restricted. In addition, the PINN framework can tackle the inverse problems associated with PDEs by inferring the unknown coefficient and/or source terms of the governing equations from measured data [

8]. PINNs are a class of neural networks designed for solving supervised learning tasks that are required to satisfy not only the constraints of the training samples but also the physical information constraints of the PDEs [

7,

11]. Compared to purely data-driven neural networks, PINNs incorporate physical information constraints into the training process. Hence, the utilization of fewer data samples to learn more generalized models is possible [

7,

12]. In recent years, PINN has become an increasingly popular research topic at the intersection of machine learning and computational mathematics and has made significant progress in both theory and applications [

7,

8,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22].

For example, Raissi et al. [

8] employed PINN to accurately solve the Schrödinger and Allen–Cahn equations, as well as to perform parameter inversions of the Navier–Stokes and Korteweg–de Vries equations. Ehsan Haghighat et al. [

13] developed SciANN, an artificial neural network framework based on Python, to solve both the forward and inverse problems of PDEs using the PINN approach. Lu et al. [

14] introduced the residual-based adaptive refinement (RAR) method and the construction geometry method to enhance the training efficacy of the PINN in complex computational domains. They also created a Python toolkit called DeepXDE, based on TensorFlow. DeepXDE has the capability to solve both forward problems, based on initial and boundary conditions, and inverse problems, taking into account additional measurements [

14]. Jagtap et al. [

15] proposed a scalable hyperparameter for the activation function of the PINN to enhance its efficiency. This hyperparameter optimizes the network’s performance by dynamically adjusting the loss function involved in the optimization process.

Researchers are increasingly focusing on combining traditional numerical methods with deep learning techniques to solve PDEs. For instance, Milan et al. [

23] proposed a hybrid approach that combines finite-volume-based CFD simulations with neural networks to accelerate the simulation of high-pressure fluid flow in propulsion applications while reducing the memory footprint. Kochkov et al. [

24] recently proposed an end-to-end deep learning approach to improve computational fluid dynamics for turbulence and large eddy simulations. The proposed method offers a remarkable acceleration factor of 40 to 80 while maintaining some stability over long simulations [

24]. Zhang et al. [

25] introduced HiDeNN-FEM, a hierarchical deep neural network representing the FEM, which has demonstrated its potential in solving multidimensional higher-order continuity and topology optimization problems. Moreover, Mitusch et al. [

26] proposed a hybrid FEM-NN model that shows good convergence for multiple types of PDEs. Moreover, Uriarte et al. [

27] proposed a deep learning approach for solving linear parametric PDEs using FEM, which utilizes a neural network architecture to simulate the finite element refinement mesh, thereby improving the interpretability and accuracy of numerical integration in deep learning.

Although many researchers have successfully combined traditional numerical methods with deep learning to solve difficult problems, the implementation of these approaches is complicated, and it is challenging to solve both forward and inverse problems simultaneously. PINN offers a novel approach to solving PDEs, and its ability to handle coupled physical laws demonstrates its potential as a surrogate model [

8]. PINN can serve as an integrated method for both training and identification purposes. During PDE solving, unknown parameters in the equation can be identified directly based on additional information. When solving forward problems, PINN only requires information about the control equations, initial conditions, and boundary conditions, and does not rely on any data. However, its computational accuracy is lower than traditional numerical computation methods [

12]. Moreover, PINN can solve inverse problems using partial data samples, which may include real field data, exact solutions to the problem, or high-fidelity synthetic data [

28]. In practical engineering problems, exact solutions are seldom attainable, and acquiring enough real field data can be arduous. Therefore, numerical calculation methods are generally utilized to synthesize the dataset required for training.

The smoothed finite element method (S-FEM), which combines the FEM with the strain smoothing technique, is a new numerical method introduced by Liu G. R. et al. [

29] in recent years. By employing strain smoothing techniques, the S-FEM eliminates the need for coordinate mapping and Jacobian transformations, which helps to prevent computational errors and inaccuracies caused by mesh distortions in complex models [

29]. Moreover, the low-order S-FEM can achieve the same level of computational accuracy as the high-order FEM while simultaneously reducing computational complexity and costs for obtaining high-fidelity numerical solutions. S-FEM represents a numerical technique that integrates the benefits of FEM and meshless methods. In the context of inverse problems, these methods demonstrate similarities to FEM and are frequently augmented with optimization algorithms [

30,

31,

32]. The present research is mainly directed toward solving inverse problems related to geometric heat conduction through the integration of the smooth gradient concept of the S-FEM with the fixed grid FEM [

33,

34].

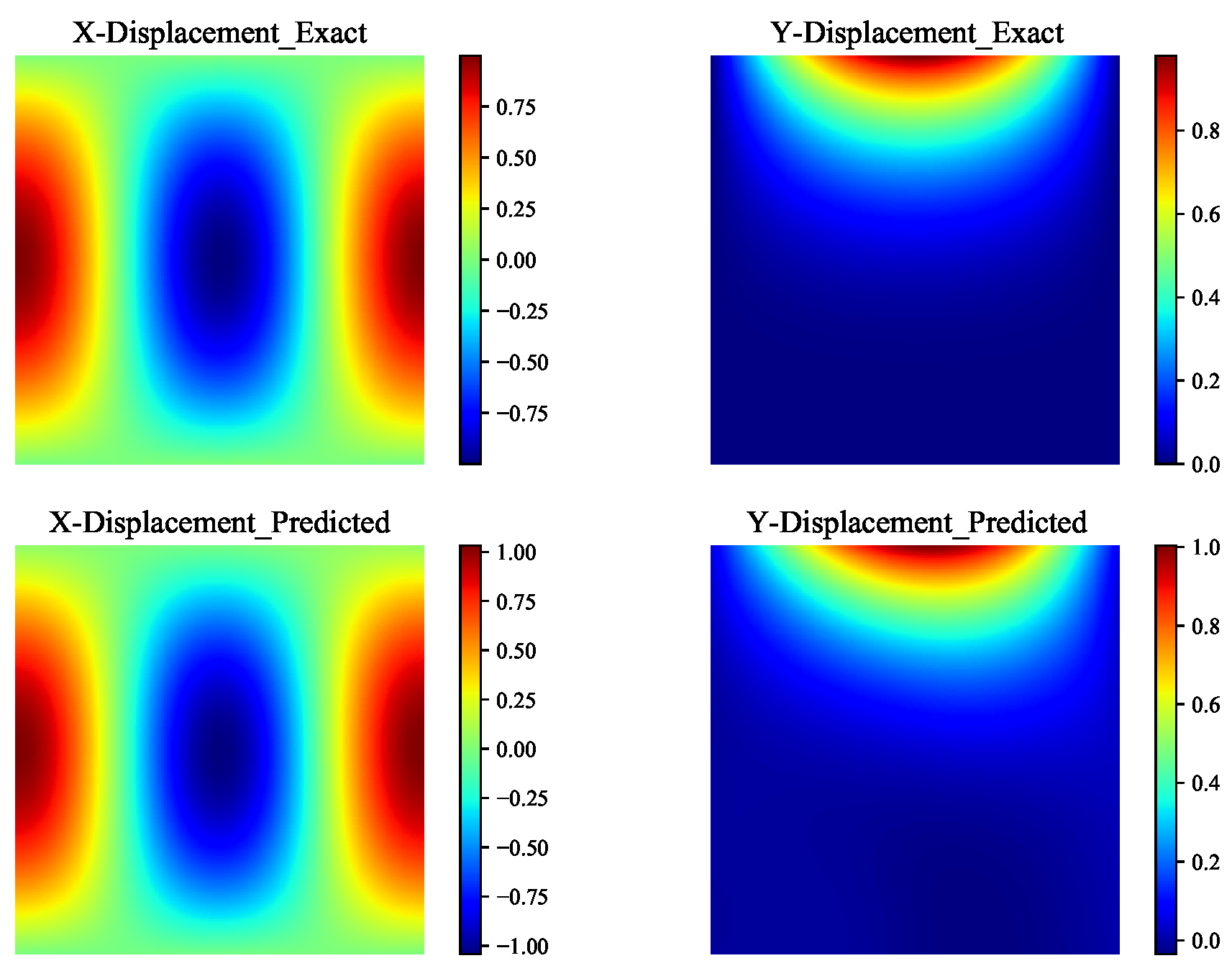

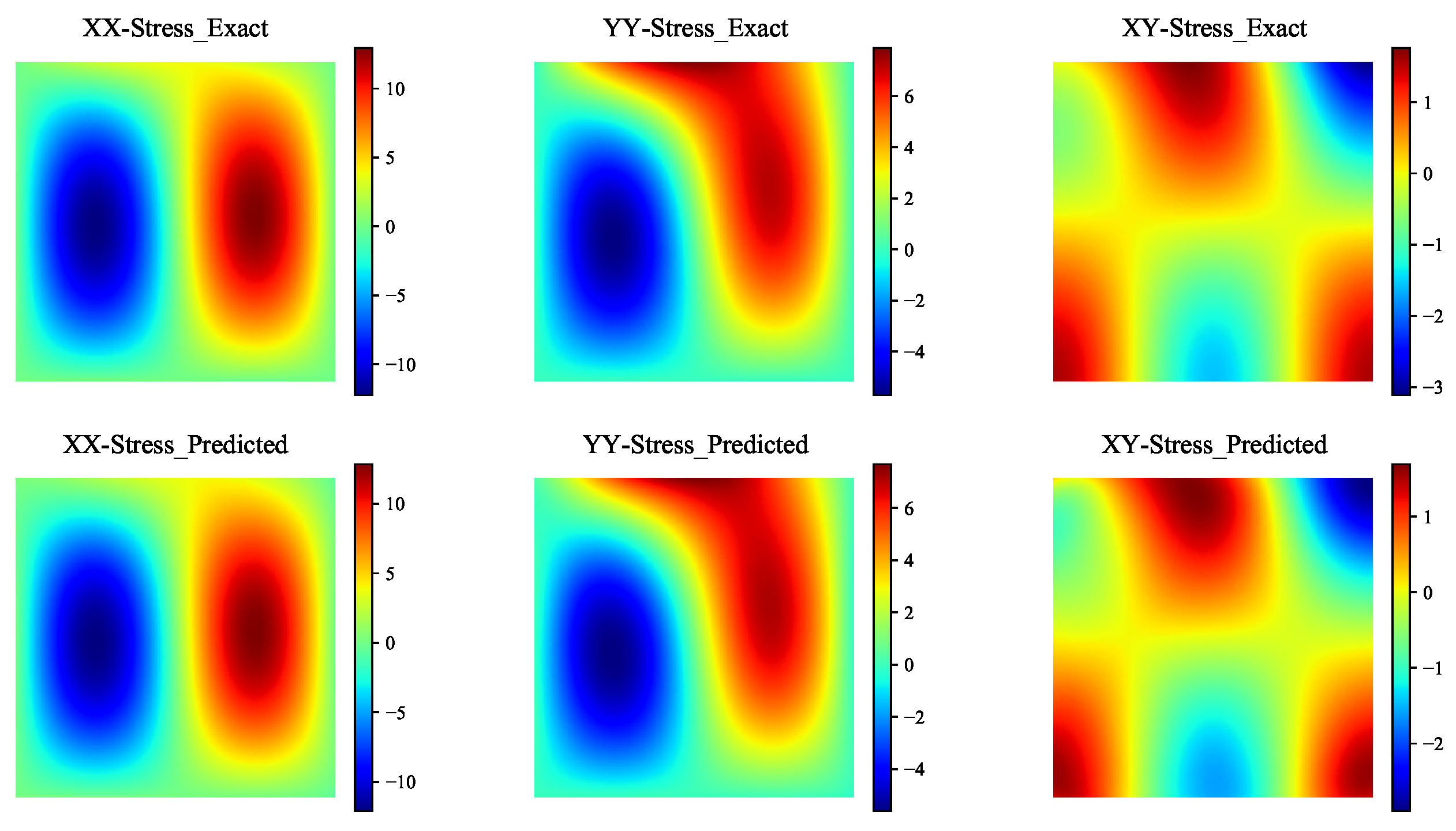

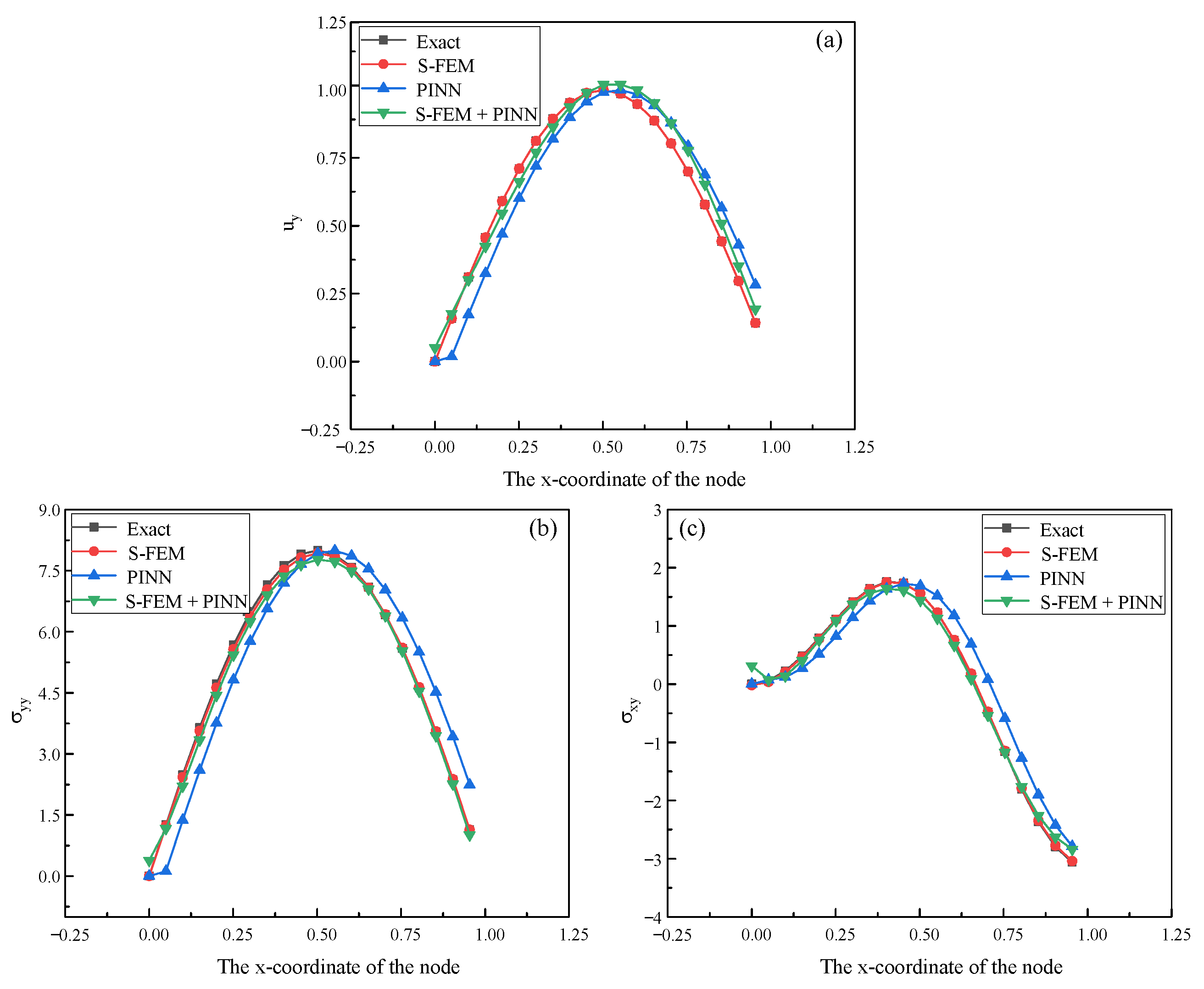

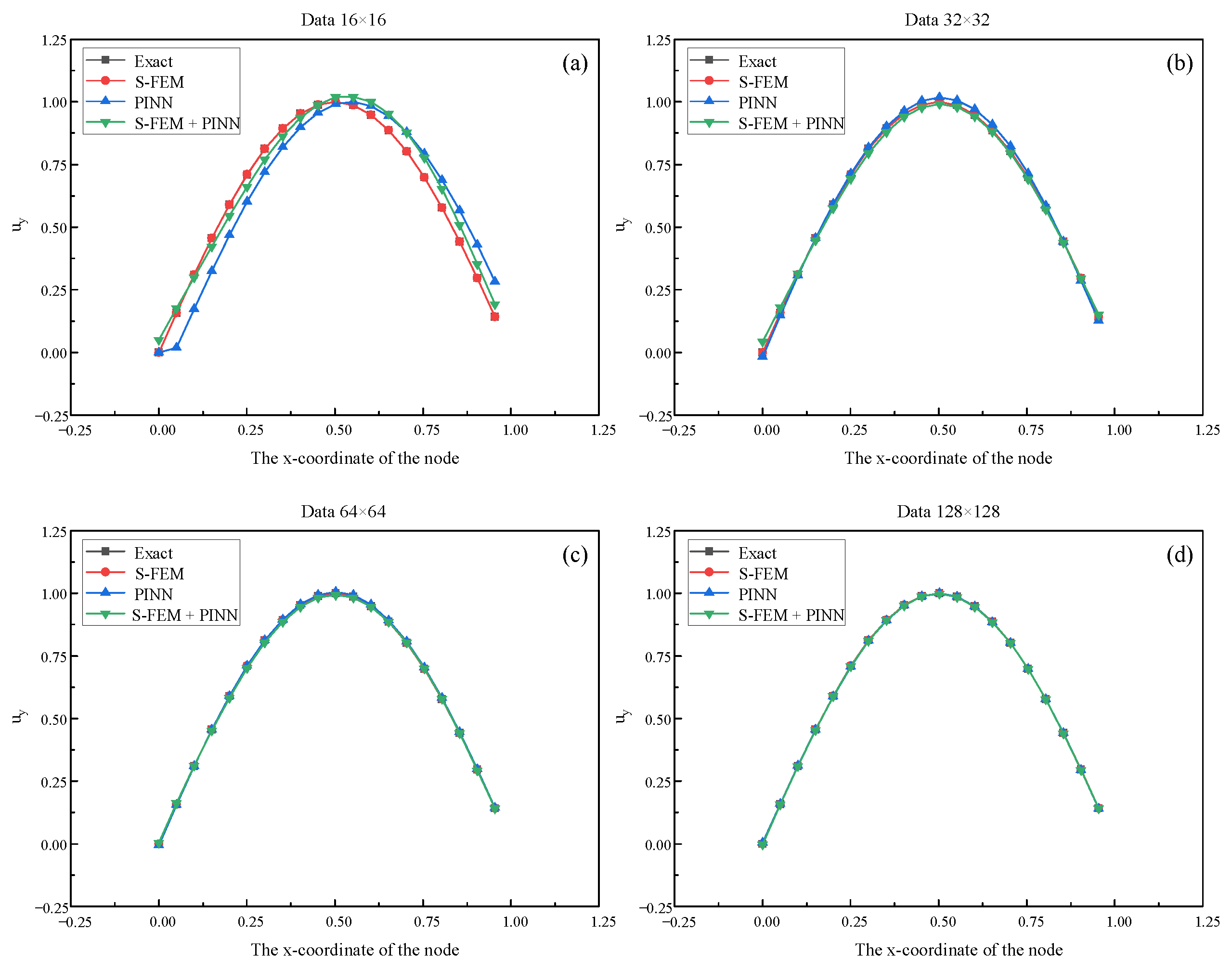

To enhance the computational accuracy of the PINN and overcome the limitation of the S-FEM for solving inverse problems [

33,

34], we propose a novel method that couples S-FEM with the PINN to solve the forward and inverse problems of PDEs. The S-FEM is employed to create a high-precision dataset that is necessary for the PINN inversion process. Initially, the material parameter combinations to be inverted are determined, followed by selecting multiple sets of material parameter combinations as inputs for the smoothed finite element simulation, within the limits of reasonable values of these parameters. The displacement–stress data are then calculated using the S-FEM. The displacement and stress data are subsequently incorporated into the loss function component of the PINN as data constraints that operate in conjunction with physical constraints to invert the unknown material parameters. The primary benefit of the pure PINN in resolving forward problems of PDE is its freedom from data dependence, which permits its solution via the control equations, and initial and boundary conditions. However, its precision is comparatively lower than that of more established numerical computational techniques [

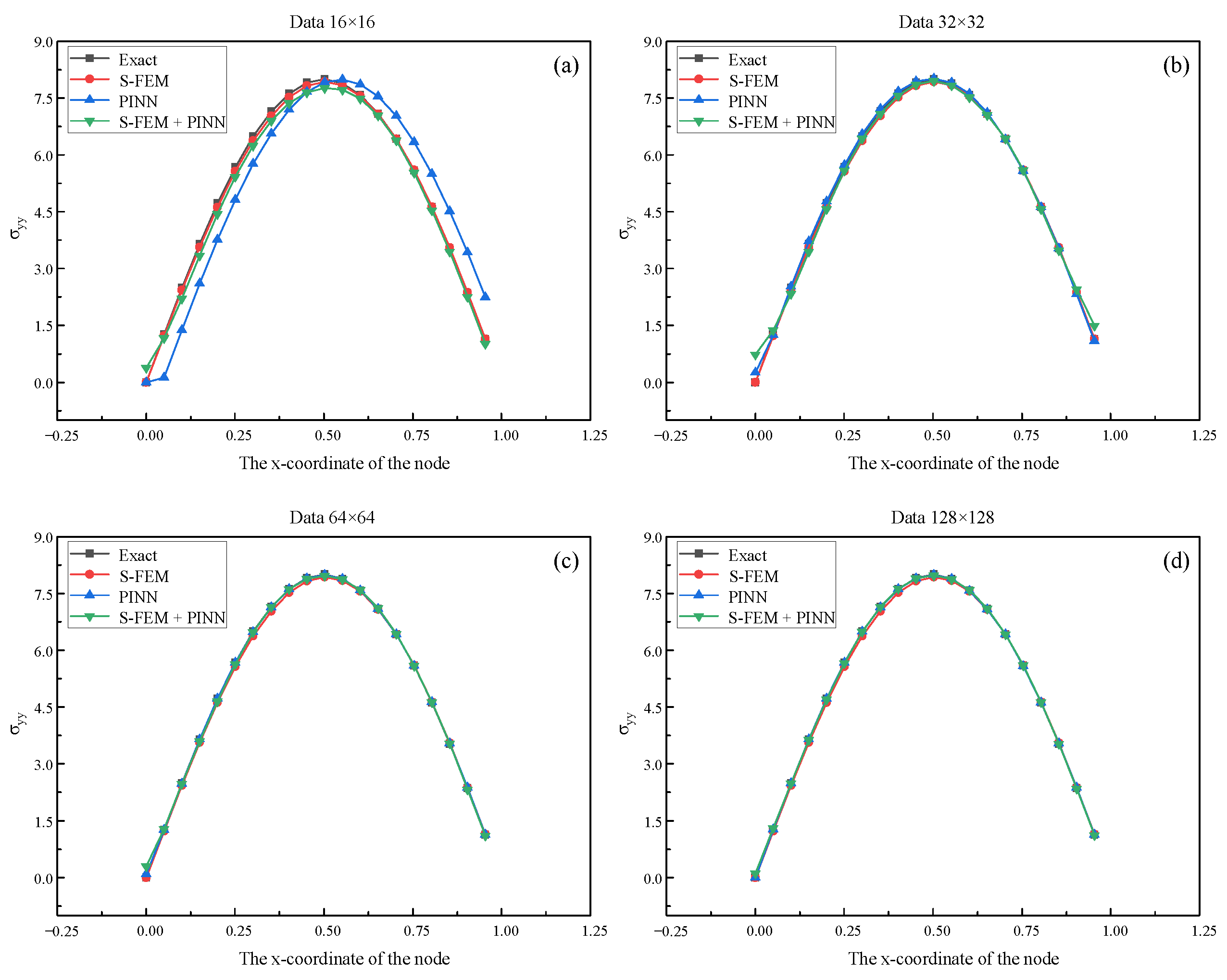

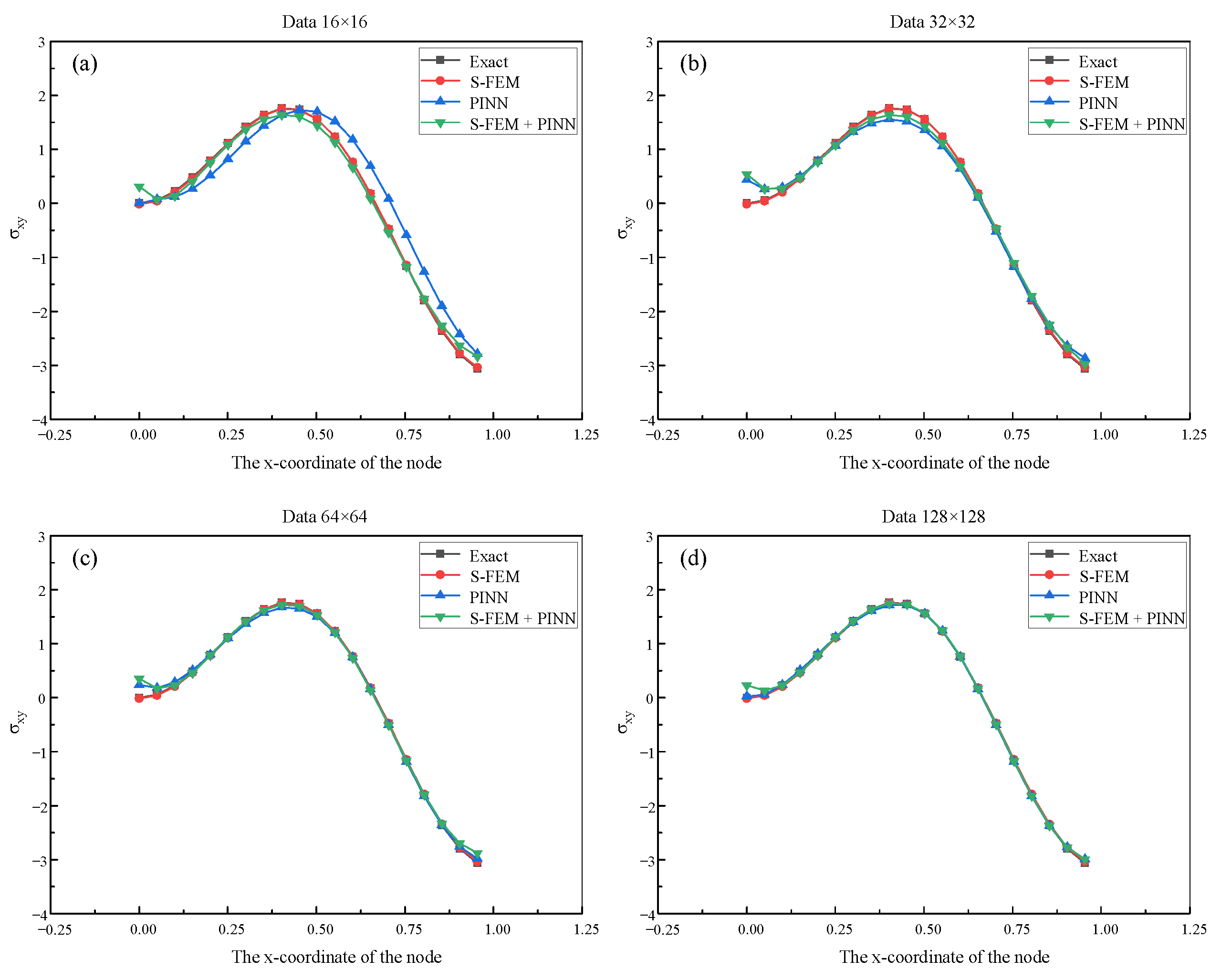

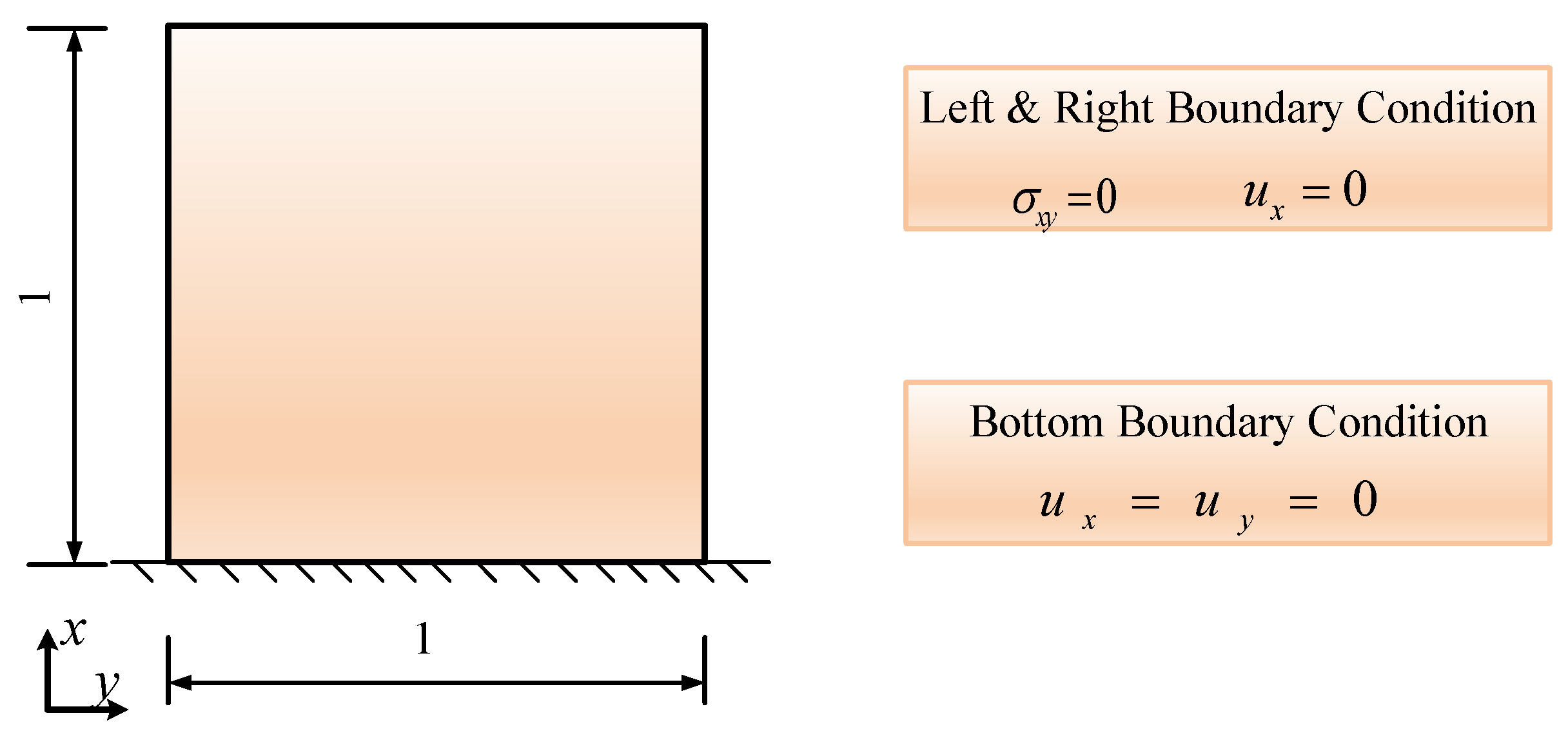

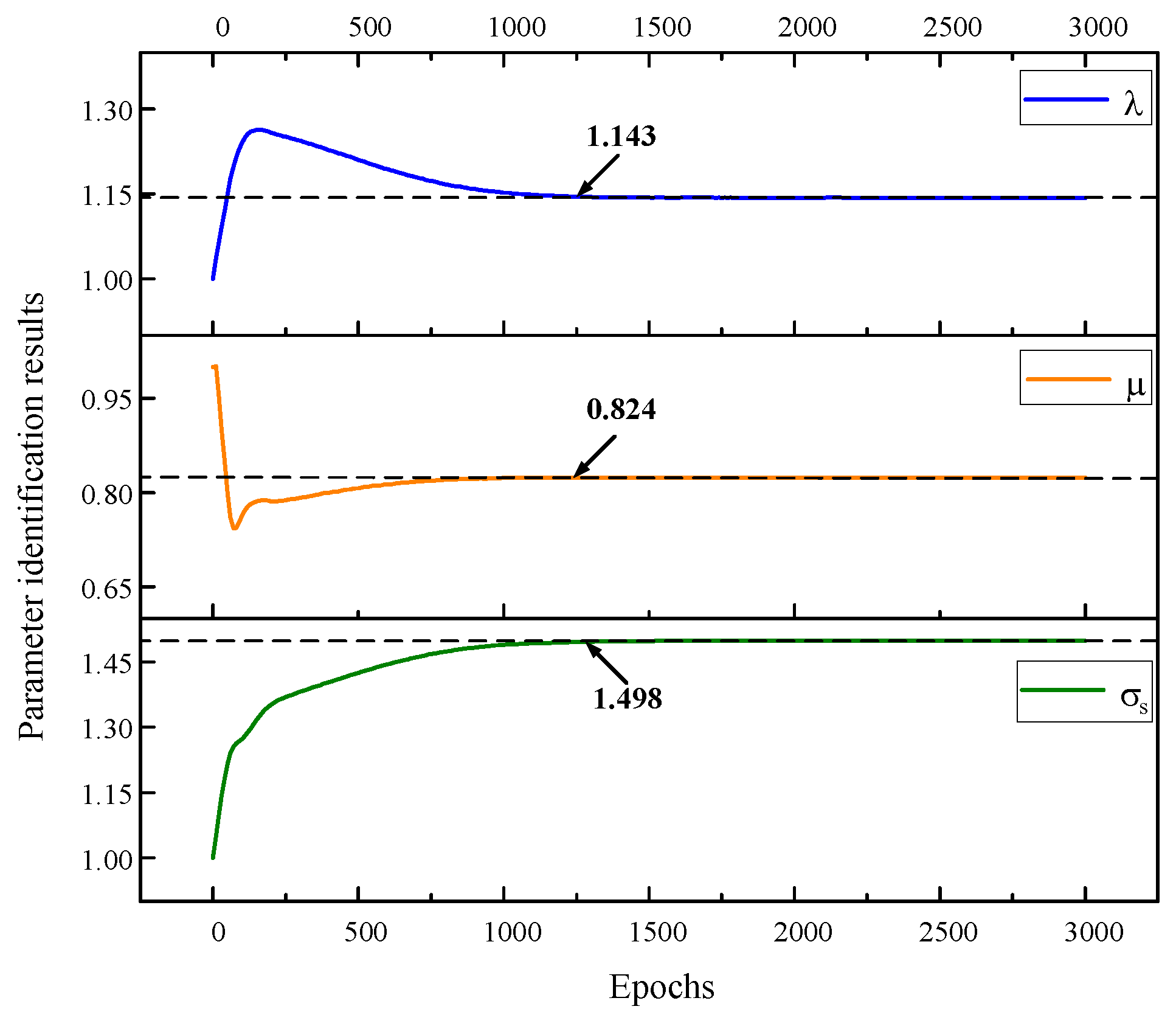

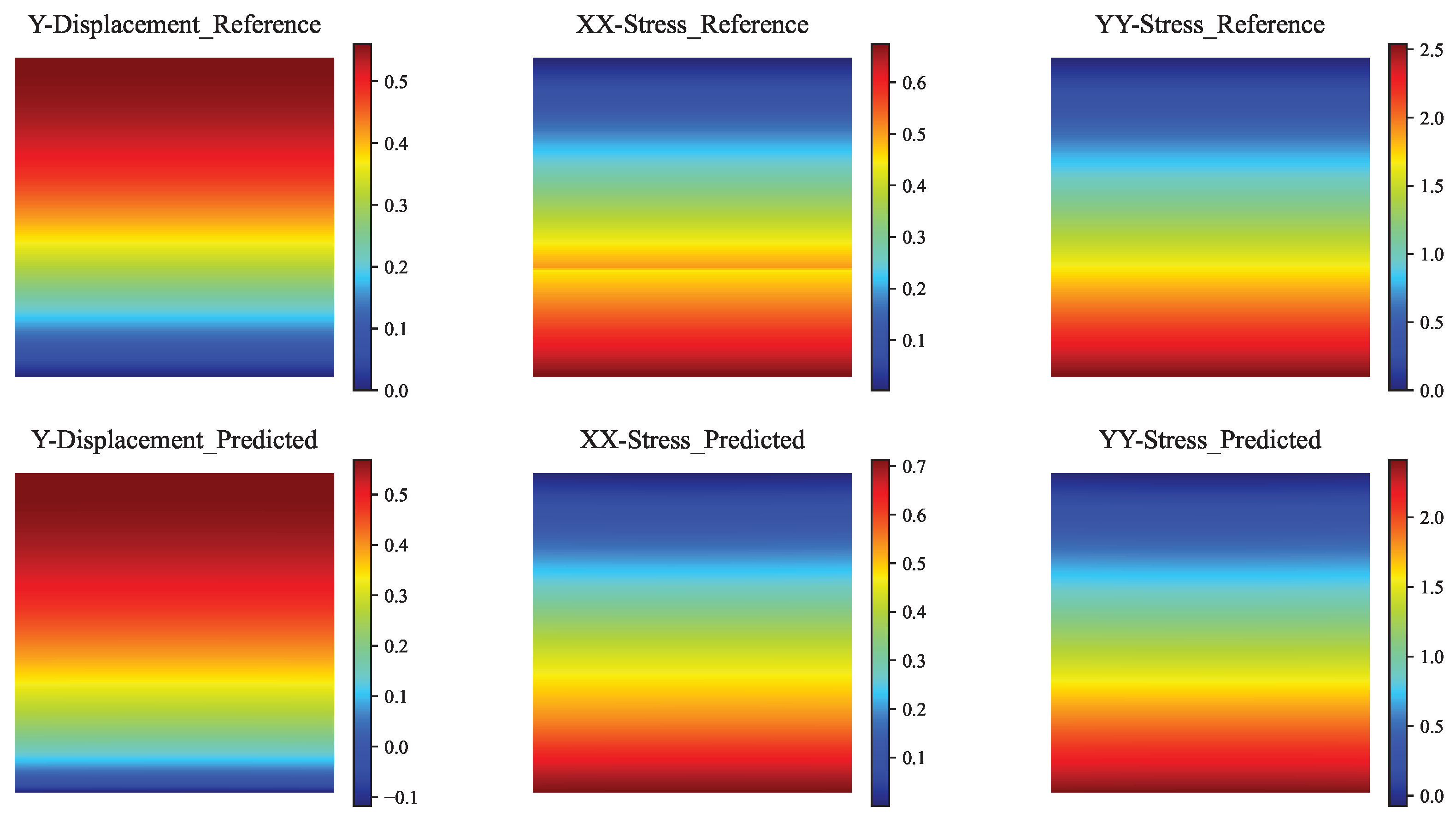

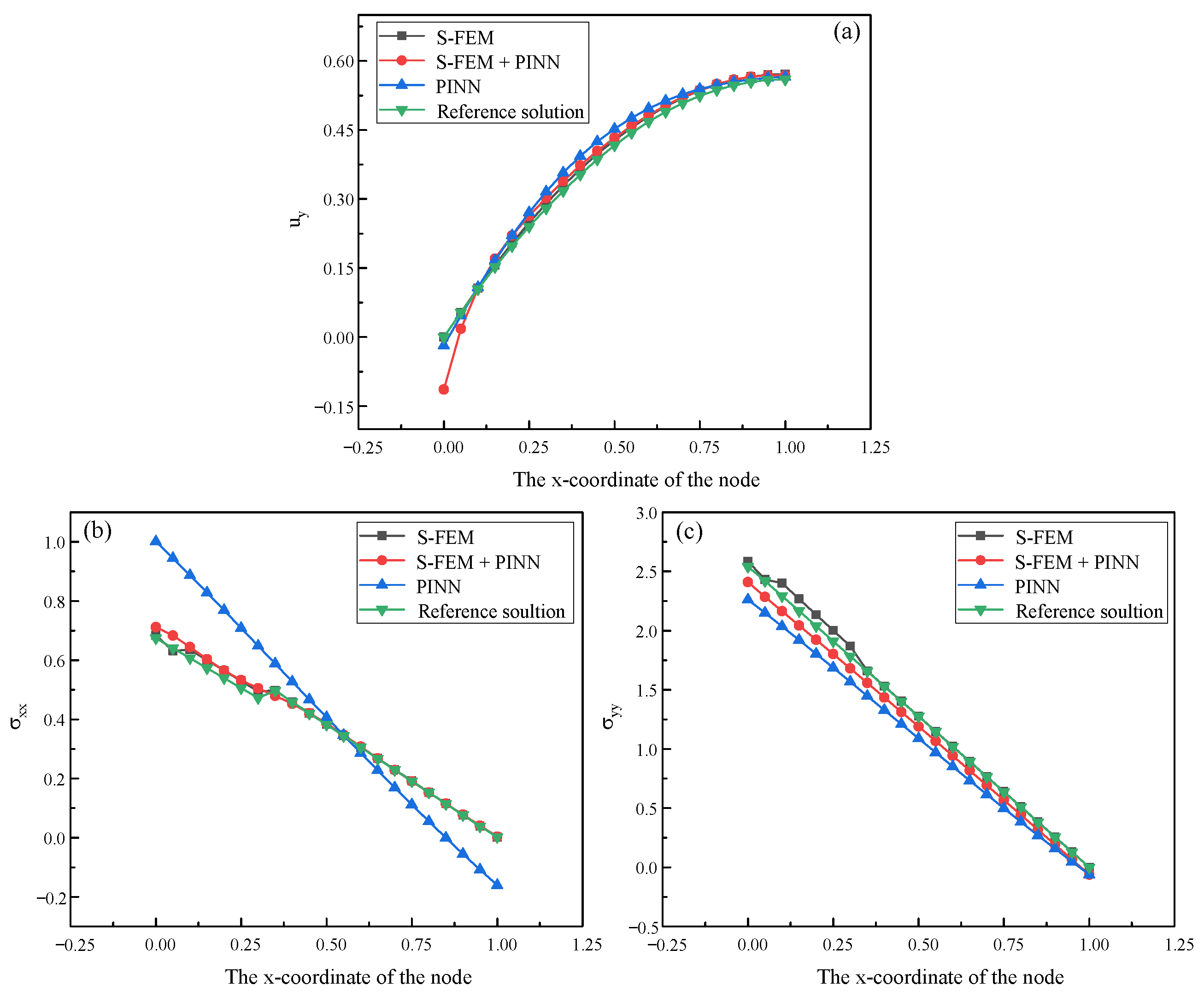

12]. Consequently, a high-precision dataset created through S-FEM is incorporated into the loss function component of the PINN that solves PDEs without data dependence. The integration of data-driven and physics-informed coordination improves the accuracy of the PINN without data dependence. To verify the computational accuracy of the S-FEM-coupled PINN, we solve the linear elastic and elastoplastic forward and inverse problems using this coupling method. The results of this solution will be used to compare the accuracy with that of pure S-FEM and PINN for solving the same problem.

The rest of this paper is organized as follows.

Section 2 provides an overview of physics-informed deep learning and the S-FEM.

Section 3 introduces the three equations of linear elastic problems, the constitutive relations of elastoplastic problems, and the implementation of the S-FEM-coupled PINN.

Section 4 analyzes the accuracy of the S-FEM-coupled PINN in comparison with S-FEM and PINN in solving linear elastic and elastoplastic problems through examples.

Section 5 presents a discussion on the benefits and limitations of coupling S-FEM with the PINN, along with the potential directions for future research. Finally,

Section 6 summarizes the contents of this paper.

3. Materials and Methods

In this section, we introduce the three equations of linear elastic problems, the constitutive relations of elastoplastic problems, and the implementation of the S-FEM-coupled PINN.

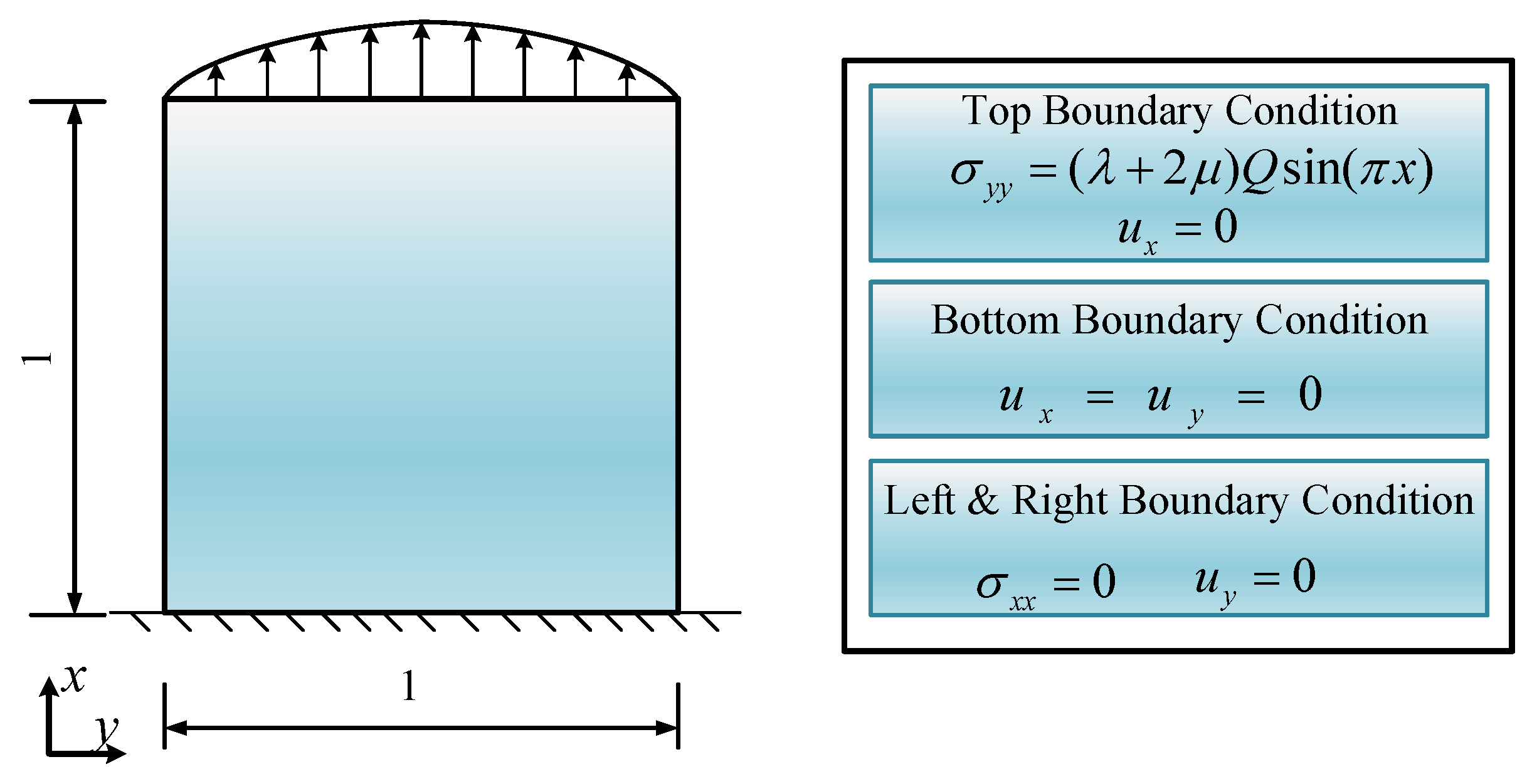

3.1. Linear Elasticity

To describe linear elastic problems, three primary equations are used: (1) the equilibrium differential equation, which represents the momentum balance relationship; (2) the physical equation, which represents the constitutive relationship; and (3) the strain compatibility equation, which represents the kinematic relationship. These equations are shown below:

where

is the stress tensor. For two-dimensional problems, here,

. The function

represents the volume force,

is the displacement,

is the strain tensor, and

is the Kronecker symbol. The summation convention is used here [

50], with subscript commas indicating partial derivatives. The forward problem of linear elastic PDEs is to solve its displacement field, stress field, and strain field, and the inverse problem is to solve the material parameters

and

.

3.2. Elastoplasticity

The appropriate selection and use of the constitutive relation is crucial in correctly solving elastoplastic problems. In this paper, the von Mises yield criterion is utilized to determine whether the material has entered the plastic stage. The power-hardening stress–strain relationship represents the constitutive relationship of the material, and the total strain theory is adopted to solve elastoplastic problems.

The von Mises yield criterion:

where

is the equivalent stress calculated according to Equation (

7),

is the yield stress of the material, and the material enters the plastic phase when

.

To make the power-hardening stress–strain curve satisfy the Hooke law when

, the following stress–strain relationship is adopted:

where

E is the Young’s modulus,

m is the power-hardening index, and

is the equivalent strain corresponding to the yield stress

of the material. To ensure that

and

are continuous at

, the values of

and

B are taken as follows:

The complete expression of the total strain theory can be found in Equations (

11)–(

13).

In Equation (

11),

is the deflection strain tensor,

is the deflection stress tensor,

is the equivalent strain, and

is the equivalent stress. Equation (

12) is calculated in this paper using the power-hardening form of Equation (

8). In Equation (

13),

is the mean stress,

is the mean strain, and

K is the bulk modulus.

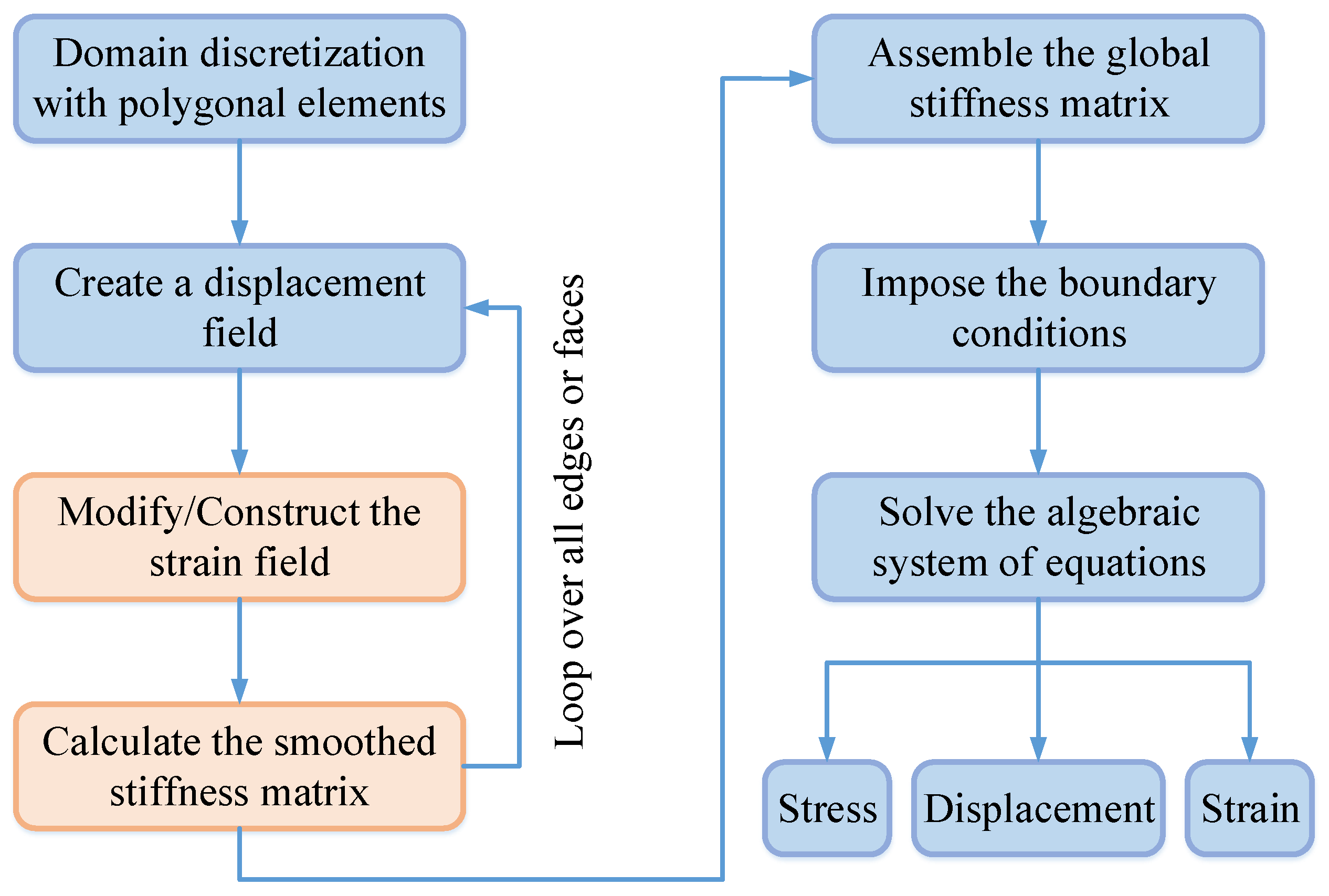

3.3. Workflow of the S-Fem

In a solid mechanics problem, the problem domain is denoted by

, and the boundary is denoted by

. The essential boundary is represented by

, while the natural boundary is represented by

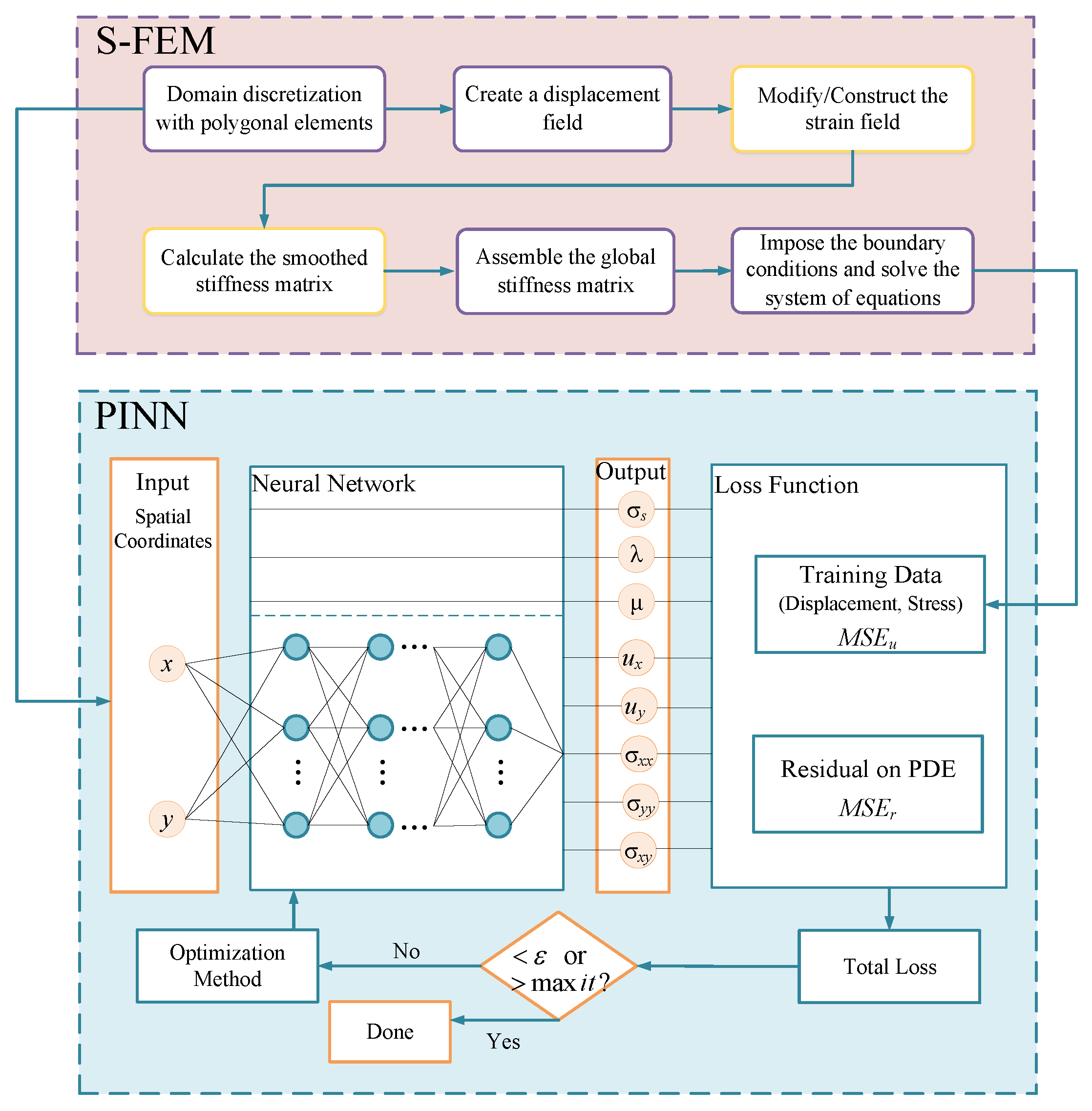

. The workflow of the S-FEM is illustrated in

Figure 2 and the detailed procedures and operations are as follows [

29,

36,

49]:

(1) The discretization of the problem domain. The S-FEM can use arbitrary polygonal elements to discretize the problem domain. Generally, triangular or quadrilateral elements are used to discretize two-dimensional domains, while tetrahedral or hexahedral elements are employed for three-dimensional domains.

(2) Construction of shape functions to create displacement fields.

(3) Construction of a strain smoothing field. The strain smoothing technique can be used directly on the smoothing domain to construct a strain smoothing field using the shape function values for any type of cell. This procedure requires only a line or area partition directly on the boundary of the smoothing domain, without coordinate mapping. This characteristic is also the reason why the S-FEM is insensitive to mesh distortions.

(4) Establishment of a discrete linear algebraic system of equations. The assumed displacement field and the strain smoothing field are used to establish a discrete linear algebraic system of equations through the smoothing Galerkin method. In the S-FEM, this process only involves simple summation operations for the relevant parameters of the smoothing domain.

(5) Imposition of boundary conditions and system equation solutions to obtain displacement solutions.

(6) Reconstruction of the strain field using the obtained displacement solution. The stress of the equivalent node is obtained in the smoothing domain using the weighted average method, and the continuous stress field in the problem domain is then obtained using the shape function interpolation method.

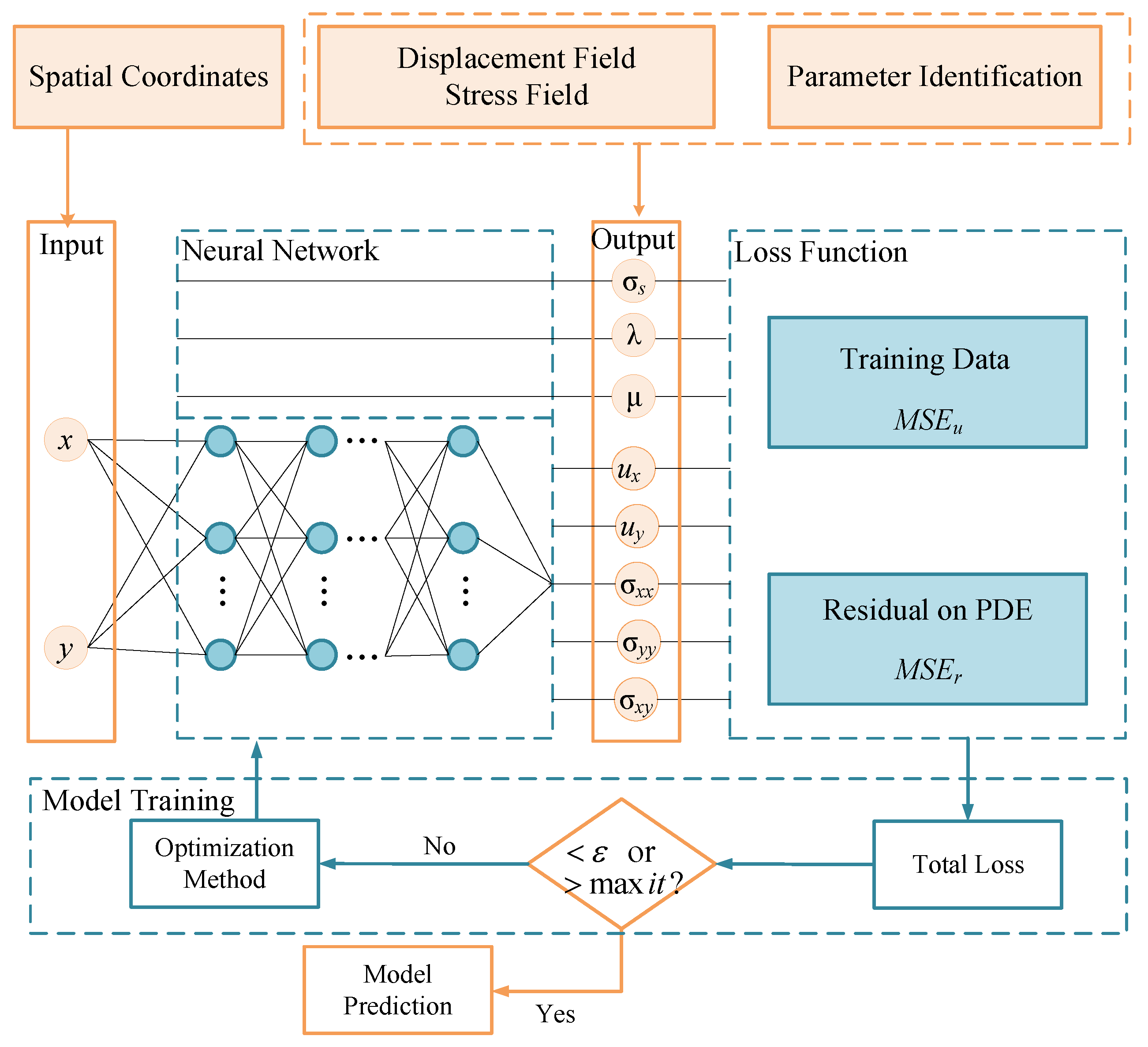

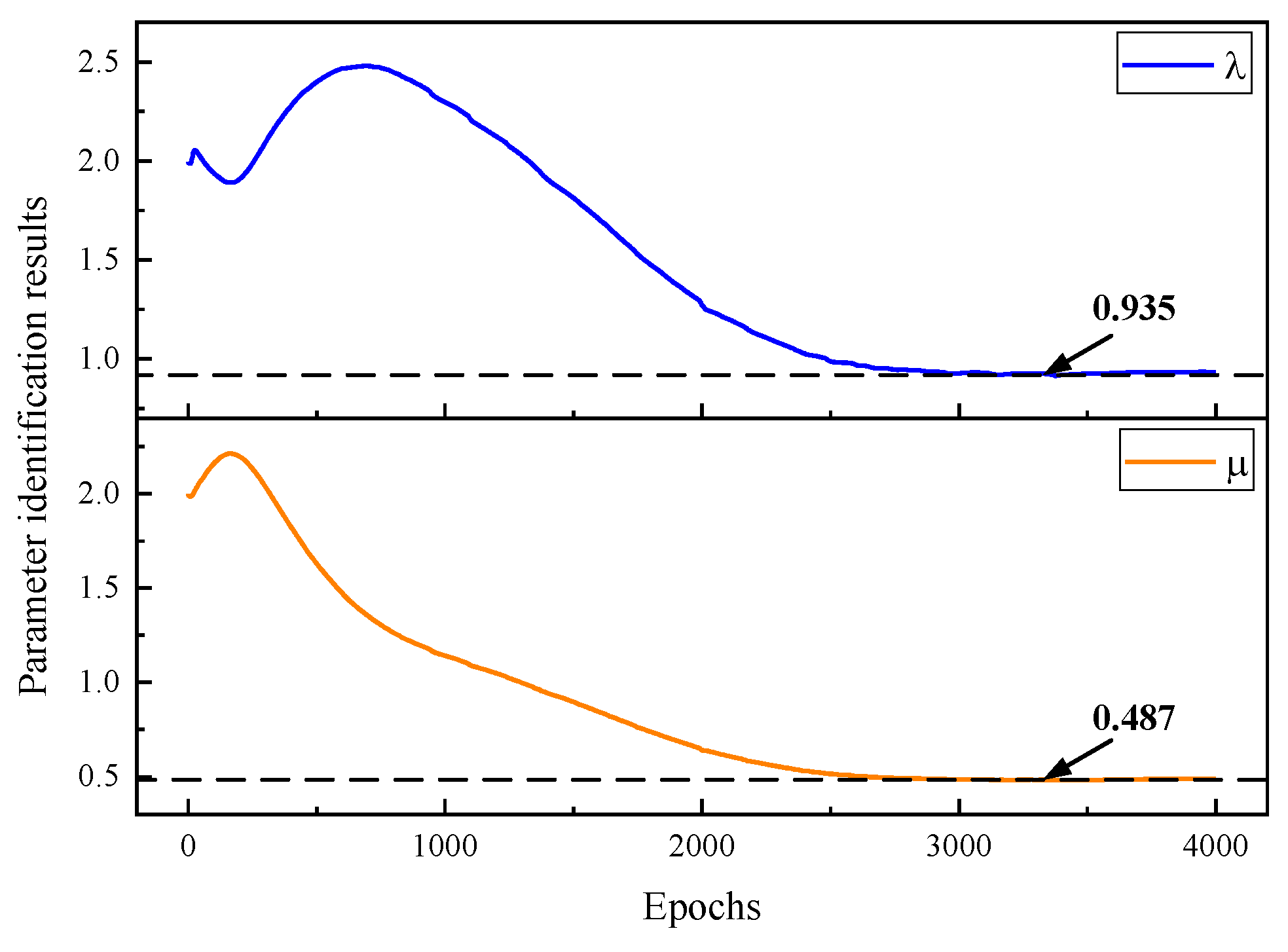

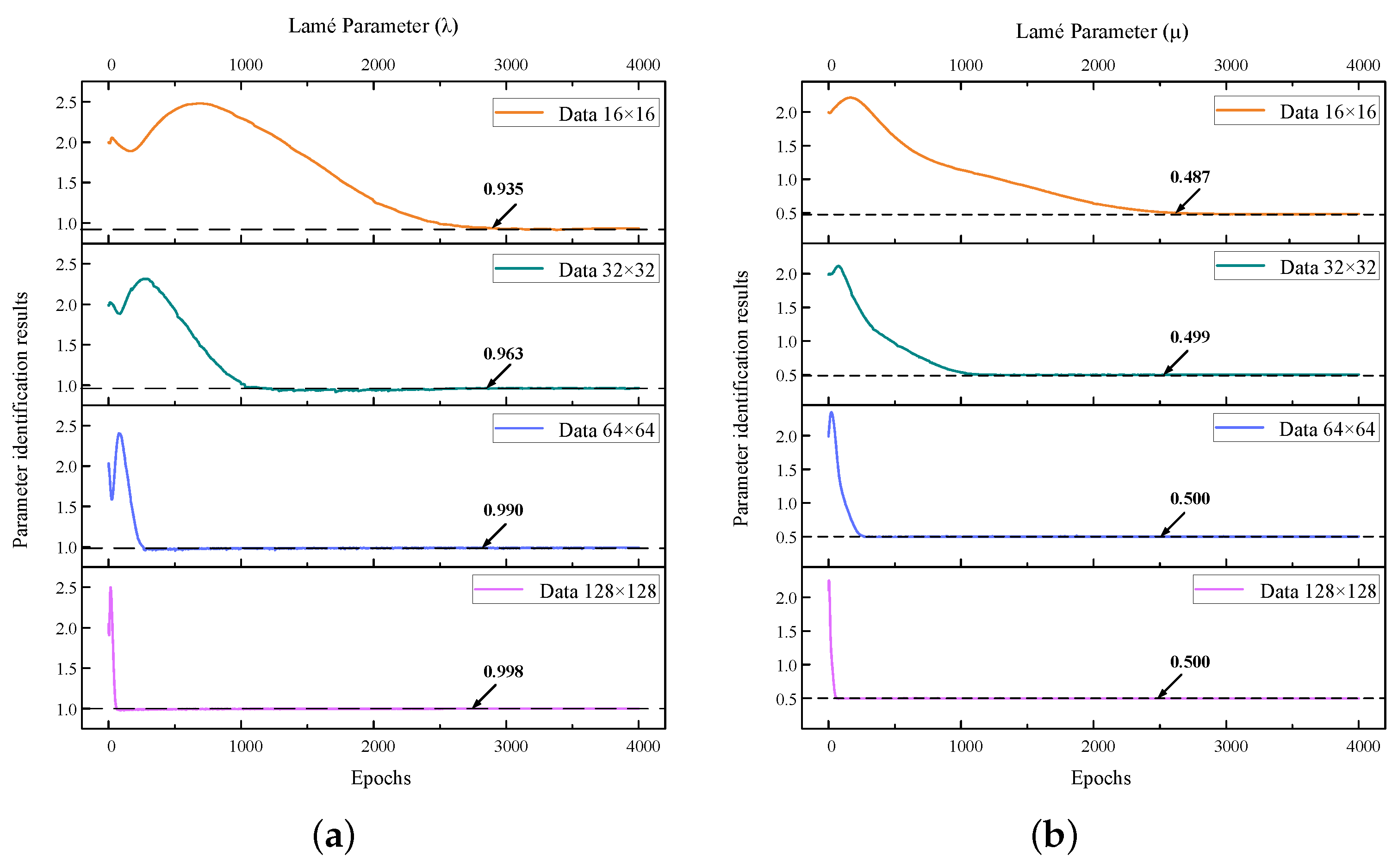

3.4. Neural Network Setup

In this paper, a fully connected neural network is implemented within the deep learning framework of TensorFlow using Python language. For the elastoplastic statics problem, the input of the neural network is the node spatial coordinates and the output is the node displacements and stresses. For the elasticity problem, the material parameters for the inversion are the Lamé parameters

,

in Equation (

5). For the elastic–plastic problem, the parameters that need to be inverted are

,

, and

. Moreover,

corresponds to

in Equation (

8), which is the condition for determining whether the material enters plasticity in Equation (

7). According to the control equations, initial conditions, boundary conditions, and sample point data, constraints are set and loss functions are computed. The physical quantities obtained from the network’s output and those labeled in the training samples are substituted into the PDEs, boundary condition, and initial condition. The difference between the two is then used to construct a loss function. The connection weights between each neuron in the neural network are adjusted by minimizing the loss function to achieve convergence.

The Adam optimizer is selected for gradient descent optimization, and tanh is used as the activation function of the neural network. The parameters of the neural network model are selected and set according to the specific problem, mainly including batch size, learning rate, learning rate decay, epochs/iterations, adaptive weights, initializer, etc. The loss function was calculated using the mean squared error (MSE). After the neural network model is established, the model is compiled first, and then the model is trained. Optimization methods are used to continuously minimize the loss function to make the neural network converge and obtain the parameter values for the inversion. Finally, the unknown displacement and stress fields of the model are predicted. The PINN structure used in this paper for the inverse elastoplastic static problem is illustrated in

Figure 3.

3.5. The Implementation of the S-FEM-Coupled PINN

In the elastic–plastic inverse problem, data for pure PINNs are typically obtained from either measured data or synthesized data from numerical methods (such as FEM). However, obtaining measured data can be challenging, while synthesized data from numerical methods may be less accurate or more expensive. In contrast, the coupling method uses synthesized data from the S-FEM, which is easier to obtain than measured data and has higher accuracy and lower cost than FEM.

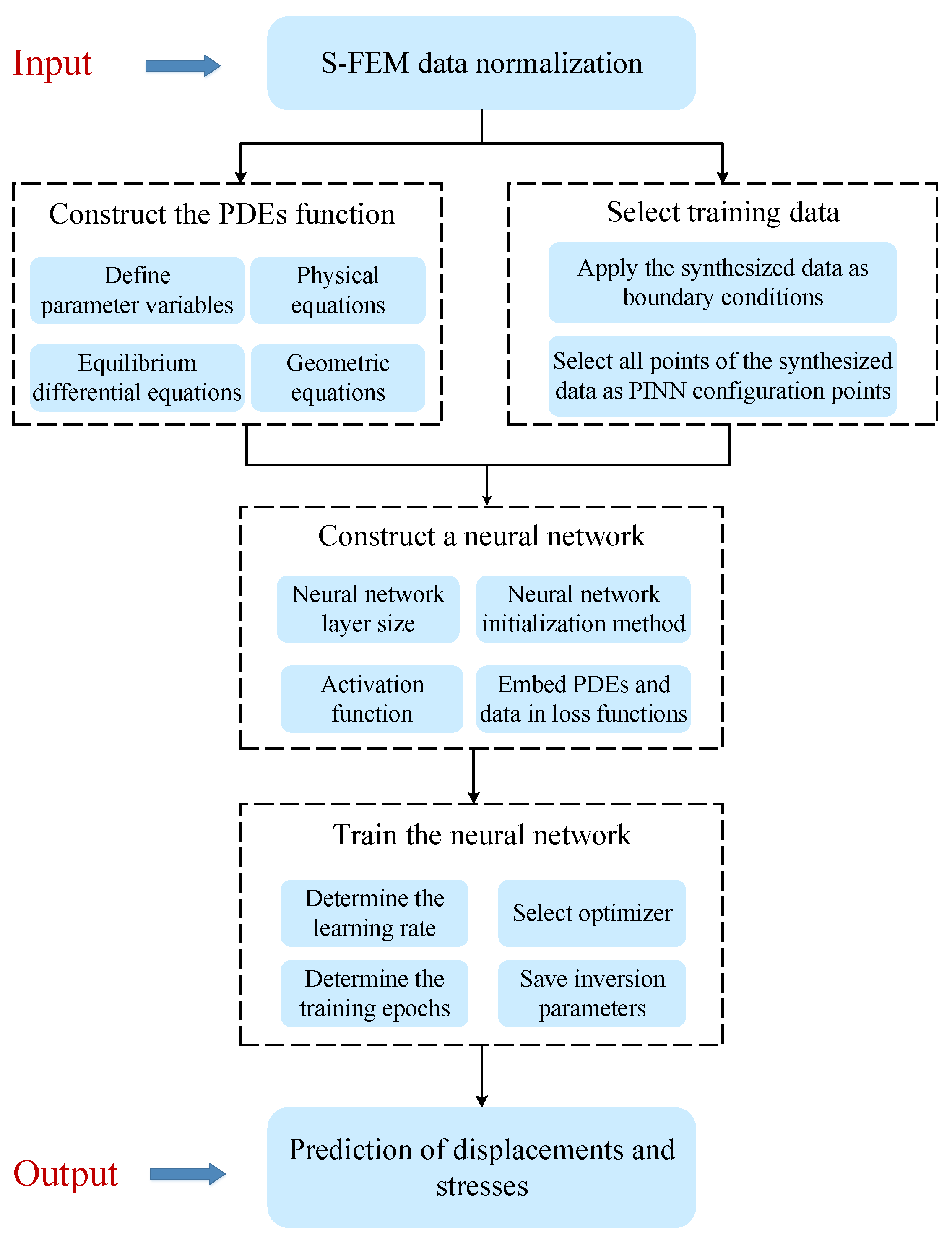

To solve the inverse problem with S-FEM-coupled PINN, material parameters are set as unknown variables in the PINN, which are identified during the training process. The input of the PINN consists of spatial coordinates, while its output involves displacement and stress fields. In the elastoplastic statics problem, the unidentified material parameters include the Lamé parameter and the yield stress. As presented in

Figure 4, the proposed method in this paper starts by discretizing the problem domain using the S-FEM to obtain the spatial coordinates of a series of nodes, which are then used as input variables for PINN. The smoothing domain, displacement field, and smoothed strain field are constructed based on the S-FEM calculation procedure. On this basis, the smoothed stiffness matrix is calculated and assembled. Finally, the system equations are solved after imposing the boundary conditions to obtain the nodal displacements and equivalent nodal stress of the problem. These values are then embedded as data constraints in the loss function of the PINN. The physical constraints, including the equilibrium differential equations, geometric equations, and physical equations of the elastic–plastic problem, are also embedded in the loss function of the PINN. The physical loss and data loss are combined as the total loss function, which is optimized using optimization methods to continuously reduce the value of the loss function. This results in the neural network output being gradually closer to the true value. A threshold value or a maximum number of iteration steps is used to determine whether to continue the training of the neural network or not. The material parameters obtained from the inversion of each iteration step of the training process are output to facilitate the analysis of the inversion results. The algorithmic flowchart for the implementation and training of the S-FEM-coupled PINN in TensorFlow is illustrated in

Figure 5.

In the elastoplastic forward problems, pure PINNs solve the forward problem without known data and are optimized by embedding boundary conditions, equilibrium differential equations, geometric equations, and physical equations into the loss function. The coupling method improves the solution accuracy by incorporating synthesized data from the S-FEM and using both physical and data constraints in the loss function. By adding constraints, the coupling method combines the advantages of both methods and achieves more accurate and efficient solutions.

To solve the forward problem with S-FEM-coupled PINN, the material parameters are known and the spatial coordinates serve as the input to the PINN, while the output is the displacement and stress fields. To obtain the spatial coordinates, a small-scale discretization of the problem domain is carried out using the S-FEM. The nodal displacements and equivalent nodal stress values are then obtained using the S-FEM and used as data constraints in the loss function of the PINN. The boundary conditions, equilibrium differential equations, and physical equations of the elastoplastic problem are also embedded in the loss function of the PINN. The neural network is trained to minimize the loss function, thereby achieving convergence. Once trained, the neural network can be used to predict the displacement and stress of a large-scale node with the same geometric boundary conditions.

5. Discussion

The S-FEM-coupled PINN is a surrogate modeling method that is driven by both knowledge and data. This approach is more interpretable and generalizable when compared to traditional machine learning techniques. Compared to traditional numerical methods, the S-FEM-coupled PINN can address the limitations of separately solving PDE inverse problems. Furthermore, it overcomes the drawbacks of traditional inverse analysis methods, such as subjectivity, complexity, low accuracy, and low efficiency. After conducting a comparative analysis of the example results presented in

Section 4, we identified several specific characteristics of the S-FEM-coupled PINN. (1) By incorporating a portion of the high-fidelity dataset synthesized by S-FEM, the accuracy of the PINN in solving PDE forward problems with no data dependence was improved. (2) The S-FEM was employed to synthesize high-fidelity datasets and coupled with the PINN to solve the inverse problem of PDEs, resulting in improved convergence and accuracy of the inverse solutions. (3) The S-FEM-coupled PINN possesses integrated training and identification, enabling simultaneous forward and inverse problem-solving of PDEs with improved accuracy.

Only regular two-dimensional elastic and plastic problems have been examined in this paper using the S-FEM-coupled PINN. Further research is necessary to implement this approach for more complex, high-dimensional problems. The S-FEM-coupled PINN has improved the accuracy of the PINN in solving forward problems but has not addressed its limitations in terms of efficiency. To train an effective PINN model, a large number of collocation points are typically necessary to match the differential equations. Relevant research has been conducted to include the input/design parameters of each instance in the input layer of the PINN network to avoid retraining the network for each new instance [

51]. However, during the training process, the PINN model still needs to undergo a large number of optimization iterations. In practice, the number of collocation points and training iterations often grows with problem complexity, thereby complicating the search for appropriate neural network hyperparameters [

16]. Establishing a rigorous initial/boundary condition for a continuous PINN presents a challenge, as the accuracy and precision of computations can be significantly affected by the proper setting of such conditions, particularly when label data are scarce or unavailable [

17].

There is always a trade-off between computational efficiency and the requirement for high-quality data. The PINN offers the advantage of employing fully connected deep neural networks for the analytical approximation of PDE derivatives through automatic differentiation. However, applying it directly to model the solution of high-dimensional systems can result in computational bottlenecks and pose optimization challenges. Convolutional neural networks offer superior scalability and faster convergence for PDE modeling systems, thanks to their lightweight architecture and efficient filtering capabilities in the computational domain [

3]. In order to reduce training costs and achieve efficient learning, there has been growing interest in physics-informed convolutional neural networks and physics-informed graph neural networks, due to their superior efficiency and scalability [

3,

17,

52,

53,

54]. In the future, integrating the S-FEM with physics-informed convolutional neural networks has the potential to enhance computational accuracy and efficiency.

The high accuracy of PINN in solving PDEs and its unique parameter inversion method make it applicable in various fields, including computational fluid dynamics [

55,

56], metamaterial design [

57], and reactive diffusion systems [

58]. Despite the need to solve PDE problems in geotechnical engineering, the exploration and application of the PINN algorithm in this field are still in their early stages, with no established trends or significant research efforts to date. The PINN algorithm has shown promise in the inversion of geotechnical engineering parameters and offers a new method with significant potential for determining and calibrating physical and mechanical parameters in this field. Combining the PINN algorithm with numerical computations holds promise for improving the reliability, accuracy, and efficiency of geotechnical parameter inversion in the future. Moreover, in the future, we will study the applicability conditions and application scenarios of the pure PINN, S-FEM, and S-FEM-coupled PINN, respectively, for specific engineering problems. These studies are expected to provide researchers with guidelines for selecting appropriate tools for solving PDEs.