Optimization of Curtain Wall Production Line Balance Based on Improved Genetic Algorithm

Abstract

:1. Introduction

1.1. The Objective of the Paper

- To build a mathematical model for Type-2 balancing of curtain wall production lines and mathematical evaluation indexes;

- To propose an improved genetic algorithm to solve the mathematical model for Type-2 balancing of curtain wall production lines;

- To compare the optimization plan for different numbers of workstations and obtain the best solution;

- To design an intelligent production factory for curtain walls and build an intelligent production line for curtain wall columns for experiments to verify the feasibility of improving genetic algorithms.

1.2. Paper Organization

2. Literature Review

3. Curtain Wall Production Line Balance Model Construction

3.1. Model Assumptions

- (1)

- The number of workstations in the production line shop, the operating time of each process, and the order in which the products will be processed are known.

- (2)

- The type and quantity of processing equipment required for the production line is known.

- (3)

- A machining process cannot be assigned to two workstations.

- (4)

- Workers on the production line operate at essentially the same level for each operational process, and each worker can skilfully complete any of the processes.

3.2. Constraints [18,19]

- (1)

- Process i should be completed at exactly one workstation.where i is the work process, , m is the workstation, , and J is the total number of workstations.

- (2)

- The operating time of each workstation does not exceed the production line beat.where is the set of operating time of the mth workstation and is the Takt Time of the production line.

- (3)

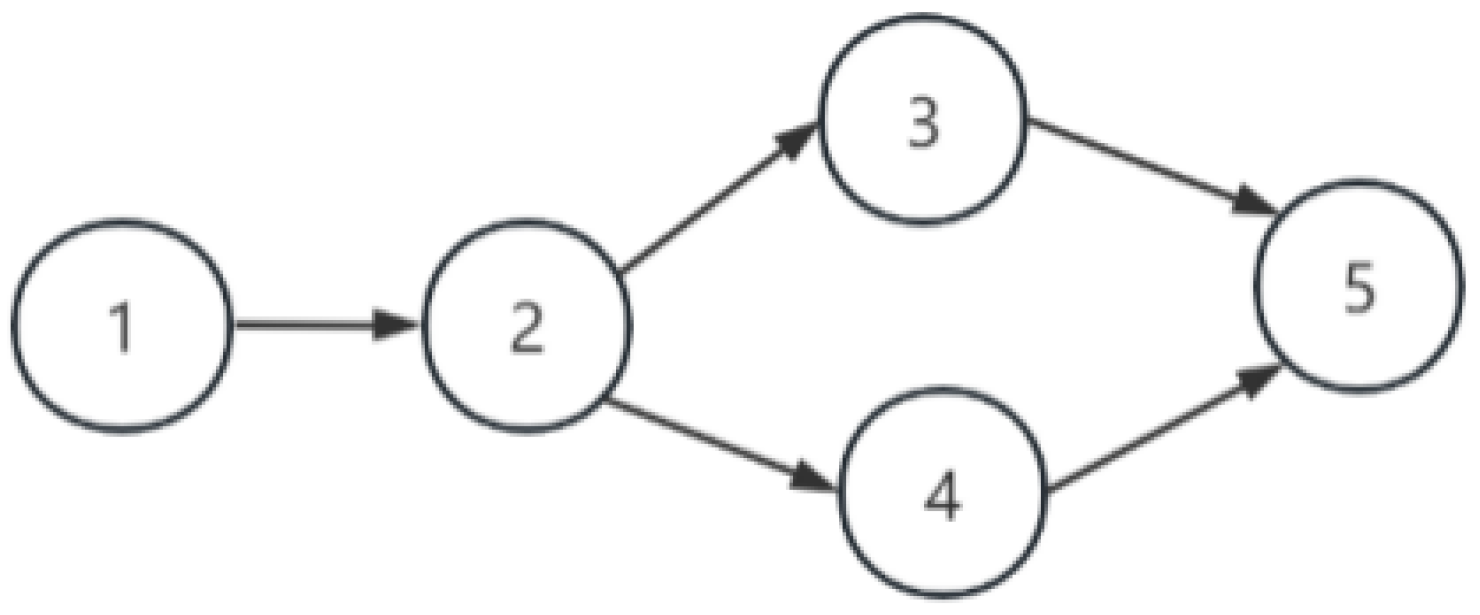

- Process Priority Constraints

3.3. Objective Function

3.4. Mathematical Evaluation Indicators

- (1)

- The balance rate of the production line P is usually used to describe the degree of balance of the entire production line operating time; the expression is as follows:

- (2)

- Equilibrium Index SI: This is used to measure the degree of deviation between a particular workstation and the average production time of the entire production line, with the following expression:

4. Improved Genetic Algorithm Design

4.1. Coding

4.2. Decoding

- (1)

- Calculate the theoretical minimum production beat:where T is the sum of operation elements and m is the given workstation. Let .

- (2)

- Using as the production beat, assign n elements to m workstations according to the logical relationship of the job elements, and the time of each workstation is: . If the time of each workstation , then is the minimum beat under this ordering, and the search stops; otherwise, proceed to the next step.

- (3)

- Calculate the potential increments for the production line, where the value of is the time of the first job element at the st workstation, respectively.

- (4)

- Let and ; if , then is the minimum beat under this ordering and the search stops; otherwise return.

4.3. Adaptation and Selection

4.4. Crossing and Mutations

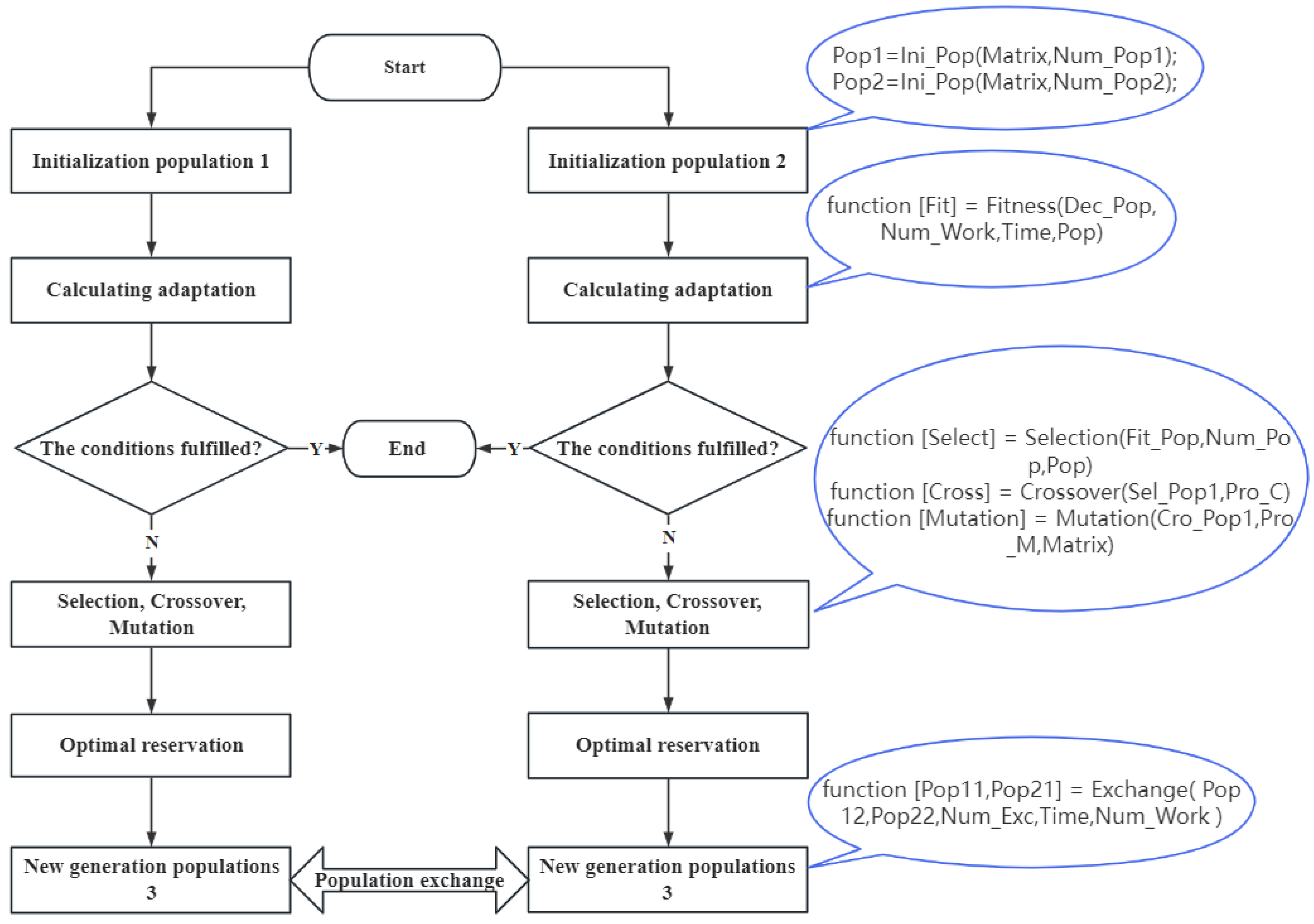

4.5. Population Gene Exchange

5. Implementation of the Algorithm

5.1. Data Preparation

5.2. Matlab-Based Implementation of Two-Population Genetic Algorithm

6. Optimization Effect Evaluation

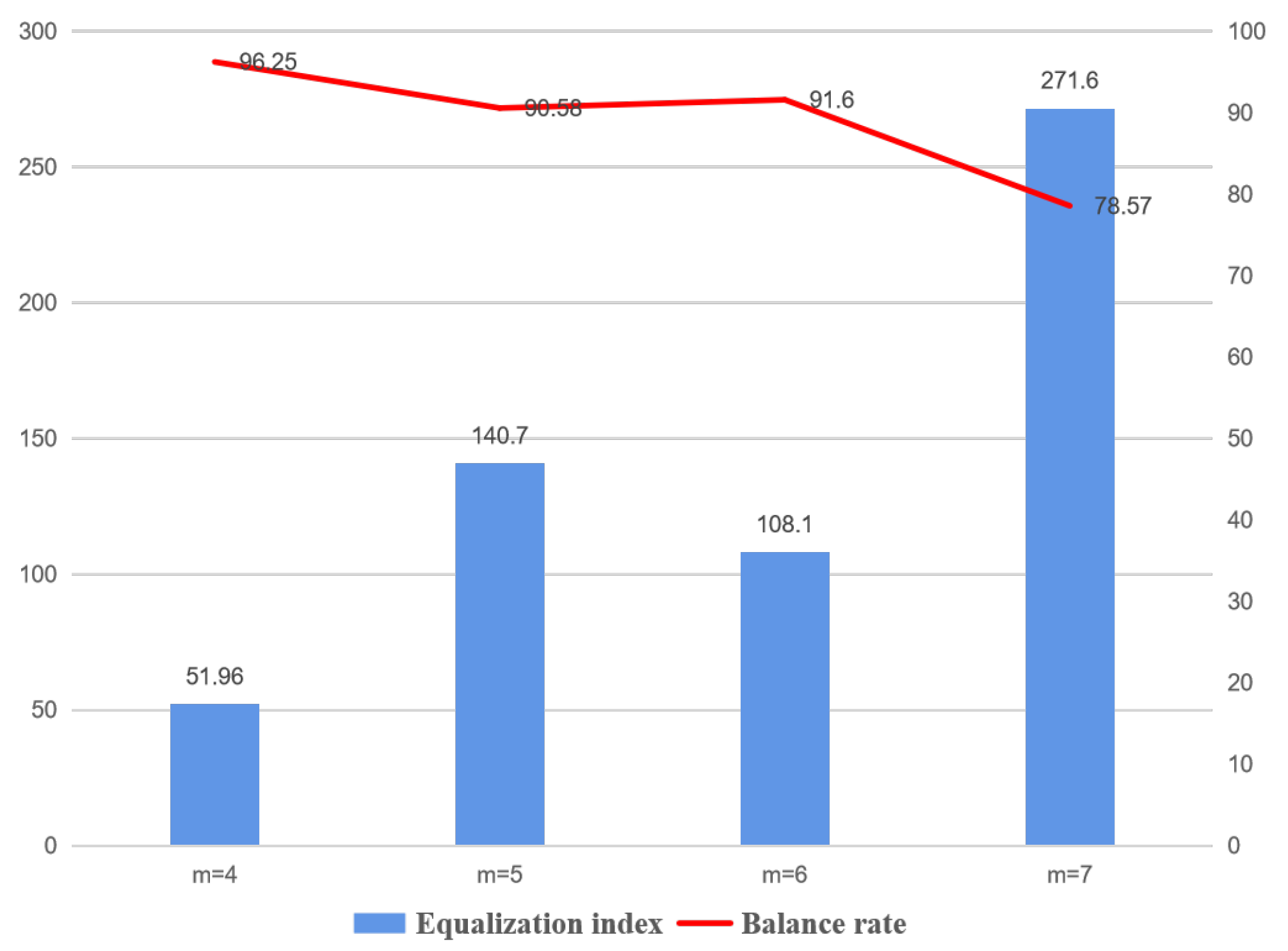

6.1. Simulation Results

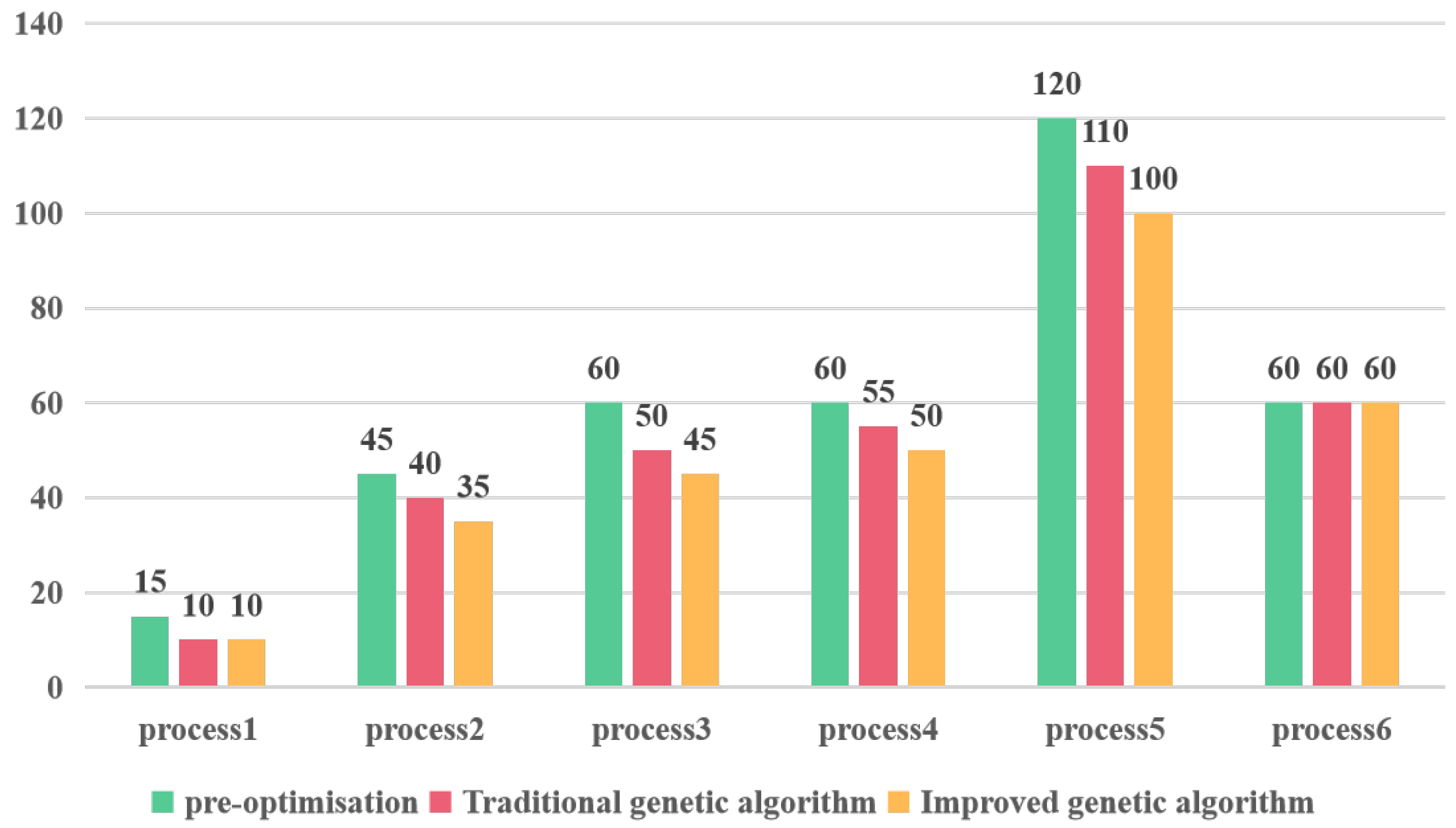

6.2. Experimental Results

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, Y.G. The Impact of High-rise Building Curtain Wall Technology in the Exploring Period (1895–1959). In Proceedings of the 2nd Annual International Conference on Advanced Material Engineering (AME 2016), Wuhan, China, 15–17 April 2016; Atlantis Press: Amsterdam, The Netherlands, 2016; pp. 1357–1361. [Google Scholar] [CrossRef]

- Chen, K.; Lu, W. Design for manufacture and assembly oriented design approach to a curtain wall system: A case study of a commercial building in Wuhan, China. Sustainability 2018, 10, 2211. [Google Scholar] [CrossRef]

- Lee, A.D.; Shepherd, P.; Evernden, M.C.; Metcalfe, D. Optimizing the architectural layouts and technical specifications of curtain walls to minimize use of aluminium. Structures 2018, 13, 8–25. [Google Scholar] [CrossRef]

- Jiang, L.; Duan, J.J.; Zheng, R.; Shen, H.; Li, H.; Xu, J. Optimizatiob and Simulation of Garment Productiob Line Balance Based on Improver GA. Int. J. Simul. Model. (IJSIMM) 2023, 22, 303–314. [Google Scholar] [CrossRef]

- Boysen, N.; Schulze, P.; Scholl, A. Assembly line balancing: What happened in the last fifteen years? Eur. J. Oper. Res. 2022, 301, 797–814. [Google Scholar] [CrossRef]

- Zhang, P.; Dong, Y. Strategy transformation of big data green supply chain by using improved genetic optimization algorithm. Soft Comput. 2023, 1–10. [Google Scholar] [CrossRef]

- Niu, H.; Hou, T.; Chen, Y. Research on Energy-saving Operation of High-speed Trains Based on Improved Genetic Algorithm. J. Appl. Sci. Eng. 2022, 26, 663–673. [Google Scholar] [CrossRef]

- Yin, Q.; Luo, X.; Sun, J.; Zhang, L. A Workstation Solution Based Heuristic Algorithm for Assembly Line Balancing Problem. In Proceedings of the 2021 33rd Chinese Control and Decision Conference (CCDC), Kunming, China, 22–24 May 2021; pp. 4010–4015. [Google Scholar] [CrossRef]

- El Ahmadi, S.E.A.; El Abbadi, L.; Elrhanimi, S. Efficiency Improveement of Automotive Assembly Lines Using Simple Assembly Line Balancing Problem Type-E. LogForum 2023, 19. [Google Scholar] [CrossRef]

- Baskar, A.; Anthony Xavior, M.; Nithyanandan, N.; Dhanasakkaravarthi, B. Analysis of a Few Heuristics Proposed Based on Slope Indices to Solve Simple Type—I Assembly-Line Balancing Problems. In Advances in Simulation, Product Design and Development: Proceedings of AIMTDR 2018; Springer: Singapore, 2019; pp. 499–506. [Google Scholar] [CrossRef]

- Zhang, H. An immune genetic algorithm for simple assembly line balancing problem of type 1. Assem. Autom. 2019, 39, 113–123. [Google Scholar] [CrossRef]

- Luo, Y.; Chang, J.; Zhang, F.; Zhang, S. A Research of Multi-Constrained Two-sided Mixed-model Assembly Line Balancing Problem Based on Genetic Algorithm. In Proceedings of the 2020 IEEE 7th International Conference on Industrial Engineering and Applications (ICIEA), Bangkok, Thailand, 16–21 April 2020; pp. 377–381. [Google Scholar] [CrossRef]

- Zamzam, N.; Elakkad, A. Time and space multi-manned assembly line balancing problem using genetic algorithm. J. Ind. Eng. Manag. (JIEM) 2021, 14, 733–749. [Google Scholar] [CrossRef]

- Jiao, Y.; Cao, N.; Li, J.; Li, L.; Deng, X. Balancing a U-Shaped Assembly Line with a Heuristic Algorithm Based on a Comprehensive Rank Value. Sustainability 2022, 14, 775. [Google Scholar] [CrossRef]

- Wang, T.; Fan, R.; Peng, Y.; Wang, X. Optimization on mixed-flow assembly u-line balancing problem. Clust. Comput. 2019, 22, 8249–8257. [Google Scholar] [CrossRef]

- Aziz, R.M.; Mahto, R.; Goel, K.; Das, A.; Kumar, P.; Saxena, A. Modified genetic algorithm with deep learning for fraud transactions of ethereum smart contract. Appl. Sci. 2023, 13, 697. [Google Scholar] [CrossRef]

- Ali, S.; Bhargava, A.; Saxena, A.; Kumar, P. A Hybrid Marine Predator Sine Cosine Algorithm for Parameter Selection of Hybrid Active Power Filter. Mathematics 2023, 11, 598. [Google Scholar] [CrossRef]

- Belkharroubi, L.; Yahyaoui, K. Solving the mixed-model assembly line balancing problem Type-I using a Hybrid Reactive GRASP. Prod. Manuf. Res. 2022, 10, 108–131. [Google Scholar] [CrossRef]

- Yadav, A.; Agrawal, S. Mathematical model for robotic two-sided assembly line balancing problem with zoning constraints. Int. J. Syst. Assur. Eng. Manag. 2022, 13, 395–408. [Google Scholar] [CrossRef]

- Anwaar, A.; Ashraf, A.; Bangyal, W.H.K.; Iqbal, M. Genetic Algorithms: Brief review on Genetic Algorithms for Global Optimization Problems. In Proceedings of the 2022 Human-Centered Cognitive Systems (HCCS), Shanghai, China, 17–18 December 2022; pp. 1–6. [Google Scholar] [CrossRef]

| Serial Number | Number of Workstations | Production Tempo (s) | Balance Rate (%) | Equalization Index |

|---|---|---|---|---|

| 1 | 4 | 600 | 96.25 | 51.90 |

| 2 | 5 | 510 | 90.58 | 140.70 |

| 3 | 6 | 420 | 91.60 | 108.10 |

| 4 | 7 | 420 | 78.57 | 271.60 |

| Workstations | Workstation Occupancy Rate (%) | Workstation Operating Time (s) |

|---|---|---|

| 1 | 88.42 | 360 |

| 2 | 83.25 | 390 |

| 3 | 85.34 | 420 |

| 4 | 86.46 | 360 |

| 5 | 81.23 | 420 |

| 6 | 82.78 | 360 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Xu, H.; Wu, W.; Zhu, D.; Xiao, Z.; Qin, G.; Li, B. Optimization of Curtain Wall Production Line Balance Based on Improved Genetic Algorithm. Mathematics 2023, 11, 4433. https://doi.org/10.3390/math11214433

Wang J, Xu H, Wu W, Zhu D, Xiao Z, Qin G, Li B. Optimization of Curtain Wall Production Line Balance Based on Improved Genetic Algorithm. Mathematics. 2023; 11(21):4433. https://doi.org/10.3390/math11214433

Chicago/Turabian StyleWang, Jianhui, Hanbin Xu, Wenqiang Wu, Dachang Zhu, Zhongmin Xiao, Guangxiang Qin, and Boji Li. 2023. "Optimization of Curtain Wall Production Line Balance Based on Improved Genetic Algorithm" Mathematics 11, no. 21: 4433. https://doi.org/10.3390/math11214433

APA StyleWang, J., Xu, H., Wu, W., Zhu, D., Xiao, Z., Qin, G., & Li, B. (2023). Optimization of Curtain Wall Production Line Balance Based on Improved Genetic Algorithm. Mathematics, 11(21), 4433. https://doi.org/10.3390/math11214433